Abstract

Various technologies have been evaluated as alternatives to conventional heating for pasteurization and sterilization of foods. Ohmic heating of food products, achieved by passage of an alternating current through food, has emerged as a potential technology with comparable performance and several advantages. Ohmic heating works faster and consumes less energy compared to conventional heating. Key characteristics of ohmic heating are homogeneity of heating, shorter heating time, low energy consumption, and improved product quality and food safety. Energy consumption of ohmic heating was measured as 4.6–5.3 times lower than traditional heating. Many food processes, including pasteurization, roasting, boiling, cooking, drying, sterilization, peeling, microbiological inhibition, and recovery of polyphenol and antioxidants have employed ohmic heating. Herein, we review the theoretical basis for ohmic treatment of food and the interaction of ohmic technology with food ingredients. Recent work in the last seven years on the effect of ohmic heating on food sensory properties, bioactive compound levels, microbial inactivation, and physico-chemical changes are summarized as a convenient reference for researchers and food scientists and engineers.

1. Introduction

Conventional thermal methods such as pasteurization, sterilization, drying, and evaporation are widely employed commercially to ensure microbiological safety in the food industry [1]. However, these methods cause extensive damage to the nutritional component of food; especially vitamins and heat-sensitive polyphenols that are linked to food quality [2]. These conventional treatments are relatively inefficient in terms of energy requirements, waste recycling, and environmental sustainability. As consumers have increased their demand for healthy foods with fresh properties and longer shelf life, researchers have explored various novel methods to improve food quality and safety [3]. Recently, a lot of research has focused on developing alternatives to conventional thermal technologies, such as reciprocation thermal processing [4], controlled agitation processing [5], microwave, radio frequency [6], and ohmic heating [7]. These alternative technologies have advantages of lower temperature and shorter time requirements than conventional methods, and are also more energy-efficient, sustainable, and environmentally friendly. Amongst these novel technologies, ohmic heating has established itself as one of the most economical alternatives available to the food industries for thermal processing, as it relies only on electricity [8]. Ohmic heating itself has been widely applied for pasteurization [6,7,8,9], drying [7,8,9,10], concentration [8,9,10,11], extraction [9,10,11,12], and nutrient preservation [10,11,12,13]. Ohmic heating results in better nutrient retention and fewer changes in the sensory properties of food [2].

With ohmic heating, heat is generated directly inside the food itself by Joule heating as the electrical current passes directly through the conductive food, and the resulting energy generation induces an increase in temperature [12,13,14]. Many liquid and liquid-solid products, in particular, can be processed in a short time through ohmic heating [15]. Many studies have confirmed that ohmic heating effectively pasteurizes juice. Extrinsic factors such as electric field and frequency, and intrinsic factors such as pH and sugar concentration, significantly affect the efficiency of ohmic heating [16,17]. With ohmic heating, there are no wide temperature gradients in the heated food, which avoids overheating of the surface of the solid food or particles and retains the food’s sensory properties [18]. Ohmic heating consumes less energy with a shorter heating time compared to conventional thermal methods used in commercial production. Some studies reported that the shelf life of ohmic treated samples was similar to or longer than that of samples heated conventionally [19].

Numerous studies have indicated that ohmic heating possessed efficient effects in many manufacturing processes and does not lead to significant effects on the nutritional, functional, and synthetic properties and sensory characteristics of food products compared to traditional techniques [14], while improving food quality [20] and inactivating enzymes [21]. Besides, ohmic heating can be widely used to heat liquid food such as citrus juice [22]. Darvishi et al. [23] analyzed and investigated the impact of the ohmic heating system on the black mulberry juice concentration, and the results were compared to the traditional heating method. The phenolics content of the juice sample using ohmic heating was 3–4.5 times higher than the traditional heating method. The pH value and total phenol content was not significantly affected by using the higher voltage gradient. The consumed energy was (3.33–3.82 MJ/kg water) using ohmic heating compared to the energy consumption by the traditional heating method (17.50 MJ/kg water). This result confirmed that the consumed energy by ohmic heating was 4.6–5.3 times lower than the energy consumption by the traditional heating method [23].

As this new technique is gaining growing industrial interest, highlighting recent research work on the impact of the ohmic technique for potential industrial applications is highly desired in the food industry. The objectives of this comprehensive review were to illustrate the developments in the ohmic heating field during the last 7 years (2013–2020) with a focused discussion on the effect of ohmic heating on sensory characteristics, maintaining bioactive compounds, microbial inactivation, and physico-chemical changes. This review emphasizes opportunities and limitations in the ohmic processing of foods, which can be possibly explored for commercial exploitation.

2. Review Methodology

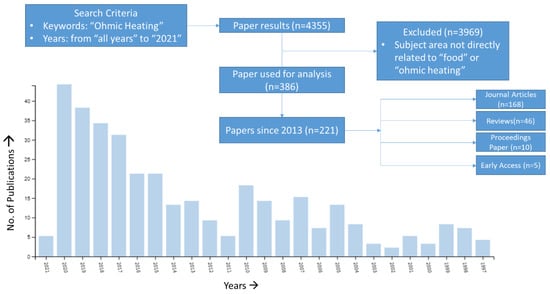

A systematic literature search was conducted via the database (Web of Science, Clavariate Analytics, London, UK) for literature obtained from keywords “Ohmic Heating”, with a further subdivision by the subtopic “Food” (as described in the search Criteria provided in Figure 1). Web of Science was selected due to its’ reputation for being a good collection of articles and numerous indexed journals, and a very user-friendly interface [24]. The search on the topic “Ohmic Heating” produced 4535 articles, of which 1869 articles were published since 2013. On further refining the search with the keyword “food”, 386 articles appeared from 1987–2021, of which 221 articles were published since 2013. Figure 1 highlights the trend of rapid development in the application of ohmic heating in the food sector over the last 25 years. It is evident that the ohmic heating food processing aspect gained momentum initially from 2005–2010, and then received even more attention (almost double publications per year) in the last 5 years from 2015–2020. More than 40% of the publications since 2013 came from the groups of Kang and Kim [16,17,25,26,27]; Pereira, Vicente, and Teixeira [28,29,30,31,32,33,34,35]; and Gavahian and Sastry [7,12,21].

Figure 1.

Search criteria and evolution of publications on ohmic heating from 1997–2021.

3. Principles of Ohmic Heating

The ohmic heating system consists mainly of heating unit, electrodes, data recording system, alternating current (AC) power source, voltage control unit, and thermocouples to measure temperature [36]. In most foods, there are large quantities of water and dissolved salts, which can increase the electrical conductivity, as with these ions that are exposed to the electric field, they will move towards the electrodes of the source of the opposite charges, generating ion collisions and thereby leading to increased temperature in the food [37]. For ohmic heating, the material must have electrical conduction. Non-conductive material may become conductive by adding an electrolyte such as NaCl (sodium chloride) or soluble organic salt (tetraalkyl ammonium), which does not interfere with the reaction, or ionic solvents can be used because they are naturally conductive [38].

The basis of electrical conduction heating (ohmic heating or electrical resistance heating) is that the alternating electric current passes through the food, which causes the ions to move towards the electrodes of opposite charges. This movement of ions causes collisions with each other, which leads to resistance to the movement of ions and increases kinetic energy. The product is heated to convert food into electrical resistance, and the heat inside it is generated instantaneously and volumetrically as a result of the movement of ions. The amount of heat depends on the current, the voltage, the electric field, and electrical conductivity of food [39,40].

The passage of electrical current through the foodstuff is subject to Ohm’s law, as heat is generated as a result of the food becoming an electrical resistance.

where

V: Voltage (volts)

I: Current strength (amps)

R: Resistance (Ohm)

4. Electrical Conductivity of Ohmic Heating

Electrical conductivity is the most important characteristic that affects the ohmic heating process. It depends on the temperature, the dissociation of ionic bonds, and the intensity of the electric field of the food material [41]. Ohmic heating depends on the type of base material to be treated, moisture content, and ion concentration. Electrical conductivity increases linearly with the conductivity of solid and liquid foodstuffs, which are affected by temperature, voltage, and concentration. The temperature is inversely proportional to the concentration of the foodstuff. The electrical conductivity increases linearly with the water content and temperature, and solid food is more impervious to electrical conductivity [42].

When AC passes through food, it converts electricity into heat [18]. Ionic compounds such as acids and bases can also help increase electrical conductivity, but they are few in non-polar compounds such as fats. Therefore, the value of the electrical conductivity of the material is not constant [43]. The electrical conductivity is expressed in Siemens per meter (S/m) [44]. In general, the electrical energy is transferred to different parts of the food by using ohmic heating. Heat is volumetrically produced, which gives a great opportunity to heat solid and liquid foods at the same rate [45]. Researchers observed that when heating tomato to reduce the water content, the contact area between the tomato sample and the two electrodes was decreased. The contact area can be calculated from the following equation:

where

A: Contact area (m2)

mt: Mass of the sample at any time (kg)

p: Tomato density (kg/m3)

L: Distance between poles (m)

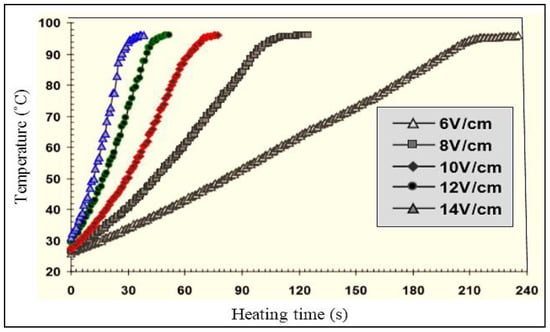

Darvishi et al. [46] found that when making tomato paste with ohmic heating and using five different levels of electrical voltage (6–14 V/cm), the ohmic heating rate was greatly affected by electrical conductivity. In this study, a temperature measurement was varied from (26–96 °C), and the results showed that electrical conductivity increased linearly with increasing temperature, and there was a significant effect (p < 0.05) of the voltage gradient on heating time. Boldaji et al. [47] studied the effect of ohmic heating on the electrical conductivity of tomato samples during the concentration process. The electrical conductivity increased linearly (3.19–95.95 S/m) with the concentration, while the treatment time decreased (28.32–4.3 min) with the increase in the electrical voltage (6–14 V/cm), which led to the decrease in energy consumption that ranged between (4.63–3.05 MJ/kg).

5. Applications of Ohmic Heating

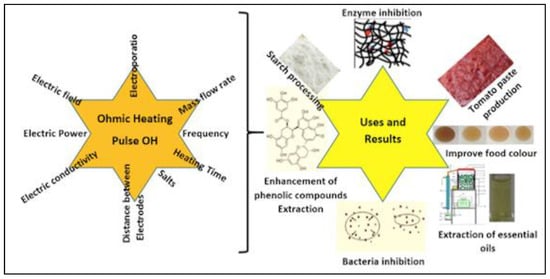

Ohmic heating is an electric heating method and also known as Joule heating [48,49], which is an advanced heat treatment, mainly used with food to be thermally processed as heating is more homogeneous [40] compared to other electrical heating techniques such as microwave and radio frequency heating [50]. This technique provides high-quality food and is also used in many applications such as pasteurization, sterilization, cooking, thawing, fumigation, extraction, and fermentation, in addition to the new trend for its use in military fields and food for long-term space missions [40]. Studies have shown that the use of this technique does not lead to significant effects on the nutritional, functional, and synthetic properties and sensory characteristics of food products compared to traditional techniques [51]. Figure 2 depicts factors and applications of ohmic heating in food processing.

Figure 2.

Factors and applications of ohmic heating in food processing.

Many researchers have studied the effect of ohmic heating on fish, meat and its products, and compared to other traditional thermal methods used in melting, heating, and cooking for food quality, food safety, and flavor. In addition, this new technology has the ability to extend shelf-life. It is a favorable alternative for heat treatment due to the shorter heating time and non-heating of surfaces, in addition to the possibility of using lower temperatures [52]. Ohmic heating may have an effect on electrical, physical, and biological characteristics of the product, which has led to many research applications such as heating, fumigation, drying, extraction, wastewater treatment, melting, and cooking for different types of fish and meat and their products. Ohmic heating technology was also used to treat many other food products such as vegetables, juices, meat, seafood, soup, creams, and pasta, and to sterilize foods used in glass containers for ready-to-eat food, to produce low-acid, high-quality foods, and to reduce acidity of foods that depend on tomato sauces [53].

Bender et al. [45] pointed to the possibility of using ohmic heating as a new method for baking without gluten and studied its effect on chemical and functional properties. Results indicated that ohmic-based baking without gluten improved qualities of size, stability, tissue, relative elasticity, pores, color, and starch gelatinization. The manufactured gluten-free (GF) bread using ohmic heating was significantly superior in its functional properties and characteristics compared to the traditional manufacturing methods. The values were 2.86–3.44 cm3/g, 45.05–56.83%, and 35.17–40.92% for specific volume, relative elasticity, and porosity, respectively. In contrast, conventional oven-baked GF bread resulted in 2.60 cm3/g of specific volume, 44.23% of relative elasticity, and 37.63% of porosity. Bender et al. [33] also improved the mechanism of ohmic heating through a three stage application of electrical power: First using 2–6 kW for 15 s, followed by 1 kW for 10 s, and lastly 0.3 kW for 1–30 min. Kautkar et al. [54] made ginger paste using an ohmic method with salt concentrations (0–2% w/w) on a laboratory level through a voltage of 5–13 V/cm. Temperature-dependent electrical conductivity was obtained at different time periods at (0, 5, 10 min) and at four temperature levels from (30–60 °C). The results indicated that there were bubbles on the surface of the product at temperatures above 70 °C, especially at higher voltage levels. The values of the electrical conductivity were in the range of 4.41–6.63 and from 3.75 to 5.87 S/cm, respectively. The study confirmed that the electrical conductivity of the ginger dough depended on the intensity of the temperature and the ionic concentration.

An ohmic heating unit was designed on a 1 L laboratory scale by [55] for testing with papaya fruit whose conventional pasteurization yield suffered from rapid deterioration causing approximately 50% losses. The electrical conductivity of papaya pulp was measured at temperature ranges of 35–95 °C, three voltage gradients 6.66, 13.33, 20 V/cm, and for 1, 2, and 3 min. Statistical results showed that the optimal conditions for improving the papaya pasteurization process were at an electrical voltage of 13.33 V/cm and 2 min retention time depending on the low microbial load. The heated pulp using ohmic heating method was compared with fresh pulp in terms of biochemical and biological properties. The obtained results showed that the heated papaya pulp retained 86.44% of lycopene, 87.13% of beta-carotene, and 85.23% of ascorbic acid compared to the fresh samples. Darvishi et al. [46] noted that the rate of ohmic heating of food is highly influenced by electrical conductivity based on heating tomato using ohmic heating at five different voltage gradients (6–14 V/cm), and temperatures from 26 to 96 °C. The results showed a linear increase in the electrical filed values with a significant increase in temperature (p < 0.05) as shown in Figure 3.

Figure 3.

Curves of ohmic heating on tomato samples using different voltage gradients (derived from Darvishi et al., 2012) [46].

Parmar et al. [56] used ohmic heating for the concentration of milk by evaporation. The main problems of using conventional thermal evaporation were the loss of aromas and color change. The effect of ohmic heating was studied on the physical, chemical, sensory, and microbial properties during the concentration of cow’s milk, buffalo milk, and mixed milk (50:50) and compared to conventional evaporation at 13.33 V/cm, current (5–20 Amp), temperatures (0–100 °C), and time 75 min. The results indicated that ohmic heating has a huge potential for rapid and homogeneous heating of liquid and semi-solid foods, resulting in a safe and high-quality microbiological product. Ohmic heating significantly increased the formation of free fatty acids (FFA) and viscosity, as well as an increase in hydroxy methyl furfural (HMF) and important color values in dye estimation such as redness (a*) and yellowness value (b*). However, the pH and brightness (L*) of concentrated milk were clearly decreased. Ohmic heating also resulted in a significant reduction in microbiological numbers, and treated milk could be preserved for a longer period. Table 1 provides a convenient summary of electrical properties, temperature, and time of recent studies of ohmic heating applications.

Table 1.

Recent studies of ohmic heating applications.

6. Advantages and Disadvantages of Ohmic Heating

Ohmic heating technology, despite its uses, is still relatively new and under study, and there have been a number of advantages and disadvantages. These advantages are the continuity of heating without transferring heat to the surfaces, a rapid and homogeneous treatment for liquid and solid phases, minimal thermal damage, minimal loss of nutritional value, an ideal process for shear-sensitive products due to low flow velocity, low risk of product damage, and high energy transfer efficiency [36]. In addition, some studies [66] reported that this technology exhibited low sedimentation compared to conventional heating, low maintenance costs due to the lack of moving parts, preserved the color and nutritional value of foods, the lowest requirements for cleaning, heating food particles and liquid solutions, low treatment temperature, retain color and nutritional value, and short treatment time for extraction. This technology increases the mobility of ions to transport the particles charged in the solution and is considered a practical method for preheating the products before the canning process [66].

In contrast, some scientists reported disadvantages for ohmic such as a narrow band of frequencies [51]. The initial cost of establishing ohmic heating systems is higher than conventional heating methods. Food that contains fat granules does not effectively heat with ohmic heating because it is not conductive due to a lack of water and salts. In addition, pathogenic bacteria present inside the fat granules are exposed to heat treatment less than the bacteria outside the fat particles [36]. In addition, the electrical conductivity increases with increasing temperature inside the system (food and solution) as a result of an increase motion of electrons [36]. Another problem with applying ohmic heating is the corrosion of the electrodes due to electrochemical reactions. The electrochemical corrosion increases even more when the ohmic heating systems are in operation, thus increasing the cost [66].

7. Effects of Ohmic Heating on Quality of Food Products

Modern food processing has given considerable attention to treating food with electrical techniques [67], including ohmic heating, which depends on the passage of alternating electric current through the food, which generates heat inside the food [29]. This technology provides fast and uniform heating and results in less thermal damage to the food. Therefore, a high-quality product can be manufactured with minimal structural or nutritional or sensory changes as a result of a short treatment time [18]. Electrical, thermophysical, and rheological properties of foods have an important role in uniform heating. It is necessary to point out the importance of potential electrochemical reactions at the contact surface between food and electrodes as well as possible non-thermal effects of the electric field that depend on treatment conditions [68]. The electric field of ohmic heating can cause various changes in the quality and biological processes of food, such as the inhibition of enzymes and microorganisms, the degradation of heat-sensitive compounds, changes in cell membranes, viscosity, pH, color, and rheological characteristics [69]. Table 2 reports some of the effects of ohmic heating on the quality and characteristics of different foods.

Table 2.

Effects of ohmic heating on some types of foods.

8. Effects of Ohmic Heating on Inactivation Microorganisms in Food

Many foodborne diseases have spread throughout the world despite the continuous development of food technology [27]. Although food products were treated at high temperatures to ensure their microbiological safety, thermal damage occurred such as changes in flavor, texture, taste, and nutrient composition. Therefore, modern studies have found that advanced thermal treatment techniques play a vital role in preventing damage to processed foods and eliminating microorganisms such as bacterial cells and spores [76].

Schottroff et al. [77] mentioned that the influence of the electric field on biological cells was depended in particular on the size of the cell. This study evaluated the inactivation of vegetative microorganisms by ohmic heating at 12 kHz and 300 kHz compared to non-thermal effects. The inactivation of Microbacterium lacticum, Escherichia coli and Saccharomyces cerevisiae were tested using conventional and ohmic heating in the 12-kHz and 300 kHz system. The results found that the inactivation levels by kilohertz ohmic heating were not increased compared to conventional heat treatment. Ohmic heating can inactivate bacteria not only by its heating effects, but also through the non-thermal effects of the electrical current [78]. Bacterial count is one of the basic and most used methods in assessing the microbial stability of the foodstuff. Several studies have been conducted to measure the effect of ohmic heating on the total number of bacteria in juices, fruits, milk, and seafood [14,79]. Lyng et al. [80] mentioned that the main reason for microbial inhibition during ohmic heating is due to the effect of heat treatment. However, other studies indicated the ability of non-thermal treatment such as chemical and mechanical effects to inhibit microbial growth [80]. The mechanism of the chemical effect is due to the formation of free radicals, oxygen, hydrogen, hydroxyl, and mineral ions that cause bacterial death, while the mechanical effect is due to the disruption of the microbial cell membrane, which leads to leakage of cell contents through electroporation. This study determined that ohmic heating had a significant effect in eliminating Bacillus subtilis spores compared to conventional methods [80].

Moreover, ref. [78] studied the effect of ohmic heating on the spores of Bacillus subtilis in an aqueous solution of sodium chloride at 101 °C (i.e., boiling point) and the effect of the intensity and frequency of the electric field during the treatment. The microbial inactivation effects of ohmic heating for all conditions of the electric field (5, 10, 20 V/cm at 20–60 kHz) and treatment times of 8, 10, 12, 14, and 16 min was better than those of samples treated by traditional method. The efficiency of eliminating bacteria increased with increasing intensity of the electric field. B. subtilis was almost completely eliminated at 14–16 min and 60 kHz, while the spores remained alive at 20 and 40 kHz for the same period. These results proved that ohmic heating inhibited B. subtilis more effectively than the traditional method [78]. Park et al. [17] studied the optimum ohmic heating conditions and investigated the effect of voltage gradients and corresponding sugar concentrations (°Bx) of apple juice to inactivate Escherichia coli O157: H7, Salmonella enterica serovar Typhimurium, and Listeria monocytogenes. The lowest heating rate was at a concentration of 72 °Bx in all voltage gradients used in the study and a similar pattern of temperature increase was shown in 18–48 °Bx juice samples. System performance coefficients (SPC) were comparatively higher under two treatment conditions (30 V/cm in 36 °Bx or 60 V/cm in 48 °Bx juice). Meanwhile, after treatment for 60 s in 36 °Bx at 30 V/cm, 5-log reductions of the three foodborne pathogens were achieved. A treatment of 8 °Bx juice at 60 V/cm for 20 s was sufficient to achieve 5-log reduction without affecting product quality [17]. Table 3 represents the effects of ohmic heating on food products for eliminating microorganisms:

Table 3.

Studies of ohmic heating effects on inactivation of microorganisms.

9. The Effect of Ohmic Heating on the Bioactive Compounds in Food

Ohmic heating is an alternative thermal treatment, which is considered to have less impact on biologically active compounds compared to traditional thermal processes. Bioactive compounds are highly valuable components because of their nutritional importance and their relation to human health. Therefore, preservation of these compounds during thermal treatment such as boiling, pasteurization, and sterilization is one of the most difficult challenges in the food industry [87]. High temperature leads to the loss of some active ingredients. For the purpose of determining the appropriate temperature for a process, the highest temperature that maintains these bioactive compounds is highly recommended [88].

Somavat [82] studied the effect of ohmic heating on carotenoids (β-carotene and lycopene), phenolic compounds (phenolic acids, narringin, quercetin, and total flavonoids), and ascorbic acid in fresh tomato juice. The results showed that ohmic heating did not affect the amount of carotenoids and phenolic compounds in tomato juice. Ohmic heating also did not cause any decrease in the amount of the β-carotene, lycopene, phenolic acids, and quercetin at temperatures of 95, 100, 105, and 110 °C, and confirmed the stability of lycopene at pH 3.9 and temperatures of 90, 95, 100, and 105 °C. Moreover, ohmic heating can successfully retain the values of ascorbic acid and dehydroxy-ascorbic acid when treated at a temperature of 90 °C. The study also confirmed the ability of ohmic heating to increase the total content of naringenin compared to untreated samples [82].

Cappato et al. [89] mentioned that the use of a low-frequency for the electric field (10 Hz) led to the highest value of ascorbic acid deterioration and an increase in the color changes due to the electrochemical reactions, while the interactions at (100 Hz) became less. As a result, the use of high electric field frequencies did not affect the dissociation of ascorbic acid, indicating that the oxidation reaction in a molecule of ascorbic acid was not affected by rapid changes in the electric field values. Mercali et al. [90] used ohmic heating to produce tomato pulp powder. The study showed that the hydrophilic part was not significantly affected, while lycopene was positively affected with significantly increased antioxidant efficacy. This study demonstrated the importance of ohmic heating in maintaining appearance and nutritional value [90]. The effect of ohmic heating on bioactive compounds content, phenolic content, and antioxidant activity are shown in the Table 4.

Table 4.

The effects of ohmic heating on bioactive compounds content, phenolic content, and antioxidant activity.

10. Effect of Ohmic Heating on Inactivation of Enzymes in Food

Enzymes are proteins that spontaneously accelerate the chemical reactions and are considered a vital catalyst [98]. The presence of enzymes significantly reduces the shelf life of fruits and vegetable products [99]. Therefore, the enzymatic activity in foods must be controlled through the treatment stages in order to get rid of their harmful effects on the quality characteristics such as the production of unwanted flavors, changes in rheological properties, and color [34]. Therefore, electrical techniques were of great importance in treating and preserving food from structural and sensory changes, maintaining the properties of enzymes and the ability to control the treatment conditions accurately [100]. Several studies have examined the effect of electrical techniques on the inhibition of enzymes in food, to understand the mechanism. Han et al. [101] found there was a strong link between enzymatic activities and their 3-D structures. The functional moieties in the proteins, which linked to the charged separation would be dissociated by using electro-technological treatments. However, there is more to discover about the mechanism of electric technologies, regarding inactivation of enzymes [102]. A number of researchers mentioned that the electric and thermal energy applied in treating food individually or mutually, affects the enzymatic structure and changes its functions [101,103,104].

Saxena et al. [105] examined the effect of ohmic heating on the polyphenol oxidase in sugar cane juice at three levels of electric field (24, 32, and 48 V/cm) and four temperatures of (60–90 °C) with a time period 5–20 min. There was a 97.8% decrease in the enzyme activity at a temperature of 60–90 °C with an increase in the electric field. Ref. [106] studied the possibility of ohmic heating to prevent brown enzymatic discoloration on the quality of the water chestnut juice using different electric fields and frequencies. Ohmic heating can increase the effectiveness of the peroxidase enzyme and then the activity begins to decrease quickly. The higher the electrical conductivity, the greater the inhibition of the enzyme was observed.

Makroo et al. [107] found that the treatment of tomato juice using ohmic heating for 1 min at 90 °C was sufficient to inhibit the pectin enzyme methyl esterase and polygalacturonase, while conventional treatment at the same temperature required 5 min to obtain the same inhibition of enzymes. Li et al. [108] studied the effect of ohmic heating on the activity of the urease in soymilk at an electrical field of 160–220 V and a frequency of 10–10 kHz. The study showed that the electric field was able to inhibit the enzyme activity. Castro et al. [35] inhibited the enzymes polyphenoloxidase, galactosidase-ox, lipoxygenase, pectinase, and alkaline phosphatase by using ohmic heating and conventional method under the same conditions. Polyphenoloxidase and lipoxygenase significantly decreased the electric field, reducing the time required for inhibition. The results showed that the electric field was able to inhibit phosphatase, alkaline phosphatase, and galactosidase-β. While both polyphenoloxidase and lipoxygenase were affected significantly by using ohmic heating compared to the conventional method regarding the required time for inactivation [35].

Jakób et al. [109] used the ohmic heating at several temperatures to study its effect on inhibition and analysis of the kinetics parameters of alkaline phosphatase, pectin methylesterase and peroxidase in milk, fruit juices, and vegetables compared with the conventional method (indirect heating). The kinetics parameters were changed while inhibition mechanisms remained constant. The changes in the kinetics parameters were relatively few for pectin methylesterase and alkaline phosphatase, while significant changes and instability of peroxidase occurred due to the effect of ohmic heating on carrot juice [109]. Somavat [82] studied the effect of ohmic heating on the methyl esterase pectin (PME) and polyacaltokronase (PG) in fresh tomato juice at pH (3.9 and 4.4). The results observed a great variation in the inactivity of the pectin methyl esterase activity at pH 3.9 due to the interactions of enzymes with the electric field, while the PG enzyme showed the least variation with a higher rate of inhibition. The results also found that when pH increased to 4.4, PG was inhibited quickly using ohmic heating.

11. Future Trends

Ohmic heating is a highly energy efficient process and it has been reported to have many promising future applications in food and other industries. It can be used alone or in combination with other processing techniques. Ohmic heating has been evaluated in combination with other thermal techniques for its effectiveness. The combination of ohmic heating and infrared heating was more effective to reduce the mesophilic microflora in the meatball samples [108].

Ohmic heating application for sterilization and aseptic packaging holds key promising features in the future. Ohmic treatment may be successfully applied as an alternative method to conventional sterilization to maintain the nutritional quality of protein in vegetable baby foods [109].

Recent findings point out that whey protein networks can be modified by ohmic heating treatments and can be potentially used as a matrix for the incorporation of probiotic entities [110]. One of the novel future applications of ohmic heating is ohmic-assisted hydrodistillation (OAHD) based on volumetric heating for distillation of ethanol and essential oils, which is considered better than traditional distillation methods [111].

Pressure ohmic thermal sterilization (POTS) involves ohmic heating of foods by applying an electric field under elevated pressure. POTS treated carrot samples had better quality attributes than those processed using ohmic heating and pressure-assisted thermal processing [112,113].

The peeling of most of the vegetables in food industries relies on the usage of lye or steam peelings, which results in high pH waste and excessive water use. Wongsa-Ngasri and Sastry [114] found tomatoes treated ohmic heating in salt solution required reduced lye concentrations.

Researchers have developed novel electrically conductive food packages that can be used to heat the food and its package after packing to avoid post-process contamination and to serve consumer needs for convenience [115].

The non-food applications of ohmic treatment includes seawater desalination and waste treatment such as sterilization of animal wastes, heating of clay slip and other slurries, sewage sludge, and compost leachate by ohmic heating have important future uses in food and other industries [116].

Scale-up of ohmic heating is an important consideration for development and future use of this technology. It is generally envisaged that scale-up of ohmic heating does not have limitations present in other novel technologies like microwave or infrared heating. The generally uniform nature of the electricity generation results in uniform heating, which makes scale-up of the process easier [4]. Obviously, with an electrode based technology, electrochemical reactions and metal ion migration occurring at the interface of food and electrodes during heating treatment present problems such as fouling and electrode corrosion [90]. These reactions generally make the process establishment task more challenging, however, with proper controls and instrumentation, coupled with a good critical control plan and hazard analysis plans, make monitoring of larger-scale ohmic heating systems easier. Additionally, with scale-up, the cleaning and maintenance becomes easier. Thus, ohmic heating is becoming increasingly attractive for large-scale processing of viscous products with particulates such as thick soups, sauces, stews, salsas, milk, ice-cream mix, egg, whey, soymilk, and other heat-sensitive liquids with particulates [114].

12. Conclusions

Considerable potential has been demonstrated for using ohmic heating as a replacement to conventional heating methods for many food processing applications. The efficiency and uniform heating of ohmic heating are highly desirable. Ohmic heating should be evaluated as an option for food processes, such as pasteurization, roasting, boiling, cooking, drying, sterilization, peeling, microbiological inhibition, and recovery of polyphenol and antioxidants.

Most studies have used ohmic heating with success on a laboratory scale. On a similar scale, ohmic heating has potential as a residential appliance for preparing food that has the shorter time advantages of a microwave while improving food quality over a cooktop. Engineers can anticipate research and development of these variable frequency, variable voltage devices. Food scientists will work on optimizing frequency, voltage, and temperature to produce the highest quality of each food product with the optimum sensory perception. Microwave appliances typically offer single button controls for selected foods to control microwave cycling. Ohmic heating appliances can similarly have preprogrammed options for various foods that optimize frequency, voltage, temperature, and duration by the press of a single button.

Although the ohmic heating process has better retention of nutritional quality, high energy efficiency, etc., higher cost input limits its commercial use on a higher scale. The foods containing fats and oils cannot be processed with ohmic heating because of a lack of electrical conductivity. The deep knowledge of effects of electric field on mass transfer properties, cold spot determination, and overall process design is prerequisite to establish industrial processes. Thus, it can be deduced that ohmic heating has a prospective for becoming the most important food processing technology of the future.

Scaling of ohmic heating devices to replace large vats used in industry will require food science and engineering research to determine any size limitations of ohmic heating and apply new electrode designs and configurations. In the future, instead of a food processor purchasing a vat with a water jacket for heating, the vat may have built-in electrodes for ohmic heating.

Author Contributions

Conceptualization, Z.T.A. and A.B.A.; methodology, A.R.S.A.-H. and A.P.-S.; funding: A.P.-S.; validation and formal analysis, D.G.W.; investigation, A.B.A. and A.P.-S., writing original draft preparation, Z.T.A., A.B.A. and A.P.-S. Writing—review and editing, A.R.S.A.-H. and D.G.W. All authors have read and agreed to the published version of the manuscript.

Funding

Authors would like to thank the funding support from National Science and Engineering Research Council of Canada, Discovery Grant Programme, Grant number RGPIN-2018-04735 to Anubhav Pratap-Singh.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable

Data Availability Statement

All data are reported in this manuscript.

Acknowledgments

The authors would like to thank the Food Science Department, Agriculture College, University of Basrah.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kurian, J.K.; Raghavan, G.S.V. Conventional and Advanced Thermal Processing Technologies for Enhancing Food Safety. In Food Safety Engineering; Springer: Cham, Switzerland, 2020; pp. 447–469. [Google Scholar]

- Zhang, Z.-H.; Wang, L.-H.; Zeng, X.-A.; Han, Z.; Brennan, C.S. Non-thermal technologies and its current and future application in the food industry: A review. Int. J. Food Sci. Technol. 2018, 54, 1–13. [Google Scholar] [CrossRef]

- Pratap-Singh, A.; Singh, A.; Ramaswamy, H.S. Heat transfer phenomena during thermal processing of liquid particulate mixtures—A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 1350–1364. [Google Scholar] [CrossRef]

- Pratap-Singh, A.; Yen, P.P.-L.; Ramaswamy, H.S.; Singh, A. Recent advances in agitation thermal processing. Curr. Opin. Food Sci. 2018, 23, 90–96. [Google Scholar] [CrossRef]

- Singh, A.; Pratap-Singh, A.; Ramaswamy, H.S. A Controlled Agitation Process for Improving Quality of Canned Green Beans during Agitation Thermal Processing. J. Food. Sci. 2016, 81, E1399–E1411. [Google Scholar] [CrossRef] [PubMed]

- Dag, D.; Singh, R.K.; Kong, F. Developments in Radio Frequency Pasteurization of Food Powders. Food Rev. Int. 2020, 1–18. [Google Scholar] [CrossRef]

- Funcia, E.S.; Gut, J.A.W.; Sastry, S.K. Effect of Electric Field on Pectinesterase Inactivation during Orange Juice Pasteurization by Ohmic Heating. Food Bioprocess Technol. 2020, 13, 1206–1214. [Google Scholar] [CrossRef]

- Tian, X.; Yu, Q.; Wu, W.; Dai, R. Inactivation of Microorganisms in Foods by Ohmic Heating: A Review. J. Food Prot. 2018, 81, 1093–1107. [Google Scholar] [CrossRef] [PubMed]

- Lyng, J.G.; Clemente, I.; McKenna, B.M. Ohmic Pasteurization of Meat and Meat Products. In Handbook of Farm, Dairy and Food Machinery Engineering; Academic Press: Cambridge, MA, USA, 2019; pp. 593–622. [Google Scholar]

- Stojceska, V.; Atuonwu, J.; Tassou, S.A. Ohmic and conventional drying of citrus products: Energy efficiency, greenhouse gas emissions and nutritional properties. Energy Procedia 2019, 161, 165–173. [Google Scholar] [CrossRef]

- Pires, R.P.; Cappato, L.P.; Guimarães, J.T.; Rocha, R.S.; Silva, R.; Balthazar, C.F.; Freitas, M.Q.; Silva, P.H.F.; Neto, R.P.; Tavares, M.I.B.; et al. Ohmic heating for infant formula processing: Evaluating the effect of different voltage gradient. J. Food Eng. 2020, 280, 109989. [Google Scholar] [CrossRef]

- Gavahian, M.; Sastry, S.; Farhoosh, R.; Farahnaky, A. Ohmic heating as a promising technique for extraction of herbal essential oils: Understanding mechanisms, recent findings, and associated challenges. In Advances in Food and Nutrition Research; Academic Press: Cambridge, MA, USA, 2020; Volume 91, pp. 227–273. [Google Scholar]

- Picart-Palmade, L.; Cunault, C.; Chevalier-Lucia, D.; Belleville, M.-P.; Marchesseau, S. Potentialities and Limits of Some Non-thermal Technologies to Improve Sustainability of Food Processing. Front. Nutr. 2019, 5, 130. [Google Scholar] [CrossRef]

- Makroo, H.A.; Rastogi, N.K.; Srivastava, B. Ohmic heating assisted inactivation of enzymes and microorganisms in foods: A review. Trends Food Sci. Technol. 2020, 97, 451–465. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Ryu, S.; Kang, D.-H. Effect of Frequency and Waveform on Inactivation of Escherichia coli O157: H7 and Salmonella enterica Serovar Typhimurium in Salsa by Ohmic Heating. Appl. Environ. Microbiol. 2013, 79, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.S.; Park, S.H.; Kim, S.H.; Kang, D.H. Synergistic effect of ohmic heating and UV-C irradiation for inac-tivation of Escherichia coli O157: H7, Salmonella Typhimurium and Listeria monocytogenes in buffered peptone water and tomato juice. Food Control 2019, 102, 69–75. [Google Scholar] [CrossRef]

- Park, I.-K.; Ha, J.-W.; Kang, D.-H. Investigation of optimum ohmic heating conditions for inactivation of Esche-richia coli O157: H7, Salmonella enterica serovar Typhimurium, and Listeria monocytogenes in apple juice. BMC Microbiol. 2017, 17, 117. [Google Scholar] [CrossRef]

- Leizerson, S.; Shimoni, E. Effect of ultrahigh-temperature continuous ohmic heating treatment on fresh orange juice. J. Agric. Food Chem. 2005, 53, 3519–3524. [Google Scholar] [CrossRef] [PubMed]

- Cho, W.-I.; Yi, J.Y.; Chung, M.-S. Pasteurization of fermented red pepper paste by ohmic heating. Innov. Food Sci. Emerg. Technol. 2016, 34, 180–186. [Google Scholar] [CrossRef]

- Alamprese, C.; Cigarini, M.; Brutti, A. Effects of ohmic heating on technological properties of whole egg. Innov. Food Sci. Emerg. Technol. 2019, 58, 102244. [Google Scholar] [CrossRef]

- Leite, T.S.; Samaranayake, C.P.; Sastry, S.K.; Cristianini, M. Polyphenol oxidase inactivation in viscous fluids by ohmic heating and conventional thermal processing. J. Food Process. Eng. 2019, 42. [Google Scholar] [CrossRef]

- Hashemi, S.M.B.; Roohi, R. Ohmic heating of blended citrus juice: Numerical modeling of process and bacterial inactivation kinetics. Innov. Food Sci. Emerg. Technol. 2019, 52, 313–324. [Google Scholar] [CrossRef]

- Darvishi, H.; Salami, P.; Fadavi, A.; Saba, M.K. Processing kinetics, quality and thermodynamic evaluation of mulberry juice concentration process using Ohmic heating. Food Bioprod. Process. 2020, 123, 102–110. [Google Scholar] [CrossRef]

- Mandal, R.; Mohammadi, X.; Wiktor, A.; Singh, A.; Singh, A.P.; Anubhav, P.S. Applications of Pulsed Light Decontamination Technology in Food Processing: An Overview. Appl. Sci. 2020, 10, 3606. [Google Scholar] [CrossRef]

- Kim, S.-S.; Sung, H.-J.; Kwak, H.-S.; Joo, I.-S.; Lee, J.-S.; Ko, G.; Kang, D.-H. Effect of Power Levels on Inactivation of Escherichia coli O157:H7, Salmonella Typhimurium, and Listeria monocytogenes in Tomato Paste Using 915-Megahertz Microwave and Ohmic Heating. J. Food Prot. 2016, 79, 1616–1622. [Google Scholar] [CrossRef] [PubMed]

- Kim, N.; Ryang, J.; Lee, B.; Kim, C.; Rhee, M. Continuous ohmic heating of commercially processed apple juice using five sequential electric fields results in rapid inactivation of Alicyclobacillus acidoterrestris spores. Int. J. Food Microbiol. 2017, 246, 80–84. [Google Scholar] [CrossRef]

- Kim, S.-S.; Kang, D.-H. Comparison of pH effects on ohmic heating and conventional heating for inactivation of Escherichia coli O157: H7, Salmonella enterica Serovar Typhimurium and Listeria monocytogene s in orange juice. LWT 2015, 64, 860–866. [Google Scholar] [CrossRef]

- Pereira, R.N.; Costa, J.; Rodrigues, R.M.; Villa, C.; Machado, L.; Mafra, I.; Vicente, A. Effects of ohmic heating on the immunoreactivity of β-lactoglobulin—A relationship towards structural aspects. Food Funct. 2020, 11, 4002–4013. [Google Scholar] [CrossRef]

- Pereira, R.; Pereira, M.D.; Teixeira, J.A.; Vicente, A.A. Effects of Ohmic Heating Technology in Chemical Properties of Foods. In Proceedings of the Slovak Society of Chemical Engineering Institute of Chemical and Environmental Engineering Slovak University of Technology in 33rd International Conference of SSCHE, Bratislava, Slovakia, 22–26 May 2006; pp. 113-1–113-9, ISBN 80-227-2409-2. [Google Scholar]

- Pereira, R.N.; Rodrigues, R.M.; Genisheva, Z.; Oliveira, H.; de Freitas, V.; Teixeira, J.A.; Vicente, A.A. Effects of ohmic heating on extraction of food-grade phytochemicals from colored potato. LWT 2016, 74, 493–503. [Google Scholar] [CrossRef]

- Jesus, M.S.; Ballesteros, L.F.; Pereira, R.N.; Genisheva, Z.; Carvalho, A.S.; Pereira-Wilson, C.; Teixeira, J.A.; Domingues, L. Ohmic heating polyphenolic extracts from vine pruning residue with enhanced biological activity. Food Chem. 2020, 316, 126298. [Google Scholar] [CrossRef] [PubMed]

- Pereira, R.; Martins, J.; Mateus, C.; Teixeira, J.A.C.; Vicente, A.A.A. Death kinetics of Escherichia coli in goat milk and Bacillus licheniformis in cloudberry jam treated by ohmic heating. Chem. Pap. 2007, 61, 121–126. [Google Scholar] [CrossRef]

- Coelho, M.; Pereira, R.; Rodrigues, A.S.; Teixeira, J.A.; Pintado, M.E. Extraction of tomato by-products’ bioac-tive compounds using ohmic technology. Food Bioprod. Process. 2019, 117, 329–339. [Google Scholar] [CrossRef]

- Vicente, A.A.; Pereira, R.N.; Penna, T.C.V.; Knirsch, M. Electricity effects on microorganisms and enzymes. In Ohmic Heating in Food Processing; CRC Press: Boca Raton, FL, USA, 2014; pp. 115–126. [Google Scholar]

- Castro, I.; Macedo, B.; Teixeira, J.A.; Vicente, A.A. The effect of electric field on important food-processing en-zymes: Comparison of inactivation kinetics under conventional and ohmic heating. J. Food Sci. 2004, 69, C696–C701. [Google Scholar] [CrossRef]

- Kaur, N.; Singh, A.K. Ohmic Heating: Concept and Applications—A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 2338–2351. [Google Scholar] [CrossRef]

- Singh, R.P.; Heldman, D.R. Introduction to Food Engineering, 5th ed.; Academic Press Incorporation: Orlando, FL, USA, 2014. [Google Scholar]

- Silva, V.L.; Santos, L.M.; Silva, A.M. Ohmic heating: An emerging concept in organic synthesis. Chem. Eur. J. 2017, 23, 7853–7865. [Google Scholar] [CrossRef]

- Al-Hilphy, A.R.S. Engineering intervention for extraction of essential oils from plants. In Engineering Interventions in Foods and Plants; Vermaz, D.K., Goyal, M.R., Eds.; Apple Academic Press: Cambridge, MA, USA, 2018; 298p, ISBN 978-1-77188-596-6. [Google Scholar]

- Kumar, T. A Review on Ohmic Heating Technology: Principle, Applications and Scope. Int. J. Agric. Environ. Biotechnol. 2018, 11, 679–687. [Google Scholar] [CrossRef]

- Kumar, T.; Smith, D.D.; Kumar, S.; Vimla, B. Effect of voltage gradient and temperature on electrical conduc-tivity of grape (Vitis vinifera L.) juice during ohmic heating. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 1914–1921. [Google Scholar] [CrossRef]

- Kumar, J.P.; Ramanathan, M.; Ranganathan, T.V. Ohmic heating technology in food processing–A review. Int. J. Food Eng. Res. Technol. 2014, 3, 1236–1241. [Google Scholar]

- Indiarto, R.; Rezaharsamto, B. A Review on Ohmic Heating and Its Use in Food. Int. J. Sci. Technol. Res. 2020, 9, 485–490. [Google Scholar]

- Sakr, M.; Liu, S. A comprehensive review on applications of ohmic heating (OH). Renew. Sustain. Energy Rev. 2014, 39, 262–269. [Google Scholar] [CrossRef]

- Bender, D.; Gratz, M.; Vogt, S.; Fauster, T.; Wicki, B.; Pichler, S.; Kinner, M.; Jäger, H.; Schoenlechner, R. Ohmic Heating—A Novel Approach for Gluten-Free Bread Baking. Food Bioprocess Technol. 2019, 12, 1603–1613. [Google Scholar] [CrossRef]

- Darvishi, H.; Hosainpour, A.; Nargesi, F. Ohmic Heating Behaviour and Electrical Conductivity of Tomato Paste. J. Nutr. Food Sci. 2012, 2, 1–5. [Google Scholar] [CrossRef]

- Boldaji, M.T.; Borghei, A.M.; Beheshti, B.; Hosseini, S.E. The process of producing tomato paste by ohmic heating method. J. Food Sci. Technol. 2014, 52, 1–9. [Google Scholar] [CrossRef]

- Varghese, K.S.; Pandey, M.C.; Radhakrishna, K.; Bawa, A.S. Technology, applications and modelling of ohmic heating: A review. J. Food Sci. Technol. 2014, 51, 2304–2317. [Google Scholar] [CrossRef]

- Arroyo, C.; Lyng, J.G. Electroprocessing of meat and meat products. In Emerging Technologies in Meat Processing: Production, Processing and Technology; Wiley: Hoboken, NJ, USA, 2016; pp. 103–130. [Google Scholar]

- Llave, Y.; Udo, T.; Fukuoka, M.; Sakai, N. Ohmic heating of beef at 20 kHz and analysis of electrical conductivity at low and high frequencies. J. Food Eng. 2018, 228, 91–101. [Google Scholar] [CrossRef]

- Muhammad, A.I.; Shitu, A.; Tadda, M.A. Ohmic Heating as Alternative Preservation Technique—A Review. Arid Zone Journal of Engineering. Technol. Environ. 2019, 15, 268–277. [Google Scholar]

- Richa, R.; Shahi, N.C.; Singh, A.; Lohani, U.C.; Omre, P.K.; Kumar, A.; Bhattacharya, T.K. Ohmic Heating Technology and Its Application in Meaty Food: A Review. Adv. Res. 2017, 10, 1–10. [Google Scholar] [CrossRef]

- Costa, N.R.; Cappato, L.P.; Ferreira, M.V.S.; Pires, R.P.; Moraes, J.; Esmerino, E.A.; Silva, R.; Neto, R.P.; Tavares, M.I.B.; Freitas, M.Q.; et al. Ohmic Heating: A potential technology for sweet whey processing. Food Res. Int. 2018, 106, 771–779. [Google Scholar] [CrossRef] [PubMed]

- Kautkar, S.; Pandey, R.K.; Richa, R.; Kothakota, A. Temperature dependent electrical conductivities of ginger paste during ohmic heating. Int. J. Agric. Environ. Biotechnol. 2014, 8, 21. [Google Scholar] [CrossRef]

- Gomathy, K.; Thangavel, K.; Balakrishnan, M.; Kasthuri, R. Effect of ohmic heating on the electrical conductivity, biochemical and rheological properties of papaya pulp. J. Food Process Eng. 2015, 38, 405–413. [Google Scholar] [CrossRef]

- Parmar, P.; Singh, A.K.; Meena, G.S.; Borad, S.; Raju, P.N. Application of ohmic heating for concentration of milk. J. Food Sci. Technol. 2018, 55, 4956–4963. [Google Scholar] [CrossRef]

- Suebsiri, N.; Kokilakanistha, P.; Laojaruwat, T.; Tumpanuvat, T.; Jittanit, W. The Pasteurization of Milk Applying Ohmic Heating in Comparison with Conventional Method and the Quality Attributes of Lactose-Free Milk. Res. J. Phranakhon Rajabhat Sci. Technol. 2019, 14, 25–35. [Google Scholar]

- Karunanithi, S.; Pare, A.; Sunil, C.K.; Loganathan, M. Optimization of Process Parameters of Ohmic Heating for Improving Yield and Quality of Tomato Seed Oil. Int. J. Pure App. Biosci. 2019, 7, 104–114. [Google Scholar] [CrossRef]

- Sarkis, J.R.; Jaeschke, D.P.; Mercali, G.D.; Tessaro, I.C.; Marczak, L.D.F. Degradation kinetics of anthocyanins in blackberry pulp during ohmic and conventional heating. Int. Food Res. J. 2019, 26, 87–97. [Google Scholar]

- Kumar, V.A.; Pravitha, M.; Pare, A. Optimization of Composite Protein-Lipid Film by Ohmic Heating using Mixture Design. Int. J. Curr. Microbiol. App. Sci. 2019, 8, 230–240. [Google Scholar] [CrossRef]

- Supratomo, S.; Laga, A.; Tahir, M.; Mochtar, A.A.; Salengke, S. Design and performance test of ohmic-assisted cocoa fermentation apparatus. ARPN J. Eng. Appl. Sci. 2019, 14, 1515–1523. [Google Scholar]

- Bansode, S.; Ranveer, R.C.; Tapre, A.R.; Ganorkar, P.M.; Sadale, S.B.; Sahoo, A.K. Enzymatic Clarification and Preservation of Aloe vera Juice by Ohmic Heating. Curr. J. Appl. Sci. Technol. 2019, 35, 1–9. [Google Scholar] [CrossRef]

- Hardinasinta, G.; Salengke, S.; Juaedi, M.; Mursalim, M. Ohmic heating characteristics and degradation kinetics of anthocyanin in mulberry juice. IOP Conf. Ser. Earth Environ. Sci. 2019, 355, 012094. [Google Scholar] [CrossRef]

- Aydin, C.; Kurt, Ü.; Kaya, Y. Comparison of the Effects of Ohmic and Conventional Heating Methods on Some Quality Parameters of the Hot-smoked Fish Pâté. J. Aquat. Food Prod. Technol. 2020, 29, 407–416. [Google Scholar] [CrossRef]

- Rocha, R.S.; Silva, R.; Guimarães, J.T.; Balthazar, C.F.; Pimentel, T.C.; Neto, R.P.; Tavares, M.I.B.; Esmerino, E.A.; Freitas, M.Q.; Cappato, L.P.; et al. Possibilities for using ohmic heating in Minas Frescal cheese production. Food Res. Int. 2020, 131, 109027. [Google Scholar] [CrossRef]

- Patel, A.; Singh, M. Ohmic Heating for Food Products- A Review. Curr. J. Appl. Sci. Technol. 2018, 27, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Müller, W.A.; Marczak, L.D.F.; Sarkis, J.R. Microbial inactivation by ohmic heating: Literature review and in-fluence of different process variables. Trends Food Sci. Technol. 2020, 99, 650–659. [Google Scholar] [CrossRef]

- Jaeger, H.; Roth, A.; Toepfl, S.; Holzhauser, T.; Engel, K.-H.; Knorr, D.; Vogel, R.F.; Bandick, N.; Kulling, S.; Heinz, V.; et al. Opinion on the use of ohmic heating for the treatment of foods. Trends Food Sci. Technol. 2016, 55, 84–97. [Google Scholar] [CrossRef]

- Kaur, R.; Gul, K.; Singh, A.K. Nutritional impact of ohmic heating on fruits and vegetables—A review. Cogent Food Agric. 2016, 2, 1159000. [Google Scholar] [CrossRef]

- Sun, H.; Kawamura, S.; Himoto, J.-I.; Itoh, K.; Wada, T.; Kimura, T. Effects of Ohmic Heating on Microbial Counts and Denaturation of Proteins in Milk. Food Sci. Technol. Res. 2008, 14, 117–123. [Google Scholar] [CrossRef]

- Olivera, D.F.; Salvadori, V.O.; Marra, F. Ohmic treatment of fresh foods: Effect on textural properties. Int. Food Res. J. 2013, 20, 1617–1621. [Google Scholar]

- Yildiz-Turp, G.; Sengun, I.; Kendirci, P.; Icier, F.; Yıldız-Turp, G. Effect of ohmic treatment on quality characteristic of meat: A review. Meat Sci. 2013, 93, 441–448. [Google Scholar] [CrossRef] [PubMed]

- Kumari, K.; Mudgal, V.D.; Viswasrao, G.; Srivastava, H. Studies on the effect of ohmic heating on oil recovery and quality of sesame seeds. J. Food Sci. Technol. 2016, 53, 2009–2016. [Google Scholar] [CrossRef]

- Abedelmaks, T.G.; Mohsen, S.M.; Duedahl-Ol, L.; Elnikeety, M.M.; Feyissa, A.H. Effect of Ohmic Heating Parameters on Inactivation of Enzymes and Quality of Not-from-concentrate Mango Juice. Asian J. Sci. Res. 2018, 11, 383–392. [Google Scholar] [CrossRef]

- Ramírez-Jiménez, A.K.; Rangel-Hernández, J.; Morales-Sánchez, E.; Loarca-Piña, G.; Gaytán-Martínez, M. Changes on the phytochemicals profile of instant corn flours obtained by traditional nixtamalization and ohmic heating process. Food Chem. 2019, 276, 57–62. [Google Scholar] [CrossRef] [PubMed]

- Mercali, G.D.; Gurak, P.D.; Schmitz, F.; Marczak, L.D.F. Evaluation of non-thermal effects of electricity on anthocyanin degradation during ohmic heating of jaboticaba (Myrciaria cauliflora) juice. Food Chem. 2015, 171, 200–205. [Google Scholar] [CrossRef] [PubMed]

- Schottroff, F.; Biebl, D.; Gruber, M.; Burghardt, N.; Schelling, J.; Gratz, M.; Schoenher, C.; Jaeger, H. Inactivation of vegetative microorganisms by ohmic heating in the kilohertz range—Evaluation of experimental setups and non-thermal effects. Innov. Food Sci. Emerg. Technol. 2020, 63, 102372. [Google Scholar] [CrossRef]

- Murashita, S. Development of Non-Thermal Microbial Inactivation Techniques: Application of Ohmic Heating and Irradiation of UVC by Light-Emitting Diode. Ph.D. Dissertation, Hokkaido University, Sapporo, Japan, 2018. [Google Scholar] [CrossRef]

- Song, W.J.; Sung, H.J.; Kang, D.H. Inactivation of E scherichia coli O157: H7 and S almonella Typhimurium in apple juices with different soluble solids content by combining ozone treatment with mild heat. J. Appl. Microbiol. 2015, 118, 112–122. [Google Scholar] [CrossRef] [PubMed]

- Lyng, J.G.; McKenna, B.M.; Arroyo, C. Ohmic heating of foods. In Alternatives to Conventional Food Processing; Royal Society of Chemistry: London, UK, 2018; pp. 95–137. [Google Scholar]

- Zell, M.; Lyng, J.G.; Cronin, D.A.; Morgan, D.J. Ohmic cooking of whole beef muscle—Evaluation of the impact of a novel rapid ohmic cooking method on product quality. Meat Sci. 2010, 86, 258–263. [Google Scholar] [CrossRef]

- Somavat, R. Applications and Effects of Ohmic Heating: Sterilization, Influence on Bacterial Spores, Enzymes, Bioactive Components and Quality Factors in Food. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2011. [Google Scholar]

- Sagong, H.-G.; Park, S.-H.; Choi, Y.-J.; Ryu, S.; Kang, D.-H. Inactivation of Escherichia coli O157:H7, Salmonella Typhimurium, and Listeria monocytogenes in Orange and Tomato Juice Using Ohmic Heating. J. Food Prot. 2011, 74, 899–904. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-Y.; Sagong, H.-G.; Ryu, S.; Kang, D.-H. Effect of continuous ohmic heating to inactivate Escherichia coli O157:H7, Salmonella Typhimurium and Listeria monocytogenes in orange juice and tomato juice. J. Appl. Microbiol. 2012, 112, 723–731. [Google Scholar] [CrossRef] [PubMed]

- Sengun, I.Y.; Turp, G.Y.; Icier, F.; Kendirci, P.; Kor, G. Effects of ohmic heating for pre-cooking of meatballs on some quality and safety attributes. LWT 2014, 55, 232–239. [Google Scholar] [CrossRef]

- Kumar, M.; Hausain, A. Effect of ohmic heating of buffalo milk on microbial quality and tesure of paneer. Asian J. Dairy. Food Res. 2014, 33, 9–13. [Google Scholar] [CrossRef]

- Salari, S.; Jafari, S.M. The Influence of Ohmic Heating on Degradation of Food Bioactive Ingredients. Food Eng. Rev. 2020, 12, 191–208. [Google Scholar] [CrossRef]

- Jatau, S.H.; Sokoto, M.A.; Almustapha, M.N.; Muhammad, C.; Dabai, M.U.; Zubairu, A.Y. Effect of heat on lycopene content of hot peppers (capsicum annum) using various processing temperature. Int. J. Sci. Eng. 2018, 14, 32–39. [Google Scholar]

- Cappato, L.P.; Ferreira, M.V.S.; Moraes, J.; Pires, R.P.; Rocha, R.S.; Silva, R.; Calado, V.M. Whey acer-ola-flavoured drink submitted Ohmic Heating: Bioactive compounds, antioxidant capacity, thermal behavior, water mo-bility, fatty acid profile and volatile compounds. Food Chem. 2018, 263, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Mercali, G.D.; Jaeschke, D.P.; Tessaro, I.C.; Marczak, L.D.F. Degradation kinetics of anthocyanins in acerola pulp: Comparison between ohmic and conventional heat treatment. Food Chem. 2013, 136, 853–857. [Google Scholar] [CrossRef]

- Sakulchuthathip, V.; Yasurin, P.; Tangduangdee, C.; Asavasanti, S. Extraction of bioactive compounds from Chinese chives using ohmic assisted hydrodistillation. Extraction 2017, 15, 17. [Google Scholar]

- Kuriya, S.P.; Silva, R.; Rocha, R.S.; Guimarães, J.T.; Balthazar, C.F.; Pires, R.P.; Raices, R.S. Assessment the impact of the electric field on the quality parameters of blueberry flavored dairy desserts. Food Res. Int. 2020, 134, 1–38. [Google Scholar] [CrossRef] [PubMed]

- Loypimai, P.; Moongngarm, A.; Chottanom, P.; Moontree, T. Ohmic heating-assisted extraction of anthocyanins from black rice bran to prepare a natural food colourant. Innov. Food Sci. Emerg. Technol. 2015, 27, 102–110. [Google Scholar] [CrossRef]

- Poojitha, P.; Athmaselvi, K. Influence of sucrose concentration on electric conductivity of banana pulp during ohmic heating. Food Sci. Technol. Int. 2018, 24, 664–672. [Google Scholar] [CrossRef]

- Saberian, H.; Esfahani, Z.H.; Abbasi, S. Effect of conventional and ohmic pasteurization on some bioactive components of aloe Vera gel juice. Iran. J. Chem. Chem. Eng. 2015, 34, 99–108. [Google Scholar]

- Jaeschke, D.P.; Marczak, L.D.F.; Mercali, G.D. Evaluation of non-thermal effects of electricity on ascorbic acid and carotenoid degradation in acerola pulp during ohmic heating. Food Chem. 2016, 199, 128–134. [Google Scholar] [CrossRef] [PubMed]

- Abedelmaksoud, T.G.; Mohsen, S.M.; Duedahl-Olesen, L.; Elnikeety, M.M.; Feyissa, A.H. Optimization of ohmic heating parameters for polyphenoloxidase inactivation in not-from-concentrate elstar apple juice using RSM. J. Food Sci. Technol. 2018, 55, 2420–2428. [Google Scholar] [CrossRef] [PubMed]

- Mäntsälä, P.; Jarmo, N. Enzymes: The biological catalysts of life. Physiol. Maintanance 2009, 2, 1–22. [Google Scholar]

- Terefe, N.S.; Buckow, R.; Versteeg, C. Quality-Related Enzymes in Fruit and Vegetable Products: Effects of Novel Food Processing Technologies, Part 1: High-Pressure Processing. Crit. Rev. Food Sci. Nutr. 2014, 54, 24–63. [Google Scholar] [CrossRef] [PubMed]

- Kostelac, D.; Putnik, P.; Markov, K.; Frece, J.; Kovačević, D.B. Effects of electrotechnologies on enzymes in foods and food model systems. Curr. Opin. Food Sci. 2020, 31, 47–56. [Google Scholar] [CrossRef]

- Han, Y.; Cheng, J.-H.; Sun, D.-W. Activities and conformation changes of food enzymes induced by cold plasma: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 794–811. [Google Scholar] [CrossRef]

- Poojary, M.; Roohinejad, S.; Koubaa, M.; Barba, F.; Passamonti, P.; Jambrak, A.R.; Greiner, R. Impact of pulsed electric fields on enzymes. In Handbook of Electroporation; Miklavbcic, D., Ed.; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Yu, L.J.; Ngadi, M.; Raghavan, G.S.V. Effect of temperature and pulsed electric field treatment on rennet co-agulation properties of milk. J. Food Eng. 2009, 95, 115–118. [Google Scholar] [CrossRef]

- Tappi, S.; Ragni, L.; Tylewicz, U.; Romani, S.; Ramazzina, I.; Rocculi, P. Browning response of fresh-cut apples of different cultivars to cold gas plasma treatment. Innov. Food Sci. Emerg. Technol. 2019, 53, 56–62. [Google Scholar] [CrossRef]

- Saxena, J.; Makroo, H.A.; Srivastava, B. Effect of ohmic heating on Polyphenol Oxidase (PPO) inactivation and color change in sugarcane juice. J. Food Process. Eng. 2016, 40, 1–11. [Google Scholar] [CrossRef]

- Li, X.; Xu, X.; Wang, L.; Regenstein, J.M. Effect of ohmic heating on physicochemical properties and the key en-zymes of water chestnut juice. J. Food Process. Preserv. 2019, 43, e13919. [Google Scholar] [CrossRef]

- Makroo, H.A.; Srivastava, B.; Sit, N.; Badwaik, L.S.; Das, A.B. Effects of ohmic heating on different liquid food materials. Trends Innov. Food Process. Technol. 2017, 3, 95–115. [Google Scholar]

- Li, F.D.; Chen, C.; Ren, J.; Wang, R.; Wu, P. Effect of ohmic heating of soymilk on urease inactivation and kinet-ic analysis in holding time. J. Food Sci. 2015, 80, E307–E315. [Google Scholar] [CrossRef] [PubMed]

- Jakób, A.; Bryjak, J.; Wójtowicz, H.; Illeová, V.; Annus, J.; Polakovič, M. Inactivation kinetics of food enzymes during ohmic heating. Food Chem. 2010, 123, 369–376. [Google Scholar] [CrossRef]

- Sengun, I.Y.; Icier, F.; Kor, G. Effects of Combined Ohmic-Infrared Cooking Treatment on Microbiological Inactivation of Meatballs. J. Food Process. Eng. 2015, 40. [Google Scholar] [CrossRef]

- Mesías, M.; Wagner, M.; George, S.; Morales, F.J. Impact of conventional sterilization and ohmic heating on the amino acid profile in vegetable baby foods. Innov. Food Sci. Emerg. Technol. 2016, 34, 24–28. [Google Scholar] [CrossRef]

- Pereira, R.N.; Teixeira, J.A.; Vicente, A.A.; Cappato, L.P.; Ferreira, M.V.D.S.; Rocha, R.D.S.; Da Cruz, A.G. Ohmic heating for the dairy industry: A potential technology to develop probiotic dairy foods in association with modifications of whey protein structure. Curr. Opin. Food Sci. 2018, 22, 95–101. [Google Scholar] [CrossRef]

- Park, S.H.; Balasubramaniam, V.; Sastry, S.K. Quality of shelf-stable low-acid vegetables processed using pressure–ohmic–thermal sterilization. LWT 2014, 57, 243–252. [Google Scholar] [CrossRef]

- Wongsa-Ngasri, P.; Sastry, S.K. Effect of ohmic heating on tomato peeling. LWT 2015, 61, 269–274. [Google Scholar] [CrossRef]

- Ramaswamy, H.S.; Marcotte, M. Food Processing: Principles and Applications, 1st ed.; CRC Press: Boca Raton, RL, USA, 2005. [Google Scholar]

- Kanogchaipramot, K.; Tongkhao, K.; Sajjaanantakul, T.; Kamonpatana, P. Ohmic Heating of an Electrically Conductive Food Package. J. Food Sci. 2016, 81, E2966–E2976. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).