Experimental Analysis of Seismic Behavior of Squat Shear Walls with Different Axial Load Ratios

Abstract

1. Introduction

2. Experimental Program

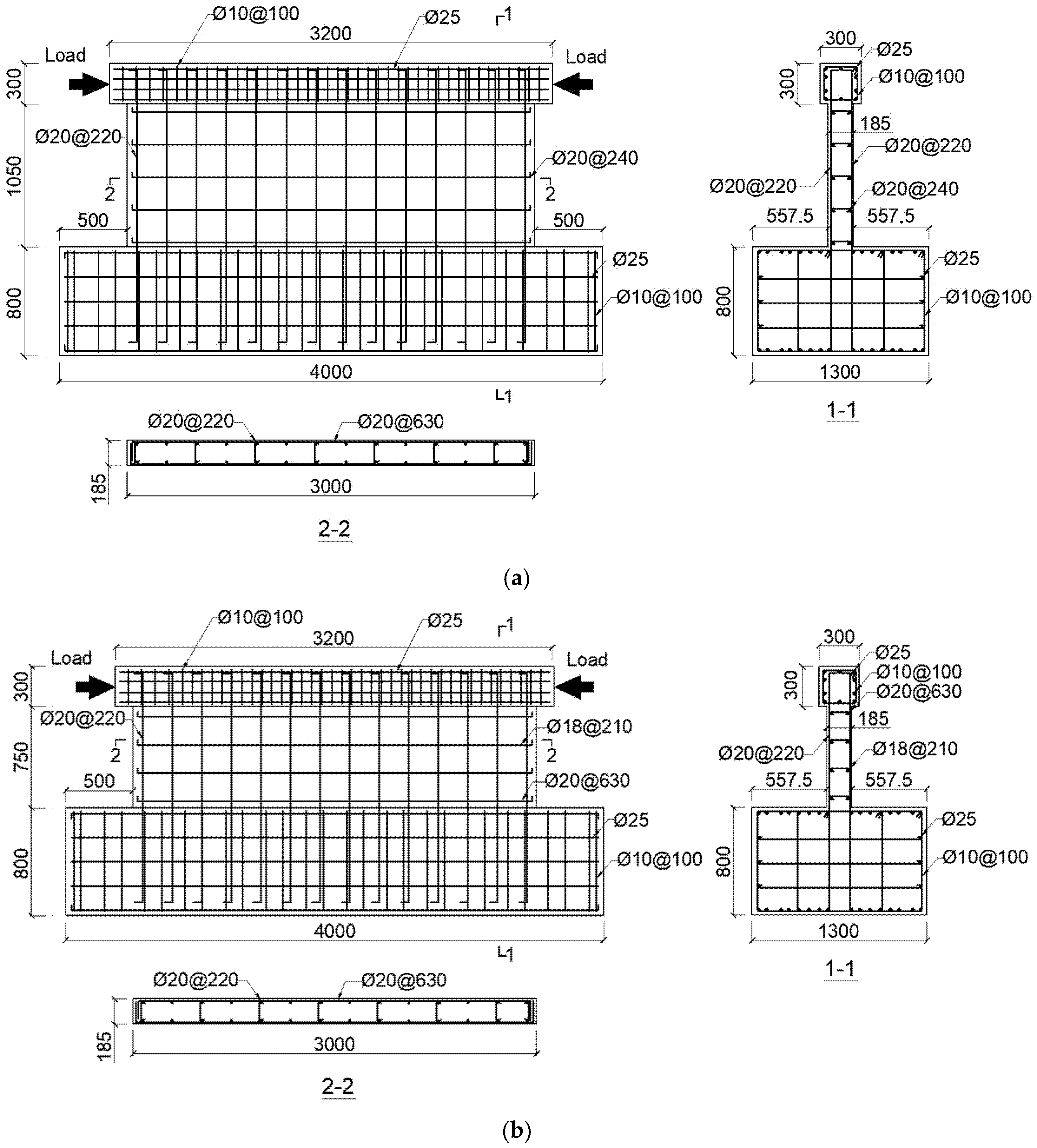

2.1. Specimens

2.2. Materials

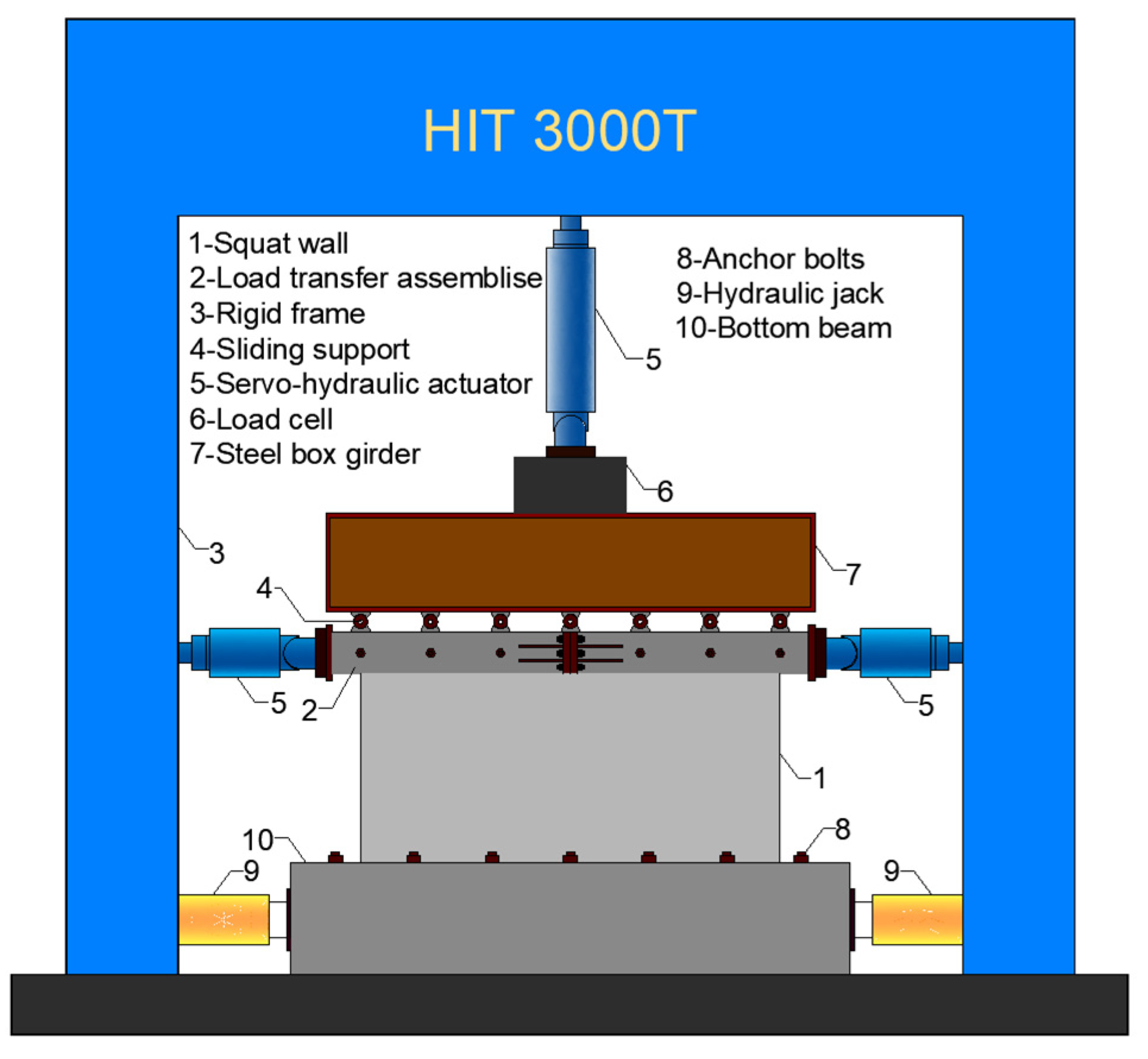

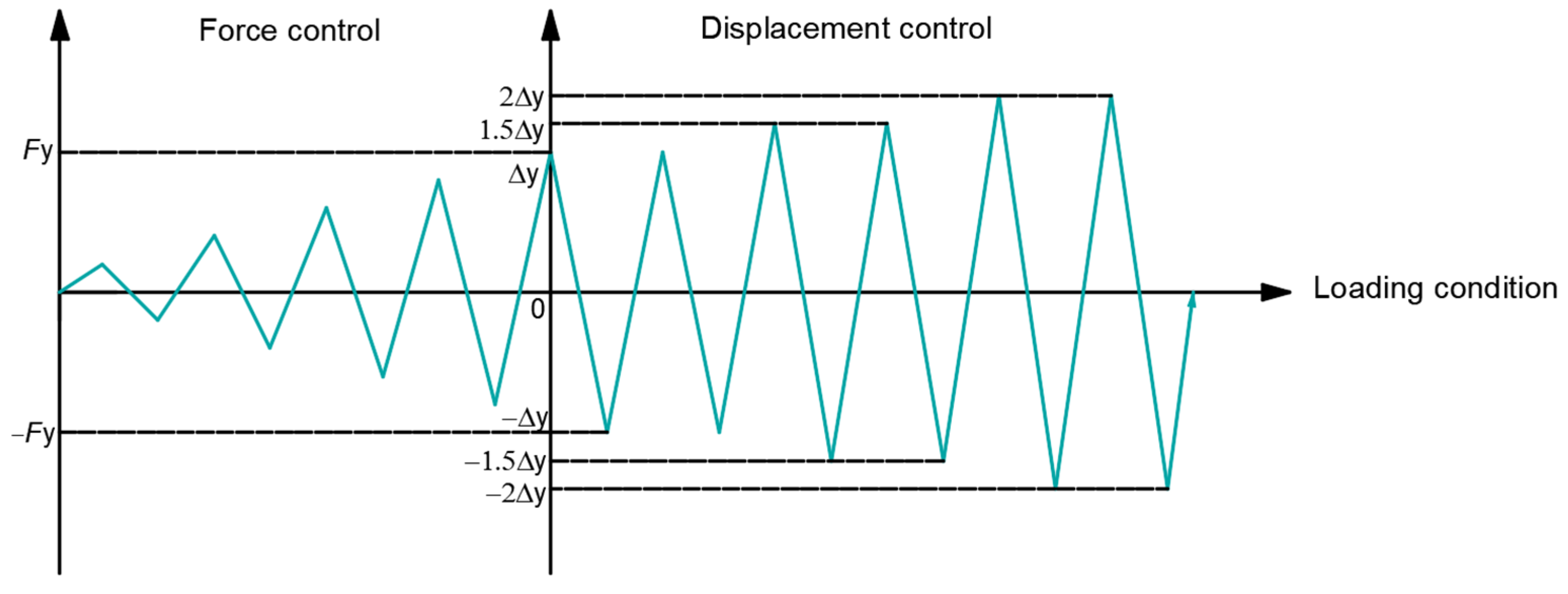

2.3. Loading Procedure and Test Setup

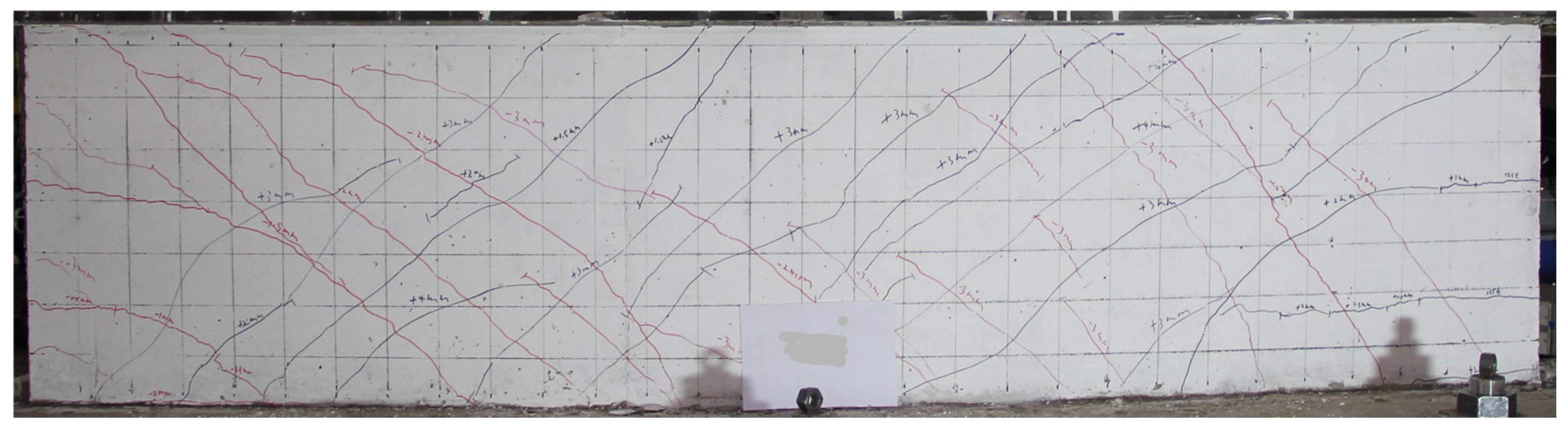

3. Failure Mode

3.1. Experimental Observations

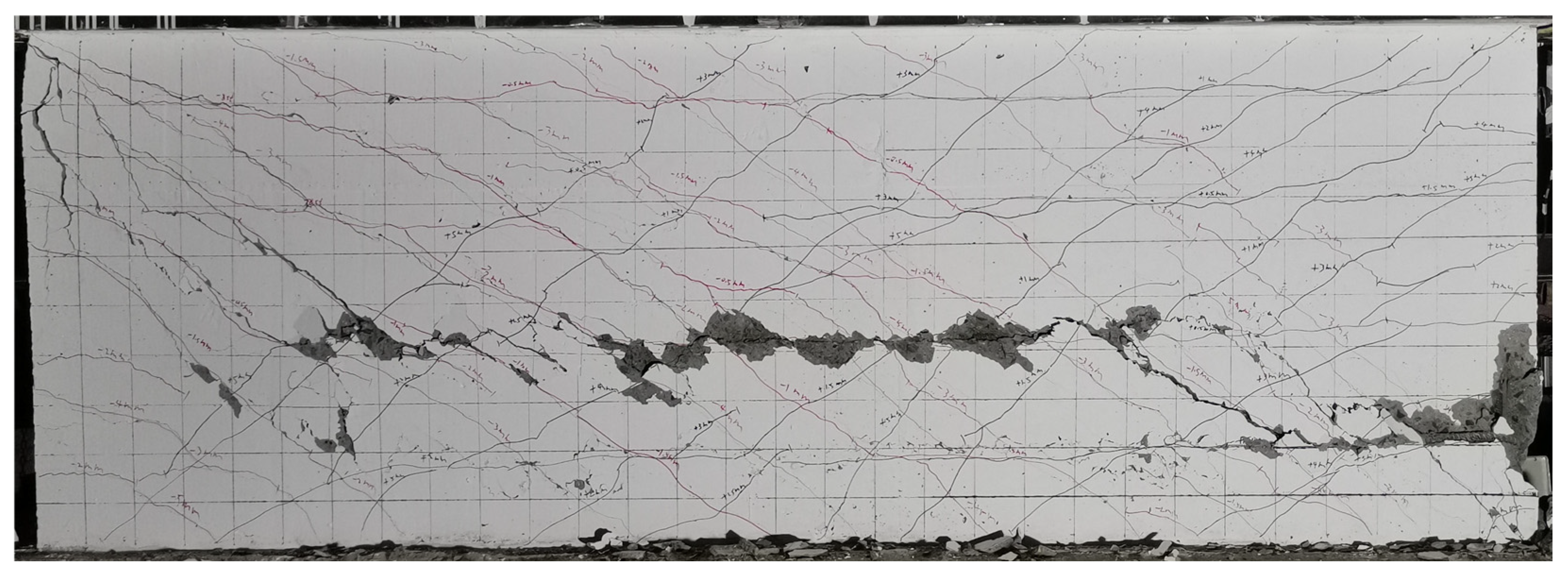

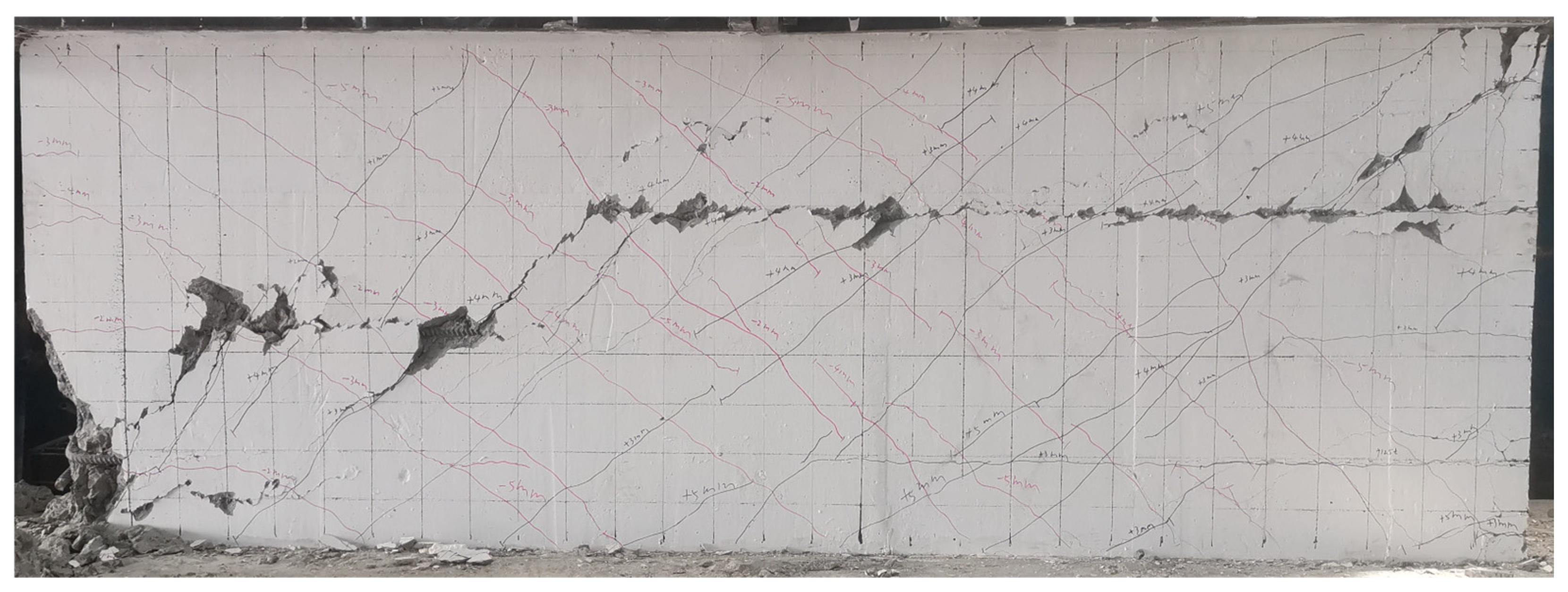

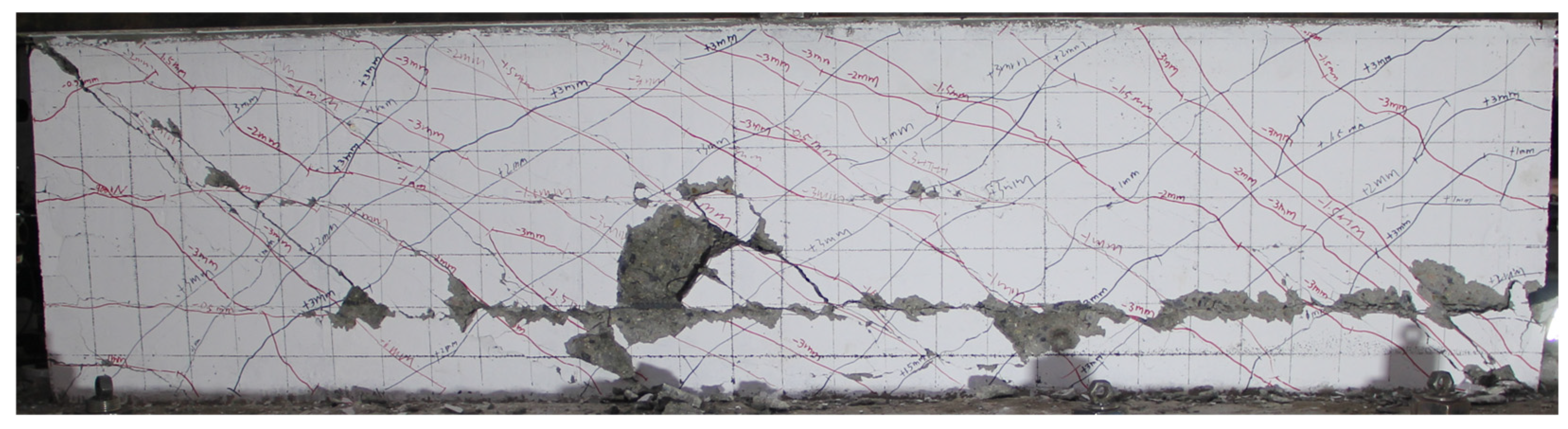

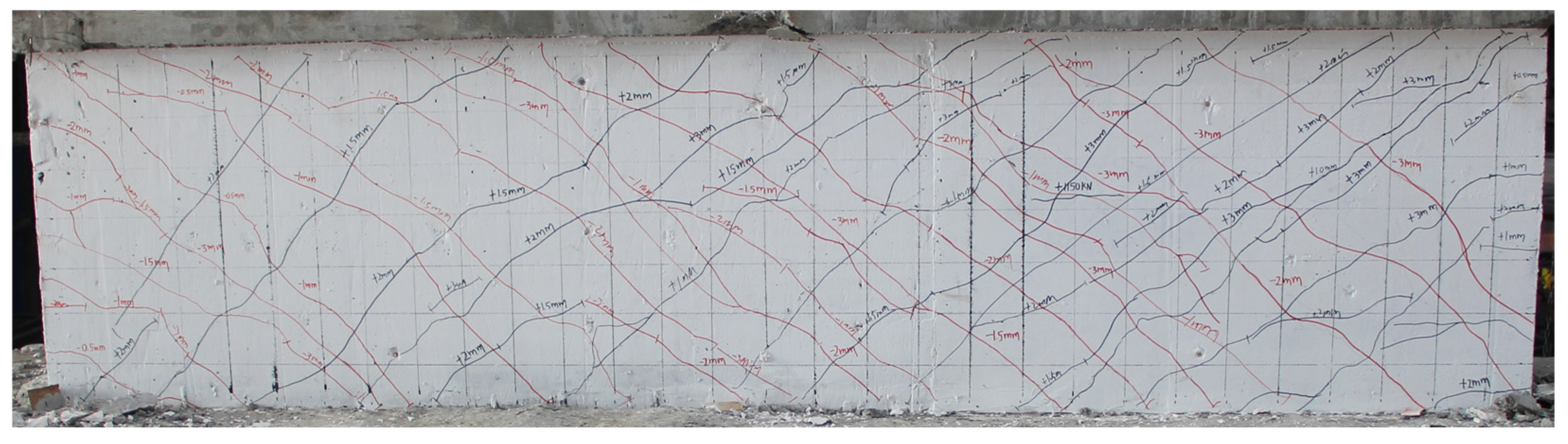

3.1.1. HA01 Specimen

3.1.2. HA02 Specimen

3.1.3. HA03 Specimen

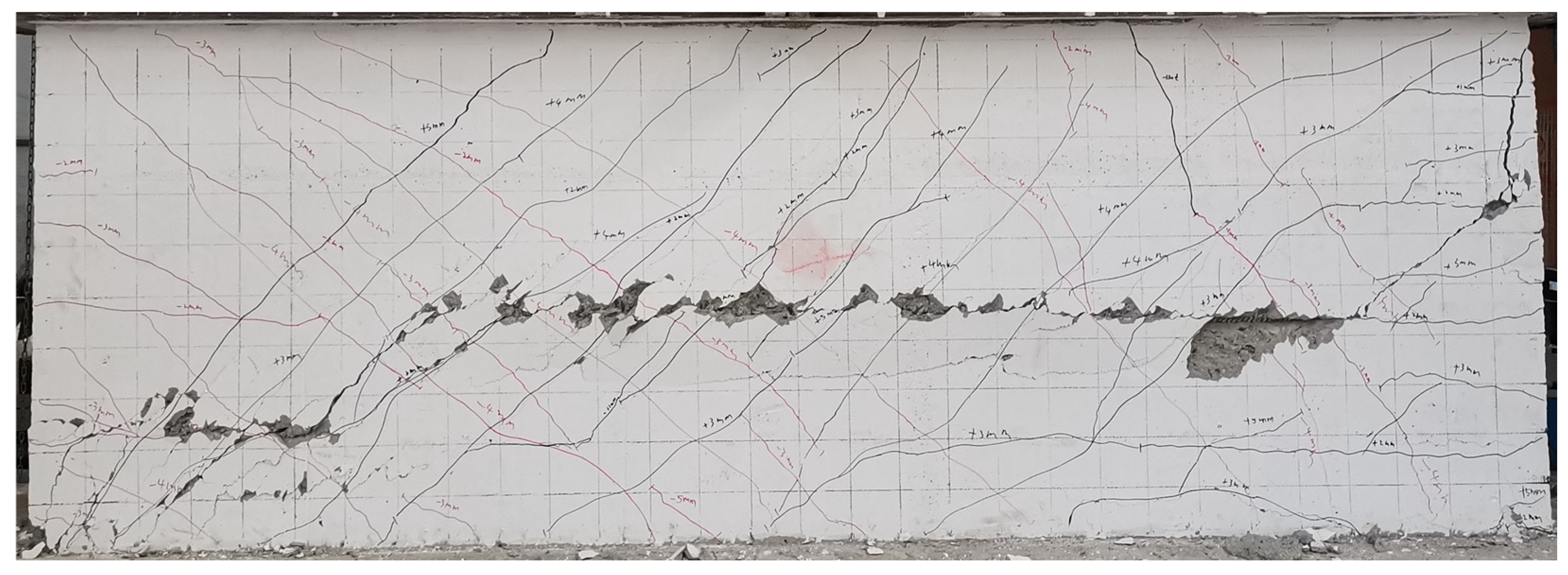

3.1.4. LA01

3.1.5. LA02

3.1.6. LA03

3.2. Failure Mode

4. Discussion

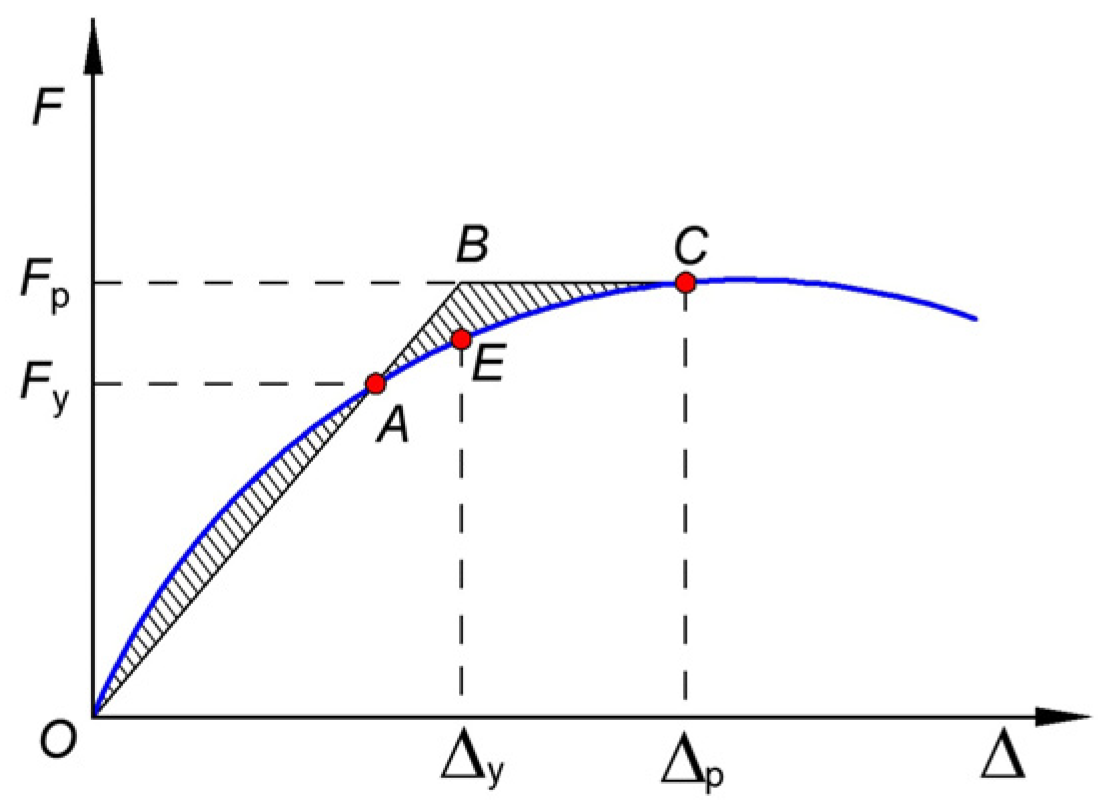

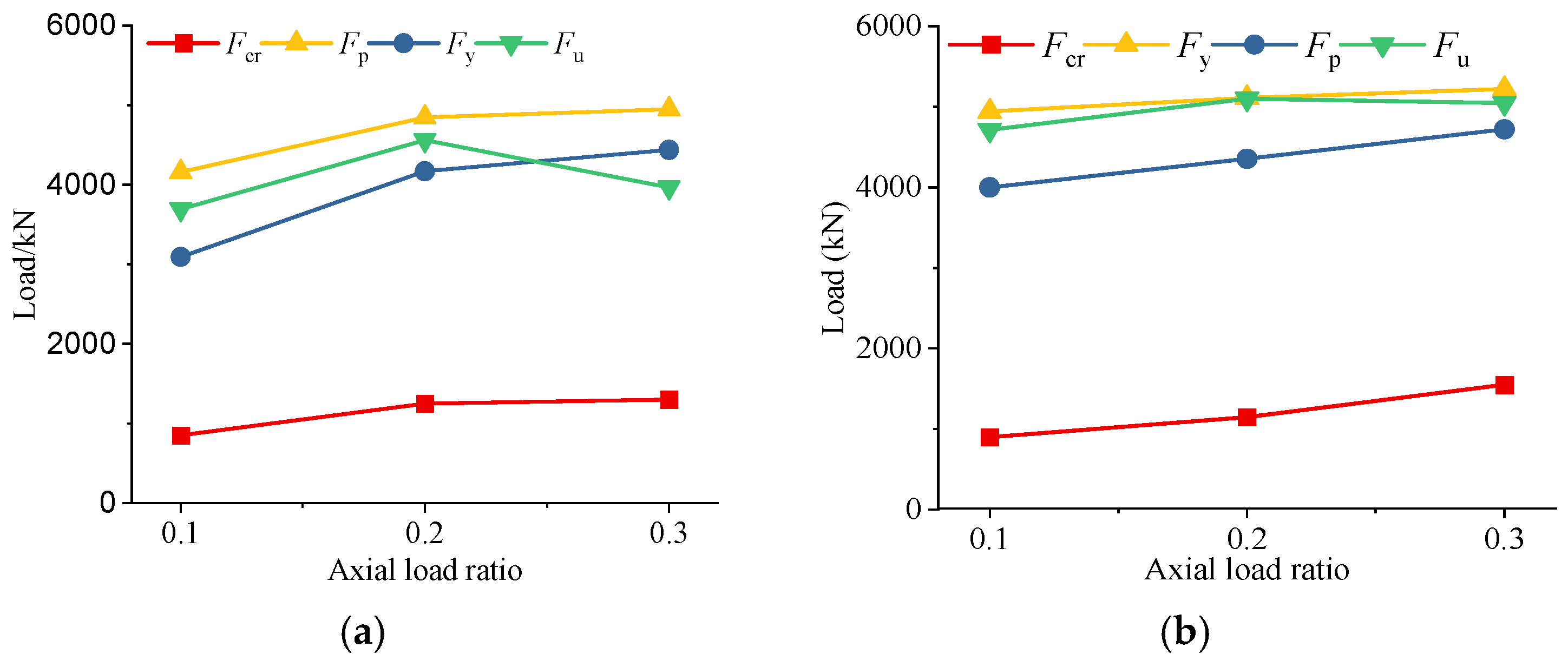

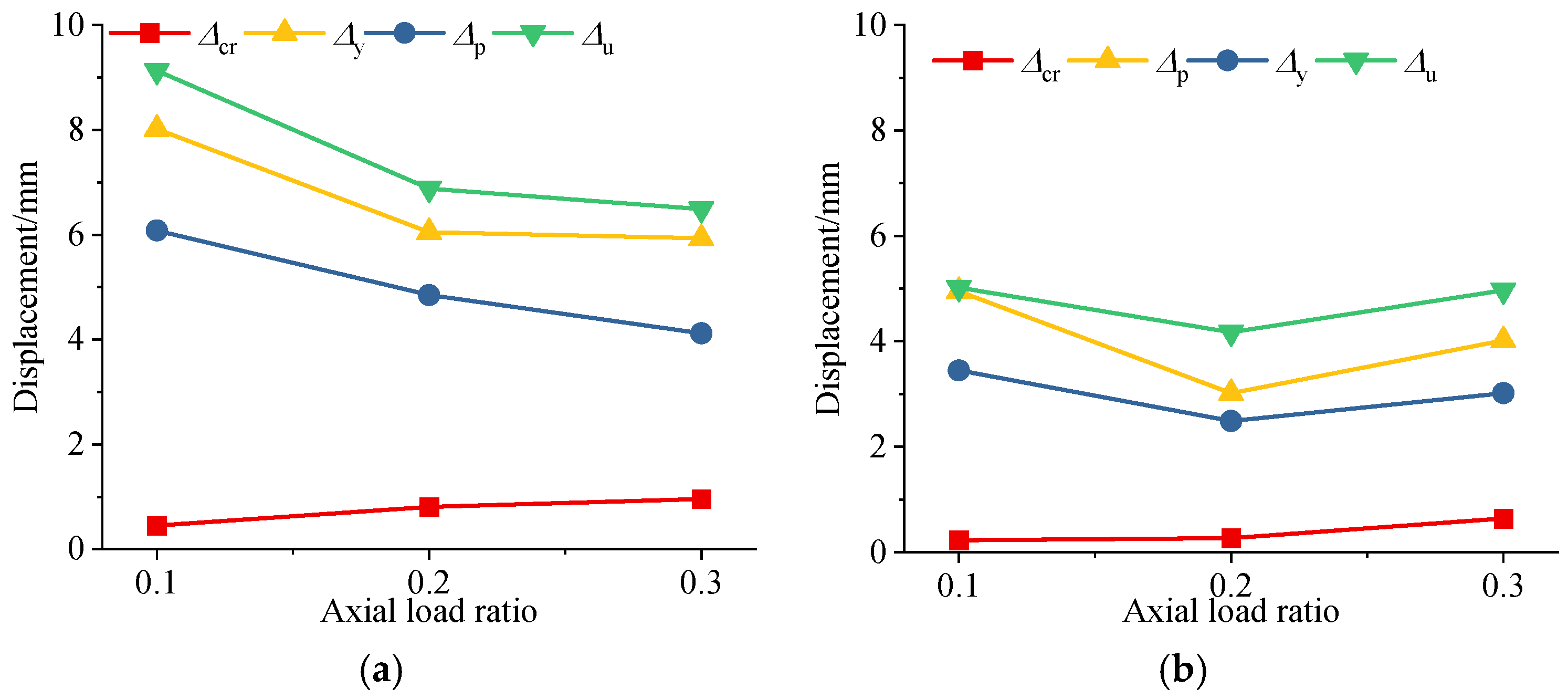

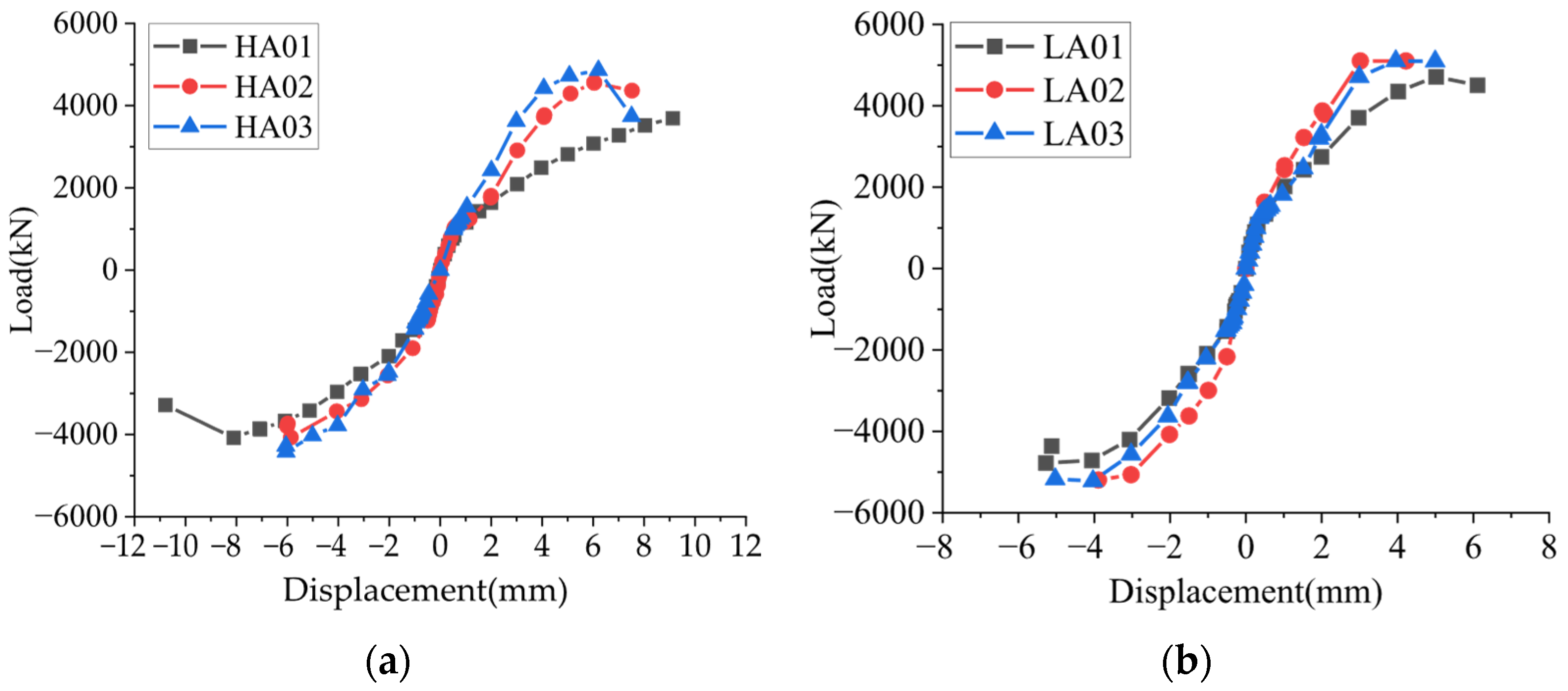

4.1. Bearing Capacity and Ductility

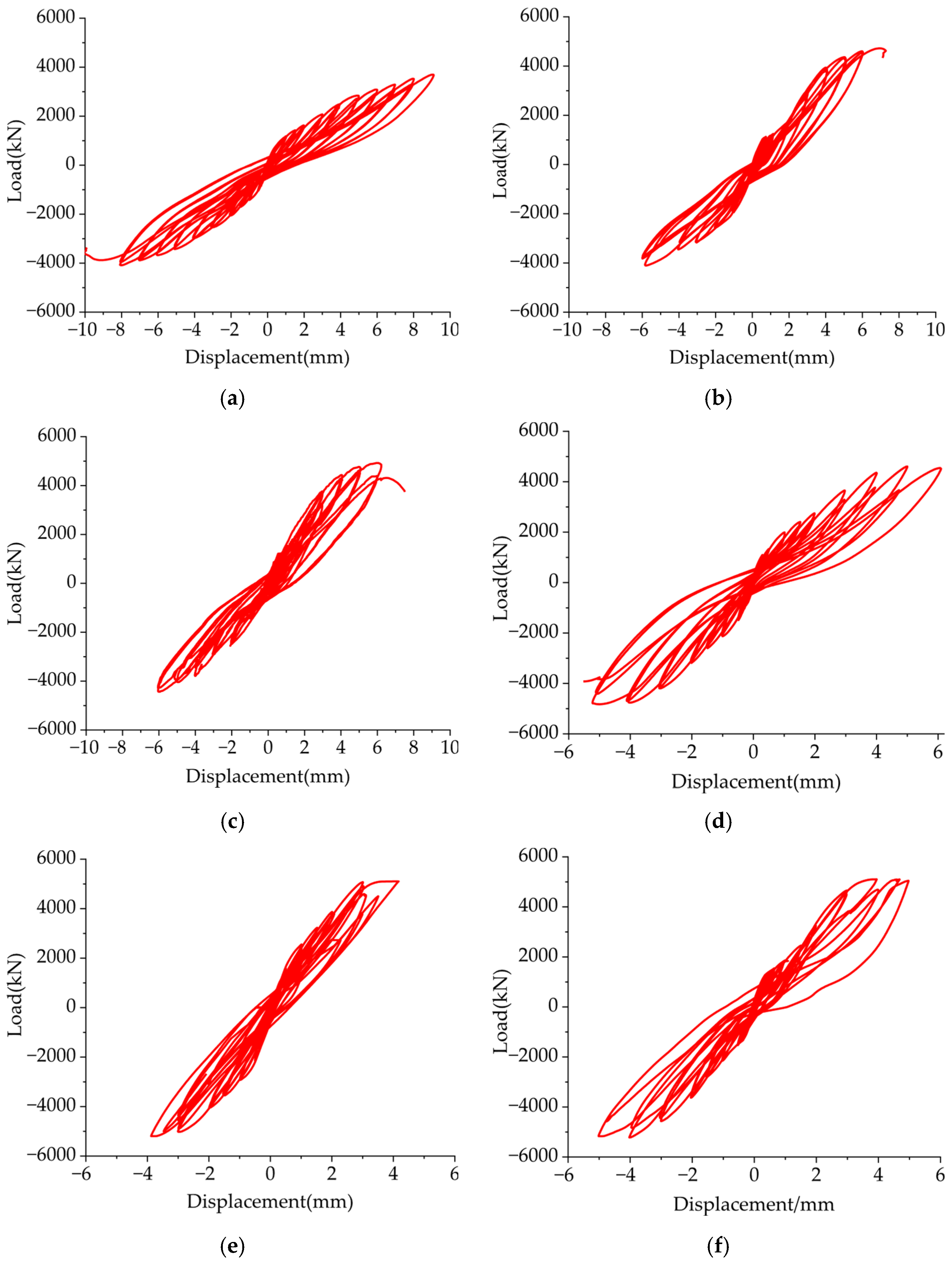

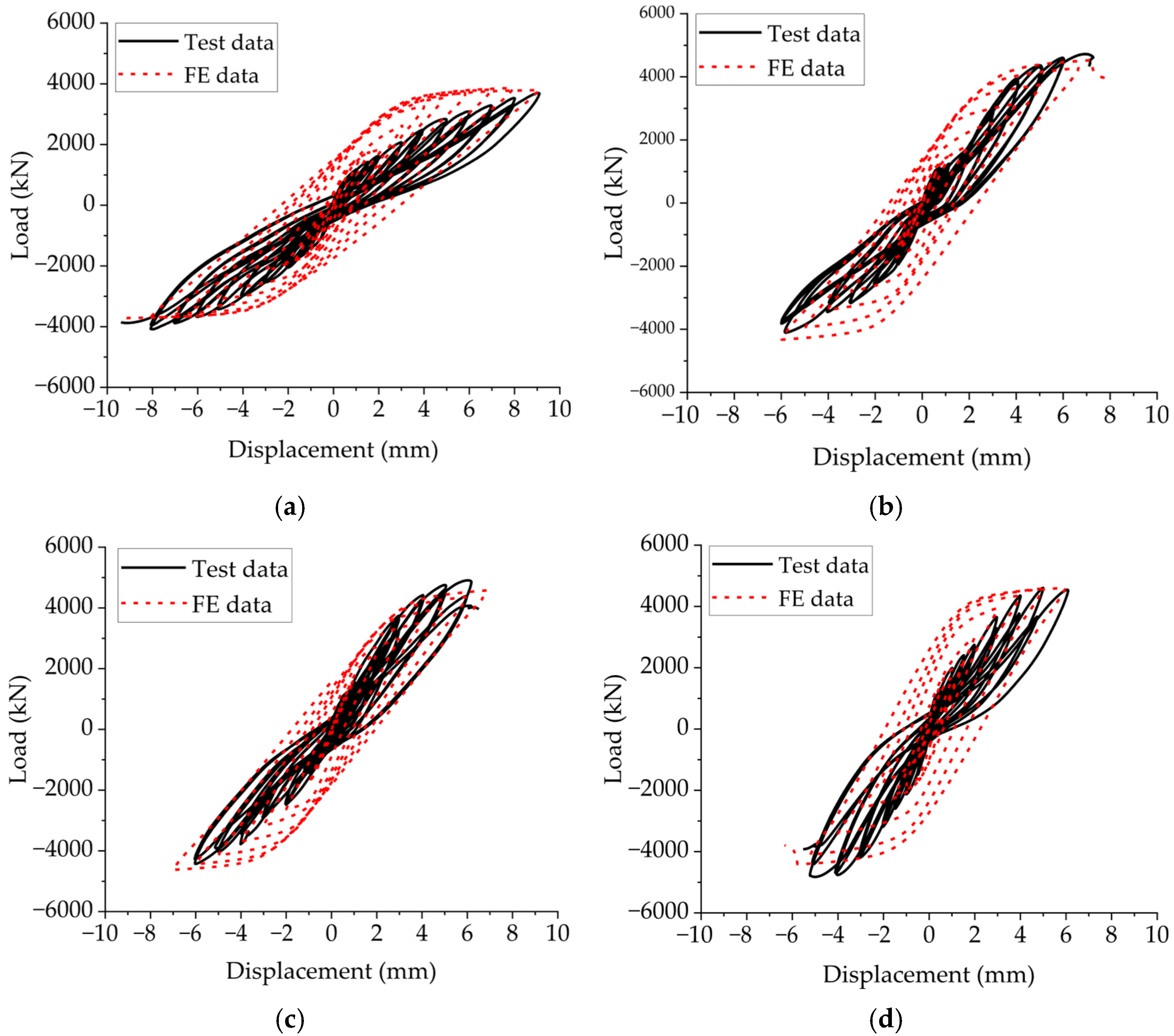

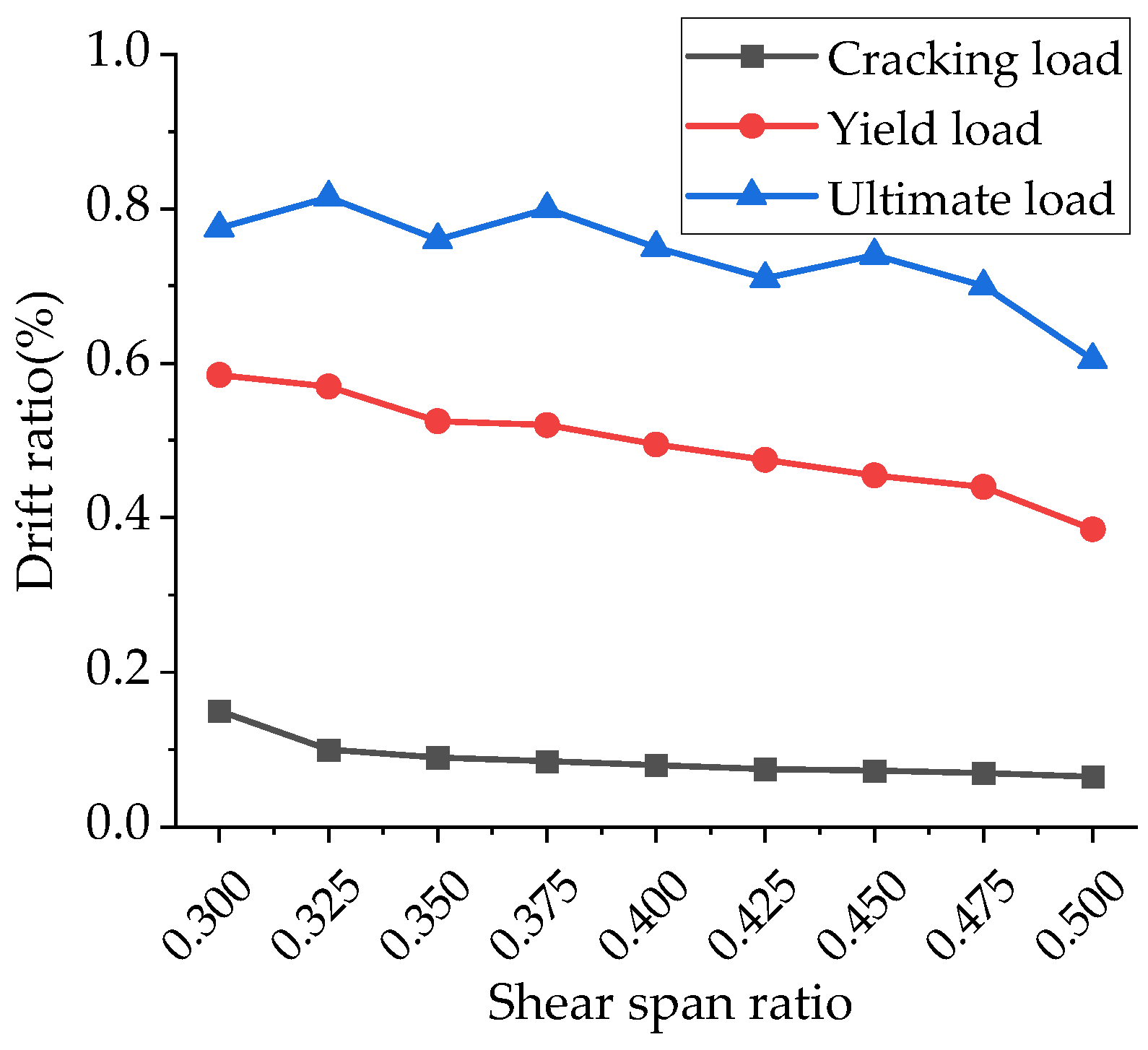

4.2. Hysteretic Behavior

4.3. Skeleton Curve

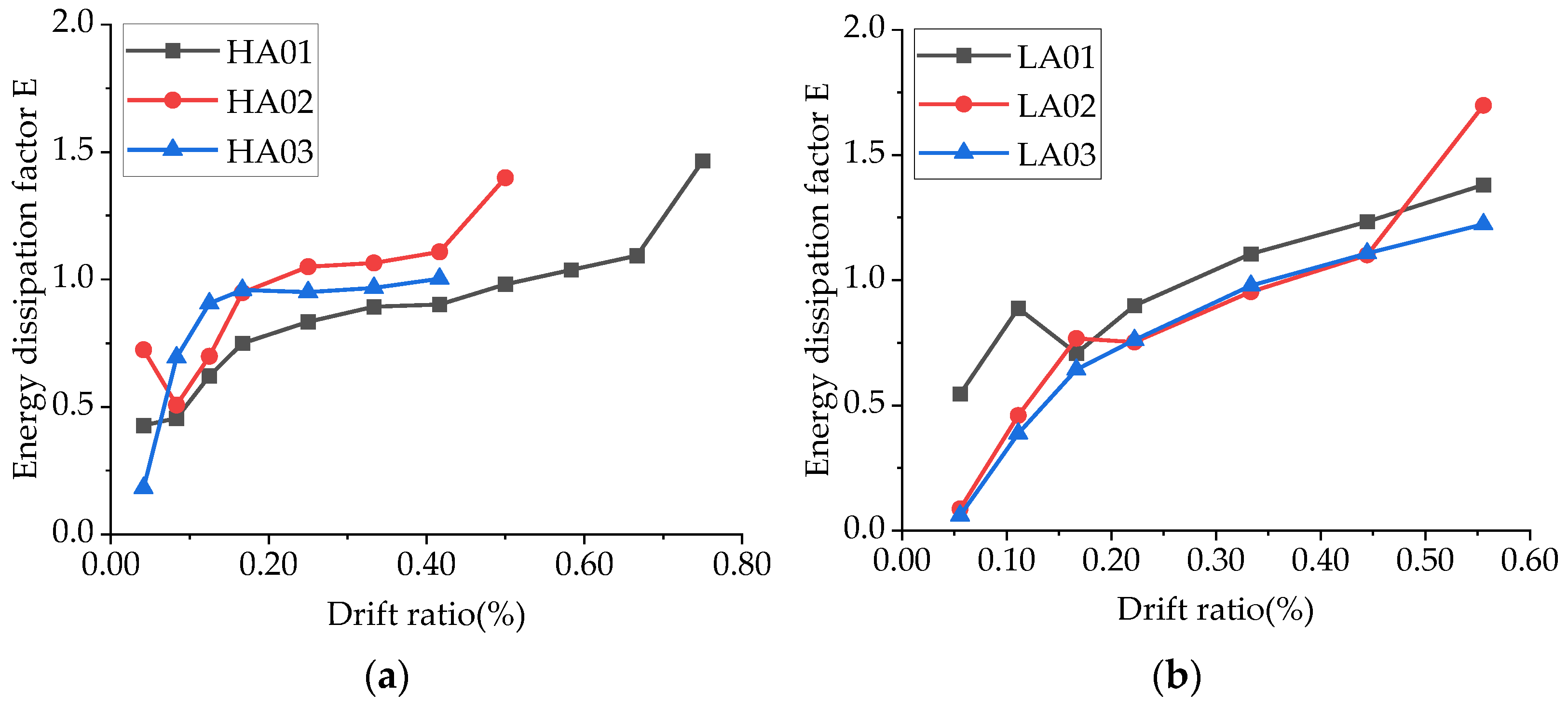

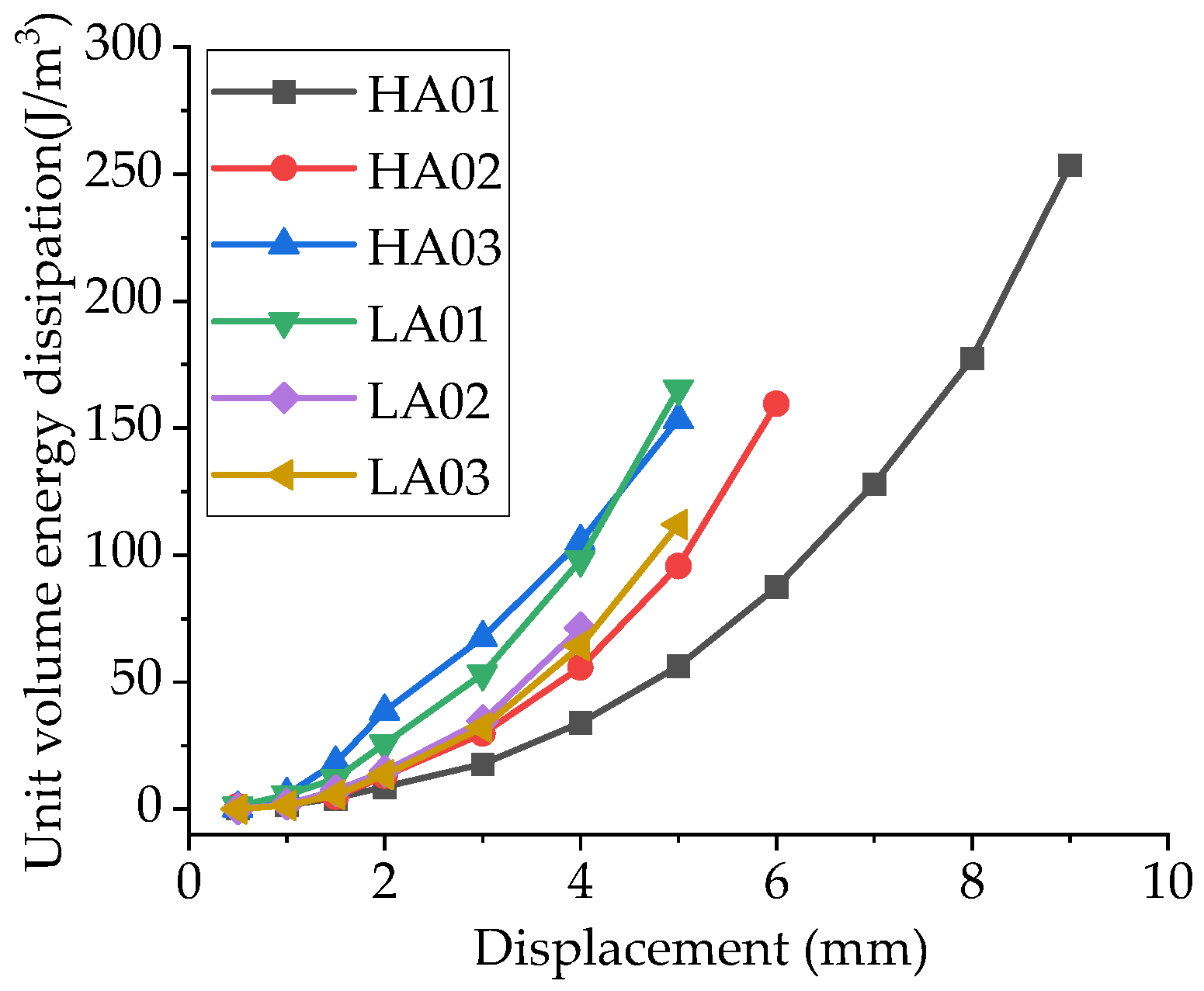

4.4. Energy Dissipations

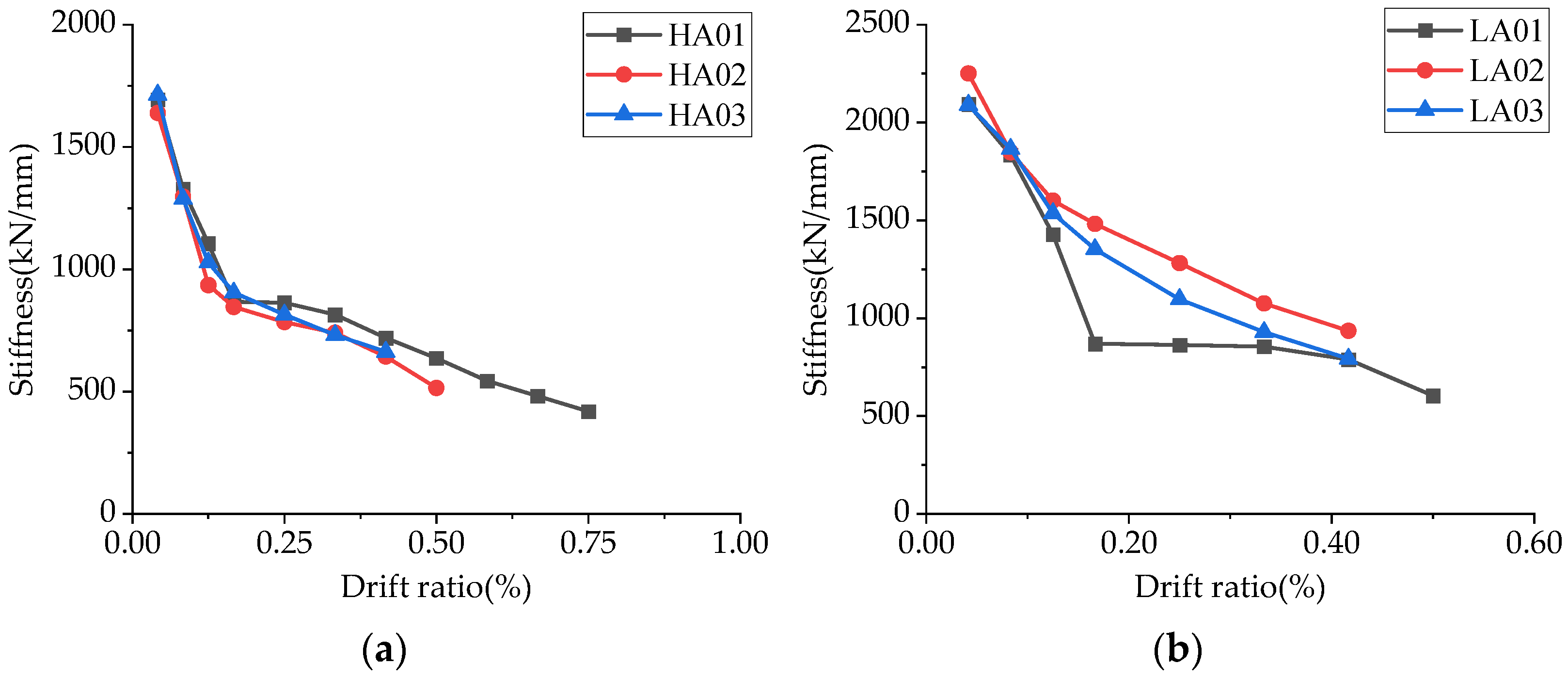

4.5. Stiffness Degeneration

4.6. Crack Width

4.7. Size Effect Analysis

| Literature | Specimen | Height H (mm) | Width L (mm) | Thickness B (mm) | ALR | θcr | θy | μ | Ev (J/m3) |

|---|---|---|---|---|---|---|---|---|---|

| Wei. et al. [5] | W1 | 500 | 1000 | 150 | 0.3 | 0.10% | - | 3.40 | 260 |

| W2 | 500 | 1000 | 150 | 0.3 | 0.06% | - | - | 42 | |

| W5 | 500 | 1000 | 150 | 0.5 | 0.11% | - | 3.66 | 213 | |

| W6 | 500 | 1000 | 150 | 0.5 | 0.07% | - | - | - | |

| W9 | 500 | 1000 | 150 | 0.3 | 0.05% | - | 3.07 | 140 | |

| W10 | 500 | 1000 | 150 | 0.3 | 0.05% | - | 3.24 | 287 | |

| W12 | 500 | 1000 | 150 | 0.5 | 0.13% | - | 3.41 | 512 | |

| W14 | 500 | 1000 | 150 | 0.5 | 0.22% | - | 3.52 | 975 | |

| Gao. et al. [30] | RCW1-03A | 1000 | 1300 | 150 | 0.3 | - | 0.62% | 3.24 | - |

| RCW2-05A | 1000 | 1300 | 150 | 0.5 | - | 0.38% | 2.91 | - | |

| RCW3-03S | 1000 | 1300 | 150 | 0.3 | - | 0.50% | 2.87 | - | |

| RCW4-05S | 1000 | 1300 | 150 | 0.5 | - | 0.39% | 2.90 | - | |

| Miao et al. [31] | 0.25%-S | 600 | 600 | 80 | - | 0.16% | 0.81% | 2.12 | - |

| 0.50%-S | 600 | 600 | 80 | - | 0.21% | 1.16% | 2.28 | - | |

| 0.25%-M | 1200 | 1200 | 160 | - | 0.12% | 1.06% | 1.95 | - | |

| 0.50%-M | 1200 | 1200 | 160 | - | 0.16% | 1.27% | 2.13 | - | |

| 0.25%-L | 1800 | 1800 | 240 | - | 0.07% | 0.93% | 1.71 | - | |

| 0.50%-L | 1800 | 1800 | 240 | - | 0.08% | 1.14% | 1.78 | - | |

| This paper | HA01 | 1200 | 3000 | 185 | 0.1 | 0.04% | 0.42% | 2.05 | 254 |

| HA02 | 1200 | 3000 | 185 | 0.2 | 0.07% | 0.38% | 1.72 | 160 | |

| HA03 | 1200 | 3000 | 185 | 0.3 | 0.08% | 0.34% | 1.59 | 153 | |

| LA01 | 900 | 3000 | 185 | 0.1 | 0.03% | 0.36% | 1.88 | 165 | |

| LA02 | 900 | 3000 | 185 | 0.2 | 0.03% | 0.24% | 1.81 | 71 | |

| LA03 | 900 | 3000 | 185 | 0.3 | 0.07% | 0.32% | 1.76 | 112 |

5. Numerical Simulation and Parameter Analysis

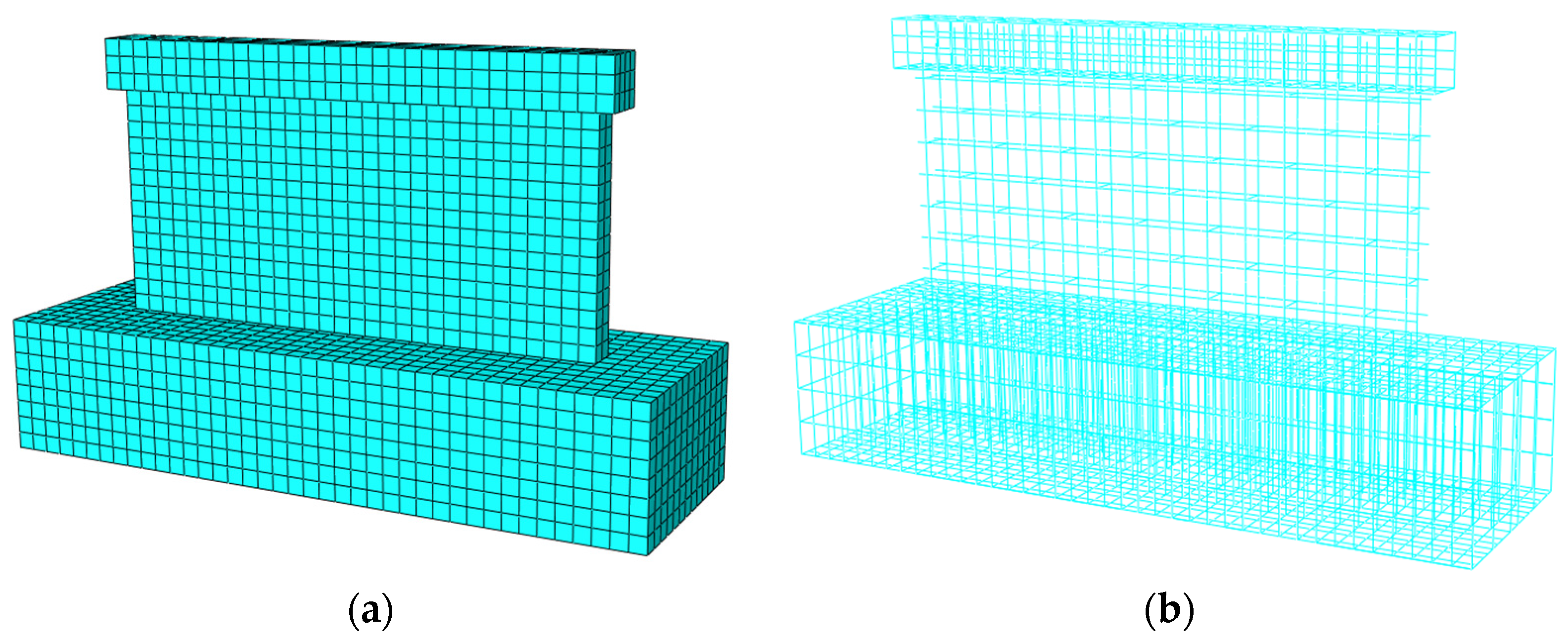

5.1. Finite Element Model

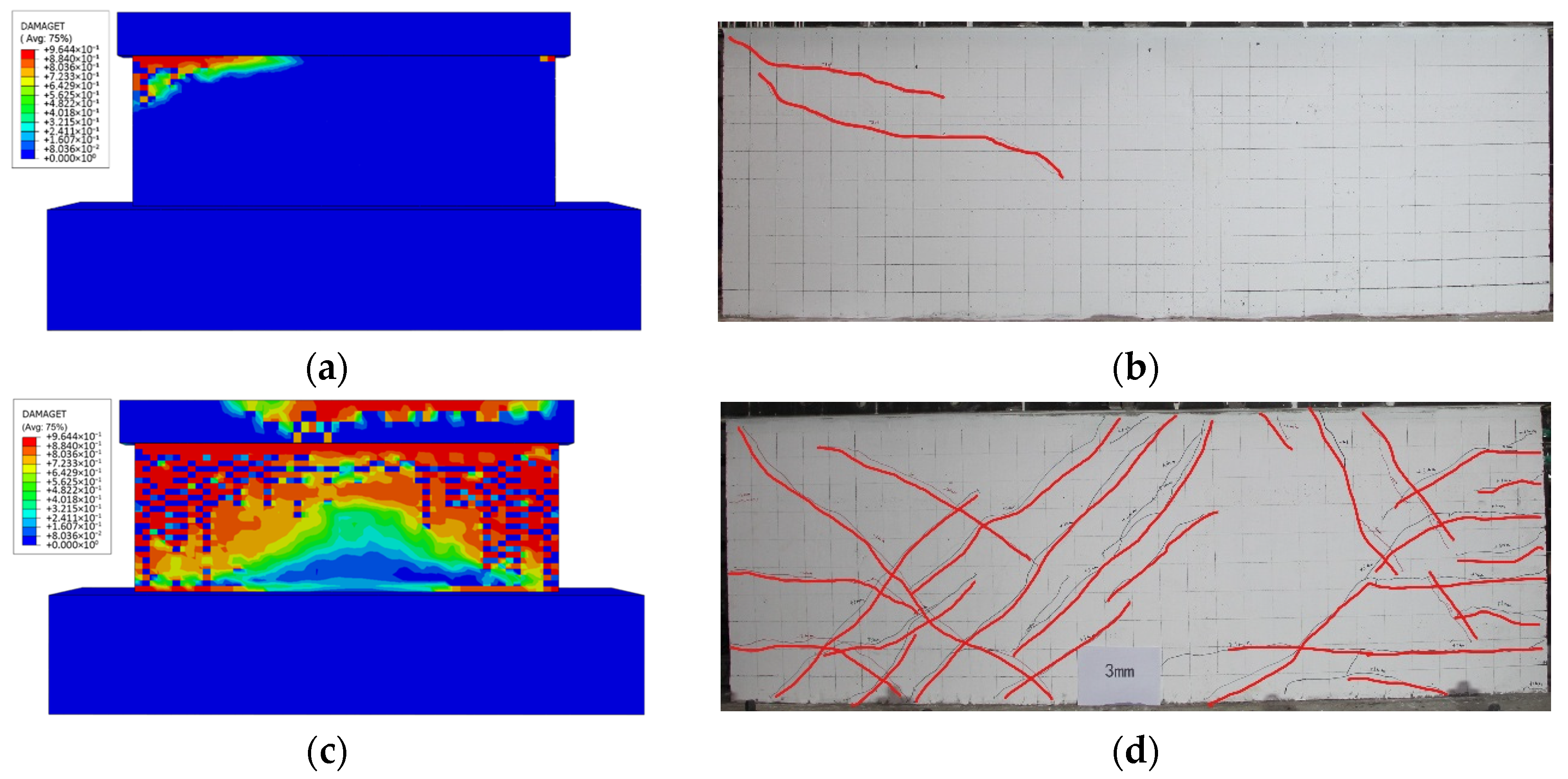

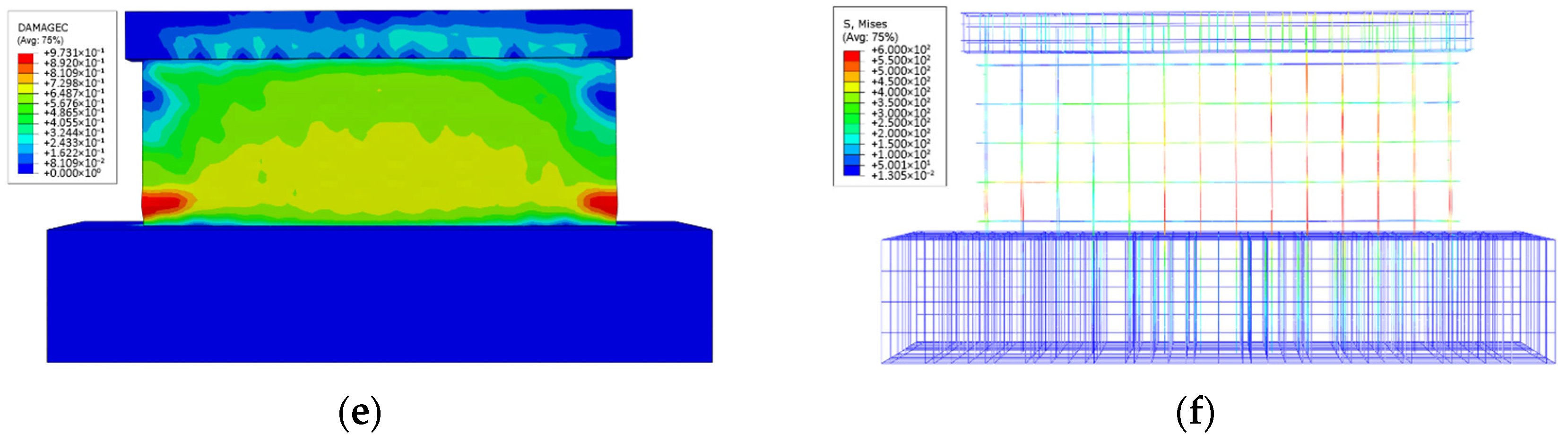

5.2. Analysis of the Results of Finite Element Simulation

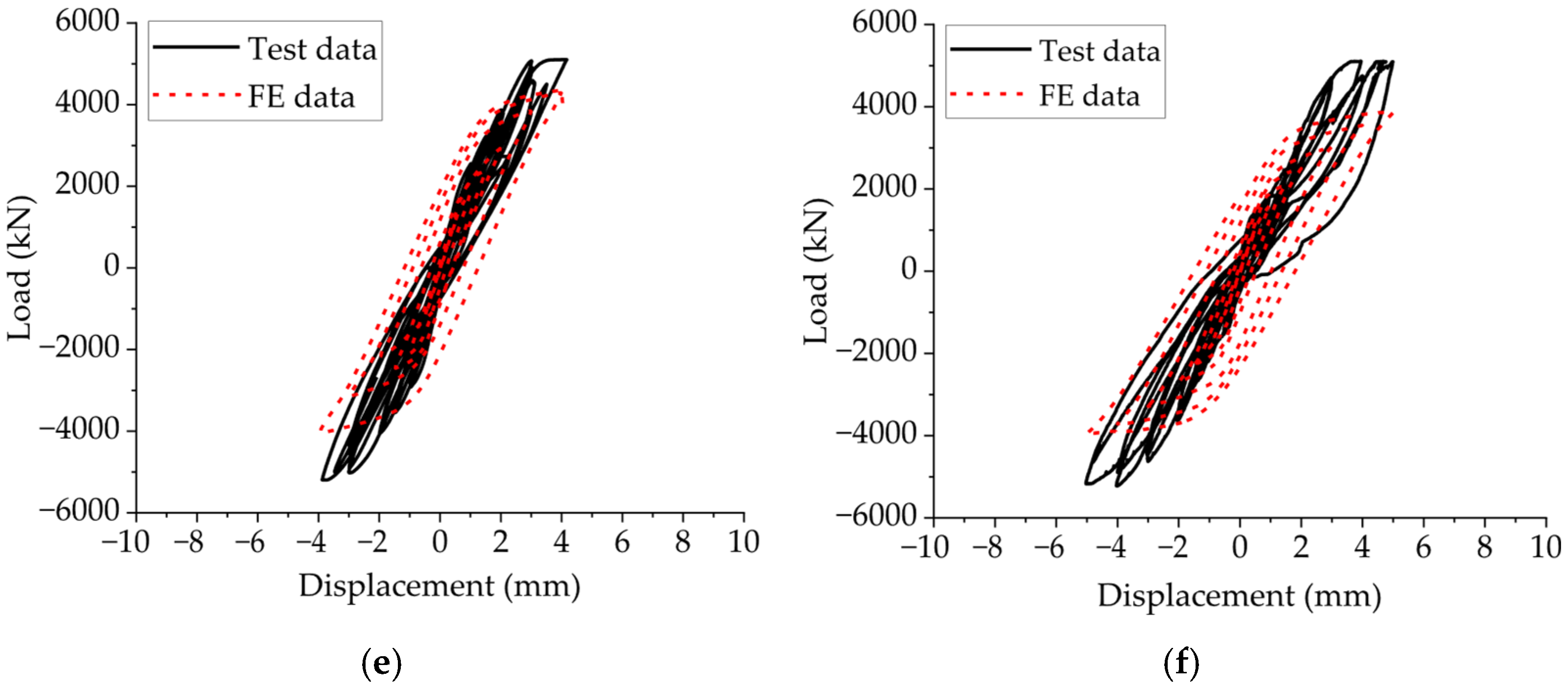

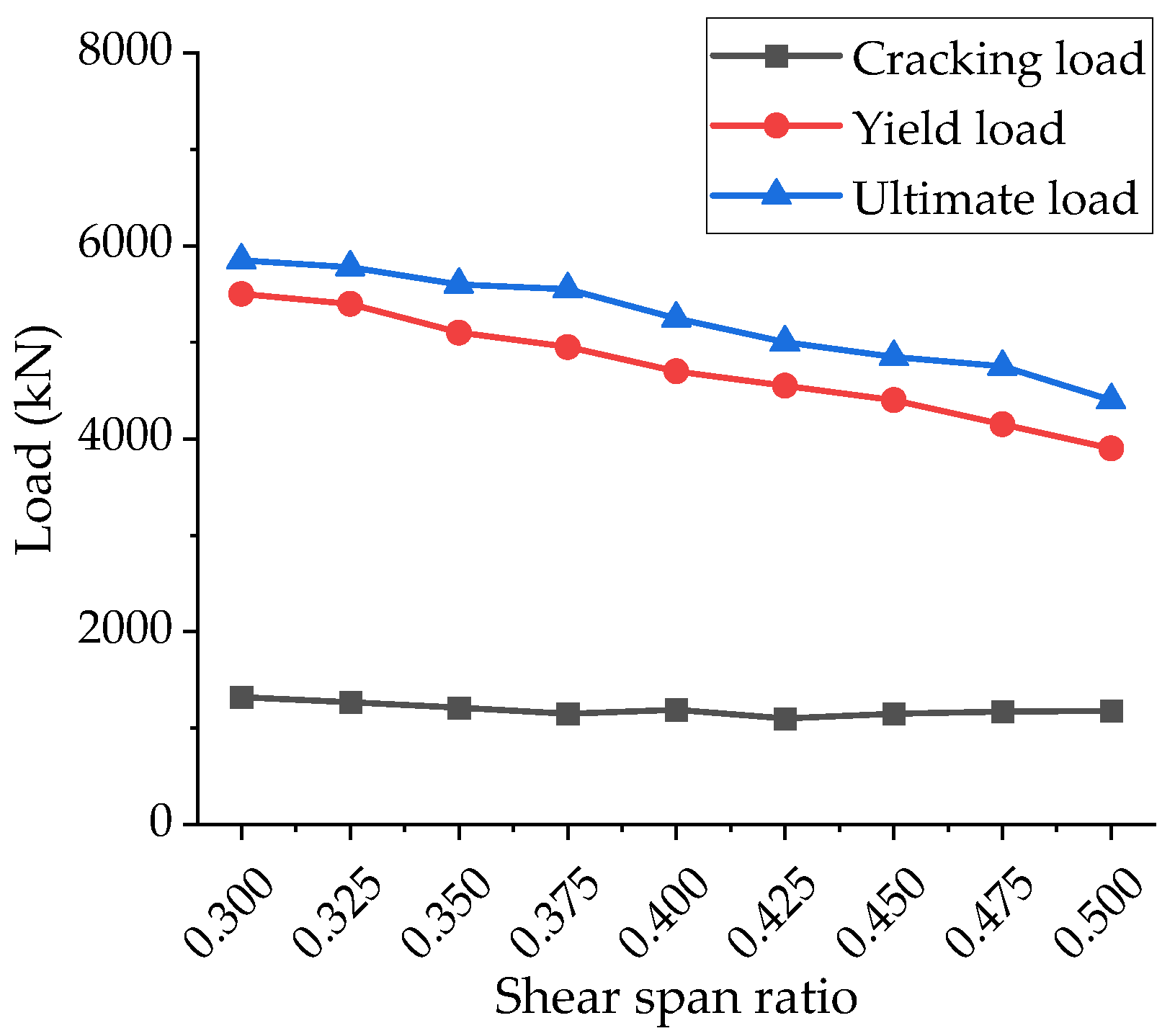

5.3. Analysis of Parameters

5.3.1. The Shear–Span Ratio

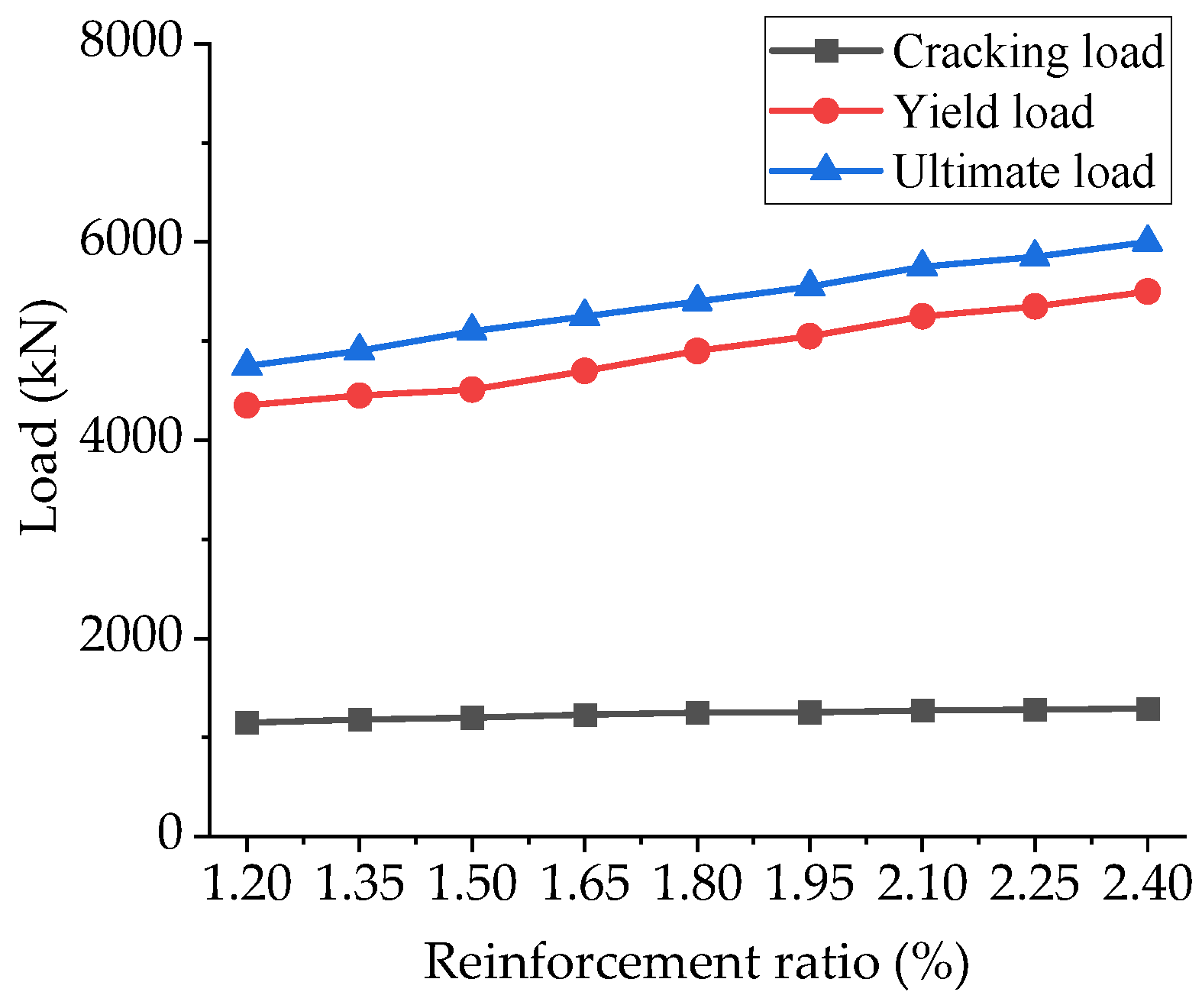

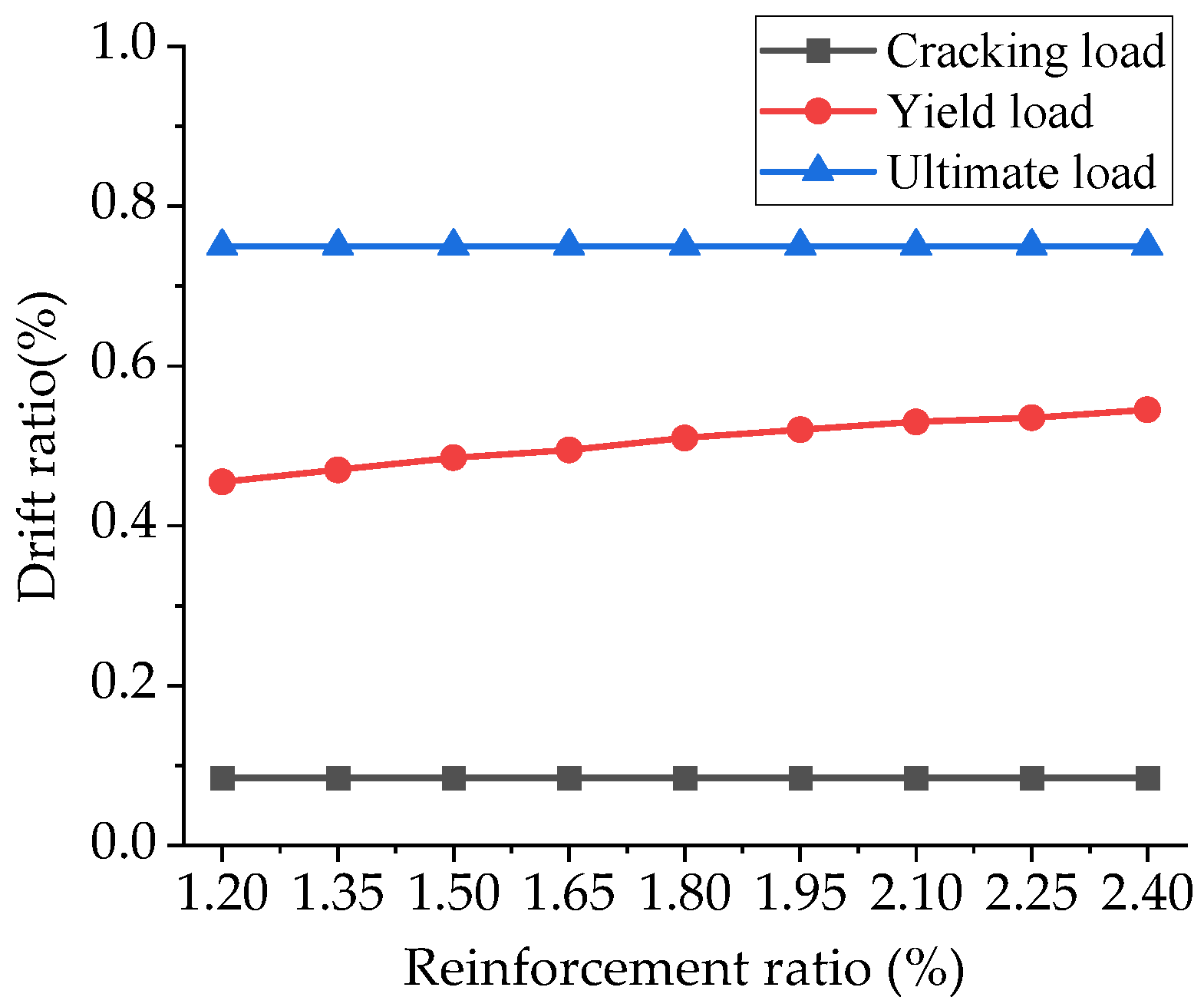

5.3.2. The Reinforcement Ratio

6. Conclusions

- A comparative analysis of recent studies involving squat shear walls under similar conditions demonstrated that the size significantly influences the deformation behavior and energy dissipation capacity of squat shear wall specimens. The large-scale squat shear wall specimens used in this study exhibited test outcomes that more closely reflect engineering scenarios, thereby offering greater theoretical and practical reference value.

- The failure modes of the six squat shear wall specimens included bending-shear failure, shear slip failure, and localized failure. The specimens with lower axial load ratios exhibited bending-shear failure, while the squat shear walls characterized by higher axial load ratios and large shear–span ratios demonstrated shear slip failure. Specimens with higher axial load ratio and low shear–span ratio failed earlier than general shear walls.

- The axial load ratio has a significant influence on the horizontal bearing capacity and seismic performance of squat shear walls. Increasing the axial load ratio can improve the horizontal bearing capacity and the stiffness of the squat shear wall, delaying its yield and cracking. The higher the axial load ratio, the higher the horizontal bearing capacity, cracking load, and yield load, and the greater its stiffness. A higher axial load ratio can delay the appearance of cracks, limit the development of cracks, and reduce the width of cracks before failure.

- The axial load ratio also has a significant impact on the seismic performance of the squat shear wall: an increase in the axial load ratio can reduce the cracking, yield, and ultimate displacement of the squat shear wall, while also reducing its ductility and energy dissipation capacity. The higher the axial load ratio, the worse the seismic performance of the squat shear wall.

- The load–displacement curve obtained through finite element analysis of a squat shear wall specimen model was relatively close to that of the test curve, and the failure mode was basically consistent with the test result. The parametric analysis results for the squat shear wall’s shear–span ratio and reinforcement ratio on the load and drift ratio can be considered as an effective supplement to experimental test results.

- Although extensive research has been conducted on squat shear walls, there are still some areas that require further study. To avoid the influence of size effects, it is crucial to use large-scale specimens to test and study the impact of the shear–span and reinforcement ratios on the seismic performance of squat shear walls. A more accurate force analysis model should be developed to effectively predict the force performance of squat shear walls and provide references for the design and wider application of squat shear walls. Numerical simulations may be further improved using machine learning and neural network technologies, thus providing more accurate predictions. However, it should be noted that such models will need to be verified based on extensive experimental data to ensure their reliability and applicability.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Habib, A.; Al-Sadoon, Z.A.; Saatcioglu, M.; al Houri, A.; Maalej, M.; Al-Toubat, S.; Shrif, M. Seismic Behavior of Squat Reinforced Concrete Shear Walls: A State-of-the-Art Review. Struct. Durab. Health Monit. 2025, 19, 417–439. [Google Scholar] [CrossRef]

- Xu, G.; Zheng, L.; Zhou, W.; Zhai, C.; Wang, D. Quasi-static tests of squat reinforced concrete shear walls with openings. Eng. Struct. 2023, 293, 116666. [Google Scholar] [CrossRef]

- Jafari, A.; Beheshti, M.; Shahmansouri, A.A.; Bengar, H.A. Plastic hinge length for coupled and hybrid-coupled shear walls. Steel Compos. Struct. 2023, 48, 367–383. [Google Scholar] [CrossRef]

- Jafari, A.; Beheshti, M.; Shahmansouri, A.A.; Bengar, H.A. Cyclic response and damage status of coupled and hybrid-coupled shear walls. Structures 2024, 61, 106010. [Google Scholar] [CrossRef]

- Wei, F.; Chen, H.; Xie, Y. Experimental study on seismic behavior of reinforced concrete shear walls with low shear span ratio. J. Build. Eng. 2021, 45, 103602. [Google Scholar] [CrossRef]

- Benjamin, J.R.; Williams, H.A. The Behavior of One-Story Reinforced Concrete Shear Walls. J. Struct. Div. 1957, 83, 1254. [Google Scholar] [CrossRef]

- Ganesan, N.; Indira, P.v.; Seena, P. Reverse Cyclic Tests on High Performance Cement Concrete Shear Walls with Barbells. In Advances in Structural Engineering; Springer: New Delhi, India, 2015; pp. 2309–2321. [Google Scholar] [CrossRef]

- Baek, J.-W.; Park, H.-G.; Shin, H.-M.; Yim, S.-J. Cyclic Loading Tests for Reinforced Concrete Walls (Aspect Ratio 2.0) with Grade 550 MPa (80 ksi) Shear Reinforcing Bars. ACI Struct. J. 2017, 114, 673. [Google Scholar] [CrossRef]

- Barda, F. Shear Strength of Low-Rise Walls with Boundary Elements; Lehigh University: Bethlehem, PA, USA, 1972. [Google Scholar]

- Terzioglu, T.; Orakcal, K.; Massone, L.M. Cyclic lateral load behavior of squat reinforced concrete walls. Eng. Struct. 2018, 160, 147–160. [Google Scholar] [CrossRef]

- Baek, J.W.; Park, H.G.; Lee, B.S.; Shin, H.M. Shear-Friction Strength of Low-Rise Walls with 550 MPa (80 ksi) Reinforcing Bars under Cyclic Loading. ACI Struct. J. 2018, 115. [Google Scholar] [CrossRef]

- Zhang, N.; Wu, Y.; Gu, Q.; Huang, S.; Sun, B.; Du, R.; Chang, R. Refined three-dimensional simulation of ribbed bar pull-out tests based on an enhanced peridynamic model. Eng. Struct. 2023, 278, 115519. [Google Scholar] [CrossRef]

- Looi, D.T.W.; Su, R.K.L.; Cheng, B.; Tsang, H.H. Effects of axial load on seismic performance of reinforced concrete walls with short shear span. Eng. Struct. 2017, 151, 312–326. [Google Scholar] [CrossRef]

- Zhang, J.-W.; Zheng, W.-B.; Cao, W.-L.; Dong, H.-Y.; Li, W.-D. Seismic Behavior of Low-rise Concrete Shear Wall with Single Layer of Web Reinforcement and Inclined Rebars: Restoring Force Model. KSCE J. Civ. Eng. 2019, 23, 1302–1319. [Google Scholar] [CrossRef]

- Hung, C.-C.; Hsieh, P.-L. Comparative study on shear failure behavior of squat high-strength steel reinforced concrete shear walls with various high-strength concrete materials. Structures 2020, 23, 56–68. [Google Scholar] [CrossRef]

- Robazza, B.R.; Brzev, S.; Yang, T.Y.; Elwood, K.J.; Anderson, D.L.; McEwen, B. Seismic behaviour and design code provisions for predicting the capacity of ductile slender reinforced masonry shear walls. Eng. Struct. 2020, 222, 110992. [Google Scholar] [CrossRef]

- Ye, B.; Pan, P.; Xiao, G.; Han, J.; Zhang, Y. Comparative study of reinforced-engineered cementitious composites and reinforced-concrete slab–column connections under a vertical monotonic load. Eng. Struct. 2021, 244, 112740. [Google Scholar] [CrossRef]

- Li, Y.Y.; Ding, R.; Nie, J.-G. Experiment study on seismic behavior of squat UHPC shear walls subjected to tension-shear combined cyclic load. Eng. Struct. 2023, 280, 115700. [Google Scholar] [CrossRef]

- FEMA356; Prestandard and Commentary for the Seismic Rehabilitation of Buildings. Federal Emergency Management Agency: Washington, DC, USA, 2000.

- ACI Committee 318; Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- Li, B.; Qian, K.; Wu, H. Flange effects on seismic performance of reinforced concrete squat walls with irregular or regular openings. Eng. Struct. 2015, 110, 127–144. [Google Scholar] [CrossRef]

- John, S.K.; Cascardi, A.; Verre, S.; Nadir, Y. RC-columns subjected to lateral cyclic force with different FRCM-strengthening schemes: Experimental and numerical investigation. Bull. Earthq. Eng. 2025, 23, 1561–1590. [Google Scholar] [CrossRef]

- FEMA273; NEHRP Guidelines for the Seismic Rehabilitation of Buildings. Federal Emergency Management Agency: Washington, DC, USA, 1997.

- JGJ3-2010; Technical Specification for Concrete Structures of Tall Building. China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- Lefas, L.D.; Kotsovos, M.K.; Ambraseys, N.N. Behavior of Reinforced Concrete Structural Walls: Strength, Deformation Characteristics, and Failure Mechanism. ACI Struct. J. 1990, 87, 23–31. [Google Scholar] [CrossRef]

- Feng, P.; Qiang, H.; Ye, L. Discussion and definition on yield points of materials, members and structures. Eng. Mech. 2019, 39, 143–150. [Google Scholar] [CrossRef]

- Rasoolinejad, M.; Bažant, Z.P. Size effect of squat shear walls extrapolated by microplane model M7. ACI Struct. J. 2019, 116, 75–84. [Google Scholar] [CrossRef]

- Jin, L.; Miao, L.; Chen, F.; Li, D.; Du, X. A Comparative Study on Shear Size Effect of Steel-And BFRP-RC Shear Walls Under Cyclic Lateral Loads. J. Earthq. Eng. 2024, 28, 3363–3386. [Google Scholar] [CrossRef]

- JGJ/T101-2015; Specification for Seismic Test of Buildings. China Architecture and Building Press: Beijing, China, 2015. (In Chinese)

- Gao, X.L.; Xu, Z.P.; Ren, X.D.; Li, J. Experimental analysis of RC and SPRC squat shear walls. J. Build. Eng. 2024, 93, 109861. [Google Scholar] [CrossRef]

- Miao, L.; Jin, L.; Chen, F.; Du, X. Experiment study on seismic performance and size effect in BFRP-RC squat shear walls with different horizontal reinforcement ratios. Eng. Struct. 2023, 295. [Google Scholar] [CrossRef]

| Specimen | fcu/MPa | fc/MPa | Ec |

|---|---|---|---|

| HA01 | 51.08 | 40.35 | 2.83 |

| HA02 | 49.45 | 39.07 | 2.90 |

| HA03 | 51.26 | 40.50 | 2.92 |

| LA01 | 48.95 | 38.67 | 2.98 |

| LA02 | 52.26 | 41.29 | 2.94 |

| LA03 | 52.33 | 41.34 | 2.92 |

| Diameter/mm | fy/N/mm2 | fu/N/mm2 |

|---|---|---|

| 10 | 475 | 682 |

| 18 | 449 | 620 |

| 20 | 416 | 598 |

| 25 | 403 | 516 |

| Specimen | Fcr (kN) | Fy (kN) | Fp (kN) | Fu (kN) | μ |

|---|---|---|---|---|---|

| HA01 | 850 | 3428 | 4087 | 3474 | 2.05 |

| HA02 | 1250 | 4234 | 4720 | 4012 | 1.72 |

| HA03 | 1300 | 4426 | 4907 | 4171 | 1.59 |

| LA01 | 900 | 4135 | 4824 | 4100 | 1.88 |

| LA02 | 1150 | 4364 | 5196 | 4417 | 1.81 |

| LA03 | 1550 | 4510 | 5220 | 5170 | 1.76 |

| Specimen | Δcr (mm) | Drift (%) | Δy (mm) | Drift (%) | Δp (mm) | Drift (%) | Δu (mm) | Drift (%) |

|---|---|---|---|---|---|---|---|---|

| HA01 | 0.45 | 0.04% | 5.04 | 0.42% | 8.03 | 0.67% | 10.35 | 0.86% |

| HA02 | 0.81 | 0.07% | 4.60 | 0.38% | 6.93 | 0.58% | 7.89 | 0.66% |

| HA03 | 0.96 | 0.08% | 4.04 | 0.34% | 6.03 | 0.50% | 6.43 | 0.54% |

| LA01 | 0.23 | 0.03% | 3.24 | 0.36% | 5.00 | 0.56% | 5.46 | 0.61% |

| LA02 | 0.27 | 0.03% | 2.17 | 0.24% | 3.78 | 0.42% | 3.93 | 0.44% |

| LA03 | 0.64 | 0.07% | 2.86 | 0.32% | 4.03 | 0.45% | 5.03 | 0.56% |

| Load Level/mm | Maximum Crack Width (mm) | |||||

|---|---|---|---|---|---|---|

| HA01 | HA02 | HA03 | LA01 | LA02 | LA03 | |

| 0.5 | 0.08 | - | - | 0.08 | 0.06 | 0.03 |

| 1 | 0.22 | 0.05 | 0.06 | 0.15 | 0.22 | 0.08 |

| 1.5 | 0.26 | - | - | 0.22 | 0.36 | 0.20 |

| 2 | 0.30 | 0.18 | 0.25 | 0.26 | 0.45 | 0.36 |

| 3 | 0.35 | 0.38 | 0.38 | 0.34 | 0.52 | 0.48 |

| 4 | 0.45 | 0.45 | 0.42 | 0.42 | 0.62 | 0.55 |

| 5 | 0.52 | 0.58 | 0.50 | 0.56 | - | 0.58 |

| 6 | 0.60 | 0.64 | 0.60 | 0.65 | - | - |

| 7 | 0.64 | 0.66 | 0.62 | - | - | - |

| 8 | 0.68 | - | - | - | - | - |

| 9 | 0.72 | - | - | - | - | - |

| Specimens | FyExp. (kN) | FyFE. (kN) | Error | FpExp. (kN) | FpFE. (kN) | Error | μExp. | μFE. | Error |

|---|---|---|---|---|---|---|---|---|---|

| HA01 | 3428 | 3352 | 2.22% | 4087 | 3853 | 5.73% | 2.05 | 2.2 | 7.3% |

| HA02 | 4234 | 3910 | 7.65% | 4720 | 4528 | 4.07% | 1.72 | 1.68 | 2.33% |

| HA03 | 4426 | 3893 | 12.04% | 4907 | 4576 | 6.75% | 1.59 | 1.7 | 6.92% |

| LA01 | 4135 | 4033 | 2.47% | 4824 | 4600 | 4.64% | 1.88 | 2.18 | 15.96% |

| LA02 | 4364 | 3785 | 13.27% | 5196 | 4285 | 17.53% | 1.81 | 1.65 | 8.84% |

| LA03 | 4510 | 3267 | 27.56% | 5220 | 3861 | 26.03% | 1.76 | 1.77 | 0.57% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, H.; Zhou, W.; Bao, Z.; Zhai, C.; Wang, D. Experimental Analysis of Seismic Behavior of Squat Shear Walls with Different Axial Load Ratios. Buildings 2025, 15, 4233. https://doi.org/10.3390/buildings15234233

Chang H, Zhou W, Bao Z, Zhai C, Wang D. Experimental Analysis of Seismic Behavior of Squat Shear Walls with Different Axial Load Ratios. Buildings. 2025; 15(23):4233. https://doi.org/10.3390/buildings15234233

Chicago/Turabian StyleChang, Hong, Wei Zhou, Zhibo Bao, Changhai Zhai, and Dongmei Wang. 2025. "Experimental Analysis of Seismic Behavior of Squat Shear Walls with Different Axial Load Ratios" Buildings 15, no. 23: 4233. https://doi.org/10.3390/buildings15234233

APA StyleChang, H., Zhou, W., Bao, Z., Zhai, C., & Wang, D. (2025). Experimental Analysis of Seismic Behavior of Squat Shear Walls with Different Axial Load Ratios. Buildings, 15(23), 4233. https://doi.org/10.3390/buildings15234233