Abstract

Since the introduction of containerization in 1956, its growth has led to a corresponding growth in the role of container seaborne traffic in world trade. To respond to such growth, requirements for setting up the common standards in various kinds of container harbor equipment, and identifying performance indicators to assess container handling equipment performance have increased. Although the operating systems in ship-to-shore cranes may be different at each container terminal, the four main movements are the same: hoist, trolley, gantry, and boom. By determining in this work the hour metrics for each movement, it was possible to define the key performance indicators to be adopted and assess ship-to-shore crane performance. The research results identified that the mean time between failures is decreasing because of the accumulation of long-lasting heavyweight operations, while the number of maintenance of machine parts incidents and man-hours is steadily increasing. The key performance indicators offer a management tool to guide future ship-to-shore container crane inspection and the results provide useful insights for future container crane equipment operation improvements.

1. Introduction

International merchandise trade by sea, measured in tons, accounts for over 80% of the total cargo volume in world trade [1]. Container shipping, as a productive sector, must be competitive and respond effectively to customer requirements [2,3]. Terminal customers are many and very different, but the requirements that all of them demand are fundamental: frequency of service and regularity to transport their loads in a fast, economical way and with minimum risk of damages and losses. In the container terminal operating system, the gantry crane is not only the most expensive and important piece of cargo-handling machinery but also a major bottleneck restricting the working efficiency of the entire marina. All container terminals expect quay cranes can conduct operations with the best efficiency. Container terminal managers pay more and more attention to improving the operational efficiency of gantry cranes [4,5]. The equipment handling containers has steadily developed by handling high loads, with high speed, and safety through technology development to accommodate the needs of the shipping companies as the volume of offshore transportation through containers has accelerated [6,7]. Among them, ship-to-shore (STS) cranes have been developed with technologies to ensure durability and reliability under these conditions, but this equipment will inevitably lead to situations where the number of failures is gradually increasing over time under the harsh conditions of the repeated heavy weight and high-speed operations [8]. Comparing the number of failures in the early stages of the equipment introduction to the number of failures after a few years is a reality that the repeated tasks will inevitably lead to increased failure rates as fatigue builds up in structures and internal components, which can lead to fatigue failure. Efforts to identify the frequency of failures and their patterns to create standardized indicators have been attempted continuously. In 2003, Hutchison Ports attempted to establish a common performance indicator for all container terminals in its hierarchy. The specification of the STS crane varies by terminal and company because when the initial specifications of the crane are drawn up in the container terminal, details such as the size to handle and twin lift operation, tandem lift operation, etc, may vary. The STS crane to be used is determined by container terminals according to their requirements [9]. With the different specifications of the STS crane in each of these container terminals, it is difficult to measure the crane performance, but if we think of STS cranes considering their operation itself, there is something in common that comes up: even if each movement of the crane has different characteristics and specifications, the four main movements match any country in the world and any container terminal [10]. These four main movements are hoist, trolley, gantry and boom, each of which has an hour meter installed for each movement, and the detection of individual usage time can be used to define and calculate the crane performance index. Therefore, this study aims to develop key performance indicators that can be applied and their use to assess ship-to-shore crane performance in container terminal operations. As a result of research and efforts on how much preventive maintenance time can be calculated quantitatively in case of failure by detecting purely the behavior of the crane and the number of failures, performance indicators have been defined and assessed for the 14 STS cranes at the Hutchison Korea Terminal (HKT) from 2013 to 2018. The key performance indicators offer a management tool to guide future ship-to-shore container crane inspection and the results provide useful insights for future container crane equipment improvement.

2. Introduction of Ship-to-Shore Crane and Performance Indicators

2.1. Ship-to-Shore Crane

Ship-to-shore cranes are called Rail Mounted Quay Cranes (RMQCs) or Portainers, and Container Cranes (C/Cs). In practical terms, they are all gantry-type cranes that handle containers that are installed on the inside wall of dock and have the ability to unload containers from a container ship to dock and load containers at the pier, sometimes with lifting beams instead of spreaders, and the capability indication method is indicated by the hoist safe working load [8]. It is categorized by the shape of the crane, divided into the modified apex-frame type, articulated type, low profile type [8], and the rope trolley type, semi rope trolley, and greave trolley types according to the type of trolley [10,11].

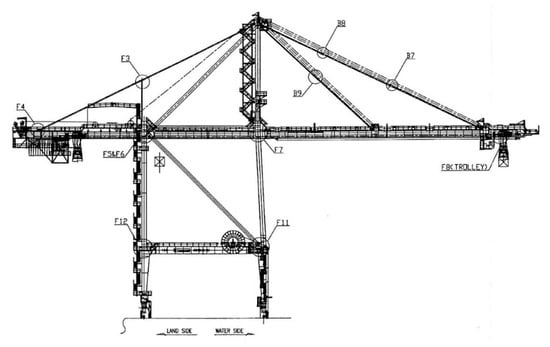

As a product feature (Figure 1), the structures all generally consist of a boom, girder, leg, top leg, top beam, diaphragm, tension bar, and the mechanical units are the gantry device that moves the entire crane to the left or right, the trolley device that moves the trolley to the boom and girder, the hoist device that moves the spreader and container vertically, and as additional devices there may be a load anti-snag device and a catenary rope support system [12].

Figure 1.

Ship-to-shore crane in container terminal operations.

2.2. Crane Performance Indicators

This section introduces the performance indicators to be defined to get to the key performance indicators. It is based on hour meters per each detailed movement of the crane. When we apply all the maintenance time and hour metrics to the crane for the defined performance indicators, we only apply the pure time when the equipment is shut down for preventive or corrective maintenance. This means that even if several workers perform the different types of maintenance (electricity, machine, or outside process maintenance) on a particular part, we can detect and apply only the absolute value of a particular time even if they perform a different type of maintenance tasks at the same time. Crane performance indicators adopted in container terminal operations are as follows:

- (1)

- Tem: Total time for emergency maintenance

- (2)

- Tps: Total time for preventive maintenance

- (3)

- Fem: Frequency of emergency breakdown

- (4)

- TLC: Twist lock count (lock + hoisting-lowering + unlock)

- (5)

- Top: Total operating time of crane (gantry + boom hoist + main hoist + trolley-overlapping motion of main hoist & trolley)

- (6)

- Tno: Time of net operation (main hoist + trolley-overlapping main hoist/trolley)

- (7)

- Toc: Total occupied time (control source on time)

- (8)

- Tmc: Total machine time (24 h/day for 24 hour terminal operations)

- (9)

- MMBF: Mean movements between failure (calculation formula: TLC/Fem)

- (10)

- MTTR: Mean time to repair (calculation formula: Tem/Fem)

- (11)

- Utilization: operation time (calculation formula: (Top/ (Tmc - Tps - Tem)) × 100%)

- (12)

- Ai: Overall availability (calculation formula: ((Tmc - Tem - Tps)/Tmc) × 100%)

- (13)

- Ao: Availability per occupied time (calculation formula: ((Toc - Tem)/Toc) × 100%)

- (14)

- Breakdown percentage (calculation formula: 1 - Ao%)

- (15)

- PM: Preventive maintenance (calculation formula: (Tps/Tmc) × 100%)

- (16)

- EM: Emergency maintenance (calculation formula: (Tem/Tmc) × 100%)

- (17)

- TDT: Total downtime (calculation formula: 1 - Ai or (PM% + EM%))

- (18)

- Net cycle time: pure time to handle 1 VAN of a container (calculation formula: (Tno × 60)/TLC)

- (19)

- Theoretical handling capacity: theoretical container handling quantity for 1 hour (calculation formula: 60/net cycle time)

Among the performance indicators above, the representative and the most import indicators are MMBF and MTTR for container terminals. In the recently built container terminals, the various indicators are managed through the system to indicate the maintenance quality control measures of the equipment while trying to increase the overall availability of equipment and minimize the failure rate of equipment through systematic equipment maintenance. The maintenance measures of general equipment are managed from a perspective such as frequency of maintenance and maintenance cost. First, as an element of the maintenance frequency, MMBF and MTTR defined in this paper can be applied. Relative to reliability and maintainability, container handling count number between failure rates, called MMBF, which is a reliability factor, are the basis for determining the frequency of failures. Maintenance is related to minimizing preventive maintenance as well as system or corrective maintenance, and preventive maintenance is intended to increase the reliability of equipment. However, too much money spent on preventive maintenance can exceed one’s budget, therefore maintenance should maintain an appropriate balance between the cost of failure maintenance and preventive maintenance. The average time spent on maintenance per unit failure (MTTR) is the average time required between unit failure, the basis for determining the need for spare parts, and in some cases, maintenance is possible without spare part replacement, but most maintenance cases require some part(s) replacement. The engineering department at the container terminal should prepare for this to maximize the average replacement cycle of the parts by anticipating and managing the life of the spare parts. Second, as a component of the maintenance cost, the maintenance cost of a system or piece of equipment accounts for a significant portion of the life cycle cost and is dependent on the design phase determination. The economic aspects of the maintenance activities are critical and maintenance should be implemented at the minimum cost possible. Maintenance costs should minimize the need for technicians for maintenance and proper usage, replacement and failure of spare parts within their life cycle. A measure of the maintenance of container terminal equipment is a measure of the quantitative readjustment of equipment operation at a container terminal, which indicates whether the equipment can be returned to normal conditions within the given time by the preventive maintenance level in the event of system or equipment failure. The measurement of maintenance is closely related not only to the design of the equipment itself, but to the level of technical skill acquisition by the technicians and the availability of spare parts. The meaning of quantitative measure of maintenance of container terminal equipment considering the characteristics of port equipment can be expressed as follows:

- (1)

- To realize the efficient and effective maintenance

- (2)

- To realize the maintenance with quality

- (3)

- To deliver the maintenance in the time allowed

- (4)

- To deliver maintenance cost and added value from manpower

- (5)

- To realize the maintenance its priority is safety

To facilitate this series of maintenance tasks, it is important to have adequate (in quantity and quality) maintenance personnel in this stage. Maintenance personnel shall have a certain level of technical skills and at least three to five years of work experience in the same field to perform the required maintenance, and securing maintenance personnel with technical skills is considered an important factor in improving maintenance efficiency and productivity of container terminals. Man-hours is a factor that has lots to do with MMBF and MTTR. Postponing performing the preventive maintenance on time with an increase in handling volume would result in a decrease in MMBF and an increase in MTTR. In the absence of a proper number of technicians, it is practically impossible to have good results for the two figures with a limited number of technicians. Also, the aging of equipment is one of factors that influences man-hours. It can be seen in Table 1 that the man-hours of mechanical and electrical maintenance of crane groups D and E whose useful life is already beyond their designed critical life are steadily increasing. In the absence of replenishment of technicians, the mathematically constant man-hours puts a load on the remaining technicians due to a series of global recessions and the global financial crisis, resulting in extreme conditions that can only be addressed with inefficient maintenance and minimal preventive maintenance. If a container terminal is financially available, outside maintenance support can be requested and used, however, this may not be the best solution to address the shortage of trained workers at each container terminal due to profitability and cost savings. Once sufficient technicians are available and new equipment is introduced, the target MMBF, MTTR, and man-hour figures can be fully achieved. If there is a surplus of man-hours left, the maintenance cost can be reduced by either dispatching those people to areas that they did not access before and where they might want to perform maintenance due to lack of time and man-hours in normal conditions or performing maintenance such as replacing wire ropes or some task that is dangerous to do with one’s own technicians using outsourced maintenance personnel.

Table 1.

Man-hour and maintenance assessment.

3. Key Performance Indicators and Man-Hours

3.1. Mean Movements between Failure (MMBF)

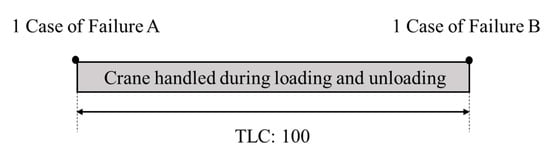

MMBF is defined as a twist lock count (TLC, Unit: VAN) divided by failure maintenance case. If this is interpreted, the crane corresponding to the denominator shall be marked with one physical failure when crane operation is stopped due to a partial defect in the crane itself and maintenance is required. The operating conditions of the TLC corresponding to the numerator are three steps to fulfill. The first step is forward or backward operation of the trolley, the second step is up or down operation of the hoist, and the third step is the lock or unlock operation of twist lock pins. MMBF is a numerical representation of how many containers the crane handled during loading and unloading operations, for instance, between one failure of "A" and one failure of "B". Figure 2 shows and example where this is expressed numerically.

Figure 2.

Mean movements between failures.

In Figure 2, if the TLC count between two failures is 100, the resulting value of MMBF is calculated as follows: MMBF = TLC/Fem = 100/2 = 50 VAN/Fem. The resulting value of MMBF is 50. It is simply a single number, but this metric has an important meaning for the engineering department. It indicates how much time and resources the engineering department has invested in preventive maintenance so that continuous work can be done without failure under the extreme conditions of climate change and heavy loading operations in the long term.

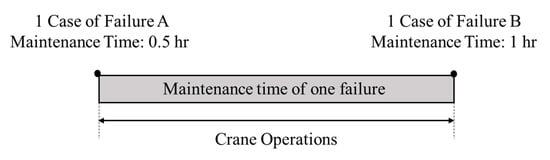

3.2. Mean Time to Repair (MTTR)

MTTR is defined as total time for emergency maintenance divided by the failure maintenance cases. If this is interpreted, the crane corresponding to the denominator is marked with one failure when its operation is stopped due to a component defect in the crane itself and maintenance is required. The total time for emergency maintenance, which corresponds to a numerator, is defined as the time from the start time when the crane is stopped during operation to the time when the crane is put back into work immediately after the repair is completed. MTTR can be expressed numerically as shown in Figure 3, if the crane has a maintenance time of one failure, e.g., A and maintenance time of one failure of B, during loading and unloading operations of a crane.

Figure 3.

Mean time to repair.

Here, MTTR = Tem/Fem = (0.5+1.0)/2 = 0.75 h/Fem. The resulting value of the MTTR is 0.75. What this figure represents is how fast the maintenance per unit failure occurs during the operation to detect the time before the crane re-enters operation. Efforts to reduce this figure require the workers in the engineering department to expertise, skill, and grasp the characteristics of the equipment on a crane. Although diagnose mechanical part failures is quick by examining the part visually and observing the symptoms, for failures occurring in electrical and control systems it may be necessary to find failed parts among a number of hidden items, so they need to learn how to use and read the Crane Monitoring System (CMS) installed on each crane and to understand various the interlocks to protect the equipment.

3.3. Man-Hour

Man-hour quota is a main indicator for the production planning and the economic evaluation, so its determination method is very important for cost accounting. Most of our small and medium-sized enterprises belong to the multi-variety kind with little mass production, and the specifications are changeable, so it is hard to establish a time quota. Now the enterprises generally use the experienced judgment, standard data and Predetermined Time Standard System (PTSS) methods to decide the man-hour quota, which needs experienced technicians and management over a long term to determine it, as it requires a longer period, a higher workload and is also easily affected by subjective factors. Accuracy and scientific precision are difficult to ensure. All of these result in great difficulty in production planning and cost control. Currently, extensive research is being conducted on determining the man-hour time and great progress has been made. Some studies show that the standard time can be calculated based on typical operations, and a rule for selecting standard time quotas of typical operations and the methods can be expounded [8].

A man-hour is the amount of work performed by the average worker in one hour. It is used for estimation of the total amount of uninterrupted labor required to perform a task. For instance, researching and writing a college paper might require eighty man-hours, while preparing a family banquet from scratch might require ten man-hours.

Man-hours exclude the breaks that people generally require from work, e.g., for rest, eating, and other bodily functions. Only pure labor is counted [9]. This concept can be adapted to port workers to calculate and plan the appropriate amount of human resources needed to increase operation productivity in a container terminal. The calculation formula is as follows: Man-hour = maintenance hour × count of the working person. For instance, if there are two persons worked on the same task for 8 hours, the result is 16 man-hours.

4. Results and Discussion

4.1. MMBF and MTTR Assessment

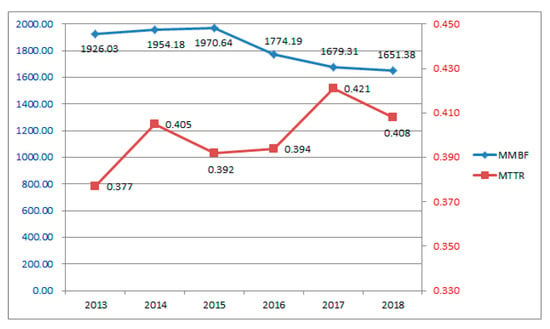

The data was collected from 14 STS cranes of Hutchison Korea Terminal (HKT) from 2013 to 2018. Table 1 lists the MMBF and MTTR values measured at HKT from 2013 to 2018.

Table 1 and Figure 4 show the results of the performance assessment from 2013 to 2018, which indicates that 2013 is the lowest and 2017 is the highest among the years measured. A high level of TLC eventually means an increase in volume. The increase also has advantages, but it also has disadvantages among performance indicators, because breakdown frequency increases together. Higher utilization also increases breakdown frequency, resulting in a fall in the value of overall availability (Ai) subtracting all preventive maintenance hours from the theoretical workable time, and an increase in availability per occupied time (Ao) subtracting only the failure maintenance time during the control power input time. What’s interesting about 2017 is that the company has been performing a certain amount of PM with the given manpower conditions without hiring more technicians and that the MMBF is not the lowest. This shows good results for MMBF if the TLC corresponding to the numerator becomes higher even if the breakdown frequency corresponding to the denominator is higher. Besides, EM levels are highest due to high utilization and due to frequent breakdowns, the physical handling capacity and MTTR are the lowest. Figure 4 shows MMBF is increasing slightly from 2013 to 2015 due to increased handling volume. Although there has been an increase in volume since 2016, it can be seen that the MTTR during maintenance time increased due to emergency maintenance and the MMBF and MTTR decreased together in 2018 due to a slight decrease in volume. The value of MMBF should be higher, but each result per year shows the values were going down gradually. On the other hand, it is better than the value of MTTR is lower, but each result per year shows the values were going up gradually. This means the aging of the cranes caused problems gradually through the whole components and fatigue accumulated in parts of the cranes.

Figure 4.

MMBF and MTTR assessment from 2013 to 2017.

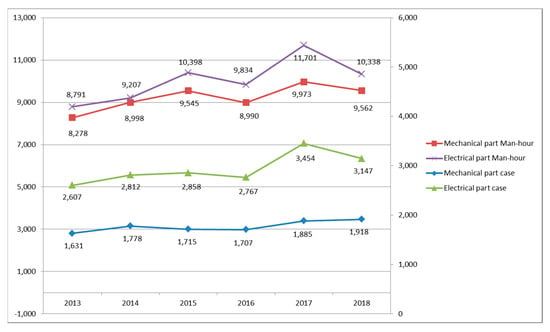

4.2. Man-Hour and Maintenance Assessment

Man-hours has been always the oldest and major standard through the whole industry to be visualized in numbers to plan a budget for the future and dispatch the appropriate amount of human resources to fulfill tasks that we need in the right spot and the parts designated to be repaired. These are the result values of man-hour and case spent on mechanical and electric parts of STS cranes from 2013 to 2018:

- (1)

- Crane group A: 4 units

- (2)

- Crane group B: 3 units

- (3)

- Crane group C: 1 unit

- (4)

- Crane group D: 3 units

- (5)

- Crane group E: 3 units

Table 2 shows that man-hours and cases in the mechanical and electrical sectors are the smallest in 2013, and the man-hour and cases in the mechanical and electrical sectors are the highest in 2017 like those of MMBF and MTTR. This man-hour value indicates all cases involving both preventive and emergency maintenance. Something interesting is that the performance indicators in Table 1 and man-hours show a similar trend. Looking at Table 1 and Table 2 above, it can be seen that the number of MMBFs is decreasing due to the continuous increase in the volume of containers handled at the terminal and the increase in fatigue of crane structures due to accumulation of long-lasting heavy load operations, whereas the number of machine part maintenance events and man-hours are steadily increasing The results of MMBF, MTTR, emergency maintenance, and preventive maintenance indicate a predictable correlation. A lower preventive maintenance rate would increase emergency maintenance and also see a decrease in the number of MMBF. Figure 5 shows that MTTR is also reduced at the same time that the failure rate is reduced. It can be seen that MMBF increases proportionally if preventive maintenance of the equipment is thoroughly carried out. The results are aggregated to maintain good maintenance rate of equipment by increasing MMBF of equipment according to the flow of emergency maintenance rates, and it is also possible to assume that equipment cannot undergo the proper preventive maintenance normally when there is more volume increase in the container terminals. Periodic preventive maintenance shall be performed to manage the maintenance of the equipment beyond the target, and a prompt response shall be made in the event of unexpected failure or equipment failure during vessel operation. Man-hours is one of the performance indicators used throughout all industries that existed before the creation of MMBF and MTTR. An engineering department in a container terminal can calculate man-hours based on statistics and provide reference values for switching to outside processed tasks when there is an insufficient man-hour figure for performing work with the current man-hour reserves for future projects or construction.

Table 2.

Crane performance assessment of Hutchison Korea Terminal (2013~2018).

Figure 5.

Man-hour and maintenance assessment results.

5. Conclusions

This study defines that KPIs can be used and adapted to STS cranes in container terminals with four main movements. With KPIs, the engineering department at a container terminal can calculate the numbers that show the performance of STS cranes in actual operation and circumstances. MMBF can describe how much time and resources the engineering department has invested in preventive maintenance in numbers. MTTR can indicate the efforts by the engineering department at the container terminal to reduce this figure, which requires the workers in the engineering department to have the needed expertise and skills and grasp the characteristics of the equipment on a crane in ongoing use. Man-hour and maintenance cases are gradually increasing from heavy load weight operation and volume increase. MMBF and MTTR are completed based on the hour meter accumulated through the motion of a crane that did not previously exist. Without the artificial intervention of humans, a pure reference to the hour meter allows us to determine the good and bad values of these figures based on the maintenance time spent on the equipment, and above all, it can be a common indicator for different container terminals operating worldwide. For instance, it may be difficult in reality to find a performance indicator with the same criteria under different characteristics and capacities of the operating crane between business unit A and business unit B, but the performance indicators described in this paper can be defined if the hour meters mentioned in this paper are installed on each crane. Of course, we expect that most of the recently introduced STS cranes are equipped with related hour meters, although the conditions necessary to install the hour meters for each action should be possible. If each container terminal produces the results on a monthly basis by setting target figures for MMBF and MTTR, it could identify general decreases in MMBF by result, and MTTR would identify which areas have experienced multiple failures, and the MTTR result allows equipment to be replaced so that there will be no disruption to the vessel operation and the intended productivity of the vessel operation. In addition, MMBF and MTTR are directly related to man-hours itself, dispatching the given and fixed manpower to the right place where they have to doing PM and EM by predicting the expected resource requirements correctly and it will allow performing PM and EM without using or hiring outside manpower in case there is a lack of man-hours that has to be handled in one’s resource, and this will eventually go to the goal that all of companies in the world pursue: cost savings. Performance indicators, which can be used in common within a container terminal, are essential, as are common indicators in all other industries. MMBF, MTTR, and man-hours are thought to be the unified and standardized criteria for many of those arithmetic indices. Lastly, suggestions for future studies employing simulation, experiment or actual machine running are required.

Author Contributions

Conceptualization, J.-H.J.; methodology J.-H.J.; validation, J.-H.J.; formal analysis, J.-H.J.; investigation, J.-H.J.; resources, J.-H.J.; data curation, J.-H.J.; writing-original draft preparation, J.-H.J.; writing-review and editing, S.K.; visualization, J.-H.J. and S.K.; supervision, S.K.. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank the anonymous reviewers and handling editors for their constructive comments that greatly improved this article from its original form.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Park, N.G.; Suh, S.C. Tendency toward mega containerships and the constraints of container terminals. J. Mar. Sci. Eng. 2019, 7, 131. [Google Scholar] [CrossRef]

- Kang, D.; Kim, S. Conceptual model development of sustainability practices: The case of port operations for collaboration and governance. Sustainability 2017, 9, 2333. [Google Scholar] [CrossRef]

- Kim, S.; Chiang, B.G. The role of sustainability practices in international port operations: An analysis of moderation effect. J. Korea Trade 2017, 21. [Google Scholar] [CrossRef]

- Haoyuan, L.; Sun, Q. Simulation-based optimization on quay crane scheduling of container terminals. In Proceedings of the 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017. [Google Scholar]

- Ali, D.; Dulebenets, M.A.; Golias, M.M.; Sheikholeslami, A. A novel continuous berth scheduling model at multiple marine container terminals with tidal considerations. Marit. Bus. Rev. 2017, 2, 1421–1457. [Google Scholar]

- Abourraja, M.N.; Mohamed, O.; Mustapha, Y.S.; Mohamed, B.; Boudebous, D.; Fazziki, A.E.; Najib, M.; Bouain, A.; Rouky, N. A multi-agent-based simulation model for rail-rail transshipment: An engineering approach for gantry crane scheduling. IEEE Access 2017, 5, 13142–13156. [Google Scholar] [CrossRef]

- Azimi, P.; Reza, G.M. Simulation modeling for analysis and evaluation of the internal handling fleet system at Shahid Rajaee container port. Int. J. Ind. Manuf. Eng. 2011, 5, 1091–1102. [Google Scholar]

- Chen, W.K. Linear Networks and Systems; Belmont: Wadsworth, OH, USA, 1993. [Google Scholar]

- Schøyen, H.; Bjorbæk, C.T.; Steger-Jensen, K.; Bouhmala, N.; Burki, U. Measuring the contribution of logistics delivery Performance outcomes and deep sea Container liner Connectivity on Port Efficiency. Res. Transp. Bus. Manag. 2018, 28, 66–76. [Google Scholar] [CrossRef]

- Dong, F.S.; Zhang, Z.M.; Jia, X.L.; Huang, L.J.; Liu, S.N. The standard time calculation based on typical operation. Mach. Des. Manuf. 2006, 10, 1741–1776. [Google Scholar]

- Euchi, J.; Moussi, R.; Ndiaye, F.; Yassine, A. Ant colony optimization for solving the container stacking problem: Case of Le Havre (France) seaport terminal. Int. J. Appl. Logist. 2016, 6, 81–101. [Google Scholar] [CrossRef]

- Zheng, S.; Sha, J.; Wang, A. An improved storage-space selection model and algorithm for outbound shipping containers: Considering the synchronous operation of multiple gantry cranes in port terminals worldwide. J. Coast. Res. 2019, 35, 1120–1130. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).