Analytic Hierarchy Process–Based Evaluation and Experimental Assessment of the Optimal Interlocking Compressed Earth Block Geometry for Seismic Applications

Abstract

1. Introduction

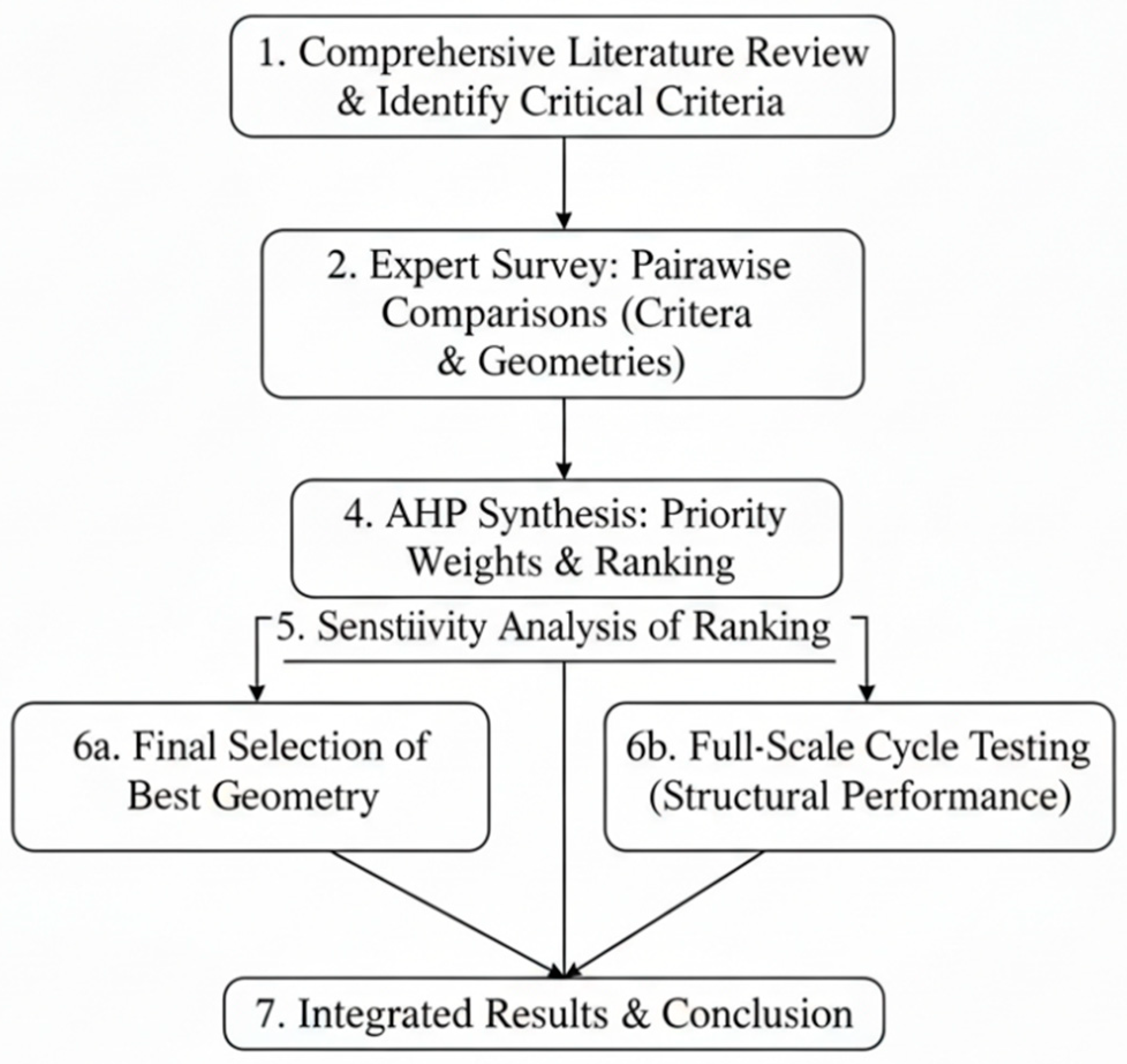

2. Research Methodology

2.1. Research Framework

2.2. Case Study

2.3. Evaluation Criteria

2.3.1. Size of ICEB

2.3.2. Weight of ICEB

2.3.3. Interlocking Capability of ICEB

2.3.4. Reinforcement and Grout Feature of ICEB

2.3.5. Ergonomics of ICEB

2.4. Scope and Rationale of Selected Criteria

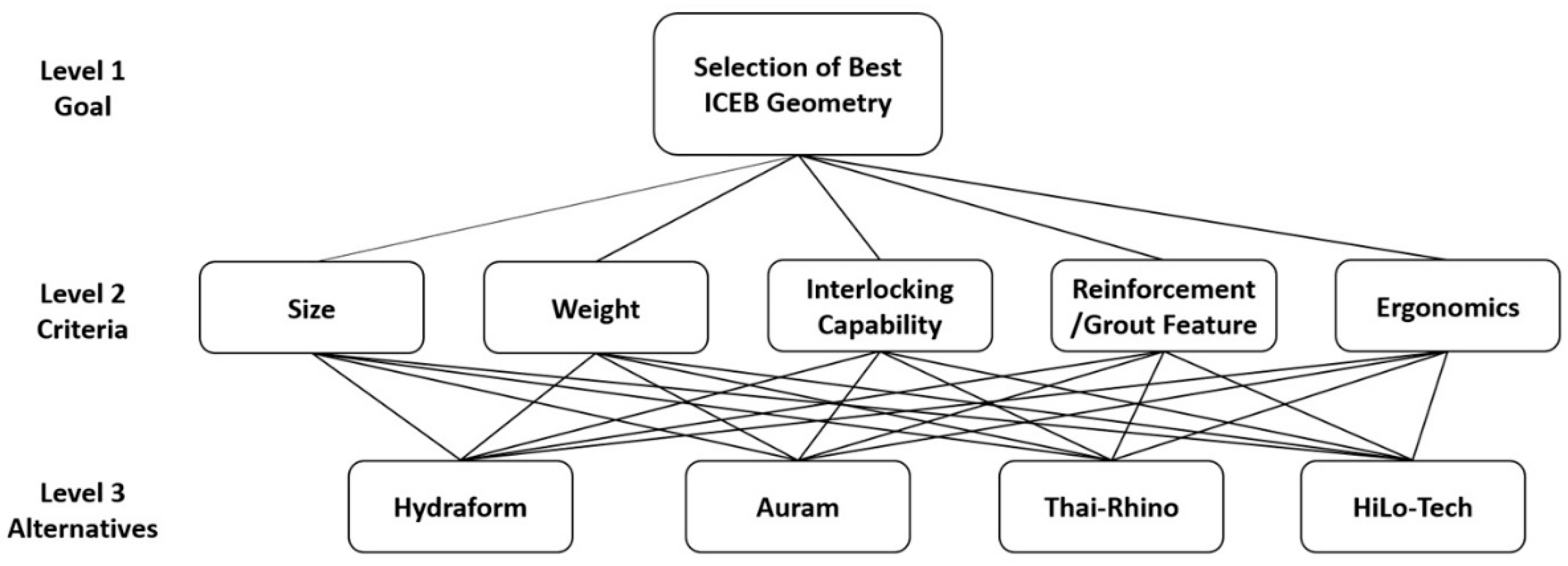

3. AHP Framework

3.1. Decision Hierarchy

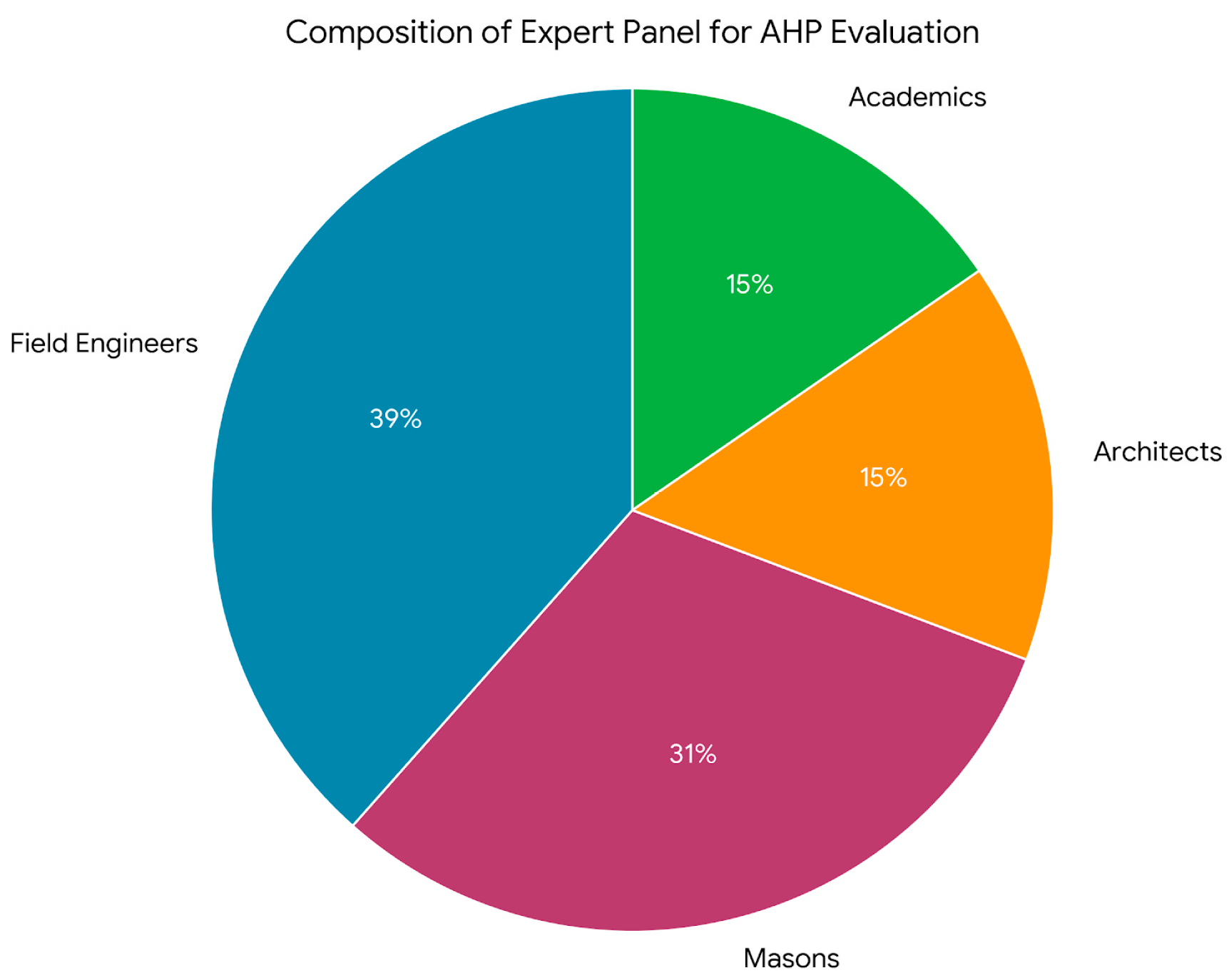

3.2. Expert Judgments and Pairwise Comparison

3.3. Consistency and Consensus Checks

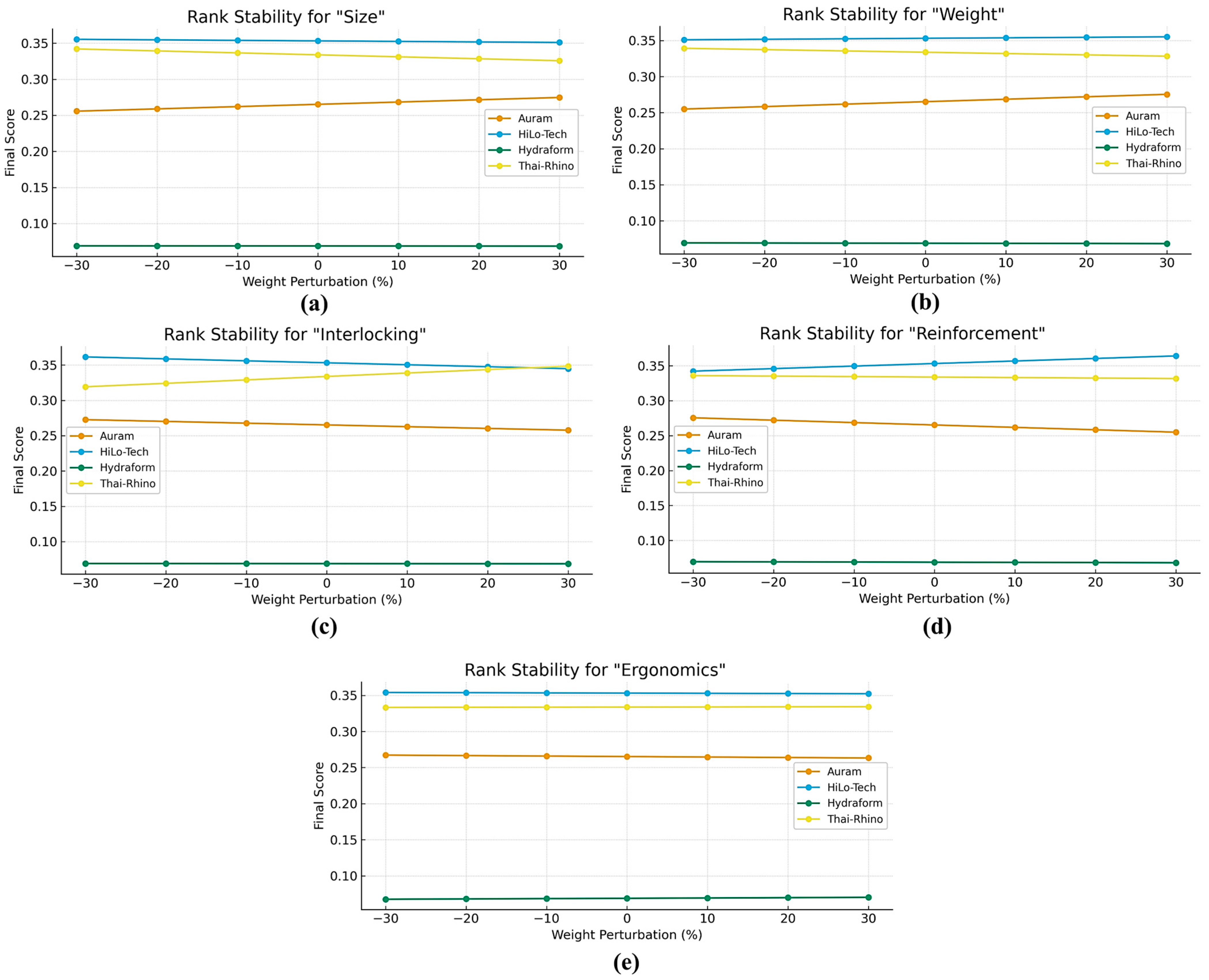

3.4. Sensitivity Analysis

4. Results

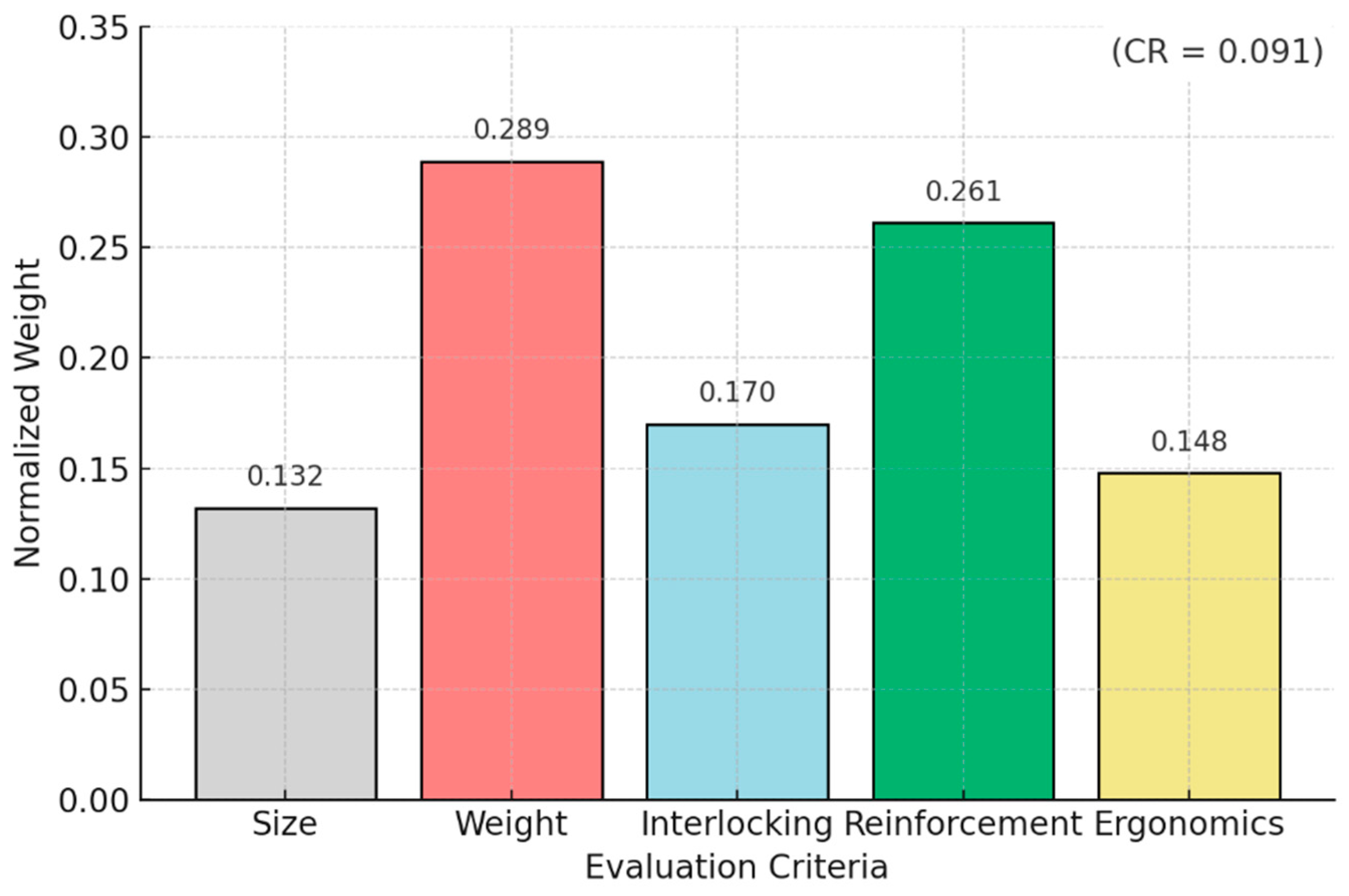

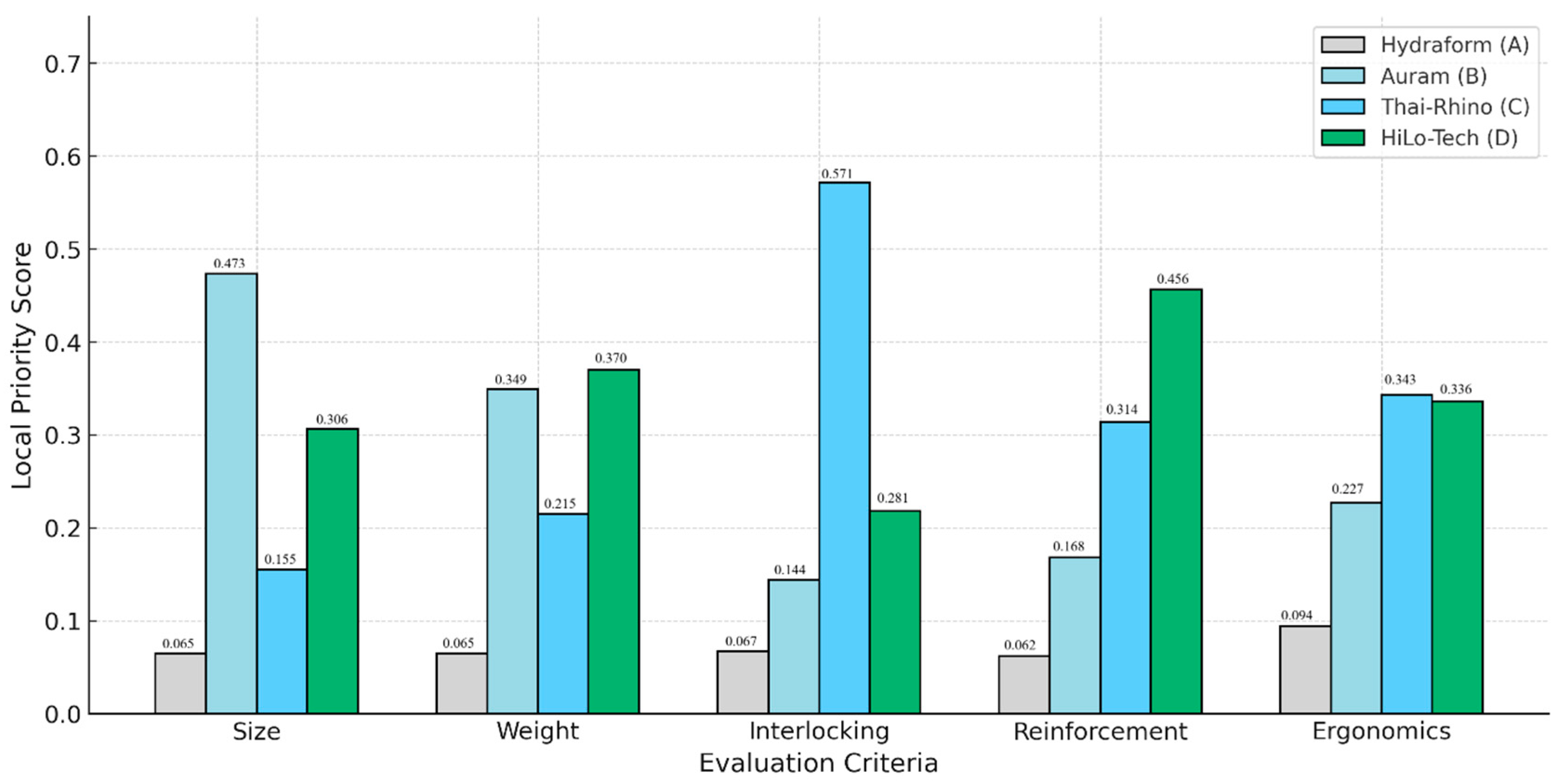

4.1. Criterion Prioritization

4.2. Ranking of Alternative Geometries

4.3. Sensitivity and Robustness Assessment

4.4. Implications for Design and Practice

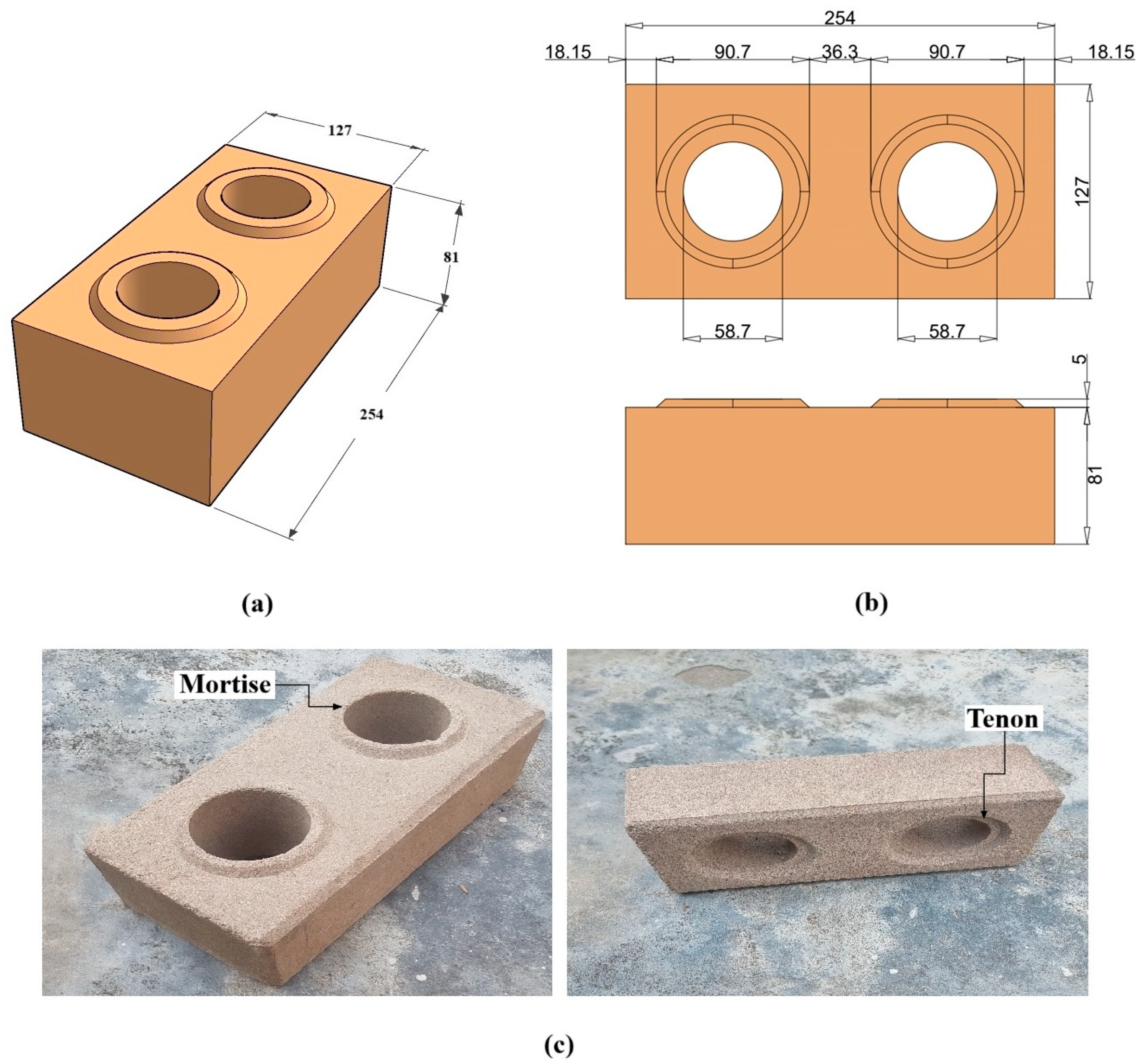

4.5. Experimental Performance Evaluation of Selected Geometry

5. Conclusions

- A manageable weight and grout/reinforcement were the main factors that determined whether the ICEB system was suitable for seismic and labor-intensive sites. The balance between constructability and structural adaptability was achieved primarily through the arrangement of lightweight, double-cavity interconnecting units. The sensitivity analysis, which supported the expert consensus, verified that this ranking remained stable under large modifications.

- Analytical results were verified through full-scale cyclic testing. The initial rigidity of the grouted double-wythe ICEB wall was lower than that of mortar-bonded brickwork, but it exhibited more robust ductility, energy dissipation, and residual strength. The analytical discovery that earthen masonry seismic resistance is contingent upon groutability and reinforcing has been verified by this performance data.

- The outcomes of the decision-making process and experimental observations suggest that ICEB systems, when effectively designed for local production and enhanced construction, can function as a technically and environmentally feasible alternative to fired-brick masonry in seismic areas. With the help of the suggested AHP framework, designers, practitioners, and policymakers can systematically incorporate expert judgment into the early stages of design to identify the best possible geometries before undertaking significant experimentation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AHP | Analytic Hierarchy Process |

| AIJ | Aggregation of Individual Judgments |

| CEB | Compressed Earth Block |

| CR | Consistency Ratio |

| CI | Consistency Index |

| ICEB | Interlocking Compressed Earth Block |

References

- Bhat, M.S.; Afeefa, Q.S.; Ashok, K.P.; Bashir, A.G. Brick kiln emissions and its environmental impact: A Review. J. Ecol. Nat. Environ. 2014, 6, 1–11. [Google Scholar] [CrossRef]

- Khan, M.W.; Ali, Y.; De Felice, F.; Salman, A.; Petrillo, A. Impact of brick kilns industry on environment and human health in Pakistan. Sci. Total Environ. 2019, 678, 383–389. [Google Scholar] [CrossRef] [PubMed]

- Houben, H.; Guillaud, H.; Houben, H. Earth Construction: A Comprehensive Guide; Earth construction series; Intermediate Technology Publications: London, UK, 1994. [Google Scholar]

- Marincic, I.; Ochoa, J.M.; Alpuche, M.G.; González, I. Comparative Analysis of the Thermal Behavior between Cellular Concrete Blocks and Stabilized Earth Blocks as Wall Materials. Energy Procedia 2014, 57, 1783–1791. [Google Scholar] [CrossRef]

- Abdullah, E.S.R.; Mirasa, A.K.; Asrah, H.; Lim, C.H. Review on interlocking compressed earth brick. IOP Conf. Ser. Earth Environ. Sci. 2020, 476, 012029. [Google Scholar] [CrossRef]

- Holliday, L.; Ramseyer, C.; Reyes, M.; Butko, D. Building with Compressed Earth Block within the Building Code. J. Archit. Eng. 2016, 22, 04016007. [Google Scholar] [CrossRef]

- Lan, G.; Wang, T.; Wang, Y.; Zhang, K. Seismic performance of interlocking compressed-earth block composite walls. Compos. Struct. 2023, 308, 116704. [Google Scholar] [CrossRef]

- Gul, A.; Alam, B.; Shahzada, K. Seismic performance evaluation of unconfined dry stacked block masonry structure. Eng. Struct. 2022, 265, 114529. [Google Scholar] [CrossRef]

- Ma, H.; Ma, Q.; Gaire, P. Development and mechanical evaluation of a new interlocking earth masonry block. Adv. Struct. Eng. 2020, 23, 234–247. [Google Scholar] [CrossRef]

- Chandra Dutta, S.; Halder, L.; Sharma, R.P. Seismic vulnerability assessment of low to mid-rise RC buildings addressing prevailing design and construction practices in the Northeastern region of the Indian subcontinent: A case study based approach. Structures 2021, 33, 1561–1577. [Google Scholar] [CrossRef]

- Punnett, L.; Wegman, D.H. Work-related musculoskeletal disorders: The epidemiologic evidence and the debate. J. Electromyogr. Kinesiol. 2004, 14, 13–23. [Google Scholar] [CrossRef]

- Ben Ayed, H.; Limam, O.; Aidi, M.; Jelidi, A. Experimental and numerical study of Interlocking Stabilized Earth Blocks mechanical behavior. J. Build. Eng. 2016, 7, 207–216. [Google Scholar] [CrossRef]

- Miccoli, L.; Müller, U.; Fontana, P. Mechanical behaviour of earthen materials: A comparison between earth block masonry, rammed earth and cob. Constr. Build. Mater. 2014, 61, 327–339. [Google Scholar] [CrossRef]

- Zahra, T.; Dorji, J.; Thamboo, J.; Asad, M.; Kasinski, W.; Nardone, A. In-plane and out-of-plane shear characteristics of reinforced mortarless concrete block masonry. J. Build. Eng. 2023, 66, 105938. [Google Scholar] [CrossRef]

- Laursen, P.T.; Herskedal, N.A.; Jansen, D.C.; Qu, B. Out-of-plane structural response of interlocking compressed earth block walls. Mater. Struct. 2015, 48, 321–336. [Google Scholar] [CrossRef]

- Anand, K.B.; Ramamurthy, K. Laboratory-Based Productivity Study on Alternative Masonry Systems. J. Constr. Eng. Manag. 2003, 129, 237–242. [Google Scholar] [CrossRef]

- Jibril, J.D.; Mukarram, M.A. An evaluation of the critical factors influencing productivity of masonry work in construction sites in Kano, Nigeria. Bayero J. Pure App. Sci. 2021, 12, 40–48. [Google Scholar] [CrossRef]

- Hema, C.; Messan, A.; Lawane, A.; Soro, D.; Nshimiyimana, P.; Van Moeseke, G. Improving the thermal comfort in hot region through the design of walls made of compressed earth blocks: An experimental investigation. J. Build. Eng. 2021, 38, 102148. [Google Scholar] [CrossRef]

- Ghaseminia, S.M.; Zahra, T.; Thambiratnam, D.P.; Thamboo, J. In-Plane Drift Characteristics of Fully Grouted Reinforced Masonry Shear Walls; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- Kasinikota, P.; Tripura, D.D. Shear capacity of interlocking compressed stabilized earth block masonry panels. Eur. J. Environ. Civil Eng. 2025, 29, 112–138. [Google Scholar] [CrossRef]

- Masonry Society. Building Code Requirements and Specification for Masonry Structures (TMS 402/602-16); Masonry Society: Boulder, CO, USA, 2016. [Google Scholar]

- Caruana, C.; Yousif, C.; Bacher, P.; Buhagiar, S.; Grima, C. Determination of thermal characteristics of standard and improved hollow concrete blocks using different measurement techniques. J. Build. Eng. 2017, 13, 336–346. [Google Scholar] [CrossRef]

- Bland, D.W. In-Plane Cyclic Shear Performance of Interlocking Compressed Earth Block Walls; California Polytechnic State University: San Luis Obispo, CA, USA, 2011. [Google Scholar]

- Samarakoon, S.M.S.M.K.; Ratnayake, R.M.C. End-of-life solution prioritization for pre-cast concrete components aligning with circular economy targets. Struct. Concr. 2022, 24, 1751. [Google Scholar] [CrossRef]

- Saaty, T.L.; Wind, Y. Marketing applications of the analytic hierarchy process. Manag. Sci. 1980, 26, 641–658. [Google Scholar] [CrossRef]

- Saaty, T.L.; Vargas, L.G. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Chao, L.; Liang, C. A refined consistency assessment for group decision-making using AHP. Mathematics 2024, 12, 828. [Google Scholar] [CrossRef]

- Ryu, J.; Banting, B.; Abdel-Rahman, E.; Haas, C.T. Ergonomic Characteristics of Expert Masons. J. Constr. Eng. Manag. 2023, 149, 04022150. [Google Scholar] [CrossRef]

- Khan, J.S.; Khan, A.; Zahra, T. Seismic performance of traditional brick–mortar and interlocking compressed earth brick walls under cyclic loading. In Proceedings of the 15th Canadian Masonry Symposium, Ottawa, ON, Canada, 2–5 June 2025; pp. 1–10. Available online: https://www.canadamasonrydesigncentre.com/wp-content/uploads/15th_symposium/094-Khan.pdf (accessed on 1 October 2025).

- Cao, Z.; Zhang, S.; Xue, Y.; Wang, Z.; Du, F.; Li, Z.; Huang, C.; Wang, S.; Yu, Y.; Wang, W.; et al. Disaster-causing mechanism of spalling rock burst based on folding catastrophe model in coal mine. Rock Mech. Rock Eng. 2025, 58, 7591–7604. [Google Scholar] [CrossRef]

- Zhengzheng, C.; Yi, X.; Yi, X.; Feng, D.; Zhenhua, L.; Cunhan, H.; Shuren, W.; Yongqiang, Y.; Wenqiang, W.; Minglei, Z.; et al. Diffusion evolution rules of grouting slurry in mining-induced cracks in overlying strata. Rock Mech. Rock Eng. 2025, 58, 6493–6512. [Google Scholar] [CrossRef]

- ASTM C476; Standard Specification for Grout for Masonry. ASTM International: West Conshohocken, Pennsylvania. Available online: https://store.astm.org/c0476-23.html (accessed on 8 October 2025).

- Sturm, T.; Ramos, L.F.; Lourenço, P.B. Characterization of dry-stack interlocking compressed earth blocks. Mater. Struct. 2015, 48, 3059–3074. [Google Scholar] [CrossRef]

- Sturm, T.; Ramos, L.F.; Lourenço, P.B.; Campos-Costa, A. Mechanical Characterization of Dry-Stack Interlocking Compressed Earth Masonry. In Proceedings of the 9th International Masonry Conference (9IMC), Guimarães, Portugal, 7–9 July 2014; Paper No 1466. Lourenço, P.B., Haseltine, B., Vasconcelos, G., Eds.; International Masonry Society/University of Minho: Guimarães, Portugal; p. 12. Available online: https://hdl.handle.net/1822/30866 (accessed on 8 October 2025).

| Alternative | Size (mm) | Weight (kg) | Interlocking | Reinforcement | Ergonomics | Keynote |

|---|---|---|---|---|---|---|

| A—Hydraform | 240 × 220 × 115 | 10–12 | Horizontal key (height ≈ 5–10 mm); alignment ridge only in bed joint | None | Solid body; no finger grip; heavy to lift, frequent trimming | Good mass and stiffness, but poor ergonomics; unsuitable for seismic reinforced walls |

| B—Auram | 295 × 145 × 95 | 6–8 | Groove-and-tongue interlocking key (height ≈ 9 mm) | 1 small central core | Side grooves and chamfered edges enable better finger hold and safe placement | Easy to handle but limited rebar use; esthetic finish preferred for façades |

| C—Thai-Rhino | 300 × 150 × 100 | 6–8 | Dual keys (height ≈ 12 mm) providing a strong mechanical fit | 2 cores + groove | Side grooves, chamfered | Secure interlock, good seismic fit, but reduced net area |

| D—HiLo-Tec | 280 × 140 × 90 | 5–7 | Dual circular keys (height ≈ 10 mm) for two-way interlock | 2 full-height cores | Integrated finger grips, chamfered corners, lightweight, stable placement | Balanced design; ergonomically superior and reinforcement-ready |

| Scale Value | Verbal Judgment of Preference | Explanation |

|---|---|---|

| 1 | Equal importance | Two variables contribute equally to the objective |

| 3 | Moderate importance | Experience somewhat advantages one variable over another |

| 5 | Strong importance | Experience judgment significantly favors a single variable |

| 7 | Very strong importance | Dominance of one variable is demonstrated in practice |

| 9 | Extreme importance | Evidence favors one element absolutely |

| 2, 4, 6, 8 | Intermediate values | Used when a compromise is needed between two adjacent judgments |

| Reciprocals (1/3, 1/5, etc.) | Inverse judgments | If element i is favored over j with a given scale, then j is valued at the reciprocal compared to i |

| Parameter | Criteria-Level (5 × 5) | Size (4 × 4) | Weight (4 × 4) | Interlocking (4 × 4) | Reinforcement (4 × 4) | Ergonomics (4 × 4) |

|---|---|---|---|---|---|---|

| Matrix order (p) | 5 | 4 | 4 | 4 | 4 | 4 |

| Principal eigenvalue (λₘₐₓ) | 5.45 | 4.15 | 4.13 | 4.19 | 4.2 | 4.18 |

| Consistency Index (CI) | 0.112 | 0.05 | 0.043 | 0.063 | 0.067 | 0.06 |

| Consistency Ratio (CR) | 0.091 | 0.056 | 0.048 | 0.07 | 0.074 | 0.066 |

| Criteria | Size | Weight | Interlocking | Reinforcement | Ergonomics | Normalized Weight (wᵢ) |

|---|---|---|---|---|---|---|

| Size | 1 | 0.455 | 0.776 | 0.505 | 0.892 | 0.132 |

| Weight | 2.198 | 1 | 1.7 | 1.106 | 1.953 | 0.289 |

| Interlocking | 1.288 | 0.588 | 1 | 0.653 | 1.148 | 0.170 |

| Reinforcement | 1.981 | 0.904 | 1.531 | 1 | 1.763 | 0.261 |

| Ergonomics | 1.121 | 0.512 | 0.871 | 0.567 | 1 | 0.148 |

| Criterion | Size (mm) | Weight (kg) | Interlocking | Reinforcement | Ergonomics | Weighted Global Score | Rank |

|---|---|---|---|---|---|---|---|

| Criterion Weight | 0.132 | 0.289 | 0.17 | 0.261 | 0.148 | ||

| Hydraform (A) | 0.065 | 0.065 | 0.067 | 0.062 | 0.094 | 0.069 | 4 |

| Auram (B) | 0.473 | 0.349 | 0.144 | 0.168 | 0.227 | 0.266 | 3 |

| Thai-Rhino (C) | 0.155 | 0.215 | 0.571 | 0.314 | 0.343 | 0.312 | 2 |

| HiLo-Tec (D) | 0.306 | 0.37 | 0.218 | 0.456 | 0.336 | 0.353 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, J.S.; Khan, A.; Alhassani, F. Analytic Hierarchy Process–Based Evaluation and Experimental Assessment of the Optimal Interlocking Compressed Earth Block Geometry for Seismic Applications. Buildings 2025, 15, 4234. https://doi.org/10.3390/buildings15234234

Khan JS, Khan A, Alhassani F. Analytic Hierarchy Process–Based Evaluation and Experimental Assessment of the Optimal Interlocking Compressed Earth Block Geometry for Seismic Applications. Buildings. 2025; 15(23):4234. https://doi.org/10.3390/buildings15234234

Chicago/Turabian StyleKhan, Junaid Shah, Azam Khan, and Faisal Alhassani. 2025. "Analytic Hierarchy Process–Based Evaluation and Experimental Assessment of the Optimal Interlocking Compressed Earth Block Geometry for Seismic Applications" Buildings 15, no. 23: 4234. https://doi.org/10.3390/buildings15234234

APA StyleKhan, J. S., Khan, A., & Alhassani, F. (2025). Analytic Hierarchy Process–Based Evaluation and Experimental Assessment of the Optimal Interlocking Compressed Earth Block Geometry for Seismic Applications. Buildings, 15(23), 4234. https://doi.org/10.3390/buildings15234234