1. Introduction

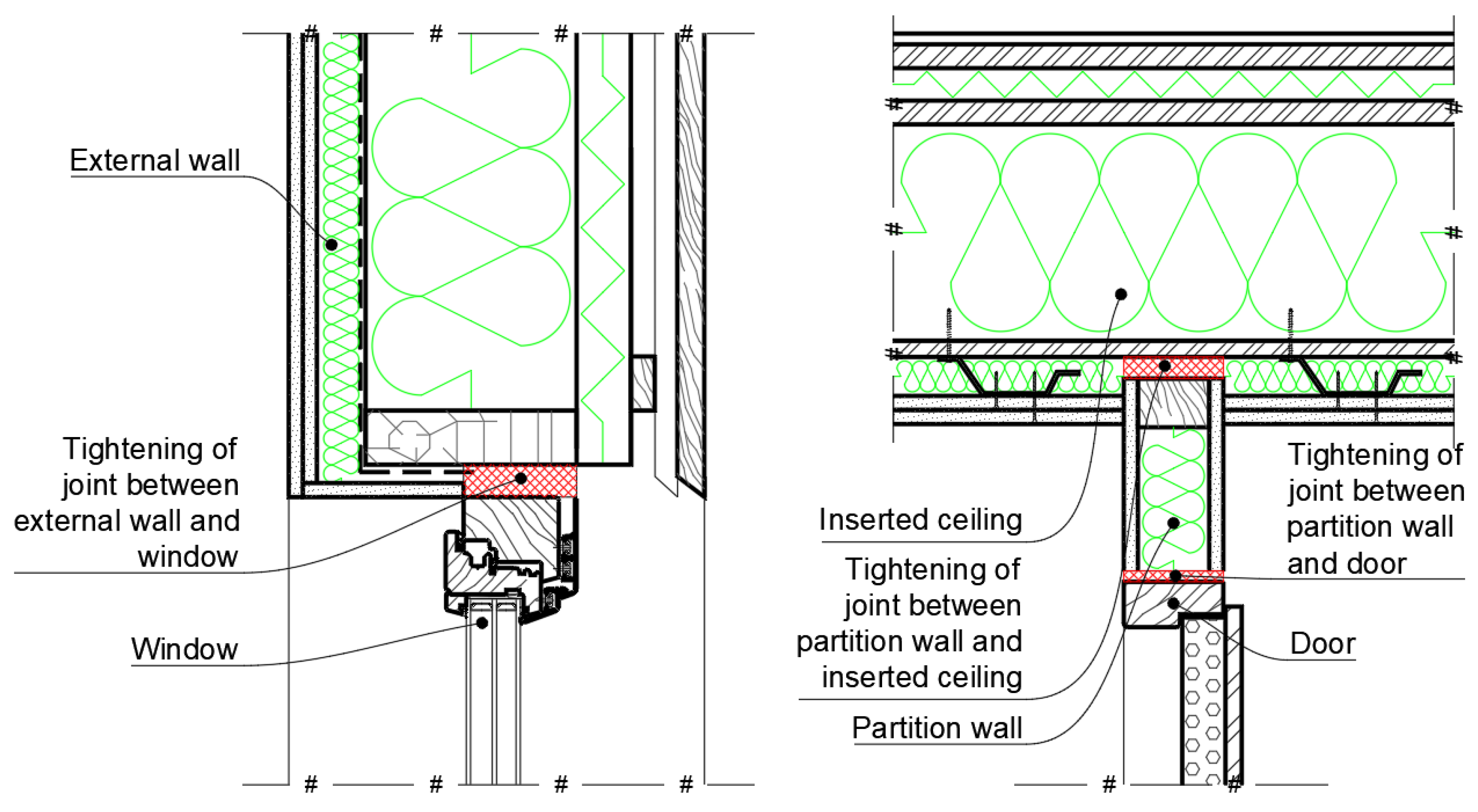

An airtight and well-insulated building envelope is a key factor for achieving the requirements set for nearly zero energy buildings (nZEB) becoming mandatory in the European Union (EU) from the year 2021. Increased insulation thickness in timber constructions creates a serious risk of moisture accumulation inside the construction and deterioration of the building structure, if air leakages are not minimised or avoided. This is especially important in the case of timber constructions where the materials are more sensitive to extensive moisture and deterioration. There are several different technical solutions for sealing the cracks, joints and penetrations through the building envelope. Special sealing tapes for different surface materials, airtight membranes, rubber collars, adhesive sealing glues and different montage foams are used with varying degrees of success. Although it has been shown that the overall airtightness of new buildings has improved significantly [

1,

2,

3], the actual leakage rate and its variation is strongly related to overall quality assurance mechanisms and local building techniques [

1,

4], especially for window-related air leakages [

5].

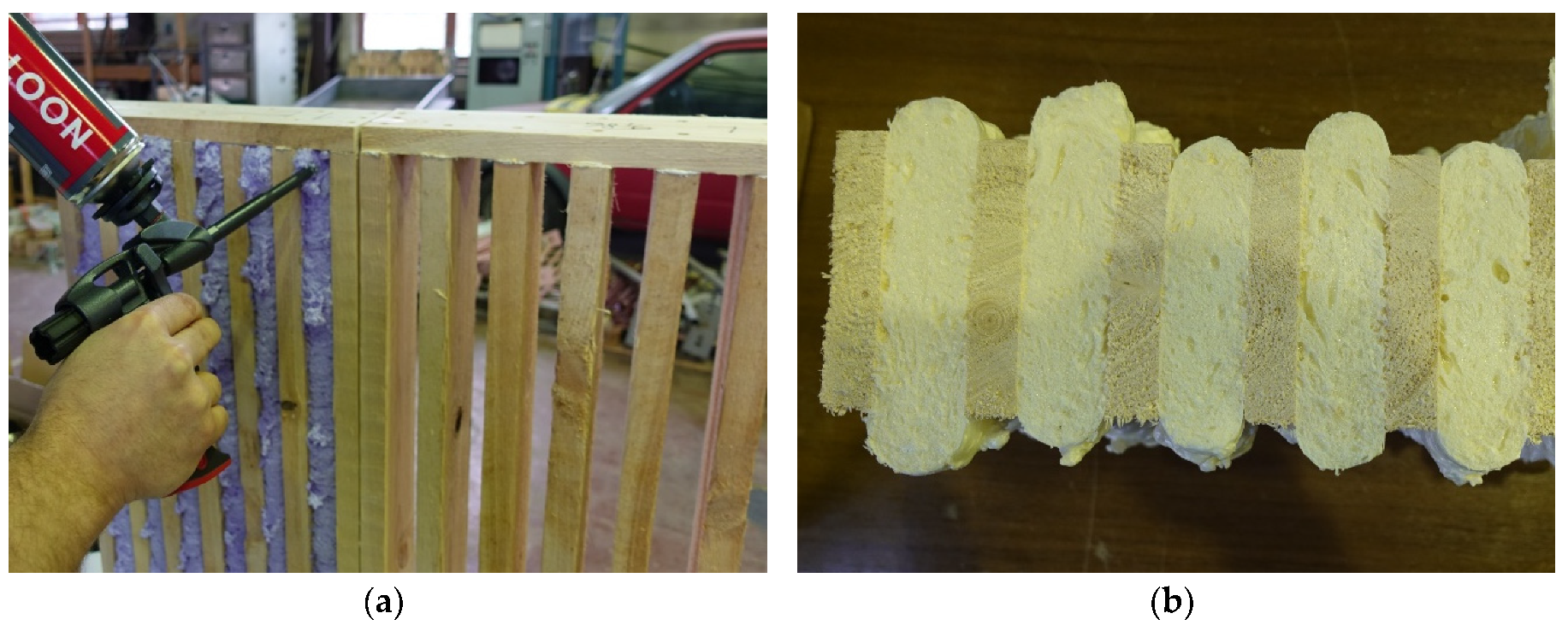

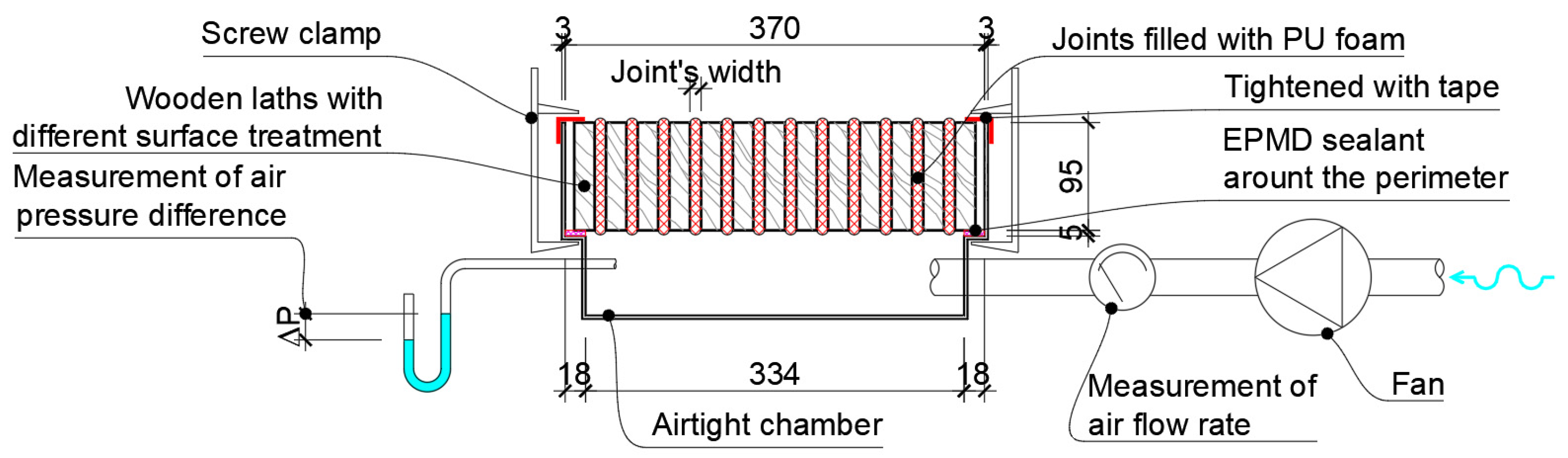

Polyurethane (PU) one-component foams (OCF) are self-adhesive and self-hardening sealing materials that are often used for door and window installation and filling other joints and gaps in the building envelope. Despite their widespread use, it is not known if the necessary airtightness can be consistently achieved without the use of additional sealing tapes. The volume of PU OCF expands after application, filling all hollow spaces and hardens on contact with the air humidity. The expansion of the foam cannot be fully controlled, and therefore successful results can be highly dependent on the surface properties along with the foam properties and the environmental conditions. Different joints in the building envelope can have different surface materials. Depending on the construction technology, a cap between different envelope elements can have a sawn wooden surface (wooden studs and beams at the end of walls, roof elements, etc.), a planed wooden surface (connection between wooden window frame, plywood and other similar wood-based products, planed wooden elements etc.) or a plastic surface (connection between wall and a window frame manufactured from polyvinyl chloride (PVC)). All three surface types were analysed in this study to quantify the differences due to surface treatment.

The objective of this study was to analyse the air leakage of joints filled with polyurethane foam and their influencing factors to see if consistent airtightness can be achieved under varying conditions. The first part of the study consisted in estimating experimentally the air leakage rates over test specimens prepared so to analyse the influence of different foams, joint widths and surface treatments. Inferential statistics was then used in the second part of the paper for the analysis and interpretation of the data. The following hypotheses were studied:

A joint between sawn wooden surfaces is leakier than a joint between planed wooden surfaces because the sawn surface is rougher;

A joint with a PVC surface has larger leakage than the other tested joints because the foam is not exposed to humidity, and water droplets on the plastic surface may cause leakage pathways;

A wider joint has larger air leaks because the pressure exerted by the expanding foam is lessened;

Different foams have different air leakage properties.

3. Results

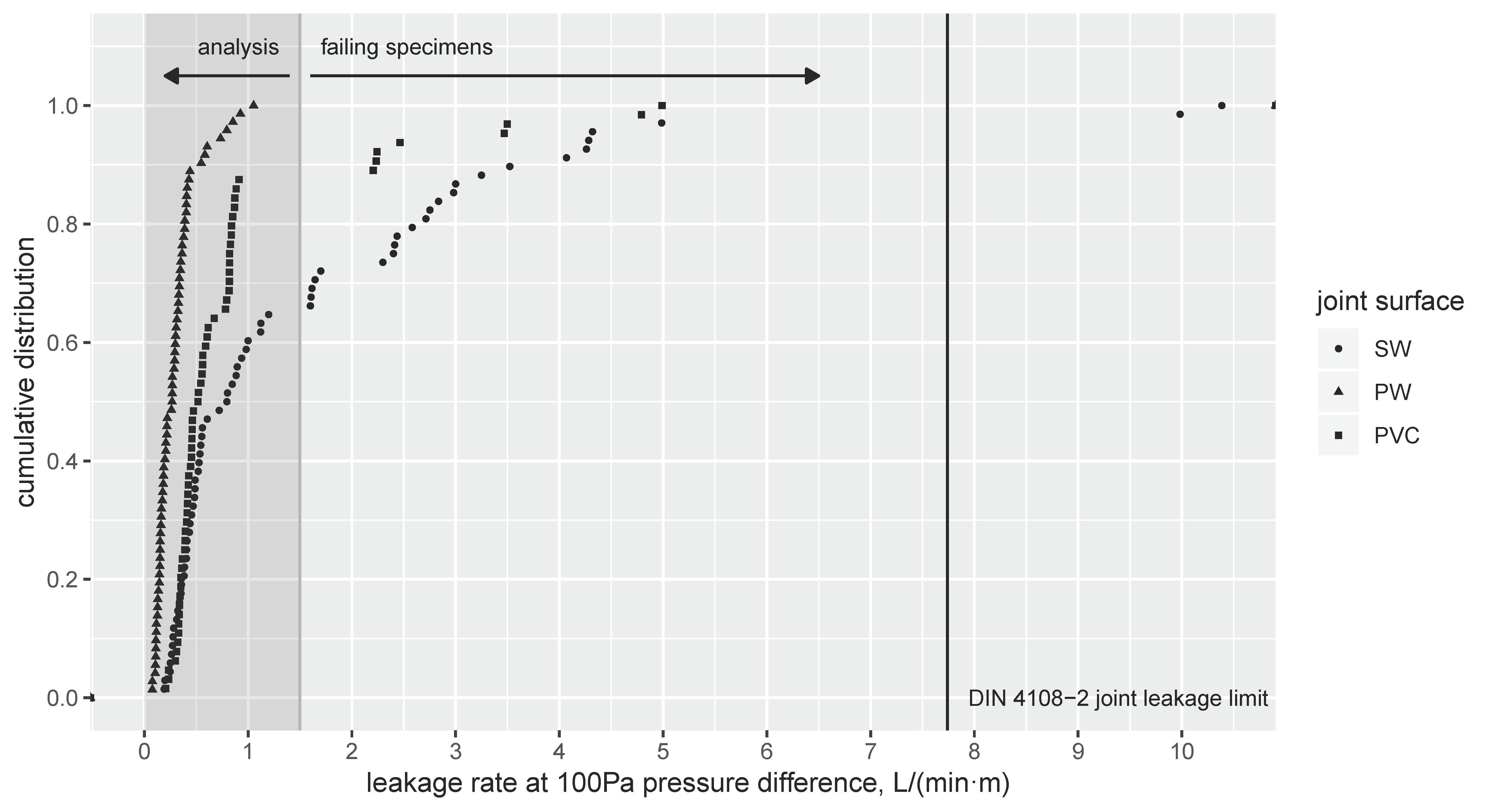

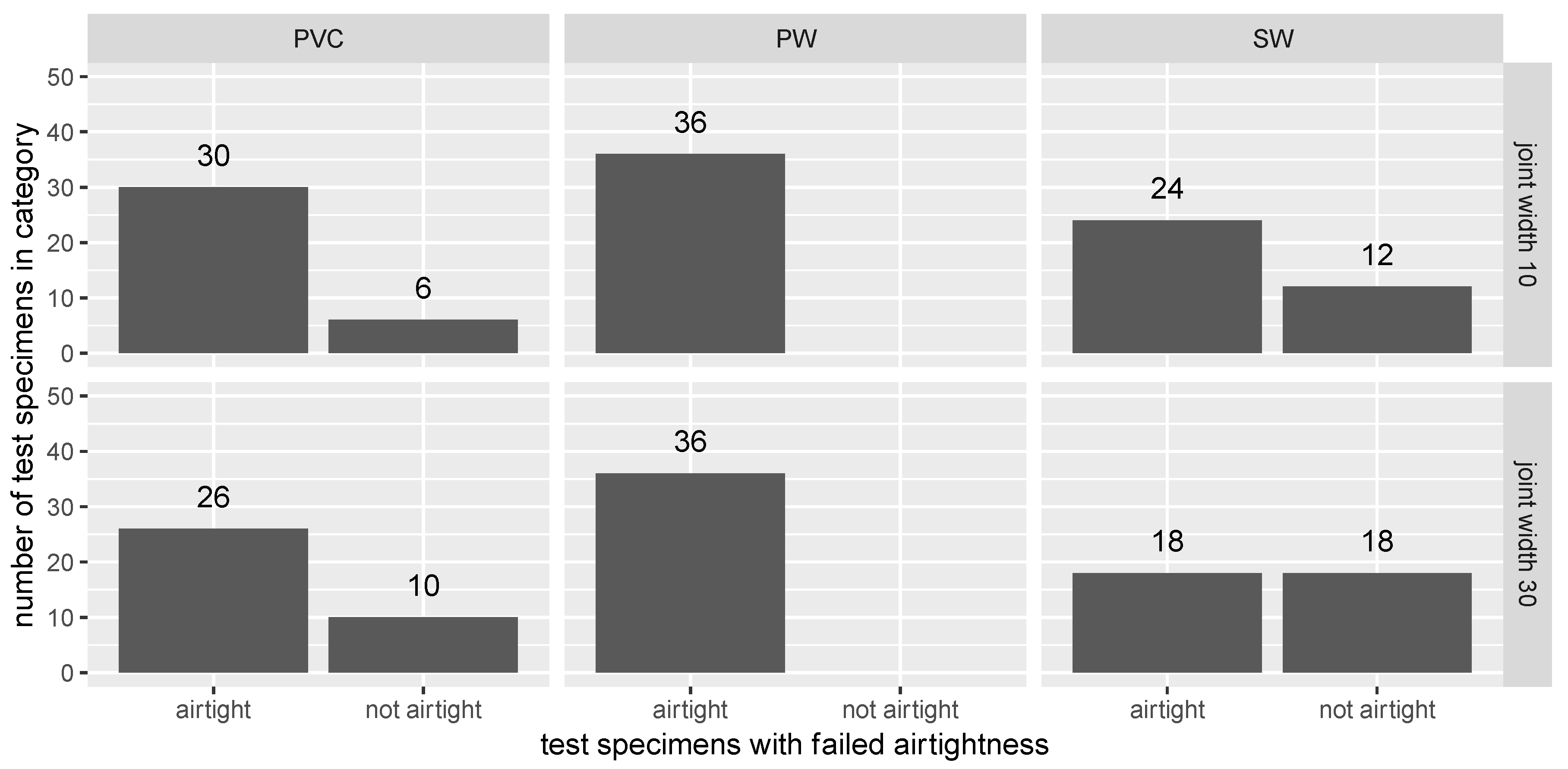

The proportion of the test specimens with failed airtightness (significantly larger air leakage compared to test specimens with exactly the same configuration or excessive air leakage of all test specimens with visible cracks) depended greatly on lath surface treatment.

Figure 7 shows that in the case of planed timber, the airtightness did not fail. In the case of the PVC surface, the proportion of failed test specimens was 16% and 28%, respectively, for 10 mm and 30 mm joint widths. Joints with a sawed wooden surface performed significantly worse, with a failure rate of 33% and 50% for 10 mm and 30 mm joint widths, respectively.

A larger joint width also contributed to a higher failure rate of airtightness. Grouping by specific foam product did not have a significant effect on the failure rate of the test specimens.

The mean air leakage rates at 400 Pa and 50 Pa pressure differences grouped by foam product, joint width and lath surface treatment are given in

Table 1 along with the variations (standard deviation) among the test specimens and in under- and overpressure conditions. For statistical testing, air leakage rates at 400 Pa pressure difference were used.

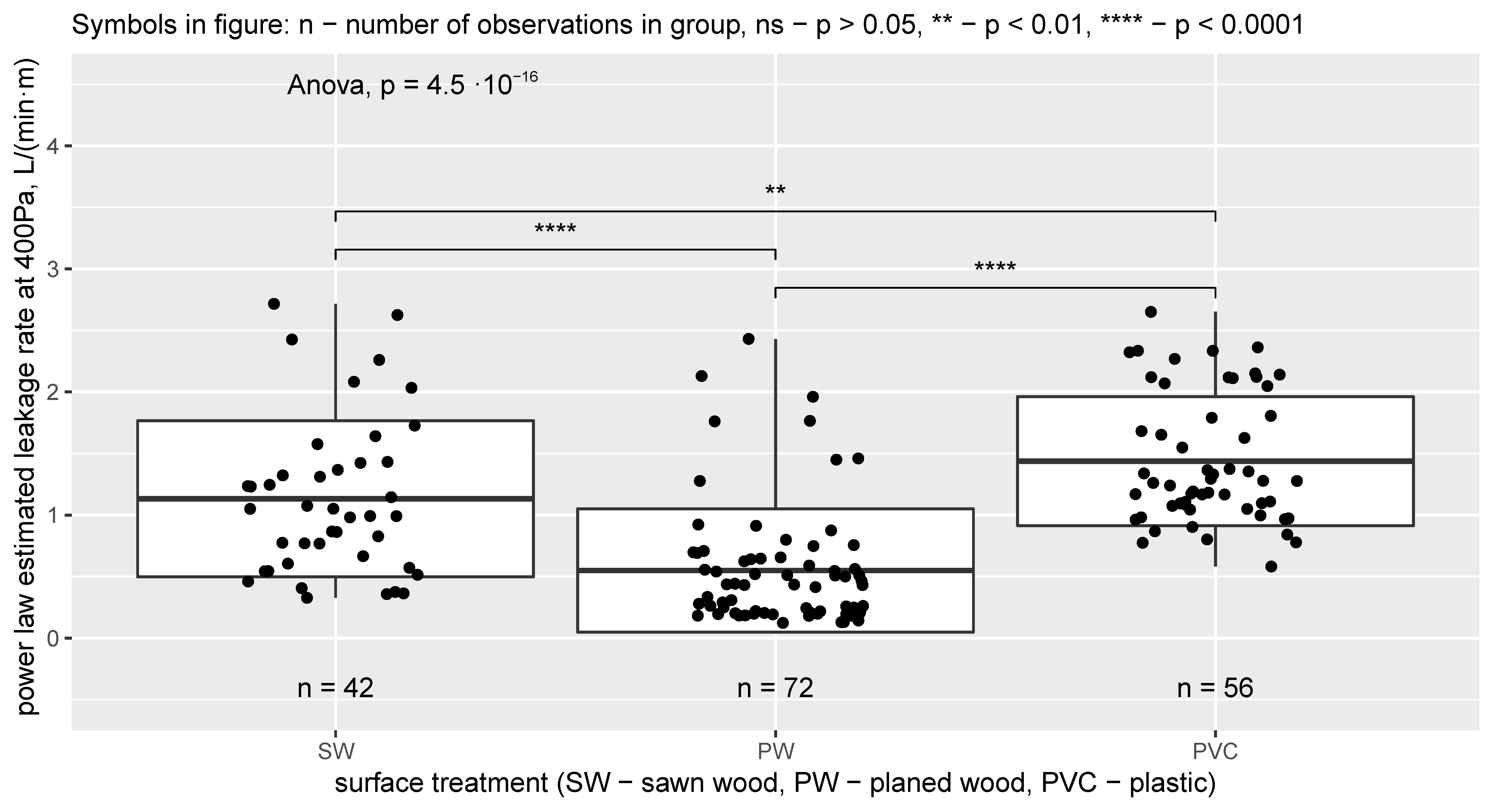

Figure 8 shows that the mean air leakage rate for joints with a planed wood surface (

V400 = 0.549 L/(min·m)) was significantly (

p < 0.0001) lower by a factor of two or more than that of joints with sawn wood surfaces (

V400 = 1.132 L/(min·m)) and plastic surfaces (

V400 = 1.438 L/(min·m)). Also, the deviation was lower for joints with a planed wooden surface (σ

V400 = 0.501 L/(min·m)) compared to those with sawn wooden surfaces (σ

V400 = 0.635 L/(min·m)) and plastic surfaces (σ

V400 = 0.524 L/(min·m)), meaning a better reliability in achieving the target result. It was expected that the smooth timber surface would enable better bonding between the timber surface and the PU foam, in contrast to the sawn timber surface, for which the foam would not fill all the small grooves etc.

For plastic-coated laths, the foam can expand similarly to planed laths, but the humidity transport from surface to foam is limited, and therefore the foam expansion is inhibited. This is usually compensated by moistening the plastic surface before applying the foam; however, exact guidelines regarding the quantities to be used are not provided by the foam producers. If the plastic surface is moistened before the foam is applied, water droplets on the plastic surface may cause random leakage pathways depending on the spraying technique and the amount of water used. The difference between PVC coating and sawed timber was small (but still significant, with p < 0.01) contributing to approximately a 27% increase of leakage, on average, in the case of plastic coating.

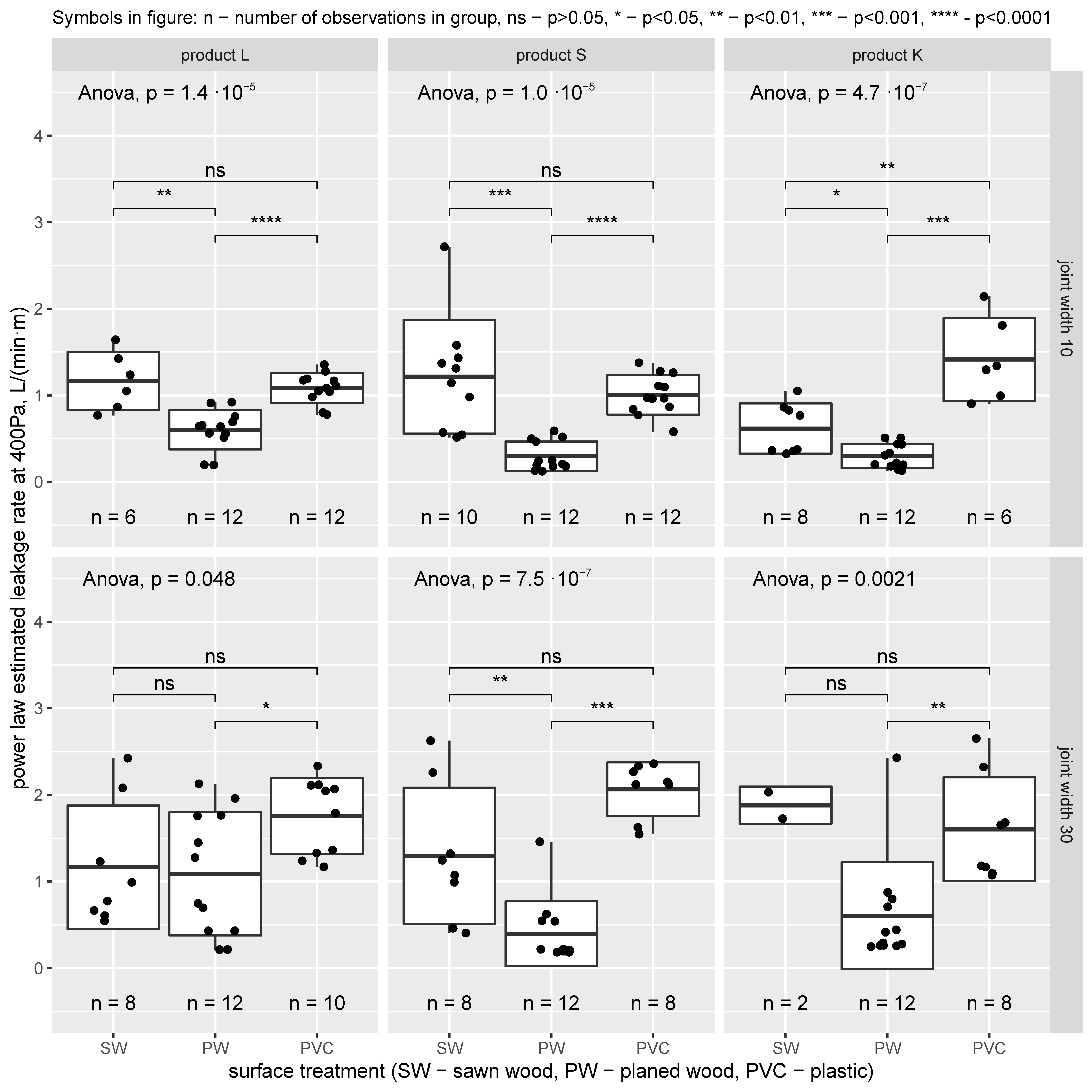

The comparison between different surface treatments within groups, for the same foam product and joint with is shown in

Figure 9.

The air leakage rate in the case of the planed timber remained significantly lower than those measured for the two other surface treatment groups, even when considering the effect of joint width (10 mm versus 30 mm) and specific foam products, except for the test specimens with 30 mm-wide joints treated with the foam product “L”, for which all measurements had large variations, and the average air flow difference between all foam products were small. The difference between the sawn wooden surface and the plastic surface was not significant in most cases.

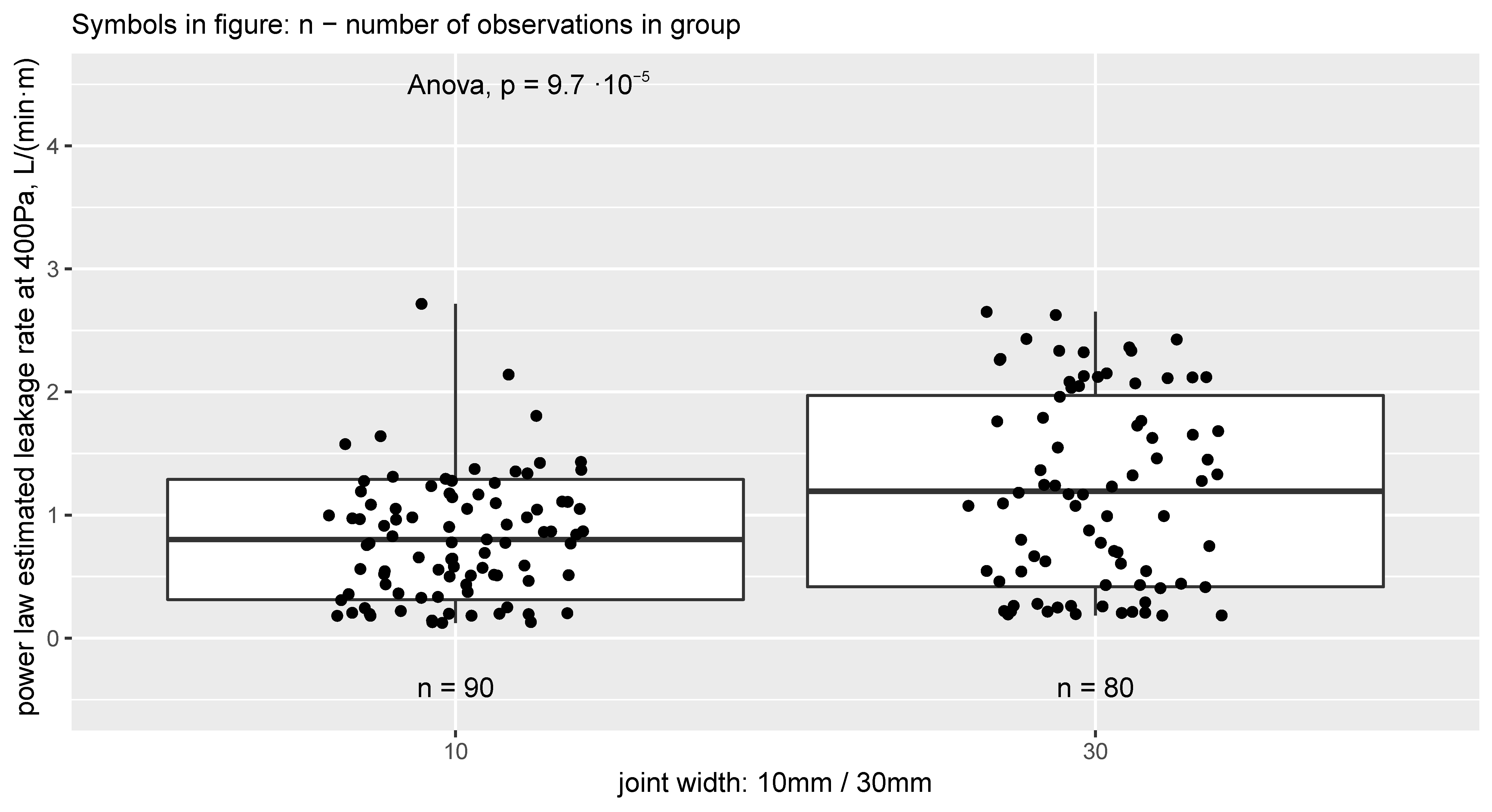

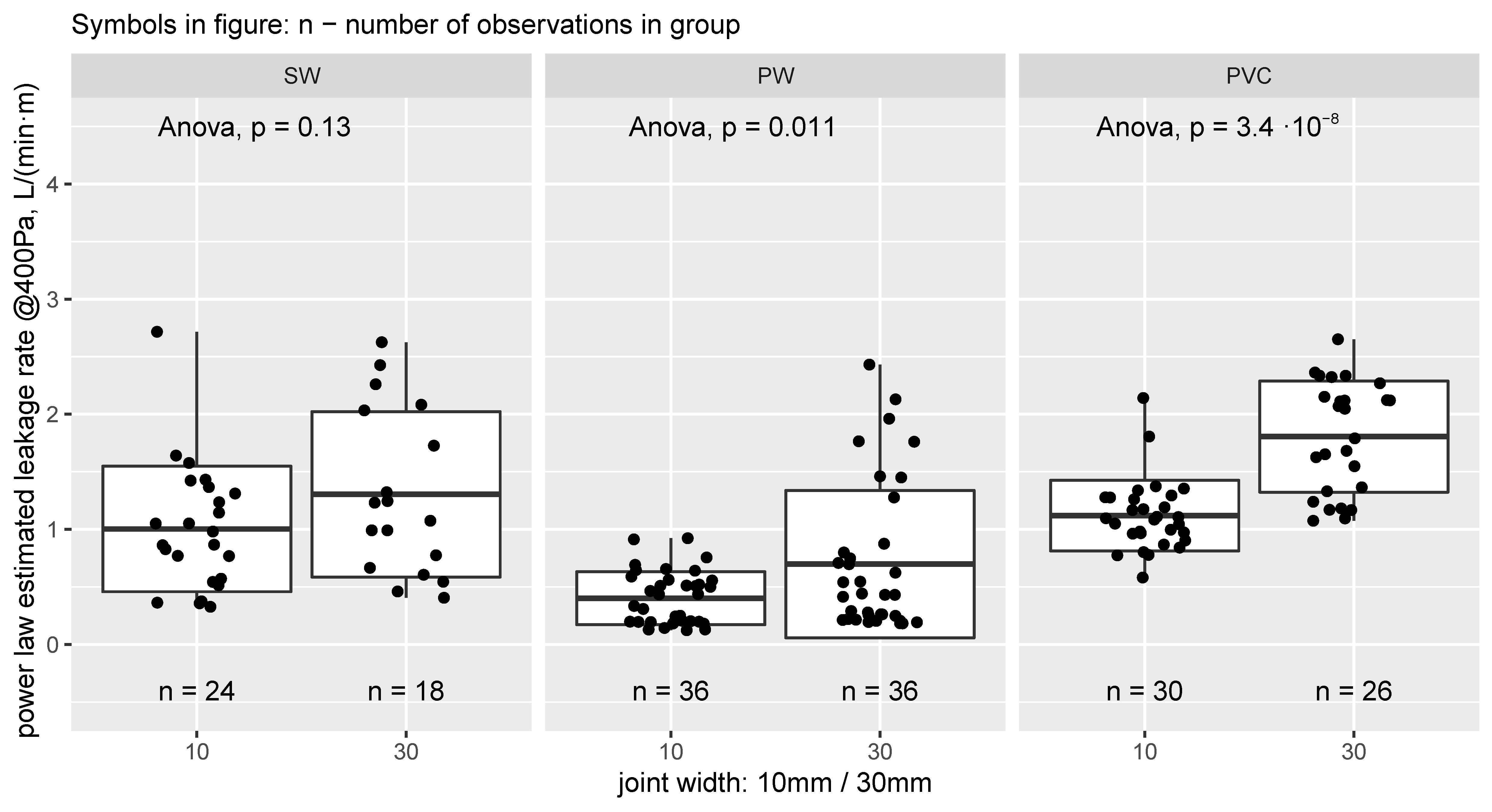

The mean air leakage rate and its variation increased with the increase in joint width (

Figure 10). The mean air leakage through a 10 mm joint with all surfaces filled with all foams (

V400 = 0.801 L/(min·m)) was significantly lower (

p < 0.0001) than mean air leakage through a 30 mm joint (

V400 = 1.194 L/(min·m)). The same phenomena were observed in the case of different lath surface treatments, although for sawn wooden surfaces, the difference was not statistically significant (

Figure 11).

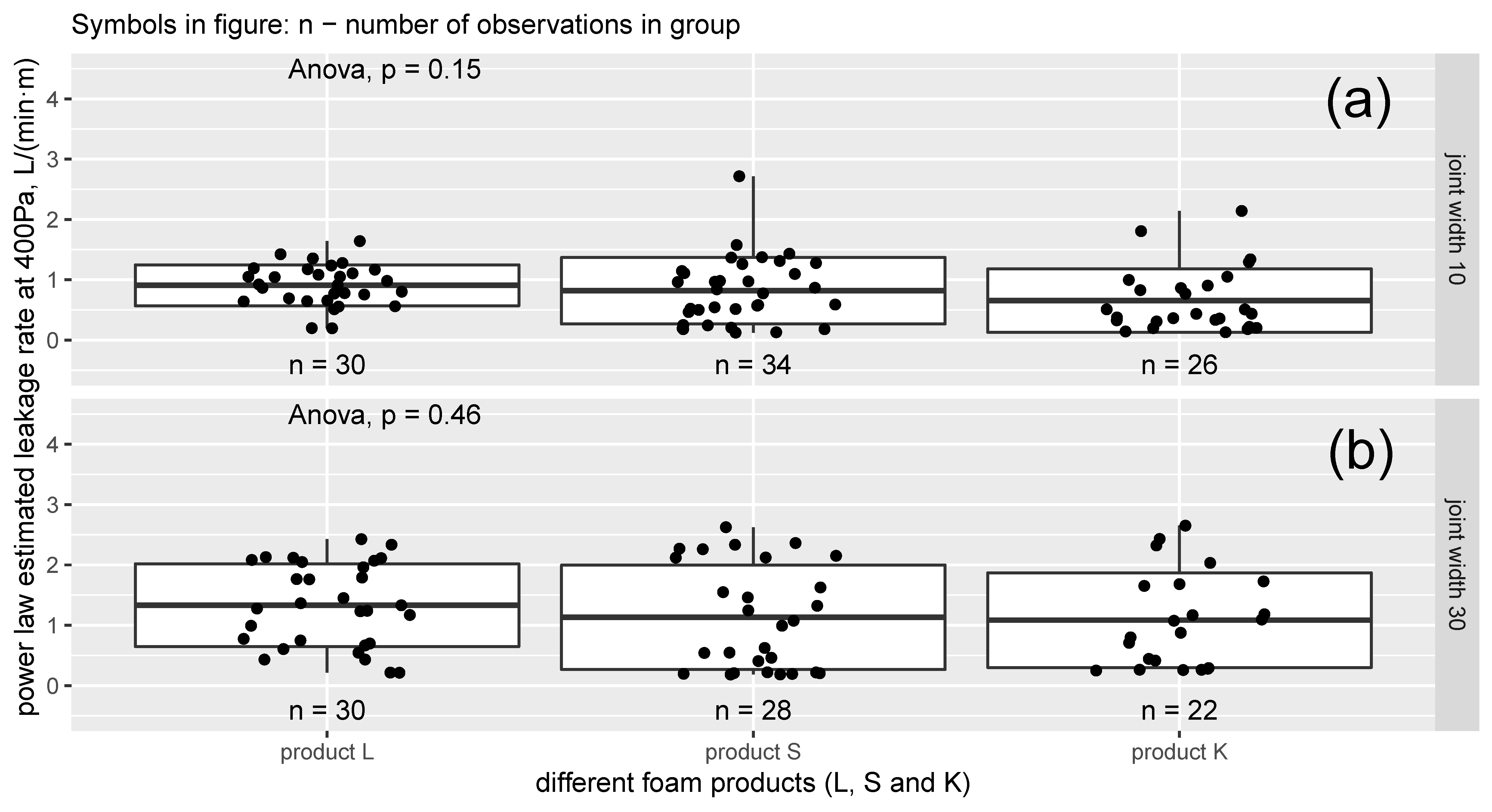

Although different analysed foam products performed slightly differently in the case of wider joints, an overall difference between these products was not statistically significant (

Figure 12), mainly due to a large variation in the measured performance of the test specimens.

4. Discussion

Although the airtightness properties of foam joints have been previously tested and these foams have been proved to be almost airtight [

13] and perform satisfactorily at the window–wall interface in cavity brick walls [

14], the current study showed that the airtightness of actual joints could vary a lot and depends strongly on many parameters. A previous study in Belgium [

14] assessed the airtightness joints filled with PU foam, among other insulating and sealing materials (tapes, mineral wool). Several joints with PU foam filling half of the cavity, full cavity and full cavity with plaster coating were measured for airtightness. Air leakage rates in the range of 1.06 to 1.77 m

3/(h·m) were measured at 50 Pa pressure difference for the test specimens treated with pure PU foam, which corresponds to 17.6 to 29.5 L/(min·m). Additional coating with plaster or additional sealing with caulking lowered the air leakages below 0.10 m

3/(h·m), which corresponds to 1.67 L/(min·m). In this study, the air leakages at 50 Pa pressure difference remained in the range of 0.156 to 0.565 L/(min·m) depending on the surface treatment and joint width. Other studies of window-to-wall interfaces sealed with PU foam have also shown somewhat higher air leakages in the range of 0.0 to 0.155 (mean 0.03) m

3/(h·m) [

15] and 0.10 m

3/(h·m) [

16].

Expanding montage foams need additional moisture from air and through adjacent surfaces to fully expand and fill the grooves and concavities. It was expected that the smooth planed surface of timber joints would provide good conditions for foam bonding, and the measured results confirmed this. The air leakages in the case of planed timber surfaces were significantly lower, averaging V400 = 0.549 L/(min·m) at 400 Pa pressure difference. During repetitive testing with three identical test specimens for each configuration, no airtightness failures were observed. The joints with sawn timber laths performed worse by more than a factor of two, averaging V400 = 1.132 L/(min·m) at 400 Pa pressure difference, and the fail rate under repetitive testing was huge, totalling 33% and 50% for 10 mm and 30 mm joint widths, respectively. This shows that the studied foams were often unable to bond with the uneven surface and, although some test specimens had air leakages comparable to those of planed timber surfaces, the foam–timber interface is systematically not airtight.

The failure rate of plastic-coated laths was significantly lower compared to that of sawn timber but, nonetheless, showed some bonding problems in the case of the wider joint, which had a failure rate of more than 28%. The surface of PVC-coated laths is smooth, but the inhibited transport of moisture through the plastic surface and the water droplets caused by surface moistening can, in some cases, create pathways for air leakages. Although this does not always cause major air leakages, it contributes to even higher average air leakage rates compared to sawn timber (V400 = 1.438 L/(min·m) at 400 Pa pressure difference).

The leakage rate through the window–wall interface can be compared to the leakage rate of the window itself to assess the additional effect of leakages on the overall airtightness. A large number of window products were tested in Belgium to assess the distribution and average airtightness of different window types [

17]. Although the variation within the test specimens was high, the median airtightness of single and double windows (independently of the material) was 0.82 m

3/(h·m

2) and 1.36 m

3/(h·m

2), respectively, for 50 Pa pressure difference. For a hypothetical window with a size of 1.0 m × 1.0 m (joint length of 4.0 m), this corresponds to air leakage of 0.82 and 1.36 m

3/(h·m

2), respectively, for single and double windows at 50 Pa pressure difference. The average air leakage rate of joints in the range of 0.156 to 0.565 L/(min·m) according to this study would add 0.04 m

3/(h·m

2) to 0.14 m

3/(h·m

2), corresponding to a 5% to 17% increase in the case of a single window, and a 5% to 10% increase in the case of a double window. For larger windows with a favourable aspect ratio, the additional effect of window–wall interface will be lower.

Similarly, the potential effect of the measured joint air leakage can be calculated for an entire building envelope. For this, a cumulative joint length for all connections between the building envelope elements was calculated for a prefabricated two-storey wooden reference building with very good airtightness and optimised window connections [

18]. The airtightness was achieved with the systematic use of special tapes and on-site quality assurance measures. The building was included in a larger study about airtightness of Estonian wooden buildings [

1] and had an average measured air leakage rate q

50 = 0.24 m

3/(h·m

2) at 50 Pa pressure difference corresponding to the measured air flow rate V

50 = 91 m

3/h. With cumulative joint length of 206 m and external envelope area of 373.5 m

2, the average air leakage rate of the joints in the range of 0.156 to 0.565 L/(min·m) at 50 Pa pressure difference according to this study would contribute to additional 1.93 m

3/h to 6.98 m

3/h, respectively, corresponding to less than 0.02 m

3/(h·m

2) increase in air leakage of the entire building envelope. A previous study has shown that the actual average air leakage rate of the building envelope in newer wooden buildings is around 1.1 m

3/(h·m

2), with very high variation (standard deviation 1.6 m

3/(h·m

2)) [

1]. This strongly suggests that the actual air leakage of the building envelope is mainly dependent on the ‘failure rate’ of the sealing measures rather than on the leakage properties of the sealing measure and its influencing factors. Previous studies have found that workmanship quality plays a critical role in achieving airtightness. Kalamees et al. [

19] showed that a comparison between air leakage readings measured in field conditions and those calculated based on laboratory measurements showed significant differences.

The joint width and, accordingly, the volume of the joint are important factors when considering the use of expanding polyurethane foam to achieve airtightness of these connections. Although more foam is used for wider joints, the pressure during foam expansion is expected to be higher in the case of a smaller volume. This can be systematically seen from our measurements, where the 10 mm-wide joints performed significantly better for all surface types. The variation of the measured air leakages along with the failure rate during repetitive testing was always higher with a 30 mm joint width compared to a 10 mm joint. The effect of long-term expansion and periodic movement of the building elements has to be further studied, as a larger joint width with the same elasticity can withstand larger movements. It is shown that PU foams are prone to fast chemical degradation [

20], which changes the mechanical properties of the foam. In this study, the measurements were carried out within a few months after the foam was applied, and the effect of ageing and chemical degradation was not considered.

Different foam products were compared in this study, and although our detailed analysis within subgroups of different lath surfaces and joint widths indicated some differences between specific foam products in some cases, statistically significant differences were not found. It has to be noted that top-of-the-line high-quality polyurethane foams from each producer applied by skilled workers in a laboratory setup were measured in this study. The skill level of the workers and real-life application conditions can significantly influence the performance of different foams and cause higher air leakages compared to those measured in the laboratory, although this has to be further studied.