Micro-Mechanism of Strength for Cement-Treated Soil Based on the SEM Experiment: Qualitative and Quantitative Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Unconfined Compression Tests

2.4. Scanning Electron Microscope Tests

3. Results

3.1. Microscopic Morphology of CTS

3.2. Quantitative Analysis of CTS

3.3. UCS and Micro-Parameter Analysis

4. Discussion

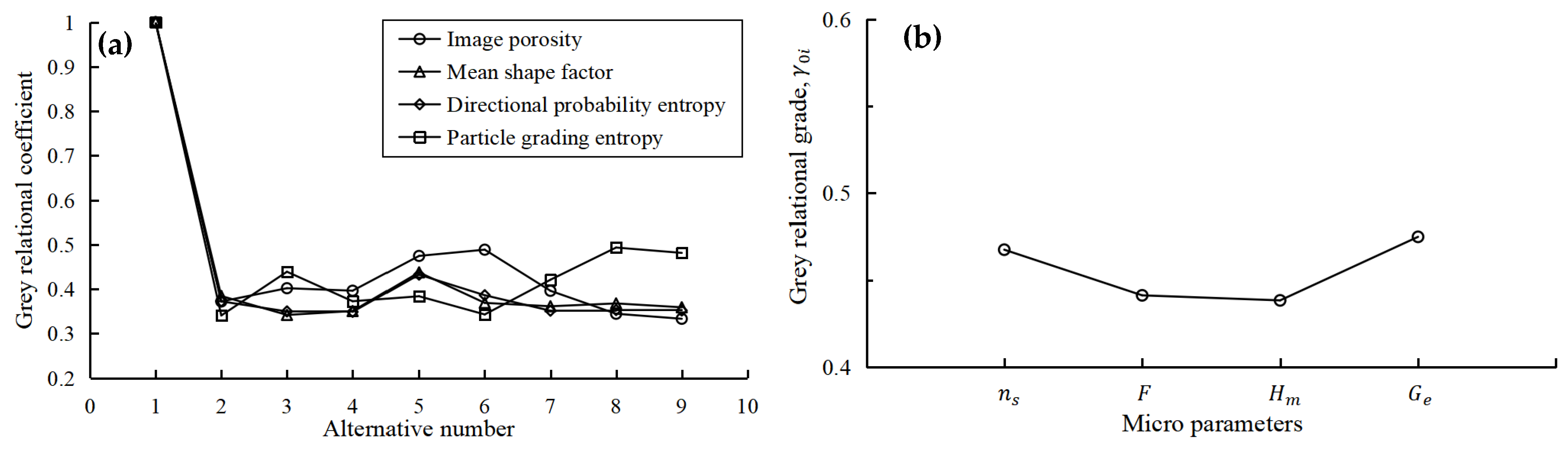

4.1. Grey Relation Analysis Method

4.1.1. Generation of Grey Relational Sequence

4.1.2. Grey Relational Normalization

4.1.3. Calculation of Grey Relational Coefficients

4.1.4. Calculation of Grey Relational Grade

4.2. The Influence of Micro-Parameters on Strength

4.3. Micro-Mechanism of UCS

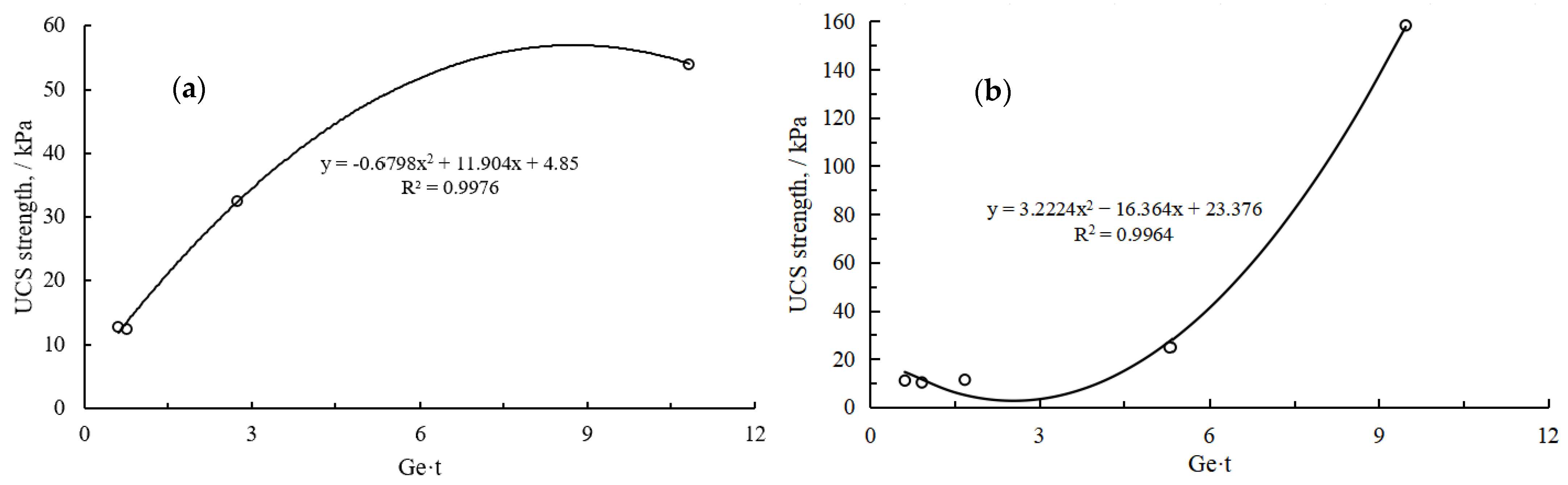

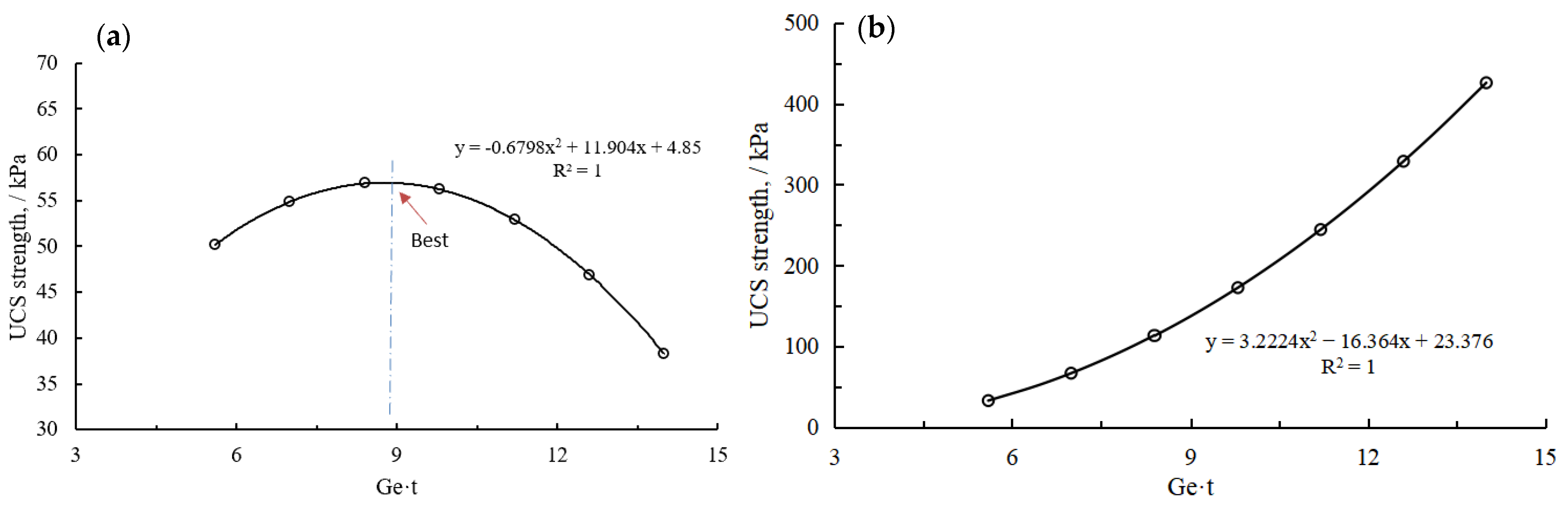

4.3.1. Relation Between UCS and Particle Grading Entropy

4.3.2. Sensitivity Analysis of Particle Grading Entropy

5. Conclusions

- 1.

- Microstructural modifications govern strength improvement in CTS. Key microstructural parameters—including image porosity (), mean shape factor (), particle grading entropy (), and directional probability entropy ()—effectively capture the micro-mechanisms underlying strength development. These parameters provide a reliable framework for analyzing strength evolution in cement-treated soils;

- 2.

- Sensitivity analysis highlights the dominant microstructural factors influencing strength. Grey Relation Analysis (GRA) reveals the relative importance of these parameters, with the order of influence being . Changing particle grading entropy () is therefore recommended as a practical strategy for achieving higher CTS strength;

- 3.

- This study establishes a quantitative foundation for strength optimization. A polynomial relationship has been established between particle grading entropy and macro-scale strength behavior, providing a quantitative basis for strength optimization. Sensitivity analysis indicates that the optimal value of for enhancing Hangzhou CTS strength is 0.3125 while, for Taizhou CTS, it is 0.5. This study offers valuable insights for material design and optimization in engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CTS | Cement-Treated Soil |

| UCS | Unconfined Compressive Strength |

| SEM | Scanning Electron Microscopy |

| PCAS | Pore/Crack Analysis System |

| GRA | Grey Relation Analysis |

References

- Feng, G.H.; Xu, C.J.; Liang, L.J.; Tey, M.W.; Chi, M.L.; Ge, S.Q. Simplified method for evaluating shield tunnel deformation induced by adjacent excavation. Int. J. Numer. Anal. Methods Geomech. 2023, 47, 54–81. [Google Scholar] [CrossRef]

- Khan, Z.A.; Balunaini, U.; Nguyen, N.H.; Costa, S. Evaluation of cement-treated recycled concrete aggregates for sustainable pavement base/subbase construction. Constr. Build. Mater. 2024, 449, 138417. [Google Scholar] [CrossRef]

- Liu, C.; Berard, C.; Deng, L. Engineering behavior of cement-treated stiff clay subjected to freezing/thawing cycles. Cold Reg. Sci. Technol. 2023, 206, 103743. [Google Scholar] [CrossRef]

- Niu, W.; Guo, B.; Li, K.; Ren, Z.; Zheng, Y.; Liu, J.; Lin, H.; Men, X. Cementitous material based stabilization of soft soils by stabilizer: Feasibility and durabiliy assessment. Constr. Build. Mater. 2024, 425, 136046. [Google Scholar] [CrossRef]

- Chen, W.B.; Zhou, W.H.; Yin, Z.Y. Recent Development on Macro–Micro Mechanism of Soil-Structure Interface Shearing Through DEM. Arch. Comput. Methods Eng. 2023, 30, 1843–1862. [Google Scholar] [CrossRef]

- Cotecchia, F.; Guglielmi, S.; Cafaro, F.; Gens, A. Micro to macro investigation of clays advising their constitutive modelling-part I. Soils Rocks 2024, 47, e2024011723. [Google Scholar] [CrossRef]

- Gaucher, E.C.; Blanc, P. Cement/clay interactions-a review: Experiments, natural analogues, and modeling. Waste Manag. 2006, 26, 776–788. [Google Scholar] [CrossRef]

- Lorenzo, G.A.; Bergado, D.T. Fundamental parameters of cement-admixed clay—New approach. J. Geotech. Geoenviron. Eng. 2004, 130, 1042–1050. [Google Scholar] [CrossRef]

- Ng, C.; Alengaram, U.J.; Wong, L.S. A review on microstructural study and compressive strength of geopolymer mortar, paste and concrete. Constr. Build. Mater. 2018, 186, 550–576. [Google Scholar] [CrossRef]

- Bi, J.; Chian, S.C. Modelling of three-phase strength development of ordinary Portland cement-and Portland blast-furnace cement-stabilised clay. Geotechnique 2020, 70, 80–89. [Google Scholar] [CrossRef]

- Uddin, K.; Balasubramaniam, A.; Bergado, D. Engineering behavior of cement-treated Bangkok soft clay. Geotech. Eng. 1997, 28, 89–119. [Google Scholar]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T. Assessment of strength development in cement-admixed high water content clays with Abrams’ law as a basis. Geotechnique 2003, 53, 439–444. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T.S. Clay-water/cement ratio identity for cement admixed soft clays. J. Geotech. Geoenvironmental Eng. 2005, 131, 187–192. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Suddeepong, A.; Chinkulkijniwat, A. Strength development in cement admixed Bangkok clay: Laboratory and field investigations. Soils Found. 2011, 51, 239–251. [Google Scholar] [CrossRef]

- He, S.H.; Yin, Z.Y.; Ding, Z.; Li, R.D. Particle morphology and principal stress direction dependent strength anisotropy through torsional shear testing. Can. Geotech. J. 2024. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Li, R.; Yin, Z.-Y.; He, S.H. 3D reconstruction of arbitrary granular media utilizing vision foundation model. Appl. Soft Comput. 2025, 169, 112599. [Google Scholar] [CrossRef]

- Guo, Q.; Wei, M.L.; Wu, H.L.; Gu, Y. Strength and micro-mechanism of MK-blended alkaline cement treated high plasticity clay. Constr. Build. Mater. 2020, 236, 117567. [Google Scholar] [CrossRef]

- Lei, H.Y.; Wang, L.; Jia, R.; Jiang, M.; Zhang, W.; Li, C. Effects of chemical conditions on the engineering properties and microscopic characteristics of Tianjin dredged fill. Eng. Geol. 2020, 269, 105548. [Google Scholar] [CrossRef]

- Zhu, K.L. Study on Solidification of Mucky Soil and Road Performance. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2021. [Google Scholar]

- Deng, Y.W. Soft Clay Micro-Quantitative Research and Its Application. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2015. [Google Scholar]

- Xu, L.Y.; Xu, R.Q.; Shashank, B.S.; Chen, X.H.; Yu, J.L.; Wu, C.Z. An Improved Quantification Method for Characterization of Clay Microstructure Using SEM. Environ. Geotech. 2022, 11, 319–338. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wang, Y.; Liu, Y.; Ding, Y. Rheological properties, compressive strength, hydration products and microstructure of seawater-mixed cement pastes. Cem. Concr. Compos. 2020, 114, 103770. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Wang, J.; Huang, R.; Lou, G.; Luo, S. Effects of coarse aggregate size on thickness and micro-properties of ITZ and the mechanical properties of concrete. Cem. Concr. Compos. 2024, 154, 105777. [Google Scholar] [CrossRef]

- Mota, B.; Matschei, T.; Scrivener, K. Impact of NaOH and Na2SO4 on the kinetics and microstructural development of white cement hydration. Cem. Concr. Res. 2018, 108, 172–185. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Li, K.; Li, M.; Lin, S.; Hao, T.; Wang, T.; Guo, Y.; Ling, Z. Investigations on the rehydration of recycled blended SCMs cement. Cem. Concr. Res. 2023, 163, 107036. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Huang, R.; Li, B.; Ran, B.; Hu, X. Investigations on micro-mechanical properties of the ITZs between recycled aggregates and recycled cement paste. Constr. Build. Mater. 2024, 450, 138640. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, G.R.; Wang, P.M.; Liu, X.P.; Zhang, G.F. Study on the retardation of re-dispersible polymer powders on cement hydration based on morphologies of Ca(OH)2. J. Chin. Electron Microsc. Soc. 2016, 35, 490–495. [Google Scholar]

- He, J.H. Evolution Characteristics and Mechanism of Microstructure and Properties of High Early Strength Cement Paste. Ph.D. Thesis, Central South University, Changsha, China, 2022. [Google Scholar]

- Tan, X.R.; Deng, J.L. Grey relational analysis: A new method of multi-factor statistical analysis. Stat. Res. 1995, 11, 46–48. [Google Scholar]

- Kuo, Y.; Yang, T.; Huang, G.W. The use of grey relational analysis in solving multipleattribute decision-making problem. Comput. Ind. Eng. 2008, 55, 80–93. [Google Scholar] [CrossRef]

| (%) | (kN·m−3) | |||

|---|---|---|---|---|

| 30.0 | 20.1 | 2.505 | 38.0 | 21.4 |

| (%) | (kN·m−3) | |||

|---|---|---|---|---|

| 59.8 | 17.3 | 2.817 | 51.9 | 24.5 |

| No. | Original Clay | Water Content (%) | Cement Content (%) | Curing Age (Days) |

|---|---|---|---|---|

| 1 | Hangzhou clay | 38 | 15 | 28 |

| 2 | Hangzhou clay | 38 | 15 | 7 |

| 3 | Hangzhou clay | 38 | 15 | 3 |

| 4 | Hangzhou clay | 38 | 16 | 3 |

| 5 | Taizhou clay | 40 | 15 | 28 |

| 6 | Taizhou clay | 40 | 15 | 14 |

| 7 | Taizhou clay | 40 | 15 | 7 |

| 8 | Taizhou clay | 40 | 15 | 3 |

| 9 | Taizhou clay | 40 | 16 | 3 |

| No. | Micro-Parameter | Definition | Calculation Equation | Meaning of Parameters |

|---|---|---|---|---|

| 1 | Directional probability entropy, | Orderliness of particles’ arrangement | is the direction of the solid, belongs to [0–180°]; is the total number of equally divided areas in the whole solid direction range [0–180°]. In this paper, it is set as ; is the percentage of solids whose directions belong to a specific range, such as [0°, 10°). | |

| 2 | Image porosity, | Ratio of pore area to total image area | Pore area in the image; Total image area in the image. | |

| 3 | Mean shape factor, | Shape of particles | is the total number of particles; is the shape factor of the No. i th solid; is the perimeter of a circle that has the same area as the particle; is the actual perimeter of the same particle. | |

| 4 | Particle grading entropy, | Distribution of particles’ size | is the normalized diameter of the solid, its value belongs to (0,1]; is the diameter of each solid, while is the biggest diameter of all; is the total number of equally divided areas in the whole solid diameter range. In this paper, it is set ; is the percentage of solids whose normalized diameter belongs to a specific range, such as [0, 0.1). |

| No. | Cement Slurry Content (%) | Curing Age (Days) | Porosity Before Test, n | UCS (kPa) | Micro-Parameter Value | |||

|---|---|---|---|---|---|---|---|---|

| 1 | 15 | 28 | 0.4884 | 54.08 | 0.3580 | 0.3862 | 0.9891 | 0.4220 |

| 2 | 15 | 7 | 0.4938 | 32.55 | 0.2914 | 0.3925 | 0.9912 | 0.4546 |

| 3 | 15 | 3 | 0.4928 | 12.42 | 0.3357 | 0.2584 | 0.9919 | 0.4121 |

| 4 | 16 | 3 | 0.4957 | 12.9 | 0.4125 | 0.2007 | 0.9890 | 0.4031 |

| No. | Cement Slurry Content (%) | Curing Age (Days) | Porosity Before Test, n | UCS (kPa) | Micro-Parameter Value | |||

|---|---|---|---|---|---|---|---|---|

| 1 | 15 | 28 | 0.5575 | 158.26 | 0.4008 | 0.3384 | 0.9938 | 0.4298 |

| 2 | 15 | 14 | 0.5673 | 24.75 | 0.3994 | 0.3792 | 0.9897 | 0.4100 |

| 3 | 15 | 7 | 0.5288 | 11.33 | 0.3257 | 0.2397 | 0.9913 | 0.4430 |

| 4 | 15 | 3 | 0.5529 | 10.21 | 0.3299 | 0.3056 | 0.9884 | 0.4242 |

| 5 | 16 | 3 | 0.5913 | 11 | 0.4272 | 0.2051 | 0.9812 | 0.4120 |

| Reference Sequence | Grey Relational Grade of Comparability Sequences | |||

|---|---|---|---|---|

| all samples | 0.4676 | 0.4413 | 0.4384 | 0.4750 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Xu, R.; Lin, Q.; Feng, G.; Yuan, C.; Ding, Z. Micro-Mechanism of Strength for Cement-Treated Soil Based on the SEM Experiment: Qualitative and Quantitative Analysis. Buildings 2025, 15, 2370. https://doi.org/10.3390/buildings15132370

Xu L, Xu R, Lin Q, Feng G, Yuan C, Ding Z. Micro-Mechanism of Strength for Cement-Treated Soil Based on the SEM Experiment: Qualitative and Quantitative Analysis. Buildings. 2025; 15(13):2370. https://doi.org/10.3390/buildings15132370

Chicago/Turabian StyleXu, Liyang, Riqing Xu, Qingfeng Lin, Guohui Feng, Chang Yuan, and Zhi Ding. 2025. "Micro-Mechanism of Strength for Cement-Treated Soil Based on the SEM Experiment: Qualitative and Quantitative Analysis" Buildings 15, no. 13: 2370. https://doi.org/10.3390/buildings15132370

APA StyleXu, L., Xu, R., Lin, Q., Feng, G., Yuan, C., & Ding, Z. (2025). Micro-Mechanism of Strength for Cement-Treated Soil Based on the SEM Experiment: Qualitative and Quantitative Analysis. Buildings, 15(13), 2370. https://doi.org/10.3390/buildings15132370