Abstract

This paper presents numerical simulation results on the nonlinear features of railway vehicles moving in transition curves at velocities close to the critical velocity. It examines six objects representing railway vehicles: three 2-axle bogies, two 2-axle freight cars, and a 4-axle passenger car. The paper aims to show how systematic variation in motion conditions, such as initial conditions, vehicle velocity, and curve radius, influences nonlinear features of the vehicle’s dynamics. Results indicate that initial conditions do not affect stable solutions, increasing velocity leads to more systematic patterns of behaviour across straight, circular, and transition curves, while increasing curve radius leads to a partly systematised picture of solutions. The findings also emphasise certain exceptions to these general trends.

1. Introduction

The paper investigates the nonlinear dynamics of railway vehicles negotiating transition curves at velocities v around the nonlinear critical velocity vn, including velocities below and above. The primary focus is on the lateral dynamics of vehicles in transition curves (TC), with references to straight track (ST) and circular curve (CC) behaviour as comparative contexts. The study involves numerical simulations of vehicle–track system dynamics for six vehicle models representing different types of bogies and cars. Their closer profile is as follows: 25TN bogie of freight cars, the bogie with average parameters, bogie of MKIII passenger car, the unloaded 2-axle freight car of average parameters, the loaded 2-axle HSFV1 freight car, and the 4-axle MKIII passenger car of two bogies. Some models have counterparts among actual railway vehicles; nevertheless, all are treated as generic thanks to their simplicity.

The paper examines how motion conditions, such as initial conditions y(0), velocity v, and curve radius R, affect vehicle nonlinear behaviour in TC, which is difficult to predict based on the behaviour in ST and CC. The results of this examination are a part of all the results already obtained. The complementary authors’ results to be published next are those considering the influence of suspension parameters on the nonlinear behaviour for the generic vehicles and the unpublished results for three existing vehicles.

The results come from the research project mentioned in the acknowledgements section of this paper. The project’s partial results for the unordered behaviours have already been published [1]. In the present paper, the results recognised as ordered are of primary interest. The unordered and ordered behaviours were equally important in the authors’ preceding publications [1,2,3,4].

The study’s and paper’s aim to solve is to answer and then publicly show how initial conditions y(0), systematically varied, influence the results of simulation in TCs for a variety of railway vehicles. It is to be performed with focus on differences between different vehicles and nonlinear behaviours or features that are not obvious. This aim is threefold because obtaining the answers and presenting analogous influence on simulations, with focus on differences between different vehicles and nonlinear behaviours or features being non-obvious, extends to variation in curve radii R and vehicle velocities v in their wide ranges.

In addition to the above three specific aims to solve, a wider, general aim exists. It is to continue to enlighten, highlight, and expand the knowledge of practitioners and theoreticians on highly nonlinear features of railway vehicles in TCs and their vicinity at velocities close to the nonlinear critical velocity vn.

Considering the results obtained by the present authors and the sporadic publications on that topic by others, this knowledge must be assessed as still low. The above general aim is hard to achieve without publishing all the relevant results by the present authors. These are based on the 3000 simulations, approximately. Only a complete results presentation could enlighten the audience about the nature and scale of the issue. As its realisation in a single paper is impossible, the need for the present paper arises.

The authors focus on presenting the nonlinearities they found, regardless of the motion conditions. That is why the last ones are scattered and do not necessarily correspond to conditions in the real railway system. Also, the reasons or insights into the disclosed nonlinear phenomena are limited. Those unexplained would require hundreds of profiled simulations, but not several or a dozen of them. Also, more sophisticated tools could be necessary, such as phase diagrams, Poincaré sections, Lyapunov exponents, or approaches typical in studies of rail vehicle chaotic motion. The authors plan to spend the next several years on this issue, and hopefully, other researchers will join to study it. Thus, the authors neither intend nor are ready to provide clear guidance for the engineering industry at the present stage.

Instead, the new hypothesis can be formally formulated for the first time in the present paper. It states that, considering the already tested six generic vehicles and three existing vehicles and the nonlinearities in TC and its vicinity at velocities close to vn found for all these objects, such a type of nonlinearities might be the inherent feature for all the railway vehicles guided based on the wheel–rail (wheelset–track) contact. To be well understood, the authors did not intend to state that the cause for the nonlinear behaviours of all wheel–rail guided railway vehicles is wheel–rail contact alone. The formulation just restricts the scope of vehicles to those for which the authors performed the study. Basically, the nonlinear features’ appearance or not depends on the interplay between at least: contact conditions, suspension parameters, mass and geometric vehicle parameters, and motion conditions. The number of results obtained by the present authors is too small to prove the above hypothesis. Many more results in the studied area are necessary, preferably by different authors using different simulation tools.

As concerns the literature survey, it is hard to find a larger number of publications by others where the topic of interest is treated directly, e.g., [5,6,7,8,9]. Examples of the present authors’ publications are [1,2,3,4].

The motivational publications are [5,6,7,8,10], where the results for TCs were generated at the stability study in ST and CCs. Concerning vehicles, a 2-axle freight car [5,6], a 4-axle heavy-haul vehicle [7], a 4-axle passenger car [8], and two bogies and two 2-axle freight cars [10] were of interest. In [5,6], behaviour in TC is a logical passage from periodic vibrations in ST to those in CC. However, perturbations in regular behaviour in TC and CC exist, caused by the non-smoothness of dry friction in the suspension. In [7], the absence of vibrations in ST, their start and development in the middle of TC length, and then continuation in CC as a limit cycle are interesting. In [8], no vibrations appear in ST. They begin immediately in TC and continue as a limit cycle in CC. In [10], the behaviour in TC usually makes a logical passage from limit cycles in ST to those in CC. However, three intriguing cases were disclosed. The first is the entire disappearance of vibrations in TC, despite limit cycles in ST and CC. The second is no vibrations in ST and TC, and their appearance after entering CC; however, for the leading wheelset only. The third is the vibrations from fundamental change (amplitude and frequency) in the middle of TC. Common in [5,6,7,8,10] is no deliberate, systematic variation in the motion conditions or other parameters to study vehicles’ behaviour changes (nonlinear features). Some exceptions are [5,6], where results for two velocities are shown.

Considering rare publications strictly in line with the present topic, it is reasonable to indicate those where coordinate courses in TC above vn were either simulated but not published or could have been potentially obtained, e.g., [11,12,13,14,15,16,17,18,19,20]. Publications are interesting, where the dynamics of the vehicle–track system is exploited to look for the proper, best, or optimum shape of TCs [21,22,23]; velocities are below vn, however. In [21], the length of the parabolic TC of the 3rd order is optimised, with three dynamical criteria. In [22], six different TC are compared, while six dynamical criteria were of interest. In [23], the optimum shape of polynomial TCs of orders from 5th to 11th is searched for at eleven dynamical quality functions.

Despite the dynamic approach, the traditional one persists. In [24], the new shape of smooth TC was proposed using analytical methods focused on the curve’s geometrical properties. Reference [25] describes a new method for designing vertical curves in the curved road/track sections. It applies a single curve connecting two STs, the so-called general TC. In [26], the result is a parametric approach to search for optimum lengths of the clothoid TC, considering passenger comfort in a curved track. In [27], an explicit interest in the presence of TC occurs. The CC radius R and TC length appeared to be key parameters, provided R ≥ 800 m and the lengths are small. The review paper [28] is impressive, discussing seventy publications about TCs. Its aspects are numerous, complete, and well-balanced. Three future research areas are defined, including the dynamical evaluation criteria with a discussion of [1], where the approach is as in the present paper.

The selected recent publications on the stability are [9,29,30,31,32,33,34,35,36,37,38]. Luckily, the authors found at least one publication [9] by others where the vehicle dynamics on TC is shown at v > vn. A hunting motion of an electric locomotive’s car body is tested with measurements and simulations. The body and wheelset hunting appear in ST and disappear in CC. The variation in suspension parameters to overcome car body hunting is outlined. Despite jointly showing the results for TC, ST, and CCs, the authors missed the discussion for the TC entirely. Publication [29] performs the stability study of a high-speed railway (HSR) train. A new approach originating from the root loci method was effectively applied and tested. Publications [30,31] present and use nonlinear wheelset models undergoing the bifurcation analysis. In [30], the possibility of coexisting stable and unstable limit cycles is demonstrated and extended to the unfavourable behaviour of Chinese HSR trains. Reference [31] includes comparisons of results for linearised and nonlinear wheel–rail contact and different field-measured wheel profiles. Publication [32] introduces a method of identifying, instead of neglecting, the hunting of low amplitudes for HSR vehicles. In [33], several methods for determining vn are compared. The direct simulation, ramping, and continuation methods were of primary interest. The methods’ comparison of exciting the hunting was performed considering vn value. A novel measuring system to monitor the rail vehicles’ hunting motion is presented in [34]. Reference [35] is of great intellectual value. The existence of parametric vibrations in a wheelset–track system, caused by wheel load fluctuations, is disclosed and experimentally verified. Their coexistence with self-exciting vibrations can cause a resonance. In [36], a nonlinear model of wheel–rail hunting kinematics, extending Klingel’s linear model, is presented. It additionally takes account of high-order odd harmonic frequencies (HOHFs). Publication [37] is a literature review for the bogie and the car body hunting instabilities’ fault diagnosis, with the small (and moderate) amplitude hunting included. In [38], the review paper, the survey of linear and nonlinear methods of the lateral stability analysis of rail vehicles is presented and discussed (some aspects are missed, while the older ones are disproportionately widely discussed).

The above review confirms that rail vehicle dynamics in TCs at velocities close to vn is rarely undertaken. Not much has happened in recent years in this area beyond the works by the present authors. To intensify such studies, the authors have recently published an encouraging paper [4].

Originality of the present paper can be highlighted by explicit formulation of its innovations, which also define the paper’s contribution. The innovation element of a general nature is expanding knowledge about railway vehicles with their properties, especially nonlinear ones, in TC and its vicinity at velocities v close to the nonlinear critical velocity vn. The innovation and contribution are both showing that nonlinear behaviours exist at all, and then what they look like and how numerous they are. The innovative elements in the study are its comprehensive, consequent, and ordered character, and performing it for a wide representation of objects (three bogies (of different applications), two 2-axle freight vehicles (empty and loaded), and a 4-axle (passenger) car). The research on the topic, as in the paper, of such a systematic and broad scope, has never been performed before. Such broad studies are also not common for other problems within the railway vehicle dynamics.

Specific innovation is the study and results of the influence of initial conditions on the simulation results in the conditions studied by the present authors. Analogous are studies and results of the influences of curve radius R and of vehicle velocity v on the simulation results. The innovative fact is putting the question about these three influences, and then the obtained answers based on the systematic variation in the system parameters. It looks like nobody has gathered such knowledge before. Detailed, contributing, and innovative results referring to discovered nonlinear phenomena and features, with reference to differences for different vehicles, are summarised in the conclusion section, while practical aspects of the results are discussed in Section 3.3.

2. Modelling Bases, Models of the Objects, and Software in the Study

2.1. The Modelling Principle

The method used for modelling the dynamics of rail vehicles is generalised, as discussed in [1,23,39,40]. The generalisation is in vehicle models, serving any motion conditions. Hence, the same equations of motion hold in TC of any type, CCs, and ST. The dynamics of relative motion, i.e., relative to track-oriented moving (non-inertial) reference systems, is applied. Hence, the explicit inertia terms (called imaginary or correction forces [41]) exist in the equations due to the moving systems. The linear and angular velocities and accelerations of transportation, i.e., of the moving systems, are the only ones needing introduction into these terms to represent the shape defined by parametric equations. The 3-D shape represents any TC with a superelevation ramp, while the 2-D and 1-D shapes represent CC and ST. The next generalisation is the validity of the modelling approach for any type of equations of motion. It covers equations traditionally derived and those numerically built with software for automatic generation of equations of motion (AGEM). The Lagrange equations of type II and Kane’s equations, adapted to the relative motion description, represent the above two cases in this paper.

The generalised forms of dynamical equations of relative motion and imaginary forces have already been presented in [1,23,39].

2.2. The Objects’ Nominal Models

Each model of the six objects, supplemented with the same track models, is a set of rigid bodies, forming discrete vehicle–track systems.

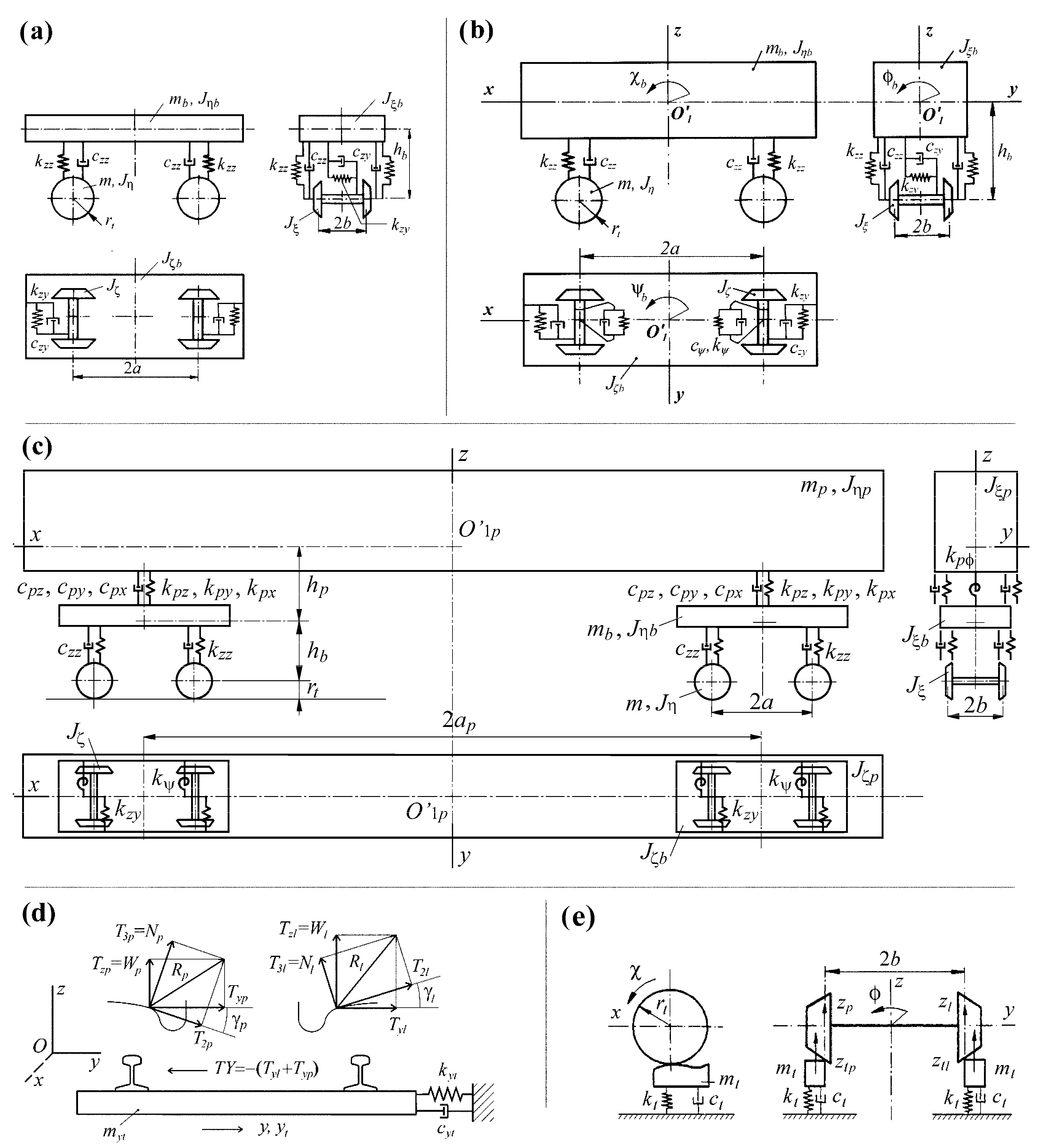

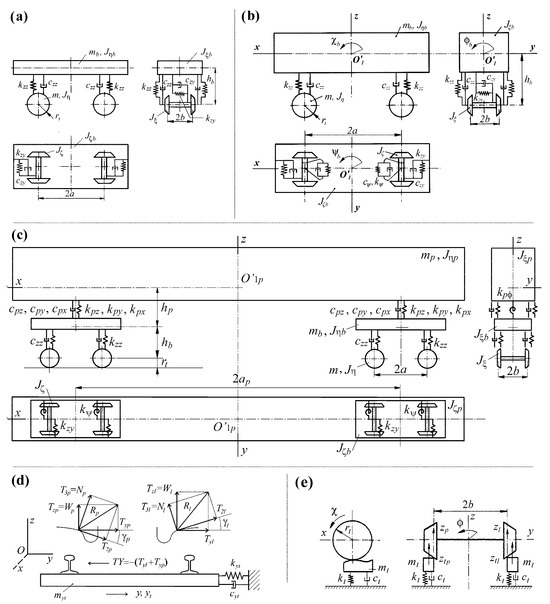

The models’ structures of the laterally and vertically flexible track are shown in Figure 1d,e, respectively. The model of lateral track raises the number of system’s degrees of freedom (DoFs) by 1 for each wheelset as compared to the rigid track model. The model of vertical track raises the system DOFs by 2 for each wheelset. On the other hand, these 2 extra DoFs, for vertical displacements of left and right rails, are eliminated due to constraints when the whole wheelset-track system is considered. At the end, inclusion of the track increases the number of system DoFs by 1 on each of the wheelsets, compared to the models on rigid track. The structures of the 2-axle bogies are given in Figure 1a, while 2-axle cars are in Figure 1b. The structures of the bogie of the MKIII car, the bogie with average parameters, and the 2-axle cars are identical. Their DoFs number is composed of three free rigid bodies DoFs and subtracts 2 structural constraints (for wheelset longitudinal direction, one for each of the wheelsets). It produces 3 × 6 − 2 × 1 = 16, and after incorporating the track, the DoFs number equals 16 + 2 × 1 = 18. The 25TN bogie-track model has different DoFs. Its constraints disable 2 DoFs, namely, yaw rotations of wheelsets relative to the bogie frame. Thus, parameters kzx and czx for 25TN bogie in Table 1 remain undefined. So, the DoFs number of 25TN bogie equals 18 − 2 × 1 = 16. The 4-axle passenger car structure is shown in Figure 1c. Its DoFs number is composed of seven free rigid bodies DoFs and four structural constraints subtracted (for wheelset longitudinal direction and peach rotation, two for each of the wheelsets). It produces 7 × 6 − 4 × 2 = 34, and after incorporating the track, it is 34 + 4 × 1 = 38 DoFs. The stiffness and dumping parameters of the track and vehicle models are assumed to be linear.

Figure 1.

Nominal models of: 2-axle objects—(a) bogies [1], (b) freight cars [1,10]; (c) 4-axle passenger car [1], and flexible track [1]—(d) laterally, (e) vertically.

Table 1.

Parameters of models for the adopted 2-axle objects.

Table 1 and Table 2 contain the parameters for 2-axle objects and for 4-axle cars and the track, respectively. The parameters origin for the 25TN bogie, the bogie of MKIII passenger car, the freight cars HSFV1 and of average parameters, and the track is [10]. The source for the bogie with average parameters and the MKIII passenger car is [1]. Vertical load for the 25TN and average parameters bogies arises from half of the 4-axle vehicle body mass (12,300 kg). The respective mass for the bogie of MKIII car is given in Table 2.

Table 2.

Parameters of the model of 4-axle passenger car (except its bogie) and models of track.

2.3. The Simulation Software

Three proprietary programs enabled motion simulation for the tested objects. The first served: the bogie with average parameters, the bogie of the MKIII passenger car, the 2-axle freight car of average parameters, and the 2-axle HSFV1 freight car of the same DoFs number. The second served the 25TN bogie of freight cars, of different DoF numbers. In the first and second programs, Lagrange formalism of type II has been used, while the equations were derived traditionally. The first use of these programs is [10]. The third AGEM-type program served the 4-axle MKIII passenger car, while Kane’s formalism has been used. It has been called ULYSSES in [29]. Its example applications for a 2-axle freight- and the MKIII cars are [1,29].

All programs exploited the same methods for wheel–rail contact. The FASTSIM program [42] generates the nonlinear tangential contact forces. The friction coefficient adopted was equal to 0.3. Nonlinear shapes of real wheel and rail profiles define the contact geometry. Contact parameters are generated by the RSGEO software [43]. The unworn (nominal) profiles S1002 and UIC60 of wheel and rail were adopted. The track gauge and rail inclination are equal to 1435 mm and 1:40, respectively.

The equations of motion were integrated with Gear’s method to solve stiff ordinary differential equations [44]. The integration procedure corrects the relative calculation error E automatically.

It should be pointed out here that the modelling approach used, the objects’ models, and the corresponding simulation software are truly well verified. Their applications, going into the tens (e.g., [1,2,3,4,10,23,40,45,46]), made it possible to present, confront, check, correct, and develop them for years. The models and software were used many times in solving railway dynamics problems, different from those in the present paper. For example, these are nonlinear lateral stability studies in CCs and TC shape optimisation. They were presented at the IAVSD Symposia many times, as well as published in prestigious, highly ranked scientific journals. Precisely, the universality of these models and their mature age make benefit in terms of their verification and credibility. In the studies like these in the present paper, these properties are great advantages rather than disadvantages.

Important to the models and software credibility is the following notice. We can divide them into two parts. The first includes calculating all the forces except the contact forces (stiffness and dumping forces in suspension and nonlinear kinematics forces (imaginary forces)), and the second includes the calculation of the tangential contact forces. Thanks to the generic, not sophisticated character of the models, the linear stiffness and dumping forces, a clear and explicit calculation of the kinematics forces the possibility of errors in the first part is considerably reduced. As to the second part, the FASTSIM and RSGEO programs are very well verified worldwide. They are accepted, appreciated, and often used by society. Also, several commercial AGEM codes exploit them.

Many direct verification actions were undertaken, too. The accuracy of calculations was studied in a few publications, e.g., in [45]. The next action was building the models of 2-axle freight cars individually and then building their models with the ULYSSES program. The results from both types of programs were compared, and the programs were corrected until the same results were obtained. Verification was also a qualitative comparison of the ULYSSES and commercial VI-Rail code results for similar passenger cars [1]. These were not the official IAVSD benchmark tests. The high similarity in this comparison was achieved.

3. Method of the Analysis and Characteristics of the Results

3.1. The Analysis Method

The analysis method follows a straightforward four-step procedure. The first step involves simulating the vehicle’s nonlinear behaviour changes due to variations in motion conditions. The second step consists of presenting the obtained results in plots. The third step involves commenting on and explaining the results, and the fourth step is drawing conclusions.

A key element in the present study related to stability is the nonlinear critical velocity, vn. It originates from the bifurcation approach to nonlinear lateral stability of rail vehicles, being in use for many years (e.g., [47,48,49]). For rail vehicles’ systems (with many DoFs), vn can only be determined via numerical simulation. Analytical methods of critical velocities determination apply to systems with a few (1–2) DoFs only. Velocity vn differs from and contrasts with the linear critical velocity vc. The vc can often overestimate the critical velocity, leading to an incorrect indication of the hunting onset for a higher velocity than the actual one. It reduces safety and eliminates vc as a useful measure, according to the present authors and many others. The vn. is the smallest velocity at which stable periodic solutions (hunting motion) can occur for the vehicle model (real object). The authors always refer to nonlinear critical velocity when using the term “critical velocity” and differentiate vn in ST and CCs of different radii (e.g., [1,2,40,45]).

According to vn definition, a fundamental in its determination is finding a stable periodic solution. In the simulation approach, it is most often based on the results of observation. Some results cause trouble when judging if they are stable periodic (limit cycle) or not, e.g., their amplitudes increase or decrease slowly. The way to determine if a simulation becomes stable after some time is the simulation route elongation. For practical reasons, such elongations cannot be too long (infinite). In practice, the thresholds for ST and CC lengths were used by the authors. In the case of a clear limit cycle, the lengths of ST and CC sections might be as short as 100 m (exceptionally, 50 m). In case of an elongation need, the lengths were increased to 300–500 m (exceptionally, 1000 m). The same operating philosophy concerned the cases with solution type change, e.g., the transition from decay to limit cycle. Even just suspicion about such a change and potential multiple solutions caused the checks in the form of the route elongation. The elongated simulations are not included in the paper, however.

The current paper does not present simulation results for determining vn, as this has already been described and published in [46] for all 2-axle objects and in [1] for a 4-axle vehicle. In [46], the authors classify the methods for determining vn as follows: (1) direct simulation method with limited accuracy; (2) direct simulation with high accuracy (extended method in [45]); (3) ramping method, where vn is determined in a single simulation at decreasing velocity; and (4) continuation methods, where simulations are carried out for different velocities, with the previous results used as initial conditions for the current simulation. The advantages and limitations of these methods are discussed in [46], where the authors justify their choice of method. They used both the first and second methods simultaneously, ensuring that jumps of solutions (bifurcations) and multiple solutions were correctly captured to determine vn.

3.2. Characteristics of Simulation Results and Conditions

Simulation results were obtained for successive sections of the route: ST, TC, and CC, separated in figures by vertical lines. The TC was a 3rd-degree parabolic curve, while superelevation h in CCs ensured the exact balance between gravity and centrifugal forces. When h exceeded the maximum allowed value of h = 150 mm (in Poland), this maximum value was applied. Variation in the superelevation h is to be performed in further studies. At this stage, it would obscure the image of the results and make understanding the nature and reasons of particular nonlinearities harder.

The results are time history plots of vehicle lateral dynamics coordinates, lateral displacements y and yaw angles ψ, with additional indices b, l, and t, for bogie frame or vehicle body, front (leading) wheelset, and rear (trailing) wheelset (2-axle objects) and p, b1, b2, 1, 2, 3, and 4 for vehicle body, front bogie frame, rear bogie frame, and wheelsets (front and rear in the b1 and front and rear b2 bogies). At intensive parameters’ variations, the indices extensions referring to radii R, velocities v, and initial conditions y(0) (separated with a slash) are applied.

The authors’ studies were quite consequent and orderly in terms of motion (simulation) conditions. In case of curve radii, the authors studied their entire possible scope from R = 300 m to R = ∞. In practice, R = 300, 450, 600, 900, 1200, 2000, 4000, 6000, 10,000 m, and ∞ were adopted; however, in obvious cases, some of these values were missed in particular sets of simulations. The restrictions for the smallest radius were sometimes numerical derailments. Namely, states where the simulation was stopped by the software, e.g., when the unlimited growth of solutions happened. The same concerns the initial conditions y(0). These concerned displacements y(0) of all rigid bodies in the models, adopted from 0 to 6.0 mm. Usual discrete values for 2- and 4-axle objects, respectively, were yi(0) = yj(0) = 0, 2.0, 3.0, 4.0, 4.5, and 6.0 mm. The most typical were yi(0) = 0.0045 m and yj(0) = 0.004 m. The values higher than 6.0 mm lead to numerical derailments too often, and in a practical sense, were not studied. Velocities v were of interest from small ones, just above zero, through the agreed maximum allowed speed vad for a particular vehicle, to values 3 times higher than vad. The vd values for freight and passenger objects were adopted between 100 and 120 and 130 and 160 km/h, respectively. The smallest v adopted was v = 5 m/s, but in obvious cases it was more, e.g., v = 20 m/s. The increment in v values was initially 5 or 10 m/s. After detecting nonlinearity, the increment was reduced to 1.0 and sometimes even to 0.1 m/s. The restrictions for the highest v were often numerical derailments, which is rather obvious. Except for the suspension parameters as in Table 1 and Table 2, their variations usually range from 0.1 to 100 times the nominal values. Again, the practical restrictions here were eventual numerical derailments.

The problem of the above parameters’ value for the cases selected as an illustration of a particular nonlinear behaviour found is another issue. Here, the parameters were neither selected randomly nor through the sensitivity analysis. They just correspond to the scope of motion conditions for which the nonlinearity was detected, through the consequent, ordered study, and were strongest. Thanks to the study’s complexity, the readers should understand that unexpected nonlinear features for the other sets of parameters were not detected.

3.3. Practical Implications of the Results

The topic relates to the bifurcation approach to lateral stability of rail vehicles. The relation is by the vn notion, and the simulation software, a numerical tool in such studies. One should be aware that stable periodic vibrations are possible for ST and CCs, as constant motion conditions exist. It is not so for TC, where track curvature and superelevation change continuously. Thus, stable periodic or stationary solutions cannot be expected or searched for in TC, identically as the vn. Despite these, any non-stationary and non-periodic solution can be examined for its stability. However, such a formal examination for the stability of solutions in TC has never been seen so far. Such stability analyses for ST and CCs, by other and present authors, can be found in, e.g., [1,33,38,45,48,49,50,51,52,53,54], respectively.

The knowledge gained in the present paper, and especially the further, deeper studies, can bring practical benefits to vehicle safety in terms of motion; comfort, especially on curved tracks; and vehicle construction. The connections of stability issues, also in conditions of motion, as those in the present paper, with the safety of motion are obvious. Although the engineering assessments of stability, running safety, and ride quality are based on the evaluation of the acceleration levels, the authors’ findings can still be inspiring. The necessary acceleration can easily be obtained in the course of simulation, as in the authors’ paper. More specifically, the studies presented can be a good inspiration for further development of the fundamental, relevant documents like [55,56,57]. Tracing the history of these documents, one can see that in their much older versions, they did not refer to curved track sections nor to simulation approaches. Several years ago, the simulation methods were not present in assessments, as in [56,57]. Now, the reference to such an approach is in both these standards. Even the process of homologation tends now to make use of simulation. What is more, ref. [56] refers to operating conditions outside the reference conditions to be used for the approval. It is similar to what the authors do with conditions of motion in the present paper. That is why the authors can rather easily imagine that assessments in the conditions as in their paper could extend the scope of the next versions of the mentioned documents, or similar ones.

As concerns the vehicle construction, comprehension is valuable when vibration amplitudes in TC are bigger than in ST and CCS, and when vibrations vanish in TC despite their existence in ST and CC (the authors obtained both such contrary results). It could contribute to vehicle construction, to eliminate the first feature (undesired state) and ensure the second (desired state). This could be performed by the variation in suspension parameters. Results of suspension parameters intensive, systematic variations will be a matter for the authors’ next publication, as announced in the Introduction. Nevertheless, the authors have already studied such variations in [40,58] in a much narrower scope. Publication [58] relates in its entirety to changes in suspension parameters of two existing objects (laden and empty gondola car) studied by the authors for their nonlinearities. Results of [58] show how effective and impressive the change in vehicle suspension parameters can be. It shows that undesirable nonlinear features can either be completely eliminated or changed for the better. In addition, the changes in suspension parameters performed in [58] concern the successful rise in the critical velocity vn and the nonlinearities that existed within the exploitation conditions of the gondola car.

4. The Impact of Initial Conditions

4.1. The 25TN Freight Car Bogie (Initial Conditions Impact)

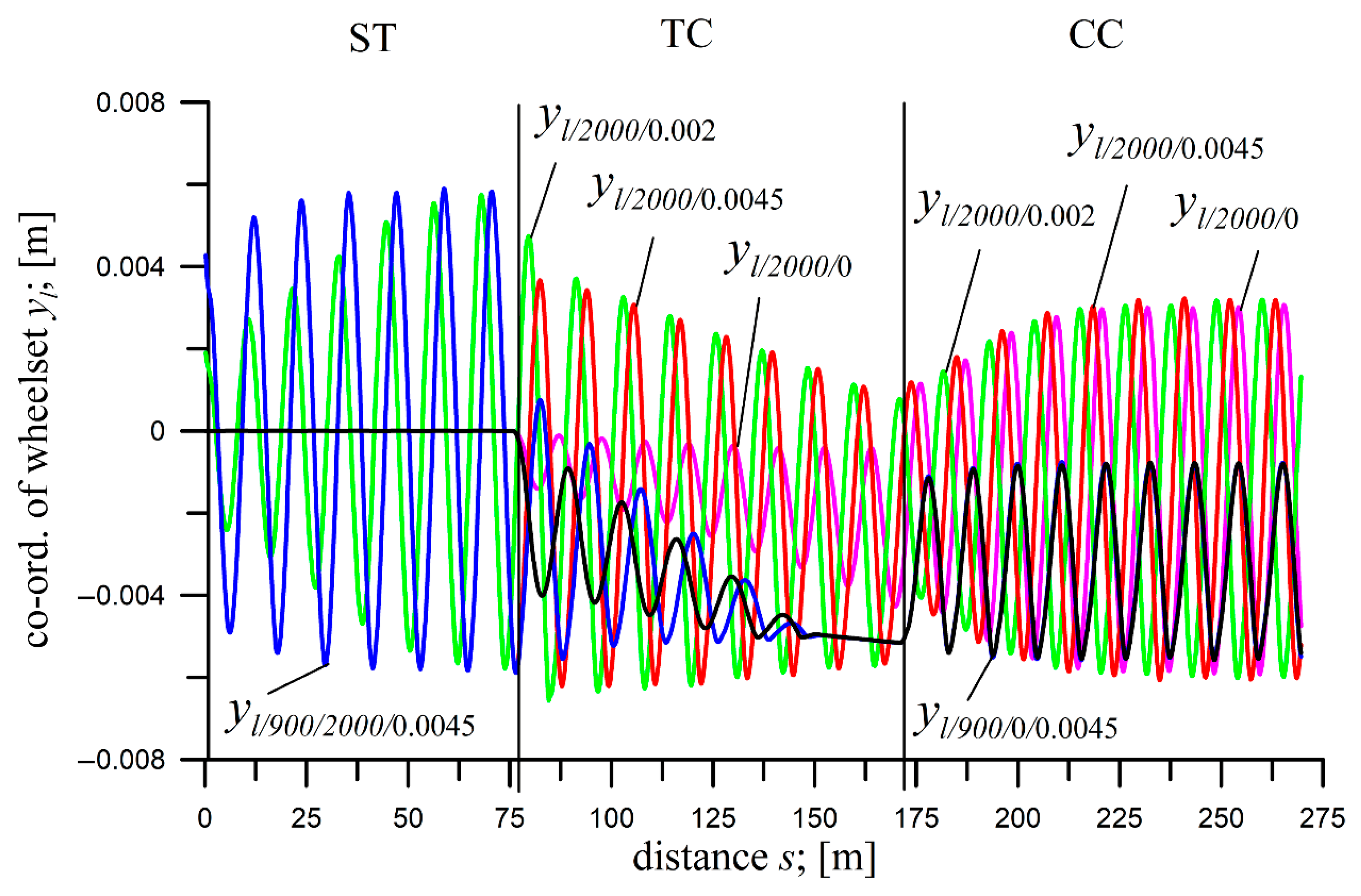

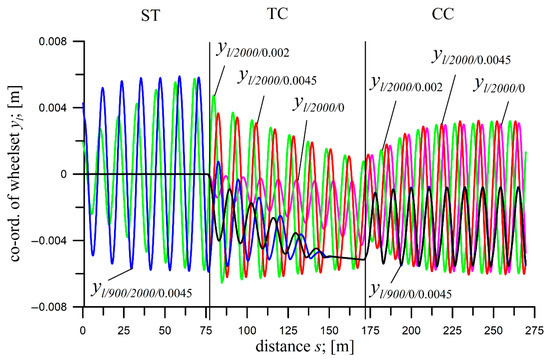

The impact of yi(0) on solutions for the 25TN bogie is illustrated in Figure 2, at integration relative error E = 0.4.

Figure 2.

Coordinate of leading wheelset of 25TN bogie of a freight car at v = 29.5 m/s and ST (l = 76.6 m), TC (l = 95 m), and CC (l = 98 m); for R = 900 m; h = 0,142 m; yi(0) = 0 m and yi(0) = 0.0045 m, and R = 2000 m; h = 0.064 m; yi(0) = 0 m; yi(0) = 0.002 m and yi(0) = 0.0045 m.

At a curve radius R = 900 m, comparing zero (yi(0) = 0 m) and non-zero (yi(0) = 0.0045 m) initial conditions reveals that the solutions in the circular curve (CC) remain unchanged. The identical periodic solutions for the front wheelset confirm that initial conditions in the straight track (ST) do not influence the behaviour in CC, aligning with the theoretical limit cycle concept.

Similarly, at R = 2000 m, zero and non-zero initial conditions (yi(0) = 0.0, yi(0) = 0.002, and yi(0) = 0.0045 m) yield nearly identical solutions in CC, differing only in phase. Adjusting the length of the ST or transition curve (TC) could align these phases fully.

An unexpected result emerges when comparing behaviour at R = 900 m and R = 2000 m for zero initial conditions. At R = 900 m, vibration amplitudes quickly rise in the TC, while at R = 2000 m, amplitudes grow gradually. Interestingly, for non-zero initial conditions, the vibration amplitudes are higher at the start of the TC at R = 2000 m than at R = 900 m.

4.2. The 4-Axle MKIII Passenger Car (Initial Conditions Impact)

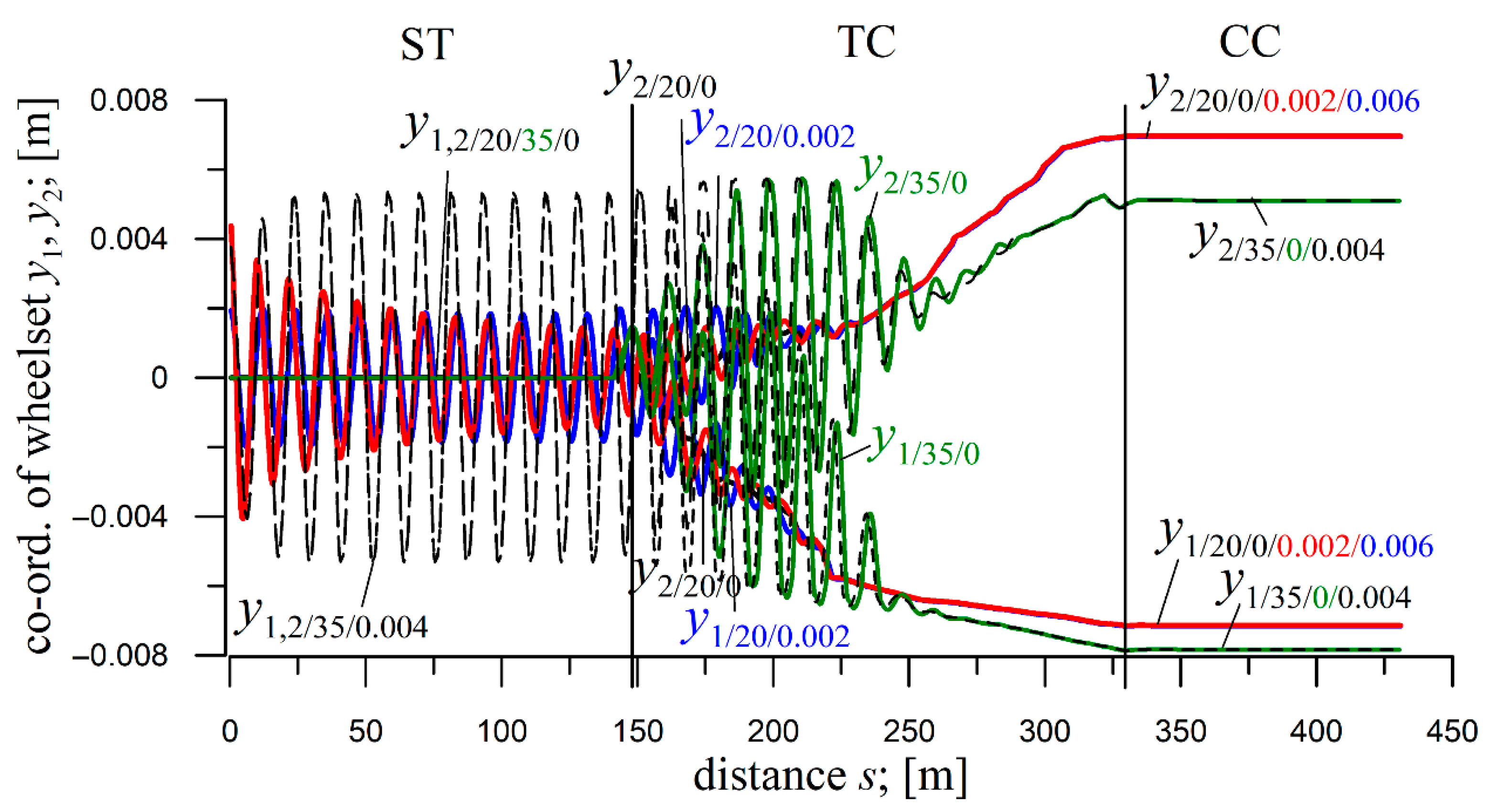

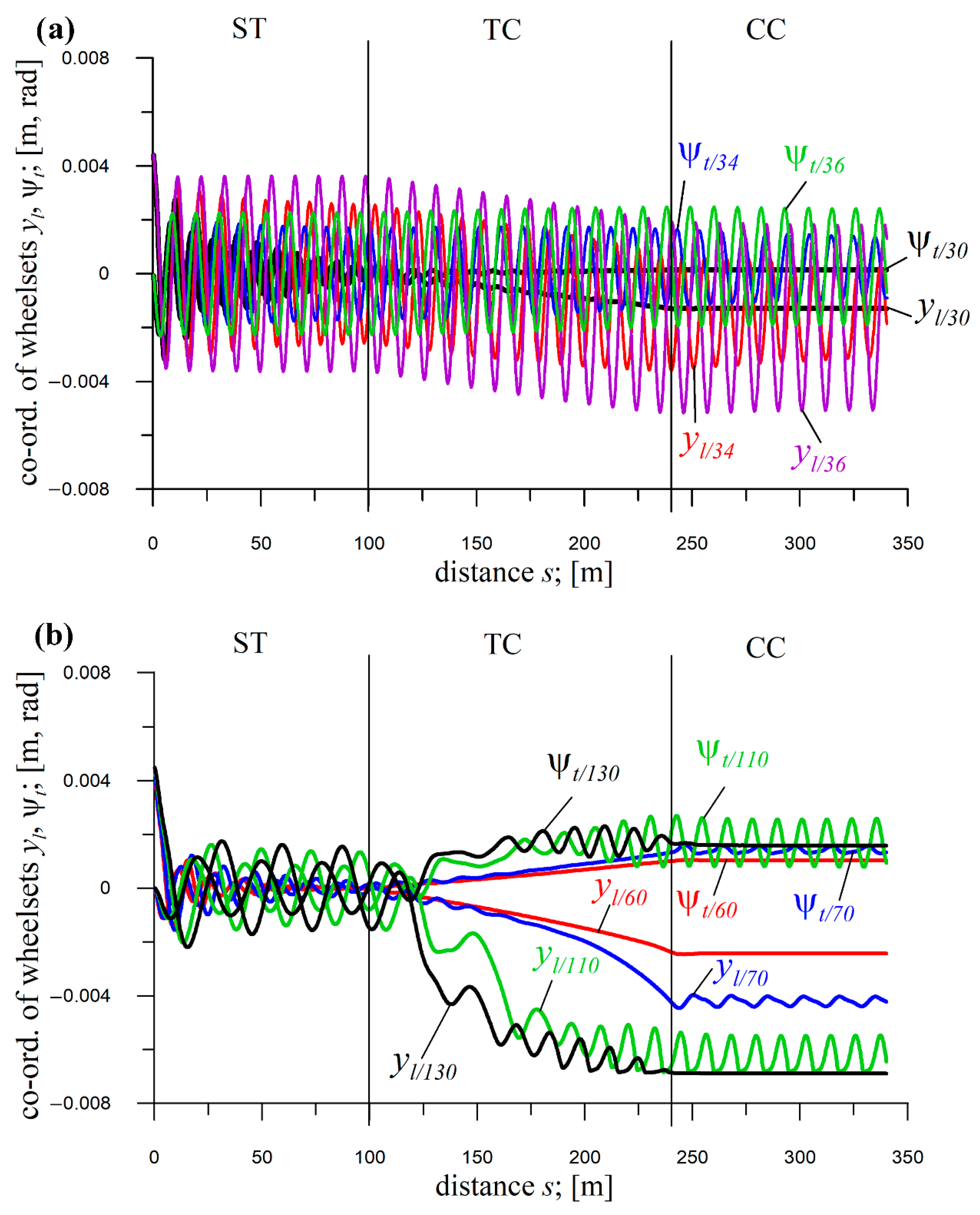

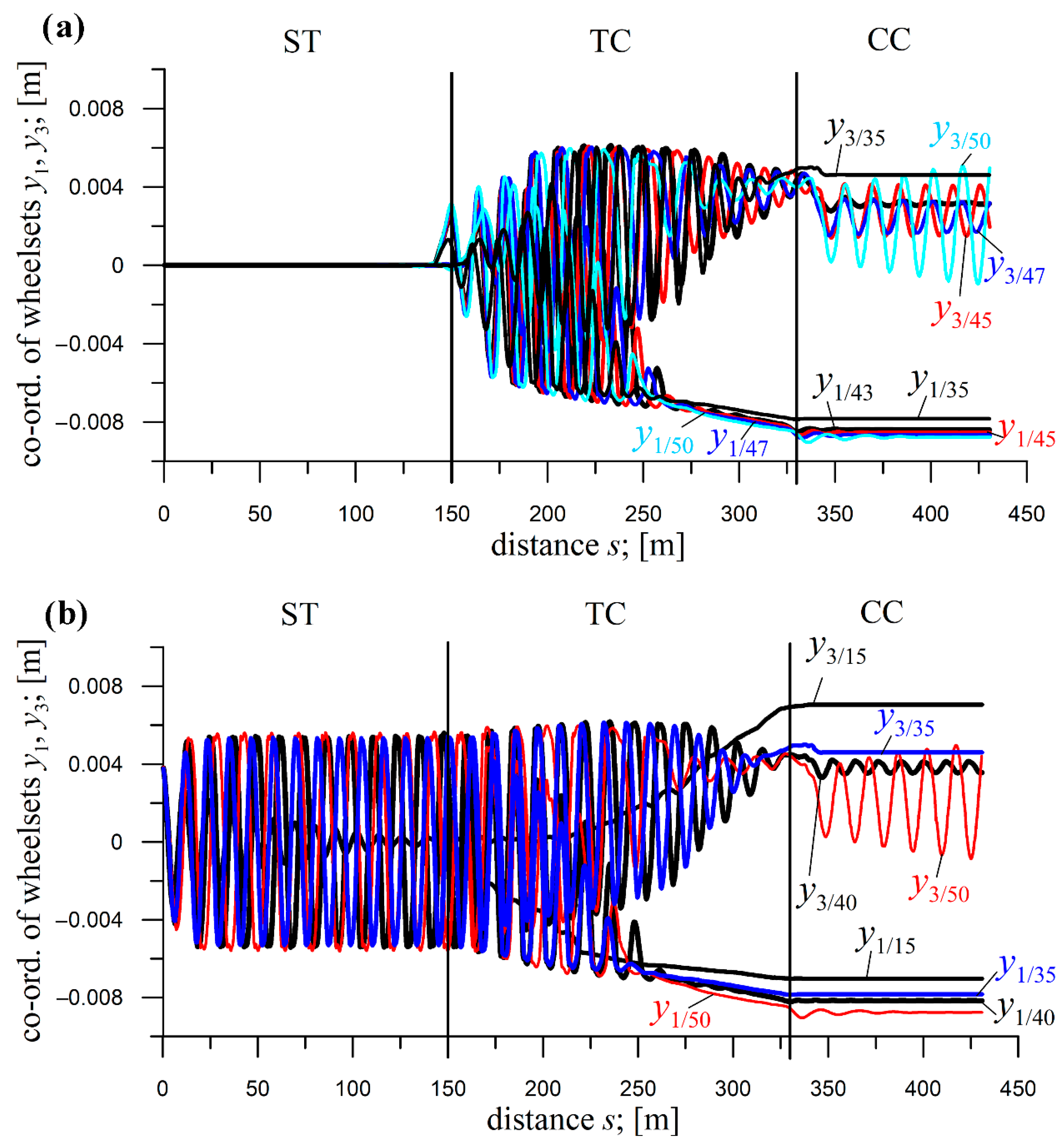

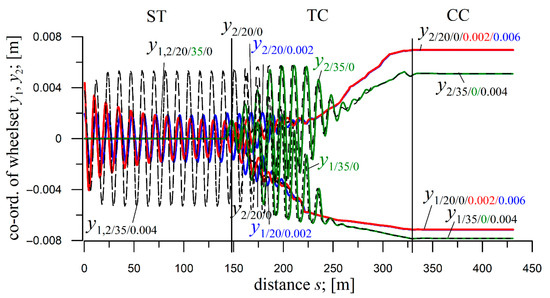

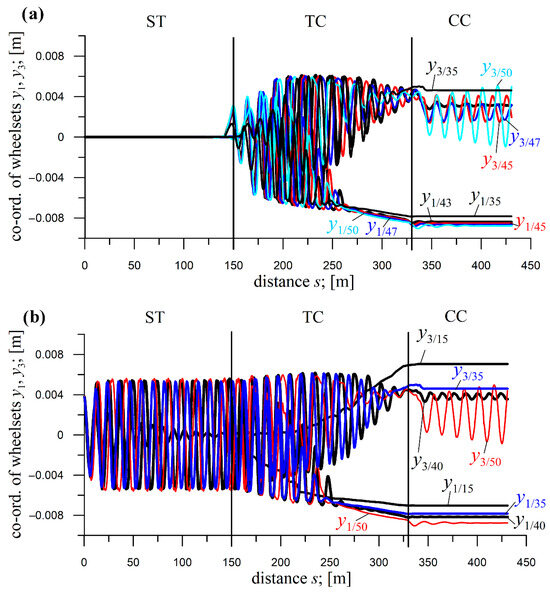

The impact of yi(0) on the solutions for the MKIII car is illustrated in Figure 3 and Figure 4, obtained at E = 0.05.

Figure 3.

Lateral displacements of wheelsets in the front bogie of passenger car MKIII for R = 600 m; h = 0,15 m; ST (l = 150 m), TC (l = 180.46 m), CC (l = 100 m): at v = 20 m/s; yj(0) = 0 m, yj(0) = 0.002 m and yj(0) = 0.006 m, and at v = 35 m/s; yj(0) = 0 m and yj(0) = 0.004 m.

Figure 4.

Lateral displacements of front wheelsets in front and rear bogies of passenger car MKIII for R = 2000 m; h = 0.045 m; ST (l = 300 m), TC (l = 180.46 m), CC (l = 500 m); v = 20 m/s at yj(0) = 0, 0.002 and 0.006 m.

At R = 600 m and velocity v = 20 m/s (Figure 3), different yj(0) values (from their entire scope) do not affect the solutions in CC, which remain identical. Minor quantitative differences appear in the TC’s final part, but the qualitative behaviour is preserved. A notable feature in ST is that larger initial conditions lead to lower vibration amplitudes on entering the TC, suggesting multiple coexisting solutions—an effect previously identified in [1].

At R = 600 m and v = 35 m/s, and for R = 1200 m at v = 20 m/s (not illustrated), results follow the same pattern, with only increased leading wheelsets’ displacements in CC due to the larger v and R, respectively.

At R = 2000 m and v = 20 m/s (Figure 4), solutions in CC remain identical for all yj(0) values (from their entire scope), but multiple solutions in ST reappear, as at R = 600 m. A peculiar observation is the delayed onset of vibrations in CC for yj(0) = 0 and 0.006 m, though there are no vibrations in TC’s final part and CC’s beginning. Vibrations already exist at the CC’s beginning for yj(0) = 0.002 m (and not illustrated 0.004 m).

5. The Impact of Vehicle Velocity

5.1. The Bogie with Average Parameters (Velocity Impact)

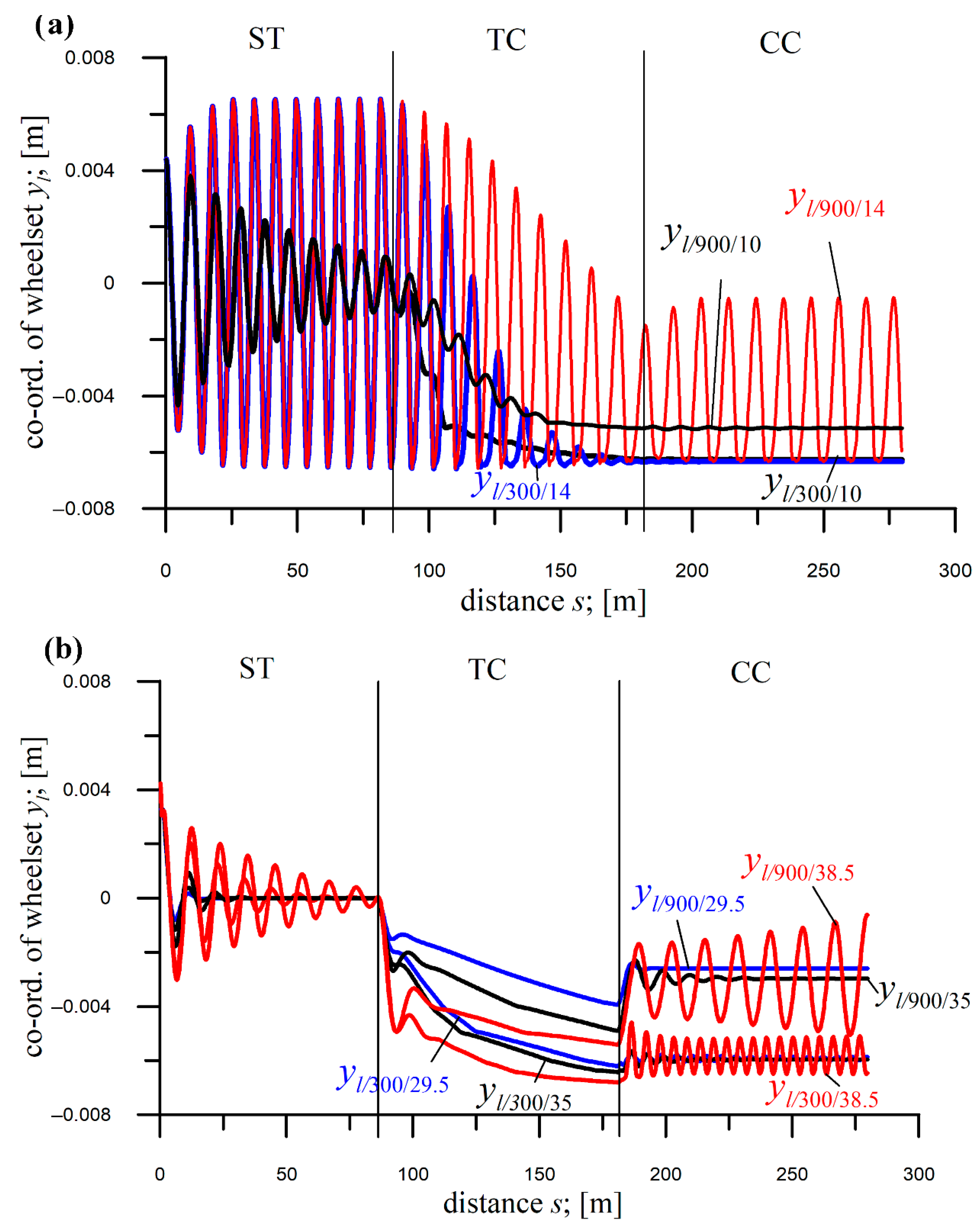

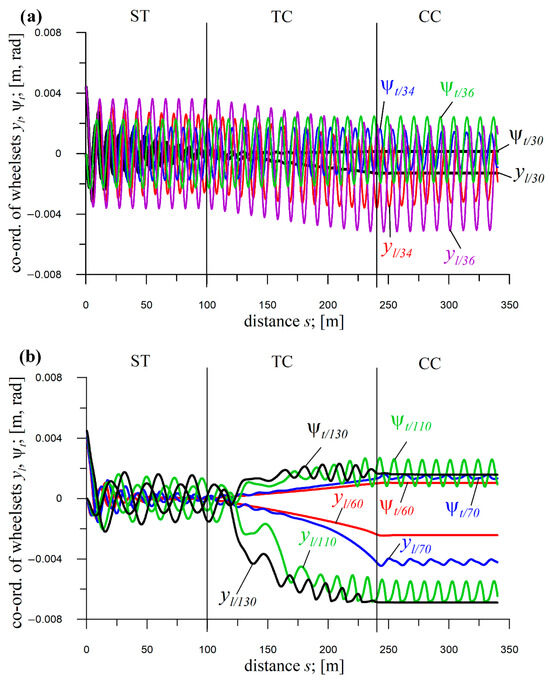

The influence of velocity v on solutions for the bogie with average parameters is presented in Figure 5a,b, obtained at E = 0.01.

Figure 5.

Coordinates of wheelsets of the bogie with average parameters for R = 2000 m; h = 0.045 m; ST (l = 100 m), TC (l = 140 m), CC (l = 100 m); yi(0) = 0.0045 m at (a) kzy = 1556 kN/m (0.4×) and v = 30, 34 and 36 m/s, and (b) kzx = 104,600 kN/m (40×) and v = 60, 70, 110 and 130 m/s.

In Figure 5a, at v = 30 and 34 m/s, vibrations in ST experience a decay (approach stationary), indicating motion below vn in ST (actual vn values not determined). A limit cycle forms at v = 36 m/s, indicating a stable periodic solution. Reducing the lateral stiffness kzy (0.4× multiple) lowers vn to below 36 m/s. Similar results occur in CC (at R = 2000 m), with a limit cycle forming at v = 36 m/s. Decreasing kzy lowers vn again (at nominal kzy and R = 2000 m, vn = 47.1 m/s [46]). The solutions in TC constitute a smooth transition from ST to CC for all mentioned v values.

In Figure 5b at v = 60 m/s (and not illustrated v < 60 m/s), vibrations in ST experience a decay (approach stationary) and become stationary in CC. So, the motion in ST and CC of R = 2000 m occurs below the respective vn. The solutions in TC constitute a smooth transition from the solutions in ST to those in CC.

The results at v = 70 m/s (Figure 5b) are still typical, but only for ST and TC. In ST, vibrations decay, while in TC, a smooth transition to CC exists. Periodic solutions in CC at v = 70 m/s mean motion above vn (at R = 2000 m). Decaying vibrations in ST at v = 110 and 130 m/s mean that this vn is atypically much lower than in ST. Moreover, 2-axle objects with nominal parameters (as in Table 1 and Table 2) show similar vn in ST and CCs [46]. In CC, at v = 110 m/s, limit cycles still exist, although already initiated halfway through TC. Atypical change in solution type happens there, opposed to vibrations initiated only in the CC at v = 70 m/s. In CC at v = 130 m/s, solutions are stationary, thus atypical. Typically, solutions at higher v become periodic, whereas at the lower, they are stationary. In TC’s second half at v = 130 m/s, solutions become atypical through specific vibrations that appear and then disappear at the TC’s end. The case of the bogie of MKIII car at R = 300 m in Section 6.2 is similar.

Increasing kzx (40× multiple) leads to a significant rise in vn in ST and CC of R = 2000 m (Figure 5b) to above 130 m/s and above 60 but below 70 m/s, respectively (at nominal kzx, the values are vn = 45.8 and 41.7 m/s [46]). Unforeseenly, the 10×, 60×, 80×, and 100× multiples (not illustrated) result in solutions qualitatively and quantitatively similar to Figure 5b.

5.2. The Bogie of MKIII Passenger Car (Velocity Impact)

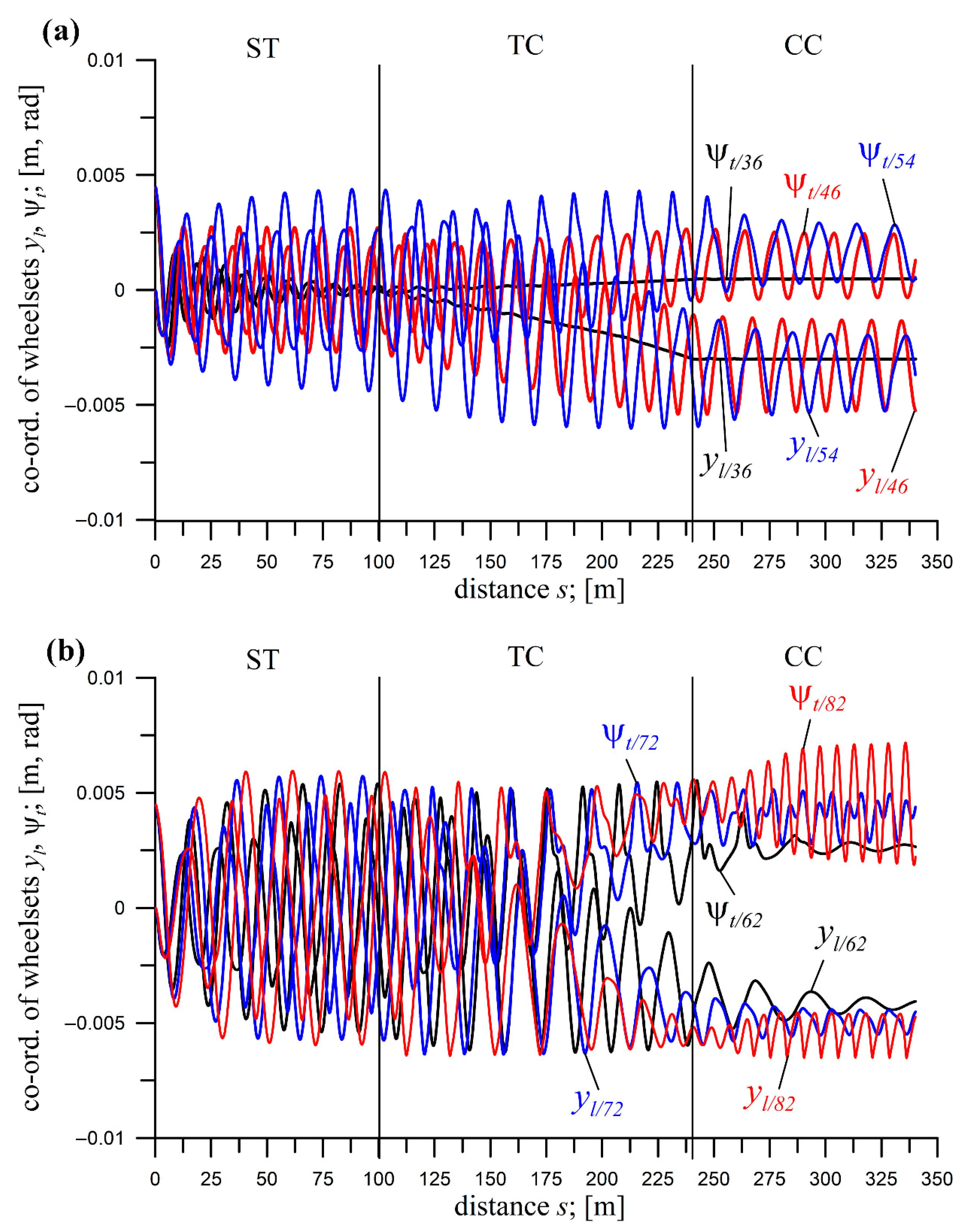

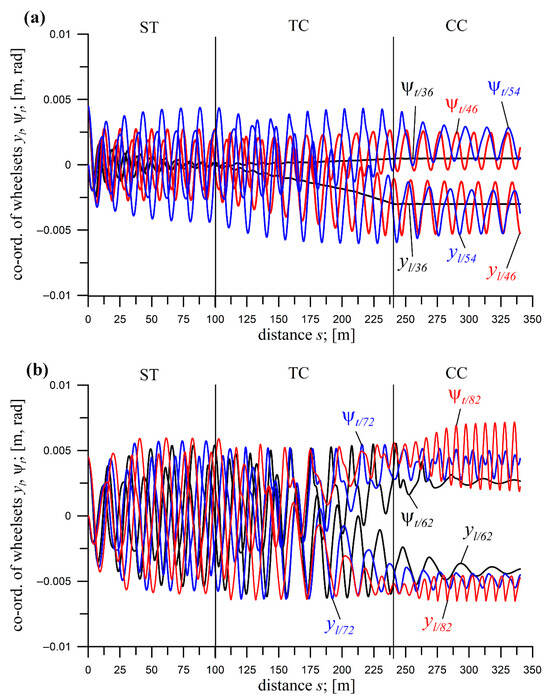

The effect of v on the solutions for the bogie of MKIII passenger car is illustrated in Figure 6a,b, at E = 0.4. Except for the v variants in these figures, v = 10, 46, and 66 m/s were studied.

Figure 6.

Coordinates of front and rear wheelsets of the bogie of MKIII passenger car for R = 1200 m; h = 0.075 m; ST (l = 100 m), TC (l = 140 m), CC (l = 100 m); yi(0) = 0.0045 m at: (a) v = 36, 46 and 54 m/s and (b) v = 62, 72 and 82 m/s.

These results are systematised, but partly. In ST, they are for all v values. In CC, they are between v = 10 and 46 m/s (Figure 6a). At v = 54 m/s and larger (Figure 6a,b), nonlinear features manifest in unsystematised solutions along v increase.

In ST, at v = 10, 36 and 41 m/s, decaying vibrations represent motion below vn for ST (v = 36 m/s in Figure 6a). At v = 46 m/s, a limit cycle is established (Figure 6a), with motion above vn. This is also so at v = 54, 62, 72 and 82 m/s (Figure 6a,b), with ST(l = 100 m) too short to properly show it at v = 54 and 62 m/s.

In CC, at v = 10, 36 and 41 m/s (v = 36 m/s in Figure 6a), the motion occurs below vn for CC of R = 1200 m. At v = 10 (not illustrated) and 36 m/s (Figure 6a), solutions are stationary, while at v = 41 m/s (not illustrated), vibrations decay. At v = 46 m/s, a limit cycle emerges in CC (Figure 6a), with motion above vn.

At v = 54 m/s (Figure 6a), the solutions in CC remain periodic, with nonlinearities manifested through the loss of the symmetrical, quasi-harmonic character of displacements yl. Surprisingly, at v = 62 m/s (Figure 6b), the solutions in the CC approach a stationary (decaying vibrations). At v = 66 m/s (not illustrated), the solutions become periodic again. However, losing the quasi-harmonic character of the yaw angle ψt reveals nonlinear features. At v = 72 m/s (Figure 6b), the solutions are still periodic. However, the more distinct loss of quasi-harmonic character of yl and ψt exists. At v = 82 m/s (Figure 6b), periodic solutions in CC continue, now with a much higher frequency than at smaller v. This frequency is also much higher than in ST and TC.

In TC, the transition from ST to CC is smooth. However, in TC’s second half, nonlinear features are noticeable at higher v = 66, 72, and 82 m/s, preceding such features in CC (Figure 6b).

Nonlinear effects, particularly at higher velocities, presumably stem from the isolated bogie model lacking secondary suspension, relatively low mass, and base length, which amplify lateral displacements and make flange contact more probable.

5.3. The 2-Axle Empty Freight Car of Average Parameters (Velocity Impact)

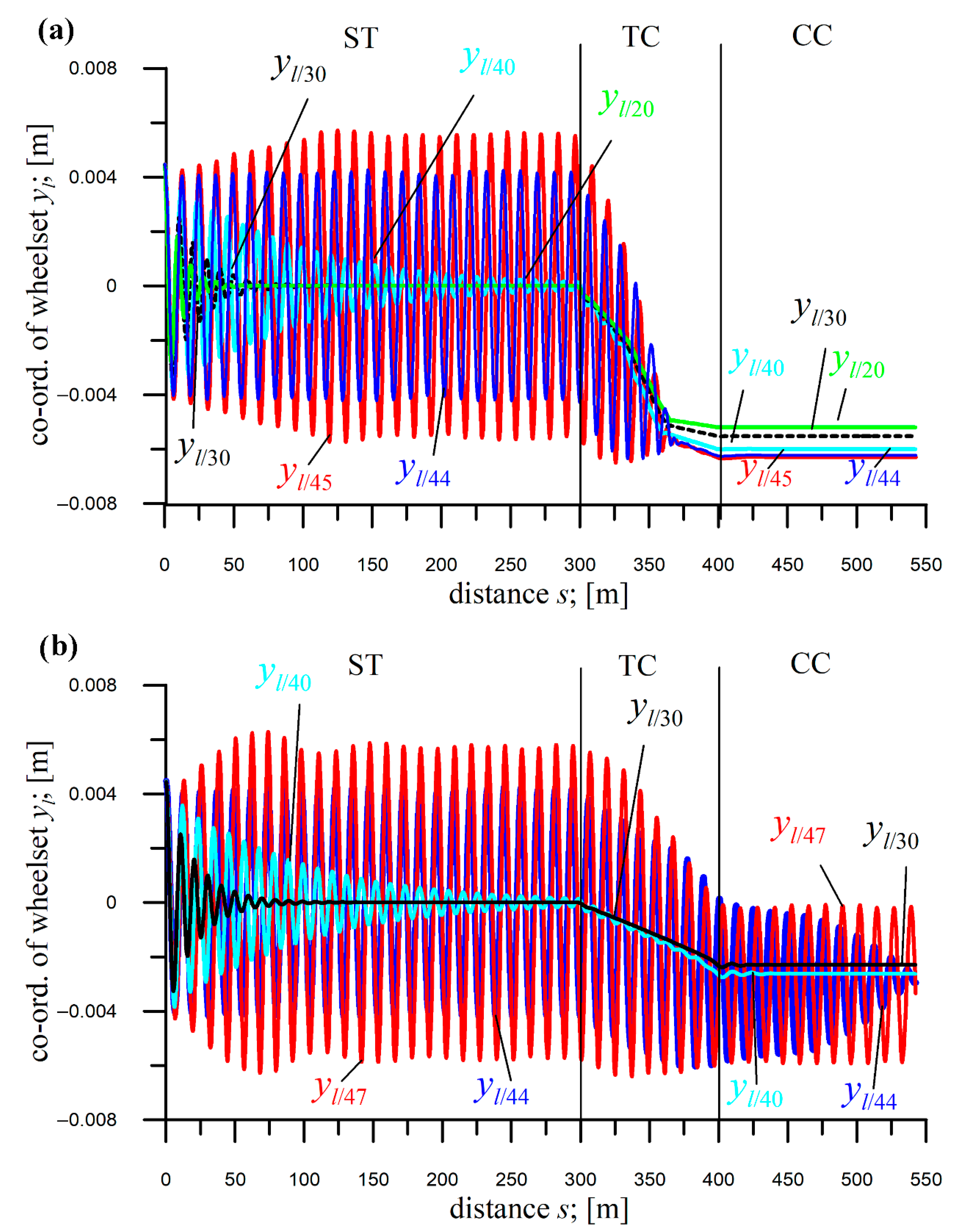

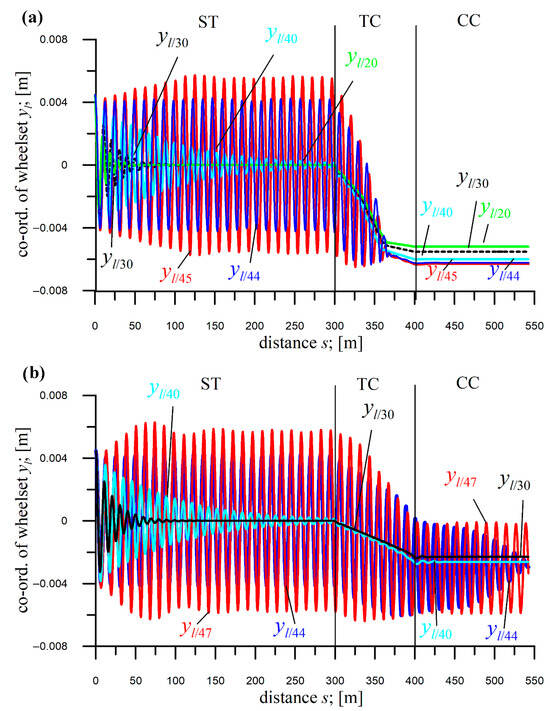

The influence of v on solutions of the 2-axle empty freight car is shown in Figure 7a,b, at E = 0.1. Except for R variants in these figures, the R = 600 and 4000 m were tested.

Figure 7.

Coordinate of leading wheelset of freight car of average parameters at ST (l = 300 m), TC (l = 102.4 m), CC (l = 140 m); yi(0) = 0.0045 m; and kzx = 960 kN/m (1.2×); kzy = 800 kN/m (1×); czx = 71,4 kN·s/m (1.7×); czy = 70,5 kN·s/m (1.5×): (a) R = 450 m; h = 0.15m; v = 20, 30, 40, 44 and 45 m/s, and (b) R = 1200 m; h = 0.075 m; v = 30, 40, 44 and 47 m/s.

These results are well systematised, showing typical behaviour around vn in ST and CC.

In ST (Figure 7a), decaying vibrations or solutions approaching a stationary form occur at v = 20, 30, and 40 m/s, while limit cycles emerge at v = 44 and 47 m/s, placing vn between 40 and 44 m/s.

In CC at R = 450 m (Figure 7a), solutions remain stationary in the v range (20–45 m/s), indicating that the vn is higher than in ST. In addition, if the calculations were feasible, vn would be larger than the velocity vs of numerical derailment in CC of R = 450 m (here vs > 45 m/s).

At R = 600 m (not illustrated), front wheelset displacements yl are stationary at v = 30, 40, 44 and 47 m/s, while rear wheelset’s yt becomes periodic at v = 44 and 47 m/s, marking vn as between 40 and 44 m/s, like in ST. This does not mean that vn in ST and CC at R = 600 m are the same.

At R = 1200 m (Figure 7b), stationary solutions at v = 30 and 40 m/s exist, while periodic behaviour starts at v = 44 m/s, again showing a similar range for vn (between 40 and 44 m/s). Again, it does not mean that the vn in ST and CCs at R = 600 and 1200 m are identical.

At R = 4000 m (not illustrated), responses qualitatively align with those at R = 1200 m. Quantitatively, at R = 4000 m, the amplitudes are larger, reduced asymmetry against the track centre line exists, similarity to the solutions in CC to those in ST appears, and the limit cycle at v = 44 m/s starts from the CC’s very beginning.

Solutions in the TC transition smoothly from ST to CC, though at existing vibrations, their behaviour varies by R. At R = 450 m (Figure 7a), they disappear from the TC’s middle. At R = 600 m (not illustrated), the yl vibrations (front wheelset) disappear at the TC’s end, while yt (rear wheelset) do not and continue in CC as a limit cycle. At R = 1200 m and v = 44 m/s (Figure 7b), the vibrations in TC’s end do not reach the amplitude as in CC. They do, at v = 47 m/s (Figure 7b). At R = 4000 m (not illustrated), the amplitudes in TC change insignificantly and have similar values as in ST and CC.

5.4. The 2-Axle-Loaded HSFV1 Freight Car (Velocity Impact)

The impact of v on solutions for the HSFV1 car is presented in Figure 8, at E = 0.01. Except for v in Figure 8 (see figure caption), results for v = 40, 45.3, and 48 m/s were studied.

Figure 8.

Coordinates of leading wheelset of HSFV1freight car; R = 600 m; h = 0.15 m; ST (l = 150 m), TC (l = 142 m), CC (l = 150 m); yi(0) = 0.0045 m; kzx = 206,7 kN/m (0.1×) at v = 38, 42, 43 and 49 m/s;.

The results in Figure 8 are naturally systematised.

In ST, stationary solutions or decaying vibrations occur at v = 38, 40, and 42 m/s, while limit cycles occur at v = 43 m/s and beyond, placing vn between 42 and 43 m/s (vn = 42.8 m/s [46]).

In CC, solutions are stationary at v = 38 m/s, while limit cycles start at v = 40 m/s only for the front wheelset and with small amplitude, placing vn between 38 and 40 m/s (vn = 40 m/s [46]). Starting from v = 42 m/s, the limit cycle concerns both wheelsets, while amplitudes grow with v. They become considerable for v = 43 and 49 m/s (also in ST). Small R = 600 m in Figure 8 induces pronounced results asymmetry in CC compared to the symmetric responses in ST.

In TC, the solutions transition smoothly from ST to CC in the entire v scope (between 38 and 49 m/s). From v = 42 m/s, vibrations exist throughout TC, while from v = 43 m/s, their amplitudes become significant.

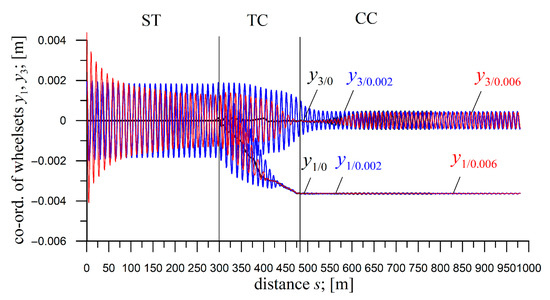

5.5. The 4-Axle MKIII Passenger Car (Velocity Impact)

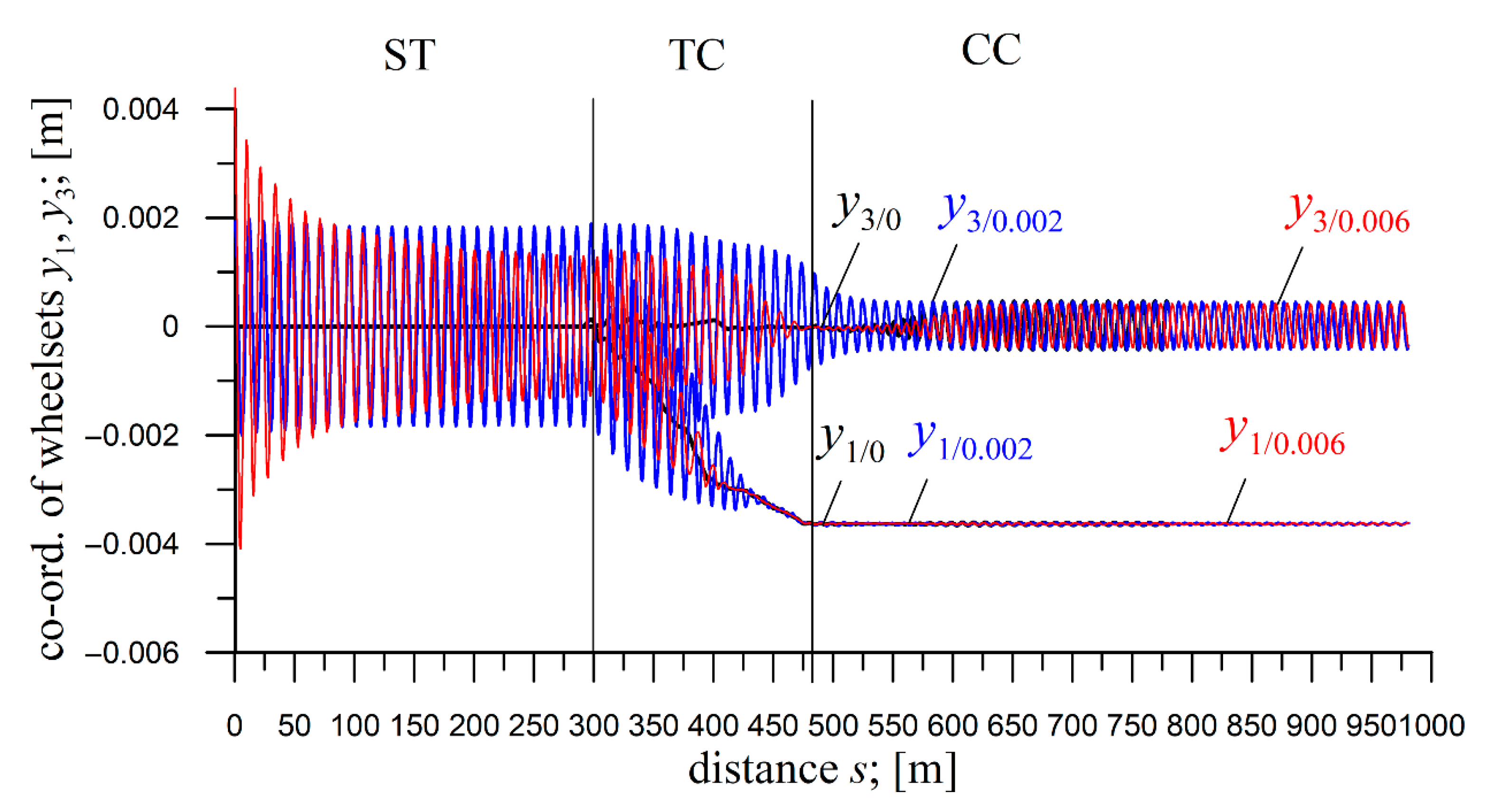

The impact of v on the solutions for the 4-axle MKIII car is shown in Figure 3 (Section 4.2) and Figure 9a,b, at E = 0.05. The impacts at zero (Figure 3 and Figure 9a) and non-zero (Figure 3 and Figure 9b) initial conditions yj(0) are considered.

Figure 9.

Lateral displacements of front wheelsets in front and rear bogies of passenger car MKIII; R = 600 m; h = 0,15 m; ST (l = 150 m), TC (l = 180.46 m), CC (l = 100 m) for (a) yj(0) = 0 m at v = 35, 43, 45, 47 and 50 m/s and (b) yj(0) = 0.004 m at v = 15, 35, 40 and 50 m/s.

For yj(0) = 0.0 m, solutions in ST are always stationary (Figure 3 and Figure 9a). For yj(0) = 0.004 m, solutions shift from decaying (at v = 15 m/s) to periodic (from v = 20 to 50 m/s—Figure 3 and Figure 9b), setting vn between bordering values (vn = 19.1 m/s [46]).

Results here confirm no influence of yj(0) applied in ST on solutions in CC (revealed in Section 4). So, solutions in CC at yj(0) = 0.0 and 0.004 m are identical, and thus discussed jointly (see line pairs for different yj(0) at v = 35 m/s in Figure 3 and at v = 50 m/s in Figure 9a,b). In CC, solutions are stationary between v = 15 and 35 m/s (Figure 3 and Figure 9a,b), then between v = 40 and 50 m/s become periodic (Figure 9a,b), but limited to the rear bogie (y3 coordinate). The y3 amplitudes are non-monotonic, varying irregularly with increasing v and highlighting strongly nonlinear features of the present vehicle. Specifically, they are greater at v = 40 m/s than at v = 43 m/s (Figure 9b); smaller at v = 43 m/s (Figure 9b) than at v = 45 m/s (Figure 9a); greater at v = 45 m/s than at v = 47 m/s (Figure 9a); and smaller at v = 47 m/s than at v = 50 m/s (Figure 9a,b).

In TC at yj(0) = 0 m, and v = 15 (not illustrated) and 20 m/s (Figure 3), vibrations resemble disturbances. At v = 35 m/s and larger (Figure 3 and Figure 9a), they become vibrations of high intensity. In TC at yj(0) = 0.004 m and v = 15 m/s (Figure 9b), solutions are identical as at yj(0) = 0 m. At v = 20 m/s and larger (Figure 3 and Figure 9a,b), such identity (high similarity) only applies to the TC’s end, with vibration intensity rising with v growth. At any yj(0), the amplitudes are significantly bigger at the TC’s beginning than at its end.

5.6. Summary of Critical Velocities for Different Objects and Curve Radii

Variation in velocity in Section 5 and this section’s content makes it possible to collect information about critical velocities vn in ST and CCs of different radii R. In particular, it enables comparisons in ST and CCs, and for different vehicles. To facilitate such cross-comparison, Table 3 was prepared based on the results of the chapter, with possible refinements based on [46]. The symbols and records vn = , vn≈, and vn between () mean precise value based on [46], approximate value being the arithmetic mean of values determining vn on the figures (in this paper), and these determining values, respectively.

Table 3.

Summary of nonlinear critical velocities vn for different objects/vehicles and curve radii R.

Concluding the content of Table 3, it can be stated that critical velocities in CCs are either of very similar value as in ST or lower. The eventual identity of vn in ST and CCs cannot be stated because the exact values of vn were not determined in the present paper. The almost identical values appear for the bogie with average parameters (with its suspension lateral stiffness reduced), bogie of MKIII passenger car, and empty 2-axle freight car of average parameters (with its suspension stiffness and damping increased). Values of vn lower in CC for R = 600 and 2000 m appear for the bogie with average parameters (with its suspension lateral stiffness increased), loaded 2-axle freight car HSFV1 (with its suspension longitudinal stiffness decreased), and 4-axle passenger car MKIII. In the case of the freight car of average parameters in CC of R = 450 m, the results obtained suggest a higher value of vn in this CC than in ST. Potentially, it could be vn > 45 m/s, while in ST it was between 40 and 44 m/s. It is not so, however, because at v = 45 m/s and higher, numerical derailments happen at R = 450 m. One should not try to conclude that critical velocities vn in Cc are either similar or lower than in ST. Results in [46] show that bigger vn in CC than in ST are also possible. One can also see in [46] that changes in vn with the R increase (or decrease) can be both monotonous and not monotonous. All these together mean no generalisations are possible based on the results in Table 3 and in [46]. One cannot assess or anticipate vn for different R. He just has to determine their approximate or exact values individually for each vehicle.

6. The Impact of the Curve Radius

6.1. The 25TN Freight Car Bogie (Curve Radius Impact)

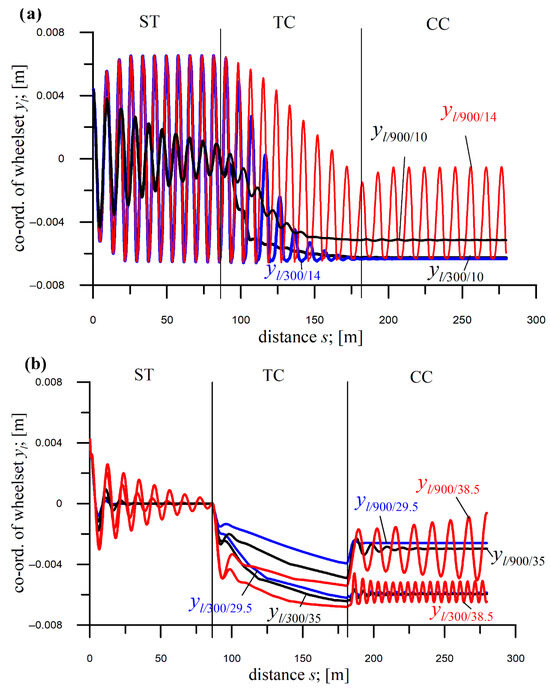

The effect of radius R on the solutions for the 25TN bogie is represented in Figure 2 (Section 4.1) and Figure 10a,b, at E = 0.01. This is discussed by comparing R = 300 and 900 m cases, but at individual v. This expands the study on the impact of v in Section 5.

Figure 10.

Coordinates of front wheelsets of 25TN bogie of a freight car for ST (l = 86.5 m), TC (l = 95 m), CC (l = 98 m); yi(0) = 0.0045 m, R = 300 m and h = 0.15 m and R = 900 m and h = 0.142 m for (a) kzy = 389 kN/m (0.1×) at v = 10 and 14 m/s and (b) kzy = 7780 kN/m (2×) at v = 29.5, 35 and 38.5 m/s.

In Figure 10a, for v = 10 m/s, solutions in ST occur below the critical velocity vn, showing decaying vibrations. In CC at R = 300 m, solutions are stationary, whereas at R = 900 m, low-amplitude vibrations decay to a stationary state. In TC, slight vibrations disappear smoothly towards TC’s end. In CC and TC, front wheelset displacements yl are larger for R = 300 m than for R = 900 m. Negative yl indicates the curve turns leftward, and the displacement is towards the curve’s outside.

In Figure 10a, as v increases to 14 m/s, the motion in ST is above vn (periodic vibrations). In CC at R = 300 m, yl are stationary, while yt of the rear wheelset (not illustrated) are periodic, with very low amplitude. At R = 900 m, yl and yt are periodic. In TC, solutions make smooth transitions to CCs, with vibrations decreasing for both R.

The v = 12 m/s, also tested (not illustrated), appeared qualitatively the same as at v = 14 m/s, but of lower amplitudes.

In Figure 10b, solutions (yl and not illustrated yt) in ST possess a similar nature at v = 29.5, 35, and 38.5 m/s, and so do those in TCs. In ST, the solutions occur below vn. However, the higher v, the longer the initial vibrations disappear. In TCs, the solutions form a vibration-free smooth passage to CCs, for both R, with disturbances during the ST-TC and TC-CC transitions.

In Figure 10b, solutions (yl and not illustrated yt) in CC differ depending on v and R. At v = 29.5 m/s, they are periodic (of low amplitude) at R = 300 m and stationary at R = 900 m. At v = 35 m/s, they become stationary after some time at R = 300 and 900 m; however, at a lower frequency for R = 900 m. At v = 38.5 m/s, they are periodic at R = 300 and 900 m; however, for R = 900 m, they have a lower frequency and longer time to establish (exceeding the CC’s length, l = 98 m). Such unordered behaviours in CC disclose strong nonlinearities.

In Figure 10b for CC and TC, at any v, the displacements towards the curve’s outside are larger at R = 300 than at R = 900 m, except for yl, at v = 38.5 m/s, in the TC’s second half, smaller.

In addition, the lowered kzy (0.1×—Figure 10a) decreased vn compared to the nominal kzy (Figure 2). Judging by Figure 10a, vn are between 10 and 12 m/s for ST, and CCs with R = 300, and 900 m, while in [46], corresponding vn at nominal kzy equal 29.2, 29.1 and 29.2 m/s, respectively. The raised kzy (2×—Figure 10b) increased vn in ST and CC at R = 900 m, compared to the nominal kzy (Figure 2). For R = 300 m, vn seems close to that for the nominal kzy. Judging by Figure 10b, vn in ST is larger than 38.5 m/s, while in CC at R = 900 m is between 35 and 38.5 m/s, which are higher than values from [46].

6.2. The MKIII Passenger Car Bogie (Curve Radius Impact)

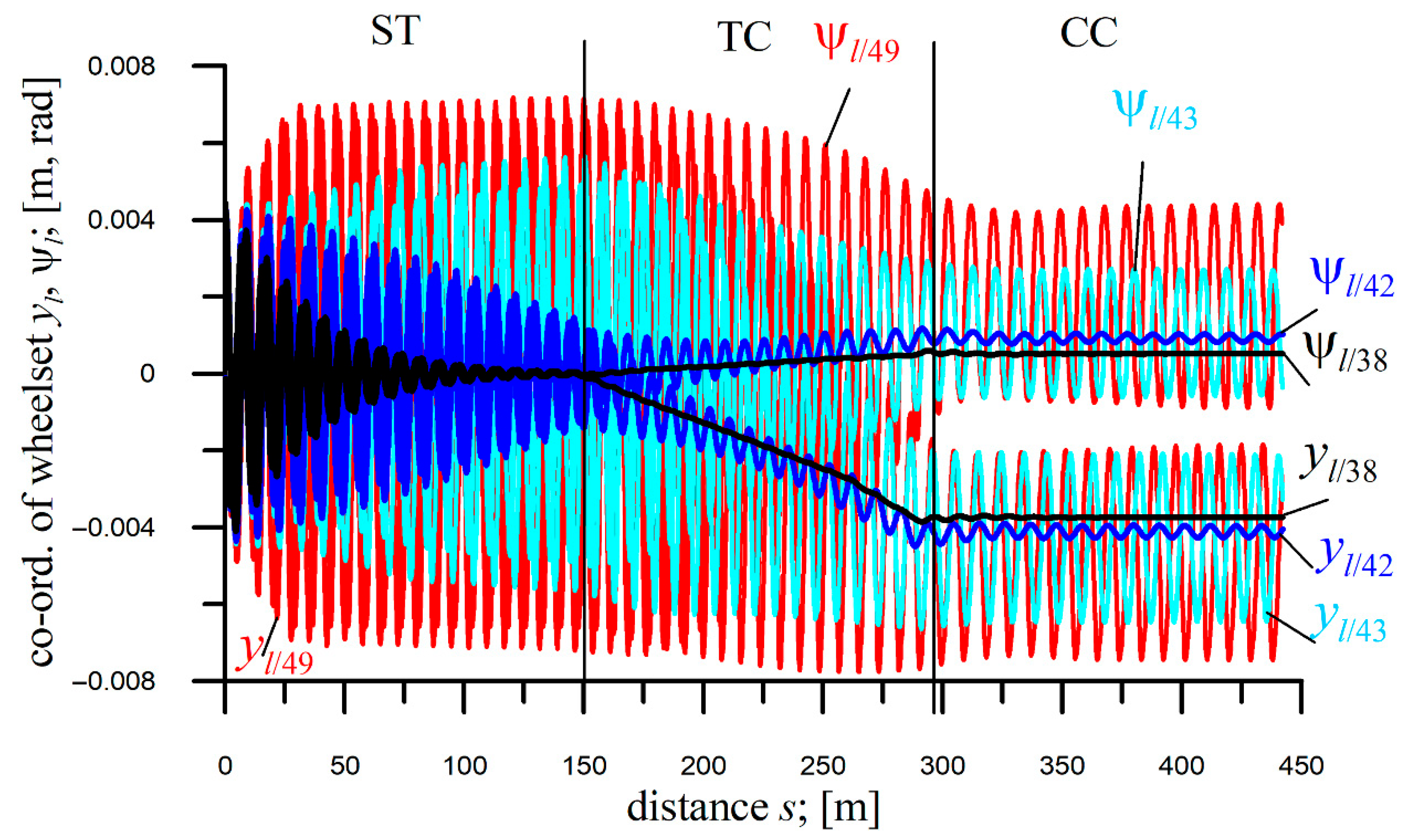

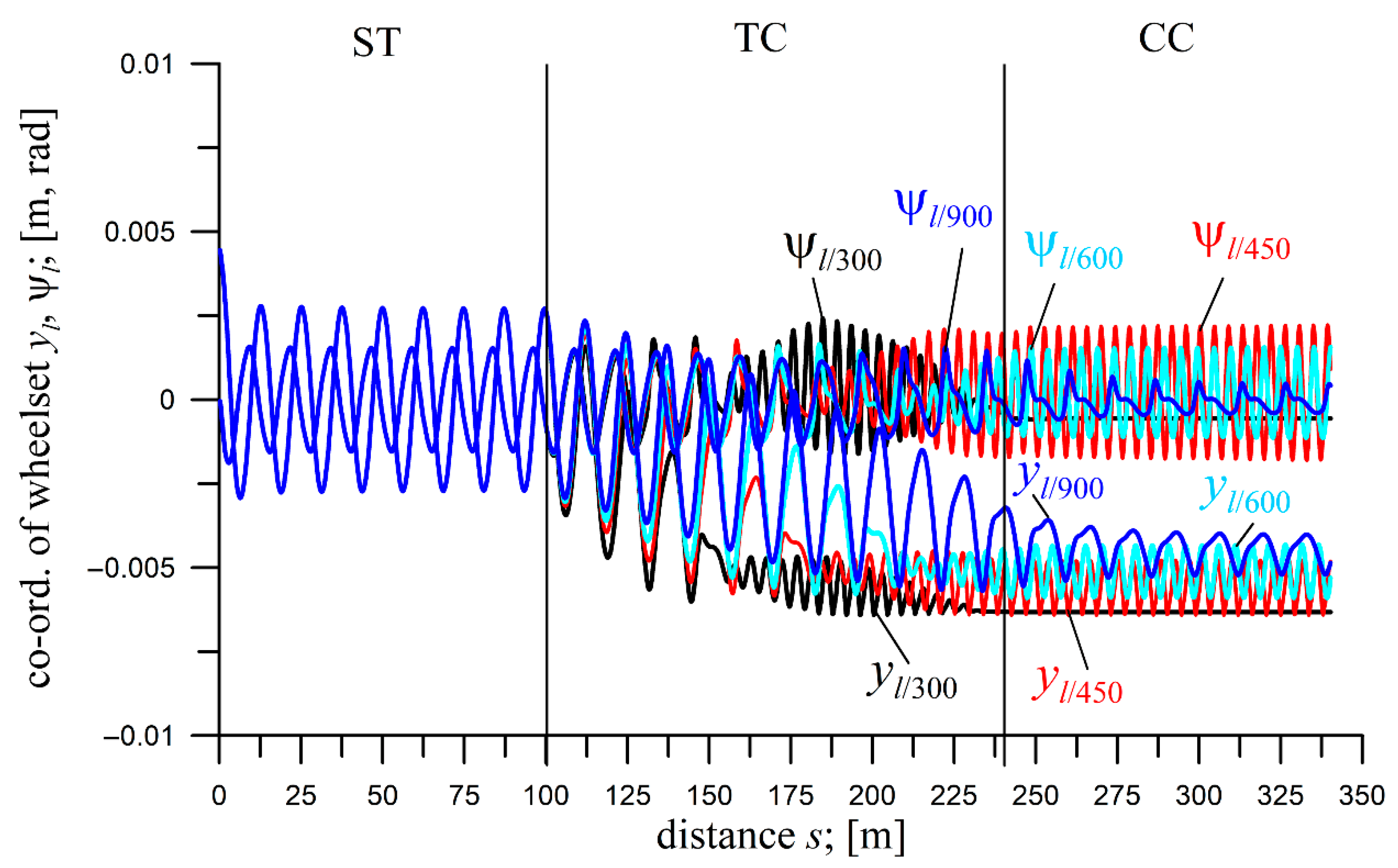

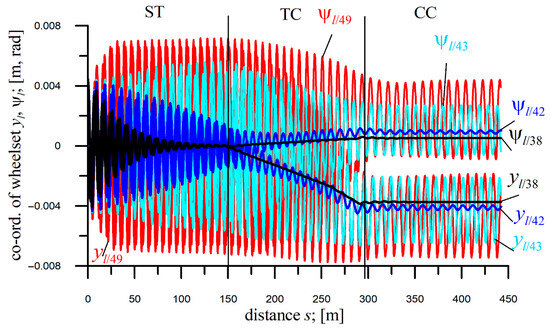

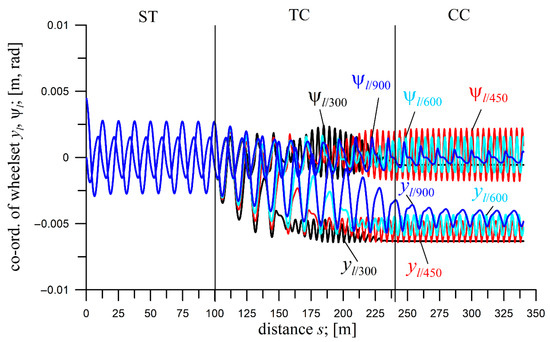

The impact of R on the bogie of MKIII passenger car is illustrated in Figure 6a and Figure 11 (Section 5.2), at E = 0.4.

Figure 11.

Coordinates of front wheelset of bogie of MKIII passenger car for v = 46 m/s; ST (l = 100 m), TC (l = 140 m), CC (l = 100 m); yi(0) = 0.0045 m at R = 300, 450 and 600 m; h = 0.15 m, and R = 900 m; h = 0.1 m.

In ST, the motion is typical for v above vn, represented by limit cycles.

Contrarily, the results for TC and CC are atypical, due to strong nonlinearities.

The result in TC at R = 300 m (Figure 11) is atypical. At about 2/5 of TC’s length, a change happens in the nature of vibrations, switching from lower to higher frequency, while at TC’s end, vibrations disappear. Such a phenomenon was identified, and the origin explained, in [1]. It reflects solutions the system takes in CC for R range that corresponds to the radii the TC in Figure 11 (for the CC of R = 300 m) possesses in its middle part (here R between 450 and 700 m). In Figure 11, in CCs for R = 450 and 600 m, periodic solutions of frequency and amplitudes identical to those in the TC for R = 300 m can be seen.

The solutions in TCs at R = 450 and 600 m (Figure 11) feature similar frequency switches as at R = 300 m. They appear slightly behind 1/2 and about 3/4 of the TC’s length. Differently, the vibrations do not disappear but increase at the TC’s end and continue in CC.

It is different in TCs at R = 900 and 1200 m (Figure 6a and Figure 11—v = 46 m/s); smooth transitions from ST to CC happen. Vibration frequencies in ST, TCs, and CCs remain similar. Different are the amplitudes, larger at R = 1200 m.

In CC, at R = 300 m, the solution is stationary (motion below vn in CC at R = 300 m), whereas at R = 450 and 600 m the solutions are periodic (limit cycles—motion above vn in CCs at R = 450 and 600 m); Figure 11. Atypical for R = 450 and 600 m are the frequencies in CCs, much higher than in ST. However, the amplitudes are somewhat lower at R = 600 m. The results in CCs at R = 900 and 1200 m (Figure 6a and Figure 11—v = 46 m/s) are periodic with frequencies close to that in ST, and the amplitudes are considerably lower. Regular quasi-harmonic picture of the solutions is spoiled at R = 900 m, while at R = 1200 m, this is preserved.

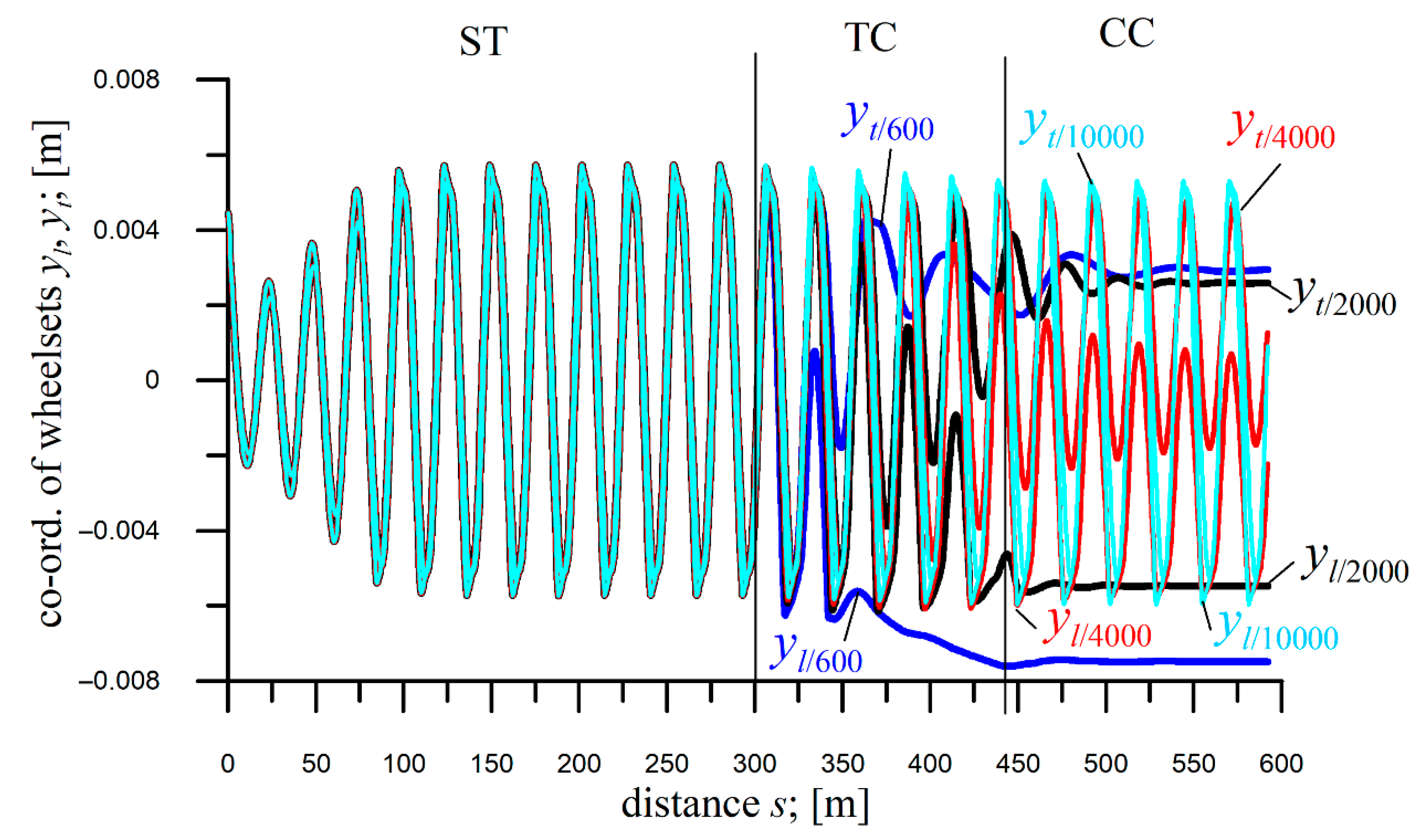

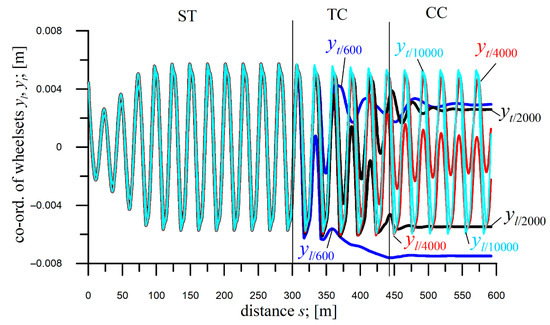

6.3. The 2-Axle Loaded HSFV1 Freight Car (Curve Radius Impact)

The R influence on the HSFV1 freight car is presented in Figure 12, at E = 0.01. Except for longitudinal stiffness kzx in Figure 12, the nominal (Table 1) and reduced (206.7 kN/m—0.1×) values were tested.

Figure 12.

Lateral displacements of front and rear wheelsets of HSFV1freight car for v = 45.3 m/s; ST (l = 300 m), TC (l = 142 m), CC (l = 150 m); yi(0) = 0.0045; kzx = 41340 kN/m (20×) at R = 600, 2000, 4000 and 10,000 m and h = 0.15, 0.045, 0.0225 and 0.009 m, respectively.

All these results are naturally systematised.

In Figure 12, for adopted v = 45.3 m/s, solutions are periodic in ST and CCs at R = 10000 and 4000 m (limit cycles–v > vn). The solutions are stationary (v < vn) in CCs of R = 600 and 2000 m. The vibrations disappear in TC for R = 600 m, while in CC at R = 2000 m. At R = 4000 m, the amplitudes in CC are smaller than in ST, while at R = 1000 m, they are almost the same. Also, at R = 4000 m, considerable solutions asymmetry against the track centre line exists, while at R = 1000 m it is virtually invisible. Despite such different solutions in CCs, the solutions in TC make smooth transitions from the ST to CC.

For the 0.1× multiple and the nominal kzx, v = 45.3 m/s proves higher than vn for CCs at any R and ST (limit cycle solutions). However, the smaller R, the smaller amplitudes, and the more considerable asymmetry of solutions against the track centre line in CCs. The bigger the R, the closer the amplitude values in CC and ST. In TC, the transition of solutions from the ST to CC is smooth for all tested R.

Confronting results for the 0.1× and 20× multiples shows that bigger kzx increases vn in CCs of medium R = 600 and 2000 m and decreases vibration frequencies in ST, TC and CC at the same v.

7. Conclusions

The aims to be solved in the present paper have been achieved. So, the scientific answer about how the initial conditions y(0) influence the simulation results, as well as possible behaviours, of railway vehicles in TCs at velocities around the nonlinear critical velocity vn was obtained and presented in the paper. In accordance with the paper’s aim, this answer was obtained in the course of systematic simulation studies with intensive y(0) variation, and variation in other motion conditions as curve radii R and vehicle velocity v. What is more, individual answers were obtained, in such a scope, for six objects representing quite spread out classes of different railway vehicles, i.e., three bogies, two 2-axle cars, and a 4-axle car. The answers obtained and results selected for presentation in the paper reveal many strongly nonlinear and often unpredictable features/phenomena/behaviours for all the studied objects.

In addition to the above, the next two entirely analogous aims have been achieved. So, the answers were obtained and presented, at the same research scope, about the influence of the curve radii R on the simulation results and vehicles’ nonlinear features. So, the same aim was also achieved in the paper for the influence of vehicle velocity v.

Hence, one can state generally that the question of the influence of motion conditions on the nonlinear behaviours of railway vehicles in TCs was answered in the paper within the scope as assumed in the paper’s aim.

Results of the study enabled the formal presentation of a supposition in the form of a hypothesis that nonlinear features found in the studied conditions may concern all the railway vehicles guided based on the wheel–rail contact. The readers are informed that, in the authors’ opinion, it is not the rail–wheel contact alone but the interplay between at least: contact conditions, suspension parameters, mass and geometric vehicle parameters, and motion conditions which are responsible for the appearance of the nonlinear features. The authors’ opinion is explicitly provided that, despite the comprehensive study, the number of obtained results is too small to prove the above hypothesis, and there is a space for other researchers to undertake the tasks on the nonlinear phenomena at railway vehicles’ motion in TCs. It hopefully fulfils the promotional purpose of the article, declared as the paper’s general aim in the introduction. This last one, in case of successful spread of the topic, is subjectively to the authors as important a contribution as the obtained research answers mentioned above.

Before the final conclusion of the detailed results of simulations, in order to formulate their ordered nature, the authors feel that the key examples of differences between particular objects should be collected. For the sake of the generalised conclusions objectivity, the collection, except for results in the present paper, sometimes takes into account the older and future publications. The different features found just for a single object are:

- It was disclosed that the 4-axle passenger car is particularly prone to the existence of multiple solutions. They were observed in ST for different yi(0) with their no-effect for solutions identity in CC at R up to 2000 m. In the case of solutions in CC, they existed at larger radii (R = 4000, 6000, 10,000 m).

- The unusual change from periodic solutions to stationary ones was disclosed for the bogie with average parameters in CC of R = 2000 m at v = 130 m/s.

- The unpredictability of the solutions was disclosed in CC for the bogie of the MKIII passenger car and the whole MKIII car at v > vn. It existed at R = 1200 m and v between 54 and 82 m/s (R = 900 m [1]) for the bogie, while for the car at R = 600 m and v between 43 and 50 m/s.

- Different solution types (stationary and periodic) were disclosed for wheelsets of the 2-axle freight car of average parameters in CC at R = 600 m (R = 900 and 1200 m [1]).

- At R = 300 to 900 m, atypical behaviours were observed for the 25TN bogie, such as disappearing vibrations in TC (despite their existence in ST and CC) and switching between periodic and stationary solutions (and vice versa) in CC [1].

- Atypical higher vibration amplitudes in CC for the smaller R than amplitudes for higher R and single or multiple changes in solution type in TC were revealed at smaller R for the bogie of MKIII car.

- Limit cycles were revealed in CC despite their absence in ST, and no vibrations in TC for the 2-axle hsfv1 car, at R between 450 and 650 m for the selected suspension parameters configuration (to be discussed in the planned following paper).

From the systematic motion conditions’ variants, the study provides the following general conclusions:

- Initial conditions in ST did not affect the solutions in CC, except in cases where multiple solutions existed in ST and/or CC.

- A mostly systematised solutions pattern exists in ST, TC, and CC for increasing velocity, except for the unpredictability of results in CCs only, facilitated by high speeds.

- The solutions for a gradually increasing curve radius showed a mostly systematic pattern. Its perturbations mainly concern small and medium R (300 to 1200 m). For the 4-axle vehicle, the perturbing multiple solutions also appear in CCs of moderate and large radii.

Author Contributions

Conceptualisation, K.Z.; methodology, K.Z.; software, K.Z.; validation, KZ. and M.G.-S.; formal analysis, K.Z.; investigation, M.G.-S., and K.Z.; resources, M.G.-S.; data curation, K.Z.; writing—original draft preparation, M.G.-S. and K.Z.; writing—review and editing, K.Z.; visualisation, M.G.-S.; supervision, K.Z.; project administration, K.Z.; funding acquisition, M.G.-S. and K.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work is a result of the research project financed by the National Science Centre, Poland, under the project no. 2014/15/N/ST8/02668.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zboinski, K.; Golofit-Stawinska, M. Investigation into nonlinear phenomena for various railway vehicles in transition curves at velocities close to critical one. Nonlinear Dyn. 2019, 98, 1555–1601. [Google Scholar] [CrossRef]

- Zboinski, K.; Golofit-Stawinska, M. Non-linear dynamics of railway vehicles in transition curves around critical velocity with focus on 2-axle cars. In The Dynamics of Vehicles on Roads and Tracks, Proceedings of the 25th International Symposium on Dynamics of Vehicles on Roads and Tracks (IAVSD 2017), Rockhampton, QLD, Australia, 14–18 August 2017; Spiryagin, M., Gordon, T., Cole, C., McSweeney, T., Eds.; CRC Press: London, UK, 2017; pp. 599–604. ISBN 978-1-138-48263-0. [Google Scholar]

- Zboinski, K.; Golofit-Stawinska, M. The impact of primary suspension stiffness of 2-axle bogie of MKIII passenger car on its dynamical behaviour. Transp. Probl. 2018, 13, 135–146. [Google Scholar] [CrossRef]

- Zboinski, K.; Golofit-Stawinska, M. Dynamics of a Rail Vehicle in a Transition Curve above the Critical Velocity with a Focus on Hunting Motion Considering a Review of the History of Stability Studies. Energies 2024, 17, 967. [Google Scholar] [CrossRef]

- Hoffmann, M. Dynamics of European Two-Axle Freight Wagons. Ph.D. Thesis, Technical University of Denmark, Informatics and Mathematical Modelling, Lyngby, Denmark, 2006. [Google Scholar]

- Hoffmann, M.; True, H. The dynamics of two-axle freight wagons with UIC standard suspension. In Proceedings of the 10th VSDIA Conference, Budapest, Hungary, 6–8 November 2006; Budapest University of Technology and Economics: Budapest, Hungary, 2006; pp. 183–190, ISBN 978-963-420-968-3. [Google Scholar]

- Wang, K.; Liu, P. Lateral stability Analysis of Heavy-Haul Vehicle on Curved Track Based on Wheel/Rail Coupled Dynamics. J. Transp. Technol. 2012, 2, 150–157. [Google Scholar] [CrossRef]

- Dusza, M. The study of track gauge influence on lateral stability of 4-axle rail vehicle model. Arch. Transp. 2014, 30, 7–20. [Google Scholar] [CrossRef]

- Sun, J.; Chi, M.; Jin, X.; Liang, S.; Wang, J.; Li, W. Experimental and numerical study on carbody hunting of electric locomotive induced by low wheel–rail contact conicity. Veh. Syst. Dyn. 2021, 59, 203–223. [Google Scholar] [CrossRef]

- Zboinski, K. Dynamical investigation of railway vehicles on a curved track. Eur. J. Mech. A-Solids 1998, 17, 1001–1020. [Google Scholar] [CrossRef]

- Zhai, W.M.; Wang, K.Y. Lateral interactions of trains and tracks on small radius curves: Simulation and experiment. Veh. Syst. Dyn. 2006, 44 (Suppl. S1), 520–530. [Google Scholar] [CrossRef]

- Kurzeck, B.; Hecht, M. Dynamic simulation of friction-induced vibrations in a light railway bogie while curving compared with measurement results. Veh. Syst. Dyn. 2010, 48 (Suppl. S1), 121–138. [Google Scholar] [CrossRef]

- Kondo, O.; Yamazaki, Y. Simulation Technology for Railway Vehicle Dynamics; Nippon Steel & Sumitomo Metal Technical Report No. 105; Nippon Steel & Sumitomo Metal: Tokyo, Japan, 2013; pp. 77–83. [Google Scholar]

- Prandi, D. Railway Bogie Stability Control from Secondary Yaw Actuators. Master’s Thesis, Politecnico di Milano, Scuola di Ingegneria Industriale e dell’Informazione, Milano, Italy, 2014. [Google Scholar]

- Matsumoto, A.; Michitsuji, Y. Analysis of Flange-Climb Derailments of Freight Trains on Curved Tracks Due to Rolling. In Proceedings of the 10th International Conference on Railway Bogies and Running Gears, Scientific Association of Mechanical Engineering, Hungary, Budapest, 12–15 September 2016; pp. 91–100, ISBN 978-963-9058-38-5. [Google Scholar]

- Shaltout, R.; Baeza, L.; Ulianov, C. Development of a simulation tool for the dynamic analysis of railway vehicle-track interaction. Transp. Probl. 2015, 10, 47–58. [Google Scholar] [CrossRef]

- Lau, A.; Kassa, E. Simulation of Vehicle-Track Interaction in Small Radius Curves and Switches and Crossings. In Proceedings of the Third International Conference on Railway Technology: Research, Development and Maintenance, Cagliari, Italy, 5–8 April 2016; Pombo, J., Ed.; Paper 126. Civil-Comp Press: Stirlingshire, UK, 2016. [Google Scholar] [CrossRef]

- Kuba, T.; Lugner, P. Dynamic behaviour of tramways with different kinds of bogies. Veh. Syst. Dyn. 2012, 50 (Suppl. S1), 277–289. [Google Scholar] [CrossRef]

- Carballeira, J.; Baeza, L.; Rovira, A.; García, E. Technical characteristics and dynamic modelling of Talgo trains. Veh. Syst. Dyn. 2008, 46 (Suppl. S1), 301–316. [Google Scholar] [CrossRef]

- Pandey, M.; Bhattacharya, B. Effect of bolster suspension parameters of three-piece freight bogie on the lateral frame force. Int. J. Rail Transp. 2020, 8, 45–65. [Google Scholar] [CrossRef]

- Kufver, B. Optimisation of Horizontal Alignments for Railway—Procedure Involving Evaluation of Dynamic Vehicle Response. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2000. [Google Scholar]

- Long, X.Y.; Wei, Q.C.; Zheng, F.Y. Dynamical analysis of railway transition curves. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2009, 224, 1–14. [Google Scholar] [CrossRef]

- Zboinski, K.; Woznica, P. Combined use of dynamical simulation and optimisation to form railway transition curves. Veh. Syst. Dyn. 2018, 56, 1394–1450. [Google Scholar] [CrossRef]

- Koc, W. New Transition Curve Adapted to Railway Operational Requirements. J. Surv. Eng. 2019, 145, 04019009-1–04019009-11. [Google Scholar] [CrossRef]

- Kobryń, A. Design of curvilinear sections in vertical alignment of roads and railways using general transition curves. Autom. Constr. 2024, 163, 105423. [Google Scholar] [CrossRef]

- Sadeghi, J.; Rabiee, S.; Felekari1, P.; Khajehdezfuly, A. Investigation on optimum lengths of railway clothoid transition curves based on passenger ride comfort. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2023, 237, 882–892. [Google Scholar] [CrossRef]

- Yang, C.; Huang, Y.; Li, F. Influence of Curve Geometric Parameters on Dynamic Interactions of Side-Frame Cross-Braced Bogie. In Proceedings of the ICRT 2021, Second International Conference on Rail Transportation, Chengdu, China, 5–6 July 2021; ASCE Library: Reston, VA, USA, 2022. [Google Scholar]

- Brustad, T.F.; Dalmo, R. Railway Transition Curves: A Review of the State-of-the-Art and Future Research. Infrastructures 2020, 5, 43. [Google Scholar] [CrossRef]

- Bustos, A.; Tomas-Rodriguez, M.; Rubio, H.; Castejon, C. On the nonlinear hunting stability of a high-speed train boogie. Nonlinear Dyn. 2023, 111, 2059–2078. [Google Scholar] [CrossRef]

- Ge, P.; Wie, X.; Liu, J.; Cao, H. Bifurcation of a modified railway wheelset model with nonlinear equivalent conicity and wheel–rail force. Nonlinear Dyn. 2020, 102, 79–100. [Google Scholar] [CrossRef]

- Guo, J.; Shi, H.; Luo, R.; Zeng, J. Bifurcation analysis of a railway wheelset with nonlinear wheel–rail contact. Nonlinear Dyn. 2021, 104, 989–1005. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, G.; Shi, H.; Zeng, J. Small amplitude bogie hunting identification method for high-speed trains based on machine learning. Veh. Syst. Dyn. 2023, 62, 1253–1267. [Google Scholar] [CrossRef]

- Skerman, D.; Colin Cole, C.; Spiryagin, M. Determining the critical speed for hunting of three-piece freight bogies: Practice versus simulation approaches. Veh. Syst. Dyn. 2022, 60, 3314–3335. [Google Scholar] [CrossRef]

- Sun, J.; Meli, E.; Song, X.; Chi, M.; Jiao, W.; Jiang, Y. A novel measuring system for high-speed railway vehicles hunting monitoring able to predict wheelset motion and wheel/rail contact characteristics. Veh. Syst. Dyn. 2023, 61, 1621–1643. [Google Scholar] [CrossRef]

- Umemoto, J.; Yabuno, H. Parametric and self-excited oscillation produced in railway wheelset due to mass imbalance and large wheel tread angle. Nonlinear Dyn. 2023, 111, 4087–4106. [Google Scholar] [CrossRef]

- Wang, X.; Lu, Z.; Wen, J.; Wie, J.; Wang, Z. Kinematics modelling and numerical investigation on the hunting oscillation of wheel-rail nonlinear geometric contact system. Nonlinear Dyn. 2022, 107, 2075–2097. [Google Scholar] [CrossRef]

- Liang, J.; Sun, J.; Jiang, Y.; Pan, W.; Jiao, W. Advances and Challenges in the Hunting Instability Diagnosis of High-Speed Trains. Sensors 2024, 24, 5719. [Google Scholar] [CrossRef]

- Bhardawaj, S.; Sharma, R.C.; Sharma, S.K. Development in the modeling of rail vehicle system for the analysis of lateral stability. Mater. Today Proc. 2020, 25, 610–619. [Google Scholar] [CrossRef]

- Zboinski, K. Modelling dynamics of certain class of discrete multi-body systems based on direct method of the dynamics of relative motion. Meccanica 2012, 47, 1527–1551. [Google Scholar] [CrossRef][Green Version]

- Zboinski, K.; Dusza, M. Bifurcation analysis of 4-axle rail vehicle models in a curved track. Nonlinear Dyn. 2017, 89, 863–885. [Google Scholar] [CrossRef]

- Lurie, A.I. Analytical Mechanics, 1st ed.; Originally: Lurie, A.I. Analiticeskaja Mechanika; FizMatGIZ: Moscow, Russia, 1961; 864p, Reprint/English Translation: Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2002. [Google Scholar]

- Kalker, J.J. A fast algorithm for the simplified theory of rolling contact. Veh. Syst. Dyn. 1982, 11, 1–13. [Google Scholar] [CrossRef]

- Kik, W. Comparison of the behaviour of different wheelset-track models. Veh. Syst. Dyn. 1992, 20 (Suppl. S1), 325–339. [Google Scholar] [CrossRef]

- Hairer, E.; Wanner, G. Solving Ordinary Differential Equations, Part II: Stiff and Differential-Algebraic Problems; Springer: Berlin/Heidelberg, Germany, 1991. [Google Scholar]

- Zboinski, K.; Dusza, M. Extended study of rail vehicle lateral stability in a curved track. Veh. Syst. Dyn. 2011, 49, 789–810. [Google Scholar] [CrossRef]

- Zboinski, K.; Golofit-Stawinska, M. Determination and Comparative Analysis of Critical Velocity for Five Objects of Railway Vehicle Class. Sustainability 2022, 14, 6649. [Google Scholar] [CrossRef]

- Xu, G.; Steindl, A.; Troger, H. Nonlinear stability analysis of a bogie of a low-platform wagon. Veh. Syst. Dyn. 1992, 20 (Suppl. S1), 653–665. [Google Scholar] [CrossRef]

- True, H. Recent advances in the fundamental understanding of railway vehicle dynamics. Int. J. Veh. Des. 2006, 40, 251–264. [Google Scholar] [CrossRef]

- True, H. Multiple attractors and critical parameters and how to find them numerically: The right, the wrong and the gambling way. Veh. Syst. Dyn. 2013, 51, 443–459. [Google Scholar] [CrossRef]

- Huilgol, R.R. Hopf-Friedrichs bifurcation the hunting of a railway axle Quart. J. Appl. Math. 1978, 36, 85–94. [Google Scholar]

- Gasch, R.; Moelle, D.; Knothe, K. The effect of non-linearities on the limit-cycles of railway vehicles. In Proceedings of the 8th IAVSD Symposium, Cambridge, MA, USA, 15–19 August 1983; Hedrick, K., Ed.; Swets & Zeitlinger: Lisse, The Netherlands, 1984; pp. 207–224. [Google Scholar]

- True, H.; Hansen, T.G.; Lundell, H. On the Quasi-Stationary Curving Dynamics of a Railroad Truck. In Proceedings of the ASME/IEEE/AREA Joint Railroad Conference, ASME-RTD 29, Pueblo, CO, USA, 16–18 March 2005; pp. 131–138. [Google Scholar]

- Polach, O. Characteristic parameters of nonlinear wheel/rail contact geometry. Veh. Syst. Dyn. 2010, 48 (Suppl. S1), 19–36. [Google Scholar] [CrossRef]

- Di Gialleonardo, E.; Bruni, S.; True, H. Analysis of the non-linear dynamics of a 2-axle freight wagon in curves. Veh. Syst. Dyn. 2014, 52, 125–141. [Google Scholar] [CrossRef]

- UIC Code 518 OR; Testing and Approval of Railway Vehicles from the Point of View of Their Dynamic Behaviour-Safety-Track Fatigue-Ride Quality. 3rd ed. International Union of Railways: Paris, France, 2009.

- EN 14363:2016+A2:2022; Railway Applications-Testing and Simulation for the Acceptance of Running Characteristics of Railway Vehicles-Running Behaviour and Stationary Tests. European Committee for Standardization: Brussels, Belgium, 2022.

- EN 12299:2024; Railway Applications-Ride Comfort for Passengers-Measurement and Evaluation. European Committee for Standardization: Brussels, Belgium, 2024.

- Dusza, M.; Golofit-Stawinska, M.; Zboinski, K. The Nonlinear Lateral Stability of a Four-Axle Freight Car with Y25 Bogies and Measures to Improve Its Faults. Appl. Sci. 2024, 14, 4545. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).