Abstract

The evaluation of interfacial bonds between polymeric cementitious composites (PCCs) and concrete is considered as a critical factor to determine structural safety, durability, and service life regarding the repair and strengthening of old concrete structures. Conventional evaluations of interfacial bond strength have primarily relied on destructive testing methods, such as the pull-off and slant shear tests. However, these methods inherently possess fundamental limitations, including localized damage, non-uniform stress distribution, and uncertainty in result interpretation. This review aims to provide a comprehensive overview of existing standards and methods for assessing interfacial bond strength. For this purpose, the evaluation methods and results for the interfacial bond strength between cementitious composites such as PCCs and concrete were systematically reviewed. It further examines the characteristics and sources of error of the representative destructive method (pull-off test), highlighting its inherent limitations. Furthermore, this study conducted an in-depth analysis of a hybrid evaluation strategy combining non-destructive testing (NDT) and artificial intelligence (AI) to overcome the limitations of conventional interfacial bond strength assessment methods and minimize prediction errors. The results demonstrated that the NDT–AI hybrid approach, based on an ANN–BFGS model, achieved the highest accuracy in bond strength prediction and was identified as the optimal method for quantitatively and non-destructively evaluating interfacial bond behavior.

1. Introduction

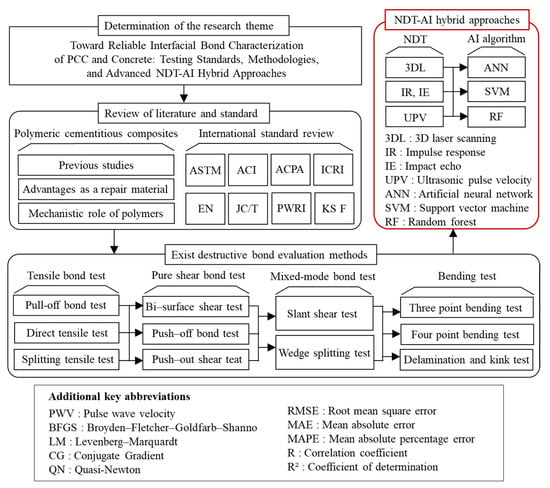

Cement-based materials have been widely used for the repair of concrete structures despite these materials exhibiting distinct limitations, including low tensile and flexural strength, insufficient chemical resistance, high drying shrinkage, high permeability, and significant water absorption []. To address these limitations, polymeric cementitious composites (PCCs) have been considered as one of the most useful repair materials for the restoration and strengthening of concrete structures. Various types of PCCs offer superior mechanical strength compared to conventional cement-based repair materials [,] and further enhance durability properties such as water resistance, chemical resistance, and freeze–thaw resistance [,,,]. In addition, PCCs demonstrate excellent adhesion to concrete substrates [,]. This is attributed to polymer’s ability to fill the pores within the cement matrix, thereby increasing density, reducing permeability, and improving mechanical performance, durability, and interfacial quality. Ensuring the quality and reliability of interfacial bonding between PCCs and existing concrete substrates is essential for the effective application of PCCs in concrete structure repair. This is because the PCC–concrete interface is often regarded as one of the most structurally vulnerable regions due to defects such as microcracks, voids, and gaps []. Adequate interfacial bond strength is required to effectively resist stresses caused by external factors such as volumetric changes, vibrations, and freeze–thaw cycles, thereby maximizing the effectiveness of the repair []. Due to this significance, precise evaluation of interfacial bond strength has remained an important research topic in both academia and engineering practice. Traditionally, destructive testing methods have been widely employed for interfacial bond strength assessment due to their procedural simplicity and ease of result interpretation. Representative standardized methods include the pull-off test, splitting tensile test, and push-off test. The quantitative evaluation of interfacial bond characteristics is considered a critical indicator for ensuring structural reliability in the performance assessment of PCCs. In particular, as a repair material, the performance of PCCs significantly depends on its integration quality with the existing concrete substrate, which directly affects the service life and maintenance efficiency of structures; thus, bond strength evaluation is essential for assessing the practical applicability of the material. Accordingly, destructive bond testing has long been employed as the most direct and standardized approach to elucidate the interfacial bond behavior between PCCs and concrete. Previous studies demonstrated that the optimal incorporation rate of epoxy resin (approximately 5%) induces maximum interfacial bond strength through direct shear tests [], while pull-off tests reported that SBR latex significantly enhances the bond strength of PCCs, reaching approximately 2.39 MPa []. These findings highlight the importance of a materials engineering approach for improving bonding mechanisms. However, destructive testing methods are inherently limited in reliability due to specimen damage and the impossibility of repeated measurements, localized failure caused by stress concentration, adhesive degradation, and variations in construction conditions. In addition, the testing process fails to sufficiently reflect the long-term bonding performance of structures and poses challenges in ensuring reproducibility. Therefore, to overcome these inherent limitations, the development of a non-destructive (NDT) and AI-based hybrid evaluation approach, complemented by a comprehensive quantitative database of destructive test results, is proposed as a crucial direction for future research. However, the splitting tensile test has been reported to overestimate bond strength compared with the pull-off test or direct tensile test [,] and fails to adequately reflect frictional effects, limiting its ability to accurately reproduce complex in situ loading conditions []. The push-off test evaluates horizontal shear strength under vertical stress applied to the interface, and test results indicate that surface roughness and cohesion parameters significantly influence shear capacity [,,]. Furthermore, the push-off test is characterized by a major drawback of stress concentration at the edges of the bonded interface []. For these reasons, the pull-off test has become the most standardized and widely adopted method for evaluating repair mortars, overlays, and polymer-modified composites in both laboratory studies and field applications [,,]. Nevertheless, the pull-off test remains vulnerable to various factors, including insufficient adhesive curing, adhesive degradation, and misalignment, and is characterized by sensitivity to testing conditions and a high standard deviation in results [,]. Consequently, numerous studies have incorporated NDT methods, including 3D laser scanning [,,], impulse response [,,], and impact echo [,,], to compensate for the limitations of the pull-off test. Recent advancements have focused on enhancing diagnostic capability through artificial intelligence (AI)-based data analysis []. As reported in the studies by Flores-Colen et al. [,], the field coefficient of variation (CoV) for the pull-off test showed high uncertainty, reaching 32% to 104%. However, previous research [] demonstrated that a unidirectional multilayer backpropagation Artificial Neural Network (ANN) applying the Broyden–Fletcher–Goldfarb–Shanno (BFGS) algorithm could effectively compensate for this variability by exhibiting high correlation in all stages: training (R = 0.9691 ± 0.0296$), testing (R = 0.9575 ± 0.0289$), and validation (R = 0.9815 ± 0.0197$). Accordingly, this review is organized to first examine existing standards, followed by a critical evaluation of the pull-off test, an overview of non-destructive testing modalities, a comparison of AI-based approaches, and finally, a discussion on practical field implementation strategies. Consequently, we reviewed the NDT-AI hybrid approach, and the overall flow of this study is presented in Figure 1 below.

Figure 1.

Research flow adopted in this study.

This review is designed to predict interfacial bond behavior with high precision across diverse PCC types and environmental conditions, explicitly combining experimental measurements, data-driven modeling, and algorithm optimization. By doing so, the present research goes beyond the mere application of existing destructive or non-destructive evaluation methods and provides a practical approach that significantly enhances the reliability and accuracy of PCC—concrete interfacial bond assessment. Consequently, the outcomes of this study demonstrate a clear academic distinction from previous work and offer a generalized methodology applicable to both laboratory settings and real structural applications. To conduct a systematic literature review, this study utilized three major academic databases: Scopus, Web of Science, and ScienceDirect. The analysis of prior research specifically focused on studies published between 2015 and 2024. The inclusion criteria were set as experimental studies evaluating the mechanical properties of polymeric cementitious composites. Studies that did not report quantitative data or were outside the scope of the research were excluded. The selected studies were thoroughly investigated based on the type of test (e.g., bond, compression, or tensile tests), the applied standard (e.g., EN or ASTM standard), and the type of NDT where applicable. This systematic approach aids in understanding the trends in existing research and the methodological approaches employed.

2. Polymeric Cementitious Composites for Concrete Repair

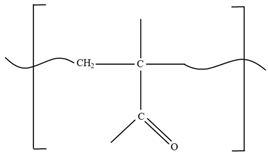

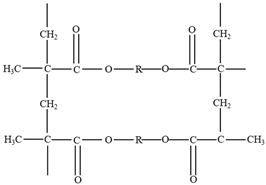

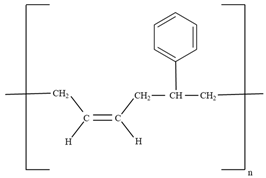

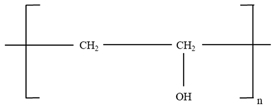

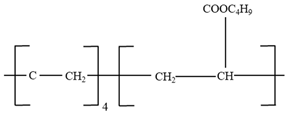

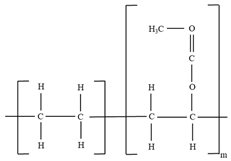

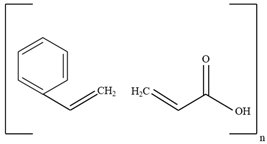

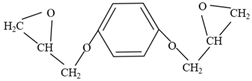

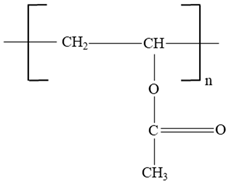

Polymers are widely utilized to enhance the mechanical performance and durability of cementitious composites, including cement mortar and concrete, thereby contributing to the repair and extended service life of structures. Representative types of polymers employed for such purposes are summarized in Table A1 [,,,,,,,,,,,,,,,,,,,,], and their performance has been validated through numerous studies. To maximize the structural performance of PCCs, it is essential to ensure uniform dispersion of polymers within the cement matrix. To achieve this, incorporation techniques such as the direct addition method, emulsion addition method, and separate mixing method are employed []. When polymers are uniformly dispersed in cementitious composites, the mechanical and durability properties of cement-based materials are improved through both the physical and chemical actions of the polymers. The physical action refers to the pore-filling effect, which occurs as polymer emulsions adsorb onto the surfaces of cement particles and hydration products during the cement hydration process. This action reduces the porosity of cement mortar and, consequently, enhances its physical and mechanical properties []. Moreover, the pore-filling effect and increased surface contact area facilitate enhanced interfacial adhesion between PCCs and the concrete substrate, as the polymer-enriched matrix can better conform to micro-textures and surface irregularities of the underlying concrete, reducing stress concentrations at the interface. A study investigated factors influencing the pore structure of PCCs using mercury intrusion porosimetry (MIP) and analysis of variance (ANOVA) []. The results reported that, in addition to curing conditions, the EVA content was a major factor affecting pore characteristics. Furthermore, previous research has shown that the water absorption of mortars incorporating acrylic polymer and epoxy resin decreased by 45% and 55%, respectively []. These results indicate that polymer incorporation significantly reduces the porosity of mortar, thereby improving its impermeability properties. The cement hydration process is a fundamental reaction that governs the structural properties of concrete and mortar. Tricalcium silicate (Ca3SiO5, C3S) and dicalcium silicate (Ca2SiO4, C2S) react with water (H2O) to form calcium silicate hydrate (CaO·2SiO2·4H2O, C–S–H) and calcium hydroxide (Ca(OH)2) (Equation (1)). C–S–H serves as a structural gel that provides mechanical strength to concrete and mortar, while Ca(OH)2 establishes a highly alkaline environment that facilitates subsequent chemical interactions with polymers. For instance, carboxyl groups (-COOH) of polymers such as polyacrylamide (PA) can interact with Ca2+ ions released from Ca(OH)2, forming a cross-linked polymer network (Equation (2)). This network plays a critical role in reducing porosity and enhancing impermeability within the mortar and acts as a key mechanism for simultaneously improving the durability, mechanical performance, and interfacial properties of polymer-modified mortars [].

2Ca3SiO5 + 6H2O → 3CaO · 2SiO2 · 4H2O + 3Ca(OH)2

2Ca3SiO4 + 4H2O → 3CaO · 2SiO2 · 4H2O + Ca(OH)2

During the initial hydration stage (5–35 min), the pH of the pure cement system increased from 10.32 to 12.80 [], indicating the formation of a highly alkaline and exothermic environment upon mixing cement and water. Under these conditions, the ester groups of polyacrylates undergo hydrolysis, converting into carboxyl groups, and the reaction rate is influenced by temperature and solution acidity. Specifically, polyacrylates exhibit the highest hydrolysis activity at approximately 80 °C under low pH conditions (3–6), whereas the reaction is inhibited as the pH increases []. This hydrolysis process provides a critical basis for explaining the adhesion mechanisms between polymers and cement hydration products. Simultaneously, calcium silicate hydrate (C–S–H) formed during cement hydration develops a gel-like structure that determines the strength of the cement matrix, while calcium hydroxide (portlandite) exists as a crystalline phase and serves to elevate the internal pH of the concrete. Polymer networks exist as three-dimensional structures, and when these networks form a continuous phase, they develop into a film-like structure known as a polymer film. When applied over existing concrete, the polymer film bridges the PCC matrix and the concrete substrate at the micro-scale, filling surface voids and enhancing mechanical interlock. Previous studies have reported that incorporating SBR latex into expanded polystyrene (EPS) lightweight concrete results in the formation of SBR films within the cement matrix, which enhances the bonding strength between the cement matrix and EPS particles. Consequently, compressive strength increased by up to 21.43% and flexural strength by 91.67% compared to mixes without polymer incorporation []. Similarly, when PVA was incorporated into concrete at dosages of 5.0% and 10.0%, a three-dimensional PVA network structure was formed within the matrix []. This structure led to increases in the 90 days compressive strength of polymer-modified concrete by 27.3% and 23.3%, respectively, compared to plain concrete. These findings demonstrate that the network and film formation mechanisms of polymers reinforce the interfacial structure of cementitious composites. Consequently, they significantly enhance mechanical performance and satisfy the performance requirements essential for repair materials.

3. Established Standards and Conventional Destructive Testing Methods

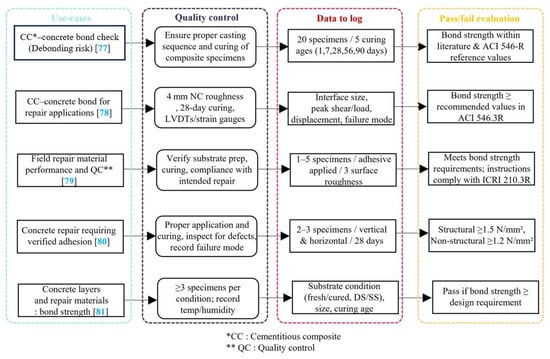

3.1. International Standards for Bond Performance Requirement for the Repair Material

The interfacial bond performance of repair and strengthening materials for concrete structures has been internationally recognized as a critical parameter for ensuring structural safety and long-term durability. Consequently, standardization bodies across various countries have developed bond strength evaluation criteria that account for diverse environmental conditions and material properties, with substantial progress made toward the standardization of testing methodologies. Table 1 summarizes representative bond performance evaluation standards established in major countries and regions, including the United States (US), Europe, China, Japan, and Korea. Also, Figure 2 presents the recommended testing methods, use cases, quality control, data to log, and conformity assessment reported in the prior literature.

Table 1.

International standards for basic bond performance requirements for concrete structure repairs [,,,,,,,,].

Figure 2.

Use cases, quality control, data log, and conformity assessment from prior research [,,,,].

In the United States, ASTM C928/C928M–20 [] and ACI 546.R–96 [] present a performance verification framework centered on the slant shear test, specifying bond strengths ranging from 2.76 MPa to 20.68 MPa depending on curing age (1 day–28 days). Additionally, ACI 546.3R–06 [] incorporates both direct tensile tests and pull-off tests to evaluate bond performance. The standard sets requirements of 0.5–2.1 MPa for direct tensile tests and 0.48–1.7 MPa for pull-off tests, reflecting a focus on balancing early strength development with long-term adhesion. The European standard EN 1504–3 [] differentiates required bond strength by performance class (Class R1–R4), stipulating a minimum tensile bond strength of 2.0 MPa at 7 days for Class R4 materials. This classification-based approach highlights a flexible design strategy for accommodating diverse repair and strengthening scenarios. In China, the JC/T–2019 [] employs a stretching test, with reference values specified according to test conditions. Japan’s PWRI standard [], based on the pull-off test, mandates a minimum bond strength of 1.5 MPa under standard conditions. Under durability assessment conditions, such as a 1-year dry/wet cycling test, the minimum required bond strength is 1.0 MPa, explicitly accounting for long-term performance. Similarly, Korea’s KS F 4042 [] standardizes the pull-off test, requiring a minimum bond strength of 1.0 MPa at 28 days. These standards collectively exhibit notable distinctions in terms of test methodology, strength thresholds, and curing age specifications. Particularly, the widespread adoption of the pull-off test in countries such as the United States and Japan demonstrates its acceptance as a reliable and widely applicable method for assessing interfacial bond performance under tensile stress. Furthermore, these national standards extend beyond mere strength verification, offering a practical foundation for design and quality control that emphasizes durability evaluation, environmental compatibility, and long-term performance assurance.

3.2. Destructive Bond Evaluation Methods

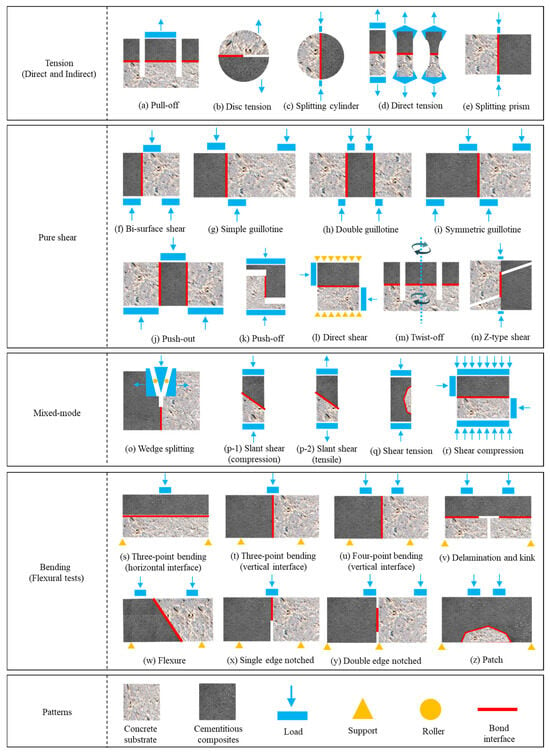

Destructive testing has historically been the most traditional and widely adopted method for evaluating the interfacial bond performance between repair and strengthening materials and substrate concrete. Destructive methods remain a critical diagnostic tool because they allow for the direct quantification of maximum bond strength, failure patterns, and behavioral characteristics at the interface. Figure 3 provides a schematic overview of destructive testing methods, classified according to load transfer mechanisms and interface failure modes into tension (direct and indirect), pure shear, mixed-mode, and bending/flexural tests. Table 2 summarizes previous studies on interfacial bond tests, categorized by bonding specifications and test types. It provides a comprehensive overview of the testing methods, types of substrate concrete, overlay materials, applicable standards, and corresponding references. This summary demonstrates that destructive testing methods have been optimized in accordance with the type of repair and strengthening material (e.g., polymer-modified mortar, fiber-reinforced concrete, ultra-high-performance concrete) and the intended application.

Figure 3.

Schematics of test methods for assessing the interfacial bond between concrete and cementitious repair composites.

Table 2.

Summary of bond tests conducted in previous studies [,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,].

Recent studies on destructive testing have actively employed a variety of methods to evaluate the interfacial bond behavior between PCCs and concrete, including pull-off, splitting, direct tension, pure shear, mixed-mode, bending, peeling, and kick tests. The scope of research has expanded to include polymer-cement mortars, fiber-reinforced concretes, ultra-high-performance concrete (UHPFRC), and self-compacting high-performance concrete (SCHPC), with analyses increasingly focusing on the interfacial strength and failure patterns as influenced by overlay thickness, surface roughness, and material composition [,,,,,,,,].

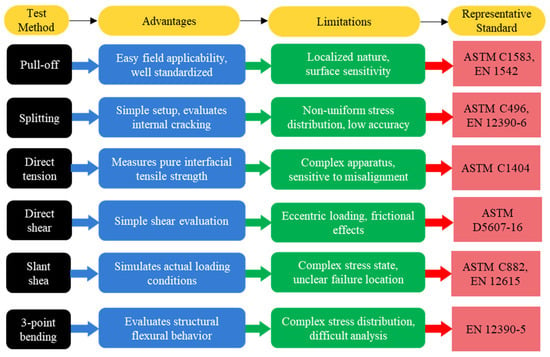

In particular, studies on inclined shear tests simulating mixed stress states [,,,,,,,,,,,] and interfacial evaluations under bending loads [,,,,,,,,] have become more prevalent. These investigations provide essential data for interfacial design and the assessment of repair material performance by more realistically reflecting actual structural conditions. A comparative framework illustrating the strengths and weaknesses of each testing method is presented in Figure 4. In addition, the potential sources of error that may occur in destructive tests are summarized in Table 3.

Figure 4.

A comparative framework illustrating the strengths and weaknesses of each testing method.

Table 3.

Sources of error depending on the testing method [,,,,,,,,,,,,].

Tension tests represent the most fundamental and intuitive approach for directly assessing interfacial bond strength, with the pull-off test being the most representative. Standardized by international protocols such as ASTM C1583, EN 1542, and KS F 2762, the pull-off test involves bonding a dolly of specified diameter to the interface and applying a vertical tensile load to induce failure. The splitting test evaluates bond performance by applying compressive loads to cylindrical or prismatic specimens to generate indirect tensile stresses, standardized under ASTM C496 and EN 12390–6. Direct tension tests are standardized under ASTM C1404. Pure shear tests are designed to replicate shear-dominated conditions in actual structures, making them suitable for analyzing shear force transfer mechanisms across interfaces. Direct shear tests, as defined in ASTM D5607–16, are used to evaluate the interfacial characteristics of high-strength materials such as UHPFRC. To reflect the combined effects of tensile and shear stresses encountered under in situ conditions, mixed-mode tests are also employed. A representative example is the slant shear test (ASTM C882, EN 12615), which induces combined shear-compression stresses through interfaces inclined at 30–45°. Flexural or bending-based tests focus on evaluating the bending resistance and failure behavior of the interface. These include three- and four-point bending tests, as well as delamination and kink tests, standardized under EN 12390–5, ASTM C78, ASTM C293–08, and KS F 2408. While these destructive methods play a critical role in interfacial bond research due to their standardized measurement protocols, they inherently require specimen destruction. Accordingly, the following section examines the intrinsic limitations of the pull-off test, which is widely recognized as a representative destructive evaluation method. Section 5 then discusses future research directions aimed at enhancing reliability through the integration of NDT and AI.

4. Methodological Overview and Constraints of the Pull-Off Test

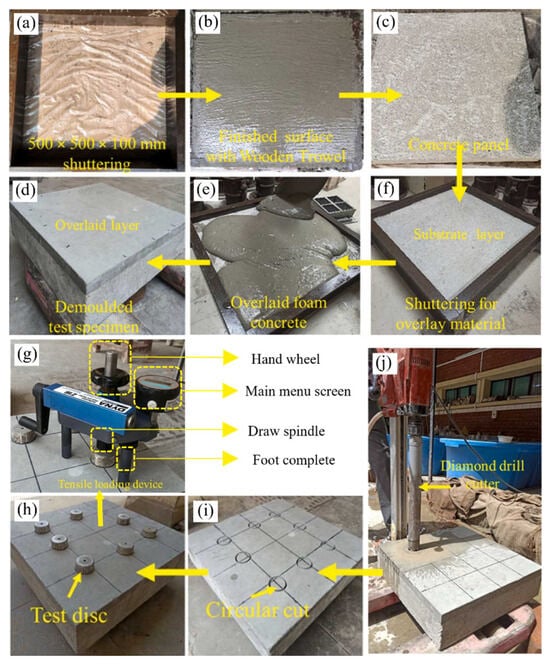

In the pull-off test, substrate concrete is cast and cured before overlay materials are applied without surface treatment. Prior to testing, a circular core is drilled beneath the interface, and an aluminum disk is bonded with epoxy to complete specimen preparation. The specimen fabrication and preparation process are illustrated in Figure 5a–f, while the testing procedure on the prepared specimens is presented in Figure 5g–j.

Figure 5.

Pull-off testing configuration and images after performing pull-off test: (a–f) procedure for producing pull-off testing panels; (g–j) procedure for pull-off testing [].

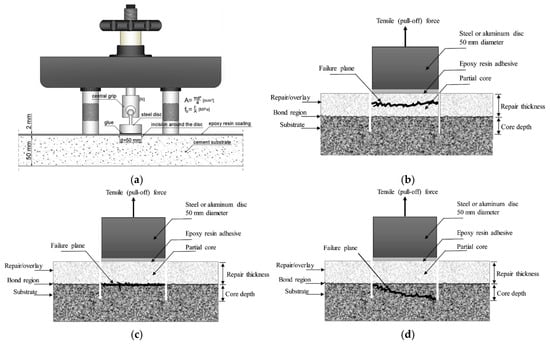

Figure 6a illustrates the schematic configuration and setup of a conventional pull-off test apparatus. According to ASTM C1583, the pull-off test is conducted by bonding a loading disk to the overlay surface with an adhesive. Once the adhesive has fully cured, the testing apparatus is attached and carefully aligned with the disk. A tensile load is then applied perpendicular to the test surface. As the tensile load increases, failure occurs along the weakest plane within the system [,,]. Interfacial failures following the pull-off test predominantly occur within the overlay (Figure 6b), along the adhesive interface (Figure 6c), or within the concrete substrate itself (Figure 6d), and may also arise in the epoxy used to bond the loading disk to the core. The size and location of the fracture surface reflect the behavior of the materials comprising the specimen [].

Figure 6.

Schematic representation of pull-off test: (a) View of the pull-off test stand []; (b–d) failure modes comprising repair mortar, interface bond, and substrate [].

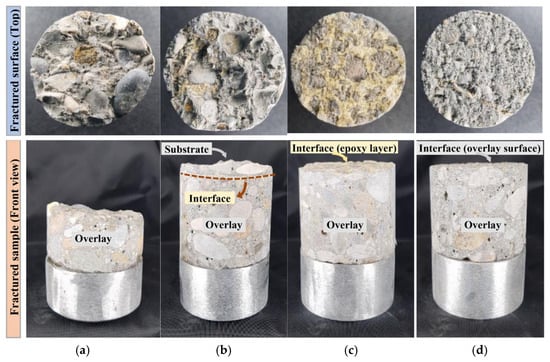

Figure 7 provides a visual representation of the various failure modes observed at the interface after testing, as viewed from both the front side of the specimen and the top failure surface. The pull-off strength (SPO) is defined as the tensile force (FT) divided by the area of the fracture surface (Af), as expressed in Equation (3).

Figure 7.

Representative pull-off test samples highlighting different failure modes. (a,b) cohesive failure in the concrete overlay and substrate; (c) adhesive alternating crack failure; (d) adhesive interfacial failure between the epoxy layer and overlay [].

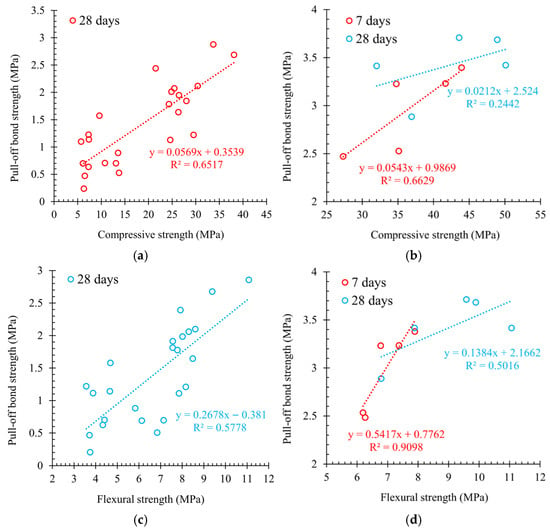

The SPO of PCCs can be utilized as a mechanical performance indicator closely associated with its compressive and flexural strengths. According to previous studies, the correlation coefficient (R2) between SPO and compressive strength has been reported to reach up to 0.6629, while that between SPO and flexural strength has been reported to reach up to 0.5778 [,]. A graphical representation of the correlations between SPO and the compressive and flexural strengths of PCCs is presented in Figure 8. Among various bond performance evaluation methods, the pull-off test has emerged as a representative tensile adhesion test for both in situ quality control and laboratory analysis of material bonding characteristics and failure patterns. Its procedural simplicity and versatility have established it as one of the most widely used evaluation method [,,]. However, the measured results of this test can be significantly influenced by a variety of test conditions, including the strength grade of the concrete substrate, coring depth, and base thickness [,]. During the test, a rotary core drill is used to cut the bonded surface, which requires the application of uniform pressure to both the concrete overlay and substrate []. In practice, however, microcracks generated during drilling can reduce bond strength, and this factor is highly dependent on the operator’s skill []. Moreover, load eccentricity is affected by the orthogonality of the core drill and the precise positioning of the loading disk [].

Figure 8.

Strength relationships of PCCs: (a,b) compressive and pull-off bond strengths; (c,d) flexural and pull-off bond strengths. Reproduced from [,].

Insufficient orthogonality can amplify eccentricity effects as coring depth increases, thereby reducing the reliability of the test results. In addition, the pull-off test is time-consuming [], and the damaged areas generated during testing require subsequent repair, limiting the number of measurable locations []. Consequently, localized zones of weak adhesion may not be adequately identified, which can compromise the long-term durability of the repair []. The checklist for the pull-off test corresponding to this is as follows.

Test Technician Checklist:

- Required alignment tolerance (°): 90 ± 0.1° to 90 ± 1.4° [];

- Acceptable coring depth range (mm) per dolly size: or a 50 mm dolly, drill 15 mm into the substrate (EN 1542 []);

- Do-not-use criteria: total test time must not exceed the limit (<90 s, EN 1542 []; 20–60 s, EN 1015-12 []).

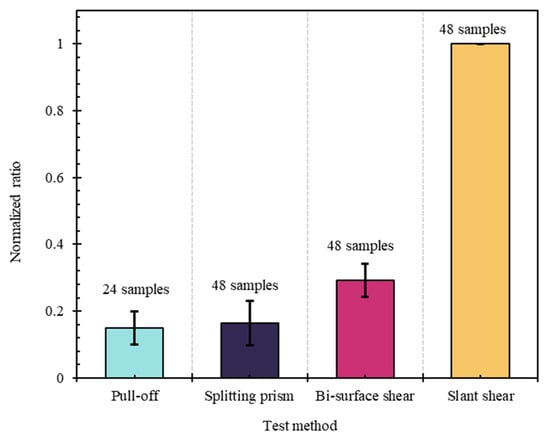

Comparative studies with other bond strength evaluation methods, such as slant shear, double shear, and splitting tensile tests, have shown that the pull-off test tends to yield relatively lower bond strength values []. The normalized bond strength ratio based on adhesion tests is presented in Figure 9. This is attributable not only to the procedural limitations but also to the structural characteristic of applying the load solely in the perpendicular direction, which does not account for frictional resistance at the interface. For these reasons, there is a continuing need to supplement or replace the pull-off test with alternative evaluation methods. Recent studies have explored hybrid approaches that integrate NDT techniques with ANN to overcome these limitations and enhance the precision of bond performance assessment [,,,].

Figure 9.

Normalized bond strength ratio based on bond tests [].

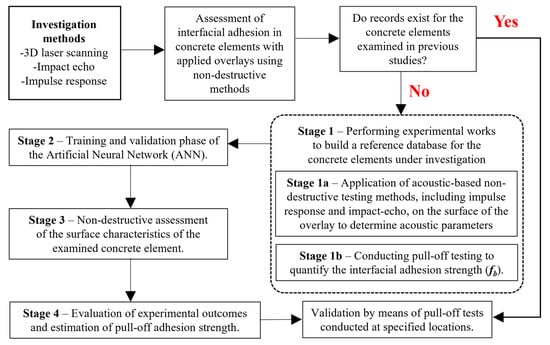

5. Hybrid NDT and AI-Based Evaluation Approaches

The conventional pull-off test, which is widely used to evaluate PCC–concrete interfacial bond strength, has inherent limitations due to its destructive nature and sensitivity to local heterogeneity. Ultrasonic NDT has been employed to investigate interfacial quality, including the assessment of adhesive bond integrity and the detection of disbonding or delamination [,]. Several studies have also been conducted to detect weak and kissing bonds [,]. Conventional longitudinal pulse-echo ultrasonic testing, as well as advanced measurement techniques such as acoustic microscopy, air-coupled ultrasonics, and guided waves have been utilized to evaluate bond quality [,]. In addition, nonlinear behavior has been reported to correlate with bond quality through nonlinear ultrasonic NDT [,]. Since ultrasonic NDT is a directional technique, it offers advantages in detecting and localizing defects. The classical pulse-echo method, being a one-sided inspection technique, provides superior performance compared to through-transmission methods, but it requires coupling between the transducer and the specimen, typically using a medium such as water. Air-coupled ultrasonics can overcome this limitation; however, a significant signal amplitude loss occurs due to the high acoustic impedance mismatch between air and the solid structure []. In contrast, guided wave testing enables the inspection of large specimens within a short period of time. Lamb waves, in particular, have been reported as an effective technique for determining joint quality [,]. Nevertheless, the analysis of the resulting data is highly complex and generally dependent on the specific characteristics of the specimen. However, NDT data, such as the frequency response of the impact echo (IE) method, provide indirect physical information related to interfacial bond strength. However, in actual structures, the signal is often distorted by a combination of factors, including the location of defects, geometric discontinuities, material heterogeneity, surface roughness, and structural noise induced by interface echoes. Consequently, it is challenging to directly derive bond strength from such signals [,]. In particular, for ultrasonic and thermographic diffusion-based signals, conventional response parameters such as absolute amplitude or time of flight difference can only indicate the presence of defects, while offering limited capability for quantitatively assessing defect depth or bonding quality. For this reason, traditional post-processing approaches relying on single-signal variables (e.g., amplitude or frequency) are insufficient to ensure a satisfactory probability of detection []. In contrast, artificial intelligence (AI) can learn multidimensional interactions among various signal features (amplitude, phase, frequency, etc.), thereby minimizing information loss inherent in traditional post-processing and identifying defect patterns hidden within noise. Neural network-based models, in particular, can quantitatively capture the nonlinear relationship between signal characteristics and response, enabling an effective interpretation of the complex correlation between NDT data and actual bond strength []. Consequently, AI serves as a key tool to overcome the intrinsic limitations of conventional NDT signal interpretation and enhance the reliability of defect detection. The procedure for correcting pull-off test results using the NDT-AI hybrid approach is schematically outlined in Figure 10. To ensure the reliability of NDT-AI-based bond strength prediction during the field verification stage, this study proposes a co-correction strategy utilizing pull-off test data. The proposed strategy consists of four core phases: data acquisition, AI training and co-correction, field application, and result verification and iterative refinement. First, in the data acquisition phase, after selecting representative areas of the target structure, various NDT methods, such as IE, infrared thermography (IR), and Acoustic Impulse Response, are performed to secure key characteristic parameters at each location. Simultaneously, the actual bond strength is measured by conducting at least one pull-off test per certain area of the structure. Test locations are selected through stratification by the overlay thickness quartiles to reflect the influence of interlayer thickness variation on bond strength. The established data constitute the core database for ANN training and validation. The AI training and co-correction phase proceeds based on the collected NDT indicators and the corresponding pull-off bond strength data. This study utilizes a Multilayer Perceptron (MLP) structure based on the Gradient Descent (GD) algorithm, applying an empirically optimized value for the number of hidden layer neurons. Crucially, by including the stratification information obtained from the pull-off tests as an input variable, the ANN can effectively correct interlayer bonding characteristics that are difficult to capture solely with NDT signals. During the training process, the dataset is appropriately split into training and validation subsets, and a data normality test and model stability assessment are performed to optimize predictive performance. In the field application phase, the trained ANN model is utilized to predict the bond strength at the NDT measurement locations across the actual structure. By applying the model based on the stratification information and representative location data secured in the previous stage, the bond strength distribution across the entire structure can be estimated more precisely. Finally, in the result verification and iterative refinement phase, the bond strength predicted by the ANN is verified against actual pull-off tests conducted in a few randomly selected test areas. Based on the verification results, the model’s predictive accuracy is evaluated, and, if necessary, the ANN model is co-corrected by repeating additional data collection and training, thereby completing the field-applicable NDT-AI-based bond strength prediction system. This stepwise approach enhances practical predictive reliability while providing a systematic methodology to structurally correct the correlation between NDT signals and actual bond strength data.

Figure 10.

NDT-AI correction procedure utilizing the pull-off test.

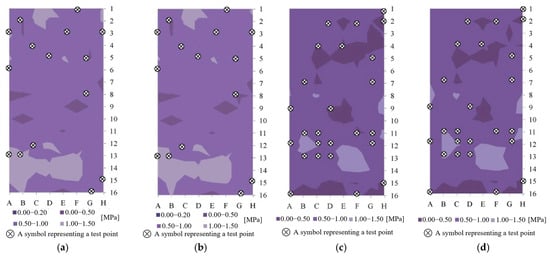

This method was designed by integrating NDT with AI to precisely map the spatial distribution of interfacial bond strength and to derive reliable bonding information even from limited test data. The results demonstrated that the NDT–AI hybrid approach accurately mapped the training data and precisely identified the test data, with the reliability of the obtained data validated by the distribution of points along the ideal regression line (Figure 11). This confirms that the proposed approach can provide a stable and reliable non-destructive estimation of bond strength as determined by the pull-off test. Non-destructive techniques include 3D laser scanning [,,,], IR [,,,], IE [,,,,], and ultrasonic pulse velocity (UPV) [,,] (Table 4). These methods provide key parameters for quantifying interfacial characteristics, such as surface roughness, bond strength, overlay thickness, mobility, stiffness, and mobility gradients. When these parameters are integrated with AI models, high correlations with pull-off test results have been demonstrated in numerous studies. The proposed AI–NDT hybrid approach demonstrates potential applicability across various types and grades of concrete, as well as multiple polymer-based repair materials. Previous studies have employed different repair materials, including polymer cement mortar, epoxy grout, and metakaolin plaster, primarily targeting ordinary concrete, and developed AI models based on datasets encompassing diverse surface roughness conditions. In particular, by integrating heterogeneous non-destructive data such as three-dimensional laser scanning and ultrasonic signals, these studies effectively captured the complex nonlinear relationships between interfacial characteristics and bond strength, achieving high predictive accuracy. These findings strongly suggest that, with sufficiently representative training data, the proposed hybrid approach can be extended to new classes of concrete and polymer materials [,,,,,,,,,,,,,,,].

Figure 11.

Comparative maps of pull-off adhesion based on test results yielded by (a) pull-off method (mechanical grinding); (b) NDT methods and ANN (mechanical grinding); (c) pull-off method; (d) NDT methods and ANN [].

Table 4.

Summary of non-destructive bond evaluation methods conducted in previous studies [,,,,,,,,,,,].

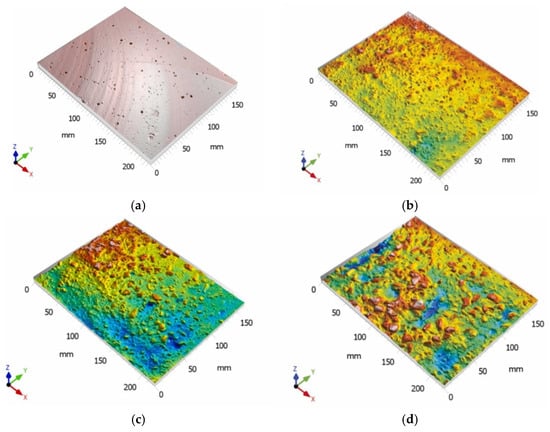

At this stage, overlay thickness and surface roughness can act as critical variables that significantly influence interfacial bond strength. In practical construction sites, overlay thickness and surface roughness vary depending on location and construction conditions, thereby necessitating bond strength evaluations that account for these factors. Previous studies conducted experiments on model concrete layers with linearly varying overlay thickness and proposed a method for reliably identifying the bond tensile strength between the concrete substrate and overlay mortar under diverse thickness conditions. In particular, parameters were derived from 3D laser scanning, infrared thermography, IE, and analytical thickness estimation. By applying these parameters to an ANN, the study demonstrated the feasibility of non-destructive evaluation of interfacial bond strength under varying overlay thicknesses []. Additionally, another study proposed an NDT–AI hybrid approach to assess the bond strength of repair material–concrete interfaces with respect to surface roughness. In this study, four types of concrete surfaces with varying roughness levels were prepared, and surface parameters were extracted through 3D laser scanning. These parameters were then combined with ANN to evaluate the corresponding bond strengths (see Figure 12). The results indicated that the bond strength increased by approximately 38.6%, from 2.16 MPa (surface I) to 3.11 MPa (surface IV). Among the 23 surface parameters, the roots mean square gradient (Sdq) and the interfacial developed area ratio (Sdr) exhibited the highest correlation with bond strength []. In the non-destructive evaluation of pull-off adhesion in concrete layers, some 3D surface roughness parameters showed correlations with bond strength. However, these parameters were insufficient on their own, and more reliable assessments were achieved when combined with other NDT methods, such as IR and IE, along with ANN []. Meanwhile, AI-based analyses utilize algorithms including ANN [,,], Support Vector Machines (SVM), and Random Forest (RF) []. ANNs are optimized using training algorithms such as Quasi-Newton (QN) [,,,,,,], Levenberg–Marquardt (LM) [,], Conjugate Gradient (CG) [,], Gradient Descent (GD) [], Imperialist Competitive Algorithm (ICA) [], and Particle Swarm Optimization (PSO) [].

Figure 12.

Three-dimensional surface morphology of four types of concrete: (a) relatively smooth; (b) moderately rough; (c) highly rough; (d) extensively rough [].

The SVM, proposed by Vladimir Vapnik, is a supervised learning model based on statistical learning theory that defines classification boundaries in the form of hyperplanes to effectively separate nonlinear trends []. In predicting the interfacial bond strength between high-performance concrete and normal-strength concrete, SVM demonstrated the highest performance when utilizing multidimensional NDT data such as age (t), curing condition (Cm), surface treatment (St), and interfacial moisture condition (Mc). Specifically, SVM achieved R2 of 0.960, an adjusted R2 of 0.928, a root mean square error (RMSE) of 0.40, a relative RMSE of 12.5, a mean absolute percentage error (MAPE) of 8.62, and a mean relative error (MRE) of 0.043, confirming its strong generalization capability for complex boundary classification and regression problems []. Due to these characteristics, SVM is particularly suitable for continuous NDT data exhibiting strong nonlinear tendencies, such as ultrasonic- or IE-based frequency responses. Meanwhile, the ANN, developed by McCulloch as a mathematical model of biological neural structures, learns the complex nonlinear relationships between inputs and outputs through nonlinear transfer functions among multiple neurons (nodes) [,]. When trained with NDT signal variables such as mobility (Nav), dynamic stiffness (Kd), vibration mode ratio, Poisson’s ratio (v), and transition frequency (fT) obtained from the IE method, the ANN model (1-5-6-5 architecture, tan-sigmoid activation function, and ICA optimization algorithm) achieved R2 values of 0.844 during training and 0.858 during validation []. This indicates that ANN is particularly suitable for NDT data characterized by strong nonlinearity and high interdependence among variables, such as three-dimensional laser-based surface roughness or vibration responses. In contrast, the RF model is an ensemble learning technique that combines multiple decision trees and outputs the average of their predictions, effectively assessing the importance of input variables []. However, in studies predicting the bond strength between cementitious composites, RF showed a relatively lower accuracy with a MAPE of 19.41%, and its prediction results for surface morphology parameters (height of surface, maximum height of summits, and maximum height of valleys) tended to converge to constant values []. These results suggest that RF is more suitable for classification tasks, such as defect detection, rather than continuous bond strength prediction. In summary, SVM exhibits strong capability in interpreting nonlinear responses in the frequency and time domains, while ANN is advantageous for processing high-dimensional nonlinear data such as 3DL-based surface roughness. In contrast, RF is effective for evaluating variable importance but shows limited precision in continuous bond strength prediction. All models adjust parameters using training data and evaluate prediction performance using validation or test data to prevent overfitting and ensure generalization capability.

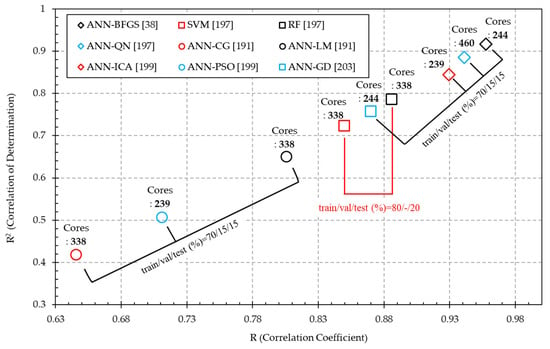

To compare their performance, representative algorithms were systematically selected from the literature. The selection was based on widely used and repeatedly validated metrics for predictive accuracy, including the correlation coefficient, RMSE, and MRE. To minimize potential biases arising from subjective judgments or data skew, the selection process was based on multiple previous studies. These studies encompassed diverse environmental conditions and data ranges. The comparative performance of the selected algorithms is presented in Figure 13 (available upon reasonable request) and the ranges of R, RMSE, and MAE/MAPE for each algorithm are provided in Table 5. The results indicate that the ANN–BFGS model exhibits the highest capability to replace pull-off testing for interfacial bond behavior assessment.

Figure 13.

Comparison of correlation and determination coefficients across AI training algorithms [,,,,].

Table 5.

Performance metrics of each algorithm: R, RMSE, and MAE/MAPE ranges [,,,,,].

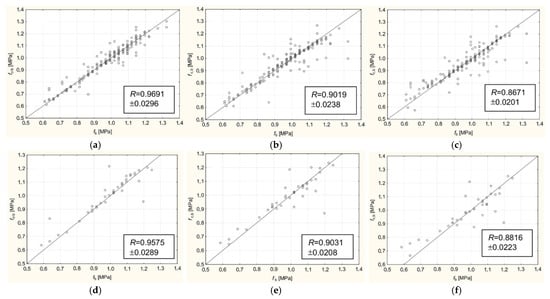

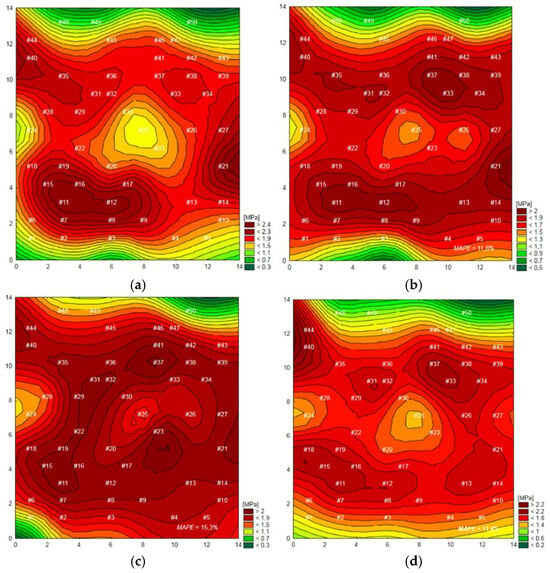

A performance comparison of representative learning algorithms indicated that the ANN BFGS model exhibited the highest performance in evaluating interfacial bond behavior, effectively replacing conventional pull-off tests. Several previous studies reported that the BFGS-based ANN outperformed SVM (R: 0.850, RMSE: 0.432 MPa) and RF (R: 0.886, RMSE: 0.315 MPa) models in prediction accuracy, achieving a R of 0.883 and RMSE of 0.341 MPa, thereby demonstrating the reliability of non-destructive interfacial bond strength prediction using the NDT AI hybrid approach []. Additional research further showed that the BFGS-based ANN achieved a correlation coefficient R of 0.89 and an MRE of 6.09 percent, indicating the highest predictive precision and suggesting that the ANN BFGS model sufficiently learns the relationships between interfacial parameters such as surface roughness, interlayer thickness, and physical properties extracted from NDT and the actual interfacial bond strength []. The influence of surface roughness parameters on interfacial bond strength has also been investigated. According to previous studies, among the height-based parameters related to concrete surface roughness, Sp, Sv, Sz, Sa, and Sq were found to play a significant role in predicting interfacial adhesion []. Here, Sp, Sv, and Sz represent the maximum peak height, maximum valley depth, and total maximum height of the surface, respectively, quantitatively reflecting local height variations and contributing to the variability in bond strength predictions. In contrast, Sa and Sq represent the average height distribution of the surface, capturing the overall roughness trend, but are relatively insensitive to local surface texture features such as peaks and valleys. Based on non-destructive evaluation results, ultrasonic velocity decreased from 5.36 km/s to 4.91 km/s (a reduction of approximately 8.3%), and signal amplitude decreased from 102.6 dB to 94.8 dB (a reduction of approximately 7.7%) as surface roughness increased. This indicates that surface texture affects acoustic signal transmission and highlights the need to consider surface characteristics in NDT-based interfacial assessments. Furthermore, increasing the developed interfacial area ratio (Sdr) through surface treatments, such as chipping, expands the contact area between epoxy repair materials and concrete under wet conditions, thereby enhancing bond strength. Thus, surface characteristics such as Sp, Sv, Sz, Sa, Sq, and Sdr act as key variables in interfacial bond prediction models and can be effectively applied in non-destructive evaluation and the design of strategies to improve adhesion considering various surface conditions. As shown in Figure 14, the ANN–BFGS model accurately reproduces the training data with high precision. This is clearly confirmed by the distribution of points along the regression line, which aligns closely with the ideal correspondence. The linear R reached a very high value of 0.9691 ± 0.0296 for variant 1, and satisfactory levels of 0.9010 ± 0.0238 and 0.8671 ± 0.0201 were observed for variants 2 and 3, respectively []. Furthermore, as shown in Figure 15, the ANN employing the BFGS training algorithm achieved a MAPE of 11.8%, which is lower than the 15.3% observed for ANN–CG, indicating more precise predictive performance. The superior performance of the ANN–BFGS algorithm is attributed to the efficient use of curvature information in the performance function by the BFGS method, enabling stable and rapid convergence even in highly nonlinear problems. These characteristics ensure both computational efficiency and predictive reliability compared to other optimization techniques, providing a significant advantage for NDT–AI hybrid approaches that demand complex signal analysis and high computational efficiency []. Meanwhile, studies integrating IR, IE, 3D laser scanning, and pull-off test data to train a QN-based ANN reported an MAE of 0.096 MPa and a mean relative error of 0.102, demonstrating high agreement with experimental values []. Using the same NDT combination and QN-based ANN model, another study reported R of 0.9775 for the training phase and 0.9725 for validation when compared to pull-off strength []. In contrast, CG-based ANN models exhibited a relatively lower predictive accuracy, with a mean relative error of 15.3% compared to 11.4% for LM-based ANN []. Studies predicting interlayer bond strength using IR and IE also showed lower performance for CG-based ANN, with a mean R of 0.8186 and RMSE of 0.013212, compared to GS (0.8704, 0.007609) and BFGS (0.8519, 0.008996) []. These findings indicate that hybrid approaches combining NDT-based data with ANN algorithms effectively address the limitations of pull-off testing. They also provide a robust alternative for precise, non-destructive evaluation of PCC–concrete interfacial bond behavior. Moreover, the integration of NDT techniques with AI algorithms establishes a quantitative evaluation framework that enhances the reliability of repair material design and structural condition assessment, thereby contributing significantly to future maintenance strategies for concrete structures. However, this approach has several limitations. First, it is highly dependent on the range and quality of the training data, and discrepancies between laboratory conditions and field environments can reduce prediction accuracy. Second, the nonlinear interactions between NDT variables and bond strength are not fully interpretable, and the model’s generalization performance may be limited under new conditions if overfitting occurs. Third, measurement errors, such as NDT equipment resolution and signal noise, can affect the reliability of predictions. Finally, when applied in the field, various factors including construction conditions, surface conditions, and environmental influences may introduce additional uncertainty in predicting actual bond strength. Despite these limitations, the AI–NDT integrated approach provides a useful quantitative framework for evaluating interfacial behavior using multivariate information and for establishing structural maintenance strategies.

Figure 14.

The relation between the bond strength (fb) and the fc,b, which was identified by the ANN–BFGS: (a) training in variant 1, (b) training in variant 2, (c) training in variant 3, (d) testing in variant 1, (e) testing in variant 2, (f) testing in variant 3 [].

Figure 15.

Pull-off adhesion maps based on experimental verification results (n = 164 cores; train/val/test = 70/15/15%): (a) conventional pull-off method; (b) ANN-BFGS (RMSE: 0.115); (c) ANN with CG (RMSE: 0.113); (d) ANN with LM (RMSE: 0.125) [].

6. Limitations and Future Studies

This review comprehensively examined conventional destructive testing methods and international standards for evaluating the interfacial bond strength between PCCs and concrete. It also investigated the effectiveness and applicability of hybrid evaluation approaches that integrate NDT techniques with AI-based analysis. In particular, the study focused on comparing the reliability of various testing methods and ANN-based models for evaluating interfacial bond behavior in concrete. Conventional pull-off testing has been widely used as a standard method for directly measuring interfacial bond strength. However, this method inherently causes specimen damage during testing and is sensitive to local material heterogeneity. These characteristics can limit test reproducibility and result reliability, particularly restricting the quantitative capture of subtle interfacial bond behavior or heterogeneous material properties. In contrast, non-destructive hybrid approaches, such as ANN–BFGS and QN-based models, learn from experimental data to predict interfacial bond behavior, allowing precise evaluations without causing damage. Specifically, the BFGS-based ANN demonstrated high correlation coefficients and low error metrics, indicating relatively higher predictive reliability compared to pull-off testing. Similarly, the QN-based ANN integrated diverse non-destructive data (IR, IE, and 3D laser scanning) to achieve high predictive accuracy, effectively addressing the limitations of conventional pull-off testing in comparative evaluations. The NDT–AI hybrid approach proposed in this study has the potential to be more cost-effective than the conventional pull-off test. Traditional pull-off testing generally involves higher per-specimen costs due to specimen damage, the need for re-testing, and the labor and equipment expenses, which collectively increase the total cost during repeated evaluations. In contrast, the NDT–AI hybrid method minimizes specimen damage while simultaneously assessing various interfacial bonding characteristics. Once the AI model is trained using experimental data, rapid evaluations can be performed without additional testing or equipment requirements. Therefore, although initial costs are incurred for AI model development and training, the approach is expected to be advantageous in terms of cost-effectiveness in the long term, considering factors such as minimized specimen damage, reduced repetitive testing expenses, and improved efficiency when applied to multilayered structural systems. Based on this review, directions for future research are proposed. First, this study did not focus on the internal mechanisms of AI-based analysis techniques or the detailed exploration of individual learning algorithms for evaluating PCC–concrete interfacial bond strength. That is, while the potential accuracy and reliability of AI-assisted data interpretation were assessed, detailed methods such as model training strategies, hyperparameter optimization, data preprocessing, and feature selection were beyond the scope of this study. Future research should systematically examine the theoretical basis of AI modeling and the process of learning from experimental data. Such efforts would allow evaluation of model generalization performance and sensitivity to various experimental conditions, thereby enhancing the reliability of integrated experimental–computational approaches. Second, the application range and limitations of non-destructive techniques and hybrid evaluation approaches have not yet been fully established. Each NDT method, including 3D laser scanning, infrared thermography, and ultrasonic techniques, is influenced by multiple factors, such as surface roughness, overlay thickness, specimen material properties, and environmental conditions [,]. Hybrid approaches leverage the complementary characteristics of these NDT methods to analyze interfacial bond behavior more precisely. However, few studies have examined their applicability and reproducibility under diverse field conditions. In particular, performance validation studies are needed that account for multi-layer overlays, extreme environmental conditions (e.g., heavy rainfall, snow, typhoons, salt exposure, and earthquakes), and long-term deterioration observed in actual structures. Based on prior research, a systematic approach for field verification can be structured as follows. First, to ensure the representativeness of the structure’s surface, it is appropriate to select measurement points by securing a certain distance (approximately 500 mm) from the edge of each specimen and then partitioning the entire surface into a grid form with 100 mm × 100 mm intervals []. This approach offers a framework for simultaneously evaluating not only the local surface characteristics but also the interlayer bonding behavior. For measurement techniques, a combined application of 3D laser scanning, IR, and IE testing can be considered []. Laser scanning is suitable for precisely identifying surface roughness and crack distribution, while IR can be utilized for detecting localized defects through temperature differences. IE can be employed as a supplementary means to evaluate interlayer bonding behavior in real time. By combining these diverse NDT techniques, the limitations of a single technique can be mutually compensated. The measured data should be used to calculate key surface parameters and evaluate surface homogeneity based on the range established in existing research []. The collected data is then analyzed through statistical methods or ANN-based predictive models, with the ratio for the training, validation, and testing dataset to follow the 80:10:10 structure validated in previous studies. Furthermore, performing a data normality test (e.g., Shapiro–Wilk) is recommended to ensure analytical reliability. This approach provides a strategic framework for establishing a multi-sensor-based evaluation system that is reproducible in actual structure environments, without demanding overly specific field parameters. In particular, by reflecting the statistical relationship between surface roughness and adhesion performance, it secures both the reliability and efficiency of the evaluation during field application. Third, the hybrid evaluation approach presented in this study is effective for relative comparisons and trend analyses of interfacial bond strength, but it cannot completely eliminate errors or uncertainties in absolute bond strength assessment. Therefore, future research should explore quantitative calibration methods, possibly through combination or hybridization with conventional destructive testing methods, such as pull-off tests. Fourth, there is a research gap regarding long-term field validation and cost–benefit or life-cycle cost (LCC) analyses. Most existing studies are limited to laboratory environments, constraining the evaluation of long-term durability and economic feasibility in real structures. Moreover, variations in testing conditions and specimen preparation methods limit reproducibility across studies, and the application of international standards remains restricted to select cases. Future studies should include long-term monitoring, LCC analyses, standardized testing protocols, and reproducibility verification. The AI–NDT hybrid system has demonstrated high predictive accuracy in laboratory experiments, suggesting the potential for non-destructive evaluation of interfacial bond strength in actual construction sites. However, environmental factors such as humidity and temperature directly influence sensor signals and interfacial characteristics. For instance, under high humidity conditions, variations in the moisture content of PCCs and existing concrete surfaces may alter ultrasonic wave velocity and laser reflection intensity. In low-temperature environments, delayed cement hydration and reduced polymer film formation rates may lead to lower measured bond strength. If such environmental variations are not reflected during the AI model training phase, prediction accuracy may decrease. Therefore, it is essential to secure training datasets and perform model calibration under various temperature and humidity conditions. In particular, AI models that integrate multiple NDT data types—such as three-dimensional laser scanning, infrared thermography, impact echo, and ultrasonic pulse velocity—can effectively learn signal variations induced by environmental factors, as well as those related to surface roughness and overlay thickness variability. Consequently, these models enable stable and reliable bond strength evaluation under diverse conditions. By incorporating sufficient environmental variability into training and implementing standardized measurement procedures, the hybrid system holds strong potential as a practical tool to complement or even replace conventional pull-off testing in field applications. In addition, this study demonstrated that the pull-off bond strength of concrete layers can be assessed using a hybrid approach that combines NDT and AI. However, existing NDT–AI hybrid approaches have several limitations. For example, IE signal analysis often considers only the amplitude of characteristic peaks, which may not sufficiently reflect various interfacial factors such as surface roughness or microcracking. This limitation can constrain the predictive accuracy of IE-based hybrid models. To address these limitations, wavelet-based multiresolution temporal scale analysis has been considered in the NDT field [,,,].

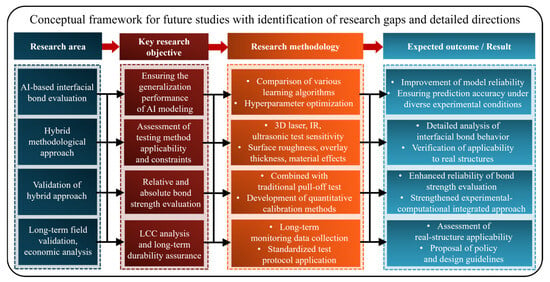

This approach allows more sophisticated analysis by utilizing time–frequency information simultaneously. By applying Continuous Wavelet Transform (CWT) and Discrete Wavelet Transform (DWT), IE signals can be decomposed into multiple scales and time intervals, enabling concurrent evaluation of low- and high-frequency components. Combining this with AI-based models can enhance the reliability of bond strength predictions compared to conventional simple peak analysis []. Therefore, future research should integrate wavelet-based signal analysis into NDT–AI hybrid approaches to improve evaluation accuracy and generalizability across diverse concrete surfaces. The mother wavelet scale, level, and extracted features for both CWT and DWT are presented in Table 6. In conclusion, this study highlights the potential of hybrid NDT- and AI-based approaches for evaluating PCC–concrete interfacial bond behavior. Nonetheless, future work must address theoretical aspects of AI models, diversify experimental conditions, and enhance the precision of data-driven predictions. Such efforts are expected to significantly improve the reliability and practicality of interfacial performance assessment for structural repair materials and long-term durability monitoring. Based on this, the present study analyzed research gaps and identified future research directions and specific research tasks. A conceptual research framework integrating these elements was visually constructed, and the results are presented in Figure 16.

Table 6.

Wavelet transform types, parameters, and feature extraction [,,,,].

Figure 16.

Proposed future research directions.

7. Conclusions

This review synthesizes the current state of knowledge regarding interfacial bond performance evaluation between PCCs and existing concrete substrates, highlighting limitations, challenges, and unresolved issues. It also emphasizes the necessity of improving testing methodologies and establishing a more robust evaluation framework to enhance the accuracy and reliability of bond performance assessment. Based on this investigation, the following conclusions can be drawn.

- The pull-off test is one of the most widely adopted tensile adhesion tests for evaluating the bonding performance between PCCs and concrete in both field and laboratory environments. On the other hand, the method inherently exhibits limitations in measurement accuracy and reproducibility due to sensitivity to various factors, including load eccentricity, microcracks induced during drilling, core depth, and substrate strength.

- Hybrid evaluation approaches combining 3D scanning, IR, and IE with AI-based learning algorithms have been recognized as effective alternatives to complement destructive testing. Nevertheless, previous studies consistently report that bond strength predictions using ANNs with the CG algorithm exhibit the lowest accuracy among hybrid approaches, with an average relative error of 15.3%.

- By integrating both infrared and IE techniques with a BFGS algorithm-based ANN, this method not only enables non-destructive and high-resolution evaluation of interfacial bond behavior but also demonstrates how AI can transform conventional testing into intelligent, data-driven characterization. For example, this method has achieved a remarkably high prediction accuracy, with a R of 0.9575.

- In future research, prioritize the refinement of AI-based modeling frameworks and systematically validate hybrid NDT approaches under diverse field conditions. Implement rigorous quantitative calibration against destructive tests, targeting a MAE ≤ 0.05 MPa for interfacial bond strength predictions, to ensure reliable and practically adoptable AI-driven evaluation methods.

Author Contributions

Conceptualization, D.K. and M.O.K.; methodology, D.K. and M.O.K.; software, D.K. and M.O.K.; validation, D.K. and M.O.K.; formal analysis, D.K. and M.O.K.; investigation, D.K. and M.O.K.; resources, M.O.K.; data curation, D.K. and M.O.K.; writing—original draft preparation, D.K.; writing—review and editing, M.O.K.; visualization, M.O.K.; supervision, M.O.K.; project administration, M.O.K.; funding acquisition, M.O.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Seoul National University of Science and Technology.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, and further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors express sincere gratitude to the Seoul National University of Science and Technology for their financial support.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Performance improvement of cementitious composites by polymer modification [,,,,,,,,,,,,,,,,,,,,].

Table A1.

Performance improvement of cementitious composites by polymer modification [,,,,,,,,,,,,,,,,,,,,].

| Polymer Type | Chemical Formula | Polymeric Cementitious Composites | Performances as a Repair Material | Ref. |

|---|---|---|---|---|

| Acrylate polymer (AC) |  | Polymeric cement mortar | Compressive strength: 31 MPa, Tensile strength: 12 MPa | [] |

| Polymeric cement mortar | Bond strength: 2.53 MPa (7 d), 2.88 MPa (28 d) | [] | ||

| Polymeric cementitious composite | Superior grouting performance (complete filling of slab voids) | [] | ||

| Polyacrylic ester (PAE) |  | Polymeric cement mortar | Flexural strength: 14.8 MPa, compressive strength: 78 MPa | [] |

| Polymeric cement mortar | Interfacial tensile strength: increased by 5%, 17%, 18%, and 22% after 4, 12, 24, and 48 d | [] | ||

| Styrene–butadiene rubber (SBR) |  | Polymeric cement mortar | Direct tensile strength: 4.1 MPa (13 d) | [] |

| Polymeric cement mortar | Compressive strength peak at 1–2% polymer dosage | [] | ||

| Polymeric cement mortar | Shrinkage: reductions of 31% relative to plain mortar | [] | ||

| Polyvinyl alcohol (PVA) |  | Polymeric cement mortar | Mortar adhesion increased in the presence of PVA compared to absence | [] |

| Polymeric concrete | Dosage of 2% PVA increased workability and reduced bleeding. | [] | ||

| Polyacrylate (PA) |  | Polymeric cement mortar | Flexural strength: 8.51 MPa (60 d) (7.59% higher than plain (7.91 MPa)) | [] |

| Ethylene vinyl acetate (EVA) |  | Polymeric cementitious composite | Bond strength: 1.607 MPa (1.63× higher than plain mortar) | [] |

| Polymeric cement mortar | Compressive strength and elastic modulus increased (10% EVA/cement ratio) | [] | ||

| Styrene–acrylic polymer (SA) |  | Polymeric cement mortar | Flowability: +155.4%, flexural strength: +130.18%, flexural toughness: +259.20% | [] |

| Polymeric cement mortar | Flexural strength 15.00 MPa (+38.50% standard, +88.68% underwater) | [] | ||

| Polymeric concrete | Height reduction 0.32 mm (lowest in sulfuric acid test) | [] | ||

| Epoxy resin (EP) |  | Polymeric cement mortar | Superior adhesion to smooth, Low-porosity substrates, improved durability and bond strength | [] |

| Polymeric concrete | Compressive strength reached 55.71 MPa at 97.6% hydration. | [] | ||

| Polymeric concrete | Splitting tensile strength: 21%, 17% (with polymer dosage of 2% to 10%) | [] | ||

| Polyvinyl acetate (PAA) |  | Polymeric cement mortar | Improves paste cohesion and strength, markedly reducing crack formation (1 wt% polymer) | [] |

| Polymeric cement mortar | Porosity: reduced to 14.8% | [] |

References

- Ramli, M.; Ramli, M.; Akhavan Tabassi, A. Effects of different curing regimes on engineering properties of polymer–modified mortar. J. Mater. Civ. Eng. 2012, 24, 468–478. [Google Scholar] [CrossRef]

- Doğan, M.; Bideci, A. Effect of Styrene Butadiene Copolymer (SBR) admixture on high strength concrete. Constr. Build. Mater. 2016, 112, 378–385. [Google Scholar] [CrossRef]

- Barluenga, G.; Hernández–Olivares, F. SBR latex modified mortar rheology and mechanical behaviour. Cem. Concr. Res. 2004, 34, 527–535. [Google Scholar] [CrossRef]

- Sakai, E.; Sugita, J. Composite mechanism of polymer modified cement. Cem. Concr. Res. 1995, 25, 127–135. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Omoniyi, T.E. Effect of moisture on thermal properties of acrylic polymer modified mortar reinforced with alkali treated bamboo fibres. J. Indian Acad. Wood Sci. 2018, 15, 45–51. [Google Scholar] [CrossRef]

- Vincke, E.; Van Wanseele, E.; Monteny, J.; Beeldens, A.; De Belie, N.; Taerwe, L.; Verstraete, W. Influence of polymer addition on biogenic sulfuric acid attack of concrete. Int. Biodeterior. Biodegrad. 2002, 49, 283–292. [Google Scholar] [CrossRef]

- Jung, K.C.; Roh, I.T.; Chang, S.H. Stress analysis of runway repaired using compliant polymer concretes with consideration of cure shrinkage. Compos. Struct. 2015, 119, 13–23. [Google Scholar] [CrossRef]

- Al–Zahrani, M.M.; Maslehuddin, M.; Al–Dulaijan, S.U.; Ibrahim, M. Mechanical properties and durability characteristics of polymer- and cement-based repair materials. Cem. Concr. Compos. 2003, 25, 527–537. [Google Scholar] [CrossRef]

- Monteny, J.; De Belie, N.; Vincke, E.; Verstraete, W.; Taerwe, L. Chemical and microbiological tests to simulate sulfuric acid corrosion of polymer–modified concrete. Cem. Concr. Res. 2001, 31, 1359–1365. [Google Scholar] [CrossRef]

- Luo, J.; Li, Q.; Zhao, T.; Gao, S.; Sun, S. Bonding and toughness properties of PVA fibre reinforced aqueous epoxy resin cement repair mortar. Constr. Build. Mater. 2013, 49, 766–771. [Google Scholar] [CrossRef]

- Emmons, P.H.; Vaysburd, A.M. Factors affecting the durability of concrete repair: The contractor’s viewpoint. Constr. Build. Mater. 1994, 8, 5–16. [Google Scholar] [CrossRef]

- Guo, S.Y.; Zhang, X.; Chen, J.Z.; Mou, B.; Shang, H.S.; Wang, P.; Ren, J. Mechanical and interface bonding properties of epoxy resin reinforced Portland cement repairing mortar. Constr. Build. Mater. 2020, 264, 120715. [Google Scholar] [CrossRef]

- Ojha, P.N.; Kaura, P.; Singh, B.; Daniel, Y.N.; Kumar, N. Evaluation of polymer modified mortar and bonding agent for structural repair. J. Asian Concr. Fed. 2021, 7, 56–62. [Google Scholar] [CrossRef]

- Zanotti, C.; Randl, N. Are concrete–concrete bond tests comparable? Cem. Concr. Compos. 2019, 99, 80–88. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Liao, Z.; Wang, L. Interfacial bond properties between normal strength concrete substrate and ultra–high performance concrete as a repair material. Constr. Build. Mater. 2020, 235, 117431. [Google Scholar] [CrossRef]

- Daneshvar, D.; Behnood, A.; Robisson, A. Interfacial bond in concrete–to–concrete composites: A review. Constr. Build. Mater. 2022, 359, 129195. [Google Scholar] [CrossRef]

- Gohnert, M. Horizontal shear transfer across a roughened surface. Cem. Concr. Compos. 2003, 25, 379–385. [Google Scholar] [CrossRef]

- Habouh, M.I. Shear Transfer Strength of Concrete Placed Against Hardened Concrete. Master’s Thesis, University of Akron, Akron, OH, USA, 2015. [Google Scholar]

- Mohamad, M.E.; Ibrahim, I.S. Interface shear strength of concrete–to–concrete bond with and without projecting steel reinforcement. J. Teknol. (Sci. Eng.) 2015, 75, 1. [Google Scholar] [CrossRef]

- Ganeshan, M.; Venkataraman, S. Interface shear strength evaluation of self–compacting geopolymer concrete using push–off test. J. King Saud Univ.–Eng. Sci. 2022, 34, 98–107. [Google Scholar] [CrossRef]

- Abo Sabah, S.H.; Zainal, N.L.; Muhamad Bunnori, N.; Megat Johari, M.A.; Hassan, M.H. Interfacial behavior between normal substrate and green ultra–high–performance fiber–reinforced concrete under elevated temperatures. Struct. Concr. 2019, 20, 1896–1908. [Google Scholar] [CrossRef]

- Gallaher, B.L. Evaluation of Thin Bonded Overlays as a Protective System for Highway Bridge Decks. Master’s Thesis, University of Colorado at Boulder, Boulder, CO, USA, 2013. [Google Scholar]

- Szymanowski, J.; Sadowski, Ł. Functional and adhesive properties of cement–based overlays modified with amorphous silica nanospheres. J. Adhes. 2020, 96, 207–228. [Google Scholar] [CrossRef]

- Croll, S.G.; Siripirom, C.; Keil, B.D. Pull-off adhesion test for coatings on large pipes: Possible variations in failure location and mode. In Pipelines 2014: From Underground to the Forefront of Innovation and Sustainability; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 1319–1333. [Google Scholar]

- Croll, S.G.; Vetter, C.A.; Keil, B.D. Variability of pipe coating pull–off adhesion measurements on cylindrical steel pipelines. In Pipelines 2012: Innovations in Design, Construction, Operations, and Maintenance, Doing More with Less; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 231–241. [Google Scholar]

- Mathia, T.G.; Pawlus, P.; Wieczorowski, M. Recent trends in surface metrology. Wear 2011, 271, 494–508. [Google Scholar] [CrossRef]

- Santos, P.M.; Júlio, E.N. A state–of–the–art review on roughness quantification methods for concrete surfaces. Constr. Build. Mater. 2013, 38, 912–923. [Google Scholar] [CrossRef]

- Zielecfei, W.; Pawlus, P.; Perłowski, R.; Dzierwa, A. Surface topography effect on strength of lap adhesive joints after mechanical pre–treatment. Arch. Civ. Mech. Eng. 2013, 13, 175–185. [Google Scholar] [CrossRef]

- ASTM C1383-15(2022); Test Method for Measuring the P–Wave Speed and the Thickness of Concrete Plates Using the Impact–Echo Method. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2010; p. 1383.

- Davis, A.G. The nondestructive impulse response test in North America: 1985–2001. NDT E Int. 2014, 36, 185–193. [Google Scholar] [CrossRef]

- Davis, A.G.; Hertlein, B.H.; Lim, M.K.; Michols, K. Impact-echo and impulse response stress–wave methods: Advantages and limitations for the evaluation of highway pavement concrete overlays. In Nondestructive Evaluation of Bridges and Highways; SPIE: Bellingham, WA, USA, 1996; Volume 2946, pp. 88–96. [Google Scholar]

- Schabowicz, K. Methodology for non–destructive identification of thickness of unilaterally accessible concrete elements by means of state–of–the–art acoustic techniques. J. Civ. Eng. Manag. 2013, 19, 325–334. [Google Scholar] [CrossRef]

- Azari, H.; Nazarian, S.; Yuan, D. Assessing sensitivity of impact echo and ultrasonic surface waves methods for nondestructive evaluation of concrete structures. Constr. Build. Mater. 2014, 71, 384–391. [Google Scholar] [CrossRef]

- Bień, J.; Hoła, J.; Sadowski, Ł. Modern NDT techniques in diagnostics of transport infrastructure concrete structures. In Proceedings of the International Workshop on Smart Materials, Structures NDT in Canada 2013 Conference & NDT for the Energy Industry, Calgary, AB, Canada, 7–10 October 2013; p. 10. [Google Scholar]

- Kim, B.W. From Destructive to Non–Destructive. Ph.D. Thesis, Seoul National University, Seoul, Republic of Korea, 2024. [Google Scholar]

- Flores-Colen, I.; Brito, J.; Freitas, V.P. Expected render performance assessment based on impact resistance in situ determination. Constr. Build. Mater. 2009, 23, 2997–3004. [Google Scholar] [CrossRef]

- Flores-Colen, I.; Brito, J.; Branco, F. In situ adherence evaluation of coating materials. Exp. Tech. 2009, 23, 51–60. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Hoła, J.; Czarnecki, S.; Wang, D. Pull-off adhesion prediction of variable thick overlay to the substrate. Autom. Constr. 2018, 85, 10–23. [Google Scholar] [CrossRef]

- Medeiros, M.H.F.; Helene, P.; Selmo, S. Influence of EVA and acrylate polymers on some mechanical properties of cementitious repair mortars. Constr. Build. Mater. 2009, 23, 2527–2533. [Google Scholar] [CrossRef]

- Kim, M.O. Influence of polymer types on the mechanical properties of polymer–modified cement mortars. Appl. Sci. 2020, 10, 1061. [Google Scholar] [CrossRef]

- Shu, X.; Zhao, Y.; Liu, Z.; Zhao, C. A study on the mix proportion of fiber–polymer composite reinforced cement–based grouting material. Constr. Build. Mater. 2022, 328, 127025. [Google Scholar] [CrossRef]

- Gao, J.M.; Qian, C.X.; Wang, B.; Morino, K. Experimental study on properties of polymer–modified cement mortars with silica fume. Cem. Concr. Res. 2002, 32, 41–45. [Google Scholar] [CrossRef]

- Rashid, K.; Ueda, T.; Zhang, D.; Miyaguchi, K.; Nakai, H. Experimental and analytical investigations on the behavior of interface between concrete and polymer cement mortar under hygrothermal conditions. Constr. Build. Mater. 2015, 94, 414–425. [Google Scholar] [CrossRef]

- Brien, J.V.; Mahboub, K.C. Influence of polymer type on adhesion performance of a blended cement mortar. Int. J. Adhes. Adhes. 2013, 43, 7–13. [Google Scholar] [CrossRef]

- Wang, R.; Wang, P.M.; Li, X.G. Physical and mechanical properties of styrene–butadiene rubber emulsion modified cement mortars. Cem. Concr. Res. 2005, 35, 900–906. [Google Scholar] [CrossRef]

- Saberi Varzaneh, A.; Naderi, M. Study of bond strength between polymer–modified mortars/concrete and their mechanical properties using “friction–transfer” and “pull–off” methods. Mech. Adv. Compos. Struct. 2021, 8, 171–184. [Google Scholar]

- Jenni, A.; Holzer, L.; Zurbriggen, R.; Herwegh, M. Influence of polymers on microstructure and adhesive strength of cementitious tile adhesive mortars. Cem. Concr. Res. 2005, 35, 35–50. [Google Scholar] [CrossRef]

- Kim, J.H.; Robertson, R.E.; Naaman, A.E. Structure and properties of poly (vinyl alcohol)–modified mortar and concrete. Cem. Concr. Res. 1999, 29, 407–415. [Google Scholar] [CrossRef]

- Ma, H.; Li, Z. Microstructures and mechanical properties of polymer modified mortars under distinct mechanisms. Constr. Build. Mater. 2013, 47, 579–587. [Google Scholar] [CrossRef]

- Shi, C.; Li, M.; Ma, C.; He, T. Interfacial bonding properties of styrene–butadiene rubber and ethylene vinyl acetate emulsion–modified OPC–CAC–G repair mortar. Constr. Build. Mater. 2023, 370, 130747. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, J.Y.; Suh, H.W.; Cho, B.Y.; Park, W.J.; Bae, S.C. Mechanical degradation and thermal decomposition of ethylene–vinyl acetate (EVA) polymer–modified cement mortar (PCM) exposed to high–temperature. Sustainability. 2019, 11, 500. [Google Scholar] [CrossRef]

- Shi, C.; Wang, P.; Ma, C.; Zou, X.; Yang, L. Effects of SAE and SBR on properties of rapid hardening repair mortar. J. Build. Eng. 2021, 35, 102000. [Google Scholar] [CrossRef]