Study on Evolution Laws of Lining Mechanical Behavior in Mountain Tunnels Under Heavy Rainfall Conditions

Abstract

1. Introduction

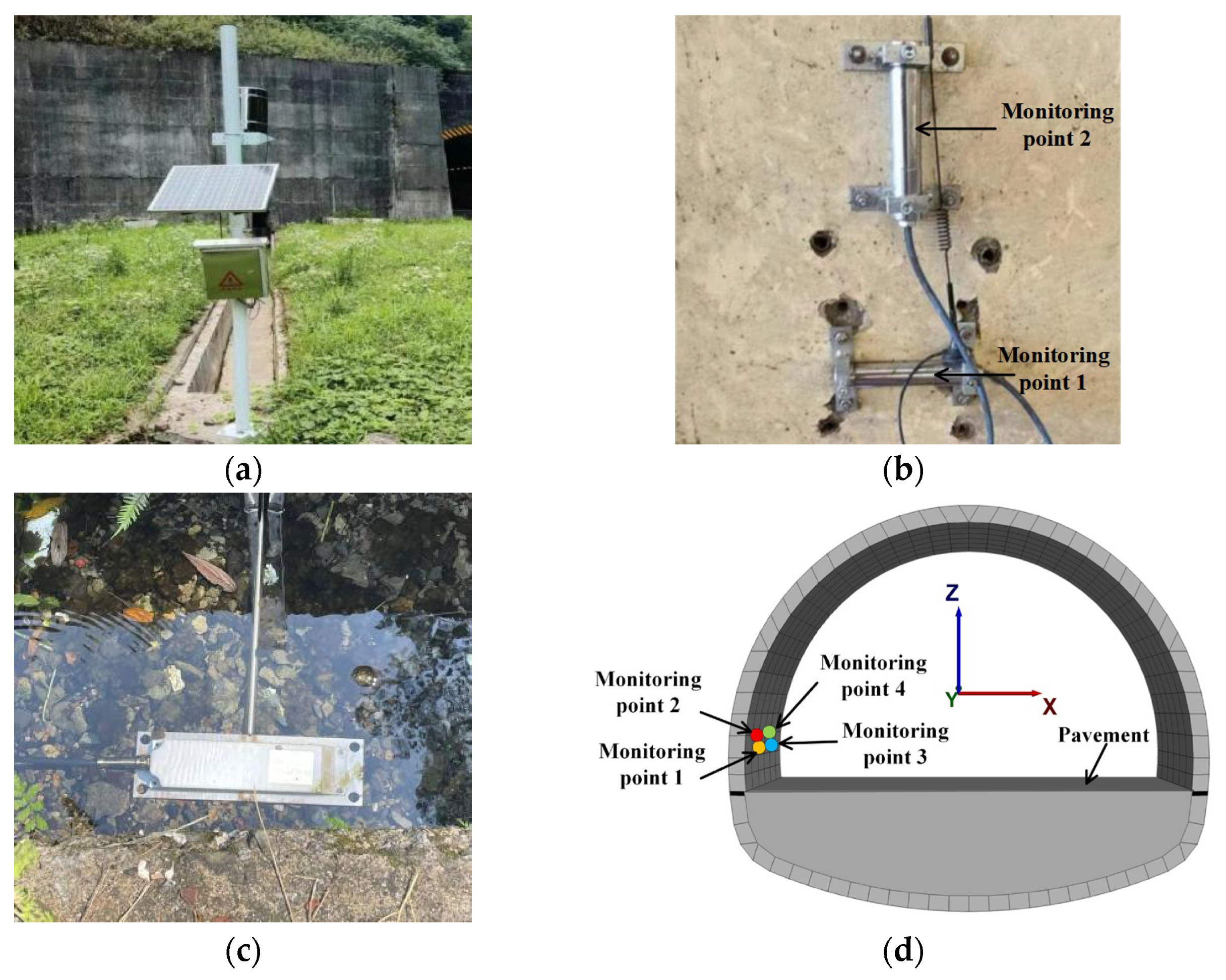

2. Field Monitoring and Dynamic Response Signatures

2.1. Project Profile

2.2. Monitoring Results

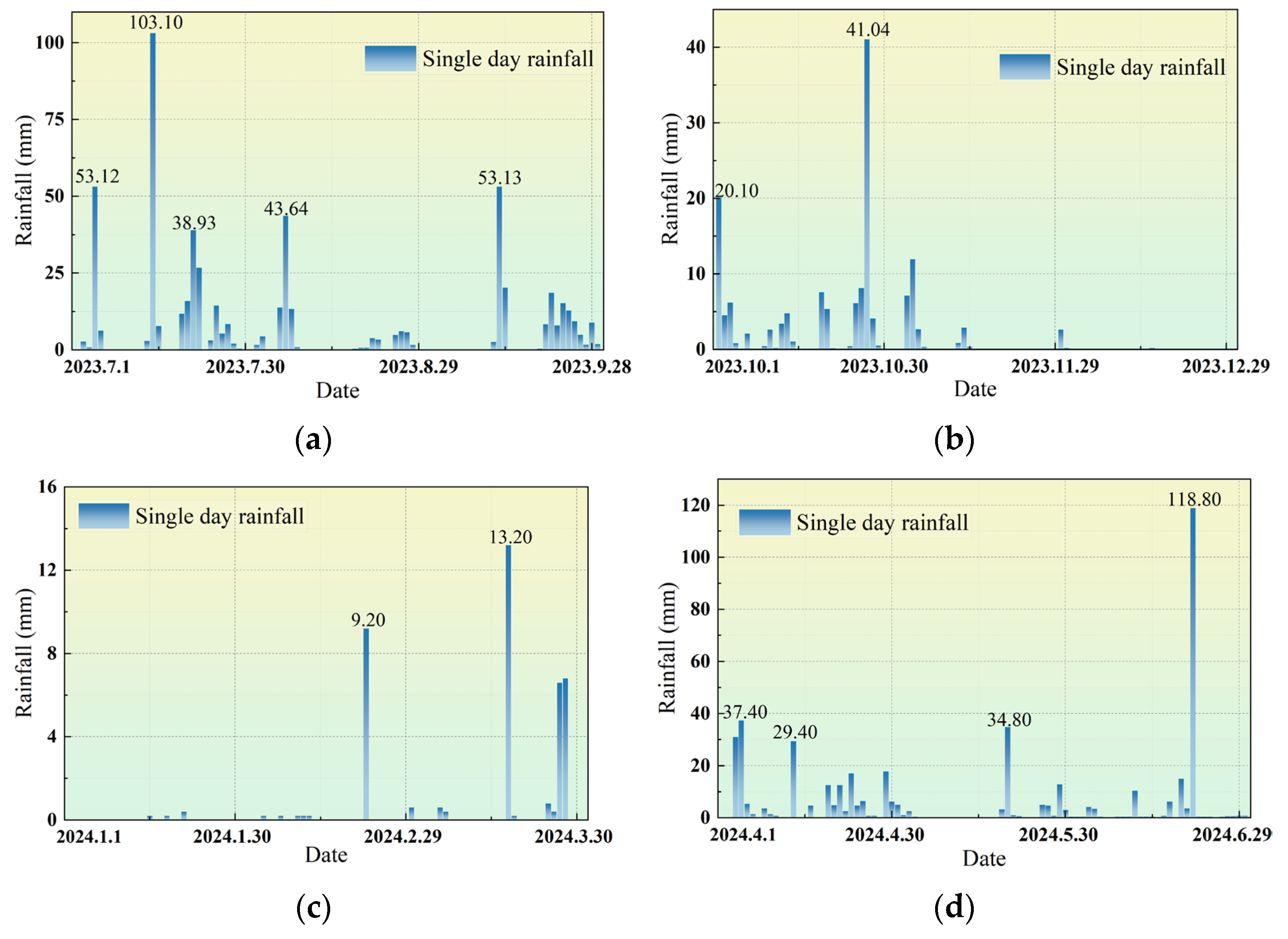

2.2.1. Analysis of Heavy Rainfall Characteristics

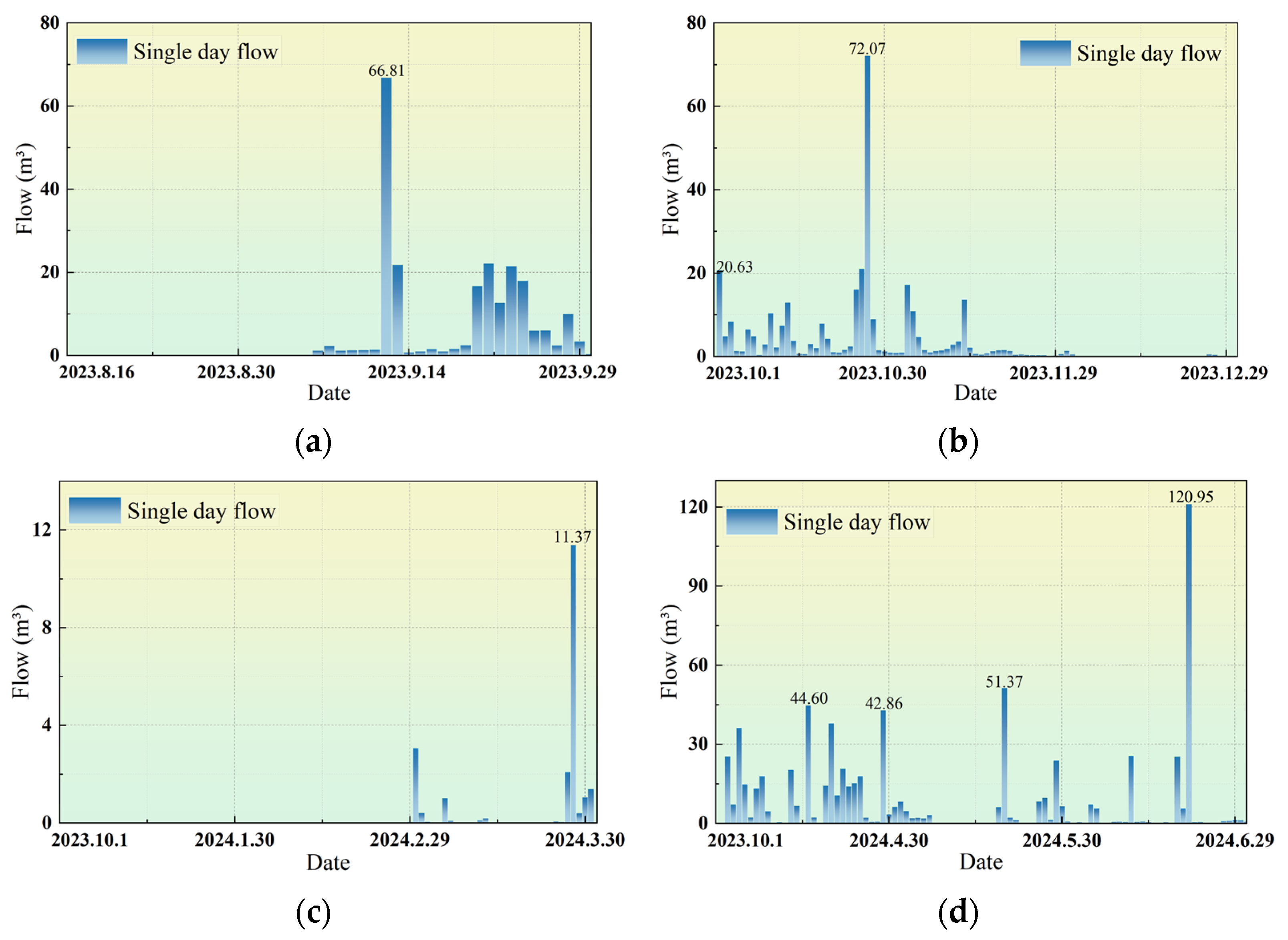

2.2.2. Analysis of Drainage Volume

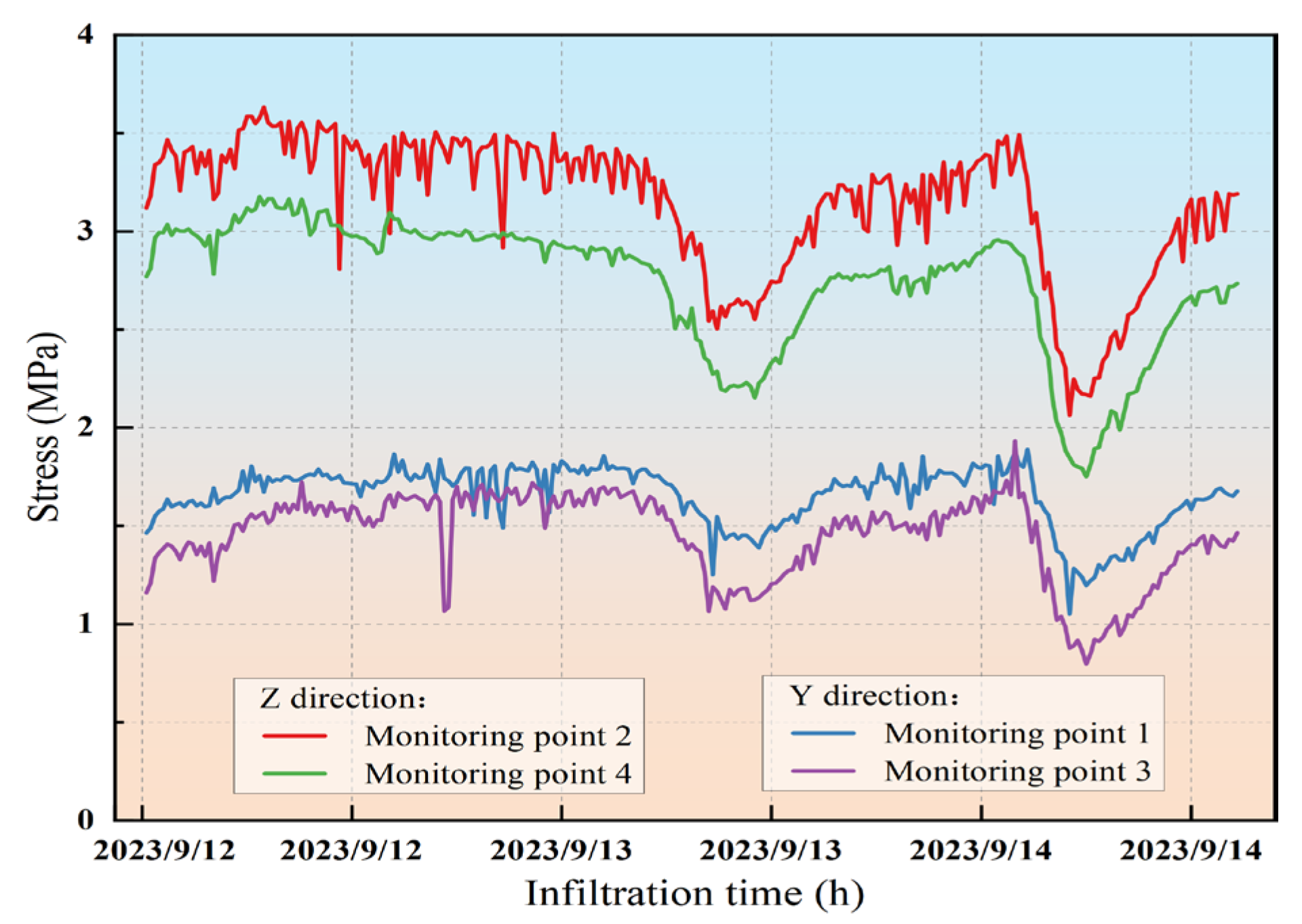

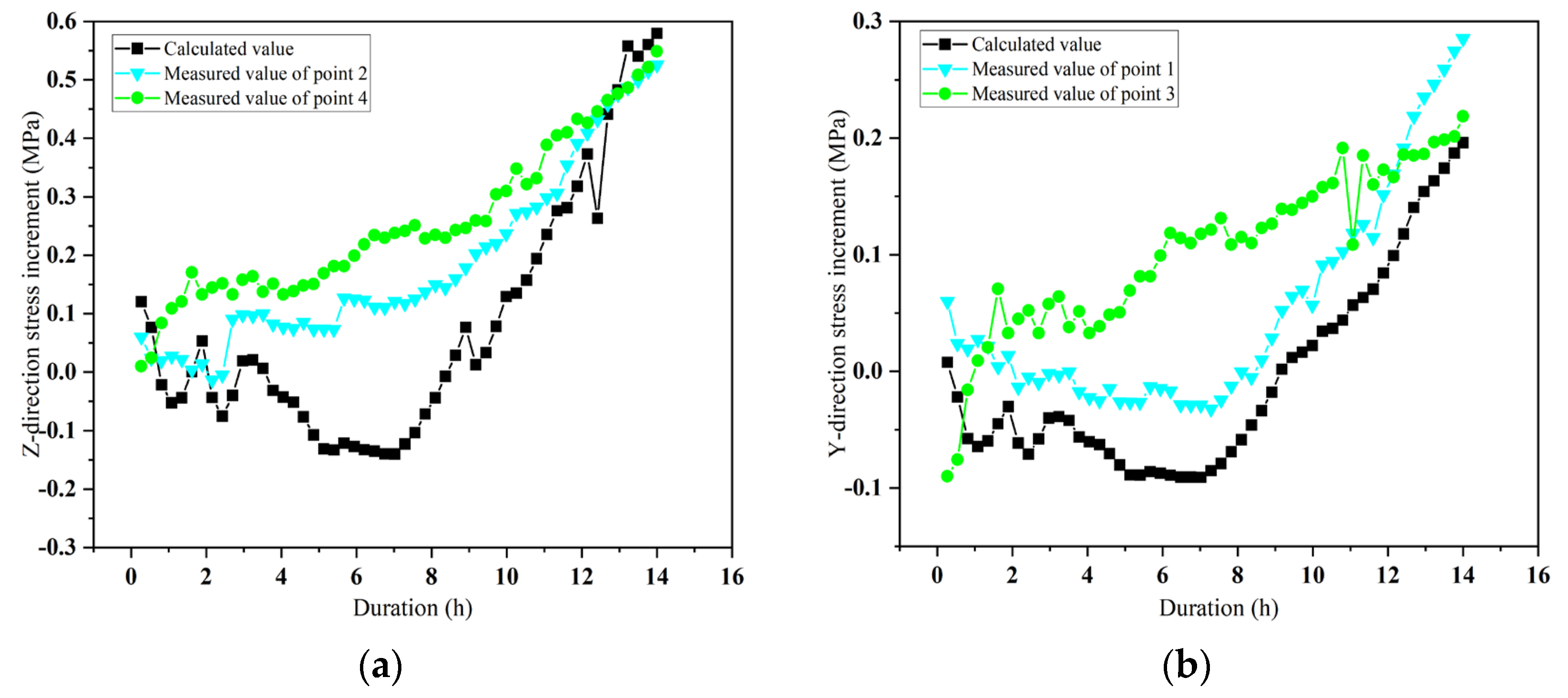

2.2.3. Stress Evolution Analysis

- 1.

- variation (Monitoring points 1 and 3)

- 2.

- variation (Monitoring points 2 and 4)

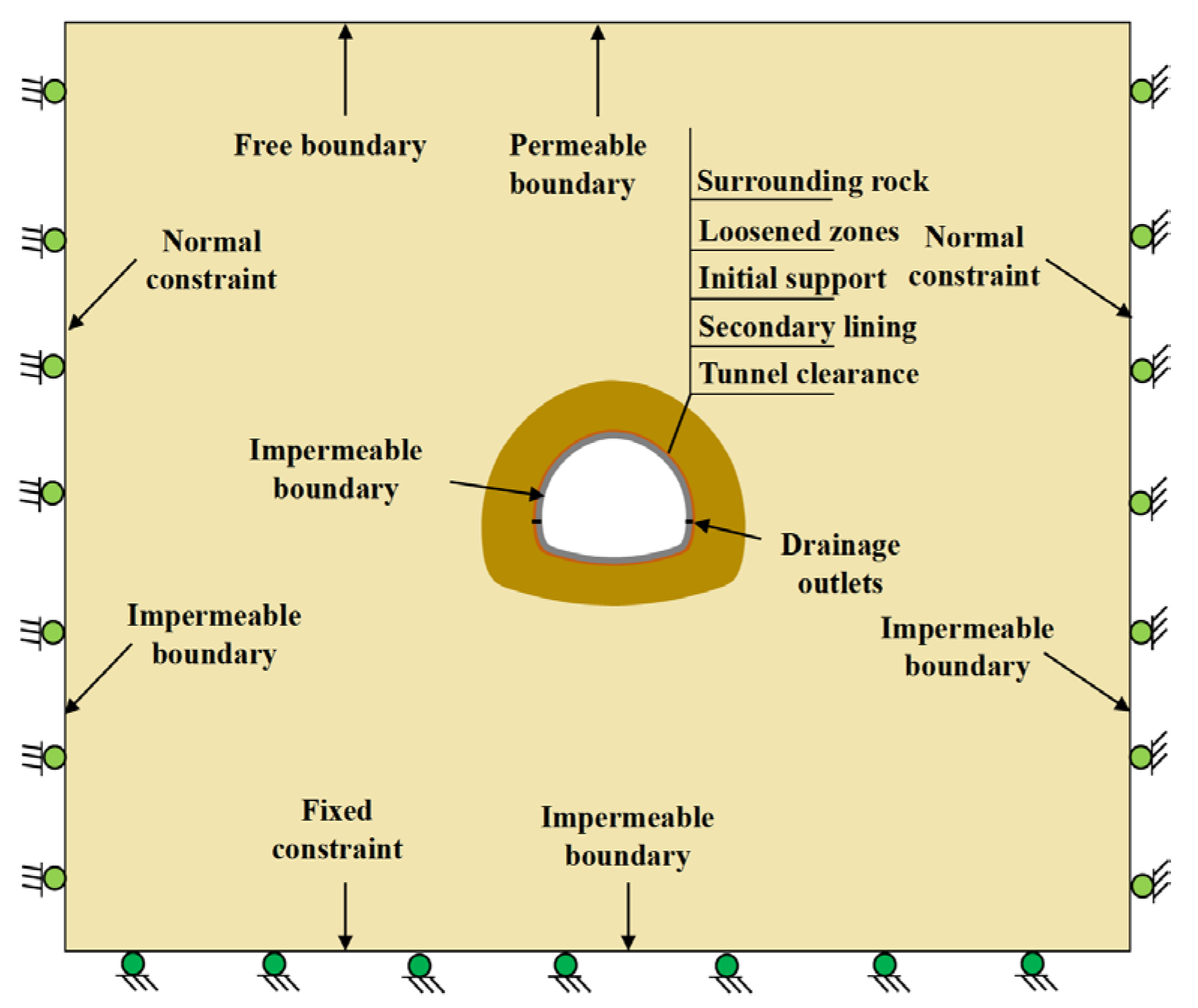

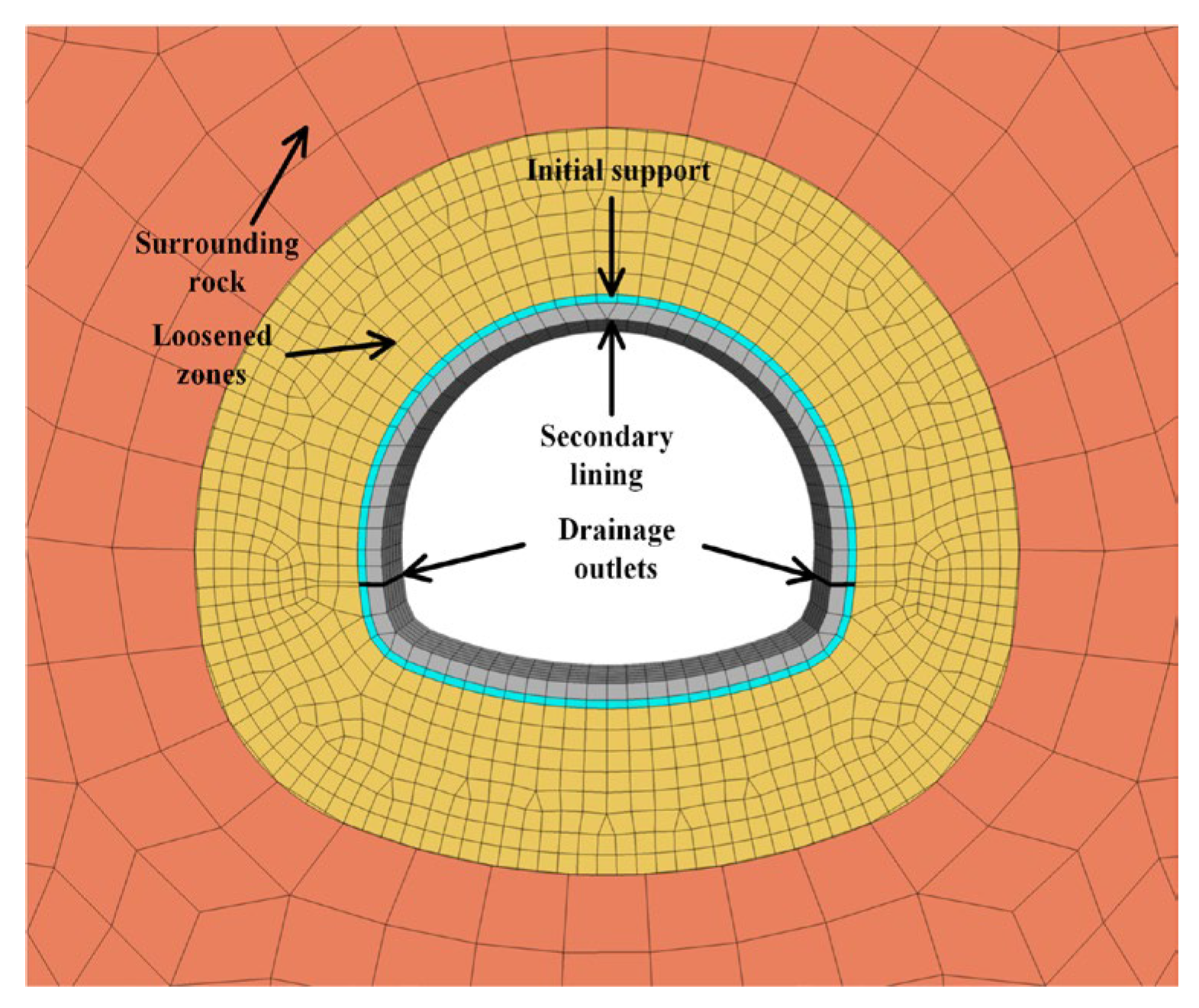

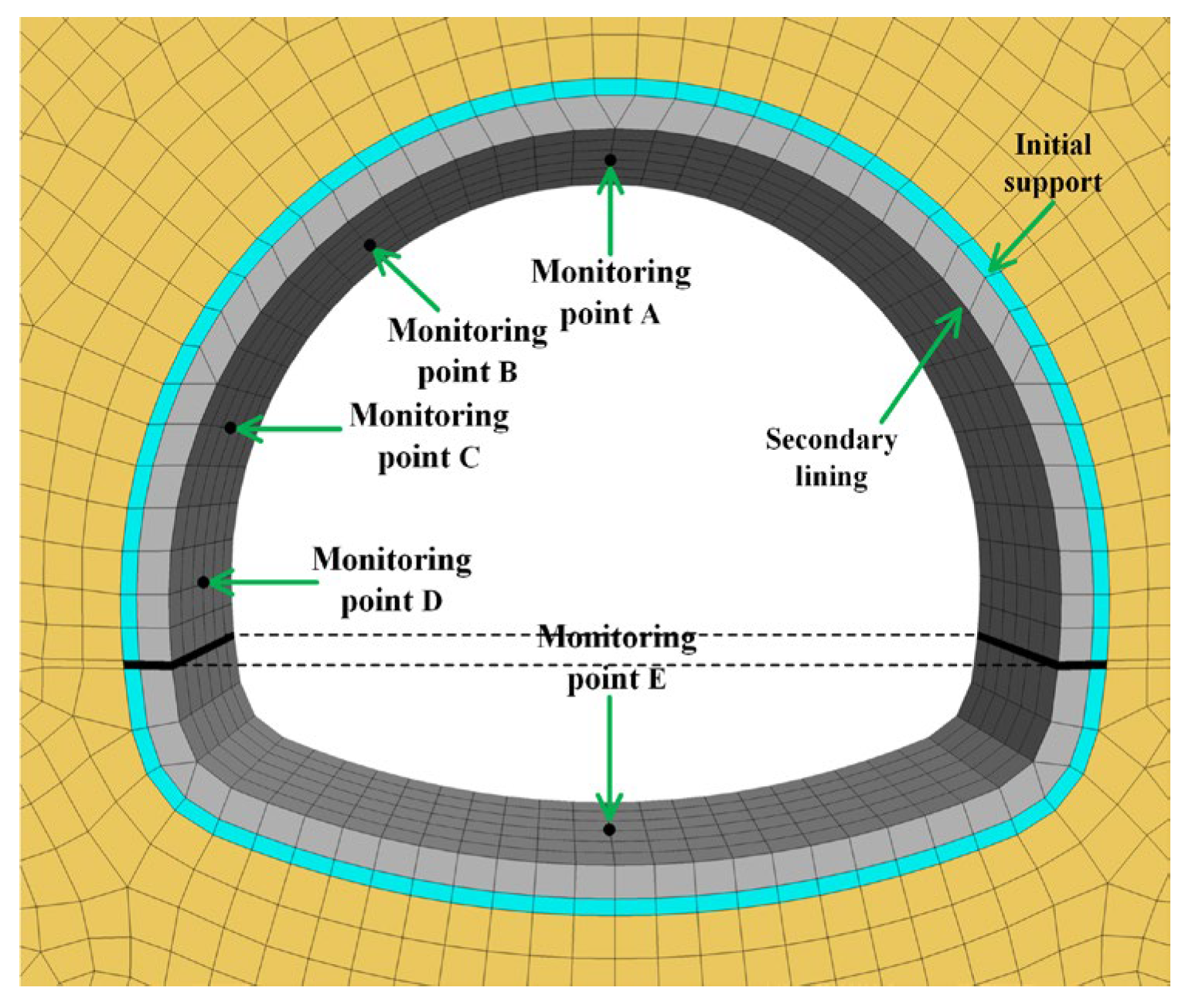

3. Fluid-Solid Coupling Numerical Model

3.1. Model Establishment

3.2. Model Validation

4. Investigation of Tunnel Lining Mechanical Behavior Under Heavy Rainfall

4.1. Effects of Rainfall Intensity on Lining Mechanical State

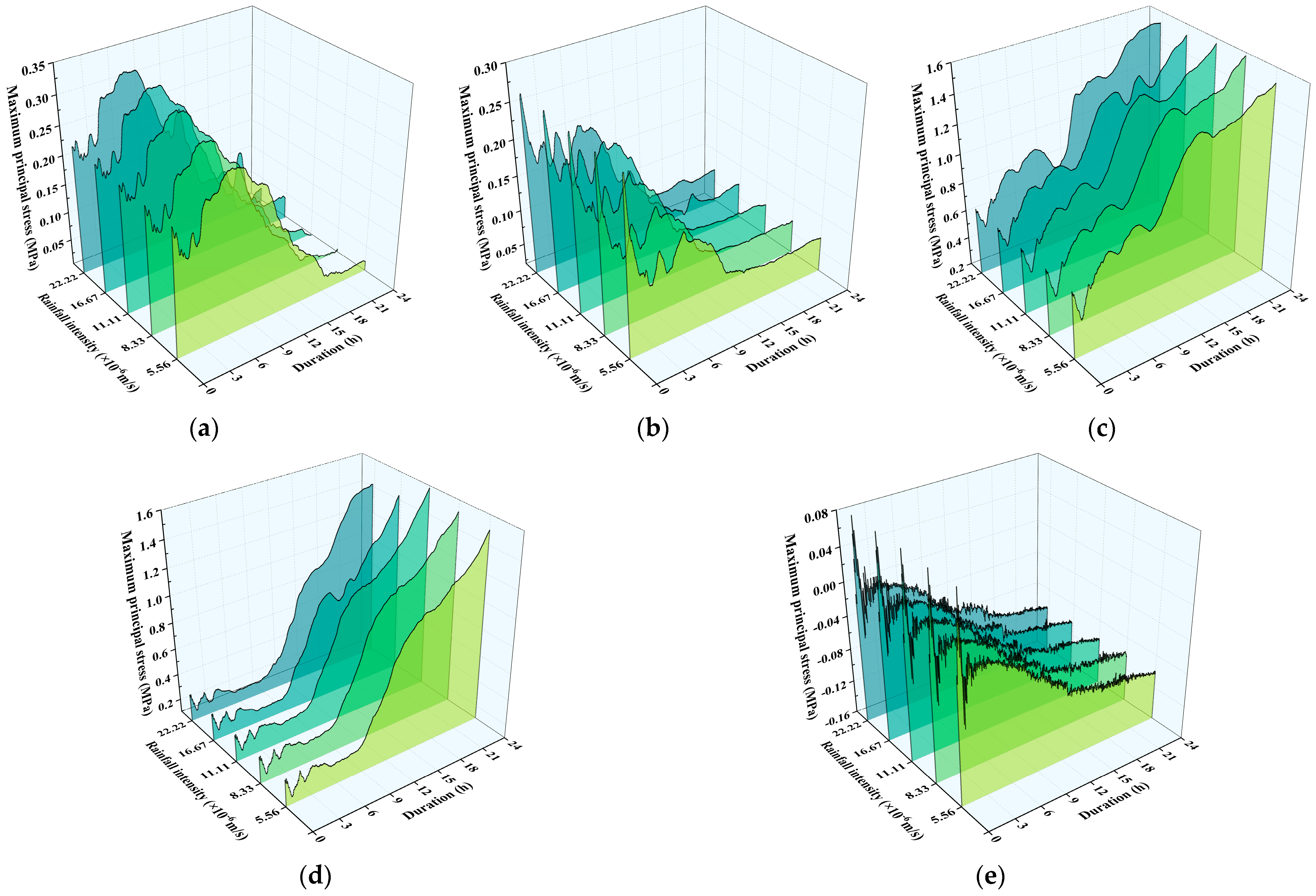

4.1.1. Effects of Rainfall Intensity on Secondary Lining Stresses

- (1)

- Maximum Principal Stress Analysis

- (2)

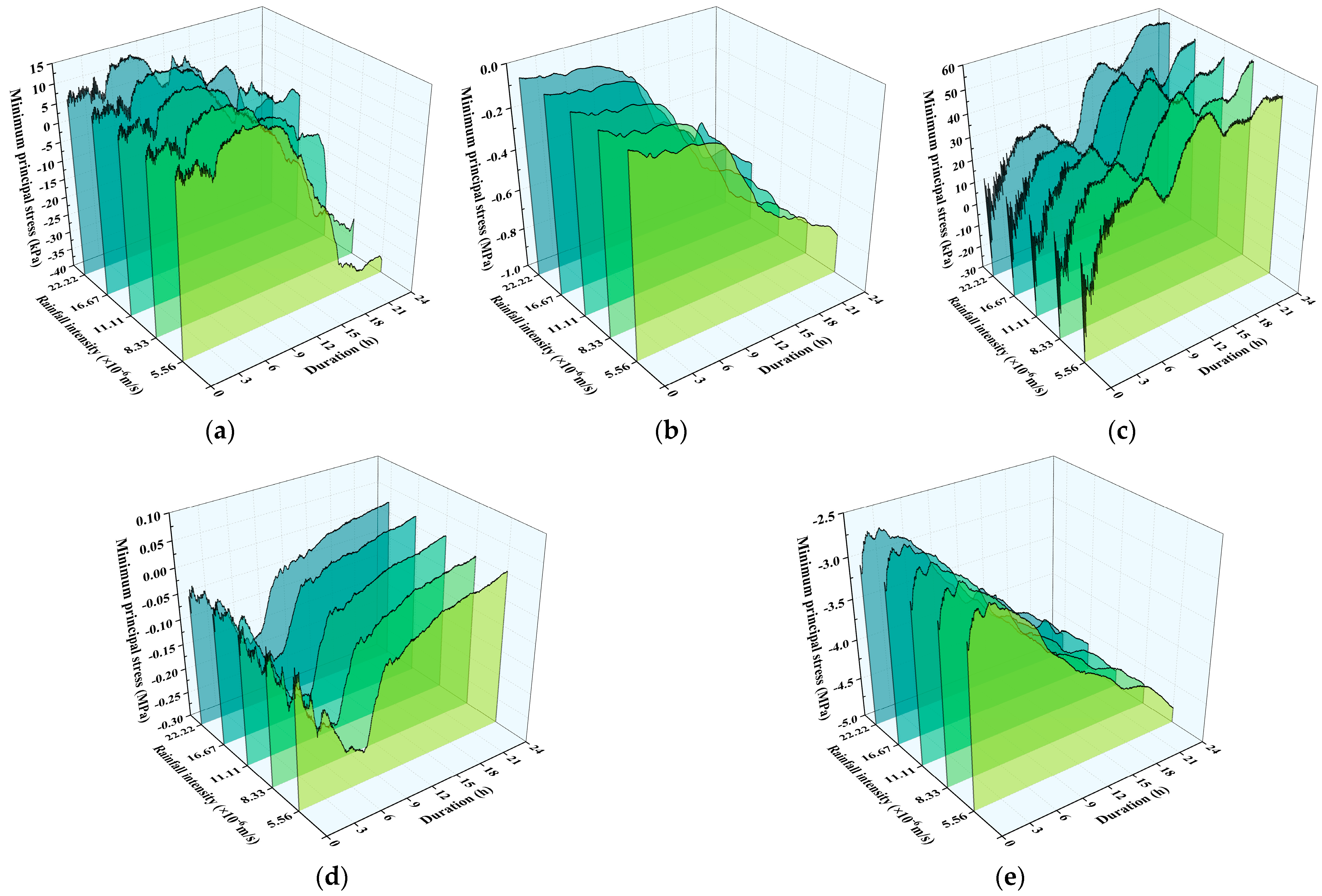

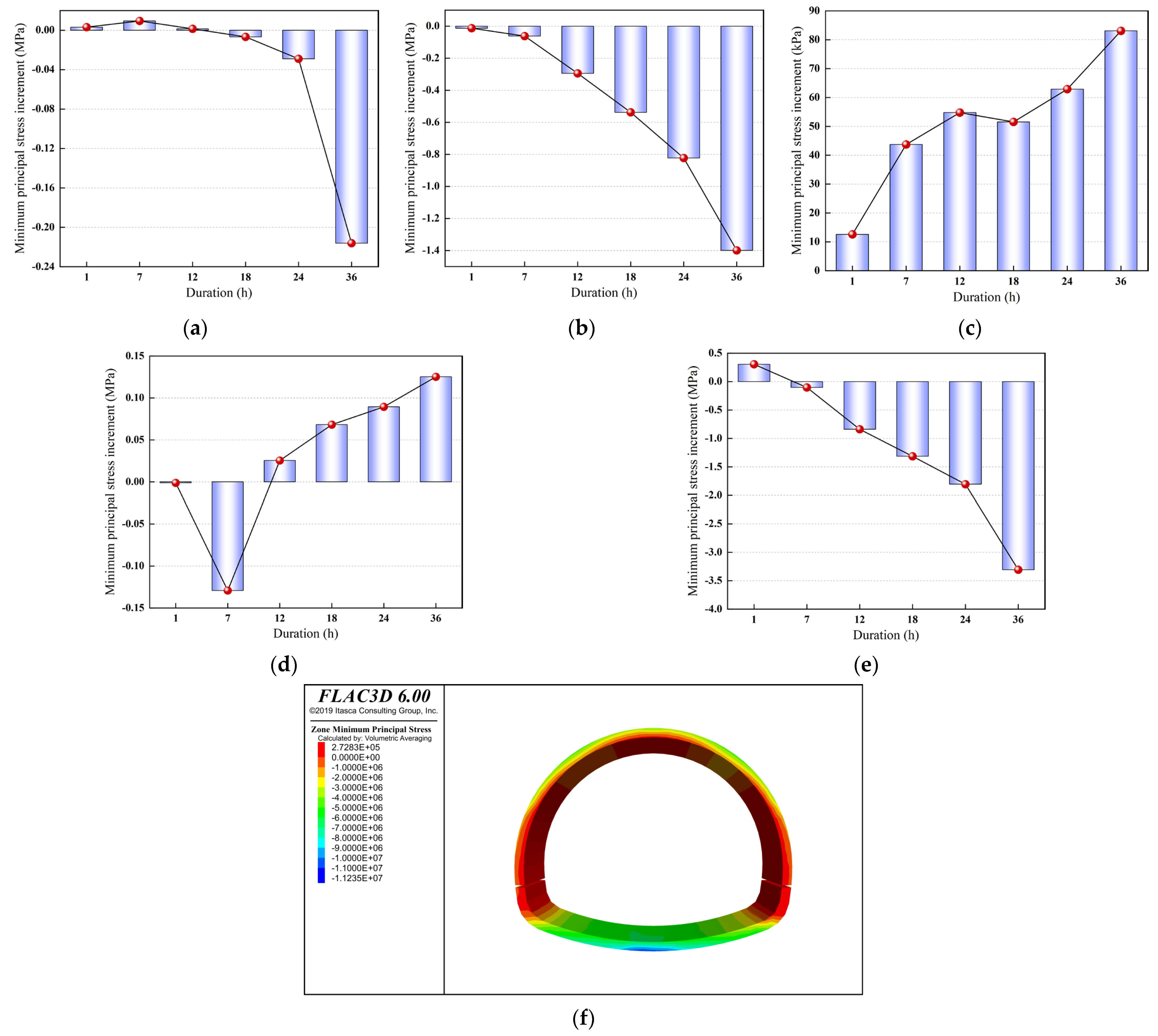

- Minimum Principal Stress Analysis

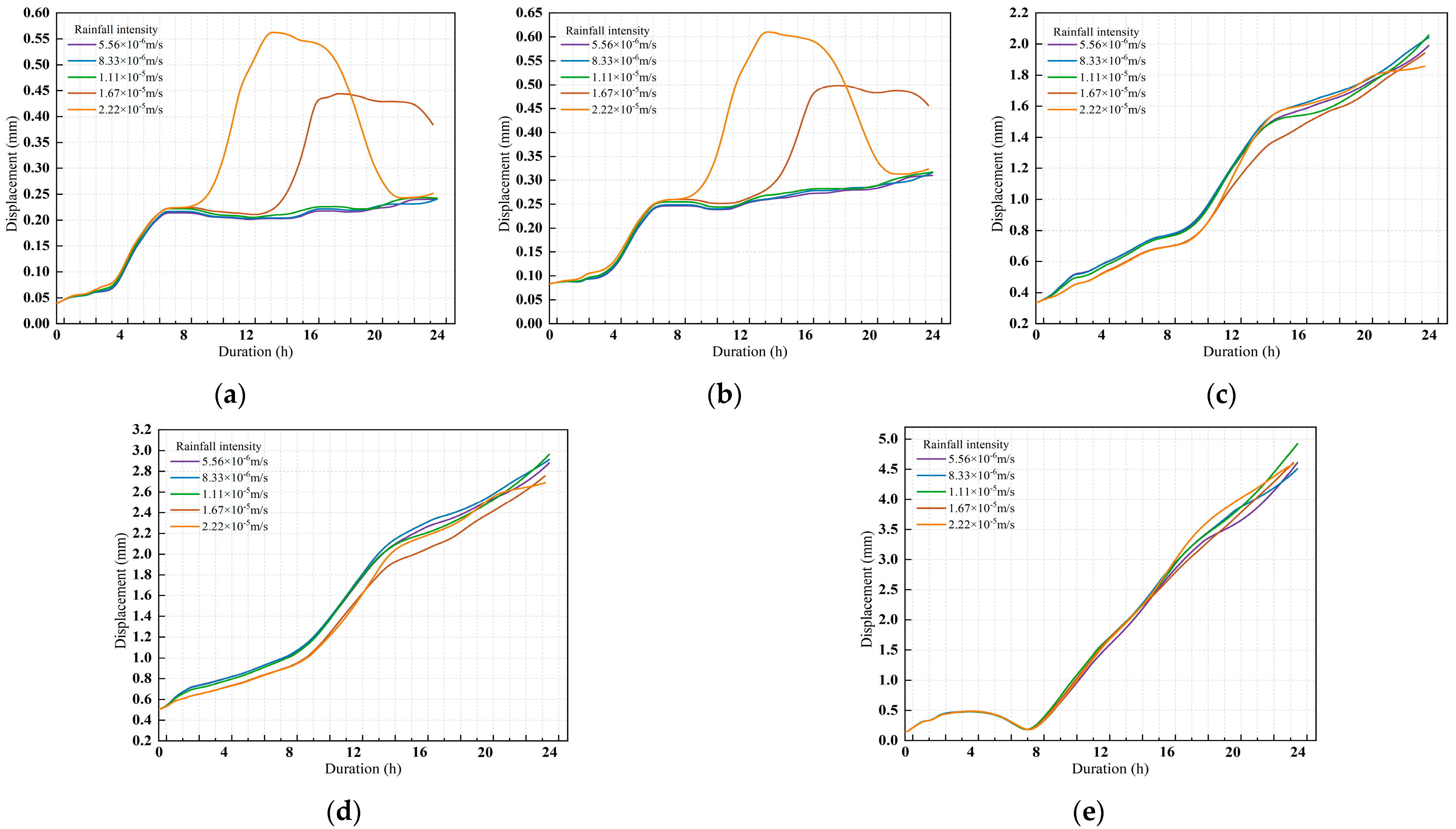

4.1.2. Effects of Rainfall Intensity on Displacements of Secondary Linings

4.2. Effects of Heavy Rainfall Duration on Mechanical Response of Tunnel Linings

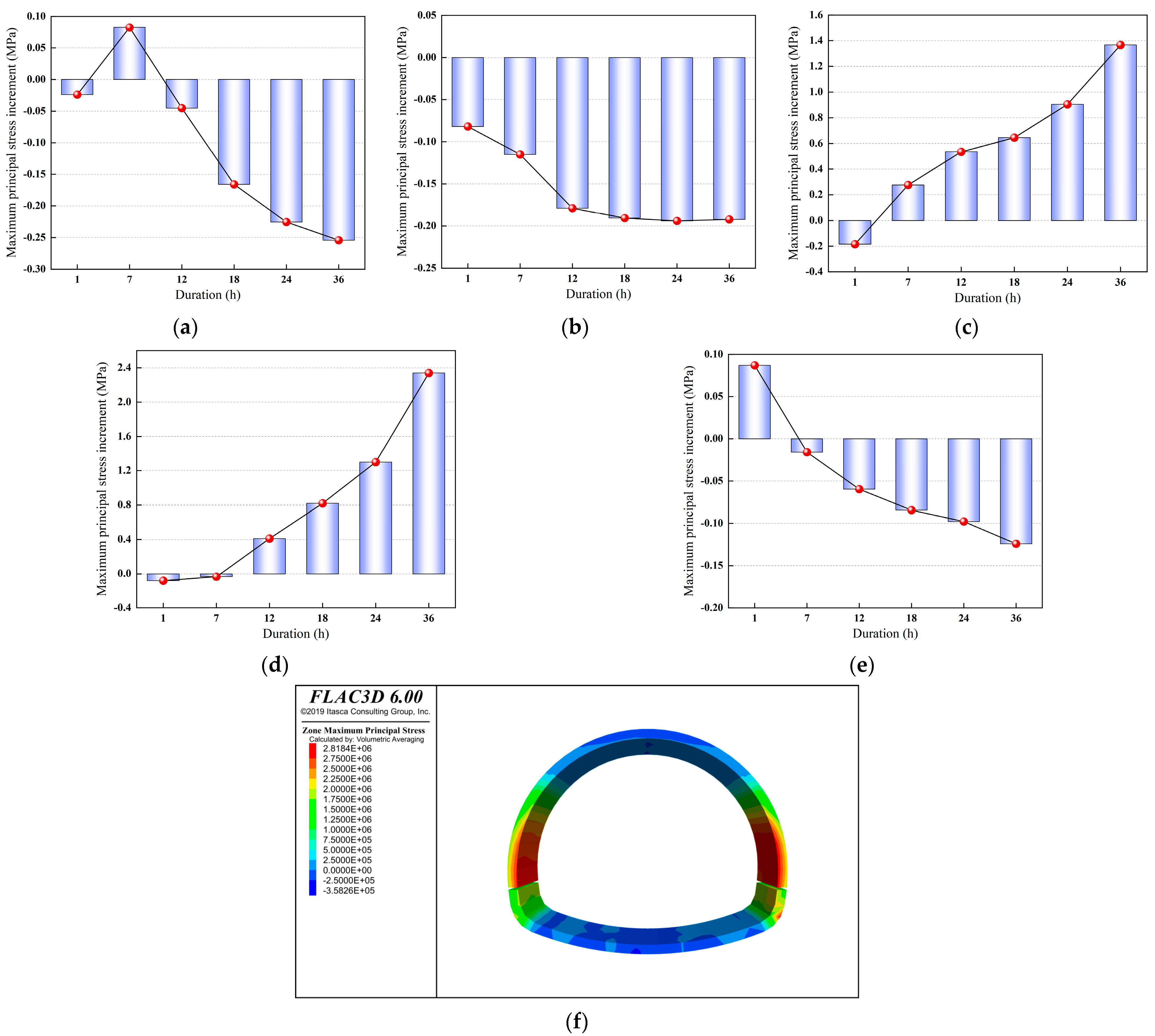

4.2.1. Effects of Rainfall Duration on Secondary Lining Stresses

- (1)

- Maximum Principal Stress Analysis

- (2)

- Minimum Principal Stress Analysis

4.2.2. Effects of Rainfall Duration on Displacements of Secondary Linings

5. Effects of Permeability Changes in Loosened Zones on Mechanical State of Tunnel Linings

5.1. Effects of Permeability Coefficient in Loosened Zones on Stress Response Characteristics of Secondary Linings

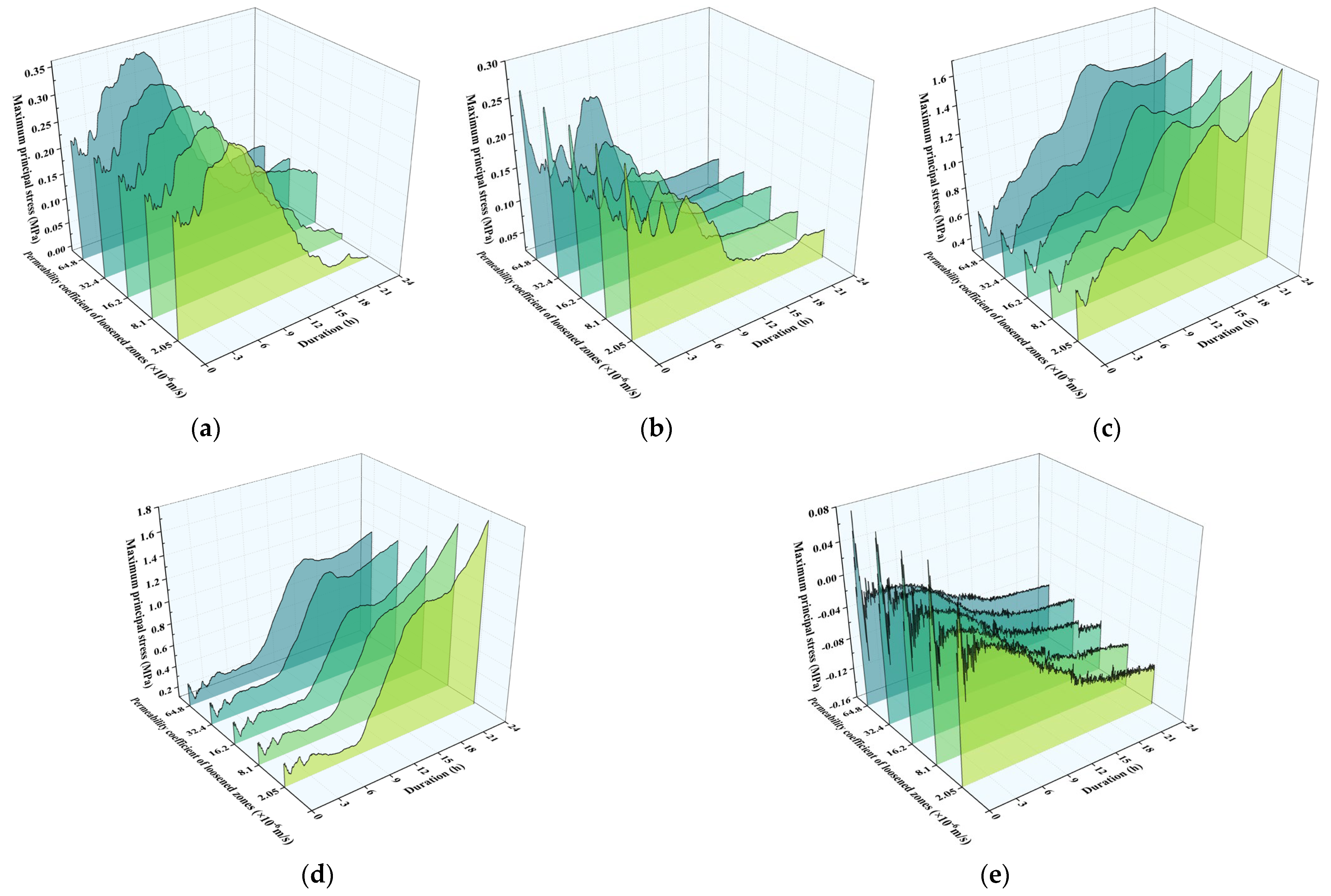

- (1)

- Maximum Principal Stress Analysis

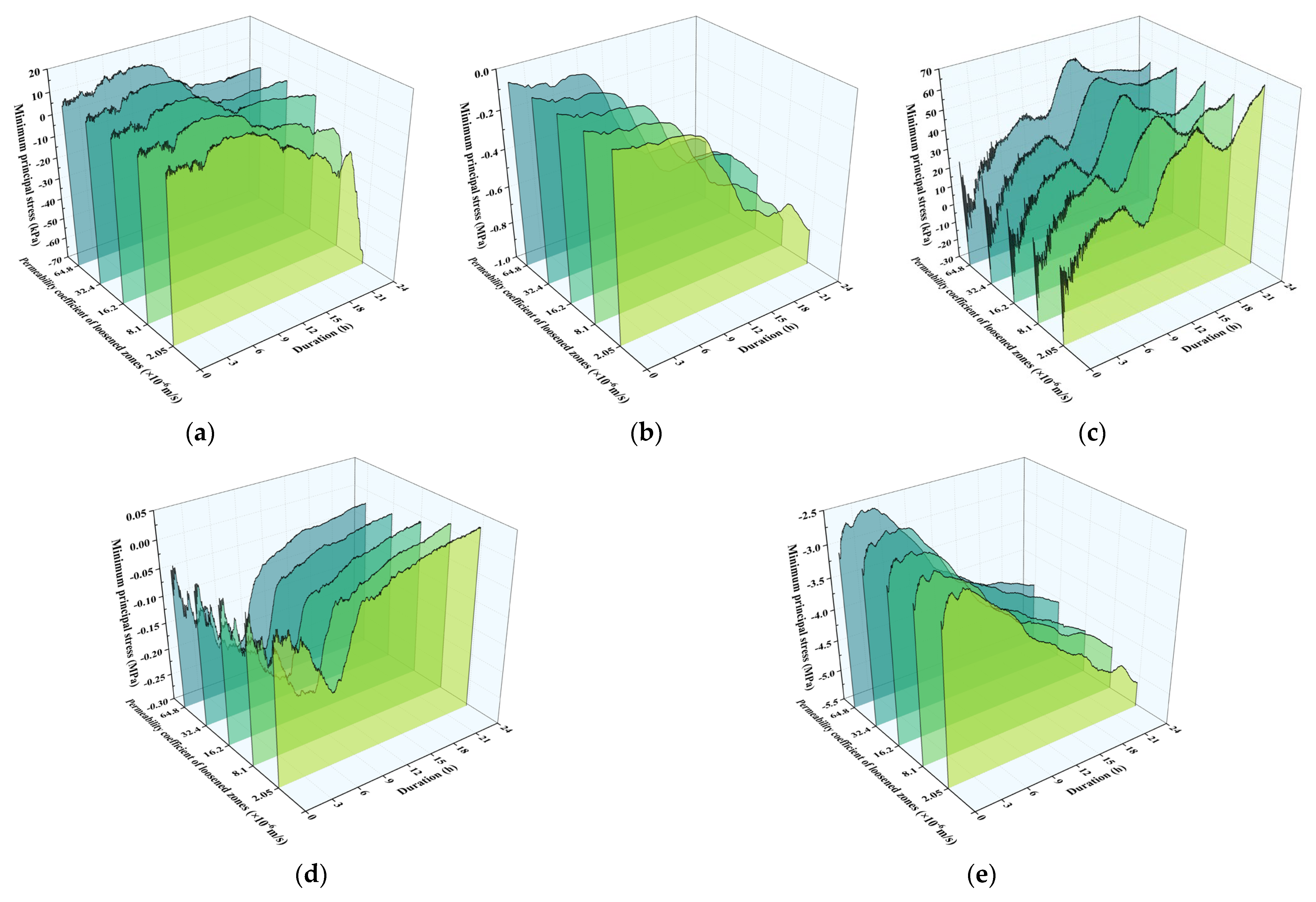

- (2)

- Minimum Principal Stress Analysis

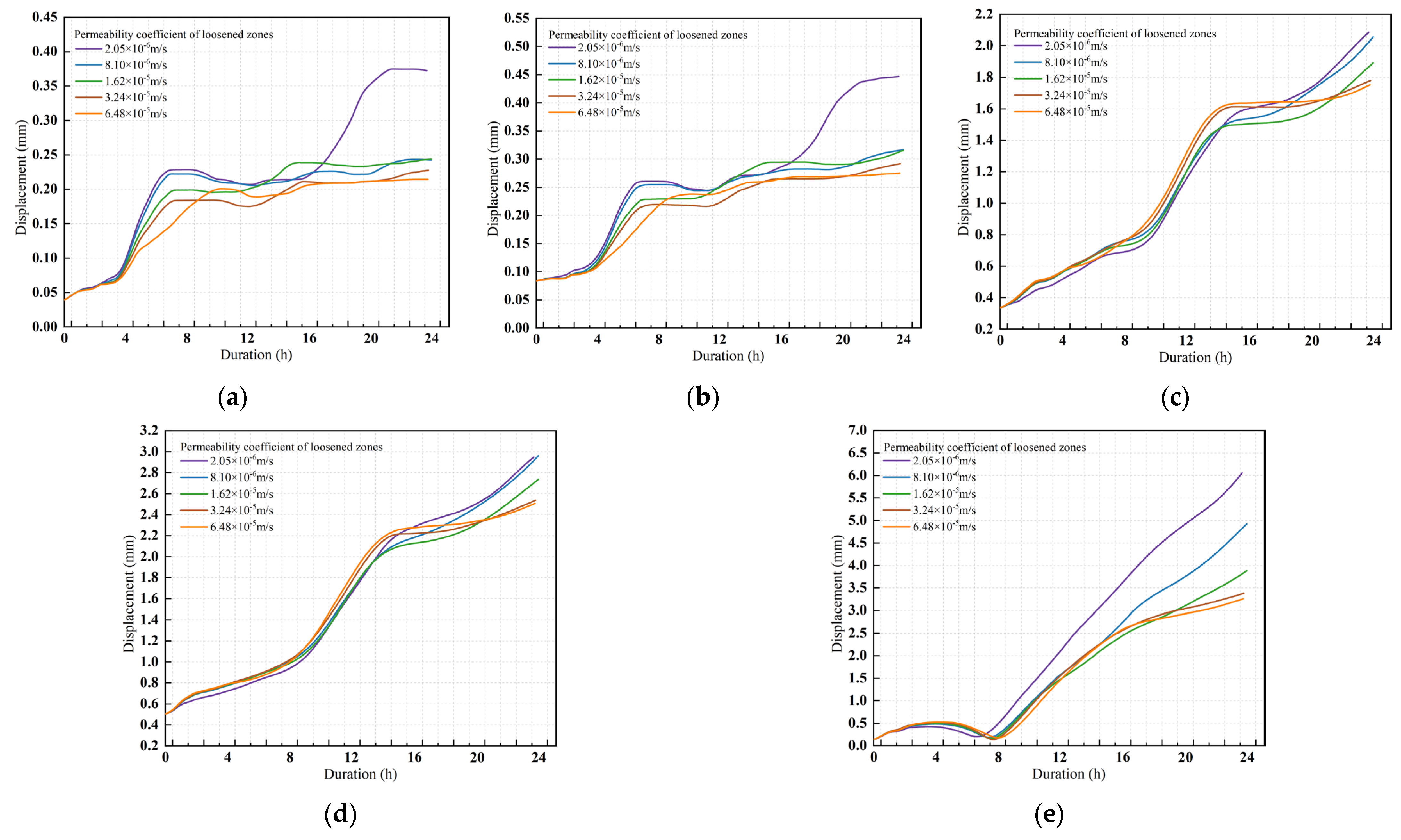

5.2. Effects of Permeability Coefficients in Loosened Zones on Displacements of Secondary Linings

6. Conclusions

- (1)

- Field monitoring results show that heavy rainfall has a significant impact on the mechanical response of mountain tunnel lining structures. During the monitoring period, rainfall was recorded on 155 days, with the maximum single-day rainfall reaching 118.8 mm, lasting for 15 h. The maximum single-day drainage volume reached 120.95 m3. Under rainstorm conditions, the maximum increment in tensile stress in the lining was 0.55 MPa, exhibiting a stress mutation characteristic, while the tensile stress remained relatively stable. Rainfall of this magnitude can easily induce local stress concentration, which may lead to lining cracking. During the model validation process, the observed stress increment was reproduced within a 10% error margin.

- (2)

- Based on the monitoring data from this study and the results of the three-dimensional fluid-solid coupling model, heavy rainfall intensity and duration significantly cause the redistribution of stress and concentration of displacement in the tunnel lining, which are core factors leading to a reduction in structural stability. When the rainfall intensity is 1.11 × 10−5 m/s, the peak maximum principal stress at the sidewall monitoring point reaches 1.58 MPa (tensile stress, with a net increment of 1.3 MPa). As the rainfall duration increases from 1 h to 36 h, the maximum stress increments at the crown foot and sidewall monitoring points reach 1.36 MPa (corresponding to tensile stress of 2.03 MPa) and 2.34 MPa (corresponding to tensile stress of 2.63 MPa), respectively, while the minimum principal stress increment at the invert monitoring point reaches 3.31 MPa (corresponding to compressive stress of 6.3 MPa).The sidewall and invert areas are the main control zones for displacement response, with the maximum displacement increments at the monitoring points in these areas reaching 3.94 mm (corresponding to displacement of 4.45 mm) and 8.47 mm (corresponding to displacement of 8.61 mm), respectively. Moreover, the maximum principal stress increment at the sidewall exceeds the tensile strength design value of 1.43 MPa for C30 concrete, indicating a significant risk of cracking. Based on these findings, it is recommended to set the rainfall-triggered inspection threshold as follows: single-day rainfall ≥ 80 mm or continuous rainfall ≥ 10 h. Additionally, monitoring frequency should be adjusted to once every 3 days during normal conditions, once every 2 h during heavy rainfall, and once every 6 h within 3 days after rainfall, to promptly capture risks.

- (3)

- The increased permeability has a positive impact on the stability of the surrounding rock-lining system. When the permeability coefficient increases from 2.05 × 10−6 m/s to 6.48 × 10−5 m/s, the maximum principal stress increment at the sidewall monitoring point is 0.84 MPa (tensile stress, with a decrement of 41%), and the minimum principal stress increment at the invert monitoring point is 1.45 MPa (compressive stress, with a decrement of 31%). The displacement increment at the invert monitoring point is 3.12 mm (a 33% reduction compared to low permeability surrounding rock). However, under low permeability conditions in the loosened zone, lining stress and deformation are particularly significant, and the risk in local areas increases noticeably. Based on these findings, it is recommended to optimize the design by reducing the sidewall blind drainage spacing from the conventional 5 m to 3–4 m, in order to enhance drainage and increase permeability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Fluid-Solid Coupling Governing Equations

Appendix A.1. Darcy’s Law

Appendix A.2. Richards Equation

Appendix A.3. Van Genuchten Mode

Appendix B. Drainage Volume Conversion Formula

References

- Lu, F.; Wang, Y.; Fu, J.; Yang, Y.; Qiu, W.; Jing, Y.; Jiang, M.; Li, H. Safety Evaluation of Plain Concrete Lining Considering Deterioration and Aerodynamic Effects. Sustainability 2023, 15, 7170. [Google Scholar] [CrossRef]

- Tang, K.; Liu, D.; Xie, S.; Qiu, J.; Lai, J.; Liu, T.; Fang, Y. Analysis of Loess Water Migration Regularity and Failure Response of Tunnel Structure under Rainfall Environment. Bull. Eng. Geol. Environ. 2024, 83, 6. [Google Scholar] [CrossRef]

- Luo, Y.; Yang, J.; Xie, Y.; Fu, J.; Zhang, C. Investigation on Evolution Mechanism and Treatment of Invert Damage in Operating Railway Tunnels under Heavy Rainfall. Bull. Eng. Geol. Environ. 2024, 83, 160. [Google Scholar] [CrossRef]

- Zou, L.; Tang, M.; Li, B. Bingham and Herschel-Bulkley Fluids Flow Regimes in Rough-Walled Rock Fractures. Int. J. Rock Mech. Min. Sci. 2024, 180, 105832. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, S.; Yin, H.; Yang, T.; Wang, P. Fracture Seepage and the Temperature Field Distribution of Rocks Surrounding High-Temperature Tunnels: A Numerical Analysis. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 112. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z. Research on the Stress Characteristic of Cracked Lining in Operating Tunnel under the Action of Fluid-Structure Interaction. Mod. Eng. Technol. Res. 2025, 10, 15–17. [Google Scholar]

- Tang, K.; Qiu, J.; Lai, J.; Xue, F.; Wang, Z.; Li, X. Experimental Investigation on Deformation-Failure Mechanisms of a Shallow-Bias Large-Section Loess Tunnel Induced by Rainfall. Tunn. Undergr. Space Technol. 2025, 157, 106253. [Google Scholar] [CrossRef]

- An, P.T.; Li, S. Analysis of the Influence Characteristics of Hidden Karst Cavities on Water Gushing in Tunnels Under Heavy Rainfall Conditions. Carbonates Evaporites 2025, 40, 85. [Google Scholar] [CrossRef]

- Tang, W.; Kong, X.; Tang, L.; Ling, X.; Yao, C. Experimental Investigation of Erosion Damage and Bearing Performance of 3D-Modeled High-Precision Segment Models under Salt-Load Coupling Effects. Constr. Build. Mater. 2025, 49, 142985. [Google Scholar] [CrossRef]

- Tian, X.; Song, Z.; Wang, H.; Zhang, Y.; Wang, J. Evolution Characteristics of the Surrounding Rock Pressure and Construction Techniques: A Case Study from Taoshuping Tunnel. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2022, 125, 104522. [Google Scholar] [CrossRef]

- Chang, Z.; Yan, C.; Yin, P.; Lan, H.; Bao, H.; Zhang, J.; Lu, Z. Case Study on Hydro-Mechanical Behavior of Tunnel Structure in Red Mudstone Adjacent to Water-Rich Fault Zones. Alex. Eng. J. 2025, 123, 620–636. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, N.; Chen, K.; Ren, F. Study on Drainage Mode and Anti-Clogging Performance of New Waterproofing and Drainage System in a Tunnel. Sci. Rep. 2023, 13, 5354. [Google Scholar] [CrossRef]

- Qian, W.; Tang, X.; Ma, X.; Wang, X. Mechanical Characteristics and Safety Evaluation of Tunnel Lining Structures in Karst Areas Under Heavy Rainfall Conditions. Buildings 2025, 15, 1756. [Google Scholar] [CrossRef]

- Fan, H.; Zhu, Z.; Song, Y.; Zhang, S.; Zhu, Y.; Gao, X.; Hu, Z.; Guo, J.; Han, Z. Water Pressure Evolution and Structural Failure Characteristics of Tunnel Lining Under Hydrodynamic Pressure. Eng. Fail. Anal. 2021, 130, 105747. [Google Scholar] [CrossRef]

- Sun, D.; Wang, N. Research on the Applied Technology for Prevention and Control of Water Seepage Disease of Highway Operation Tunnel in Northern Cold Region. North Commun. 2024, 12, 83–87. [Google Scholar]

- Tian, C.; Xiao, Z.; Ye, F.; Tong, Y.; Cao, X.; Sun, J.; Li, Z. The Impact of Extreme Rainfall and Drainage System Failure on Rock Tunnels: A Case Study of Deep-Buried Karst Tunnel. Eng. Fail. Anal. 2025, 171, 109345. [Google Scholar] [CrossRef]

- Li, H.; Tan, Y.; Zeng, D.; Su, D.; Qiao, S. Attitude-Predictive Control of Large-Diameter Shield Tunneling: PCA-SVR Machine Learning Algorithm Application in a Case Study of the Zhuhai Xingye Express Tunnel. Appl. Sci. 2025, 15, 1880. [Google Scholar] [CrossRef]

- Si, J.; Liu, S.; Zhang, H.; Zhu, Y.; Zheng, Y. Failure Investigation and Treatments of Tunnel Entrance Collapse in Weak Diatomaceous Soil Induced by Heavy Rainfall Through Coupling Surface and Groundwater Flows. Eng. Fail. Anal. 2023, 150, 107337. [Google Scholar] [CrossRef]

- Wang, Z.; Dong, J.; Zhao, Y.; Wang, Z. Analysis of Fluid–Structure Coupling of Sudden Water Deformation in Tunnels Under Construction. Water 2024, 16, 3479. [Google Scholar] [CrossRef]

- Jin, C.; Sun, C.; Lan, S.; Zhang, J. Progressive Collapse Mechanism Analysis of Tunnel Roof with Weak Surrounding Rock Considering Seepage Effect. Int. J. Geomech. 2025, 25, 04025170. [Google Scholar] [CrossRef]

- Shi, Z.; Xu, J.; Xie, X.; Li, P.; Chai, L.; Li, S. Failure Mechanism Analysis for Tunnel Construction Crossing the Water-Rich Dense Fracture Zones: A Case Study. Eng. Fail. Anal. 2023, 149, 107242. [Google Scholar] [CrossRef]

- Yu, H.T.; Li, T.T.; Yan, X. Multi-Scale Response Characteristics of Overlying Soil-Tunnel System Under Reverse Fault Dislocation. Hydrogeol. Eng. Geol. 2025, 52, 202–213. [Google Scholar]

- Geng, X.; Wu, S.; Yan, Q.; Sun, J.; Xia, Z.; Zhang, Z. An Optimized XGBoost Model for Predicting Tunneling-Induced Ground Settlement. Geotech. Geol. Eng. 2023, 42, 1297–1311. [Google Scholar] [CrossRef]

- DB62/T 2755-2017; Grades of Short-Duration Heavy Precipitation. Gansu Provincial Administration of Quality and Technology Supervision: Lanzhou, China, 2017.

- He, Z.; Xie, M.-W.; Wu, Z.-X.; Zhao, C.; Sun, G.-C.; Xu, L. Field Measurement Study on the Pre-Collapse Inclination Deformation Characteristics of Tension-Cracking Slope Rock Mass Using Micro-Core-Pile Sensor. Rock Soil Mech. 2024, 45, 3399–3415. [Google Scholar] [CrossRef]

- Xu, X.; Liu, J.; Zhang, J.; Ji, M.; Zhang, K.; Shi, S. Spatial and Temporal Distribution Characteristics of Rainfall in Daqing River Basin in the Haihe “23·7” Basin-Wide Extreme Flood. China Flood Drought Manag. 2024, 34, 45–51. [Google Scholar]

- Ma, Y.; Wang, Z.; Wang, D. The Safe Load-Bearing Capacity of Railway Tunnel Linings under High-Pressure and Water-Rich Conditions. Buildings 2023, 13, 2154. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, J.-J.; You, L.; Lu, J.-T.; Cui, L.; Yang, W.-Y.; Huang, Z.-F. An Analytical Solution for 2D Plane Strain Consolidation in Unsaturated Soils with Lateral and Vertical Semipermeable Drainage Boundaries under Time-Dependent Loading. Int. J. Geomech. 2022, 22, 12. [Google Scholar] [CrossRef]

- JTG 3370.1-2018; Highway Tunnel Design Code. Ministry of Transport of the People’s Republic of China: Beijing, China, 2018.

- GB 50021-2001; Geotechnical Engineering Investigation Code. Ministry of Construction of the People’s Republic of China: Beijing, China, 2001.

- GB/T 50010-2010; Standard for Concrete Structure Design. Ministry of Housing and Urban-Rural Development of the People’s Republic of China & Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- Yang, Y.; Li, Z.; Tan, Z.; Lin, C.; Liu, Z. Mechanics Analysis of Weak Rock Progressive Squeezing Deformation Characteristics for Tunnel in Suture Zone: A Case Study. Arch. Civ. Mech. Eng. 2025, 25, 5–6. [Google Scholar] [CrossRef]

- Wang, R. Method and Application Study on Determining the Loose Zone of Tunnel Surrounding Rock. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

| Date of Heavy Rainfall | Maximum Rainfall per Hour (mm) | Duration of Heavy Rainfall (h) |

|---|---|---|

| 4 July 2023 | 21.80 | 2 |

| 13 July 2023 | 29.80 | 3 |

| 21 July 2023 | 21.20 | 1 |

| 5 August 2023 | 27.60 | 1 |

| 12 September 2023 | 20.00 | 2 |

| 21 June 2024 | 35.00 | 3 |

| Materials Name | Elastic Modulus/GPa | Poisson’s Ratio | Density/(kg/m3) | Internal Friction Angle/(°) | Cohesion/MPa | Porosity |

|---|---|---|---|---|---|---|

| Surrounding rock | 6.00 | 0.33 | 2300 | 35.00 | 0.80 | 0.30 |

| Loosened zones | 5.00 | 0.35 | 2200 | 35.00 | 0.70 | 0.30 |

| Initial support | 11.40 | 0.21 | 2300 | 52.10 | 2.10 | 0.01 |

| Secondary lining | 30.00 | 0.19 | 2400 | 52.50 | 2.60 | 0.01 |

| Materials Name | Permeability Coefficient/(m/s) | Saturation/(%) | Specific Weight for Fluid/(kN/m3) | Fluid Modulus/GPa |

|---|---|---|---|---|

| Surrounding rock | 8.1 × 10−6 | — | 1000 | 2.00 |

| Loosened zones | 8.1 × 10−6 | — | 1000 | 2.00 |

| Rainfall Intensity (×10−6 m/s) | Rainfall Duration (h) | Permeability Coefficient of Loosened Zones (×10−6 m/s) |

|---|---|---|

| 5.56, 8.33, 11.10, 16.70, 22.20 | 1, 7, 12, 18, 24, 36 | 2.05, 8.10, 16.20, 32.40, 64.80 |

| Permeability Coefficient of Loosened Zones (×10−6 m/s) | Permeability Coefficient of Surrounding Rock (×10−6 m/s) | Rainfall Intensity (×10−6 m/s) | Rainfall Duration (h) |

|---|---|---|---|

| 8.10 | 8.10 | 5.56, 8.33, 11.10, 16.70, 22.20 | 24.00 |

| Permeability Coefficient of Loosened Zones (×10−6 m/s) | Permeability Coefficient of Surrounding Rock (×10−6 m/s) | Rainfall Intensity (×10−5 m/s) | Rainfall Duration (h) |

|---|---|---|---|

| 8.10 | 8.10 | 1.11 | 1, 7, 12, 18, 24, 36 |

| Permeability Coefficient of Loosened Zones (×10−6 m/s) | Permeability Coefficient of Surrounding Rock (×10−6 m/s) | Rainfall Intensity (×10−5 m/s) | Rainfall Duration (h) |

|---|---|---|---|

| 2.05, 8.1, 16.2, 32.4, 64.8 | 8.1 | 1.11 | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, K.; Wang, Z.; Zhou, X.; Liu, L.; Zhen, Y.; Meng, W.; Zhou, Y. Study on Evolution Laws of Lining Mechanical Behavior in Mountain Tunnels Under Heavy Rainfall Conditions. Buildings 2025, 15, 3970. https://doi.org/10.3390/buildings15213970

An K, Wang Z, Zhou X, Liu L, Zhen Y, Meng W, Zhou Y. Study on Evolution Laws of Lining Mechanical Behavior in Mountain Tunnels Under Heavy Rainfall Conditions. Buildings. 2025; 15(21):3970. https://doi.org/10.3390/buildings15213970

Chicago/Turabian StyleAn, Ke, Zhenwei Wang, Xueyong Zhou, Lilong Liu, Yongqi Zhen, Wei Meng, and Yuanfu Zhou. 2025. "Study on Evolution Laws of Lining Mechanical Behavior in Mountain Tunnels Under Heavy Rainfall Conditions" Buildings 15, no. 21: 3970. https://doi.org/10.3390/buildings15213970

APA StyleAn, K., Wang, Z., Zhou, X., Liu, L., Zhen, Y., Meng, W., & Zhou, Y. (2025). Study on Evolution Laws of Lining Mechanical Behavior in Mountain Tunnels Under Heavy Rainfall Conditions. Buildings, 15(21), 3970. https://doi.org/10.3390/buildings15213970