2.1. Development and Application of BIM in the Construction Field

BIM constitutes a suite of information technologies [

12]. The term itself dates back to 1992 and embodies the concept of creating an intelligent virtual model that systematically supports the entire asset life cycle, spanning design, construction, operation, and maintenance. This process is enabled by cloud-based shared digital platforms that standardize data exchange, facilitating multi-party collaboration through unified data formats. The resulting integrated data management system is known as the “Common Data Environment” (CDE).

A key advantage of BIM lies in its capacity to leverage computer-based pre-construction simulation, which provides guidance for actual construction operations. It also offers lightweight modeling tools that assist designers in rapidly developing physical engineering models and generating model-based animation simulations of the construction process. As such, BIM [

13] represents the integrated application of a series of technological solutions aimed at enhancing cross-organizational and interdisciplinary collaboration within the construction industry, thereby improving productivity and quality across architectural design, construction, and maintenance.

In recent years, with the advancement of BIM technology, its integrated application with other new digital tools—such as the Internet of Things (IoT), big data, and artificial intelligence (AI)—has demonstrated significant advantages. Compared to conventional methods, these integrated approaches greatly optimize resource allocation and enhance efficiency throughout the entire building life cycle. Each of these technological integrations contributes distinctly to reducing carbon emissions across the building’s lifespan.

Y Jia [

14] indicates that the integration of BIM and IoT technologies serves as a driving force for the digital transformation of the construction industry, with analysis showing a steady annual increase in the research literature in this field. Peiming Qiao [

15] discusses specific applications of BIM technology across various stages of the construction process, including model integration, design optimization, construction schedule control, site navigation and walkthroughs, as well as on-site management in smart construction. These applications not only improve the precision of construction activities but also enhance the intellectualization of project management. Wei Cui [

16] and colleagues integrated real-time dynamic data from environmental monitoring sensors with building information models to simulate, monitor, and manage environmental changes on construction sites. In addition, the combined use with IoT technology helps leverage the strengths of both approaches, offering a more efficient and intelligent management platform for engineering projects.

Liang Zhao et al. [

17] point out that although BIM technology has been widely adopted in numerous projects, its application in energy-efficient retrofitting of existing buildings often faces challenges due to difficulties in acquiring relevant data. By utilizing a scan-to-BIM approach, which involves creating a BIM model through approximate and boundary matching with point cloud data within modeling tools, the completeness and accuracy of data acquisition can be significantly improved.

While the integration of new technologies such as the Internet of Things (IoT), big data, and artificial intelligence (AI) with BIM is gradually becoming a key driver of innovation in the construction industry, most current studies have only demonstrated the utility of BIM for specific purposes or processes, overlooking the importance of enhancing BIM’s intelligence throughout entire projects. Moreover, the inherently fragmented nature of the construction industry itself constitutes another critical barrier hindering the widespread adoption of intelligent technologies in the field [

18].

2.2. Life Cycle Carbon Emissions of Buildings

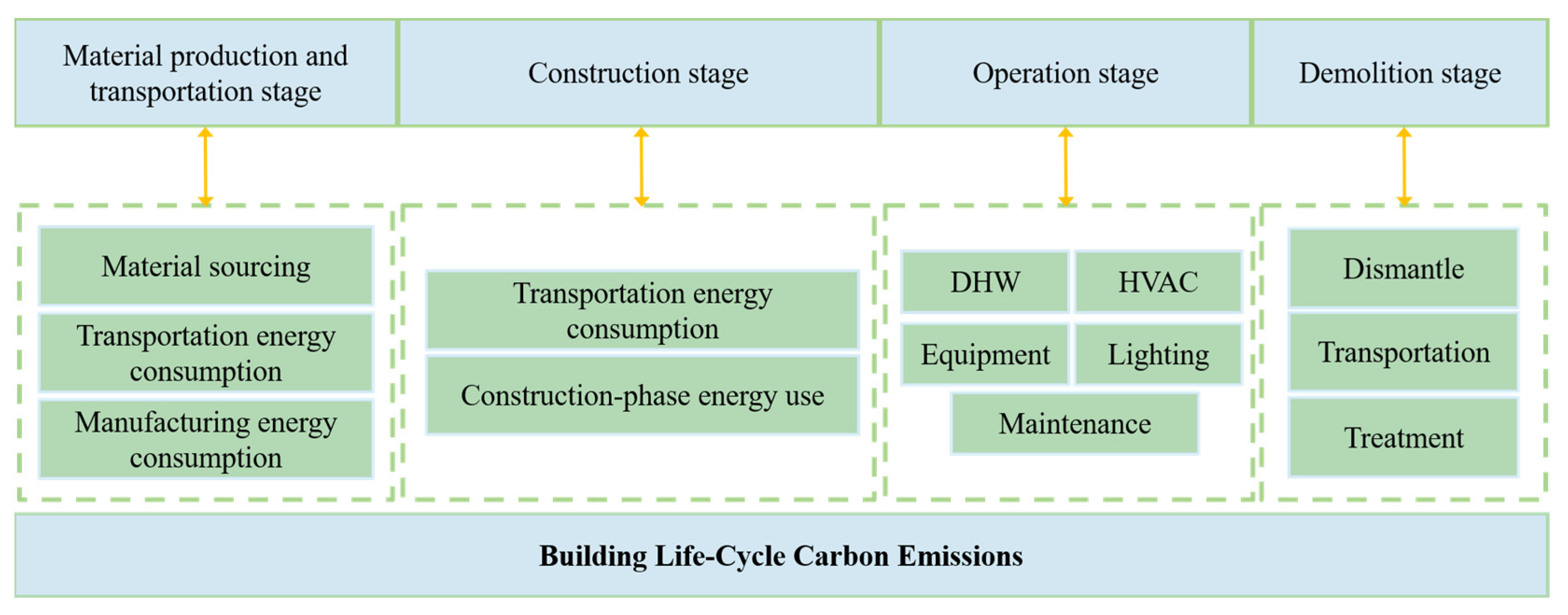

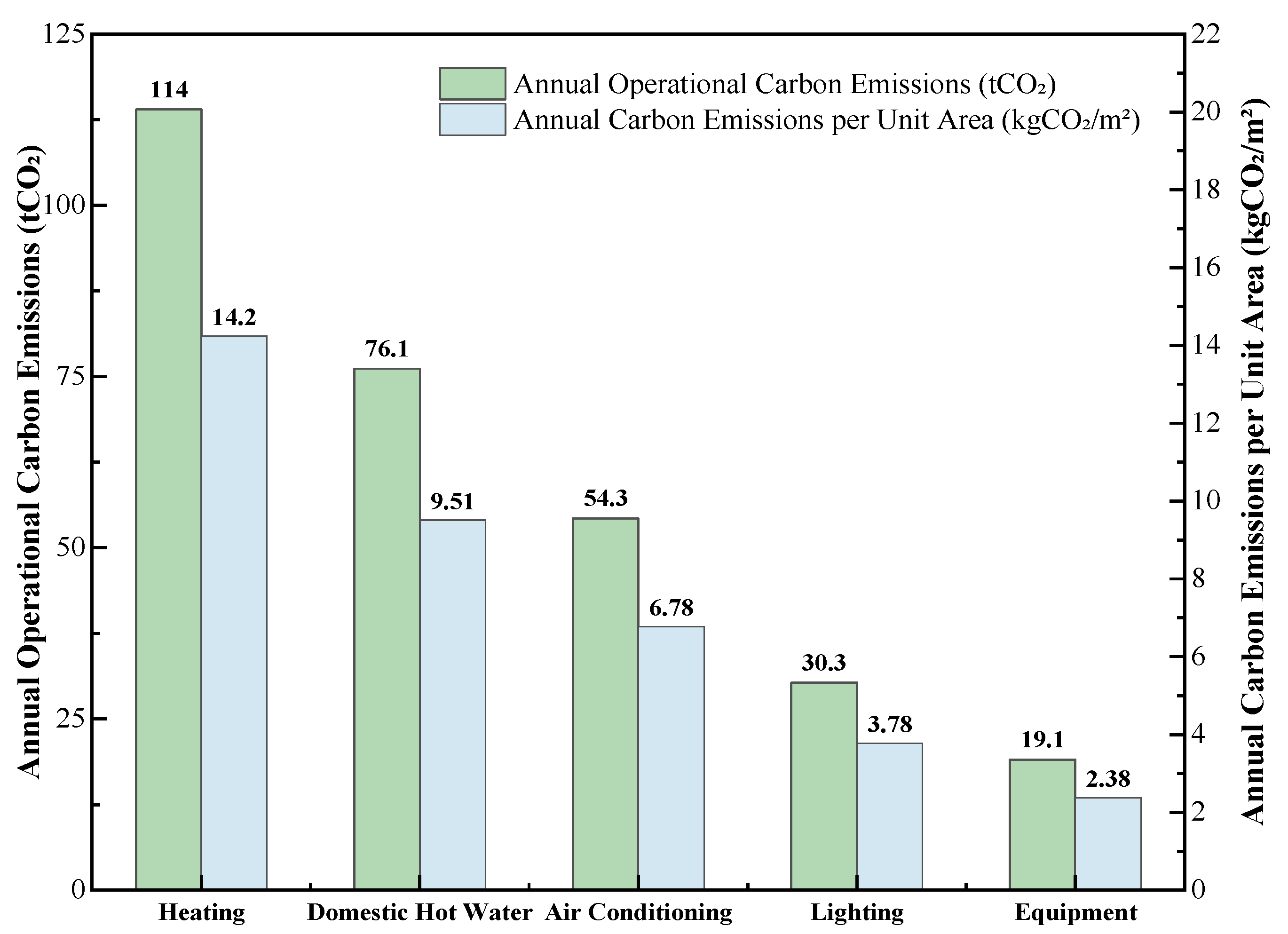

Most studies categorize the calculation of life cycle carbon emissions from buildings into distinct phases: embodied carbon, construction, operation, and demolition. Based on the theory of building life cycle, researchers have developed various methods to construct carbon emission calculation models for conducting comprehensive assessments of carbon footprints over the entire lifespan of buildings.

Yubing Zhang [

19] proposed a BIM-based methodology to integrate life cycle carbon emissions with life cycle cost, aiming to assess the carbon emission intensity (CEI) of buildings. Using a case study of a public building in China, the feasibility of this approach was validated. Through CEI analysis, key stages contributing to carbon emissions were identified, and strategies for transitioning from high-carbon to low-carbon materials were explored.

Farah Adilah Binti Jamaludin [

20] employed a LCA approach to calculate the carbon emissions of buildings by integrating relevant indicators, conducting a comprehensive multi-dimensional evaluation of the low-carbon performance of green buildings. The research conducted quantitative analysis across five stages of the building construction process and five evaluation dimensions, establishing a conceptual model for low-carbon assessment of green buildings. Gray relational analysis and the analytic hierarchy process (AHP) were applied to rank and evaluate the projects.

Feifei CHEN [

21] proposed a method for calculating and evaluating building thermal energy consumption and carbon emissions. The study first emphasized the important value and application potential of BIM technology in the energy consumption evaluation of green buildings. Taking a stadium as an example, a carbon emission accounting system for the building construction and installation processes was established based on BIM technology, through which the carbon emissions during these phases were calculated and analyzed. Yong Yang [

22] developed a rapid calculation and analysis system for bridge carbon emissions based on BIM and LCA. This system, centered around a bridge information model, integrates data on material consumption, mechanical equipment, transportation, and energy use to compute carbon emissions at each stage of the bridge’s life cycle.

Due to differences in the selected research objects, objectives, methodologies, and platforms, studies on building carbon emissions vary in their focus. Some research [

23,

24] concentrates on building materials and construction methods. For instance, Jiawei Zhang [

25] proposed a metamaterial-inspired controllable steel structure, which integrates periodically arranged local resonance substructures within the main system, overcoming the traditional limitation of requiring extensive additional mass for effective local resonance. Xiaojuan Li [

26], targeting the embodied stage of precast concrete composite panel (PCC) projects, integrated LCA, BIM, and Geographic Information System (GIS) technologies to develop a carbon footprint accounting model covering the production, transportation, and installation stages, enabling a quantitative analysis of carbon emission distribution. Case studies revealed a significant negative correlation between the prefabrication rate and carbon emissions per unit area and cost, indicating that increased application of PCC can reduce the carbon footprint by decreasing material consumption.

Other studies [

27,

28] focus primarily on reducing operational energy consumption in buildings to achieve carbon emission reduction. For example, Mahmoud Ouria [

29] optimized residential building design by incorporating phase change materials (PCMs) and high-efficiency HVAC systems, aiming to control thermal discomfort to below 1%, achieve negative carbon emissions, and reduce costs. Most significantly, Yang et al., (2025) developed a comprehensive spatial LCA framework that systematically integrates GIS, BIM, and LCA methodologies for urban-scale building assessment [

30]. This framework, compliant with ISO 14040/14044 standards [

31,

32], demonstrates that Urban Net Zero Energy Building strategies can achieve 40% reduction in life-cycle carbon emissions. The research highlights the importance of identifying impact hotspots (e.g., low-rise apartments) and addresses burden-shifting across life-cycle phases. This macro-level urban assessment approach complements our focused study on residential buildings in Central China, together advancing BIM-LCA applications in building carbon management.

Recent methodological advances show the growing sophistication of LCA applications. Payandeh et al., (2025) combined LCA with Data Envelopment Analysis to optimize environmental efficiency in production systems, demonstrating how operational benchmarks can guide environmental improvements [

33]. This approach offers valuable insights for optimizing building operational carbon management. Furthermore, Aruta et al., (2025) developed a multi-objective optimization framework that balances private economic interests with public policy goals in building energy retrofit [

34]. Their methodology, which identifies optimal trade-offs between cost savings and energy benefits, provides important implications for designing effective incentive policies to promote PV integration in building retrofit projects.

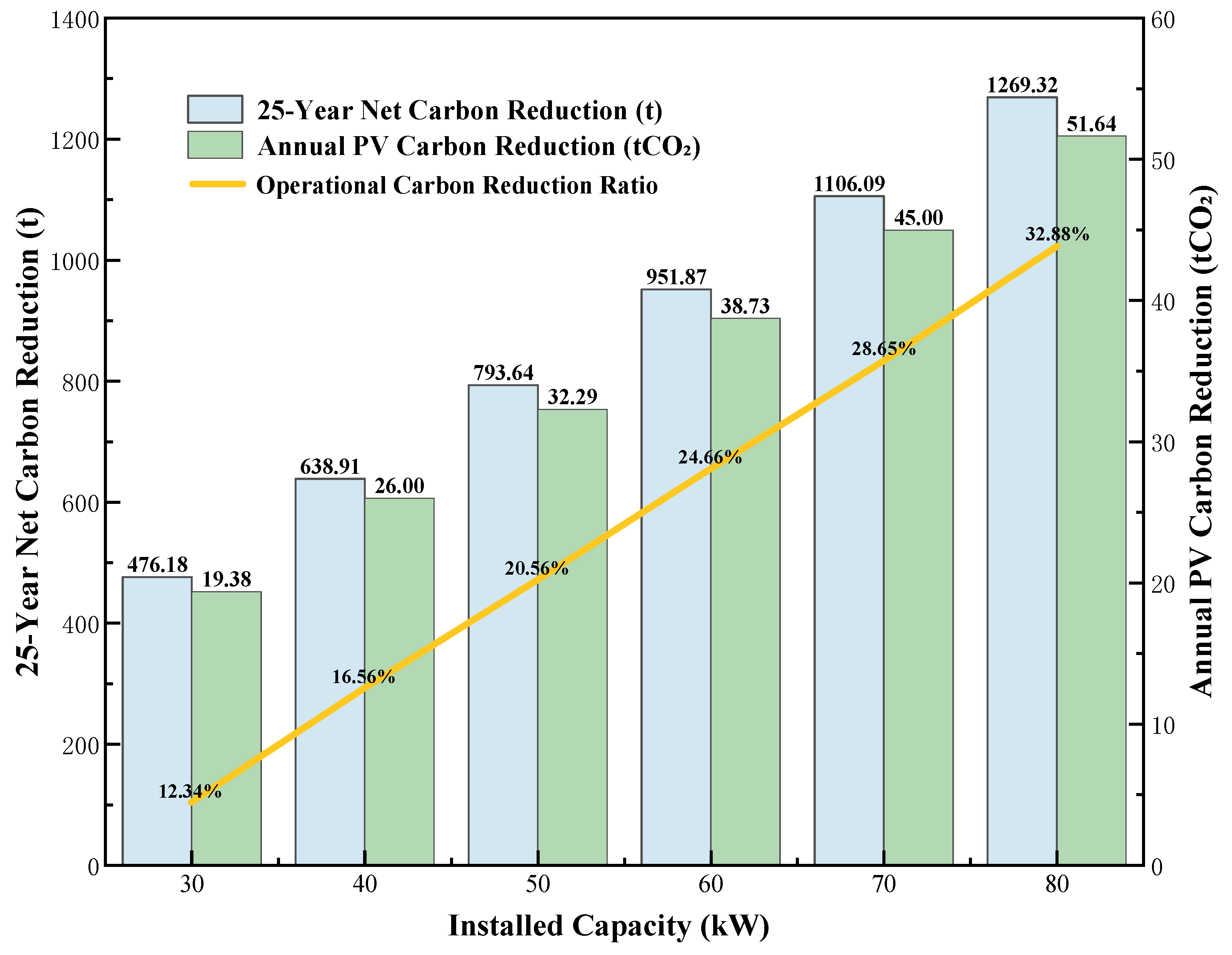

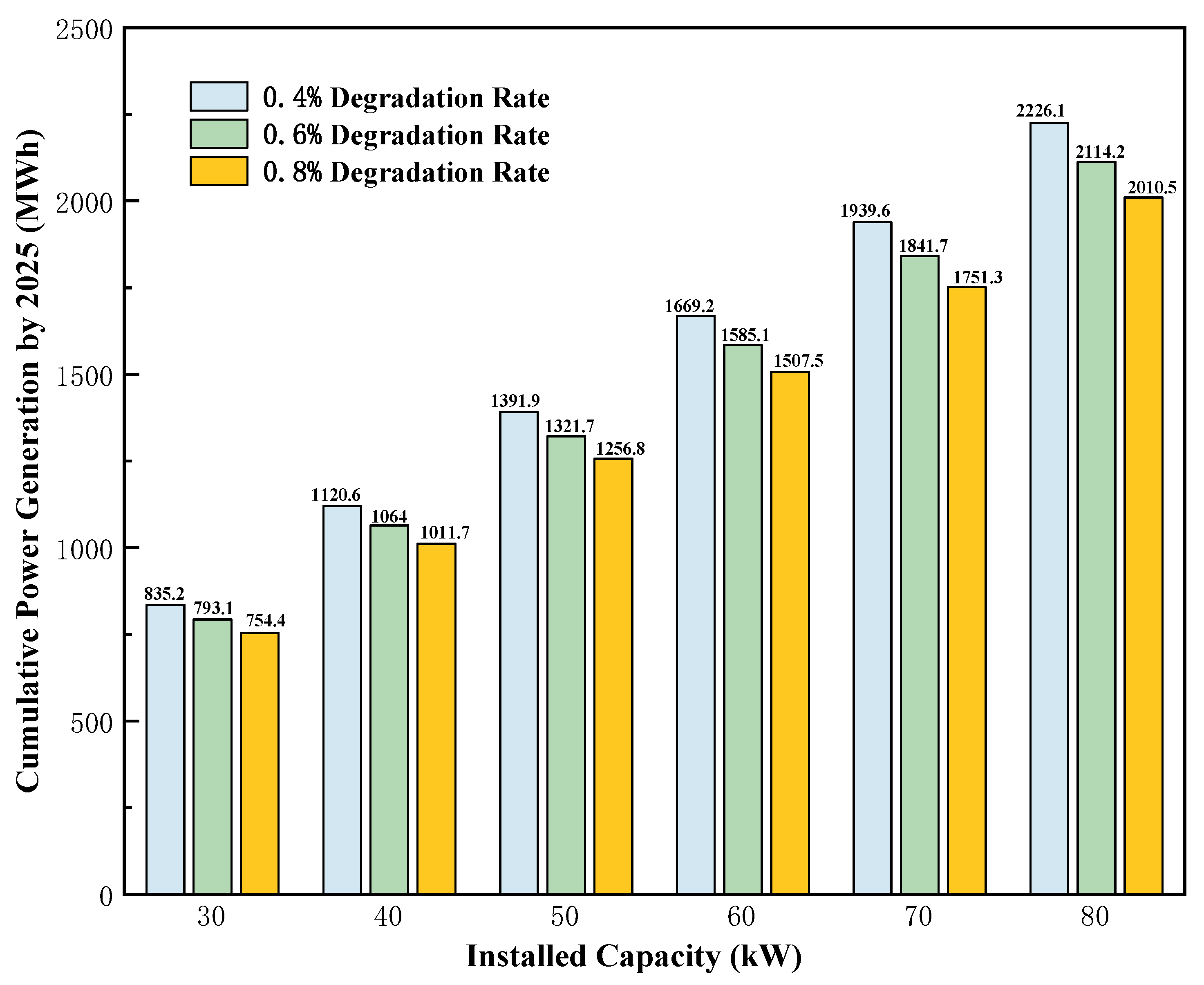

Regarding photovoltaic carbon accounting, Guo et al., established a comprehensive carbon emission model for China’s PV supply chain, demonstrating significant emission reduction potential [

35]. Yu et al., conducted a comprehensive energy-economy-environment evaluation of BIPV across Chinese climate zones, revealing that combined rooftop and facade systems can reduce urban CO

2 emissions by 35.50% [

36]. From an international perspective with relevant climatic conditions, Lodhi et al. proposed a novel framework combining deep learning and atmospheric modeling for urban PV assessment in Lahore, Pakistan, demonstrating substantial carbon reduction potential [

37]. Buyak et al., evaluated low-carbon regeneration strategies in Eastern Europe, emphasizing the synergistic role of PV systems in building modernization [

38].

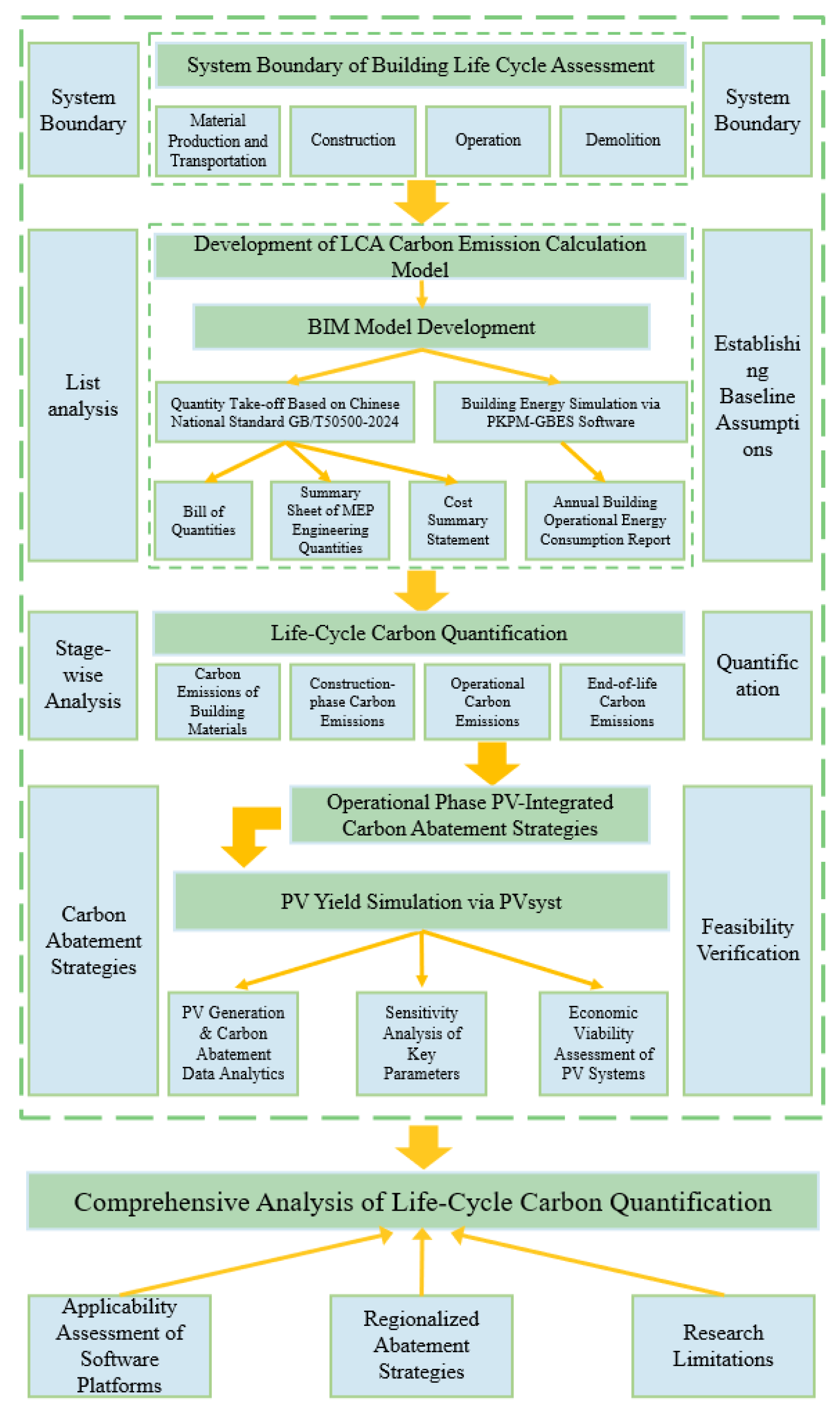

In summary, although current research on life-cycle carbon emission assessment in buildings has established fundamental methodologies, significant limitations remain: most assessment models fail to deeply integrate dynamic building information flows, resulting in fragmented data and insufficient accuracy. At the same time, quantitative analysis of the benefits of renewable energy carbon reduction strategies—such as photovoltaic (PV) systems—particularly in the context of regionally optimized applications for residential buildings, remains relatively underdeveloped. BIM technology, with its capability for digital integration and simulation across the entire process of planning, design, construction, and operation, provides core support to overcome these challenges. Therefore, this study focuses on residential buildings in Central China and innovatively develops a BIM-based life-cycle assessment framework. Specifically, BIM-enabled parametric modeling and data linkages are utilized to achieve accurate quantification of carbon emissions throughout stages such as embodied carbon, construction, operational energy consumption, and demolition and recycling. Furthermore, PV systems are incorporated as a key carbon reduction variable to simulate their power generation performance, carbon reduction potential, and life-cycle economic performance under the climatic conditions of Central China. Finally, multi-scenario analysis is conducted to propose cost-effective PV integration strategies, offering empirical support and technical pathways for the low-carbon design and retrofitting of residential architecture in the region.