Abstract

The low flexural strength and high brittleness of cement-based materials greatly compromise their safety, durability, and service life. In situ polymerization is a promising strategy for enhancing the toughness of cement-based materials. However, the underlying mechanisms responsible for this mechanical improvement remain insufficiently understood. This study introduces acrylamide (AM) monomer into a cement matrix, where in situ polymerization forms a strong polymer–cement network, demonstrably enhancing mechanical performance. The factors influencing this mechanical enhancement were investigated across multiple scales using techniques including nanoindentation, crack width measurement, solid-state silicon nuclear magnetic resonance (29Si NMR), thermogravimetric analysis (TGA), and so on. This research confirms that in situ polymerization influences silicate chain length (from 3.405 to 3.714) and pore structure at the nanoscale, modifies the morphology of hydration products, enhances the hardness of the interfacial transition zone (0.025 ± 0.002 to 0.055 ± 0.004 GPa) at the microscale, and reveals that at monomer concentrations below 1 wt%, both the compressive and flexural strengths of the cement-based material are improved, with 28d compressive and flexural strength increasing by 23.86% and 26.58%, respectively. Conversely, higher monomer dosages lead to a simultaneous reduction in both compressive and flexural strengths. Consequently, through tracking the hydration process on the mechanical properties of cement-based materials across multiple scales, this study provides deeper insights into the in situ polymerization system and offers an effective strategy for the design and preparation of high-performance concrete.

1. Introduction

Owing to their exceptional compressive strength and low cost, cement-based materials have become the most widely used construction materials in the world [,,,]. However, their intrinsic quasi-brittle characteristics are detrimental to structural safety, durability, and service life [,,]. This brittleness comes from their complex microporous structure and weak chemical bonding at the nanoscale []. When subjected to stress, the lack of an effective energy dissipation pathway allows microcracks to readily propagate and coalesce, finally leading to destructive structural failure.

To improve the toughness of cementitious materials, various modification technologies have emerged [,]. Among them, polymer modification has proven to be an effective strategy for enhancing the toughness and improving the fracture behavior of cement-based materials by introducing an organic phase into the inorganic matrix [,]. Polymers are typically used in the form of latexes, emulsions, or redispersal powders, such as styrene-butadiene rubber (SBR), polyvinyl acetate (PVA), ethylene-vinyl acetate copolymer (EVA), and acrylics [,]. Commonly employed and easily operable cement–polymer paste mixing methods include directly blending the cement with polymers acting as binders or additives, or immersing the hardened cement paste into a polymer solution. However, this simple physical addition and blending method possesses numerous drawbacks, which prevent the optimized adjustment of the performance of the modified concrete. To improve the dispersion of polymers and enable the formation of an interconnected, continuously reinforcing network within the cement matrix, water-soluble polymers or their blends have been incorporated, such as epoxy resins [,], polyacrylates [], as well as their copolymers and mixtures with other types of latexes. However, when a polymer solution is added, a higher dosage can lead to retarded setting, a lower degree of hydration, and thus limited reinforcing effects. In the case of polymer emulsion addition, the organic polymer phase, with a size ranging from 10 to 500 μm, introduces “macro-defects” into the cement matrix. Moreover, the larger the polymer phase size, the more pronounced the weakening effect on strength becomes. As a result, current polymer toughening strategies for concrete generally come at the expense of reduced compressive strength.

Among existing polymer modification technologies, in situ polymerization modification has recently demonstrated several advantages due to its unique action mechanism [,]. Unlike traditional physical incorporation of pre-synthesized polymer emulsions or resins, this method introduces monomers, initiators, and other components directly into the cement paste. During or at specific stages of the cement hydration process, polymerization of the monomers is initiated within the matrix simultaneously, thereby constructing an organic polymer network []. This in situ pathway overcomes issues such as poor dispersion and weak interfacial binding often occurring with traditional emulsion mixing. It promises a more uniform three-dimensional distribution of the polymer phase and forms stronger bonding with hydration products [,]. Recent studies have confirmed that this intrinsic bonding process can lead to enhancement on mechanical performance, especially the flexural strength. This pathway can fundamentally change their failure mode from a typical brittle fracture to a ductile fracture exhibiting an obvious yield plateau, sustained strain hardening, and considerable deformation capacity [,]. This qualitative change in macroscopic mechanical behavior strongly suggests the formation of a new microstructure and effective mechanisms within the material. Hence, there is an urgent need for in-depth analysis from multiple perspectives.

Despite many published studies on the enhancement mechanisms by in situ polymerization, the current understanding still remains at the level of qualitative or semi-quantitative descriptions [,]. For instance, Shao et al. [] studied the relationship between cement hydration and the polymerization process, suggesting that the timing of polymerization process happened during the hydration and can be controlled. Xu et al. [] observed that the introduction of in situ polymerization alters the morphology of cement hydration products, which become enveloped or covered by polymer, resulting in blurred contours and edges compared to the control group. Chai et al. [] investigated changes in the pore structures by in situ polymerization, concluding that the polymerization process can refine pores and reduce porosity.

Although researchers have conducted some studies on the mechanisms of enhanced mechanical properties from in situ polymerization, most literature either focuses on characterizing macroscopic mechanical properties or is limited to observations at a specific microscale. Systematic research on different scales of the enhancement process are still lacking. It is hard to establish clear links between mechanical performance at various scales. The toughness enhancement induced by in situ polymerization is the result of synergistic evolution between multiple scales. To systematically elucidate the mechanical enhancement mechanisms imparted by in situ polymerization on cement-based materials, a multiscale investigation was conducted. The influence of the polymerization process on the hydration reaction was probed at the molecular level using 29Si nuclear magnetic resonance (NMR), Fourier transform infrared spectroscopy (FTIR), isothermal calorimetry, and mercury intrusion porosimetry (MIP). At the microscale, the microstructural evolution was characterized by scanning electron microscopy (SEM) and hardness of hydrates was measured by nanoindentation. The macroscopic performance was evaluated through thermogravimetric analysis (TGA) and mechanical tests. This integrated approach establishes a clear structure–property relationship, linking the evolution of chemical bonds at the nanoscale to the macroscopic mechanical behavior through tracking the hydration process. The results demonstrate that the in situ polymerization promotes the cement hydration, reduces porosity, and enhances the macroscopic mechanical properties. This not only helps us understand the toughening mechanism of in situ polymerization but also provides a theoretical and experimental basis for better design and optimization of future high-performance, high-toughness cement-based materials.

2. Materials and Methods

2.1. Materials

Ordinary Portland cement P⋅II 52.5, supplied by Jiangsu Helin Cement Co., Ltd., Zhengjiang, China, was used to prepare the cement paste, The density is 3.11 g/cm3 and the specific surface area is 3970 cm2/g. The chemical compositions of the cement particles were measured by the X-ray fluorescence (XRF) method, and the results are listed in Table 1. Acrylamide (AM, Purity: ≥99%, lot number: A108465), ammonium persulfate (APS, Purity: ≥98%, lot number: A112448), and polyacrylamide (PAM, Mn: ~8,000,000, lot number: P1103930) were purchased from Aladdin Reagent Co., Ltd., Shanghai, China.

Table 1.

Phase composition of standard cement.

2.2. Preparation of the Polymer Modified Cementitious Composite Material

AM was incorporated into cement at concentrations of 0%, 0.5%, 1%, 2.7%, 5%, and 10% by weight of cement, with a constant water-to-cement ratio of 0.4. To initiate the polymerization reaction during cement hydration, APS was added as an initiator at 0.8 wt% relative to the monomer mass. APS was first dissolved in tap water and stirred for 5 min to prepare the initiator solution, designated as Solution B. Meanwhile, the monomer was dissolved in water to form Solution A. Solution A was initially mixed with cement and stirred for 3 min. Subsequently, Solution B was added, and stirring continued for an additional minute. The mixture was then transferred to a blender to obtain a homogeneous cement slurry.

2.3. Sample Preparation for the Measurement of Crack Width and Nanoindentation

The sample observation surface was initially ground flat using sandpaper. Presi epoxy resin (00042020) and epoxy catalyst (0042010) were mixed according to the specified ratio, and the mixture was degassed under vacuum to remove bubbles. The sample was then immersed in the epoxy resin and cured for 24 h. After curing, the sample was ground with sandpaper until the target surface was exposed. Subsequently, the sample was ultrasonically cleaned. A three-step polishing procedure was then performed using 9 µm, 3 µm, and 1 µm polishing pastes at a rotational speed of 150 rpm and an applied pressure of 18–25 N. During polishing, kerosene was continuously dripped for lubrication at a rate of one drop every 2 s. Each polishing step was continued until no significant change was observed on the sample surface. Between each change of polishing paste, the sample was thoroughly cleaned in an ultrasonic cleaner. After polishing, the sample was dried in a vacuum oven for 48 h.

2.4. Compressive Strength and Flexural Strength Test

For compressive strength testing, a 40 mm × 40 mm × 40 mm cement mortar was prepared and water cured at 20 °C. Place these mortars in a universal testing machine and load them at a speed of 2.4 kN/s. The failure point was set when the load decreases by 10%. Flexural strength was tested by three-point bending test. The mortars were water cured and fixed at 160 mm × 40 mm × 40 mm. The span for each test is 120 mm and the loading rate is 50 N/s.

2.5. Characterizations

The heat flow of the cement paste was monitored using a microcalorimeter (I-Cal 8000HPC, Calmetrix, Boca Raton, FL, USA). Fourier transform infrared (FTIR) spectroscopy was performed on a Nicolet 370 spectrometer (Thermo Nicolet, Waltham, MA, USA). The morphology of the specimens was examined using a scanning electron microscope (SEM, Quanta 250, FEI, Hillsboro, OR, USA) at an accelerating voltage of 20 kV. To halt hydration, the mortar samples were crushed and immersed in ethanol for 24 h at specific curing ages, followed by drying in a vacuum oven at room temperature. Thermogravimetric analysis (TGA) was conducted on a TGA 550 instrument (TA Instruments, New Castle, DE, USA) at a heating-up rate of 10 °C/min under N2 atmosphere. The derivative thermogravimetry (DTG) curve was directly derived from the TGA data by calculating the first derivative of mass with respect to time (DTG = dm/dt). Nanoindentation testing was carried out with a TI-750L instrument (Hysitron, Bruker, Karlsruhe, Germany) and performed by making scratches, each 300 μm in length, on the sample surface. A total of 350 data points were collected per scratch, and three parallel scratches were tested on a single sample. The hardness of the sample was calculated based on the scratch depth and the instrument parameters. Statistical analysis was then conducted to obtain the frequency distribution of the sample hardness. Mercury intrusion porosimetry (MIP) measurements were performed on an AutoPore IV 9620 (Micromeritics, Norcross, GA, USA). Solid-state 29Si nuclear magnetic resonance (NMR) spectra were acquired on a Varian Infinityplus-400 spectrometer (Varian, Palo Alto, CA, USA).

3. Results and Discussions

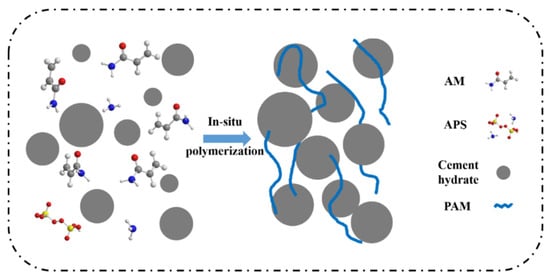

The schematic of the in situ polymerization reaction of AM is presented in Figure 1. Prior to the cement hydration, the monomer was mixed to achieve a homogeneous distribution. After that, a certain amount of initiator was introduced to the matrix for the initiation of the polymerization. The polymerization reaction was subsequently triggered alongside hydration, leading to the formation of a PAM network that connects and binds the hydration products [].

Figure 1.

Schematic illustration of polymerization reaction.

3.1. Verification and Characterization of the In Situ Polymerization Process

3.1.1. Retarding Effect of In Situ Polymerization on the Hydration Heat

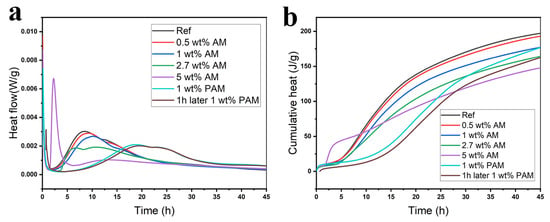

To understand the influence of introduced in situ polymerization on the cement hydration process, we compared the heat release curves before and after their addition. As shown in Figure 2a, it can be observed that when the AM dosage is 0.5–1 wt%, it has almost no effect on the initiation time (~1.32 h) of the hydration acceleration period. However, increasing the dosage to 2.7 wt% delays the onset (~3.29 h) of the acceleration period. When increasing the dosage of AM, the height of the hydration exothermic peak decreases and the time to the hydration peak increases, which is in agreement with other studies []. The peak height is obviously reduced at a 2.7 wt% dosage compared with 0.5 wt% dosage. For the two samples where PAM was added directly without in situ polymerization, the hydration peak is noticeably shifted later, and the height of the peak is also greatly reduced. A comparison of the position of the hydration peaks for different samples is as follows: Blank sample: 8.27 h; 0.5 wt% AM: 9.19 h; 1 wt% AM: 10.1 h; 2.7 wt% AM: 10.7 h; 5 wt% AM: 12.05 h; 1 wt% PAM (directly added): 18.5 h; 1 wt% PAM (delayed addition): 19.4 h. Based on this, it is clear that samples with in situ polymerization exhibit a delaying effect on cement hydration and PAM has a direct retarding effect on cement hydration compared to AM. Furthermore, it is easy to find the heat release peak from the polymerization process. In the sample with 2.7 wt% AM, two peaks appear: the earlier one is the peak of the polymerization, and the later one is the hydration peak. The peak area ratio between polymerization and hydration over 24 h is 23:77, suggesting that the heat generated by polymerization is less than that from hydration and hydration remains the dominant reaction during this period. This phenomenon is also found in the 5 wt% AM dosage, where the polymerization exothermic peak appears earlier at 2.5 h. This confirms that the polymerization occurs after mixing with the cement sample. In terms of the total heat released over 50 h (Figure 2b), ranked from highest to lowest, the order is as follows: Blank reference sample, 0.5 wt% AM, 1 wt% PAM, 1 wt% AM, 1 wt% PAM (delayed addition), 2.7 wt% AM, 5 wt% AM. Since calcium ions can react with the amide groups in AM, reducing the concentration of free calcium ions in the aqueous phase and thereby retarding cement hydration. Simultaneously, the newly formed PAM film may encapsulate cement particles, hindering their contact with external water and further limiting the dissolution and hydration of the cement particles. Therefore, adding AM to the reaction system consistently imparts a retarding effect on hydration. However, by controlling the monomer concentration and dosage, the impact on the hydration of cement particles can be minimized.

Figure 2.

The effect of in situ polymerization on hydration heat. (a) Heat release curves; (b) Cumulative heat release.

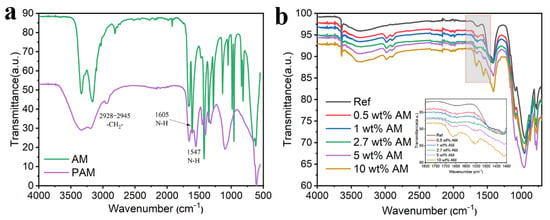

3.1.2. In Situ Polymerization Process Evidenced by FTIR

To further demonstrate that the AM monomer undergoes polymerization within the cement system, this study employed Fourier transform infrared spectroscopy (FTIR) to monitor changes in the infrared spectra of the hydration products in the cement hydration environment. Figure 3a presents the FTIR spectra of pure AM and PAM, with the chemical groups corresponding to the peak positions annotated in the figure. It is notable that the formation of PAM is identified by the characteristic peaks of the methylene group around 2945–2928 cm−1 and the N-H bending vibration peak at 1547 cm−1 []. Figure 3b displays the FTIR spectra of hydration products after the in situ polymerization of monomers at different concentrations. Compared to the blank sample, new peaks clearly appear at 2945–2928 cm−1 and 1547 cm−1 in the modified samples, indicating the formation of PAM. Simultaneously, no characteristic peak is observed at 1605 cm−1, suggesting that the AM monomer is absent in the final hydration product system. This further confirms that the AM monomer polymerized within the cement hydration environment.

Figure 3.

The FTIR spectrum of the in situ polymerization modified cement paste. (a) Pure AM and PAM; (b) Hydration products after the in situ polymerization.

3.2. Influence of the In Situ Polymerization on Cement Hydration at Nanoscale

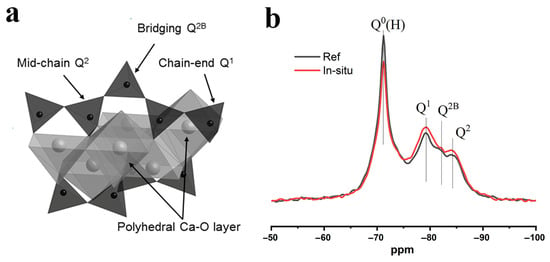

3.2.1. Increased Silicate Polymer Chain Length Through In Situ Polymerization

To understand the effect of in situ polymerization on cement hydration at the nanoscale, we compared the solid-state 29Si NMR data (Figures S1 and S2) under two conditions. Here, Q0 represents a silicon atom with no connected silicon atoms, corresponding to an isolated silicate tetrahedral structure. Q1 denotes an end-group silicon atom in a chain, while Q2 and Q2B both represent middle-group silicon atoms within the chain, as illustrated in Figure 4a. The in situ polymerization of AM (1 wt%) significantly altered the nanostructure of the silicate chains in the cement paste, as revealed by the normalized 29Si NMR spectra (Figure 4b, Table 2). An obvious reduction in Q0 content was observed, suggesting an accelerated consumption of unhydrated silicate phases []. At the same time, the relative proportions of Q1 and Q2 species increased. This shift in the Qn distribution directly indicates an increase in the mean chain length (MCL, from 3.405 to 3.714) of the C-S-H gel and a higher overall degree of hydration (from 46.44% to 54.70%), confirming that the polymer promotes the hydration process and modifies the microstructure of the primary hydration product.

Figure 4.

29Si NMR spectrum of the blank and in situ polymerization modified cement hydrates. (a) Illustration of the Q0–Q2 species; (b) 29Si NMR spectrum.

Table 2.

Relative abundance of the Q0–Q3 species integrated from 29Si NMR.

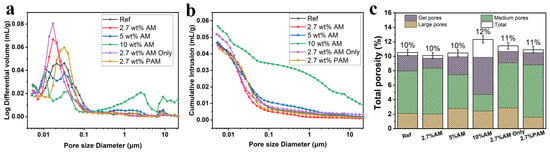

3.2.2. Refined Pore Structures Through In Situ Polymerization

A study on the influence of different dosages of AM, PAM, and in situ polymerized AM on the microstructure of cement mortar was conducted using MIP. Compared to the in situ polymerized AM system, the direct addition of PAM did not markedly increase the total pore volume, but it resulted in relatively larger pore sizes. Figure 5c and Table 3 summarize the proportions of gel pores (5–10 nm), medium pores (10–60 nm), and large pores (60 nm–10 μm). A notable finding is that the sample with 10 wt% in situ polymerized AM exhibited an increase in large pores and total pore volume. In the in situ polymerization system, as the monomer dosage increased, the volume of medium pores showed a clear decreasing trend, while the volume of gel pores increased. This is because when AM monomers undergo in situ polymerization within the cement matrix, the resulting PAM forms a continuous gel-like film or a three-dimensional network structure. This PAM gel can directly fill larger capillary pores and air voids. More importantly, these polymer films and networks can encapsulate cement hydration products (such as ettringite (AFt) and C-S-H gel), binding them together more tightly and thus the pore structure was refined. The increase in small pores arises from the filling of medium pores by the PAM gel and the formation of a new organic–inorganic interfacial transition zone between the PAM network and the cement hydration products. As a result, the in situ polymerization system can effectively modify the pore structure by filling medium pores and binding smaller pores between larger ones. This refinement can greatly contribute to the enhancement of the mechanical properties.

Figure 5.

The influence of in situ polymerization on the pore structures. (a) Pore size distribution curves; (b) Cumulative pore volume; (c) The fractal characteristics of pore size distribution.

Table 3.

Quantitative data from the MIP test of different AM dosages.

3.3. Influence of the In Situ Polymerization on Cement Hydration at Microscale

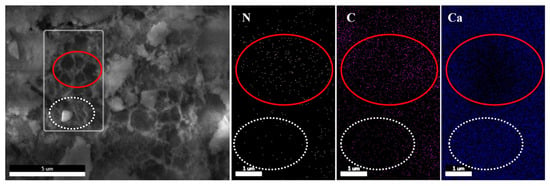

3.3.1. Polymer Network Formed by In Situ Polymerization

Figure 6 shows the SEM image of the hydration products of cement under the condition of in situ polymerization. The image reveals the formation of a connected region surrounding the hydration products. Energy-dispersive X-ray spectroscopy (EDS) mapping was performed on this area. Since it is located within a concave region of the sample, the intensity of the electron signal was relatively low. By careful observation of the element distribution maps, both element N and C (main elements in AM) show detectable signals within the red circle on the image, while the Ca (element in hydrates) signal is relatively weak. Conversely, within the blue circle, a distinct hydration product is clearly observed in the SEM image and the Ca signal is strong, while the signals for N and C are both weak in the element distribution maps. These observations confirm that the in situ polymerization formed a spatial polymer network structure among the cement hydration products.

Figure 6.

SEM image and EDS mappings of the polymer–hydrates network. The red and white circles mark the polymer-rich and hydrate-rich areas, respectively.

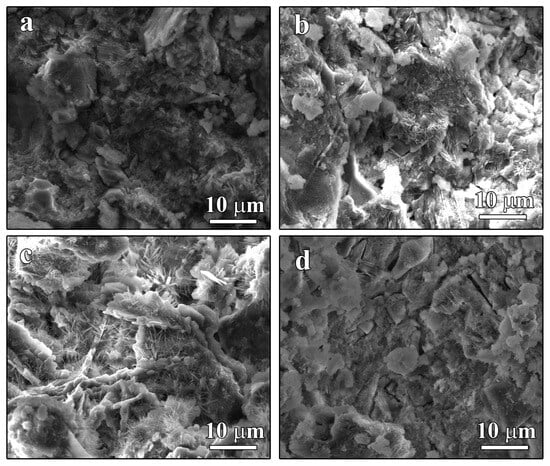

3.3.2. Modified Morphology of Hydration Products by In Situ Polymerization

Figure 7 shows the SEM images of cement paste incorporated with different dosages of AM. The hydration products in the plain paste exhibit distinct angular morphologies (Figure 7a), whereas the incorporation of AM leads to the appearance of sharp, needle-like products (Figure 7b,c) []. This suggests that with the addition of AM, C-S-H tends to form a structure with a longer dimension, which is consistent with the observation in 29Si NMR (increased length of silicon chain). The modification in the morphology of the hydration products indicates that AM copolymers may influence the crystallization process of C-S-H, revealing an interaction between the AM copolymers and the cement hydration products. Furthermore, at low AM dosages, angular portlandite (CH) crystals remain detectable within the hydration products. When the AM dosage reaches 2.7 wt%, a continuous gel-like film can be observed covering and encapsulating the hydration products, whose edges simultaneously become blurred. This phenomenon is more obvious in samples where PAM is directly added, presenting a structure with corroded edges. From the SEM analysis, it can be concluded that the polymer covers the hydration products’ surfaces, thereby modifying the morphology and packing arrangement of both CH and C-S-H.

Figure 7.

SEM images of the in situ polymerization cement. (a) ref; (b) 1 wt% AM; (c) 2.7 wt% AM; (d) 2.7 wt% PAM.

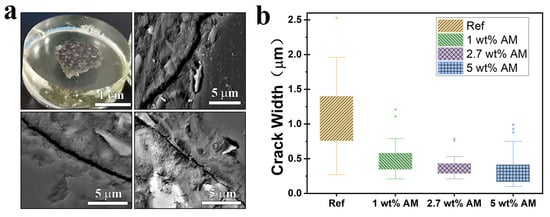

3.3.3. Decreased Crack Width Through In Situ Polymerization

In addition, we conducted measurements on the crack width around the mortar aggregates under different conditions. Figure 8a presents the appearance of the prepared samples and SEM images of cracks under different AM dosages. Figure 8b shows the statistical results of the crack widths for different samples and the width of each crack was measured 60 times. The cement sample without the in situ polymerized AM system exhibited significantly larger crack widths. However, with the addition of the in situ polymerized AM system, the crack width was markedly reduced, decreasing from 1.16 ± 0.81 µm (97% CI) to 0.49 ± 0.29 µm (95% CI). Moreover, as the AM concentration increased, the crack width could be further reduced. This experiment provides additional evidence that the in situ polymerization system enhances the interfacial bonding strength and contributes to pore filling.

Figure 8.

Crack width of the prepared cement mortar. (a) The appearance of the prepared samples and SEM images of cracks; (b) Statistical results of the crack widths.

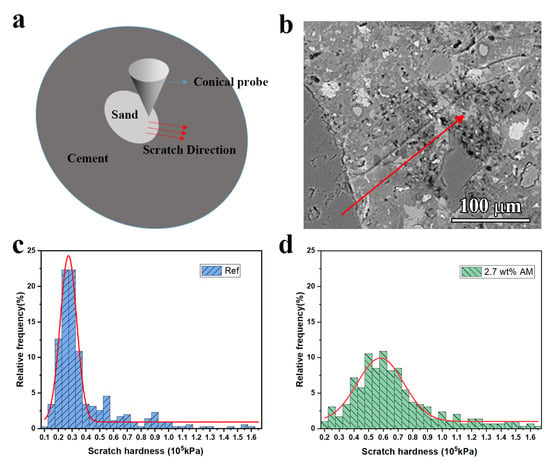

3.3.4. Increased Hardness by In Situ Polymerization

The nanoindentation experiments were conducted to analyze the influence of in situ polymerization on the micro-mechanical properties and calculated the scratch hardness using the ratio of the indentation load to the projected contact area []. The calculated scratch hardness distribution is shown in Figure 9. The results indicate that, after in situ polymerization modification, the scratch hardness distribution of the interfacial transition zone within the sample becomes more dispersed compared to the unmodified sample. Meanwhile, the peak value in the hardness distribution increased from 0.25 ± 0.02 × 105 kPa to 0.55 ± 0.04 × 105 kPa, indicating an enhancement in the overall hardness of the interfacial transition zone at the microscopic scale. The improvement can be attributed to the network structure formed by PAM and the hydration products, which acts like a microscopic “reinforcement net” woven within the cement matrix. This net effectively transfers and disperses localized indentation loads, demonstrating a greater resistance to deformation during nanoindentation testing. When the indenter presses into the material, the polymer chains with high ductility deform to absorb energy and inhibit the propagation of microcracks. Hence, the hardness of the interfacial transition zone was greatly increased.

Figure 9.

Hardness of in situ polymerization modified mortar. (a) Scheme of the nanoindentation; (b) SEM image of the area where nanoindentation was performed; (c,d) Frequency histogram of scratch hardness.

3.4. Influence of the In Situ Polymerization on Cement Hydration at Macroscale

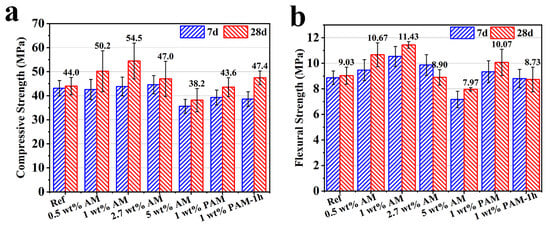

3.4.1. Enhanced Compressive and Flexural Strength

Figure 10 shows the effect of AM dosage on the mechanical strength of cement paste. The incorporation of AM at a certain dosage led to an improvement in both the compressive and flexural strengths of the test specimens. As shown in Figure 10a, the sample with 1 wt% AM achieved a 28d compressive strength of 54.5 ± 7.45 MPa, which is approximately 23.86% higher than that of the reference group (44 ± 3.62 MPa). This enhancement in compressive strength is attributed to the tougher interfacial bonding resulting from the reaction between cement and in situ polymerized AM. Simultaneously, the polymer films connect hydration products, forming a cohesive structure, and can inhibit the development of microcracks under compressive loading, thereby increasing the compressive strength. However, when the AM dosage reached 5 wt%, the specimens exhibited the lowest compressive and flexural strengths. This is because the excessively intense polymerization reaction of AM (evidenced by the exothermic peak in Figure 2a) can entrap air bubbles into the matrix. In addition, the rapidly formed polymer itself can create structural defects within the system (Figure S3), consequently reducing the compressive strength. As the AM dosage increased from 1 wt% to 5 wt%, the compressive strength showed a slight decreasing trend. In contrast, the direct addition of PAM and the delayed addition of PAM did not show obvious enhancement (strength levels similar to the reference sample). Notably, the sample with 1 wt% in situ polymerized AM not only showed a modest increase in compressive strength, but also an improvement in flexural strength. Its 28d flexural strength increased from 9.03 ± 0.67 MPa (reference) to 11.43 ± 0.27 MPa, representing an increase of 26.58%. Specimens with AM dosages greater than 1 wt% experienced a decrease in flexural strength, which can be attributed to their inhibition of early-age hydration []. Therefore, establishing an in situ polymerization system within the cement matrix requires strict control over the polymer concentration to achieve optimal strengthening effects.

Figure 10.

The influence of in situ polymerization on the mechanical properties of mortar. (a) Compressive strength; (b) Flexural strength.

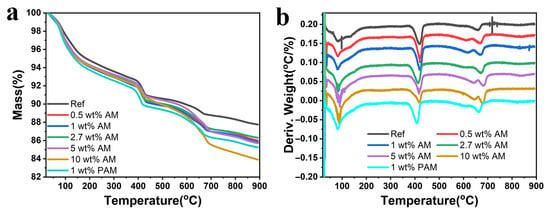

3.4.2. Increased Amount of Hydration Products Through In Situ Polymerization

Figure 11 shows the mass loss temperature curves of the samples after 28 days of curing. It can be observed from the figure that for all samples, the decomposition temperature of Portlandite (CH) ranges from 380 °C to 450 °C. As the AM content increases, the decomposition temperature of CH shifts towards lower temperatures (leftward direction), indicating a reduction in the thermal stability of the polymer-modified cement paste. This phenomenon can be attributed to the weak thermal stability of the AM copolymer itself compared to cement hydration products. In the temperature range of 600–800 °C, calcium carbonate decomposes. Notably, the decomposition temperature also advances for the sample with directly added PAM, which is because the introduction of PAM inhibits the complete growth of calcium carbonate crystals, leading to the formation of smaller crystals with more crystalline defects. Such smaller and defective crystals exhibit lower thermal stability. To quantitatively analyze the change in CH content after incorporating AM, TGA curve was used to calculate the total CH content. The total CH content was calculated from the TGA curves using the following Formula (1):

Figure 11.

TGA and DTG curves of ref and in situ polymerization modified mortar. (a) TGA curves; (b) DTG curves.

Here, represents the mass loss percentage of calcium hydroxide, while and are the relative molecular masses of CH and water, respectively. Considering that PAM itself undergoes mass loss in this temperature range, the mass of PAM resulting from the assumed complete polymerization of all added AM was subtracted within this interval. The calculated data of the CH content and AM concentration is listed in Table 4. From the corrected data in the table, when the monomer dosage was 0.5 wt% and 1 wt%, the mass loss rate of CH was greater than that of the plain sample, indicating the promotion of the hydration process at a low dosage of AM []. However, when the monomer dosage was too high, or when the directly added PAM dosage was excessive, the CH content significantly decreased. This is because AM monomers or oligomers can coordinate or adsorb the calcium ions (Ca2+) in the solution through their amide groups (-CONH2). This interaction could influence the migration, crystallization, or precipitation behavior of Ca2+ in local environments. It might change the chemical pathway of hydration product formation, which may potentially benefit the formation or preservation of CH under certain conditions. Conversely, when the AM dosage is too high (5 wt% or 10 wt%), the newly formed polymer film may excessively hinder the contact between water and cement particles, greatly inhibiting the overall hydration reaction. This leads to a reduced formation of all hydration products, including CH. The experimental results once again demonstrate that in an in situ polymerization system, the monomer concentration should be strictly controlled to minimize its negative impact on cement hydration.

Table 4.

CH content of 28d hydration products against the AM dosage.

3.5. Discussions

This study, through multiscale experimental techniques, reveals the intrinsic unified mechanism linking molecular structural evolution to macroscopic performance enhancement in cement-based materials. The key lies in the progression of hydration degree, a process that serves as a common thread connecting and tightly integrating all observed scales. At the molecular/nano scale, nuclear magnetic resonance (NMR) results directly capture the core chemical process of hydration: as hydration proceeds, the polymerization degree of the silicate chains continuously increases. This signifies longer silicate chains and a higher cross-linking density, essentially forming a stronger and more stable calcium silicate hydrate (C-S-H) gel framework. This nano scale structural strengthening effect is directly reflected in the micro-mechanical properties. Nanoindentation tests demonstrate a significant enhancement in material hardness. This is precisely because the C-S-H gel with a higher polymerization degree, as revealed by NMR, forms a denser and tougher nanostructure. When this matrix bears local indentation loads, it can more effectively resist plastic deformation and crack initiation. The micro-mechanical enhancement, driven by optimized molecular structures, turns out to have superior mechanical performance at the macroscopic scale. The simultaneous increase in flexural and compressive strengths is the result of the synergistic action of countless dense C-S-H gel matrix, together with other hydration products at the microscale, forms a composite system with a higher load-bearing capacity and fewer defects.

It is noteworthy that the increased content of calcium hydroxide (CH) and decreased porosity within the hydration products provides critical corroborating evidence and driving force for this entire chain. As a primary product of cement hydration, the increase in CH content is a direct chemical indicator of the hydration reactions. It ensures the continuous formation of C-S-H gel and polymerization of silicate chains.

In situ polymerization technology demonstrates significant potential in practical applications for enhancing concrete performance. Its core advantage lies in the direct formation of a uniformly distributed organic–inorganic interpenetrating network structure within the cement matrix through monomer polymerization, thereby achieving the goals of improved toughness and optimized microstructure. The method offers practical implementation benefits: monomer solutions can be directly added during the concrete mixing stage without requiring complex special equipment, ensuring compatibility with existing construction processes. Moreover, by selecting different monomers and adjusting the initiator ratio, the rheological properties, flexural strength, and durability of concrete can be tailored for specific needs. However, practical application faces several challenges: (1) The polymerization reaction is sensitive to environmental factors such as temperature and humidity, where low temperatures may lead to incomplete reaction, while high temperatures could trigger uncontrolled polymerization, adversely affecting the concrete’s microstructure. (2) In engineering applications, cost-related factors must be comprehensively evaluated. (3) Ensuring long-term stability requires precise control over the polymerization process and the judicious selection of monomers to mitigate the risks of polymer chain hydrolysis or degradation, as well as the formation of microcracks induced by wet–dry cycles or freeze–thaw actions. Therefore, although in situ polymerization offers outstanding advantages in toughening concrete, its large-scale application still depends on precise control of reaction conditions and optimization of material design.

4. Conclusions

By adding the monomer AM and initiator into the cement matrix, the in situ polymerization was successfully introduced to the cement-based materials. Experimental results indicate that the introduction of AM-based in situ polymerization system into cementitious materials facilitates the formation of an organic–inorganic network structure. This structure, in turn, significantly influences the cement hydration process and the development of the final microstructure.

- -

- At the nanoscale, it increases the silicate chain length from 3.405 to 3.714 and reduces the volume of mesopores (from 0.0262 to 0.0106 mL/g), thereby refining the pore structure.

- -

- At the micrometer scale, it forms a cross-linked network, reduces crack width from 1.16 ± 0.81 µm (97% CI) to 0.49 ± 0.29 µm (95% CI), and enhances hardness from 0.25 ± 0.02 × 105 kPa to 0.55 ± 0.04 × 105 kPa of the interfacial transition zone.

- -

- At the macroscopic scale, it promotes hydration, increases the content of CH (from 6.74% to 6.95%), and demonstrates certain improvements in both compressive (23.86%) and flexural strength (26.58%).

In summary, from the elongation of silicate chains in NMR to the increase in hardness in nanoindentation, and finally to the enhancement of compressive and flexural strength at the macroscopic level, the observations across the three scales are interconnected through the core driver of hydration degree. The increased content of calcium hydroxide (CH) serves as strong validating evidence for the driver. This establishes a clear structure–property relationship, linking the evolution of chemical bonds at the nanoscale to the macroscopic mechanical behavior. However, the effectiveness of this system is highly dependent on the monomer dosage, with an optimal range identified in this study. Excessive dosage can negatively impact the properties by severely retarding hydration and introducing defects. The systematic investigation into the multiscale synergistic enhancement of mechanical performance through in situ polymerization has advanced the understanding of this system, thereby providing a theoretical foundation for the design and fabrication of high-performance concrete.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/buildings15234246/s1, Figure S1: Full NMR spectra; Figure S2: Representative images for NMR; Figure S3: Defects formed at high dosage of AM.

Author Contributions

L.C. performed the majority of sample preparation, formal analysis, conceptualization, and writing of the original draft and revision. C.L. and J.Z. provided suggestions and ideas. Y.M., Y.H., and Y.C. performed the mortar preparation. M.Q. and X.S. played a role in validation, supervision, and editing. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the financial support from National Natural Science Foundation of China (No. 52308254, 52178215, 52578292, 52178213), Natural Science Foundation of Jiangsu Province (BK20221153).

Data Availability Statement

Data is contained within the article or Supplementary Material.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Christensen, B.J.; Coverdale, T.; Olson, R.A.; Ford, S.J.; Garboczi, E.J.; Jennings, H.M.; Mason, T.O. Impedance spectroscopy of hydrating cement-based materials: Measurement, interpretation, and application. J. Am. Ceram. Soc. 1994, 77, 2789–2804. [Google Scholar] [CrossRef]

- Li, W.; Zhou, Y.; Yin, J.; Peng, Y.; Wang, Y.; Tang, S.; Shi, Y.; Wang, Y.; Wang, L. Thermodynamics-based simulations of the hydration of low-heat Portland cement and the compensatory effect of magnesium oxide admixtures. J. Zhejiang Univ.-Sci. A 2025, 26, 305–319. [Google Scholar] [CrossRef]

- Yu, W.; Zhou, Y.; Zhao, Z.; Li, Y.; Long, Y.; Tang, S. Simulation of low-heat Portland cement permeability and thermal conductivity using thermodynamics. Proc. Inst. Civ. Eng.-Transp. 2025, 178, 404–414. [Google Scholar] [CrossRef]

- Fang, M.; Chen, Y.; Deng, Y.; Wang, Z.; Zhu, M. Toughness improvement mechanism and evaluation of cement concrete for road pavement: A review. J. Road Eng. 2023, 3, 125–140. [Google Scholar] [CrossRef]

- Zhang, X.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- Gettu, R.; García-Álvarez, V.O.; Aguado, A. Effect of aging on the fracture characteristics and brittleness of a high-strength concrete. Cem. Concr. Res. 1998, 28, 349–355. [Google Scholar] [CrossRef]

- Beygi, M.H.; Kazemi, M.T.; Nikbin, I.M.; Amiri, J.V. The effect of water to cement ratio on fracture parameters and brittleness of self-compacting concrete. Mater. Des. 2013, 50, 267–276. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Ming, X.; Zhao, H.; Sun, Z.; Li, Z.; Sun, G. Optimizing concrete performance with polymer-cement networks: Enhanced flexural strength and crack resistance. Mater. Today Commun. 2025, 42, 111068. [Google Scholar] [CrossRef]

- Chen, L.; Li, C.; Ran, Q.; Shu, X. Synthesis of calcium silicate-based nanofibers and its application in cement-based materials. Mater. Lett. 2023, 333, 133589. [Google Scholar] [CrossRef]

- Sakai, E.; Sugita, J. Composite mechanism of polymer modified cement. Cem. Concr. Res. 1995, 25, 127–135. [Google Scholar] [CrossRef]

- Fan, L.; Xu, F.; Wang, S.; Yu, Y.; Zhang, J.; Guo, J. A review on the modification mechanism of polymer on cement-based materials. J. Mater. Res. Technol. 2023, 26, 5816–5837. [Google Scholar] [CrossRef]

- Kardon, J.B. Polymer-modified concrete. J. Mater. Civ. Eng. 1997, 9, 85–92. [Google Scholar] [CrossRef]

- Ohama, Y. Polymer-based admixtures. Cem. Concr. Compos. 1998, 20, 189–212. [Google Scholar] [CrossRef]

- Pang, B.; Zhang, Y.; Liu, G. Study on the effect of waterborne epoxy resins on the performance and microstructure of cement paste. Constr. Build. Mater. 2018, 167, 831–845. [Google Scholar] [CrossRef]

- Pang, B.; Zhang, Y.; Liu, G.; She, W. Interface properties of nanosilica-modified waterborne epoxy cement repairing system. ACS Appl. Mater. Interfaces 2018, 10, 21696–21711. [Google Scholar] [CrossRef]

- Wang, M.; Wang, R.; Zheng, S.; Farhan, S.; Yao, H.; Jiang, H. Research on the chemical mechanism in the polyacrylate latex modified cement system. Cem. Concr. Res. 2015, 76, 62–69. [Google Scholar] [CrossRef]

- Shao, L.; Feng, P.; Liu, Q.; Zhang, Y.; Yu, Z.; Yan, S. In-situ polymerization-modified cement composites: A critical review. Constr. Build. Mater. 2024, 449, 138294. [Google Scholar] [CrossRef]

- Chen, B.; Qiao, G.; Hou, D.; Wang, M.; Li, Z. Cement-based material modified by in-situ polymerization: From experiments to molecular dynamics investigation. Compos. Part B-Eng. 2020, 194, 108036. [Google Scholar] [CrossRef]

- Liu, Q.; Lu, Z.; Hu, X.; Chen, B.; Li, Z.; Liang, R.; Sun, G. A mechanical strong polymer-cement composite fabricated by in situ polymerization within the cement matrix. J. Build. Eng. 2021, 42, 103048. [Google Scholar] [CrossRef]

- Hua, X.; Han, K.; Lin, Z.; Yin, B.; Wang, P.; Qi, D.; Hou, D.; Chen, J. Modification of in-situ polymerization of acrylamide and synergies with fiber in enhancing cement-based composite. J. Build. Eng. 2024, 85, 108605. [Google Scholar] [CrossRef]

- Yin, B.; Qi, D.; Hua, X.; Fan, F.; Han, K.; Hou, Y.; Hou, D.; Chen, B. Mechanical properties and micro-mechanism of cement-based materials strengthened by in-situ organic-inorganic polymerization. Cem. Concr. Compos. 2023, 142, 105202. [Google Scholar] [CrossRef]

- Shao, L.; Liu, X.; Feng, P.; Liu, Q.; Chen, C.; Zhang, Y.; Yu, Z.; Qu, Z. Mechanistic understanding of strength and microstructural evolution of in-situ polymerization modified cement pastes. J. Build. Eng. 2025, 113, 114165. [Google Scholar] [CrossRef]

- Zhang, H.; Yao, S.; Wang, J.; Zhou, R.; Zhu, Y.; Zou, D. Tensile properties of sulfoaluminate cement-based grouting materials toughened by in-situ polymerization of acrylamide. Constr. Build. Mater. 2023, 375, 130885. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, C.; Zhao, L.; Chai, H.; Zhang, H. Study on the toughening of calcium aluminate cement-based grouting materials by in-situ polymerization of acrylamide and the mechanism of toughness change. Constr. Build. Mater. 2025, 469, 140524. [Google Scholar] [CrossRef]

- Demirdag, S. The effect of using different polymer and cement-based materials in pore filling applications on technical parameters of travertine stone. Constr. Build. Mater. 2009, 23, 522–530. [Google Scholar] [CrossRef]

- Shao, L.; Liu, Q.; Wang, H.; Wang, C.; Wang, W.; Hong, J.; Miao, C.; Feng, P. A new strategy to enhance 3D printability of cement-based materials: In-situ polymerization. Addit. Manuf. 2024, 89, 104299. [Google Scholar] [CrossRef]

- Xu, C.; Dai, Y.; Peng, Y.; Wang, J.; Zhang, Z.; Gui, Q.; Zeng, Q. Multi-scale structure of in-situ polymerized cementitious composites with improved flowability, strength, deformability and anti-permeability. Compos. Part B-Eng. 2022, 245, 110222. [Google Scholar] [CrossRef]

- Chai, H.; Liu, S.; Zhao, L.; Tian, Y.; Guo, Z.; Zhang, H. Enhancing sulfate resistance of sulfate-aluminate cement grouting material through acrylamide in-situ polymerization modification. Constr. Build. Mater. 2023, 408, 133799. [Google Scholar] [CrossRef]

- Wu, K.; Long, J.; Qing, L.; De Schutter, G. Recent advance of monomer in-situ polymerization modified cement-based materials. Constr. Build. Mater. 2024, 432, 136542. [Google Scholar] [CrossRef]

- Patel, G.; Sureshkumar, M.B. Preparation of PAM/PVA blending films by solution-cast technique and its characterization: A spectroscopic study. Iran. Polym. J. 2014, 23, 153–162. [Google Scholar] [CrossRef]

- Rejmak, P.; Dolado, J.S.; Stott, M.J.; Ayuela, A. 29Si NMR in cement: A theoretical study on calcium silicate hydrates. J. Phys. Chem. C 2012, 116, 9755–9761. [Google Scholar] [CrossRef]

- Sato, M.; Fujishima, A.; Shibata, Y.; Miyazaki, T.; Inoue, M. Nanoindentation tests to assess polymerization of resin-based luting cement. Dent. Mater. 2014, 30, 1021–1028. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.; Liu, S.; Yao, S.; Gao, X.; Zhang, H.; Zhu, J.; Shen, P.; Guan, X.; Li, H. Influence of acrylamide in-situ polymerization on the mechanical properties and microstructure of OPC-CSA-Cs-FA quaternary system. J. Build. Eng. 2023, 67, 105906. [Google Scholar] [CrossRef]

- Su, Z.; Bijen, J.M.J.M.; Larbi, J.A. Influence of polymer modification on the hydration of portland cement. Cem. Concr. Res. 1991, 21, 242–250. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).