A New Mode of a Natural Convection Solar Greenhouse Dryer for Domestic Usage: Performance Assessment for Grape Drying

Abstract

1. Introduction

2. Materials and Methods

2.1. Solar Drying Setup

2.1.1. Solar Greenhouse Dryer (SGD)

2.1.2. Solar Air Heater (in Case of Forced Convection Drying Mode)

2.1.3. PV System

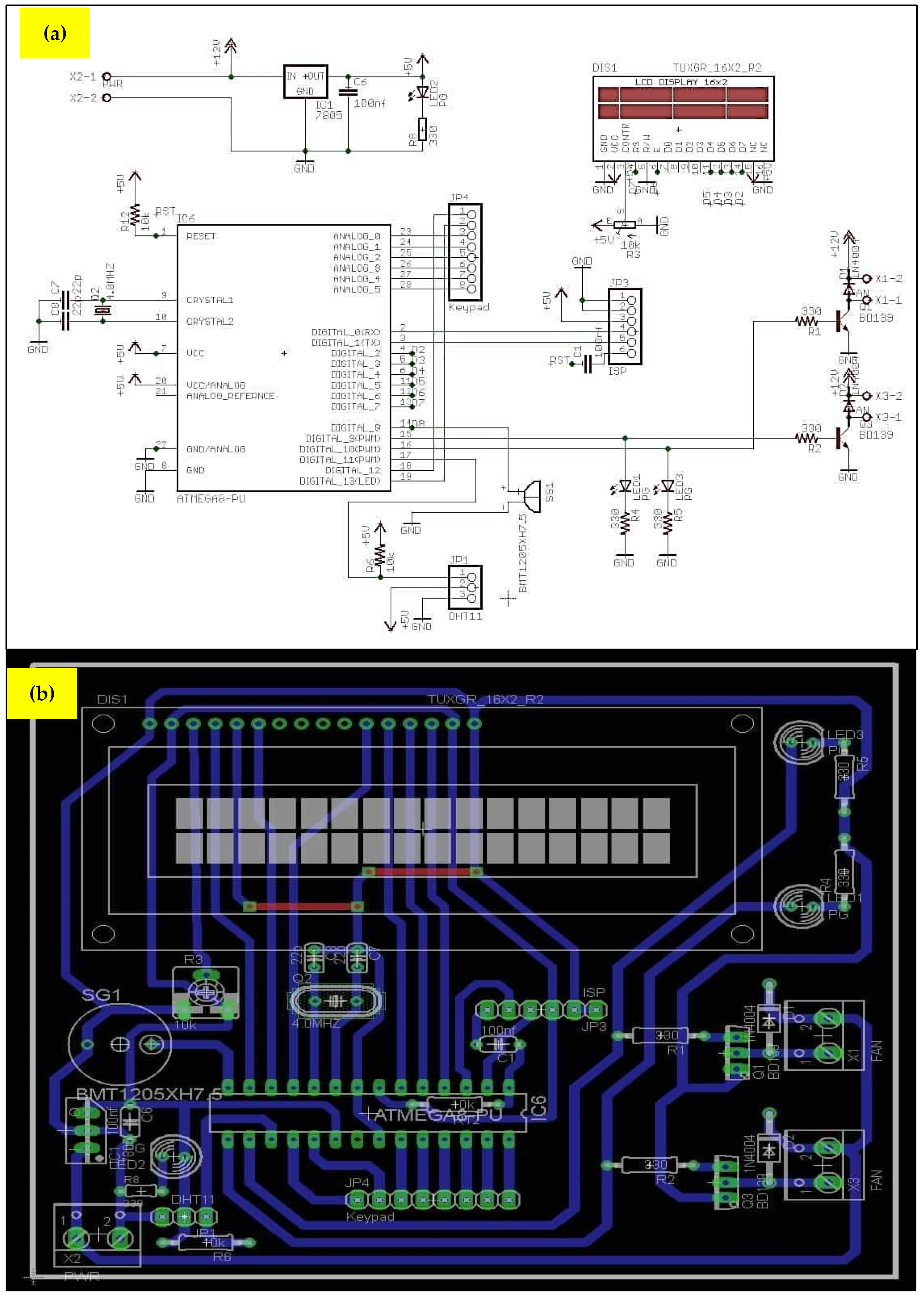

2.1.4. Automatic Control Unit (ACU)

2.2. Experimental Procedure

2.3. Measuring Instruments

2.4. Solar Drying Modes

2.4.1. Natural Convection Mode for SGD (CN-SGD)

2.4.2. Forced Convection Mode for SGD (FC-SGD)

2.4.3. Controlled Natural Convection Mode for SGD/New Mode (CNC-SGD)

2.5. Calculations and Determinations

2.5.1. Thermal Efficiency of SAH

2.5.2. Drying Kinetics

2.5.3. Performance of the Dryer

2.6. Economic Assessment

3. Results and Discussions

3.1. Fluctuation in Solar Radiation Intensity (SRI)

3.2. Thermal Performance of SAHs (for FC Drying Mode)

3.3. Variation in Temperature and Relative Humidity of Ambient Air and Across SGD

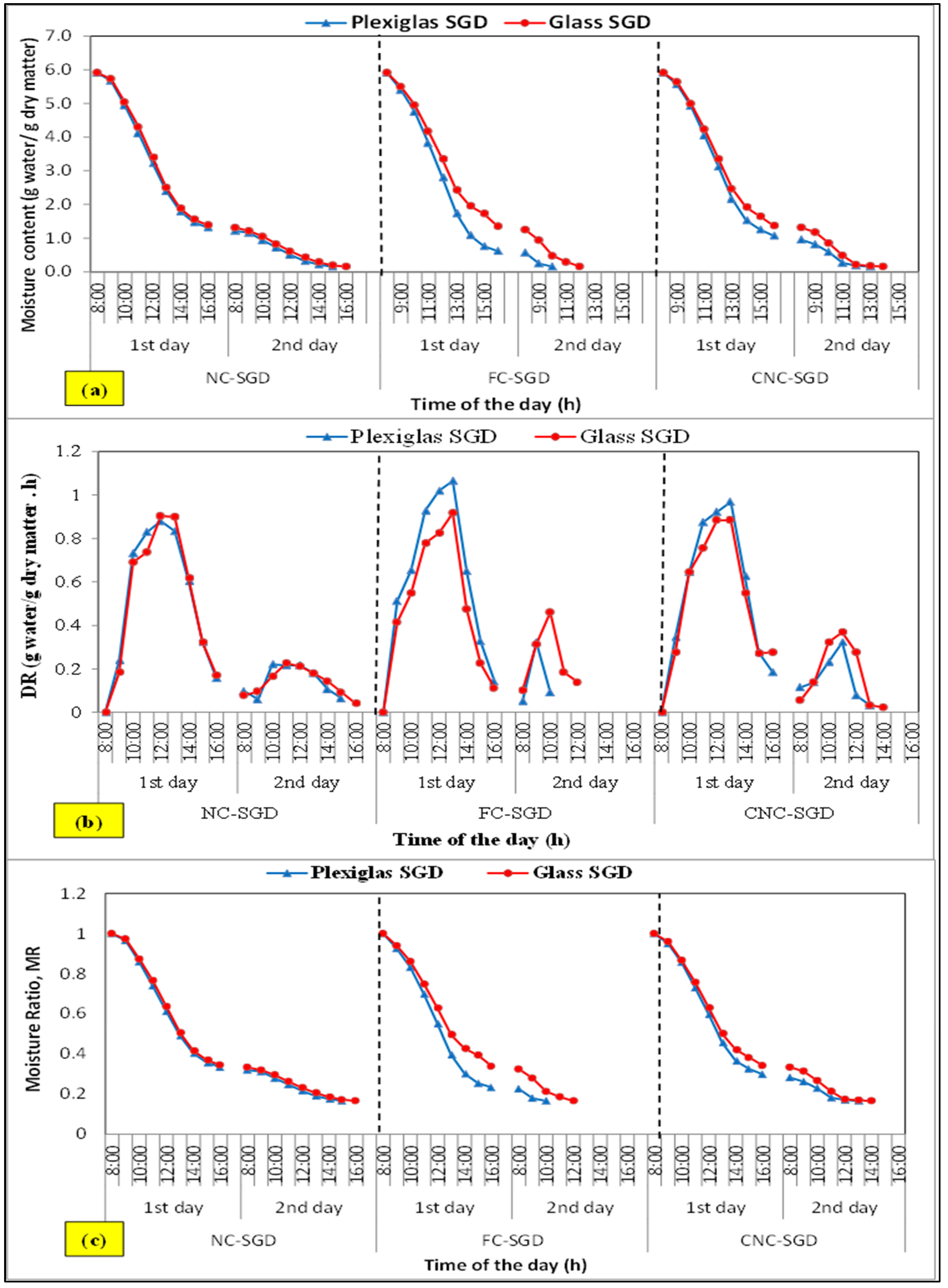

3.4. Variation in Moisture Content, Drying Rate and Moisture Ratio during Grape Drying

3.5. The Mathematical Thin-Layer Drying Model for Grapes

3.6. Economic Assessment

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ac | Surface area of the solar air heater/collector (m2) |

| Ad | Area of dryer (m2) |

| Experimental constant | |

| Experimental constant | |

| Experimental constant | |

| Specific heat of air (J/kg K) | |

| Annualized cost (USD) | |

| Annualized capital cost (USD) | |

| Capital cost of dryer (USD) | |

| Drying cost per 1 kg of dried grapes (USD/kg) | |

| Cost of 1 kg of solar dried grapes (USD/kg) | |

| Fresh product rate (USD/kg) | |

| Annualized operating and maintenance cost (USD) | |

| Cmar | Commercial cost of 1 kg of the dried grapes (raisins) in the market (USD) |

| Annualized running cost (USD) | |

| CRF | Capital recovery factor |

| D | Number of days for drying in use in one year (days) |

| DR | Drying rate (kg/kg. h) |

| Db | Time taken for drying one batch of grapes sample (h) |

| d | Inflation rate (%) |

| hl | Latent heat of vaporization (kJ/kg) |

| Ic | Total incident solar radiation intensity on the solar air heater(W/m2) |

| Iv | Average incident solar radiation intensity on the dryer (W/m2) |

| i | Discount rate (%) |

| j | Lifespan of the drying system (years) |

| Experimental constant | |

| M | Moisture content (g) |

| M0 | Initial moisture content of product on dry basis (kg water/kg dry matter) |

| Mb | Mass of dried grapes from one batch (kg) |

| Me | Moisture content at equilibrium state on dry basis |

| Mi | Initial mass of one batch of grapes (kg) |

| Mt | Moisture content of product at time t on dry basis (kg water/kg dry matter) |

| MRexp | Experimental moisture ratio, % (wb) |

| MRpre | Predicted moisture ratio, % (wb) |

| Mass flow rate of air (kg/s) | |

| md | Mass of dry matter (kg) |

| mp | Mass of product (kg) |

| Np | Payback period (years) |

| Experimental constant | |

| P | Annual mass of dried grapes produced by the dryer (kg/year) |

| R2 | Coefficient of determination |

| RHa | Relative humidity of ambient air (%) |

| RHg | Relative humidity of air inside the glass dryer(%) |

| RHp | Relative humidity of air inside the Plexiglas dryer(%) |

| S | Salvage value (USD) |

| S1 | Savings during first year using solar dryer (USD) |

| Sa | Annualized salvage value (USD/year) |

| Sdb | Savings per day during base year using solar dryer (USD) |

| SFF | Sinking fund factor |

| Ta | Ambient temperature (°C) |

| Tci | Inlet temperature of solar air heater (°C) |

| Tco | Outlet temperature of solar air heater (°C) |

| Tg | Temperature inside the glass dryer (°C) |

| Tp | Temperature inside the Plexiglas dryer (°C) |

| t | Time (s) |

| X2 | Chi-squared |

| Greek symbols | |

| Thermal efficiency of solar air heater (%) | |

| Drying thermal efficiency (%) | |

| Δt | Time interval (h) |

| Abbreviations | |

| FC-SGD | Forced convection solar greenhouse dryer |

| FC | Forced convection |

| CNC-SGD | Controlled natural convection solar greenhouse dryer |

| CNC | Controlled natural convection |

| NC-SGD | Natural convection solar greenhouse dryer |

| NC | Natural convection |

| GHG | Greenhouse gases |

| RH | Relative humidity |

| RMSE | Root mean square error |

| SAH | Solar air heater |

| SGD | Solar greenhouse dryer |

| SRI | Solar radiation intenisty |

References

- Tawfik, M.A.; Sagade, A.A.; Palma-Behnke, R.; Abd Allah, W.E.; Hanan, M. Performance evaluation of solar cooker with tracking type bottom reflector retrofitted with a novel design of thermal storage incorporated absorber plate. J. Energy Storage 2022, 51, 104432. [Google Scholar] [CrossRef]

- United Nations Department of Economic and Social Affairs, Population Division. World Population Prospects 2022: Summary of Results 2022. UN DESA/POP/2022/TR/NO.3. 2022. Available online: https://reliefweb.int/report/world/world-population-prospects-2022-summary-results (accessed on 30 July 2022).

- Tawfik, M.A.; El-Tohamy, M.; Metwally, A.A.; Khallaf, A.M.; Abd Allah, W.E. Experimental and numerical investigation of thermal performance of a new design solar parabolic dish desalination system. Appl. Therm. Eng. 2022, 214, 118827. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A.; Kumar, A.; Jain, A. Thermal energy storage based solar drying systems: A review. Innov. Food Sci. Emerg. Technol. 2016, 34, 86–99. [Google Scholar] [CrossRef]

- Moses, J.A.; Norton, T.; Alagusundaram, K.; Tiwari, B.K. Novel drying techniques for the food industry. Food Eng. Rev. 2014, 6, 43–55. [Google Scholar] [CrossRef]

- Mugi, V.R.; Chandramohan, V.P. Energy, exergy and economic analysis of an indirect type solar dryer using green chilli: A comparative assessment of forced and natural convection. Therm. Sci. Eng. Prog. 2020, 24, 100950. [Google Scholar] [CrossRef]

- Sethi, V.P.; Dhiman, M. Design, space optimization and modelling of solar-cum-biomass hybrid greenhouse crop dryer using flue gas heat transfer pipe network. Sol. Energy 2020, 206, 120–135. [Google Scholar] [CrossRef]

- Patil, R.; Gawande, R.A. Review on solar tunnel greenhouse drying system. Renew. Sustain. Energy Rev. 2016, 56, 196–214. [Google Scholar] [CrossRef]

- Rabha, D.K.; Muthukumar, P. Performance studies on a forced convection solar dryer integrated with a paraffin wax–based latent heat storage system. Sol. Energy 2017, 149, 214–226. [Google Scholar] [CrossRef]

- Saini, V.; Tiwari, S.; Tiwari, G.N. Environ economic analysis of various types of photovoltaic technologies integrated with greenhouse solar drying system. J. Clean. Prod. 2017, 156, 30–40. [Google Scholar] [CrossRef]

- Mohana, Y.; Mohanapriya, R.; Anukiruthika, T.; Yoha, K.S.; Moses, J.A.; Anandharamakrish, C. Solar dryers for food applications: Concepts, designs, and recent advances. Sol. Energy 2020, 208, 321–344. [Google Scholar] [CrossRef]

- Debnath, S.; Das, B.; Randive, P.R.; Pandey, K.M. Performance analysis of solar air collector in the climatic condition of North Eastern India. Energy 2018, 165, 281–298. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, D. Advanced technologies and performance investigations of solar dryers: A review. Renew. Energy Focus 2020, 35, 148–158. [Google Scholar] [CrossRef]

- Nukulwar, M.R.; Tungikar, V.B. A review on performance evaluation of solar dryer and its material for drying agricultural products. Mater. Today Proc. 2021, 46, 345–349. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.; Al-Helal, I. Development and recent trends in greenhouse dryer: A review. Renew. Sustain. Energy Rev. 2016, 65, 1048–1064. [Google Scholar] [CrossRef]

- Vivekanandan, M.; Periasamy, K.; Babu, C.D.; Selvakumar, G.; Arivazhagan, R. Experimental and CFD investigation of six shapes of solar greenhouse dryer in no load conditions to identify the ideal shape of dryer. Mater. Today Proc. 2021, 37, 1409–1416. [Google Scholar] [CrossRef]

- Lamrani, B.; Draoui, A.; Kuznik, F. Thermal performance and environmental assessment of a hybrid solar-electrical wood dryer integrated with Photovoltaic/Thermal air collector and heat recovery system. Sol. Energy 2021, 221, 60–74. [Google Scholar] [CrossRef]

- Kumar, R.; Rosen, M.A. A critical review of photovoltaic–thermal solar collectors for air heating. Appl. Energy 2011, 88, 3603–3614. [Google Scholar] [CrossRef]

- César, L.-V.E.; Lilia, C.-M.A.; Octavio, G.-V.; Orlando, S.S.; Alfredo, D.N. Energy and exergy analyses of a mixed-mode solar dryer of pear slices (Pyrus communis L.). Energy 2021, 220, 119740. [Google Scholar] [CrossRef]

- Chauhan, Y.B.; Rathod, P.P. A comprehensive review of the solar dryer. Int. J. Ambient Energy 2020, 41, 348–367. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N. Energy and exergy analysis of a mixed-mode greenhouse-type solar dryer, integrated with partially covered N-PVT air collector. Energy 2017, 128, 183–195. [Google Scholar] [CrossRef]

- Bal, L.M.; Satya, S.; Naik, S.N. Solar dryer with thermal energy storage systems for drying agricultural food products: A review. Renew. Sustain. Energy Rev. 2010, 14, 2298–2314. [Google Scholar] [CrossRef]

- Murthy, M.V.R. A review of new technologies, models and experimental investigations of solar driers. Renew. Sustain. Energy Rev. 2009, 13, 835–844. [Google Scholar] [CrossRef]

- Srinivasan, G.; Muthukumar, P. A review on solar greenhouse dryer: Design, thermal modelling, energy, economic and environmental aspects. Sol. Energy 2021, 229, 3–21. [Google Scholar] [CrossRef]

- Gorjian, S.; Hosseingholilou, B.; Jathar, L.D.; Samadi, H.; Samanta, S.; Sagade, A.A.; Kant, K.; Sathyamurthy, R. Recent advancements in technical design and thermal performance enhancement of solar greenhouse dryers. Sustainability 2021, 13, 7025. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A. Performance analysis of greenhouse dryer by using insulated north-wall under natural convection mode. Energy Rep. 2016, 2, 107–116. [Google Scholar] [CrossRef]

- Kumar, M.; Sahdev, R.K.; Tiwari, S.; Manchanda, H.; Chhabra, D.; Panchal, H.H.; Sadasivuni, K.K. Thermal performance and kinetic analysis of vermicelli drying inside a greenhouse for sustainable development. Sustain. Energy Technol. Assess. 2021, 44, 101082. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A.; Gupta, B. A review on thermal models for greenhouse dryers. Renew. Sustain. Energy Rev. 2017, 75, 548–558. [Google Scholar] [CrossRef]

- Prakashm, O.; Kumar, A. Historical review and recent trends in solar drying systems. Int. J. Green Energy 2013, 10, 690–738. [Google Scholar] [CrossRef]

- Singh, S.; Gill, R.S.; Hans, V.S.; Mittal, T.C. Experimental performance and economic viability of evacuated tube solar collector assisted greenhouse dryer for sustainable development. Energy 2022, 241, 122794. [Google Scholar] [CrossRef]

- ELkhadraoui, A.; Kooli, S.; Hamdi, I.; Farhat, A. Experimental investigation and economic evaluation of a new mixed-mode solar greenhouse dryer for drying of red pepper and grape. Renew. Energy 2015, 77, 1–8. [Google Scholar] [CrossRef]

- Janjai, S.; Intawee, P.; Kaewkiewa, J.; Sritus, C.; Khamvongsa, V. A large-scale solar greenhouse dryer using polycarbonate cover: Modeling and testing in a tropical environment of Lao People’s Democratic Republic. Renew. Energy 2011, 36, 1053–1062. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A.; Nuntadusit, C. Thermo-environomical and drying kinetics of bitter gourd flakes drying under north wall insulated greenhouse dryer. Sol. Energy 2018, 162, 205–216. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Annual performance of a modified greenhouse dryer under passive mode in no-load conditions. Int. J. Green Energy 2015, 12, 1091–1099. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Solar greenhouse drying: A review. Renew. Sustain. Energy Rev. 2014, 29, 905–910. [Google Scholar] [CrossRef]

- Karthikeyan, M.G.; Lavanya, M.V.; Dharani, M.N.; Nagulan, M.T. Grapes (Vitis vitaceae)-potent medicinal fruit serves as a source of antioxidants and antibacterial agent. Int. J. Curr. Sci. Res. Rev. 2020, 3, 70–81. [Google Scholar] [CrossRef]

- Sehery, A.A.; Gallali, Y.M.; Wafa, M.J. Preservation of Fruits and Vegetables Using Solar Dryers. A Comparative Study for Solar and Natural Drying of Grapes, Figs, Tomatoes and Onions. IV. Temperatu. In World Renewable Energy Congress VI; Pergamon: Brighton, UK, 2000; pp. 2167–2169. [Google Scholar]

- Gallali, Y.M.; Abujnah, Y.S.; Bannani, F.K. Preservation of fruits and vegetables using solar drier: A comparative study of natural and solar drying, III, chemical analysis and sensory evaluation data of the dried samples (grapes, figs, tomatoes and onions). Renew. Energy 2000, 19, 203–212. [Google Scholar] [CrossRef]

- Yaldiz, O.; Ertekin, C.; Uzun, H.I. Mathematical modeling of thin layer solar drying of sultana grapes. Energy 2001, 26, 457–465. [Google Scholar] [CrossRef]

- Al-Juamily, K.E.; Khalifa, A.J.N.; Yassen, T.A. Testing of the performance of a fruit and vegetable solar drying system in Iraq. Desalination 2007, 209, 163–170. [Google Scholar] [CrossRef]

- Essalhi, H.; Benchrifa, M.; Tadili, R.; Bargach, M.N. Experimental and theoretical analysis of drying grapes under an indirect solar dryer and in open sun. Innov. Food Sci. Emerg. Technol. 2018, 49, 58–64. [Google Scholar] [CrossRef]

- Sharma, V.K.; Colangelo, A.; Spagna, G. Experimental performance of an indirect type solar fruit and vegetable dryer. Energy Convers. Manag. 1993, 34, 293–308. [Google Scholar] [CrossRef]

- Tiris, C.; Ozbalta, N.; Tiris, M.; Dincer, I. Performance of a solar dryer. Energy 1994, 19, 993–997. [Google Scholar] [CrossRef]

- Tiris, C.; Tiris, M.; Dincer, I. Investigation of the thermal efficiencies of a solar dryer. Energy Convers. Manag. 1995, 36, 205–212. [Google Scholar] [CrossRef]

- Zomorodian, A.; Dadashzadeh, M. Indirect and mixed mode solar drying mathematical models for sultana grape. J. Agric. Sci. Technol. 2009, 11, 391–400. [Google Scholar]

- Pardhi, C.B.; Bhagoria, J.L. Development and performance evaluation of mixed-mode solar dryer with forced convection. Int. J. Energy Environ. Eng. 2013, 4, 23. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Aboul-Enein, S.; Ramadan, M.R.I.; El-Gohary, H.G. Experimental investigation of an indirect type natural convection solar dryer. Energy Convers. Manag. 2002, 43, 2251–2266. [Google Scholar] [CrossRef]

- Papade, C.V.; Boda, M.A. Design and development of indirect type solar dryer with energy storing material. Int. J. Innov. Res. Adv. Eng. 2014, 1, 109–114. [Google Scholar]

- Fuller, R.J.; Charters, W.W.S. Performance of a solar tunnel dryer with microcomputer control. Sol. Energy 1997, 59, 151–154. [Google Scholar] [CrossRef]

- Barnwal, P.; Tiwari, G.N. Grape drying by using hybrid photovoltaic-thermal (PV/T) greenhouse dryer: An experimental study. Sol. Energy 2008, 82, 1131–1144. [Google Scholar] [CrossRef]

- Rathore, N.S.; Panwar, N.L. Experimental studies on hemi cylindrical walk-in type solar tunnel dryer for grape drying. Appl. Energy 2010, 87, 2764–2767. [Google Scholar] [CrossRef]

- Hamdi, I.; Kooli, S.; Elkhadraoui, A.; Azaizia, Z.; Abdelhamid, F.; Guizani, A. Experimental study and numerical modeling for drying grapes under solar greenhouse. Renew. Energy 2018, 127, 936–946. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N.; Al-Helal, I.M. Performance analysis of photovoltaic–thermal (PVT) mixed mode greenhouse solar dryer. Sol. Energy 2016, 133, 421–428. [Google Scholar] [CrossRef]

- Gopinath, G.R.; Muthuvel, S.; Muthukannan, M.; Sudhakarapandian, R.; Kumar, B.P.; Kumar, C.S.; Thanikanti, S.B. Design, development, and performance testing of thermal energy storage based solar dryer system for seeded grapes. Sustain. Energy Technol. Assess. 2022, 51, 101923. [Google Scholar] [CrossRef]

- Nagarajan, S.; Prem Kumar, M. Analysis of Thermal Performance in Solar Dryer. IOSR J. Mech. Civ. Eng. 2022, 11, 71–74. [Google Scholar]

- Di Matteo, M.; Cinquanta, L.; Galiero, G.; Crescitelli, S. Effect of a novel physical pretreatment process on the drying kinetics of seedless grapes. J. Food Eng. 2000, 46, 83–89. [Google Scholar] [CrossRef]

- Pangavhane, D.R.; Sawhney, R.L.; Sarsavadia, P.N. Effect of various dipping pretreatment on drying kinetics of Thomson seedless grapes. J. Food Eng. 1999, 39, 211–216. [Google Scholar] [CrossRef]

- Richard, J.M.; Bernadette, K.N.; Trude, W.; Lucy, M.C.; Bernard, E.C. Effect of solar drying methods on total phenolic contents and antioxidant activity of commonly consumed fruits and vegetable (mango, banana, pineapple and tomato) in Tanzania. Afr. J. Food Sci. 2015, 9, 291–300. [Google Scholar] [CrossRef]

- Saxena, A.; Cuce, E.; Singh, D.B.; Sethi, M.; Cuce, P.M.; Sagade, A.A.; Kumar, A. Experimental studies of latent heat storage based solar air heater for space heating: A comparative analysis. J. Build. Eng. 2023, 69, 106282. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Kianmehr, M.H.; Arabhosseini, A. Modelling of thin layer drying of potato slices in length of continuous band dryer. Energy Convers. Manag. 2009, 50, 1348–1355. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H. Mathematical modeling of thin layer drying of pistachio by using solar energy. Energy Convers. Manag. 2003, 44, 1111–1122. [Google Scholar] [CrossRef]

- Lingayat, A.; Chandramohan, V.P.; Raju, V.R.K.; Suresh, S. Drying kinetics of tomato (Solanum lycopersicum) and Brinjal (Solanum melongena) using an indirect type solar dryer and performance parameters of dryer. Heat Mass Transf. 2021, 57, 853–872. [Google Scholar] [CrossRef]

- Kesavan, S.; Arjunan, T.V.; Vijayan, S. Thermodynamic analysis of a triple-pass solar dryer for drying potato slices. J. Therm. Anal. Calorim. 2019, 136, 159–171. [Google Scholar] [CrossRef]

- Cesar, L.V.E.; Ana Lilia, C.M.; Octavio, G.V.; Isaac, P.F.; Rogelio, B.O. Thermal performance of a passive, mixed-type solar dryer for tomato slices (Solanum lycopersicum). Renew. Energy 2020, 147, 845–855. [Google Scholar] [CrossRef]

- Henderson, S.M.; Pabis, S. Grain drying theory I. temperature effect on drying coefficient. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Ozdemir, M.; Devres, Y.O. The thin layer drying Characteristics of hazelnuts during roasting. J. Food. Eng. 1999, 42, 225–233. [Google Scholar] [CrossRef]

- Sharma, G.P.; Prasad, S. Effective Moisture Diffusivity of Garlic Cloves Undergoing Microwave Convective Drying. J. Food Eng. 2004, 65, 605–617. [Google Scholar] [CrossRef]

- Kumar, M.; Sahdev, R.K.; Tawfik, M.A.; Elboughdiri, N. Natural convective greenhouse vermicelli drying: Thermo-environ-econo-kinetic analyses. Sustain. Energy Technol. Assess. 2023, 55, 103002. [Google Scholar] [CrossRef]

- Badaoui, O.; Hanini, S.; Djebli, A.; Brahim, H.; Benhamou, A. Experimental and modeling study of tomato pomace waste drying in a new solar greenhouse: Evaluation of new drying models. Renew. Energy 2019, 133, 144–155. [Google Scholar] [CrossRef]

- Deng, S.; Wen, Z.; Su, F.; Wang, Z.; Lou, G.; Liu, X.; Dou, R. Converter sludge drying in rotating drum using hot steel balls. Appl. Therm. Eng. 2021, 197, 117368. [Google Scholar] [CrossRef]

- Dharmadurai, P.L.; Vasanthaseelan, S.; Bharathwaaj, R.; Dharmaraj, V.; Gnanasekaran, K.; Balaji, D.; Sathyamurthy, R. A comparative study on solar dryer using external reflector for drying grapes. Mater. Today Proc. 2022, 50, 552–559. [Google Scholar] [CrossRef]

- Singh, P.P.; Singh, S.; Dhaliwal, S.S. Multi-shelf domestic solar dryer. Energy Convers. Manag. 2006, 47, 1799–1815. [Google Scholar] [CrossRef]

- Sodha, M.S.; Chandra, R.; Pathak, K.; Singh, N.P.; Bansal, N.K. Techno-economic analysis of typical dryers. Energy Convers. Manag. 1991, 31, 503–5013. [Google Scholar] [CrossRef]

- Akpinar, E.K. Drying of mint leaves in a solar dryer and under open sun: Modelling, performance analyses. Energy Convers. Manag. 2010, 51, 2407–2418. [Google Scholar] [CrossRef]

| Reference | Location | Shape of SGD/Cover Type | Operating Mode | Max. Solar Radiation/Avg. Temperature inside SGD | Variety of Grape (Pre-Treatment Solution) | Load/Drying Range and Time | Drying Efficiency |

|---|---|---|---|---|---|---|---|

| El Khadraoui et al. [31] | Borj Cedria, (36°43′ N, 10°25′ E), Tunisia | Chapel-shaped/Plexiglas | Mixed-mode forced convection using flat plate SAH | ~808 W/m2/49.88 °C | Sultana (1% NaOH) | 130 kg/From 5.49 gWater/g dry matter to 0.22 (gWater/g dry matter) in 50 h | N.A |

| Fuller and Charters [49] | Northern Victoria (35°57′ S 144°36′ E) Australia | Tunnel- shaped/Polyethylene sheets, two layers | Forced convection | ~23 MJ/m2 /60 °C | Sultana (untreated) | From 76% to 13% in 288 h | 15–17% |

| Barnwal and Tiwari [50] | New Delhi (28°35′ N, 77°12′ E), India | Roof type even span/ Polyethylene sheets | Hybrid PV/T Forced convection | N.A | Thompson Seedless (untreated) | 8 kg/(N.A) | 38.40–43.6% |

| Rathore and Panwar [51] | Udaipur (27° 42′ N, 75° 33′ E), India | Tunnel-shaped/Polyethylene sheets | Natural convection | ~950 W/m2 /~65 °C | Thompson Seedless (untreated) | 320 kg/From 85% to 16% in 168 h | 30% |

| Hamdi et al. [52] | Borj Cedria, (36°43′ N, 10°25′ E), Tunisia | Chapel-shaped/Plexiglas | Mixed flow/Forced convection | 795 W/m2/28.08 °C–55.94 °C | Sultana (treated with 1% NaOH) | 130 k/From 5.5 g water/g dry matter to 0.22 (g water/g dry matter) in 128 h | N.A |

| Tiwari et al. [53] | New Delhi (28°35′ N, 77°12′ E), India | Single-slope PV/T solar greenhouse dryer | Hybrid PV/T Forced convection | ~890 W/m2/~60 °C | Seedless (N.A) | N.A/1618 gWater to 594 gWater in 144 h | 15–30% |

| Gopinath et al. [54] | Tamil Nadu (9°34′ N, 77°40′ E), India | Parabola-shaped/Poly-carbonate | Forced convection | N.A/45 °C for without PCM, 47.50° for with 100 g PCM and 58 °C for 200 g PCM | Seedless (treated with 6% K2CO3 and 0.5% olive oil) | N.A/From weight 80.20% −18.60% -Without PCM = 34 h -With PCM 100 g = 22 h With PCM 200 g = 10 h | N.A |

| Nagarajan and Premkumar [55] | Coimbatore-Tamil Nadu (11° N, 76° 57′ E), India | Tunnel-shaped/poly-carbonate | Forced convection using SAH | ~830 W/m2/35 °C–75 °C | Grapes (variety not determined) | 1 kg/From 75% to 7% within 48 to 72 h | N.A |

| Parameters of PV Module | Specifications |

|---|---|

| Type | Polycrystalline Silicon |

| Dimensions (mm) | 651 L × 526 W × 35 T |

| Weight (g) | 5500 |

| Maximum Power, Pmax (W) | 40 |

| Optimum Operating Voltage, VMP (V) | 17.40 |

| Optimum Operating Current, Imp (A) | 2.48 |

| Open Circuit Voltage, VOC (V) | 21.70 |

| Short Circuit Current, Isc (A) | 2.56 |

| SI No. | Component | Description |

|---|---|---|

| 1 | LCD 16 × 2 | Display of module |

| 2 | ATMEGA 328p | High-performance, low-power AVR® 8-bit microcontroller |

| 3 | Crystal oscillator 16 MHZ | Designed to handle off-chip crystals that have a frequency of 4–16 MHz |

| 4 | Voltage regulator 7805 |

|

| 5 | Transistor BD 139 | Designed for audio amplifiers and drivers utilizing complementary or quasi-complementary circuits |

| 6 | Capacitor 22p | Used with crystals for loading purposes |

| 7 | Red LED | Indicator |

| 8 | DHT 11 | Temperature + humidity sensor |

| 9 | Keypad 4 × 4 |

|

| 10 | Fan | Air ventilation fan (Exhaust fan) |

| Parameter | Equipment | Measuring Range | Resolution | Accuracy |

|---|---|---|---|---|

| Temperature | Digitalthermometer, 4 channels (TENMARS, TM747DU, Taiwan) | −100–+1300 °C for K-type | 0.1 °C | ±0.1% rdg +0.7 °C |

| Temperature and relative humidity (RH) of ambient air | Digital temperature–humidity meter with probe (Pro’sKit NT-312, Taiwan) | Temperature: −50–+70 °C RH: 20–90% | 0.10 °C 1% RH | ±1% °C ±5% RH |

| Solar radiation intensity (pyranometer) | Digital data logging solar power meter (TENMARS, TES-132, Taiwan) | 0–2000 W/m2 | 1 W/m2 | ±10 W/m2 |

| Air velocity (anemometer) | Digital hot-wire air velocity meter and probe (TENMARS, TM-4002, Taiwan) | 0.01–25 m/s | 0.01 m/s | ±3% rdg, ±1.6% FS |

| Weight of grape sample | Digital electronic balance (WANT WT-N, China) | Up to 5000 g | 0.10 g | ±2 d at max capacity |

| Component | No. of Pieces | Cost (USD) | Notes |

|---|---|---|---|

| Plexiglas SGD | 1 | 40 | - |

| Glass SGD | 1 | 37 | - |

| Plexiglas SAH | 1 | 35 | For Plexiglas FC mode only |

| Glass SAH | 1 | 32 | For Glass FC mode only |

| Air duct | 2 | 10 | For Glass and Plexiglas FC modes |

| PV panel | 1 | 25 | For Glass and Plexiglas FC and CNC modes |

| Voltage regulator, dimmer and wires | 2 | 10 | For Glass and Plexiglas FC modes |

| ACU and exhaust fan | 2 | 10 | For Glass and Plexiglas CNC modes |

| Wooden platform | 2 | 25 | For Glass and Plexiglas CN modes |

| Assembly cost | - | 24 | For all designs |

| Total cost | NC-SGD | USD 86 (Glass) | USD 89 (Plexiglas) |

| FC-SGD | USD 148 (Glass) | USD 154 (Plexiglas) | |

| CNC-SGD | USD 106 (Glass) | USD 109 (Plexiglas) |

| Drying Mode | Model Name | Type of Cover | Constants | R2 | X2 | RMSE | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| NC-SGD | Lewis | Plexiglas | 0.1405 | 0.7237 | 0.0741 | 0.2640 | ||||

| glass | 0.1375 | 0.7000 | 0.0686 | 0.2545 | ||||||

| Page | Plexiglas | 0.4015 | 0.9702 | 0.9479 | 0.0018 | 0.0395 | ||||

| glass | 0.3496 | 1.0102 | 0.9373 | 0.0022 | 0.0443 | |||||

| Wang and Singh | Plexiglas | −0.162 | 0.0074 | 0.8810 | 0.0517 | 0.2063 | ||||

| glass | −0.178 | 0.0086 | 0.9068 | 0.0488 | 0.2016 | |||||

| Henderson and Pabis | Plexiglas | 0.3200 | 0.6780 | 0.9665 | 0.0129 | 0.1068 | ||||

| glass | 0.3060 | 0.6828 | 0.9669 | 0.0134 | 0.1092 | |||||

| Parabolic | Plexiglas | 0.8193 | −0.1618 | 0.0074 | 0.8810 | 0.0116 | 0.0976 | |||

| glass | 0.8686 | −0.1784 | 0.0086 | 0.9068 | 0.0183 | 0.1236 | ||||

| FC-SGD | Lewis | Plexiglas | 0.2010 | 0.8614 | 0.0660 | 0.2450 | ||||

| glass | 0.1747 | 0.8561 | 0.0596 | 0.2346 | ||||||

| Page | Plexiglas | 0.5200 | 1.0030 | 0.9926 | 0.0001 | 0.0094 | ||||

| glass | 0.4525 | 0.9555 | 0.9893 | 0.0002 | 0.0147 | |||||

| Wang and Singh | Plexiglas | −0.235 | 0.0150 | 0.9450 | 0.0309 | 0.1523 | ||||

| glass | −0.193 | 0.0104 | 0.9311 | 0.0372 | 0.1709 | |||||

| Henderson and Pabis | Plexiglas | 0.5010 | 0.8977 | 0.9871 | 0.0016 | 0.0386 | ||||

| glass | 0.3900 | 0.8944 | 0.9822 | 0.0014 | 0.0364 | |||||

| Parabolic | Plexiglas | 0.8654 | −0.2351 | 0.0150 | 0.9450 | 0.0059 | 0.0730 | |||

| glass | 0.8475 | −0.1926 | 0.0104 | 0.9311 | 0.0066 | 0.0780 | ||||

| CNC-SGD | Lewis | Plexiglas | 0.1643 | 0.7933 | 0.0691 | 0.2533 | ||||

| glass | 0.1579 | 0.7874 | 0.0626 | 0.2418 | ||||||

| Page | Plexiglas | 0.4425 | 0.9854 | 0.9775 | 0.0006 | 0.0242 | ||||

| glass | 0.3886 | 1.0030 | 0.9716 | 0.0010 | 0.0299 | |||||

| Wang and Singh | Plexiglas | −0.186 | 0.0096 | 0.9142 | 0.0421 | 0.1835 | ||||

| glass | −0.172 | 0.0082 | 0.9073 | 0.0397 | 0.1797 | |||||

| Henderson and Pabis | Plexiglas | 0.3880 | 0.7786 | 0.9779 | 0.0065 | 0.0779 | ||||

| glass | 0.3620 | 0.8321 | 0.9758 | 0.0044 | 0.0644 | |||||

| Parabolic | Plexiglas | 0.8390 | −0.1860 | 0.0096 | 0.9142 | 0.0082 | 0.0873 | |||

| glass | 0.8392 | −0.1722 | 0.0082 | 0.9073 | 0.0087 | 0.0901 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tawfik, M.A.; Oweda, K.M.; Abd El-Wahab, M.K.; Abd Allah, W.E. A New Mode of a Natural Convection Solar Greenhouse Dryer for Domestic Usage: Performance Assessment for Grape Drying. Agriculture 2023, 13, 1046. https://doi.org/10.3390/agriculture13051046

Tawfik MA, Oweda KM, Abd El-Wahab MK, Abd Allah WE. A New Mode of a Natural Convection Solar Greenhouse Dryer for Domestic Usage: Performance Assessment for Grape Drying. Agriculture. 2023; 13(5):1046. https://doi.org/10.3390/agriculture13051046

Chicago/Turabian StyleTawfik, M. A., Khaled M. Oweda, M. K. Abd El-Wahab, and W. E. Abd Allah. 2023. "A New Mode of a Natural Convection Solar Greenhouse Dryer for Domestic Usage: Performance Assessment for Grape Drying" Agriculture 13, no. 5: 1046. https://doi.org/10.3390/agriculture13051046

APA StyleTawfik, M. A., Oweda, K. M., Abd El-Wahab, M. K., & Abd Allah, W. E. (2023). A New Mode of a Natural Convection Solar Greenhouse Dryer for Domestic Usage: Performance Assessment for Grape Drying. Agriculture, 13(5), 1046. https://doi.org/10.3390/agriculture13051046