Abstract

Chili pepper (Capsicum annuum L.), a globally important economic crop, faces production challenges characterized by high labor intensity, cost, and inefficiency. Intelligent technologies offer key opportunities for sector transformation. This review begins by outlining the diversity of major chili pepper cultivars, differences in key quality indicators, and the resulting specific harvesting needs. It then reviews recent progress in intelligent perception, recognition, and automation within the chili pepper industry. For perception and recognition, the review covers the evolution from traditional image processing to deep learning-based methods (e.g., YOLO and Mask R-CNN achieving a mAP > 90% in specific studies) for pepper detection, segmentation, and fine-grained cultivar identification, analyzing the performance and optimization in complex environments. In terms of automation, we systematically discuss the principles and feasibility of different mechanized harvesting machines, consider the potential of vision-based keypoint detection for the point localization of picking, and explore motion planning and control for harvesting robots (e.g., robotic systems incorporating diverse end-effectors like soft grippers or cutting mechanisms and motion planning algorithms such as RRT) as well as seed cleaning/separation techniques and simulations (e.g., CFD and DEM) for equipment optimization. The main current research challenges are listed including the environmental adaptability/robustness, efficiency/real-time performance, multi-cultivar adaptability/flexibility, system integration, and cost-effectiveness. Finally, future directions are given (e.g., multimodal sensor fusion, lightweight models, and edge computing applications) in the hope of guiding the intelligent growth of the chili pepper industry.

1. Introduction

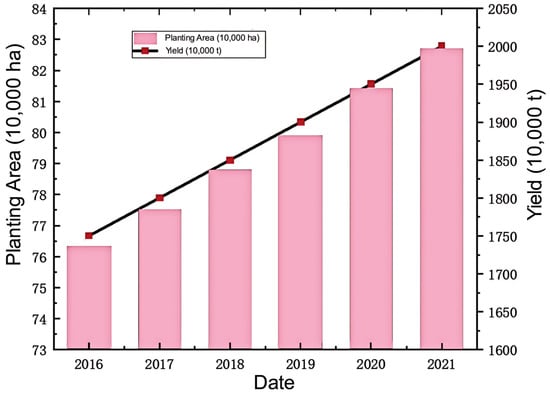

Chili pepper (Capsicum annuum L.), one of the most widely grown Solanaceous crops globally, not only contributes a distinctive pungency to global foods, but also occupies a prominent position in the global agricultural economy due to its high nutrient content and widespread economic uses [1,2]. China has a long history of cultivating chili peppers, and there are producing areas all across China, making it one of China’s major economic crops, being extensively grown in the southwest part of the country. Statistical data prove that China is one of the world’s biggest producers, ranking first in terms of production and planting area (Figure 1). During 2017–2022, domestic production rose from 18.11 million tons to 20.53 million tons, on a total area of approximately 852,800 hectares [1]. Not only does the chili pepper sector meet the large domestic demand, but the product forms keep expanding, from fresh consumption, dried chili, and chili paste to deep-processing products such as capsanthin and capsicum oleoresin. This ongoing expansion of the value chain leads to continually increasing economic value [3,4]. Regional brands, like specialty varieties of Zunyi and Chaotian chili of Guizhou, for instance, not only form regional brands, but also promote local economic development and the farmers’ incomes [5,6,7,8].

Figure 1.

Planting area and production of pepper in China. The data presented in the figure were derived from the National Bureau of Statistics of China (NBS) [9].

However, despite this apparent prosperity, the development of the chili pepper industry, especially in its production stages, faces a series of severe challenges. Traditional chili pepper production processes, including cultivation management, pest and disease identification, maturity assessment and harvesting, and seed cleaning, remain heavily reliant on manual labor [2,10,11]. Due to the plant’s characteristic of simultaneous flowering and fruiting, the peppers do not ripen uniformly within a concentrated period. Unlike many staple crops with uniform maturation and robust structures, chili peppers exhibit significant varietal diversity in morphology as well as simultaneous flowering and fruiting, leading to non-uniform ripening and fruit fragility. This necessitates repeated, selective manual harvesting cycles (Figure 2) [8,12], a practice rendered increasingly unsustainable by escalating labor shortages. This labor-intensive production model is inherently inefficient. Furthermore, evolving socio-economic conditions and demographic shifts in rural areas have led to increasing labor shortages and rising labor costs, significantly constraining further industrial development and improvements in profitability [13]. The diversity among chili pepper cultivars, with variations in morphology, size, color, and growth habits—and even subtle differences within the same cultivar at different maturity stages or under varying light conditions—poses considerable difficulties for standardization and mechanization [14,15]. During harvesting, the relative fragility of chili peppers makes them susceptible to damage during mechanized operations, potentially impacting the commercial quality and subsequent processing. Moreover, unique botanical features, such as dense foliage, frequent fruit occlusion by leaves or other fruits, and the pronounced color similarity between green peppers and leaves, pose substantially greater challenges for automated visual perception systems compared with, for instance, fruits exhibiting a distinct color contrast against foliage or cultivated in more open canopy structures. In seed production, where seeds constitute a significant by-product accounting for 30–60% of the dry weight, traditional cleaning and separation methods suffer from low efficiency and high rates of loss and breakage, failing to meet the demands for precision sowing and high-quality seed sources [3,13]. Moreover, the complex and variable growing environment—characterized by mutual occlusion between plants, color similarity between foliage and fruits, and uneven illumination—places higher demands on precise recognition and automated operations. In hilly and mountainous regions, such as those in southwest China, topographical constraints further exacerbate the difficulties in promoting and adopting mechanized and automated technologies [12].

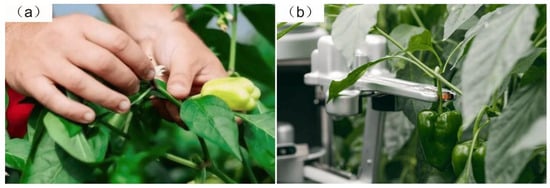

Figure 2.

(a) Cultivation systems of chili peppers and (b) manual harvesting practices.

Facing these bottlenecks and challenges, the deep integration of modern information technology and artificial intelligence (AI) with agricultural production, alongside the development of intelligent and automated technologies and equipment, has become an inevitable choice and an urgent necessity for driving the transformation, upgrading, and high-quality development of the chili pepper industry [1,12,16,17]. In recent years, AI technologies, particularly deep learning, have achieved breakthrough advancements in areas like image recognition and object detection, providing powerful technical support for tasks such as accurately perceiving crop status, identifying different cultivars and maturity levels, and locating optimal picking points (Figure 3) [18,19,20]. Researchers have started utilizing convolutional neural networks, object detection systems, and keypoint detection models to address issues like spotting chili fruits against intricate backgrounds, recognizing plants, and identifying where to harvest the fruits. They wish to improve the way, precisely and reliably, that these systems spot the objects. In parallel with this, research on robot technologies for the automatic harvesting of chili pepper is more active on themes from manipulator motion planning and control, picking sequence optimization, to the end-effector design, all toward the goal of optimizing the operating efficiency without damaging the fruit and plant. In seed processing, research focusing on the design and optimization of seed cleaning and separation devices, integrating techniques like fluid dynamics and simulation, is opening new avenues for improving the seed quality and utilization rates [21,22,23,24,25]. The use of these new technologies can not only emancipate farmers from time and labor-consuming and inefficient manual work, but also greatly improve the efficiency, quality, and consistency of chili pepper cultivation [26] and harvesting [27,28,29,30,31,32,33,34,35,36,37,38,39,40] as well as lower costs, therefore, possessing great practical value and strategic importance to the sustainable development of the industry.

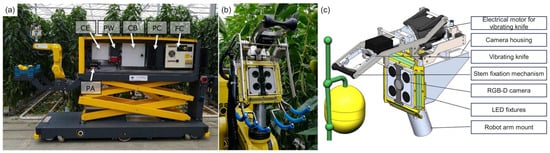

Figure 3.

(a) The SWEEPER prototype consists of a Fanuc LR Mate 200iD robot arm (Fanuc Corporation, Oshino, Yamanashi, Japan) mounted on an automated cart with a scissor lift. The end effector mounted at the tip of the robot arm contains a cutting mechanism, an imaging system, and a fruit catching device. The photo shows the prototype with the side panel opened. CB, controller box power and network; CE, controller box end effector; FC, FANUC robot controller; PA, compressor for pressured air; PC, computer; PW, power inverter. (b) End effector with cutting device, Fotonic F80 camera (Fotonic Inc., Sweden) LED illumination, and fruit catching device. (c) End effector components. The figure was reproduced from [18] with permission from Wiley Periodicals, Inc., 2020.

The aim of this review was to systematically summarize recent progress in research related to the intelligent development of the chili pepper industry, with a focus on intelligent perception and recognition technologies for the crop, key technologies and equipment for automated operations, and the main challenges associated with these developments. First, we outline the main chili pepper varieties, differences in quality traits, and specific harvesting demands. Here, we explore how the methods to detect and identify chili peppers developed, from classical approaches to deep learning. This includes analyzing the principles and adaptability of different types of chili harvesting devices and exploring motion planning strategies for harvesting robots. The current status of seed cleaning and separation technologies will also be discussed. Building upon this foundation, the review will summarize the main challenges confronting the current research and prospective future development directions. The ultimate goal is to provide valuable references for researchers and industry practitioners in related fields, thereby collectively advancing the intelligent transformation of the chili pepper industry.

While this review primarily focused on intelligent recognition for harvesting and post-harvest processing, it is acknowledged that automation opportunities in chili pepper production extend to other critical operations. These include precision irrigation, automated pest and disease scouting using drones or ground robots, targeted spraying systems to reduce chemical usage, and robotic weed management, all contributing to more sustainable and efficient cultivation practices.

We initiated this study by conducting a comprehensive literature review. Articles were retrieved from the Web of Science database and “CNKI” (China National Knowledge Infrastructure), resulting in the examination of 168 manuscripts.

2. Major Cultivars, Quality Variations, and Harvesting Requirements of Chili Pepper

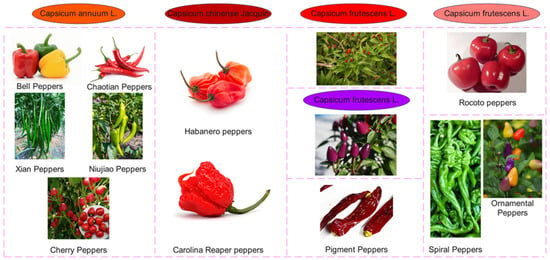

The genus Capsicum, which is native to South America, has more than 20 species today. Five of these are the principal species grown, and each of these has several cultivars with a notable variation in pungency, shape of the fruit, and color [41]. The primary categories and some sample cultivars are given below (Figure 4):

Figure 4.

The primary categories and some sample cultivars of chili peppers.

1. Capsicum annuum L.; cultivated varieties are:

Bell peppers (sweet peppers): Thick-fleshed, not strongly pungent, and variable fruit color (most often red, green, yellow); consumed predominantly as vegetables [42].

Chaotian peppers (Facing Heaven peppers): The fruits develop upward and have an intense pungency [43]. This upward orientation presents specific opportunities and challenges for mechanized harvesting, potentially favoring designs that approach from below or utilize stripping actions aligned with the plant’s vertical growth.

Xian peppers (linear peppers): Have long, rod-shaped fruits, often dried or used as a spice.

Niujiao peppers (Ox-horn peppers): Ox horn-shaped and are typically mild to moderately pungent.

Cherry peppers: Small, cherry-shaped fruits of intense pungency [44].

2. Capsicum chinense Jacquin; tropical Central and South American native, with frequently lantern-shaped or wrinkled fruits [45]. The species is renowned for its highly pungent cultivars (e.g., Habanero and Carolina Reaper peppers).

3. Capsicum frutescens L.; extensively used in the production of chili seasonings and sauces [46]. The common variety is the Xiaomila pepper, with erect fruits and very high pungency.

4. Capsicum baccatum; predominantly found in South America. Notable cultivars encompass Peru’s Ají Amarillo, recognized for its distinctive fruity and sweet-tart flavor characteristics, alongside a moderate level of heat [47].

5. Capsicum pubescens Ruiz. & Pav.; defined by the presence of pubescence (small hairs) on the fruit surface [48]. A well-known example is the rocoto pepper, which is defined by a relatively high cold tolerance and medium pungency.

6. Other significant categories:

Ornamental peppers (e.g., Wucaijiao): Cultivated for ornamental purposes, bearing fruit of multiple colors at maturity, suitable for container cultivation.

Luosijiao (spiral peppers): Characterized by thin skin (pericarp), a distinct spiral shape, and intense pungency [49], requiring extremely gentle handling during automated harvesting to prevent bruising or damage, influencing the end-effector design and force control.

Pickling peppers: Firm flesh, are apt for processing techniques such as pickling [50].

Pigment peppers: Usually cultivated to dry and from which colorants are naturally obtained (e.g., paprika oleoresin) [51].

Variations in chili pepper quality exist mainly in the texture/mouthfeel, pungency level, fruit shape, and nutritional content [52]. For example, thinly skinned pickling peppers (Bopi Paojiao) are often selected for fresh consumption because they have a crispy texture and fresh taste brought about by a thinner pericarp and lower cellulose content. Spiral-shaped peppers (Luosijiao), with the additional values of both pungency and aroma, are eaten because of their special shape and tender-crisp texture. Pungency varies greatly among cultivars, ranging from non-pungent cultivars like bell peppers to mildly pungent cultivars like Xian peppers and highly pungent cultivars like Xiaomila peppers. Pungency reflects the content of capsaicinoids and is quantified on the Scoville heat unit (SHU) scale [53]. Nutritional value (e.g., vitamin C, with the highest concentration in bell peppers in this genus) and carotenoids (e.g., capsanthin) also influence the market value and consumer acceptability [54,55]. Varieties such as wrinkled peppers (Zoupi Jiao) are sought after for their wrinkled nature and deep mature color, which offers novelty along with desirable textural attributes.

Harvesting practices and standards differ with cultivar and purpose [56], as illustrated in Table 1. Those intended for fresh use (e.g., pickling peppers with thin skins, spiral peppers) are typically harvested when fruits are full size and well-colored and have maximum crispness and moderate pungency; early or late harvest reduces the quality. For spiral peppers, the optimal quality is normally at the tender green phase, while Hangzhou peppers (Hangjiao) are typically picked at 10–14 cm in length with a slightly shriveled surface. Those to be dried must be harvested at biological maturity when the fruits are completely red or purple for the maximum capsaicinoid and oil content (e.g., Chaotian peppers, clustered peppers). Greenhouse peppers (usually early varieties) are two weeks ahead of field peppers at harvest time because of the controlled conditions. In low-pungent sweet pepper varieties, such as bell peppers, the smoothness of the skin and color are the criteria for deciding when to harvest. Xian peppers to be dried need to be harvested in a way to develop the desirable characteristics before wrinkles set in excessively after drying.

Table 1.

Comparison of main chili pepper types, physical characteristics, and harvesting consequences.

Existing chili combine harvesters primarily employ a single-pass, non-selective harvesting mode. While suitable for the large-scale collection of dried and industrial pigment chili varieties, this approach cannot effectively differentiate fruit maturity, often resulting in high rates of missed pods and mechanical damage. This “single-pass” harvesting method fails to meet the agronomic requirements for fresh-market chilies, which necessitate multiple, selective harvests throughout their ripening period; for instance, fresh market chilies in Ordos City, China, require harvesting in 3–4 distinct batches. Although traditional manual selective harvesting can distinguish maturity levels, it is hampered by low efficiency and inconsistent picking standards, bottlenecks that have become key factors constraining the development of the fresh-market chili industry. Therefore, achieving precise and efficient selective harvesting for fresh market chilies urgently requires the integration of deep learning, computer vision algorithms, and advanced sensor technologies to develop intelligent harvesting systems capable of autonomously identifying mature fruits and executing precise picking operations.

The rise of organic farming also presents specific considerations for chili pepper cultivation and automation. Cultivars exhibiting natural resilience to local pests and diseases, or those with growth habits that facilitate non-chemical weed control (e.g., vigorous canopy development), may be more suitable for organic systems. Automation can significantly support organic chili pepper farming by enabling precise, non-chemical weed management through robotic cultivators or targeted thermal/laser weeding, reducing the reliance on manual labor. Furthermore, automated monitoring systems can facilitate early pest/disease detection, allowing for timely intervention with organic-approved treatments. The requirements for automated harvesting in organic systems might even be more stringent regarding gentle handling to maintain the premium quality associated with organic produce, potentially influencing the end-effector design toward softer materials and more delicate force control.

3. Intelligent Perception and Recognition Technologies for Chili Pepper Crops

Successful and correct perception and recognition are at the core of enabling intelligence in the chili pepper industry. Key automatic applications, such as robotic harvesting (Figure 5), disease and pest identification, and quality grading, are all essentially based on the successful recognition of the chili pepper plants themselves and their immediate surrounding growing conditions. Researchers have attempted a series of technical paths, progressing from conventional image processing methods to advanced deep learning networks. This has continuously driven the advancement of the intelligent perception and recognition of chili peppers.

Figure 5.

Manual harvesting of chili peppers (a) and robotic harvesting of chili peppers (b).

3.1. Traditional Image Processing Methods and Their Limitations

Initial studies used conventional image processing methods as the primary means of segmenting chili pepper fruits from the background. These methods would typically exploit color, shape, or texture differences between the pepper fruits and the background (e.g., stems, leaves) to carry out segmentation and recognition. For example, amplification of the target-background color contrast through color space conversion (e.g., RGB (Red, Green, Blue) to HSV (Hue, Saturation, Value) or Lab space), followed by thresholding techniques (e.g., the standard Otsu’s approach of inter-class variance maximization [57]) for pepper area segmentation, was a popular approach [58,59]. Fourier analysis was employed to process image information in the frequency domain to enhance edges [60], whereas convex hull techniques facilitated the determination of the minimum convex boundary of the fruit contours, aiding in fruit separation and shape description [17,61]. Techniques such as the Hough transform were also applied to detect objects with specific geometric shapes (e.g., circles) within images [62,63], although their direct applicability remains limited for irregularly shaped chili peppers. With the advent of the machine learning era, researchers began utilizing feature descriptors, such as histogram of oriented gradients (HOG), to extract image features, subsequently employing classifiers like support vector machine (SVM) for identification purposes [64].

These conventional methods demonstrated a degree of effectiveness under specific, simplified scenarios, particularly within controlled laboratory environments characterized by uniform backgrounds and stable illumination conditions. However, their limitations become readily apparent when confronted with the complexities of real-world agricultural production environments. Factors such as dynamic variations in natural illumination, mutual occlusion, and overlap among fruits and between fruits and foliage (leaves and stems), color gradations resulting from different maturity stages, the high degree of color similarity between green peppers and green leaves, and complex, variable background interference significantly challenge the robustness and accuracy of these methods, which rely heavily on pre-defined parameters, fixed thresholds, or rigid feature extraction patterns. For instance, immature green chili peppers are notoriously difficult to segment from foliage using traditional color-based methods. Indeed, certain pepper types present greater recognition challenges. Green cultivars against dense green foliage, small and clustered varieties (e.g., some ornamental or bird’s eye types where individual fruit segmentation is difficult), peppers with highly variable morphology even within the same cultivar, or those significantly occluded by leaves or other fruits consistently test the limits of the current perception algorithms.

3.2. Deep Learning-Based Object Detection and Segmentation

The rapid evolution of deep learning methods in recent years has yielded breakthrough improvements, effectively breaking the limitations of traditional methods [18,19,20]. Convolutional neural networks (CNNs), a basic deep neural network, possess the ability to automatically learn and extract complex, hierarchical feature representations from large-scale data. This capacity gives them more robustness to illumination variation, scale variation, viewpoint variation, and occlusion variation, thereby significantly enhancing the performance of object detection and recognition. Due to these reasons, deep learning-based object detection and segmentation models have emerged as the mainstream approach for intelligent chili pepper recognition.

Single-stage object detection algorithms, exemplified by the YOLO (You Only Look Once) series [65,66], are particularly favored in agricultural applications demanding real-time processing capabilities due to their effective balance between computational speed and detection accuracy. Researchers have extensively applied and adapted YOLO-series models specifically for the task of chili pepper detection. For example, Yang et al. enhanced the model’s speed and precision for tomato recognition (a task analogous to chili pepper recognition) in complex environments by modifying the detection head of YOLOv4-tiny, incorporating attention mechanisms (e.g., CBAM) and optimizing the activation function (e.g., Mish) [67]. Zhu et al. reported the fast and precise detection of tomato fruits based on an enhanced version of YOLOv5s by incorporating cross-stage partial connections and Soft-NMS (non-maximum suppression), which significantly increased the accuracy along with a decrease in the miss rate [68]. Focusing specifically on chili peppers, Wei et al. suggested an improved YOLOv5s model with a bidirectional feature pyramid network (BiFPN) that improved the detection accuracy and showed high robustness under different light conditions (weak and strong light) [69]. Further refinements were made to YOLOv7-tiny by Wang et al. [70], who integrated a parameter-free attention mechanism (SimAM) and an improved loss function (Focal-EIOU) to boost the recognition accuracy and efficiency for sweet peppers (including deformed fruits), while Zhao et al. [71] enhanced the detection accuracy in field environments by incorporating a diverse branch block (DBB) module, the SimAM attention mechanism, and an optimized BiFPN for feature fusion. Xie et al. [72] leveraged the YOLOv8 model to boost the detection accuracy on chestnuts (like peppers in recognition challenge) through incorporating partial convolutions, a weighted BiFPN, and a redefined Wise-IoU (WIoU) loss function. Researchers have extensively applied and adapted YOLO-series models (e.g., YOLOv5s, YOLOv7-tiny), often achieving mean average precision (mAP) scores exceeding 90–95% in controlled or semi-controlled environments, with real-time processing capabilities (e.g., >30 FPS on suitable hardware) [65,66].

Aside from the YOLO family, other frameworks such as Faster R-CNN, SSD (Single Shot MultiBox Detector) [73], and instance segmentation-specific networks such as Mask R-CNN [74], while typically more computationally intensive, provide pixel-level masks crucial for precise localization and have demonstrated high intersection over union (IoU) scores (e.g., >0.85) for chili fruit segmentation. For example, Xiang et al. [75] employed an improved Mask R-CNN to achieve the effective stem classification of tomatoes. Lu et al. [76] also made a comparison between traditional segmentation techniques and deep learning algorithms like U-Net for segmenting chili peppers, empirically demonstrating the excellence of the deep learning approach; notably, U-Net exceeded in IoU and MPA when segmenting multiple, unoccluded peppers.

While conventional methods struggled with occlusion and real-time processing in dynamic field conditions, deep learning models, particularly single-stage detectors like the YOLO series, offer a compelling balance. YOLO variants are favored for their speed, crucial for real-time robotic harvesting, though their accuracy can sometimes be slightly lower than two-stage detectors like Faster R-CNN under severe occlusion. Conversely, instance segmentation models like Mask R-CNN, while providing detailed segmentation, often come with higher computational costs, making real-time deployment on mobile platforms challenging without significant model optimization or specialized hardware [77,78,79,80]. Therefore, advancements should focus on lightweight architectures and attention mechanisms to improve the robustness against occlusion and illumination changes while maintaining real-time performance.

These studies demonstrate the tremendous potential of deep learning-based models for the classification of chili peppers, as illustrated in Table 2.. They also report ongoing research for the further improvement in model performance (i.e., accuracy, reliability, and effectiveness) under challenging agricultural environments by means of, for example, the introduction of attention mechanisms [81,82], more feature fusion channels, improved loss functions [83], and very advanced data augmentation strategies (e.g., Mosaic, Cutout).

Table 2.

Comparison of key intelligent recognition models for chili pepper detection and segmentation.

3.3. Advances in Fine-Grained Chili Pepper Recognition Research

Apart from traditional object detection and segmentation, the fine-grained recognition of chili pepper crops is becoming a fundamental research issue. Fine-grained recognition aims to differentiate various chili pepper cultivars with high visual similarity. Such capability has important practical implications in cultivar purity certification, precision breeding, quality inspection, and cultivar-specific differential management. However, the mission is also made more challenging by the reality that various chili pepper cultivars can have minimal disparity in morphology, color, or texture (low inter-class variance), while the same cultivar can have significant disparity in appearance when subjected to varying growth stages, lighting, or cultivation practices (high intra-class variance).

Although deep learning research specifically targeting fine-grained chili pepper recognition is still in its nascent stages, leveraging insights from studies on the fine-grained recognition of other crops or species is of considerable importance. For instance, Feng et al. [84] proposed the CL (Contrastive Learning) ConvNeXt (Convolutional Neural Network for the Next Decade) model, which incorporates contrastive learning principles and a nonlinear projection layer, achieving promising results in the fine-grained classification of succulent plants. Zheng et al. [85] constructed a fine-grained grape pest recognition model based on an attribute feature knowledge graph, while Huang et al. [86] investigated few-shot detection and fine-grained recognition methods for apple leaf diseases, focusing on feature separation techniques. Furthermore, Jia et al. [87] utilized Res2Net combined with bilinear attention mechanisms to enhance the fine-grained recognition capability for different stages of tomato leaf diseases.

The methods utilized in these associated research, including attention mechanisms, feature disentanglement, knowledge graph embedding, and contrastive learning, provide transferable solutions and insights to the prospective task of the fine-grained recognition of various chili pepper species.

4. Key Technologies and Equipment for Automated Chili Pepper Operations

Driven by ever-increasing labor costs and pressures for enhanced production efficiency and product quality, the automation of processes of chili pepper production, particularly the harvesting and seed cleaning stages, has emerged as an essential prerequisite for industrial development and is an area of focused research priority [12,13]. Correspondingly, extensive research studies and practical endeavors have addressed areas that include mechanized harvesting machines, robotic approaches to harvesting, and efficient seed processing systems.

While mechanized harvesting and seed cleaning represent critical areas for automation due to their high labor intensity, the scope of automated operations in chili pepper production is broader. This section primarily details harvesting and seed processing technologies, but it is pertinent to acknowledge advancements in other areas. These allied automation technologies, while not the central focus here, contribute to the overall intelligent management of chili pepper crops, such as:

(1) Automated field monitoring: Utilizing drones or ground-based robots equipped with multispectral/hyperspectral cameras for assessing plant health, water stress, and nutrient deficiencies.

(2) Precision spraying and fertigation: Sensor-guided systems for targeted application of inputs, minimizing waste and environmental impact.

(3) Robotic weeding: Implementing mechanical or vision-guided laser systems for non-chemical weed control, particularly relevant for organic production.

4.1. Mechanized Chili Pepper Harvesting Technologies and Devices

Traditional chili harvesting is primarily based on manual labor, but its low efficiency severely constrains the development of the chili industry. Research into mechanized chili harvesting began earlier in Western countries (Europe and America), mainly focusing on pigment chilies and utilizing combine harvesting methods. Consequently, large agricultural machinery in Europe and America is often designed for multi-crop harvesting versatility; for example, Whitney [88] et al. modified and compared prototypes based on cotton harvesters, providing a theoretical research foundation for chili harvesters. In the United States, the Pik Rite company developed the Pik Rite tractor-pulled chili harvester (Figure 6a) [89]. China has gradually developed a chili cutting and drying machine (Figure 6b); the Xinjiang Machinery Research Institute, targeting the specific growth characteristics of linear (Xianla) and flat (Banjiao) chili types, developed the Mushen 4JZ-3600A self-propelled chili harvester (Xinjiang New Research Mshen Technology Co., Ltd., Urumqi, Xinjiang, China) [90].

Figure 6.

(a) Pik Rite two-row trailed chili harvester. (b) Chili cutting and drying machine. (c) Xinjiang combined chili harvester.

Mechanized harvesting is a straightforward method to substitute manual labor and increase the efficiency of chili pepper harvesting. Due to the variety of chili pepper cultivars and the susceptibility of the fruit to damage, many types of harvesting devices have been domestically and internationally developed (Figure 7). The most important issue is how to efficiently detach fruits from the plant without damage [91,92]. According to the composition and working principles of harvesting parts, widely used chili pepper harvesting machines mainly include the drum-finger type, double-helix type, and comb-type [93].

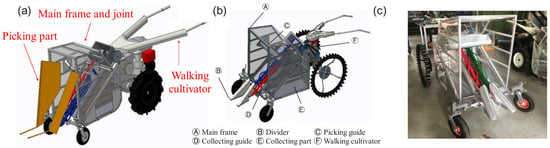

Figure 7.

(a) 3D design of the first prototype of a chili pepper harvester attached to a walking cultivator, 3D design (b), and image (c) of the second prototype of a chili pepper harvester attached to a walking cultivator. The figure was reproduced from [4] with permission from MDPI, 2020.

1. Drum-finger type: This type of device is typically employed for harvesting chili pepper cultivars with relatively long fruits and fragile structures such as pointed peppers and Chaotian peppers [93]. Its working principle involves utilizing flexible tines (fingers) mounted on a rotating drum to simulate the stripping or plucking action of human hands. Contact and flicking motions between the tines, the plant, and the fruits cause the peppers to detach [93,94]. The design of these flexible tines is critical to balance effective fruit detachment with minimal damage, influencing gripping interaction rather than precise force. This method is comparatively gentle, adapts well to densely growing fruits, and reduces fruit damage. However, parameters such as tine material, stiffness, arrangement, and drum rotational speed significantly influence the harvesting effectiveness (i.e., harvesting completion rate and damage rate) and require optimization based on specific cultivars and operating conditions [94].

2. Double-helix type: Double-helix harvesting devices, particularly those with an open double-helix structure, are primarily suited for harvesting relatively larger chili peppers such as green peppers and bell peppers. They operate by using two counter-rotating helical rods (augers) to clamp, comb, and strike the chili pepper plants entering the harvesting channel, causing the fruits to dislodge due to vibration or direct impact [95]. The advantages of this method include a relatively simple structure and strong capability for grasping and detaching larger fruits and has seen relatively widespread application in chili pepper harvesting in regions like the United States [96,97]. However, a drawback is the exertion of comparatively large forces, which can lead to higher damage rates for more fragile chili pepper cultivars [95].

3. Comb-type: Comb-type harvesting devices represent another significant category of mechanized harvesting. Depending on the morphology and structure of the combing elements, they can be further subdivided into rod-finger and belt-comb types.

Rod-finger type: The tines in these devices are typically rigid, rod-like structures. They function by combing through the plant’s foliage to dislodge the chili peppers. This method is suitable for cultivars with larger fruits and relatively tall plants such as certain red pepper varieties. However, it may result in a higher fruit damage rate, and its efficiency is constrained by the movement speed and density of the tines [98].

Belt-comb type: These devices utilize comb belts made of flexible material. The cyclic movement of these belts combs and detaches the fruits. This design is generally used for harvesting smaller, densely growing peppers like small chilies and Chaotian peppers. Its advantages lie in the gentle action of the flexible tines, better conformity to plant morphology, reduced damage, and the potential for continuous operation. Employing this belt-comb structure, an inverted trapezoidal grooved plate design was incorporated to enhance the harvesting efficiency and device durability [11].

While mechanized harvesters have improved efficiency to some degree, they are still plagued by a host of problems like restricted adaptability over a range of cultivars, impossibility to minimize the damage levels further, and an unsatisfactory operational accuracy. Accordingly, robotic technology-based precision harvesting is a higher grade of automation. One of the key steps of robotic harvesting is the localization of picking points [99]. This requires a vision system that is not only able to recognize the chili fruit, but can also precisely locate and identify good points to grasp or cut—most commonly the juncture of the pepper peduncle (fruit stalk) with the plant, or the peduncle itself [1].

Classical geometric feature or template matching-based methods struggle to address problems such as the dynamic morphology of chili peduncles and their susceptibility to occlusion. Recent years have seen a high potential being provided by deep learning-based keypoint detection models. Such models have the ability to learn intricate visual patterns corresponding to the chili peduncle and its environment and allow for reasonably good picking point localization despite partial occlusion or viewpoint change. Inspired by the ideas of human pose estimation [100,101] or face landmark detection [102], networks can be adjusted to recognize chili fruits and the corresponding picking points. Tafuro et al. [103] successfully applied a keypoint detection method (based on a modified Mask R-CNN within the Detectron2 framework) to locate strawberry picking points, achieving promising results and validating the feasibility of this technical approach in the domain of fruit and vegetable harvesting. Although deep learning-based keypoint detection research specifically targeting chili pepper picking points is still relatively scarce, this direction undoubtedly represents a crucial avenue for achieving precise, low-damage robotic harvesting.

4.2. Motion Planning and Control for Harvesting Robots

Chili pepper harvesting robots are typically composed of a mobile platform, a robotic arm (manipulator), an end-effector (e.g., gripper or cutter), and a visual perception system [12,104]. Among these components, the motion planning and control of the robotic arm represent the core technologies for enabling efficient, safe, and precise harvesting [12,105]. The objective of motion planning is to generate an optimal or sub-optimal trajectory for the manipulator, moving from a starting configuration to the target picking point while adhering to the kinematic and dynamic constraints as well as obstacle avoidance requirements [105,106].

Kinematic modeling of the harvesting robot is necessary to describe the relationship between the joint variables of the manipulator and the position and orientation (pose) of the end-effector in Cartesian space [107]. Forward kinematics calculates the end-effector pose based on known joint angles, whereas inverse kinematics solves for the corresponding joint angles given a desired end-effector pose. The latter forms the basis for trajectory planning but can be more complex to solve, potentially yielding multiple solutions or no solution [107,108]. For common collaborative robots like the AUBO i5, kinematic modeling can be accomplished by establishing standard Denavit–Hartenberg (D–H) parameter tables [108].

An effective end-effector design is paramount, ranging from soft grippers that conform to fruit shape and apply distributed, controlled gripping forces to minimize damage, to specialized cutting tools for precise peduncle severing. Motion control involves precise trajectory planning (e.g., using quintic polynomials or S-curve profiles) to ensure smooth, jerk-minimized movements, and robust control algorithms (e.g., PID (Proportional-Integral-Derivative), adaptive control) to handle dynamic uncertainties and ensure accurate positioning of the end-effector [109,110].

This can be executed either in joint space or Cartesian space [105]. Joint space planning involves the direct interpolation of each joint angle. It is computationally less demanding, easier to implement, and effectively avoids singularity issues; however, the resulting path shape of the end-effector is difficult to predict and control precisely [111]. Common methods include cubic polynomial interpolation, quintic polynomial interpolation, and trajectory planning using trapezoidal or S-curve velocity profiles that account for velocity and acceleration constraints [111,112]. Conversely, Cartesian space planning directly defines the path of the end-effector in three-dimensional space (e.g., as straight lines or circular arcs). This approach provides an intuitive trajectory, facilitating obstacle avoidance and coordinated tasks, but is computationally more intensive, requires solving the inverse kinematics problem, and is susceptible to encountering singularities [105,113].

To achieve superior trajectories (e.g., minimizing time, energy consumption, or jerk), researchers have widely applied intelligent optimization algorithms [73]. For example, algorithms such as the genetic algorithm (GA) [114], particle swarm optimization (PSO) [115,116], ant colony optimization (ACO) [117], simulated annealing (SA) [118], and neural networks (e.g., radial basis function neural networks, RBFNN) [119,120] have been utilized to optimize the trajectory parameters or directly search for optimal paths. Han et al. [75] combined an improved PSO algorithm with piecewise polynomial interpolation to optimize the trajectory of an industrial robot, effectively reducing the operational time. Li et al. [83] employed B-spline curves and an enhanced GA to achieve time-optimal trajectory planning for a six-axis robotic arm. These methodologies provide robust tools for generating smooth and efficient motion trajectories for chili pepper harvesting robots operating in complex environments.

When addressing multi-fruit harvesting tasks, picking sequence planning becomes necessary. This is often analogous to the traveling salesperson problem (TSP), aiming to find the shortest total path that visits all target fruits [99]. Heuristic algorithms such as GA, SA [118], ACO, and grey wolf optimization (GWO) [121] are commonly used to find approximate solutions for the optimal sequence. Furthermore, obstacle avoidance is a critical consideration in motion planning. The robot must be capable of perceiving obstacles within its workspace (e.g., plant branches, other fruits, parts of the robot itself) and actively avoids collisions during trajectory execution [113]. This typically requires integrating visual perception data with effective obstacle avoidance algorithms such as the artificial potential field (APF) method or rapidly-exploring random tree (RRT).

4.3. Chili Pepper Seed Cleaning and Separation Technologies

Chili pepper seeds serve not only as the vector for propagating subsequent crop generations, but also constitute a significant by-product of pepper processing, possessing considerable economic value [3]. Consequently, efficient and high-quality seed cleaning and separation technologies are of paramount importance to both the chili pepper seed production and processing industries [13,122,123,124,125,126,127,128,129,130,131]. The primary objective of cleaning and separation is to isolate the seeds from impurities such as the fruit pericarp (pulp), placenta, and other extraneous materials, and, where necessary, to grade the seeds based on specific criteria.

Traditional chili pepper seed extraction methods have, in general, been based on manual labor, which is a low-efficiency and high-labor-intensity process [13]. The introduction of mechanical cleaning and separating devices has significantly eased the situation. Based on different working principles, the main primary cleaning and separation processes are:

1. Air screening (winnowing): This involves the utilization of air flow to impose differential forces on materials (seeds, pericarp, trash, etc.) with varying densities and aerodynamic characteristics, thereby sorting them out [132,133]. The adjustment of air velocity and direction is crucial for controlling the efficacy of separation. Air screening systems typically feature a simple structure and relatively low cost, making them commonly employed for the initial removal of lighter impurities [133,134].

2. Sieving: This technique employs screens equipped with apertures of specific sizes and shapes to separate materials based on differences in their geometric dimensions [135,136]. Through the use of single or multiple layers of vibrating screens, seeds can be effectively isolated while removing both oversized and undersized impurities [136]. Key factors influencing the sieving performance include aperture shape and size, screen inclination angle, and the frequency and amplitude of vibration [136,137]. For instance, the chili seed extractor designed by Chayalakshmi et al. [138] incorporated a double-layer vibrating screen structure.

3. Air classification (cyclone separation): Materials are introduced into a high-velocity rotating airflow. Leveraging the combined effects of centrifugal force and gravity, materials with different densities settle and separate at distinct locations within the separator [21,22,23,24,25]. Cyclone separators are frequently utilized for removing dust and light impurities, exhibiting high separation efficiency [24,25].

4. Hydro-separation (flotation): This method leverages differences in the settling velocities of materials in water to achieve separation. For chili peppers, mature, viable seeds typically sink, whereas pericarp fragments and some non-viable or immature seeds tend to float, thus enabling separation. The chili seed extraction and separation machine engineered by Gao [139] utilized buoyancy within a water tank to achieve this separation between the seeds and pericarp.

To enhance the design efficiency and optimize the performance of these cleaning and separation devices, simulation technologies are assuming an increasingly vital role. Computational fluid dynamics (CFD) can simulate the airflow field distribution during the cleaning process, enabling the analysis of how air velocity and pressure influence material trajectories [58,140,141,142,143,144,145,146,147]. The discrete element method (DEM), conversely, allows for the simulation of interactions among particulate materials like seeds and pericarp as well as simulating behaviors such as collisions and friction between the materials and equipment surfaces [61,148,149,150,151,152,153,154,155,156,157,158]. Coupling CFD with DEM (CFD-DEM) facilitates a more comprehensive simulation of the complex gas-solid two-phase flow phenomena involved. This coupled approach provides detailed data support for the design optimization of equipment such as air screeners and air classifiers [72,73,99,159]. Researchers have employed the CFD–DEM coupled method to analyze the interplay between airflow fields and material movement within air-and-screen cleaning devices [76] and to optimize the structural parameters of cyclone separators for enhanced separation efficiency [81]. For instance, CFD software (e.g., ANSYS Fluent, OpenFOAM) is used to simulate airflow patterns and pressure distributions within air screeners or cyclone separators, allowing for the optimization of fan speeds, duct geometries, and baffle placements [58,140,141,142,143,144,145,146,147]. DEM software (e.g., EDEM, LIGGGHTS) models the discrete particulate behavior of seeds and impurities, simulating their trajectories, collisions, and interactions with machine components like vibrating sieves or conveyor belts [61,148,149,150,151,152,153,154,155,156,157,158]. Coupled CFD–DEM simulations are increasingly employed to analyze the complex gas–solid interactions, for example, to predict the lifting and transport of chaff by airflow while seeds are sieved, leading to more efficient designs [76]. Use of these simulation methods leads to improved comprehension of the basic cleaning and separating mechanisms, predictions of equipment performance, the possibility to reduce research and development times, and provides theoretical guidance for the design of more efficient, low-damaging chili pepper seed processing equipment.

5. Challenges and Future Prospects

Although the research into intelligent technologies in the chili pepper industry has achieved significant progress, demonstrating great promise in areas such as the accuracy of perception and recognition, efficiency of automated processing, and design of specialized equipment, tremendous challenges remain prior to the realization of large-scale, effective, and flawless application being achieved. Meanwhile, ongoing technology development keeps illuminating promising directions for future research endeavors.

5.1. Major Challenges in Current Research

1. Limited environmental adaptability and robustness: This represents a core challenge universally encountered in agricultural intelligent systems. The natural growing environment for chili peppers is characterized by dramatic variations in illumination, complex and mutable backgrounds (including soil, weeds, and plastic mulch), and frequent occlusion of target fruits by foliage or other fruits. These factors significantly compromise the stability and recognition accuracy of visual perception systems [1]. Variations in weather conditions (e.g., sunny, cloudy, rainy), time of day (e.g., morning, noon, dusk), and geographical differences in soil and climate impose stringent requirements on the generalization capabilities of the models. Presently, the majority of models are trained and evaluated under specific or constrained conditions; consequently, their performance often diminishes when deployed in authentic, dynamic field environments [12].

2. Need for improved operational efficiency and real-time performance: Although automation technologies aim to enhance efficiency, many current chili pepper harvesting robots still exhibit relatively long cycle times for single-fruit picking (existing cucumber harvesting requires tens of seconds [19,20], and apple harvesting over ten seconds [16]), falling significantly short of manual harvesting speeds [12,93]. This latency is primarily attributed to the time consumed by the perception, decision-making, planning, and control phases, compounded by the significant computational demands inherent in complex environments. For commercial applications necessitating high throughput (i.e., harvesting numerous fruits within constrained timeframes), the current operational efficiencies frequently prove inadequate. Concurrently, the efficiency of downstream processes, such as seed cleaning, must be commensurate with the harvesting stage to ensure the seamless and efficient operation of the overall production pipeline.

3. Insufficient multi-cultivar adaptability and operational flexibility: Chili peppers encompass a vast number of cultivars exhibiting significant variations in morphology, size, color, firmness, and growth habit. Existing recognition models and harvesting mechanisms are frequently tailored to specific cultivars or a narrow range thereof, limiting their generalizability across the diverse spectrum of chili pepper types [1,14,93]. For example, a drum-finger harvester suitable for elongated pointed peppers may be ill-suited for harvesting globe-shaped bell peppers. Similarly, a model trained to recognize mature red peppers might fail to accurately detect immature green or yellow fruits. Developing intelligent systems possessing enhanced adaptability to diverse cultivars and the capacity for flexible adjustment of operational strategies and parameters represents a critical unresolved challenge.

4. Challenges in system integration and cost control: Realizing intelligent automation in the chili pepper industry necessitates the efficient integration of multiple subsystems including perception, decision-making, control, and actuation (e.g., vision systems, robotic manipulators, end-effectors, mobile platforms, cleaning devices) [12,93,104,160]. The complexity of system integration is high, demanding coordinated operation and seamless data transfer among various modules. Critically, the hardware costs associated with advanced sensors (e.g., high-resolution cameras, LiDAR), high-performance computing units, and precision robotic arms remain substantial. When compounded by the expenses related to complex algorithm development and ongoing system maintenance, the overall price of integrated intelligent systems often becomes prohibitive for individual farmers or small-to-medium-sized agricultural enterprises, thereby constraining the widespread adoption and application of these technologies [12,93,161,162,163,164,165,166,167,168]

5.2. Future Research Directions

Addressing the aforementioned challenges, future research endeavors should concentrate on the following key areas:

1. Multimodal sensor fusion methods: A single sensor like typical RGB cameras has limited information prone to interference in harsh agro-environmental conditions. Future research will focus on the combined use of multimodal sensing technologies. This is the combination of information from multiple sensors, for example, RGB cameras, depth cameras (to capture three-dimensional information), thermal infrared cameras (to sense temperature gradients, which can be a sign of disease or ripeness levels), and hyperspectral/multispectral cameras (to capture more fine-grained spectral information to allow for fine-grained identification and quality assessment). Using more advanced data fusion algorithms to gain more comprehensive and credible environmental and crop information is essential to improving the anti-interference ability and recognition accuracy of perception systems.

2. Light-weight models and edge computing applications: In order to satisfy the strict demands on real-time responsiveness and affordability in farm vehicles, studies on light-weight deep learning models are called for. It is intended to greatly decrease the model computational complexity and the number of parameters without affecting the acceptable levels of accuracy. In parallel, the implementation of optimized models on edge devices or embedded platforms of relatively lower computing powers (i.e., edge computing) is needed. This approach reduces the reliance on cloud servers, allows for fast, local data processing and decision-making, and is an inherent way to address system responsiveness, reduce latency, and reduce network bandwidth demands.

3. Human–robot collaboration (HRC) and intelligent decision-making: Since the total replacement of human labor can be unrealistic and not economically viable in the near future, research in HRC models offers a more practical way forward. In such paradigms, humans can take on the role of complex decision-making, exception handling, and general operational oversight, while robots perform routine, repetitive tasks. At the same time, creating more and more sophisticated intelligent decision-making systems is important. Such systems must have the ability to optimize operational procedures (e.g., harvesting sequences) autonomously and dynamically regulate operational parameters (e.g., picking force, air screening velocity) according to the real-time sensor feedback, crop conditions, prevailing ambient environmental conditions, and pre-defined agronomic specifications, thus facilitating intelligent and adaptive operation control.

4. Agronomic environment-specific robotics technology: As a response to the complexity added by terrains, such as in hilly and mountainous areas as well as diverse patterns of cultivation, there is a necessity to design mobile platforms and robotic systems with improved traversability and flexibility. The need to promote synergistic cooperation between agronomy and robotics cannot be overemphasized. Research is needed to create predictive maintenance schedules and precision operation plans from dynamic crop growth models and real-time environmental sensing so that robot operations are increasingly aligned with known agronomic best practices and needs.

5. Deep interdisciplinary integration of technologies: Intelligent transformation of the chili pepper industry is, in essence, a systems engineering task involving the deep, synergistic integration of a broad range of disciplines, from agronomy to mechanical engineering, computer science, materials science, and control theory. Some of the most promising fields of interdisciplinary research cooperation include creating new chili pepper varieties that are specifically developed for compatibility with mechanized and automated processes (e.g., having characteristics like easy detachment of fruit, suitable peduncle strength, and compact maturation periods); inventing new biomimetic and soft materials to be utilized in low-damage harvesting end-effectors; and implementing advanced control theories for the improvement of motion precision, stability, and robustness of robots working in unstructured and dynamic farm settings.

6. Development of robotics for sustainable practices: Future research should increasingly focus on robotic systems that directly support sustainable agriculture including mechanical or targeted-energy (e.g., laser) weeding robots to reduce herbicide reliance and precision spraying robots that minimize pesticide application. This is crucial for both integrated pest management and certified organic farming systems, reducing the environmental load and meeting consumer demand for cleaner produce.

7. Tailored automation for diverse cultivation systems: Chili peppers are grown in both open-field and controlled greenhouse environments, each presenting unique automation challenges and opportunities. Greenhouse cultivation offers a more structured setting, potentially simplifying navigation and perception, but demands high precision for valuable crops. Open-field systems contend with greater environmental variability (unpredictable lighting, weather, complex terrain, larger scales), requiring more robust and adaptable robotic solutions. Future developments must address these distinct needs, potentially leading to specialized robotic platforms and algorithms for each system.

6. Conclusions

As an important industry in China’s agricultural economy, the intelligentization transformation and upgrading of the chili pepper industry have crucial implications for improving industrial competitiveness and the farmers’ revenue. This article, through the description of the main cultivars, quality differences, and harvesting demands of chili peppers, and the introduction of research achievements such as intelligent perception and recognition, the main intelligent operation technologies, and related equipment, has indicated the enormous potential and broad scope for the use of intelligent technologies in this industry. Spanning the path of evolution from traditional image processing to deep learning for precise chili pepper detection and recognition, the development of different mechanized harvesting machines to more sophisticated motion planning and control for harvesting robots, and the application of simulation techniques for efficient seed cleaning and separation, the relevant research has achieved great progress. They provide practical technological remedies to some of the biggest industry problems such as labor shortages, inefficiency of operations, and inability to ensure consistent quality control.

However, the way to the intelligent automation of the chili pepper business is still beset with difficulties. The intricate and highly variable agro-production environment places exacting demands on the ruggedness and versatility of such technologies. The current levels of cost-effectiveness and operational efficiency need to be further developed to be able to satisfy the demands of large-scale commercialization. Lack of multi-cultivar adaptability and operational flexibility hinder the universal application of current solutions. Moreover, intricacies in system integration and the cost factor constrain the broader acceptance and spread of such technologies.

Multimodal sensor fusion, lightweight models in conjunction with edge computing, human–robot collaboration combined with intelligent decision-making, robotics specialized for intricate agronomic settings, and profound interdisciplinary integration are some of the essential strategic orientations for the smart growth of the chili pepper industry. With persistent innovation and advances in these fields, it is hoped that additional efficient, stable, affordable, and intelligent technology and equipment can be established. This innovation will eventually culminate in the actual smart management of the whole value chain of chili peppers, from farm to table, giving a powerful impetus to the sustainable growth of the industry.

The systematic approach to reviewing intelligent recognition and automation, as applied here to chili peppers, alongside the identified technological challenges and future directions, is highly transferable. Indeed, many other specialty crops characterized by high labor intensity, significant varietal diversity, and stringent quality requirements (e.g., berries, tomatoes, cucumbers, table grapes, and various tree fruits) would benefit from similar comprehensive analyses to guide their respective paths toward intelligent and sustainable automated production.

Author Contributions

Conceptualization, S.T.; Methodology, S.T.; Investigation, S.T.; Data Curation, S.T.; Writing—Original Draft Preparation, S.T.; Visualization, S.T.; Writing—Review & Editing, Z.T., B.L., S.W. and X.G. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Key Laboratory Equipment of Modern Agricultural Equipment and Technology (Jiangsu University), Ministry of Education (MAET202306), the Xinjiang Production and Construction Corps Youth Talent Development Program, and the Science and Technology Project of the Xinjiang Production (2025CYL07).

Data Availability Statement

The data and the related conclusions presented in this article were all derived from the Web of Science database and “CNKI”(China National Knowledge Infrastructure).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Qiao, L.; Zhao, B.; Zong, Y.; Kou, C.; Dong, Y. Development Current Situation, Tendency, and Countermeasure for China’s Pepper Industry. China Veg. 2023, 9–15. [Google Scholar] [CrossRef]

- Zou, X.; Ma, Y.; Dai, X.; Li, X.; Yang, S. Spread and industry development of pepper in China. Acta Hortic. Sin. 2020, 47, 1715–1726. [Google Scholar] [CrossRef]

- Yong, S.S.; Cho, Y.; Kim, S.-B.; Chul, K.D. Field performance analysis of a card cleaner type separating system for a self-propelled pepper harvester. Korean J. Agric. Sci. 2020, 47, 921–931. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, D.-C.; Cho, Y. Performance Comparison and Evaluation of Two Small Chili Pepper Harvester Prototypes That Attach to Walking Cultivators. Appl. Sci. 2020, 10, 2570. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, H.; Wu, K. Research Progress of Breeading of Pepper in Guizhou. Tillage Cultiv. 2022, 42, 56–58. [Google Scholar] [CrossRef]

- People’s Daily Online. Guizhou: Transitioning from a Major Pepper Province to a Leading Pepper Powerhouse. China Veg. 2020, 105. [Google Scholar]

- Zhang, H.; Yang, S. Research on the current ctatus and countermeasures of vegetable industry development in Guizhou under the background of rural revitalization. China Cucurbits Veg. 2024, 37, 177–183. [Google Scholar] [CrossRef]

- Mao, D.; Jiang, H.; Tong, X.; Hu, J. Zunyi Chaotian Pepper Industry: Current Status and Development Considerations. China Veg. 2021, 7–9. [Google Scholar] [CrossRef]

- National Bureau of Statistics. Available online: https://data.stats.gov.cn/ (accessed on 22 April 2025).

- Fu, M.; Li, C.; Zheng, Z. Design and analysis of semi-automatic screw type pineapple picking-collecting machine. Chin. J. Eng. Des. 2020, 27, 487–497. [Google Scholar]

- Wang, S.; Wang, L. Pepper Harvester (CN201220199869.X); China National Intellectual Property Administration: Beijing, China, 2012. [Google Scholar]

- Liu, G.; Lin, S.; Wu, D.; Tang, Y.; Xu, W. Chaotian Pepper Harvesting Device: Design, Analysis, and Verification Machinery. 2021, 59, 29–33+62. Available online: https://m.fx361.com/news/2021/0122/20440717.html (accessed on 22 April 2025).

- Xu, L.; Li, Y.; Wang, X. Research development of grain damage during threshing. Trans. CSAE 2009, 25, 303–307. [Google Scholar]

- Chen, Y.; Wang, X.; Yang, W.; Peng, G.; Chen, J.; Yin, Y.; Yan, J. An efficient method for chili pepper variety classification and origin tracing based on an electronic nose and deep learning. Food Chem. 2025, 479, 143850. [Google Scholar] [CrossRef] [PubMed]

- Orobiyi, A.; Loko, Y.L.; Sanoussi, F.; Adjatin, A.; Gbaguidi, A.; Dansi, A.; Sanni, A. Horticultural practices and varietal diversity of chili pepper (Capsicum annuum L.) in Central and Northern Benin. Genet. Resour. Crop Evol. 2017, 64, 419–436. [Google Scholar] [CrossRef]

- Onishi, Y.; Yoshida, T.; Kurita, H.; Fukao, T.; Arihara, H.; Iwai, A. An automated fruit harvesting robot by using deep learning. ROBOMECH J. 2019, 6, 13. [Google Scholar] [CrossRef]

- Li, L.; Yang, H. Revised Detection and Localization Algorithm for Camellia oleifera FruitsBased on Convex Hull Theory. Trans. Chin. Soc. Agric. Mach. 2016, 47, 285–292+346. [Google Scholar]

- Arad, B.; Balendonck, J.; Barth, R.; Ben-Shahar, O.; Edan, Y.; Hellstrom, T.; Hemming, J.; Kurtser, P.; Ringdahl, O.; Tielen, T.; et al. Development of a sweet pepper harvesting robot. J. Field Robot. 2020, 37, 1027–1039. [Google Scholar] [CrossRef]

- Cheng, Y.; Tseng, C.-Y.; Nguyen, D.-M.; Lin, Y. YOLOv4-Driven Appearance Grading Filing Mechanism: Toward a High-Accuracy Tomato Grading Model through a Deep-Learning Framework. Mathematics 2022, 10, 3398. [Google Scholar] [CrossRef]

- Huang, J.; Zhao, X.; Gao, F.; Wen, X.; Jin, S.; Zhang, Y. Recognizing and detecting the strawberry at multi-stages usingimproved lightweight YOLOv5s. Trans. CSAE 2023, 39, 181–187. [Google Scholar]

- Xu, L.; Li, Y.; Li, Y.; Chai, X.; Qiu, J. Research Progress on Cleaning Technology and Device of Grain Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–16. [Google Scholar]

- Shen, Y.; Wu, M.; Guan, C.; Xie, W. Present Situation of Research and Expectation on Picking up Mechanism ofPlastic Film Collectors. J. Agric. Mech. Res. 2016, 38, 263–268. [Google Scholar] [CrossRef]

- Wei, Z.; Su, G.; Li, X.; Wang, F.; Sun, C.; Meng, P. Parameter Optimization and Test of Potato Harvester Wavy Sieve Based on EDEM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 109–122. [Google Scholar]

- Wang, B.; Yu, Z.; Hu, Z.; Cao, M.; Zhang, P.; Wang, B. Numerical Simulation and Experiment of Flow Field in Three Air Systems of Air Separation System of Peanut Pickup Harvester. Trans. Chin. Soc. Agric. Mach. 2021, 52, 103–114. [Google Scholar]

- Liu, D.; Lu, W.; Wang, X.; Li, X.; Xie, F. Research Status and Development Trend of Cyclone Separating Cleaning Unit of Combine Harvesters. Agric. Equip. Veh. Eng. 2016, 54, 8–13. [Google Scholar]

- Zhou, M.; Sun, H.; Xu, X.; Yang, J.; Wang, G.; Wei, Z.; Xu, T.; Yin, J. Study on the Method and Mechanism of Seedling Picking for Pepper (Capsicum annuum L.) Plug Seedlings. Agriculture 2024, 14, 11. [Google Scholar] [CrossRef]

- Wang, G.; He, B.; Han, D.; Zhang, H.; Wang, X.; Chen, Y.; Chen, X.; Zhao, R.; Li, G. Investigation of Collision Damage Mechanisms and Reduction Methods for Pod Pepper. Agriculture 2024, 14, 117. [Google Scholar] [CrossRef]

- Du, C.; Fang, W.; Han, D.; Chen, X.; Wang, X. Design and Experimental Study of a Biomimetic Pod-Pepper-Picking Drum Based on Multi-Finger Collaboration. Agriculture 2024, 14, 314. [Google Scholar] [CrossRef]

- Han, D.; Zhang, H.; Li, G.; Wang, G.; Wang, X.; Chen, Y.; Chen, X.; Wen, X.; Yang, Q.; Zhao, R. Development of a Bionic Picking Device for High Harvest and Low Loss Rate Pod Pepper Harvesting and Related Working Parameter Optimization Details. Agriculture 2024, 14, 859. [Google Scholar] [CrossRef]

- Song, Z.; Du, C.; Chen, Y.; Han, D.; Wang, X. Development and test of a spring-finger roller-type hot pepper picking header. J. Agric. Eng. 2024, 55. [Google Scholar] [CrossRef]

- Guan, C.; Fu, J.; Cui, Z.; Wang, S.; Gao, Q.; Yang, Y. Evaluation of the tribological and anti-adhesive properties of different materials coated rotary tillage blades. Soil Tillage Res. 2021, 209, 104933. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, E.; Mao, H.; Zuo, Z.; Peng, H.; Zhao, M.; Yu, Y.; Li, Z. Design and Testing of an Electric Side-Mounted Cabbage Harvester. Agriculture 2024, 14, 1741. [Google Scholar] [CrossRef]

- Ma, Z.; Wu, Z.; Li, Y.; Song, Z.; Yu, J.; Li, Y.; Xu, L. Study of the grain particle-conveying performance of a bionic non-smooth-structure screw conveyor. Biosyst. Eng. 2024, 238, 94–104. [Google Scholar] [CrossRef]

- Ma, Z.; Zhu, Y.; Wu, Z.; Traore, S.N.; Chen, D.; Xing, L. BP neural network model for material distribution prediction based on variable amplitude anti-blocking screening DEM simulations. Int. J. Agric. Biol. Eng. 2023, 16, 190–199. [Google Scholar] [CrossRef]

- Qing, Y.; Li, Y.; Xu, L.; Ma, Z. Screen oilseed rape (Brassica napus) suitable for low-loss mechanized harvesting. Agriculture 2021, 11, 504. [Google Scholar] [CrossRef]

- Qing, Y.; Li, Y.; Yang, Y.; Xu, L.; Ma, Z. Development and experiments on reel with improved tine trajectory for harvesting oilseed rape. Biosyst. Eng. 2021, 206, 19–31. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y.; Li, Y.; Ji, K. Research and experiment on variable-diameter threshing drum with movable radial plates for combine harvester. Agriculture 2023, 13, 1487. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Z.; Li, X.; Xue, Z.; Jin, M.; Deng, B. Near-Infrared-Based Measurement Method of Mass Flow Rate in Grain Vibration Feeding System. Agriculture 2024, 14, 1476. [Google Scholar] [CrossRef]

- Zhu, Z.; Chai, X.; Xu, L.; Quan, L.; Yuan, C.; Tian, S. Design and performance of a distributed electric drive system for a series hybrid electric combine harvester. Biosyst. Eng. 2023, 236, 160–174. [Google Scholar] [CrossRef]

- Barboza, G.E.; Carrizo Garcia, C.; de Bem Bianchetti, L.; Romero, M.V.; Scaldaferro, M. Monograph of wild and cultivated chili peppers (Capsicum L., Solanaceae). Phytokeys 2022, 200, 1–423. [Google Scholar] [CrossRef]

- Sanchez, E.S.; Butzler, T.M.; Bogash, S.M.; Elkner, T.E.; Oesterling, R.E.; Orzolek, M.D.; Stivers, L.J. Pennsylvania Statewide Bell Pepper Cultivar Evaluation. Horttechnology 2011, 21, 384–390. [Google Scholar] [CrossRef]

- Duan, Y.; Li, J.; Zou, C. Research on Detection Method of Chaotian Pepper in Complex Field Environments Based on YOLOv8. Sensors 2024, 24, 5632. [Google Scholar] [CrossRef] [PubMed]

- Valdez-Fragoso, A.; Saenz-Hernandez, C.M.; Welti-Chanes, J.; Mujica-Paz, H. Cherry pepper pickling: Mass transport and firmness parameters and stability indicators. J. Food Eng. 2009, 95, 648–655. [Google Scholar] [CrossRef]

- Martinez, M.; dos Santos, C.P.; Verruma-Bernardi, M.R.; Vasconcelos Martins Carrilho, E.N.; Moreira da Silva, P.P.; Fillet Spoto, M.H.; Ciarrocchi, I.R.; Sala, F.C. Agronomic, physical-chemical and sensory evaluation of pepper hybrids (Capsicum chinense Jacquin). Sci. Hortic. 2021, 277, 109819. [Google Scholar] [CrossRef]

- Lima, M.F.; Carvalho, S.I.C.; Ragassi, C.F.; Bianchetti, L.B.; Faleiro, F.G.; Reifschneider, F.J.B. Characterization of a pepper collection (Capsicum frutescens L.) from Brazil. Genet. Mol. Res. GMR 2017, 16, gmr16039704. [Google Scholar] [CrossRef]

- Guillen, N.G.; Tito, R.; Mendoza, N.G. Capsaicinoids and pungency in Capsicum chinense and Capsicum baccatum fruits1. Pesqui. Agropecuária Trop. 2018, 48, 237–244. [Google Scholar] [CrossRef]

- Perez-Reyes, T.Q.; Leyva-Mir, S.G.; Perez-Grajales, M.; Martinez-Damian, M.T.; Ramirez-Ramirez, I.; Castro-Brindis, R. Fruit quality of manzano pepper (Capsicum pubescens RUIZ & PAV.) Grafted on CM-334 (Capsicum annuum L.) Grown in Soil Infested With Phytophthora capsici Leonian. Rev. Fitotec. Mex. 2024, 47, 253–260. [Google Scholar] [CrossRef]

- Santos, R.M.C.; Nascimento, N.F.F.; Borem, A.; Finger, F.L.; Carvalho, G.C.; Nascimento, M.F.; Lemos, R.C.; Rego, E.R.; Rego, M.M. Ornamental Pepper Breeding: Could a Chili be a Flower Ornamental Plant? In Proceedings of the 7th International Symposium on New Floricultural Crops, Buenos Aires, Argentina, 22–25 November 2011; pp. 451–456. [Google Scholar]

- Lee, S.Y.; Sim, S.Y.; Seo, M.W.; Lee, S.W.; Lim, J.W.; Lee, Y.B. Changes in Fruit Characteristics after Brining of Pickling Pepper (Capsicum annuum L.) Cultivars. Hortic. Sci. Technol. 2006, 24, 168–176. [Google Scholar]

- Jiang, R.; Yang, S.; Yuan, L.; Xiao, H. Research progress of capsicum pigment in pepper fruit. Xinjiang Agric. Sci. 2024, 61, 2648–2657. [Google Scholar]

- Park, E.; Zhou, B.; Luo, Y.; Fonseca, J.M.; Stommel, J.R. Jalapeno Pepper Varieties Affect Fresh-Cut Product Qualities. Hortscience 2023, 58, S179. [Google Scholar]

- Bosland, P.W.; Coon, D.; Reeves, G. ‘Trinidad Moruga Scorpion’ Pepper is the World’s Hottest Measured Chile Pepper at More Than Two Million Scoville Heat Units. Horttechnology 2012, 22, 534–538. [Google Scholar] [CrossRef]

- Reis, R.C.; Castro, V.C.; Devilla, I.A.; Oliveira, C.A.; Barbosa, L.S.; Rodovalho, R. Effect Of Drying Temperature On The Nutritional And Antioxidant Qualities Of Cumari Peppers From Para (Capsicum chinense Jacqui). Braz. J. Chem. Eng. 2013, 30, 337–343. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, X.; Battino, M.; Wei, X.; Shi, J.; Zhao, L.; Liu, S.; Xiao, J.; Shi, B.; Zou, X. A comparative overview on chili pepper (capsicum genus) and sichuan pepper (zanthoxylum genus): From pungent spices to pharma-foods. Trends Food Sci. Technol. 2021, 117, 148–162. [Google Scholar] [CrossRef]

- Joukhadar, I.S.; Walker, S.J.; Funk, P.A. Comparative Mechanical Harvest Efficiency of Six New Mexico Pod-type Green Chile Pepper Cultivars. Horttechnology 2018, 28, 310–318. [Google Scholar] [CrossRef]

- Liao, J.; Wang, Y.; Yin, J.; Liu, L.; Zhang, S.; Zhu, D. Segmentation of Rice Seedlings Using the YCrCb Color Space and an Improved Otsu Method. Agronomy 2018, 8, 269. [Google Scholar] [CrossRef]

- Dong, F.; Guo, H.; Pan, J.; Han, Y. Study on safflower image segmentation based on an improved color difference model. For. Mach. Woodwork. Equip. 2023, 51, 68–74. [Google Scholar] [CrossRef]

- Zhao, W.; Ji, C.; Li, Y. Recognition of Ripe Apples Images in Natural Growth Conditions. Sci. Technol. Eng. 2012, 12, 6889–6891+6896. [Google Scholar]

- Kupe, M.; Sayinci, B.; Demir, B.; Ercisli, S.; Baron, M.; Sochor, J. Morphological Characteristics of Grapevine Cultivars and Closed Contour Analysis with Elliptic Fourier Descriptors. Plants 2021, 10, 1350. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y. Occluded Citrus Fruit Recognition Algorithm Based on Color Model and Threshold Segmentation. Comput. Technol. Autom. 2022, 41, 136–140. [Google Scholar] [CrossRef]

- Lin, G.; Tang, Y.; Zou, X.; Cheng, J.; Xiong, J. Fruit detection in natural environment using partial shape matching and probabilistic Hough transform. Precis. Agric. 2020, 21, 160–177. [Google Scholar] [CrossRef]

- Bargoti, S.; Underwood, J.P. Image Segmentation for Fruit Detection and Yield Estimation in Apple Orchards. J. Field Robot. 2017, 34, 1039–1060. [Google Scholar] [CrossRef]

- Xu, Y.; Imou, K.; Kaizu, Y.; Saga, K. Two-stage approach for detecting slightly overlapping strawberries using HOG descriptor. Biosyst. Eng. 2013, 115, 144–153. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 27–30 June 2016; IEEE: New York, NY, USA, 2016; pp. 779–788. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLO9000: Better, Faster, Stronger. In Proceedings of the 30th IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2016; IEEE: New York, NY, USA, 2017; pp. 6517–6525. [Google Scholar]

- Yang, J.; Qian, Z.; Zhang, Y.; Qin, Y.; Miao, H. Real-time recognition of tomatoes in complex environments based on improved YOLOv4-tiny. Trans. Chin. Soc. Agric. Eng. 2022, 38, 215–221. [Google Scholar]

- Zhu, Z.; Shan, J.; Yu, X.; Kong, D.; Wang, Q.; Xie, X. Target Detection Technology of Tomato Picking Robot Based on YOLOv5s. Transducer Microsyst. Technol. 2023, 42, 129–132. [Google Scholar] [CrossRef]

- Wei, T.; Liu, T.; Zhang, S.; Li, S.; Miao, H.; Liu, S. Research on Pepper Picking Robot Recognition and Positioning Method Based on Improved YOLOv5s. J. Yangzhou Univ. (Nat. Sci. Ed.) 2023, 26, 61–69. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, X.; Li, B.; Xu, S.; Yi, Z.; Zhao, J. Malformed Sweet Pepper Fruit Identification Algorithm Based on Improved YOLO v7 tiny. Trans. Chin. Soc. Agric. Mach. 2023, 54, 236–246. [Google Scholar]

- Zhao, P.; Qian, M.; Zhou, K.; Shan, Y.; Wu, H. Improvement of Sweet Pepper Fruit Detection in YOLOv7-Tiny Farming Environment. Comput. Eng. Appl. 2023, 59, 329–340. [Google Scholar]

- Li, M.; Xiao, Y.; Zong, W.; Song, B. Detecting chestnuts using improved lightweight YOLOv8. Trans. Chin. Soc. Agric. Eng. 2024, 40, 201–209. [Google Scholar]

- Biswas, D.; Su, H.; Wang, C.; Stevanovic, A.; Wang, W. An automatic traffic density estimation using Single Shot Detection (SSD) and MobileNet-SSD. Phys. Chem. Earth Parts A/B/C 2019, 110, 176–184. [Google Scholar] [CrossRef]