A Novel Organic–Inorganic Composite with Outstanding Comprehensive Reinforcement Properties for Dealing with Salt Efflorescence of Pottery

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Preparation and Firing of Simulated Pottery

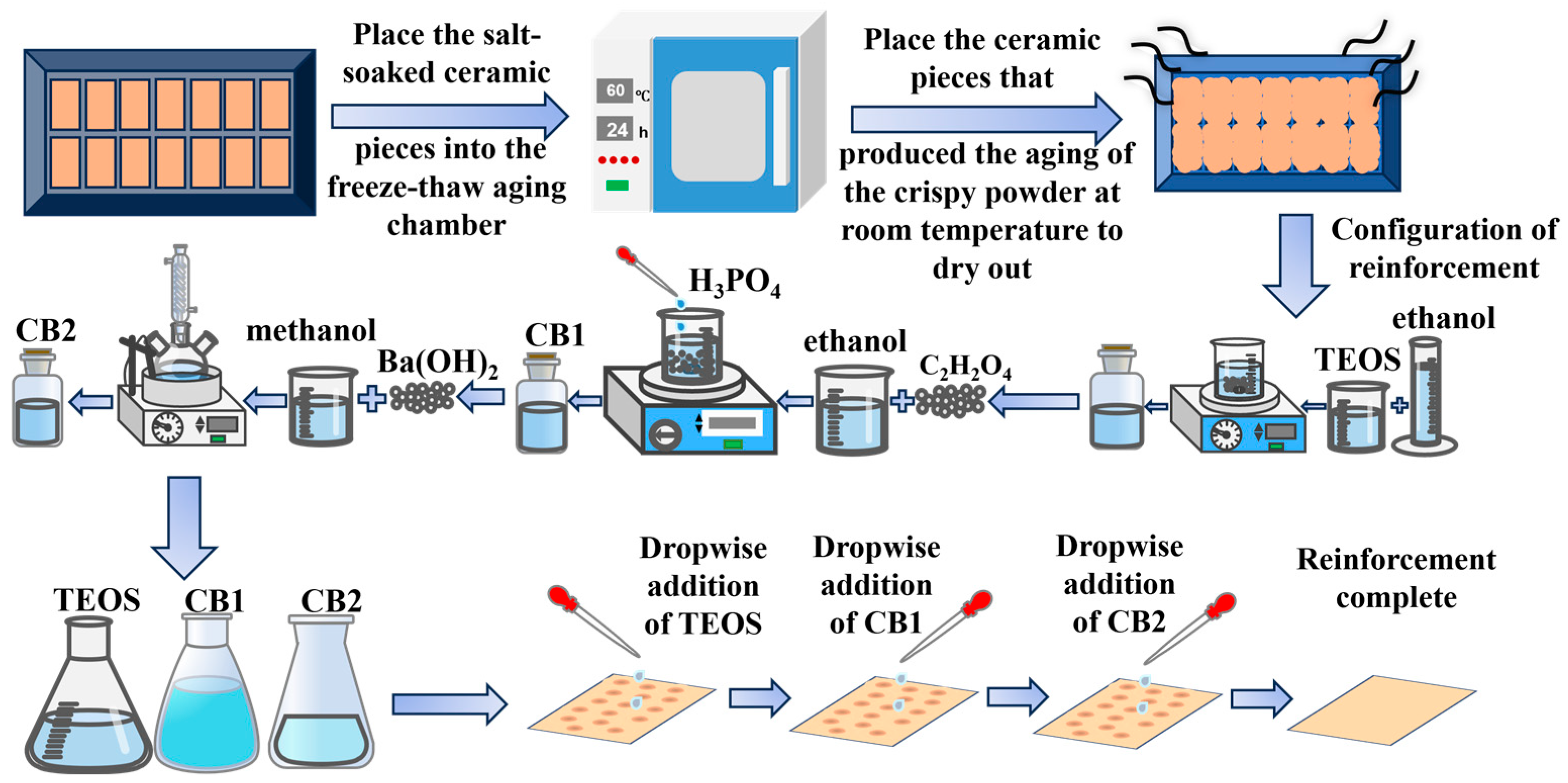

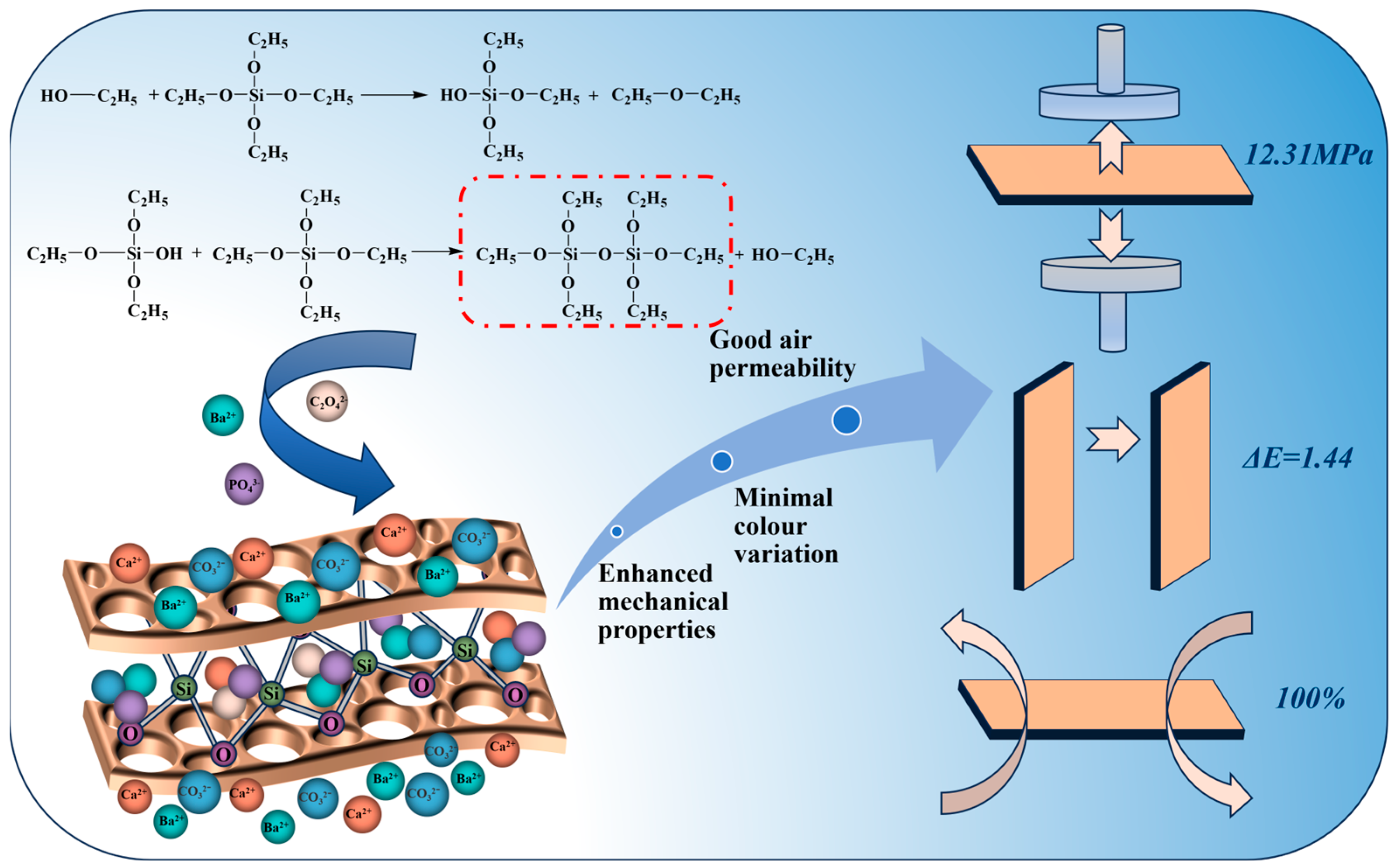

2.3. Synthesis of Reinforcing Agents

2.3.1. Preparation of Ethyl Orthosilicate Hydrolysates

2.3.2. Preparation of CB Two-Component Inorganic Reinforcing Agent

2.4. Reinforcement Process

2.5. Characterization

2.5.1. Colorimetric Analysis

2.5.2. Penetration Testing

2.5.3. Air Permeability Test

2.5.4. Compressive Strength Test

2.5.5. Flexural Strength Test

3. Results and Discussion

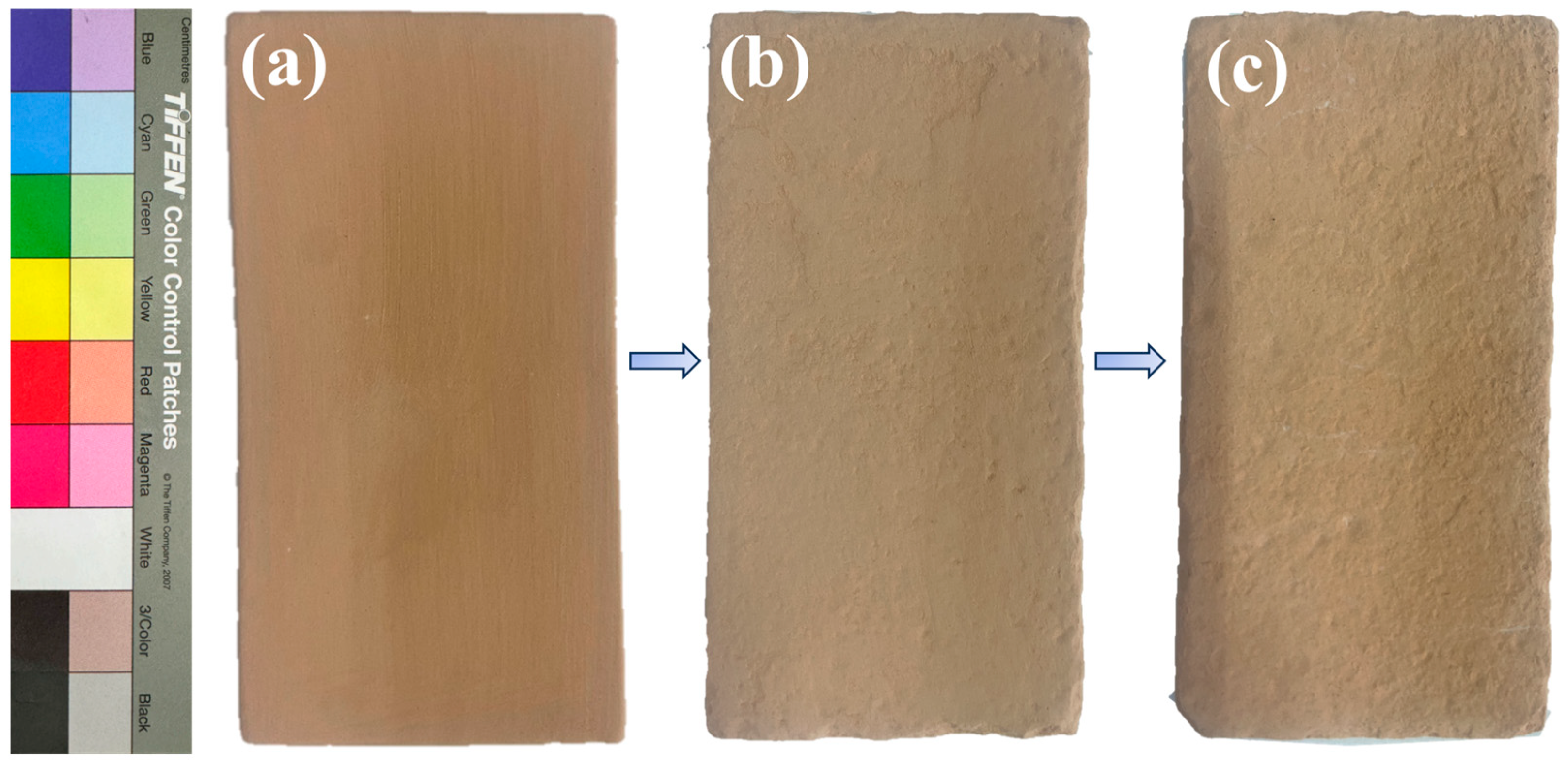

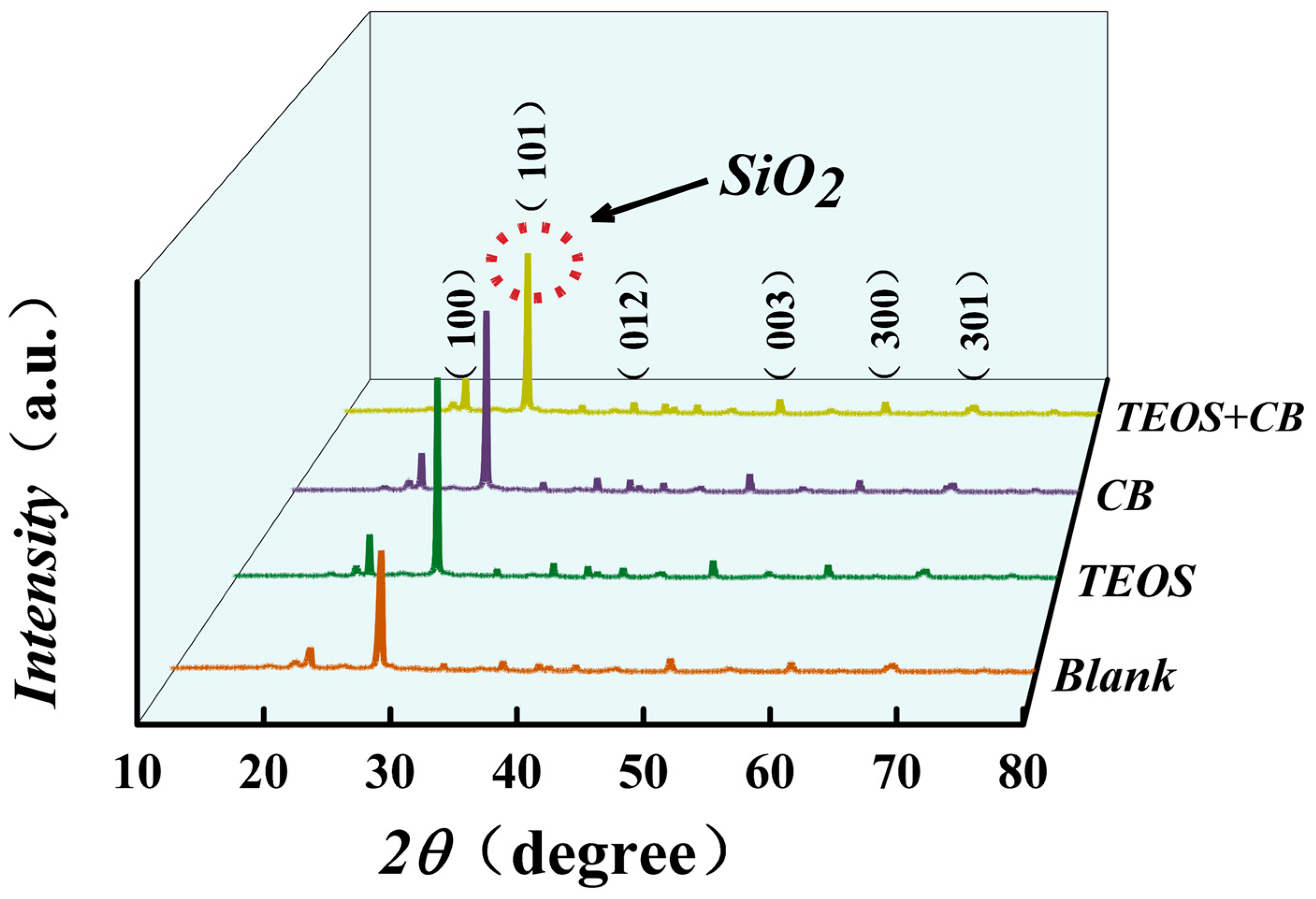

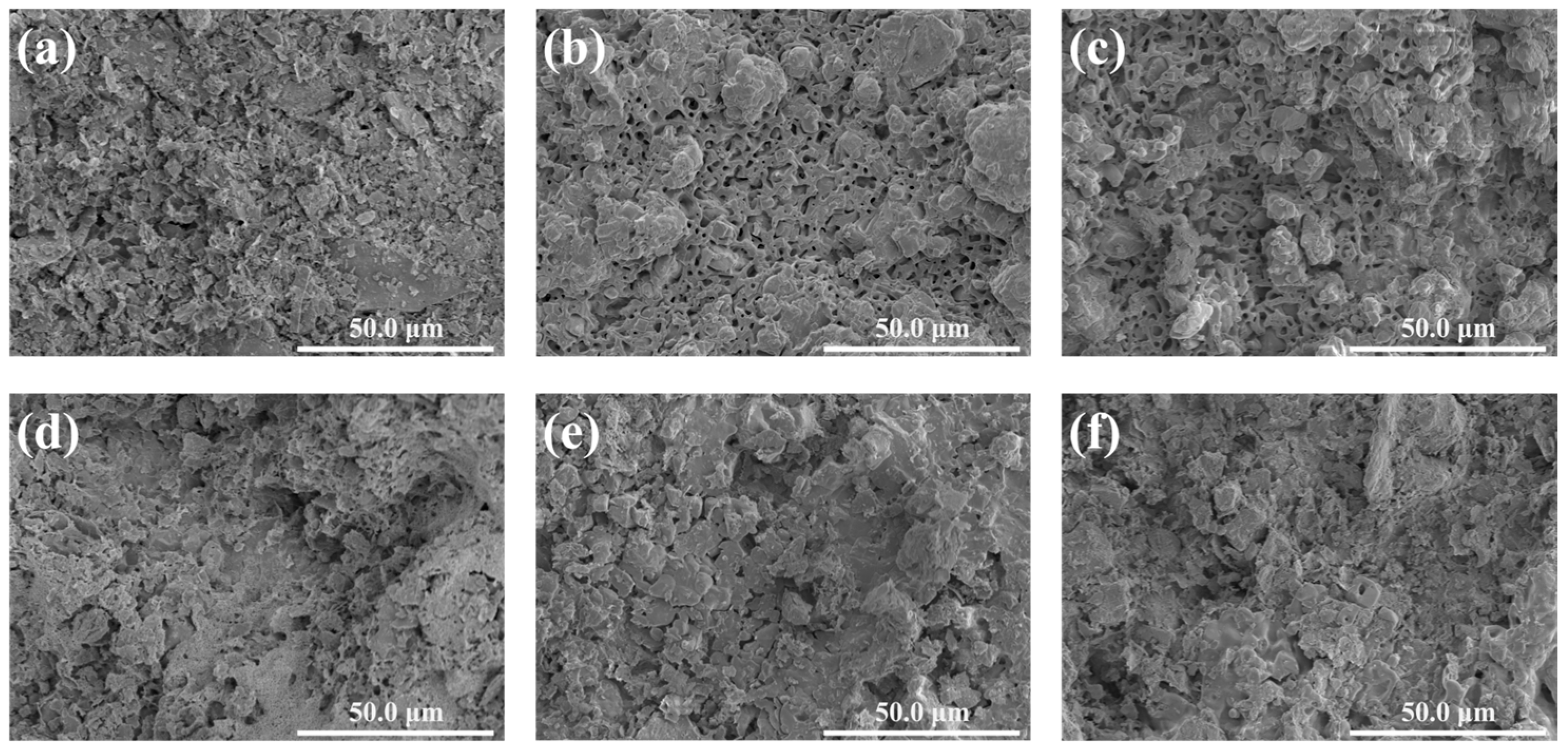

3.1. Phase Structure Analysis and Surface Micro-Morphological Analysis

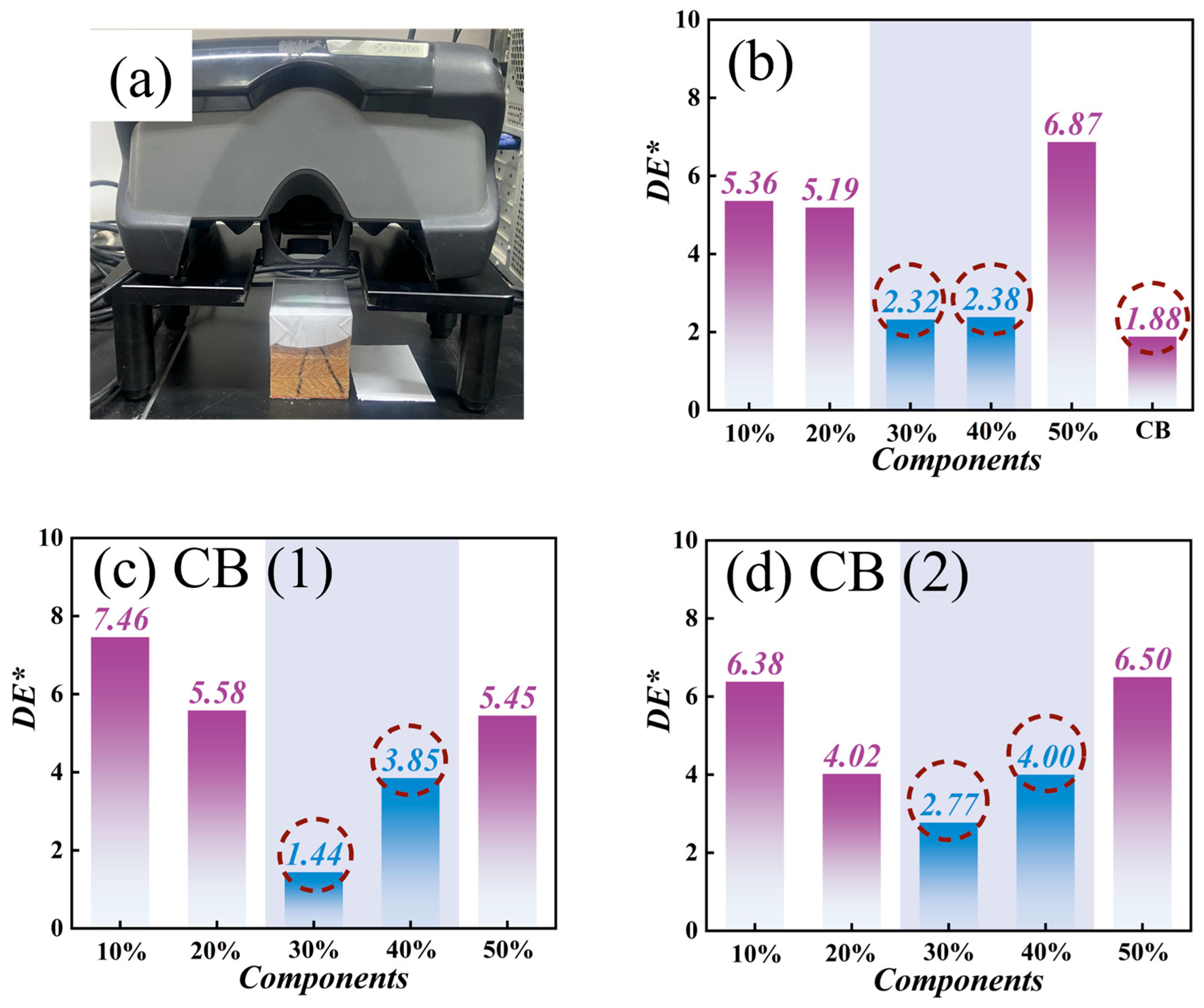

3.2. Colorimetric Analysis

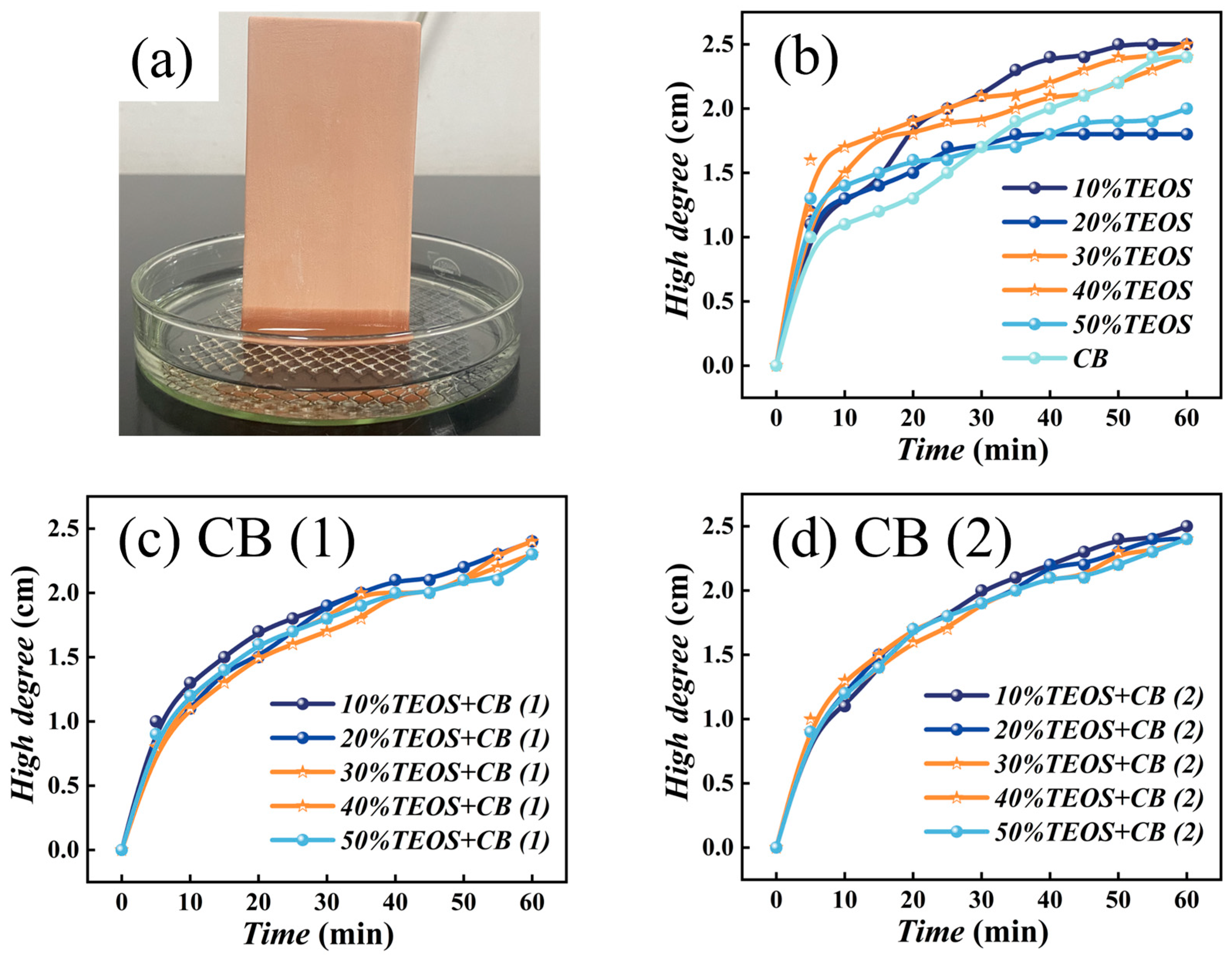

3.3. Permeability

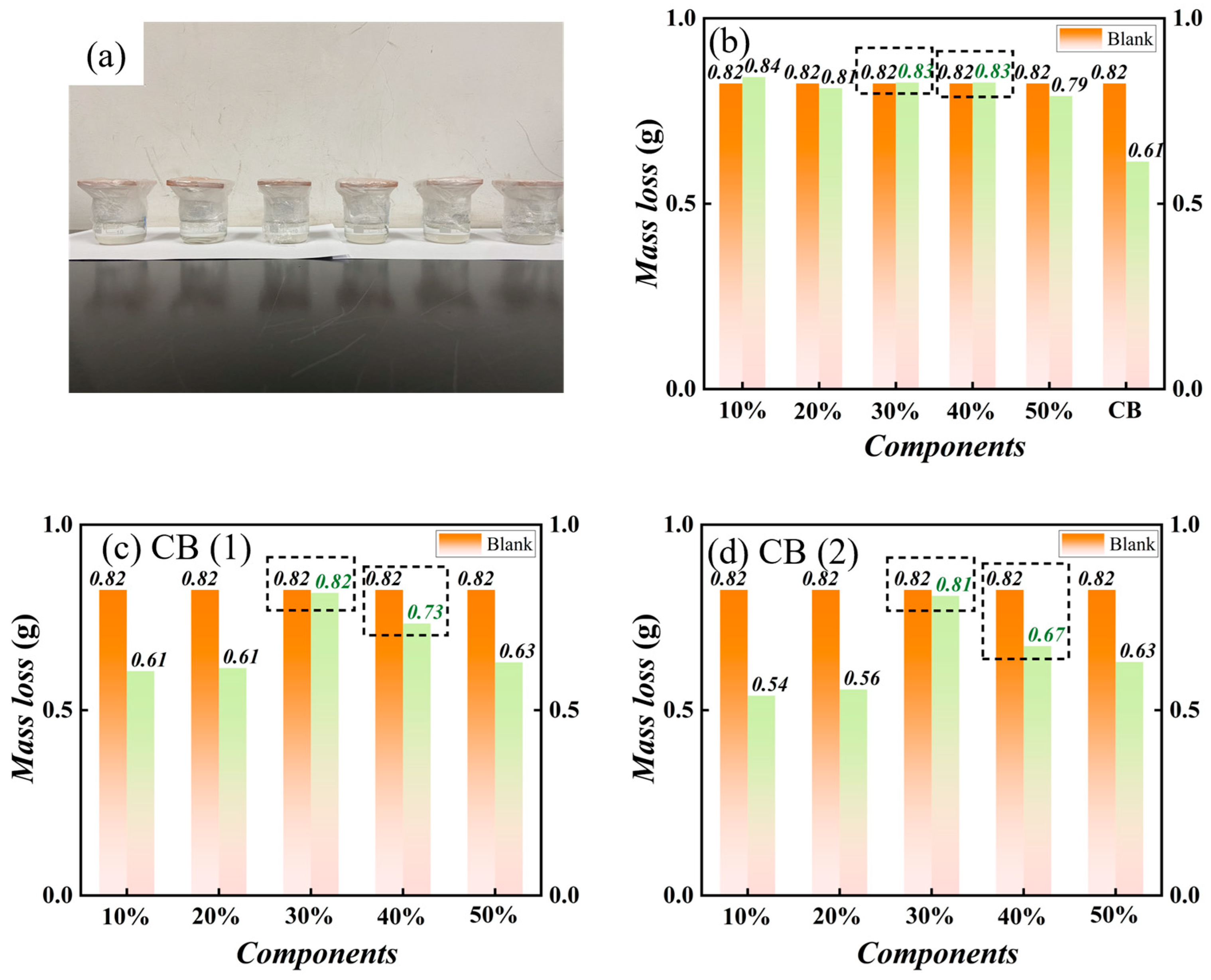

3.4. Breathability Test

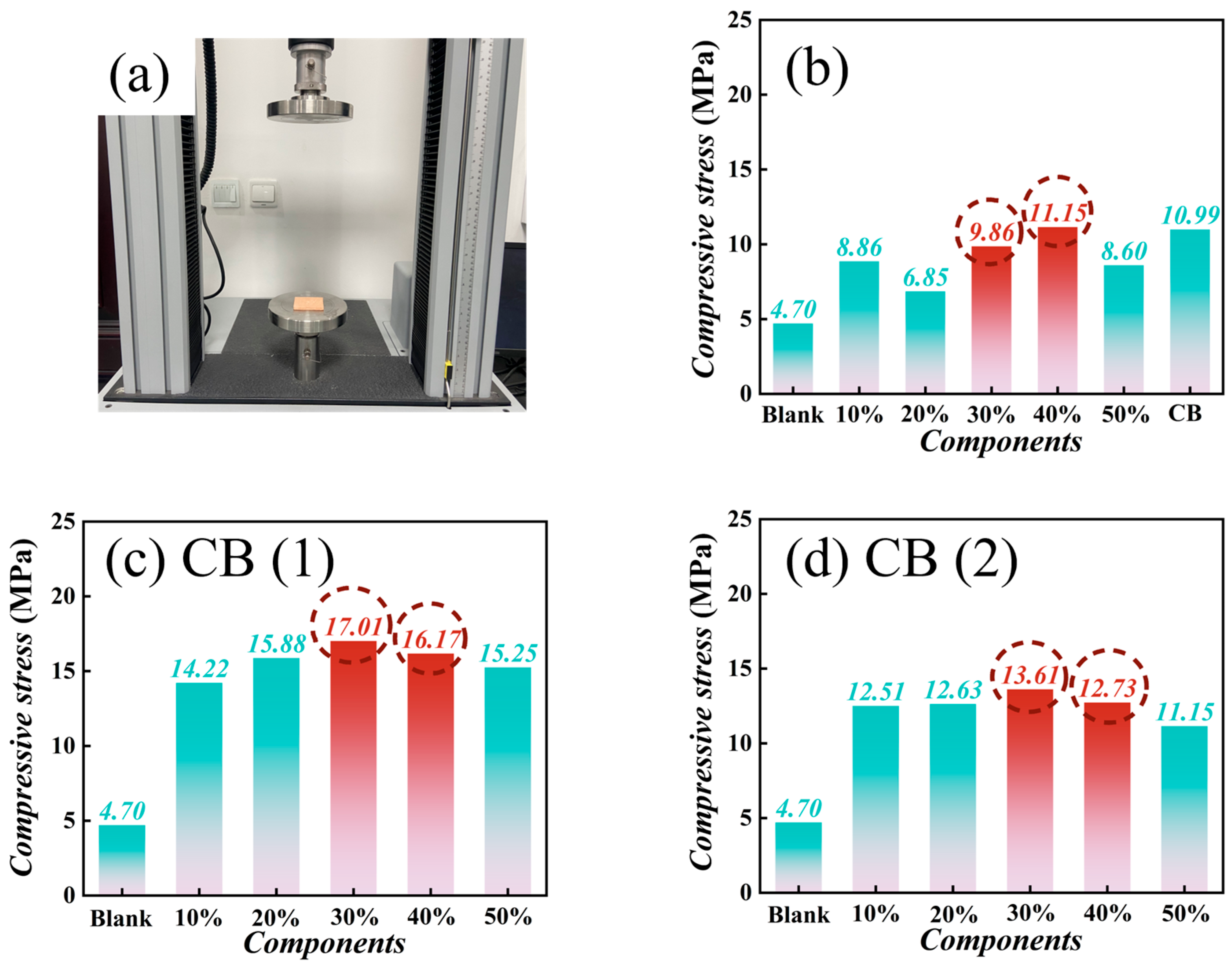

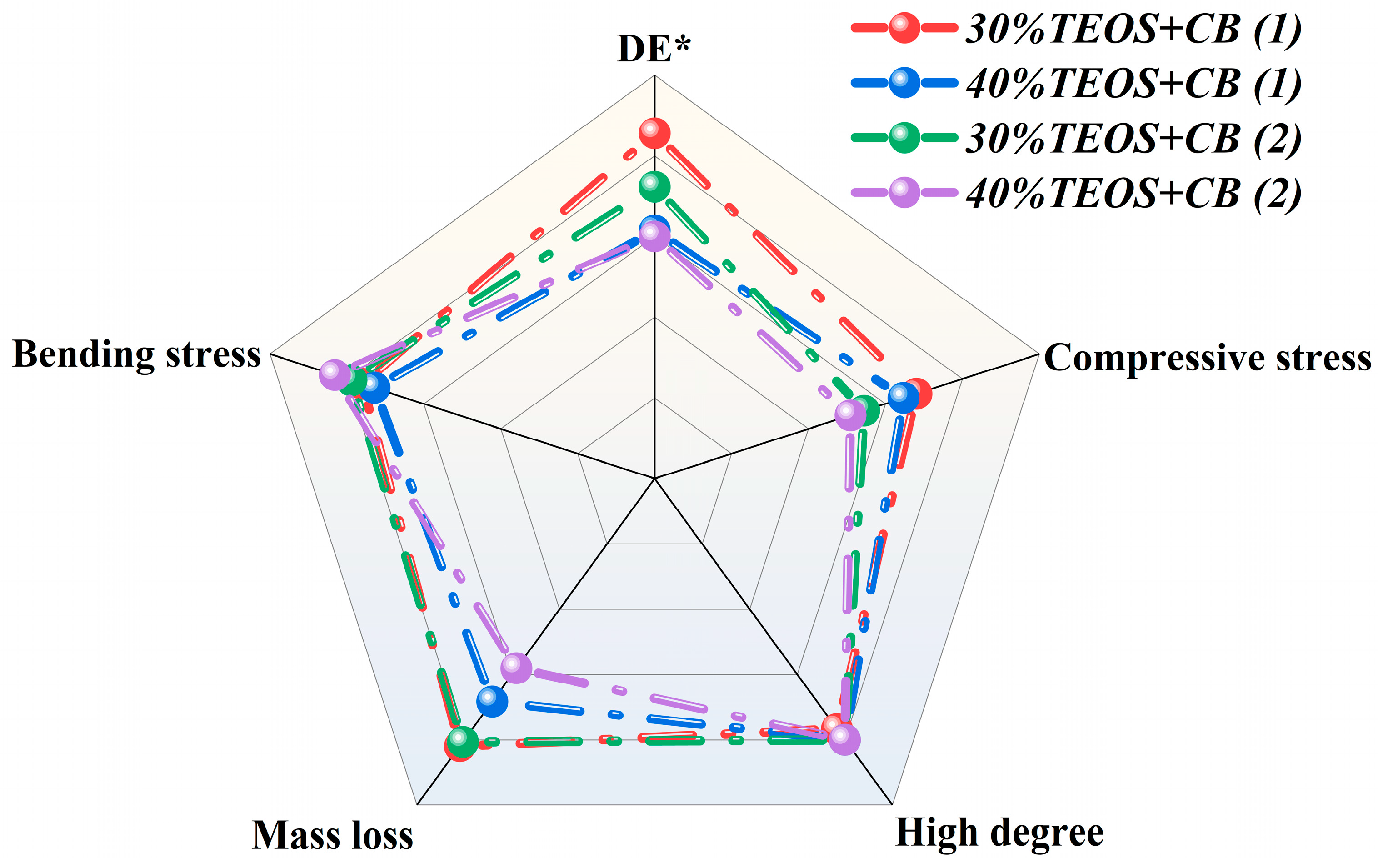

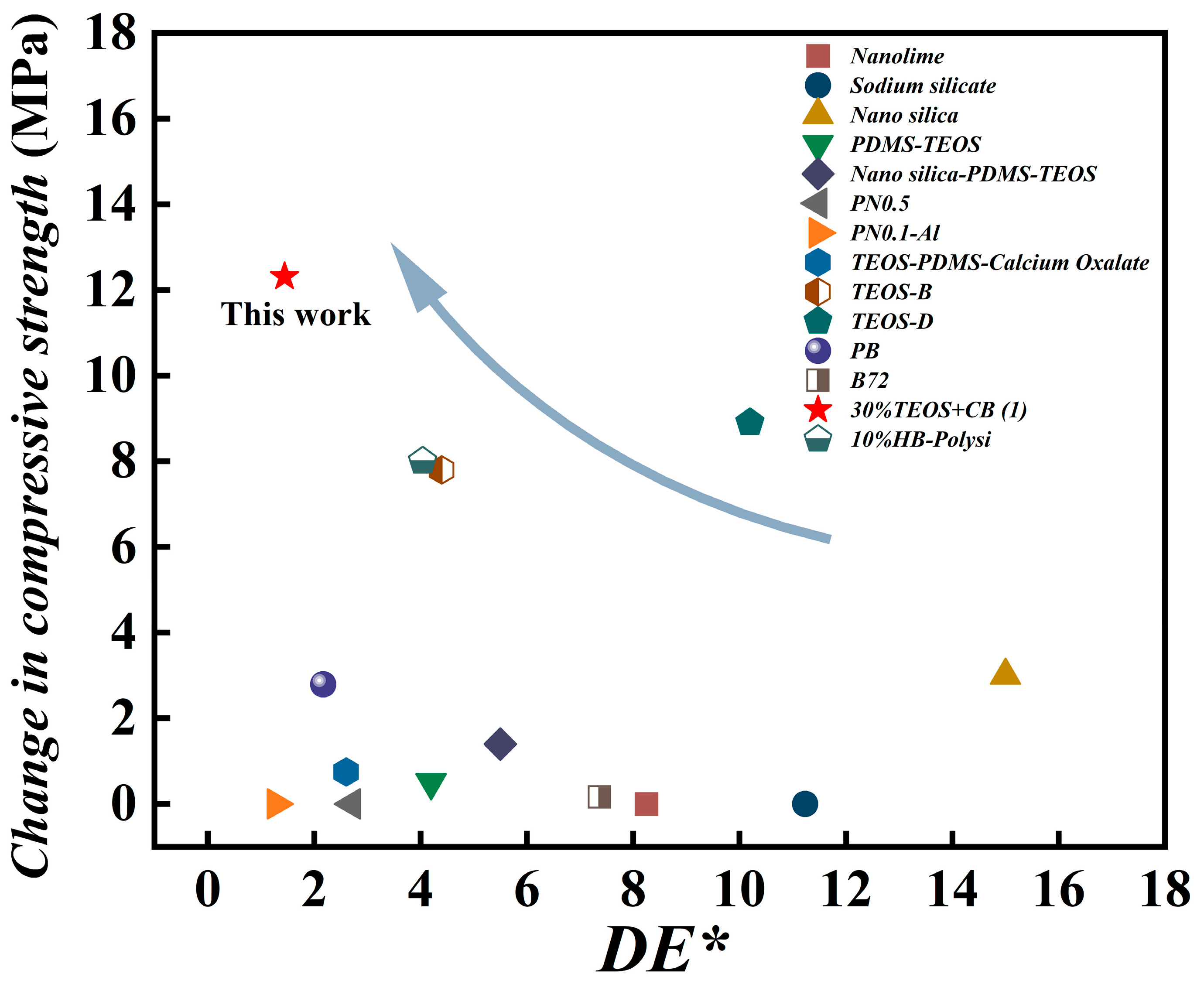

3.5. Pressure-Resistant Property

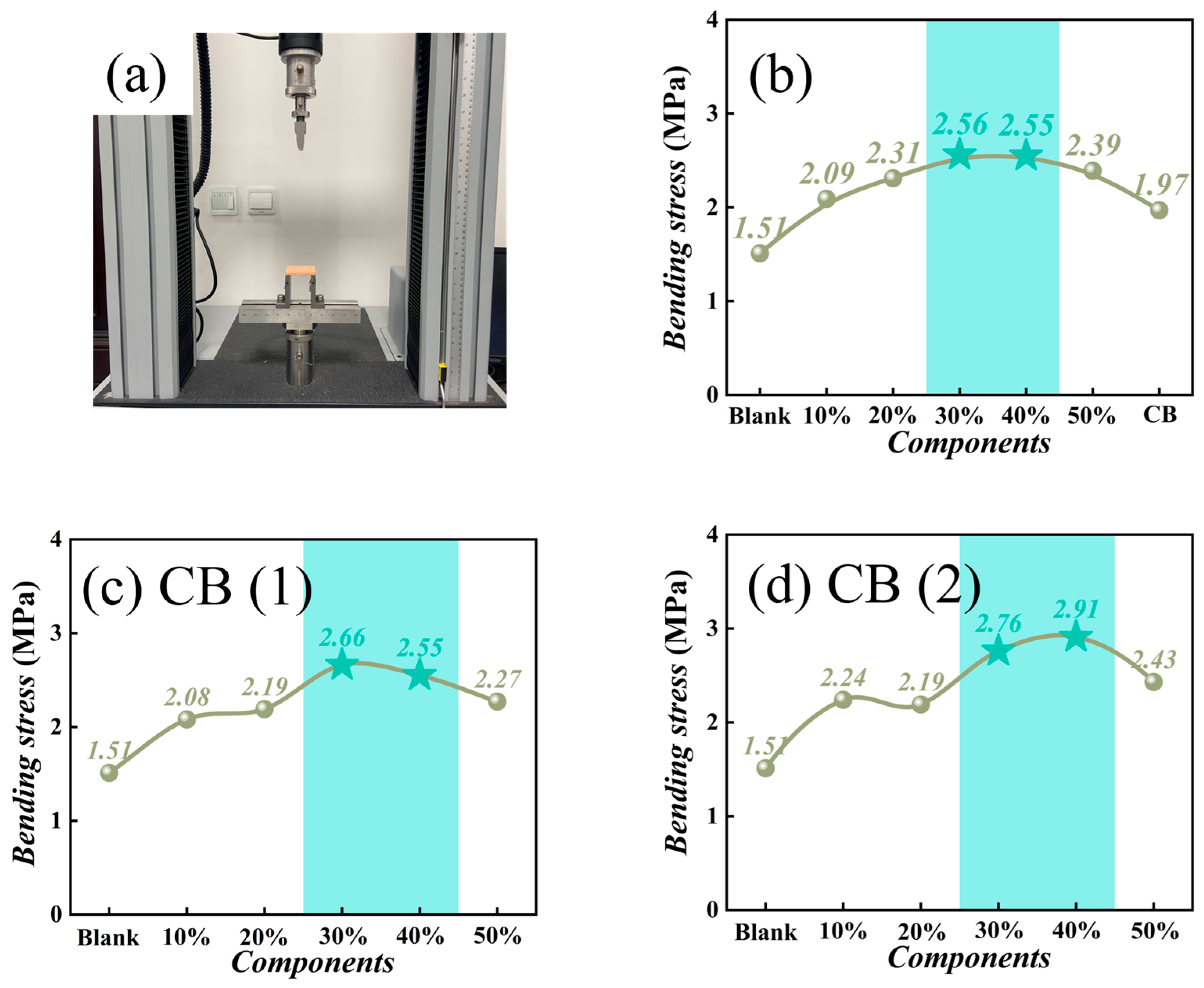

3.6. Bending Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohamed, H.M. A Comparison Study of Titanium Dioxide and Zinc Oxide Nanoparticles for Cleaning Archaeological Pottery. J. Nano Res. 2022, 76, 61–77. [Google Scholar] [CrossRef]

- Maggetti, M. Archaeometric Analyses of European 18th–20th Century White Earthenware—A Review. Minerals 2018, 8, 269. [Google Scholar] [CrossRef]

- Stefanidou, M.; Karozou, A. Testing the effectiveness of protective coatings on traditional bricks. Constr. Build. Mater. 2016, 111, 482–487. [Google Scholar] [CrossRef]

- David, M.E.; Ion, R.-M.; Grigorescu, R.M.; Iancu, L.; Andrei, E.R. Nanomaterials Used in Conservation and Restoration of Cultural Heritage: An Up-to-Date Overview. Materials 2020, 13, 2064. [Google Scholar] [CrossRef] [PubMed]

- Ricca, M.; Cámara, B.; Fort, R.; de Buergo, M.A.; Randazzo, L.; Petriaggi, B.D.; La Russa, M.F. Definition of analytical cleaning procedures for archaeological pottery from underwater environments: The case study of samples from Baia (Naples, South Italy). Mater. Des. 2021, 197, 109278. [Google Scholar] [CrossRef]

- Li, Y.; Guo, H.; Xiao, K.; Liu, P.; Chao, X.; Fu, P.; Xing, H.; Li, Y. A Study of Pigment, Adhesive, and Firing Temperature in Pottery Figurines Excavated from the Tomb of Qibi Ming, China. Molecules 2023, 28, 7739. [Google Scholar] [CrossRef]

- Mohamed, H.M.; Mohamed, W.S. Evaluating nano Primal AC33 for protection and consolidation processes of archaeological pottery: A comparison study with silica and montmorillonite nanoparticles. Pigment Resin Technol. 2024, 53, 484–492. [Google Scholar] [CrossRef]

- Cultrone, G.; Sebastián, E.; Elert, K.; de la Torre, M.J.; Cazalla, O.; Rodriguez–Navarro, C. Influence of mineralogy and firing temperature on the porosity of bricks. J. Eur. Ceram. Soc. 2004, 24, 547–564. [Google Scholar] [CrossRef]

- Bruni, S.; Longoni, M.; De Filippi, F.; Calore, N.; Bagnasco Gianni, G. External Reflection FTIR Spectroscopy Applied to Archaeological Pottery: A Non-Invasive Investigation about Provenance and Firing Temperature. Minerals 2023, 13, 1211. [Google Scholar] [CrossRef]

- Daniele, V.; Taglieri, G.; Quaresima, R. The nanolimes in Cultural Heritage conservation: Characterisation and analysis of the carbonatation process. J. Cult. Herit. 2008, 9, 294–301. [Google Scholar] [CrossRef]

- Dei, L.; Salvadori, B. Nanotechnology in cultural heritage conservation: Nanometric slaked lime saves architectonic and artistic surfaces from decay. J. Cult. Herit. 2006, 7, 110–115. [Google Scholar] [CrossRef]

- Zornoza-Indart, A.; López-Arce, P.; López-Polín, L. Durability of traditional and new nanoparticle based consolidating products for the treatment of archaeological stone tools: Chert artifacts from Atapuerca sites (Burgos, Spain). J. Cult. Herit. 2017, 24, 9–21. [Google Scholar] [CrossRef]

- Franzoni, E.; Graziani, G.; Sassoni, E.; Bacilieri, G.; Griffa, M.; Lura, P. Solvent-based ethyl silicate for stone consolidation: Influence of the application technique on penetration depth, efficacy and pore occlusion. Mater. Struct. 2014, 48, 3503–3515. [Google Scholar] [CrossRef]

- Sierra-Fernandez, A.; Gomez-Villalba, L.S.; Rabanal, M.E.; Fort, R. New nanomaterials for applications in conservation and restoration of stony materials: A review. Mater. Constr. 2017, 67, e107. [Google Scholar] [CrossRef]

- Ricciotti, L.; Occhicone, A.; Ferone, C.; Cioffi, R.; Tarallo, O.; Roviello, G. Development of Geopolymer-Based Materials with Ceramic Waste for Artistic and Restoration Applications. Materials 2022, 15, 8600. [Google Scholar] [CrossRef]

- Bonazza, A.; Vidorni, G.; Natali, I.; Ciantelli, C.; Giosuè, C.; Tittarelli, F. Durability assessment to environmental impact of nano-structured consolidants on Carrara marble by field exposure tests. Sci. Total Environ. 2017, 575, 23–32. [Google Scholar] [CrossRef]

- Fistos, T.; Fierascu, I.; Doni, M.; Chican, I.E.; Fierascu, R.C. A Short Overview of Recent Developments in the Application of Polymeric Materials for the Conservation of Stone Cultural Heritage Elements. Materials 2022, 15, 6294. [Google Scholar] [CrossRef]

- Ikeoka, R.A.; Appoloni, C.R.; Scorzelli, R.B.; dos Santos, E.; Rizzutto, M.d.A.; Bandeira, A.M. Study of Ancient Pottery from the Brazilian Amazon Coast by EDXRF, PIXE, XRD, Mössbauer Spectroscopy and Computed Radiography. Minerals 2022, 12, 1302. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J. Synthesis of TEOS/PDMS-OH/CTAB composite coating material as a new stone consolidant formulation. Constr. Build. Mater. 2016, 122, 90–94. [Google Scholar] [CrossRef]

- Drelich, A.; Miller, J.; Donofrio, R.; Drelich, J. Novel Durable Antimicrobial Ceramic with Embedded Copper Sub-Microparticles for a Steady-State Release of Copper Ions. Materials 2017, 10, 775. [Google Scholar] [CrossRef]

- Zendri, E.; Biscontin, G.; Nardini, I.; Riato, S. Characterization and reactivity of silicatic consolidants. Constr. Build. Mater. 2007, 21, 1098–1106. [Google Scholar] [CrossRef]

- Ion, R.-M.; Pungoi, A.-E.; Iancu, L.; Grigorescu, R.M.; Vasilievici, G.; Gheboianu, A.I.; Slamnoiu-Teodorescu, S.; Alexandrescu, E. Compositional and Microstructural Investigations of Prehistoric Ceramics from Southern Romania (Middle Neolithic Pottery). Appl. Sci. 2024, 14, 5755. [Google Scholar] [CrossRef]

- Ferreira Pinto, A.P.; Delgado Rodrigues, J. Impacts of consolidation procedures on colour and absorption kinetics of carbonate stones. Stud. Conserv. 2014, 59, 79–90. [Google Scholar] [CrossRef]

- Cultrone, G.; Sanchez-Ibanez, V. Consolidation with ethyl silicate: How the amount of product alters the physical properties of the bricks and affects their durability. Mater. Constr. 2018, 68, 173. [Google Scholar] [CrossRef]

- Hu, X.; Lai, Y.; Hu, Y.; Li, Y.; Zhao, D.; Tong, F. Research on the Application of Polymer Materials in Contemporary Ceramic Art Creation. Polymers 2022, 14, 552. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Yin, H.; Yuan, S.; Chen, Z. Film morphology and orientation of amino silicone adsorbed onto cellulose substrate. Appl. Surf. Sci. 2009, 225, 8435–8442. [Google Scholar] [CrossRef]

- He, W.; Zhang, Z.; Zheng, Y.; Qiao, S.; Xie, Y.; Sun, Y.; Qiao, K.; Feng, Z.; Wang, X.; Wang, J. Preparation of aminoalkyl-grafted bacterial cellulose membranes with improved antimicrobial properties for biomedical applications. J. Biomed. Mater. Res. Part A 2020, 108, 1086–1098. [Google Scholar] [CrossRef] [PubMed]

- Licchelli, M.; Malagodi, M.; Weththimuni, M.; Zanchi, C. Nanoparticles for conservation of bio-calcarenite stone. Appl. Phys. A 2013, 114, 673–683. [Google Scholar] [CrossRef]

- Chelazzi, D.; Poggi, G.; Jaidar, Y.; Toccafondi, N.; Giorgi, R.; Baglioni, P. Hydroxide nanoparticles for cultural heritage: Consolidation and protection of wall paintings and carbonate materials. J. Colloid Interface Sci. 2012, 392, 42–49. [Google Scholar] [CrossRef]

- Giorgi, R.; Ambrosi, M.; Toccafondi, N.; Baglioni, P. Nanoparticles for Cultural Heritage Conservation: Calcium and Barium Hydroxide Nanoparticles for Wall Painting Consolidation. Chem.-A Eur. J. 2010, 16, 9374–9382. [Google Scholar] [CrossRef]

- Yan, J.C.; Huang, G.; Li, X.N.; Liu, Q.; Liu, Y.; Yang, F.W.; Zhang, K.; Sun, Y.C. A comparative study between aqueous and methanol solutions of barium hydroxide: Implications for applying barium protectants in gypsification calcareous relics. Herit. Sci. 2024, 12, 203. [Google Scholar] [CrossRef]

- Lu, R.C.; Wang, L.; Liu, Y.; Yang, F.W.; Yang, L.; Wang, L.Q.; Gao, X. Conservation of surface gypsification stone relics using methanol solution of barium hydroxide as a novel treating agent. Appl. Phys. A-Mater. Sci. Process. 2022, 128, 37. [Google Scholar] [CrossRef]

- Bourguignon, E.; Tomasin, P.; Detalle, V.; Vallet, J.-M.; Labouré, M.; Olteanu, I.; Favaro, M.; Chiurato, M.A.; Bernardi, A.; Becherini, F. Calcium alkoxides as alternative consolidants for wall paintings: Evaluation of their performance in laboratory and on site, on model and original samples, in comparison to conventional products. J. Cult. Herit. 2018, 29, 54–66. [Google Scholar] [CrossRef]

- Ibrahim, M.M.; Mohamed, S.O.; Hefni, Y.K.; Ahmed, A.I. Nanomaterials for Consolidation and Protection of Egyptian Faience Form Matteria, Egypt. J. Nano Res. 2019, 56, 39–48. [Google Scholar] [CrossRef]

- Rodrigues, J.D.; Grossi, A. Indicators and ratings for the compatibility assessment of conservation actions. J. Cult. Herit. 2007, 8, 32–43. [Google Scholar] [CrossRef]

- Graziani, G.; Sassoni, E.; Franzoni, E. Consolidation of porous carbonate stones by an innovative phosphate treatment: Mechanical strengthening and physical-microstructural compatibility in comparison with TEOS-based treatments. Herit. Sci. 2015, 3, 1–6. [Google Scholar] [CrossRef]

- Rong, Y.; Yang, J.; Huang, S.; Li, Y. Barium Hydroxide Nanoparticle–Phosphoric Acid System for Desalination and Consolidation of Tomb Murals. Crystals 2022, 12, 1171. [Google Scholar] [CrossRef]

- Franzoni, E.; Pigino, B.; Leemann, A.; Lura, P. Use of TEOS for fired-clay bricks consolidation. Mater. Struct. 2013, 47, 1175–1184. [Google Scholar] [CrossRef]

- Maravelaki, P.-N.; Kapetanaki, K.; Stefanakis, D. TEOS-PDMS-Calcium Oxalate Hydrophobic Nanocomposite for Protection and Stone Consolidation. Heritage 2021, 4, 4068–4075. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Yang, X.; Xu, S. New method for the protection of calcareous cultural heritage stones by aluminium phosphate modified hydroxyapatite. Constr. Build. Mater. 2024, 431, 136551. [Google Scholar] [CrossRef]

- Liu, R.; Han, X.; Huang, X.; Li, W.; Luo, H. Preparation of three-component TEOS-based composites for stone conservation by sol–gel process. J. Sol-Gel Sci. Technol. 2013, 68, 19–30. [Google Scholar] [CrossRef]

- Navarro-Moreno, D.; Martínez-Arredondo, A.; García-Vera, V.E.; Lourdes Gutiérrez-Carrillo, M.; Antonio Madrid, J.; Lanzón, M. Nanolime, ethyl silicate and sodium silicate: Advantages and inconveniences in consolidating ancient bricks (XII–XIII century). Constr. Build. Mater. 2021, 277, 122240. [Google Scholar] [CrossRef]

- Zhao, G.; Ma, X.; Shao, Z.; Huang, X.; Huang, J.; Luo, H. Breathable hyperbranched polysiloxane for the conservation of silicate cultural heritages. J. Sol-Gel Sci. Technol. 2022, 106, 518–529. [Google Scholar] [CrossRef]

- Xu, Q.; Zhou, H.; Huang, X.; Zhao, X.; Huang, J.; Luo, H. In-situ formation of one-dimensional silica for conservation of silicate relics using cellulose nanocrystals as templates. J. Cult. Herit. 2023, 62, 349–355. [Google Scholar] [CrossRef]

- Ilieș, D.C.; Apopei, A.-I.; Ilieș, A.; Caciora, T.; Zharas, B.; Hodor, N.; Turza, A.; Hassan, T.H.; Barbu-Tudoran, L.; Pereș, A.C.; et al. Preserving Cultural Heritage: Enhancing Limestone Durability with Nano-TiO2 Coating. Heritage 2024, 7, 4914–4932. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, T.; Xu, N.; Su, X.; Chu, R.; Peng, Z.; Shen, S.; Jia, Z.; Zhou, Y.; Xing, H.; Li, Y.; et al. A Novel Organic–Inorganic Composite with Outstanding Comprehensive Reinforcement Properties for Dealing with Salt Efflorescence of Pottery. Coatings 2025, 15, 1209. https://doi.org/10.3390/coatings15101209

Tan T, Xu N, Su X, Chu R, Peng Z, Shen S, Jia Z, Zhou Y, Xing H, Li Y, et al. A Novel Organic–Inorganic Composite with Outstanding Comprehensive Reinforcement Properties for Dealing with Salt Efflorescence of Pottery. Coatings. 2025; 15(10):1209. https://doi.org/10.3390/coatings15101209

Chicago/Turabian StyleTan, Tao, Nuo Xu, Xinyuan Su, Rui Chu, Zhanhui Peng, Shukun Shen, Zhihui Jia, Yajun Zhou, Huiping Xing, Yuhu Li, and et al. 2025. "A Novel Organic–Inorganic Composite with Outstanding Comprehensive Reinforcement Properties for Dealing with Salt Efflorescence of Pottery" Coatings 15, no. 10: 1209. https://doi.org/10.3390/coatings15101209

APA StyleTan, T., Xu, N., Su, X., Chu, R., Peng, Z., Shen, S., Jia, Z., Zhou, Y., Xing, H., Li, Y., & Chao, X. (2025). A Novel Organic–Inorganic Composite with Outstanding Comprehensive Reinforcement Properties for Dealing with Salt Efflorescence of Pottery. Coatings, 15(10), 1209. https://doi.org/10.3390/coatings15101209