Abstract

To meet the material requirements for repairing cracked components serving in cold temperatures, the differences in the setting hardening characteristics and physical and mechanical properties of fly ash-modified magnesium phosphate cement (MPC) repair mortar cured at 0 °C and 20 °C were comparatively studied in this paper. The results show that under the same fly ash content, the compressive strength of MPC repair mortar cured at 0 °C is lower than that cured at 20 °C, and the setting time, fluidity, flexural strength, interfacial bonding strength, strength retention rate, and linear shrinkage rate are not significantly deteriorated. The above properties of MPC repair mortar vary with the increase in the fly ash content but still, remain appropriate when the fly ash content is not higher than 15 wt%. The microstructure of MPC is obviously refined when the content of fly ash is 10 wt%. Therefore, the MPC repair mortar cured at 0 °C and 20 °C has good physical and mechanical properties. In particular, the flexural strength and interfacial bonding strength of the specimens cured at 0 °C are higher than that cured at 20 °C at all curing ages, and at the curing age of 3 days, those are 7.9 MPa and 5.4 MPa, respectively.

1. Introduction

Magnesium phosphate cement (MPC) is a new cementitious material prepared by dead burned magnesium oxide (MgO), acid phosphates, chemical additives, and mineral admixtures, and it hardens through an acid-base reaction at room temperature [1]. MPC is quite different from ordinary Portland Cement (OPC) in terms of raw material characteristics, hydration process, and hydrate composition [2,3]. MPC has high early strength, quick hardening properties, good volume stability, excellent property in ultra-low temperature environments, small drying shrinkage, high bonding strength, and good abrasion resistance [4,5], and is a rapid repair adhesive material widely used in old structures and damaged pavements.

The physical and mechanical properties, hydration product types, and micromorphology of MPC are affected by mixed ratio parameters, such as phosphate type, magnesium phosphorus ratio [6], water binder ratio [7], borax content [8], and mineral content [9]. In addition, the influence of curing temperature is also very significant. Seehra et al. [10] and Yang et al. [11] concluded that increasing the environment temperature or hydration temperature accelerated MPC setting time. Wang et al. [12] found that the increase in environmental temperature promoted early strength, and the higher temperature, the faster the early strength development. According to You et al. [13], magnesium ammonium phosphate cement (MPC) dehydrated struvite (Mg(NH4)PO4·6H2O) to dittmarite (Mg(NH4)PO4·H2O) above 70 °C, resulting in a significant strength loss.

MPC has excellent mechanical properties and workability at room temperature and can hydrate and harden under higher or lower temperature conditions, which indicates that it has good adaptability to various temperatures. Yang [14] and Yue [15] showed that when the temperature was below 0 °C, the setting time of MPC was prolonged. Popovics et al. [16] demonstrated that the final setting time of MPC mortar with a water binder ratio of 0.11 cured at 0 °C was 12 min and the compressive strength at 3 h reached 19.3 MPa, which indicated that MPC could set and harden normally at 0 °C. Li et al. [15] observed that MPC prepared at room temperature could be set rapidly even curing at −20 °C. According to the research results of Wang [17], MPC mortar was prepared at room temperature and then cured in a low-temperature curing box at −20 °C. The compressive strengths of MPC mortar at 2 h and 1 day were 10.0 MPa and 19.0 MPa, respectively, which indicated that it still has high early strength at negative temperature.

At present, MPC has not been widely promoted and applied owing to its high hydration temperature, concentrated heat release, poor water resistance, and high cost. To overcome the above problems, the MPC is modified by mineral admixtures, such as fly ash [18], blast furnace slag [19], metakaolin [20], silica fume [21], etc. Nonetheless, the influence of mineral admixture on the properties of MPC depends on its type, chemical composition, and physical properties, as well as additional dosage. The hydration kinetics of magnesium potassium phosphate cement, partly replaced by wollastonite, is slowed down hydration kinetics, and its heat release is lowered [22]. Metakaolin is conducive to prolonging the setting time of MPC [20]. Red mud played a positive role in the water resistance of MPC due to its strong alkalinity and high iron oxidation content [23]. Based on volcanic ash and the micro-aggregate effect, fly ash can effectively reduce harmful pores, reduce expansion rate, reduce cracking, make the structure more compact and enhance strength in a low-temperature environment [24,25].

The aforementioned research demonstrates that mineral admixtures not only improve the fluidity, later strength, water stability, and volume stability of MPC but also reduce the cost [26]. At the same time, the cracked components serve in the natural environment, and their structural repair requires that the repair materials can set and harden at various ambient temperatures, especially at low temperatures, and has good mechanical properties and interfacial bonding properties. MPC and its repair mortar show obvious advantages, which are worthy of in-depth and systematic research. Based on previous research [27], MPC repair mortar modified by fly ash was cured at 0 °C and 20 °C in this paper. The influence of fly ash content and curing temperature on the setting time, fluidity, mechanical properties, water resistance, interfacial bonding strength, and linear shrinkage rate of MPC repair mortar were discussed.

2. Materials and Methods

2.1. Materials

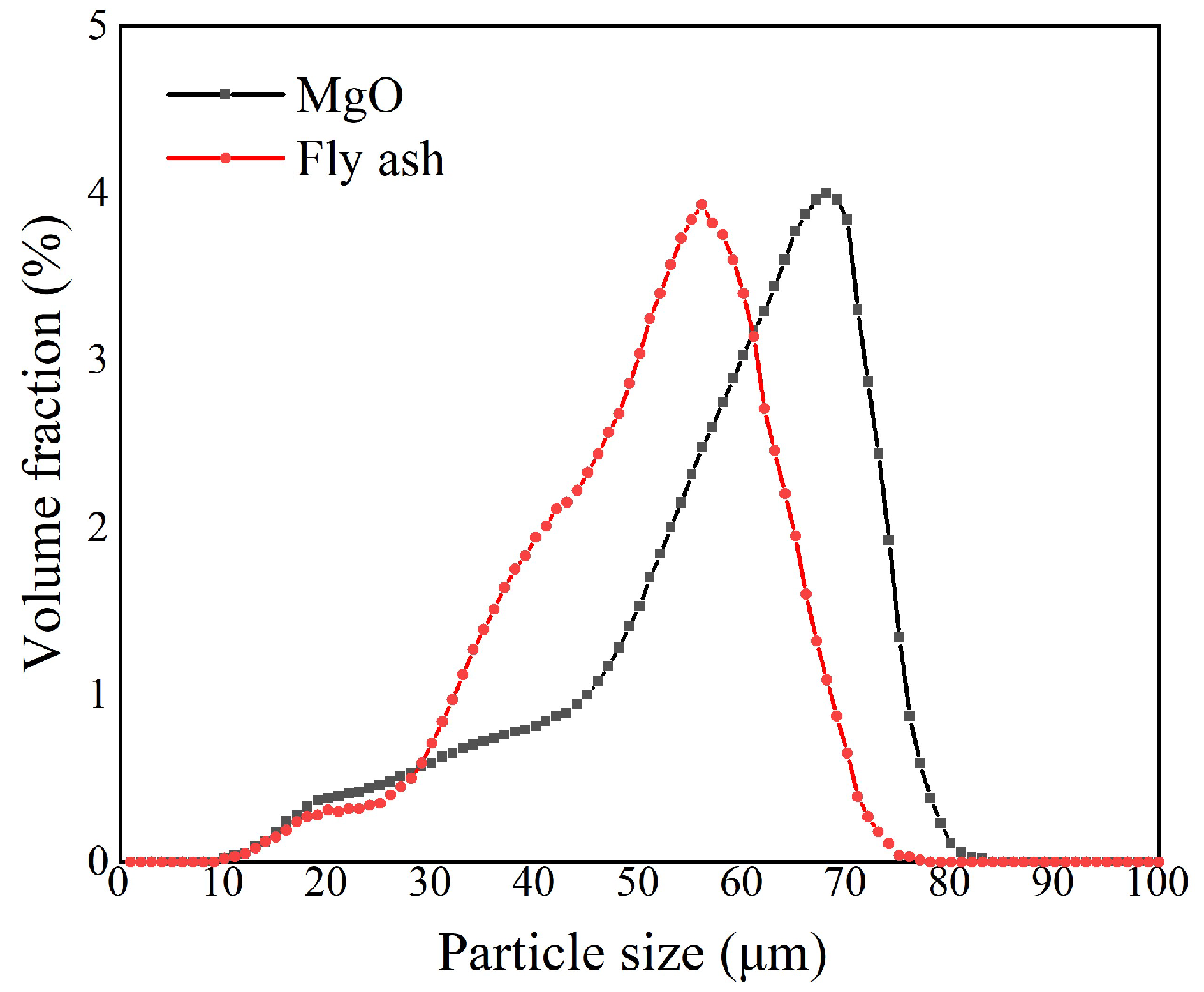

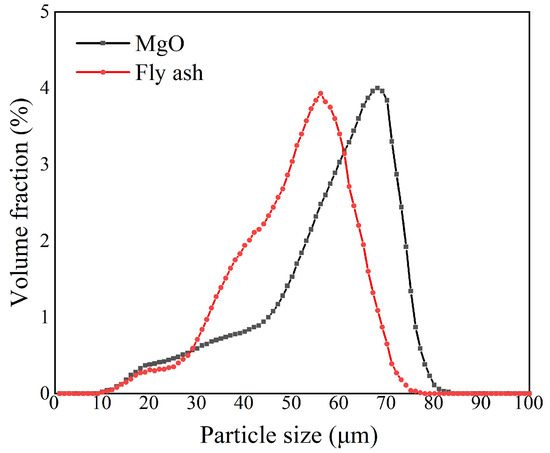

Dead-burnt MgO was produced by calcining magnesite under a temperature of 1780 °C. The specific surface area and average particle size were 764.0 m2/kg and 28.0 μm, respectively measured by a laser particle size analyzer. The chemical composition is shown in Table 1, and particle distribution is presented in Figure 1. The specific surface area of secondary fly ash used in the research was 393.5 m2/kg, and the particle distribution was also presented in Figure 1. The chemical composition analyzed by X-ray fluorescence spectrometer is listed in Table 1. NH4H2PO4 was industrial grade; its purity exceeded 90%. The retarder adopted analytical pure Na2B4O7·5H2O and industrial sugar. The standard quartz sand with 99.5% SiO2 and a size of 0.45–0.71 mm.

Table 1.

Chemical composition of dead-burnt magnesia oxide and fly ash (%).

Figure 1.

Particle size distribution of calcined magnesia and fly ash.

2.2. Mixture Proportion

Table 2 shows the mixed proportions of the investigated MPC repair mortars. The cementitious materials included magnesia oxide, fly ash, and NH4H2PO4 (abbreviated as B). All the mixes had the same W/B ratio of 0.2 and the same M/P of 2, a sand-to-cementitious materials ratio (S/B) of 1, 12 wt% borax, by weight of dead-burnt MgO, 3 wt% industrial sugar, by weight of cementitious materials (abbreviated as T/B). The fly ash replacements were 0 wt%, 5 wt%, 10 wt%, 15 wt%, 20 wt%, 25 wt% and 30 wt%, respectively, by weight of dead-burnt MgO and NH4H2PO4. According to the fly ash replacement level, the mixtures are referred to as FA0, FA5, FA10, FA15, FA20, FA25, and FA30, respectively.

Table 2.

Mixure of MPC mortars.

2.3. Specimens Preparation

According to Table 2, raw materials were weighed. The raw materials were precooled in a low-temperature curing box at 0 °C for 24 h so that the temperature of the raw materials was as close as possible to the test temperature in the severely cold environment. When preparing, the raw materials of MPC repair mortars were first mixed and stirred slowly for 1 min, and the mixing water was added and mixed at a slow speed for 0.5 min, afterward, mixed for 2 min at high speed. Finally, MPC repair mortar paste was obtained and quickly poured into the triple mold of 40 mm × 40 mm × 160 mm for vibration molding. Then, the specimens were placed in a curing box at 0 °C and 20 °C, respectively. The relative humidity was RH 0% and RH 55%, respectively, until the test age was reached.

2.4. Experimental Methods

2.4.1. Physical and Mechanical Properties

Experiments on the setting time of the MPC repair mortar were conducted according to JGJ/T 70-2009 [28]. The fluidity of the MPC repair mortar was tested according to GB/T 2419-2005. The compressive strength, flexural strength, and interfacial bonding strength were tested according to GB/T 17671-2021 [29].

2.4.2. Interfacial Bonding Strength

The interfacial bonding strength of MPC repair mortar with old Portland cement was indirectly measured with flexural strength. The Portland cement mortar specimens (40 mm × 40 mm × 160 mm) were made according to GB/T 17671-2021 [29] and split into two nearly uniform sections after being cured for 28 days under standard curing conditions. Half of the Portland cement mortar block was put into the mold and placed the fracture cross-section in the middle of each mold. And then, the MPC repair mortar mixture was poured into the remaining space and vibrated to mold. At last, the specimens were put into respective curing boxes after demolding and cured until the test age. According to the above standards, the interface flexural strength specimens are air cured for 1.5 h and 7 days, and the immersed water specimens are cured for 7 days of air curing and then 7 days of water curing.

2.4.3. Strength Retention Coefficient

The strength retention coefficient was widely used for evaluating the water resistance of MPC. In this study, the strength retention coefficient was estimated according to GB/T 50082-2009 [30]. Place the shaped specimens in the corresponding curing box for curing. The curing temperature is 20 °C and 0 °C, respectively, and the curing humidity is 50% and 0%, simulate air curing and water curing test pieces are put into water after air curing for 3 days. The room temperature curing shall be carried out in 20 °C water, and the zero cured specimens shall be carried out in the 0 °C water curing box, and the calculation formula is as follows:

where, wn is for the strength retention coefficient at a given age, fcn represents the average compressive strength of wet specimens after immersion in water for 28 days (MPa), fc represents the average compressive strength of dry specimens cured under the same days in air condition (MPa).

2.4.4. The Linear Shrinkage Rate

The linear shrinkage of MPC repair mortar was tested by a comparator according to JC/T 603-2004 [31]. The sample size was 25 mm × 25 mm × 280 mm. The specimens were demolded after 1 h of casting and immersed in 20 °C and 0 °C water, respectively. After curing for 3 days, the L0 of the specimens was measured by a dial gauge. Then, the specimens were cured for 28 days under the conditions of 20 °C, 50% relative humidity, and 0 °C, 0% relative humidity, respectively, and then the final length, L28, was measured. The calculation formula is as follows:

where, S28 represents the drying shrinkage of MPC mortar cured for 28 days (%), its accuracy is 0.001%; L0 is for the initial length (mm); L28 is for the final length (mm); and 250 is the effective length of the specimens (mm).

2.4.5. Micro-Morphology of Hydration Products and Chemical Composition of Raw Materials

After testing the strength of MPC specimens at different ages, the broken pieces were collected and soaked in anhydrous ethanol for at least 7 days to stop hydration, and the specimens were dried in a vacuum drying oven at 60 °C to constant weight before the microscopic test.

Before the SEM test, gold spraying was performed. The samples were subjected to a Quanta 250 FEG FE-SEM from an FEI company in the United States under the conditions of 3 kV accelerating voltage and 3 spot sizes. The micro-morphology of fly ash particles, the changes in the interfacial transition zone between fly ash and paste, and the morphological characteristics of hydration products of MPC at each age were observed.

The XRF test adopted the Epsilon3 desktop energy star dispersive X-ray British spectrometer (Malvern Panalytical, Almelo, Holland). The voltage of the light tube test was 20 kV, the current was 100A, and the detection was SDDultra brick drift detector so as to obtain the chemical composition of MgO and fly ash.

3. Results

3.1. Setting Time

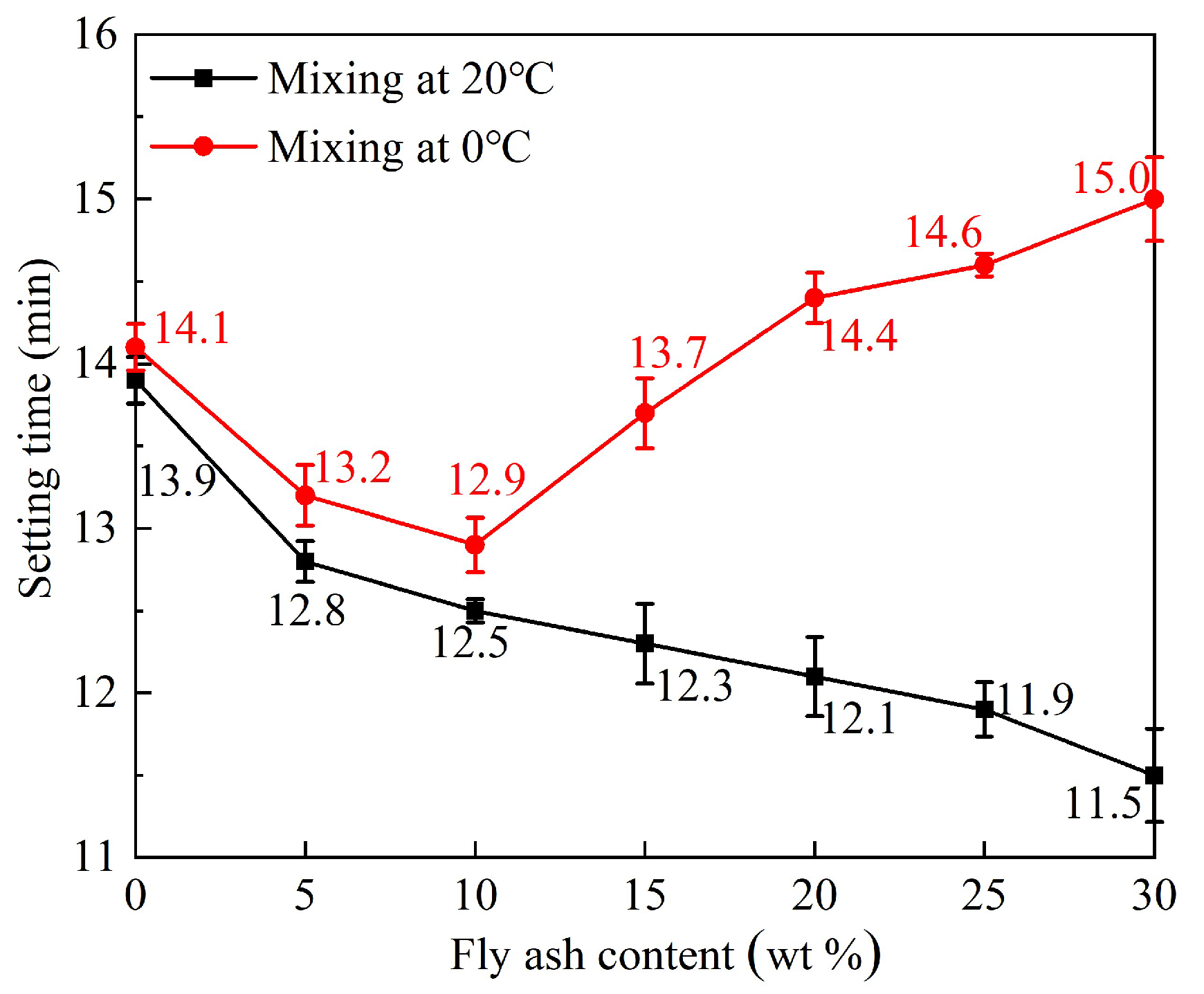

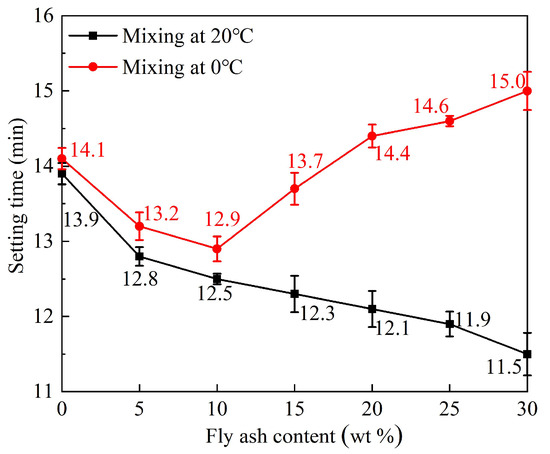

The setting time effects of fly ash-modified MPC repair mortar cured at 20 °C, and 0 °C are shown in Figure 2. When fly ash-modified MPC repair mortar is mixed at 20 °C, the setting time gradually decreases with the increase in fly ash content. The initial setting time decreases from 13.9 min to 11.5 min when the content of fly ash is 30 wt%. This is because fly ash partially replaces NH4H2PO4 and MgO, which reduces the concentration of MgO and the retarder of the mixture, delays MgO dissolution and acid-base interaction, and, finally, shortens the setting time.

Figure 2.

The variation of setting time with mixing temperature and fly ash content.

It can be seen from Figure 2 that the setting time of MPC repair mortar with the same fly ash content at 0 °C is longer than that at 20 °C. MPC setting, and hardening are based on the solution-diffusion mechanism, and the ambient temperature has a significant impact on the rate of NH4H2PO4, MgO, and borax, so it will also change the setting time of MPC repair mortar [32]. The solubility and dissolution rate of NH4H2PO4 and MgO in an aqueous solution decrease as ambient temperature decreases [25]; as a result, the hydration rate of MPC repair mortar and the formation of struvite decrease at low temperature. Therefore, the setting time is prolonged.

Figure 2 also shows that the initial setting time of MPC repair mortar mixed at 0 °C slightly decreases from 14.1 min to 10.9 min when the fly ash content gradually increases from 0 wt% to 10 wt%, and the setting time extends from 10.9 min to 15.0 min when the fly ash content continues to increase to 30 wt%. The setting time of MPC repair mortar at 0 °C is mainly affected by the solubility of borax and the continuity of struvite. First of all, the solubility of borax at 0 °C is 2.77 g/100 g, which is significantly lower than 4.87 g/100 g at 20 °C, its retarding effect is weakened, and the setting time of MPC repair mortar is shortened. Secondly, the increase in fly ash content is bound to reduce the formation and continuity of struvite and prolong the setting time of MPC repair mortar. Under the combined effect of the above two factors, when the fly ash content is lower, the setting time of MPC repair mortar is dominated by the solubility of borax, and when the fly ash content is higher, it is controlled by the continuity of struvite. In addition, when the proportion of fly ash exceeds 10 wt%, the aluminosilicate glass phases in fly ash can hardly participate in the violent acid-base reaction of MPC repair mortar [33]; that is to say, the setting time of MPC is not affected by the hydration of fly ash.

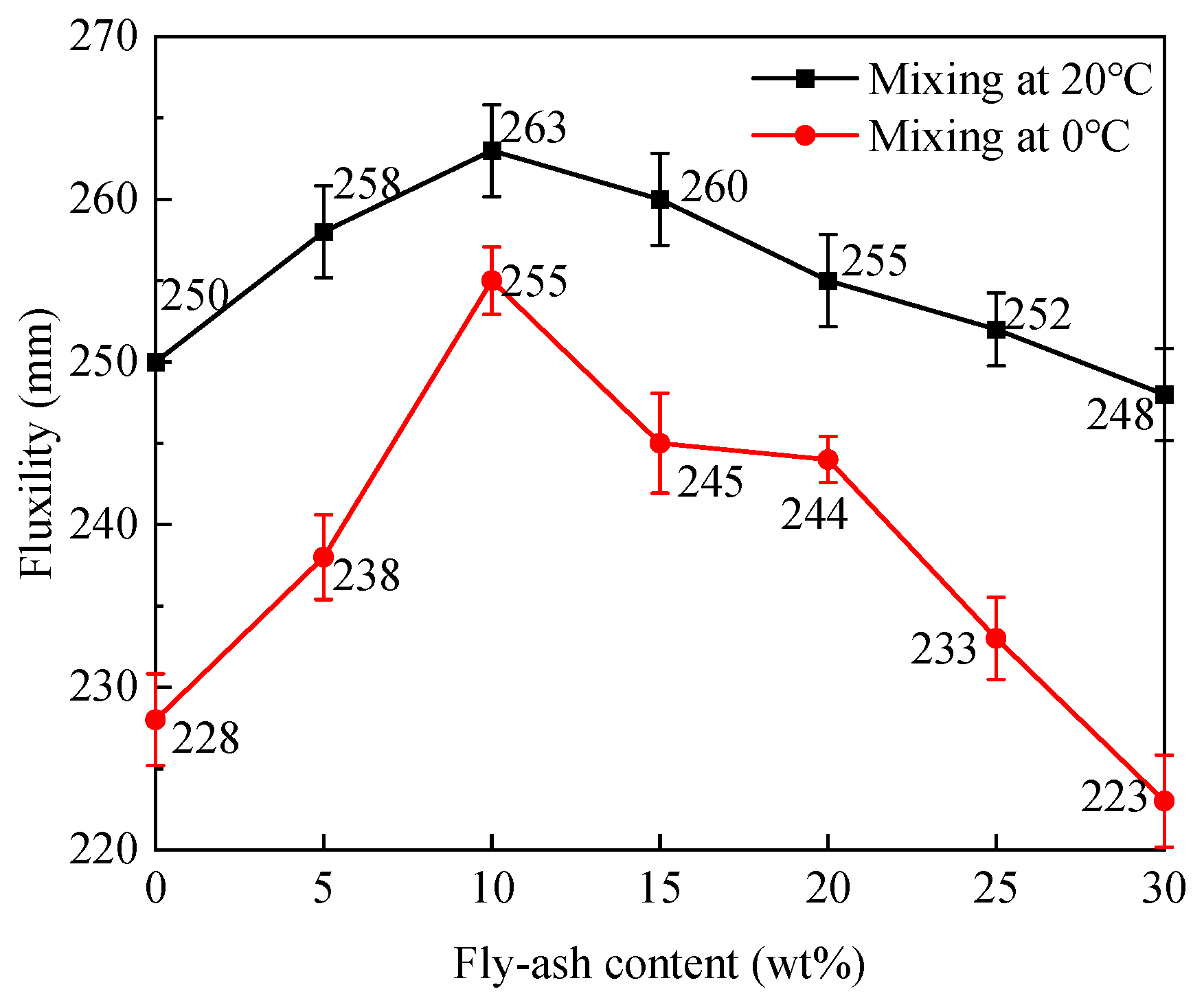

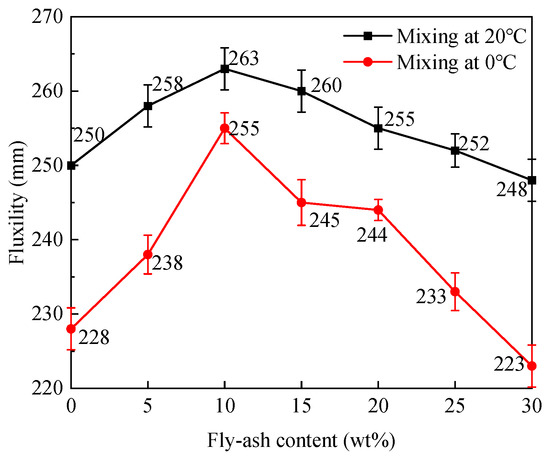

3.2. Fluidity

The influences of mixing temperature and fly ash content on the mixture fluidity of MPC repair mortar are shown in Figure 3. As can be seen from Figure 3 the fluidity of MPC repair mortar mixture both increases first and then decreases with the increasing of fly ash content at 20 °C and 0 °C, and it mixed at 0 °C is lower than that mixed at 20 °C, both of which reach the maximum when the content of fly ash is 10 wt%. This is because the spherical fly ash particles have a good “ball-bearing” effect in MPC mortar when the content of fly ash is lower. Figure 1 shows that fly ash is finer than MgO, and so, when the proportion of fly ash exceeds 10 wt%, the increase in the total surface area of raw materials will lead to an increase in water demand, a decrease in the free water volume in the mixture and in the fluidity. When the mixing temperature of MPC repair mortar is reduced from 20 °C to 0 °C, the decrease in solubility of soluble raw materials leads to the further increase in the surface area of solid particles to be wetted by water, and a slight reduction in the fluidity of the mixture.

Figure 3.

The variation of fluidity with mixing temperature and fly ash content.

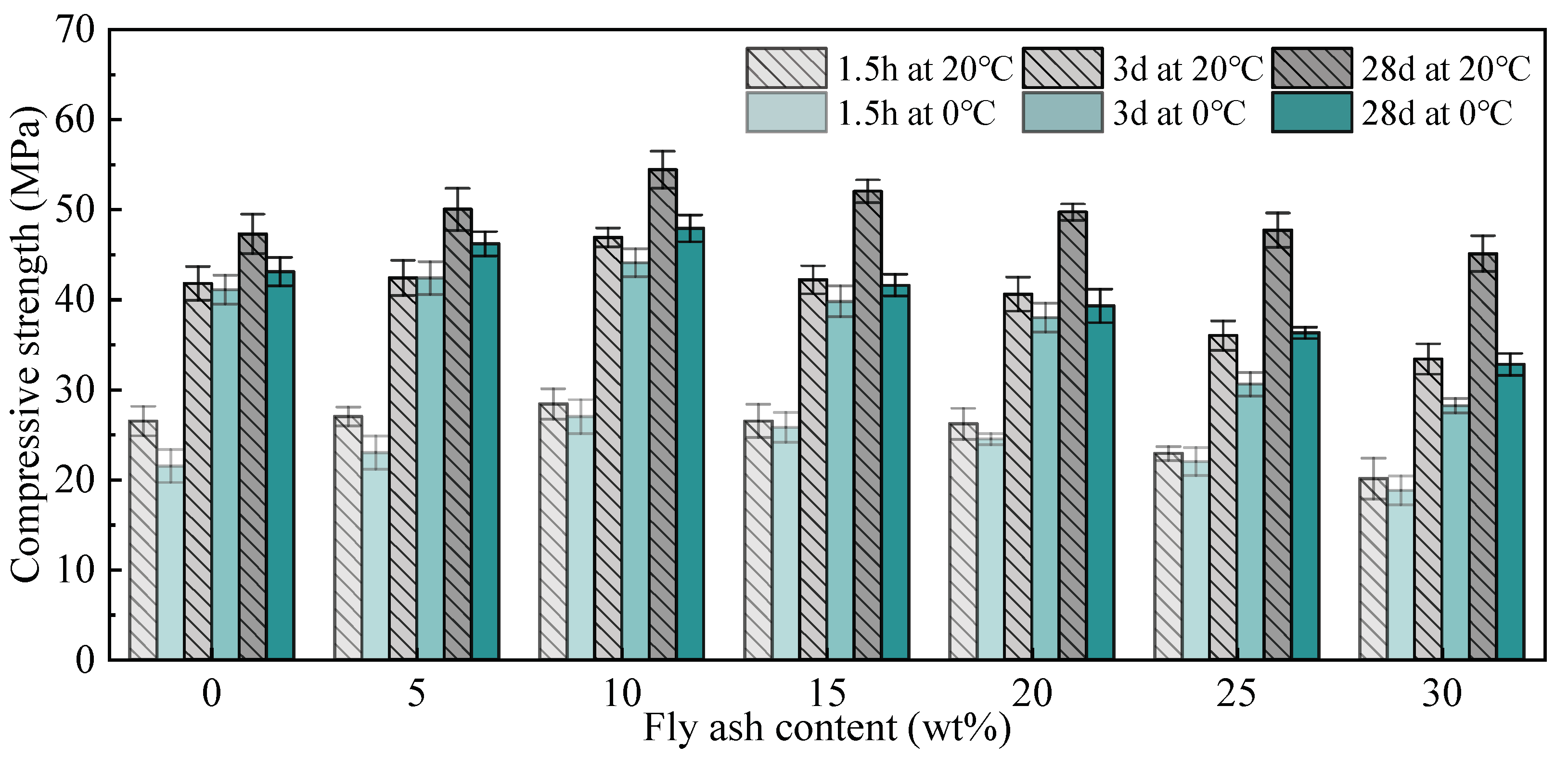

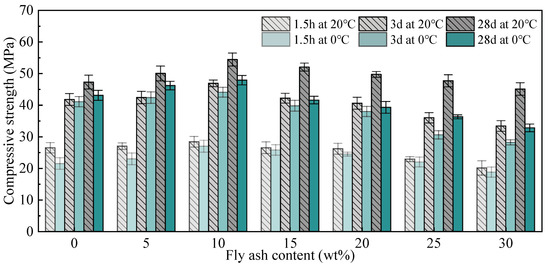

3.3. Mechanical Properties

Figure 4 shows the influences of the temperature and fly ash content on the compressive strength of MPC mortar paste. As shown in Figure 4 that, the compressive strength of MPC mortar cured for 1.5 h, 3 days, and 28 days all increases first and then decreases with the increasing of fly ash content at 20 °C and 0 °C, and the specimens mixed at 0 °C is lower than the mixed at 20 °C, all of which reach the maximum when the content of fly ash is 10 wt%, and reduce to the minimum when the content of fly ash is 30 wt%. The compressive strength of FA10 cured for 1.5 h, 3 days, and 28 days at 20 °C reach 28.4 MPa, 46.9 MPa, and 54.4 Mpa, respectively, while that at 0 °C is 27.0 MPa, 44.1 MPa, and 47.9 MPa. In a word, compared with ordinary cement-based repair mortar, MPC repair mortar still has good mechanical properties when cured at 0 °C.

Figure 4.

The variation of compressive strength with mixing temperature and fly ash content.

It can be seen from Figure 1 that the particle size of fly ash is smaller than MgO. When the content of fly ash is lower, the spherical particles are evenly dispersed in MPC repair mortar and act as crystal nuclei, continuously promoting the formation of hydrous magnesium ammonium phosphate and its transformation to the final form of struvite [34]. However, when the fly ash content continues to increase, a large number of fly ash particles reduce the continuity of struvite crystals, and the adhesion of the hardened MPC repair mortar sample gradually decreases [35]. When MPC is curing at 0 °C, the solubility of NH4H2PO4 and the acidity of the fresh mortar mixture decrease correspondingly, resulting in a significant decrease in the dissolution rate of MgO and the reduction in the formation of struvite, the main cementing component of the hardened MPC repair mortar [25], and a slight decrease in its compressive strength.

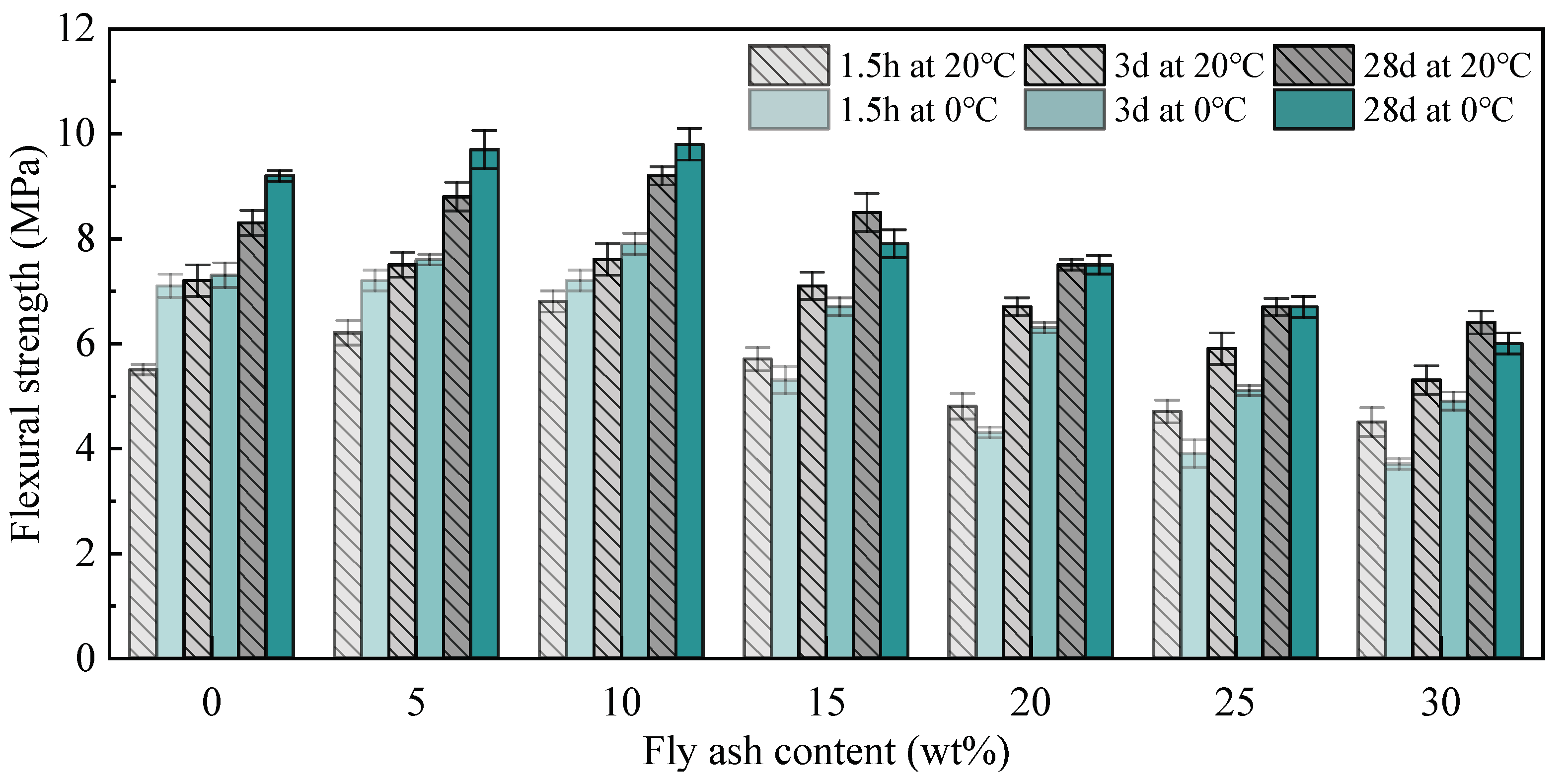

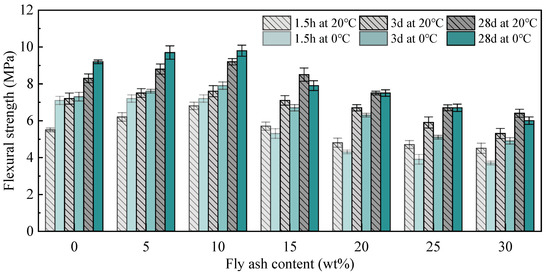

Figure 5 shows that the flexural strength of MPC repair mortar gradually increases with curing age at 20 °C and 0 °C, and its variation law is consistent with the compressive strength with fly ash content, and both reach the maximum when the fly ash content is 10 wt%. The flexural strength of MPC repair mortar cured for 28 days at 20 °C and 0 °C is 9.2 MPa and 9.8 Mpa, respectively. The particular difference is that when the content of fly ash is not higher than 10 wt%, the flexural strength of MPC repair mortar cured at 0 °C at each curing age is slightly higher than that of specimens cured at 20 °C. This is because the compactness of hydration products is improved the fly ash when its content is lower, and struvite still keeps good continuity.

Figure 5.

The variation of flexural strength with mixing temperature and fly ash content.

On the one hand, when the temperature is close to 0 °C, the viscosity of water increases from 1.00 mPa·s at 20 °C to 1.79 mPa·s, which leads to the decrease in migration rate of capillary water in the hardened structure under bending load and the increase in flexural strength of MPC cured at 0 °C. On the other hand, the smaller the capillary pores are, the more difficult the water migration is, and so, the flexural strength of MPC increases slightly when the fly ash content is less than 10 wt%. Moreover, under the zero-temperature curing condition, there is some ice in the internal structure of the sample, and they are connected with each other, thus improving the flexural strength of the materials [36].

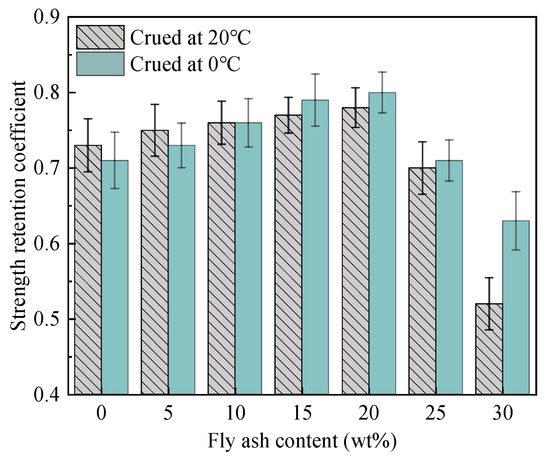

3.4. Water Resistance

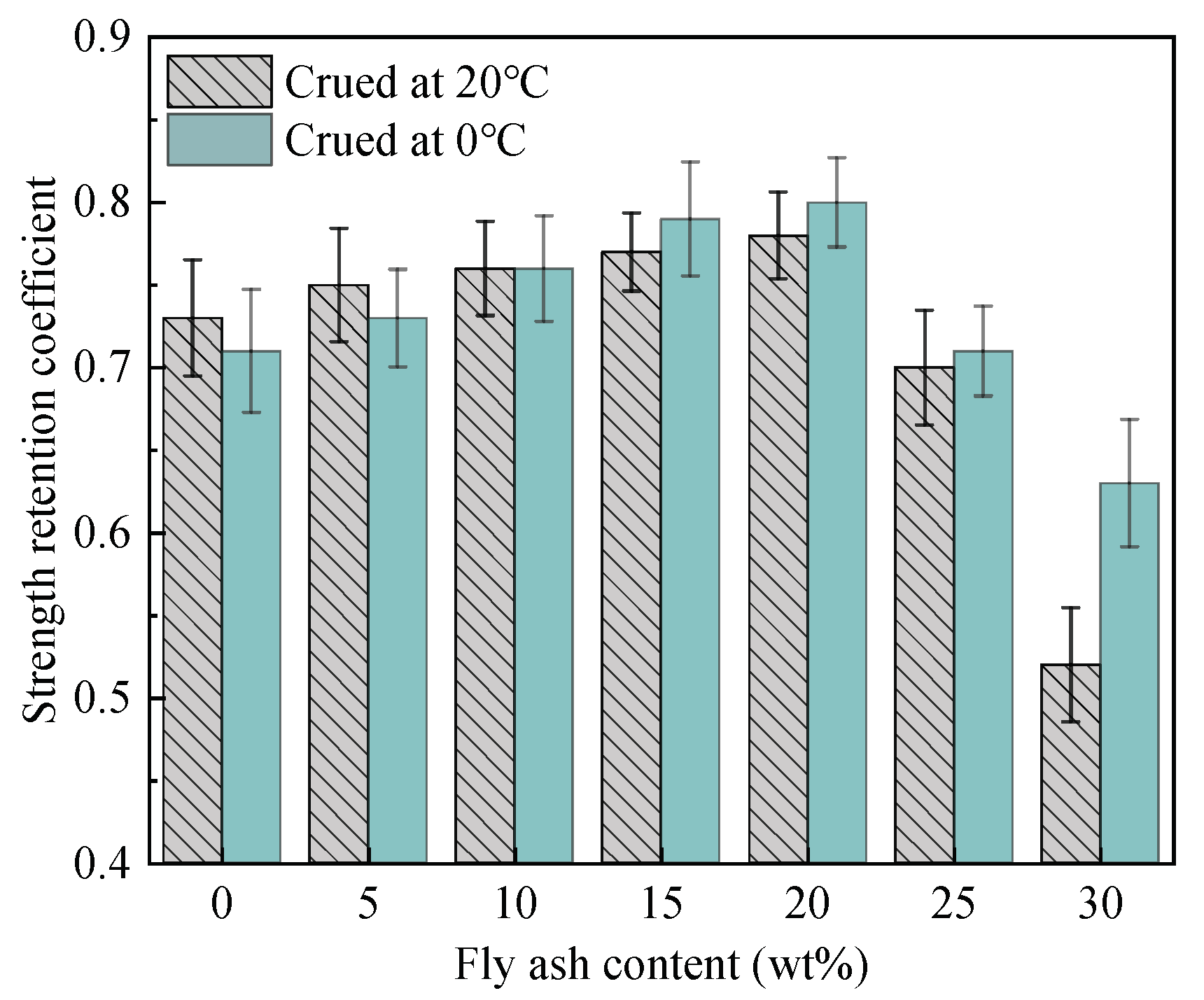

The influences of the temperature and fly ash content on the water resistance of MPC mortar paste are shown in Figure 6. When the fly ash content increases from 0 wt% to 20 wt%, the strength retention coefficient of the MPC repair mortar gradually increases. When the content is higher than 20 wt%, the strength retention coefficient gradually decreases with the increase in fly ash content.

Figure 6.

The variation of water resistance with mixing temperature and fly ash content.

This is due to the morphological effect of fine spherical fly ash particles, which makes its microstructure more compact and reduces the dissolution of soluble ammonium salt in hardened MPC, thus improving the water resistance of MPC repair mortar [33]. However, the content of fly ash continues to increase, and the “equal ball accumulation” effect produced by a large number of fine particles will increase the porosity of MPC and also weaken the continuity between struvite. During long-term immersion, more water will enter the hardened MPC repair mortar through the capillary pores, which will eventually reduce its compressive strength retention coefficient.

It is noteworthy that when the fly ash content is from 10 wt% to 30 wt%, the compressive strength retention coefficient of MPC repair mortar cured at 0 °C is higher than that of 20 °C.

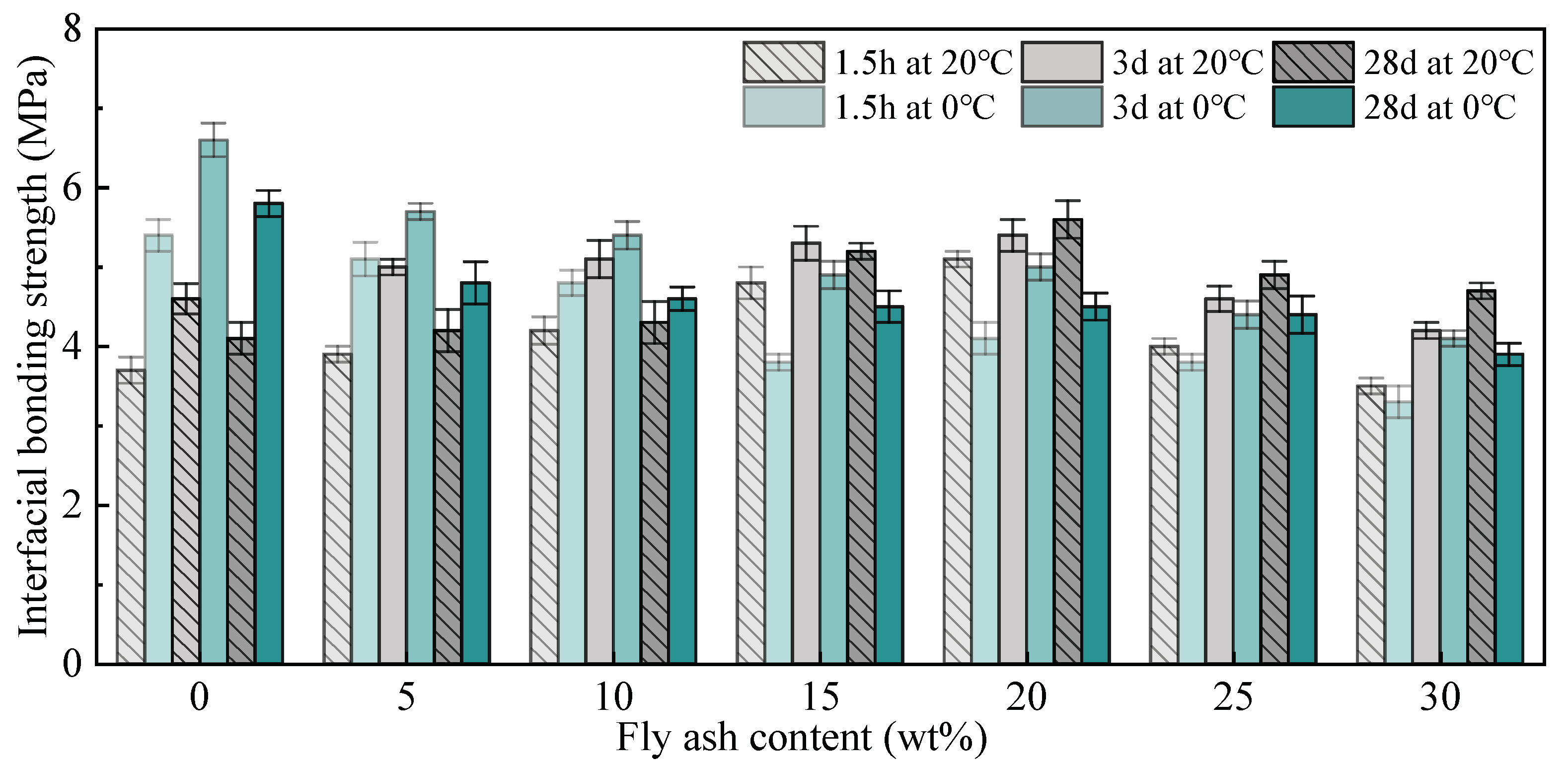

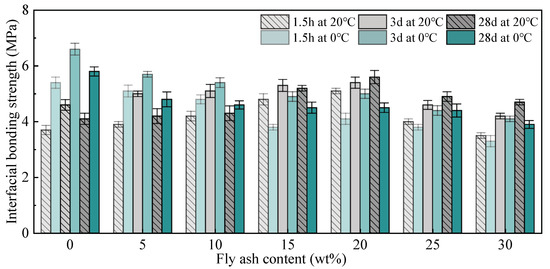

3.5. Interfacial Bonding Strength

It can be seen from Figure 7 that the interfacial bonding strength of MPC repair mortar curing at 20 °C increases with the increasing of fly ash content, reaches the maximum at the content of 20 wt%, and decreases slightly when the content of fly ash continues to increase. The interfacial bonding strength of FA20 is up to 5.1 MPa, 5.4 Mpa, and 5.6 MPa, respectively, which is 37.8%, 17.4%, and 36.6% higher than that of FA0, respectively.

Figure 7.

The variation of interfacial bonding strength with mixing temperature and fly ash content.

The interfacial bonding strength of fly ash-modified MPC repair mortar comes from two sources as follows: One is the cohesiveness of the main hydration products in the MPC repair mortar, and the other is the Ca(OH)2 existed in the pore solution and the finer fly ash beads in the mixture carry out material transport in the interface area between the Portland cement mortar and the MPC repair mortar through the capillary pores, and the active SiO2 and Al2O3 of the fly ash occur the secondary hydration reaction under the action of Ca(OH)2 to form C-S-H gel, which helps to improve the interfacial bonding strength between the interfaces through chemical adhesion [37]. At the early hydration age of MPC repair mortar, when the content of fly ash is lower than 20 wt%, under the combined mechanism of the above two effects, the interfacial bonding strength is slightly improved. When the content of fly ash is more than 20 wt%, the content of cohesive struvite in the hardened structure is reduced, and the interfacial bonding strength is correspondingly decreased.

When the curing temperature is 0 °C, the interfacial bonding strength of MPC repair mortar at all tested ages decreases gradually with the increasing of fly ash content; it fluctuates slightly when the fly ash content is in the range of 15 wt% to 20 wt%. That is because the content of cohesive struvite in the hardened structure is reduced with the increase in fly ash content. At the same time, fly ash cannot be place. Secondary hydration occurred at 0 °C. It indicates that MPC repair mortar without fly ash is the best for rapidly repairing building structures in low-temperature environments. In addition, similar to the flexural strength, the interfacial bonding strength of MPC repair mortar cures at 0 °C at each curing age MPC is evidently higher than that of specimens cured at 20 °C when the content of fly ash is not higher than 10 wt%, which illustrates that MPC repair mortar has good flexural resistance and bonding performance at low temperature. Thus, struvite still has good performance at low temperatures.

It is worth noting that the interfacial bonding strength cures for 14 days are less than that of 3 days except FA20, FA25 and FA30 cured at 20 °C. It needs to be explained again here that the curing method of 14 days at 20 °C and 0 °C includes air curing for 7 days and water curing for 7 days after that, which is specified in the specification. The immersed water interfacial bonding strength of MPC repair mortar cures for 14 days and is tested according to the above curing conditions. The decrease in mechanical properties of MPC repair mortar during immersion curing is the main reason for the 14 days interface bonding strength reduction. Only when the curing temperature is 20 °C, and the content of fly ash is no less than 20 wt%, the interfacial bonding strength of MPC repair mortar cures 14 days is a little higher than that of 1.5 h and 3 days. This is due to the fact that water infiltration during the soaking process accelerates the leaching and migration of Ca(OH)2 in the interface area between Portland mortar and MPC repair mortar and stimulates the pozzolanic activity of fly ash.

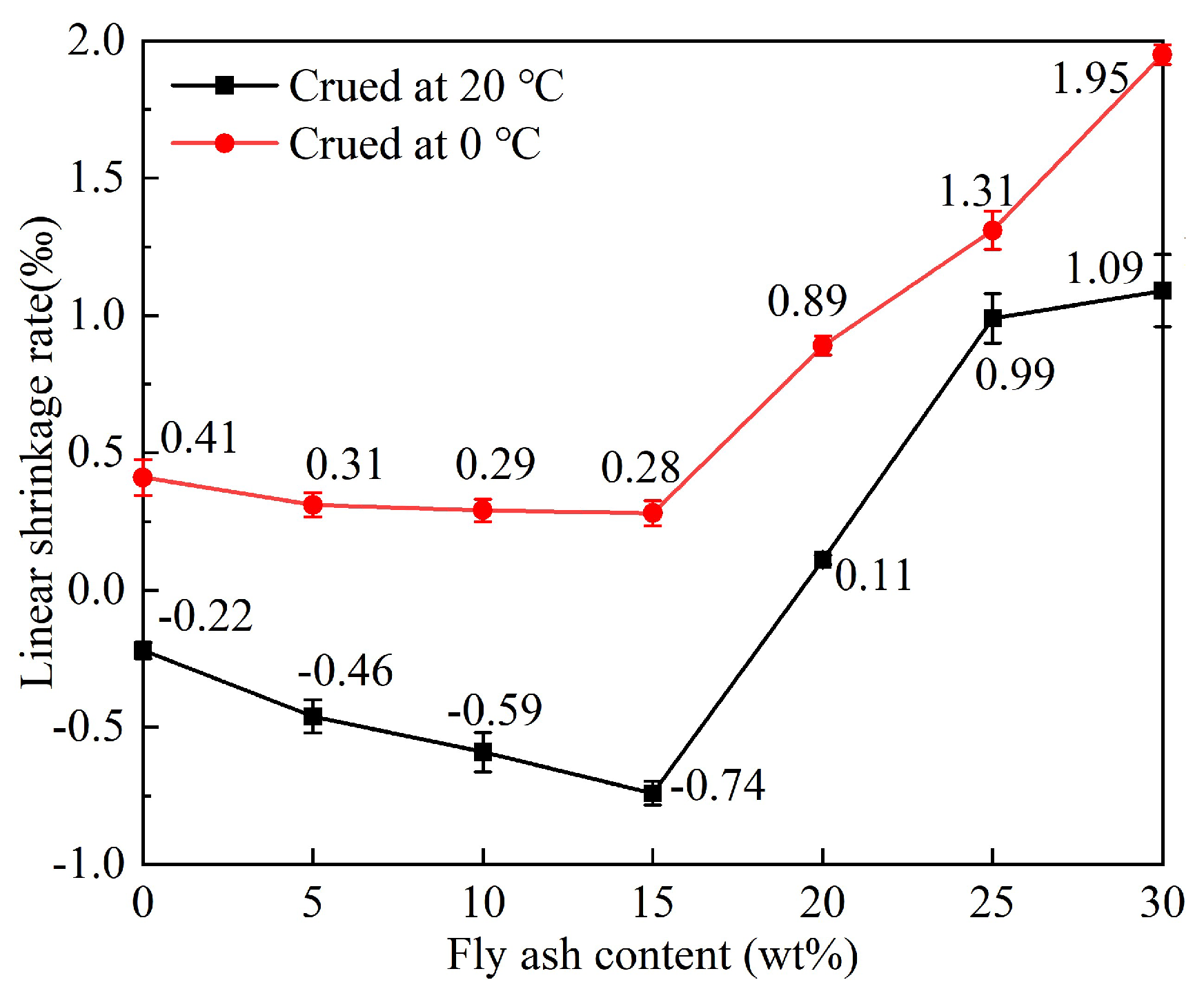

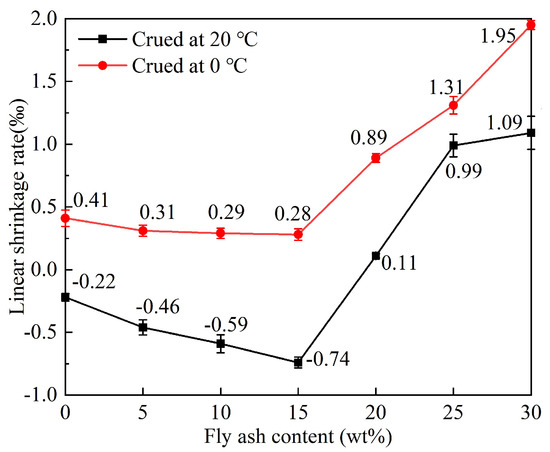

3.6. Drying Shrinkage

As shown in Figure 8, the linear shrinkage rate of MPC repair mortar curing at 20 °C decreases first and then increases with the increase in fly ash content and reduces to the minimum when the fly ash content is 15 wt%, which is −0.74‰. The linear shrinkage rate is negative when the fly ash content is no more than 15 wt%, which is to say, MPC repair mortar expands slightly during drying. This is because the active component Al2O3 in fly ash reacts with phosphate to form aluminum phosphate cementitious material, which fills between the pores and causes the expansion of the MPC repair mortar [15]. The linear shrinkage rate is only 0.11‰ when the content of fly ash is 20 wt%, and it increases rapidly when the content of fly ash continues to increase to 30 wt%, which indicates that MPC repair mortar occurs shrinkage during drying. However, when the fly ash content is too high, more MgO and NH4H2PO4 are replaced, and the amount of struvite is reduced [38]. Most of the water adsorbed on the surface of the fly ash particles does not participate in the hydration reaction, and it is more likely that it will be lost during the drying process, so the linear shrinkage rate increases.

Figure 8.

The variation of linear shrinkage rate with mixing temperature and fly ash content.

The linear shrinkage rate of MPC repair mortar cured at 0 °C varies with the fly ash content the same as that cured at 20 °C, which is the lowest when the fly ash content is 15 wt%. The difference is that the linear shrinkage of all MPC repair mortar is positive, which indicates that they all shrink during the drying process. The linear shrinkage rate is from 0.41 ‰ to 0.28 ‰ when the content of fly ash increases from zero to 15 wt% and increases rapidly when the content is greater than 15 wt%. According to the specification requirements and operability of the drying shrinkage test, the relative humidity of the 20 °C curing specimen is 50%, while that of the 0 °C specimen is 0%. During the 25 days of the drying process, the moisture in the MPC specimens is almost completely lost through sublimation, so the drying shrinkage of the 0 °C specimen is higher than that of the 20 °C specimens.

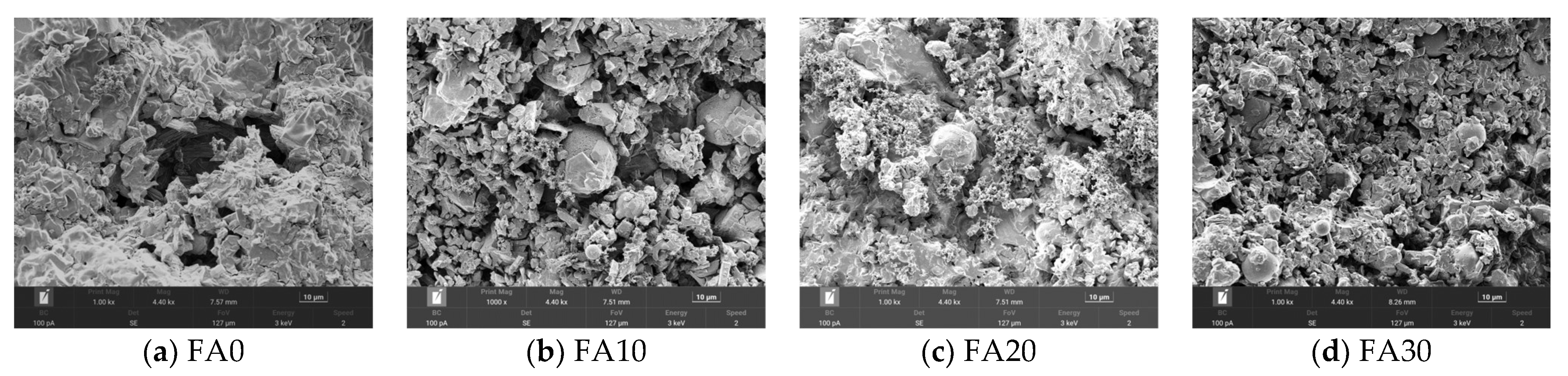

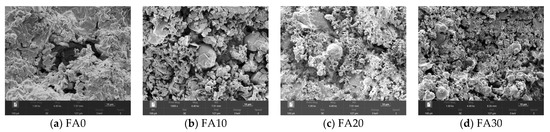

3.7. SEM Analysis of MPC Cured at 20 °C

It can be seen from Figure 9a that the struvite is distributed in blocks and columns, and the structure is closely connected with MgO in the microscopic morphology of sample FA0 cured for 28 days. Previous studies have shown that struvite tends to generate large crystals in open spaces such as pores or porous areas, while in the confined region, it tends to form less regular but closely clustered block crystals [39,40], which is consistent with our observation. As is shown in Figure 9b, the hydration products are obviously refined and bonded to the surface of fly ash particles, and thus the morphology of FA10 was obviously more compact compared with sample FA0. On the one hand, fly ash with finer particles can fill the microcracks and gaps of the MPC matrix, making the structure more compact. On the other hand, fly ash has reactivity in the system. Its glassy aluminosilicate part reacts in the initial acidic environment of MPC to form new hydrated gelling products, which optimizes the single struvite structure in FA0, thus improving the mechanical properties [19,41]. Figure 9c,d shows that the struvite of FA20 and FA30 is further refined, and its continuity is further reduced, especially since the microstructure becomes looser when the content of fly ash is 30 wt%, and no hydration product of fly ash is observed. This indicates that an excessive amount of fly ash will lead to insufficient content of struvite, the main hydration product, which is detrimental to the densification of the MPC matrix structure and the decline of mechanical properties.

Figure 9.

SEM images of fly ash-modified MPC cured for 28 days at 20 °C.

4. Conclusions

This paper studies the difference in properties, such as setting time, fluidity, mechanical properties, water resistance, interfacial bonding strength, and linear shrinkage, of fly ash-modified magnesium phosphate cement repair mortar cured at between 20 °C and 0 °C. The influence of fly ash content on MPC microstructure is analyzed by SEM. According to the experimental results, the following conclusions can be drawn:

- (1)

- The setting time of MPC repair mortar with the same fly ash content mixing at 0 °C is longer than that at 20 °C, and the fluidity mixing at 0 °C is lower than that at 20 °C. The setting time of MPC repair mortar decreases with the increase in fly ash content at 20 °C, and decreases first and then increases with the fly ash content at 0 °C. With the increase in fly ash content, the fluidity of MPC repair mortar mixture mixed at 20 °C and 0 °C first increases and then decreases and reaches the maximum when the content of fly ash is 10 wt%.

- (2)

- The compressive strength of MPC cured at 0 °C is obviously lower than that cured at 20 °C, while the flexural strength, strength retention rate, and interfacial bonding strength vary slightly with that cured at 20 °C. Those are not lower than the latter when the content of fly ash is not higher than 10 wt%. Except that the interfacial bonding strength cured at 0 °C decreases with the increase in fly ash content, the above properties of MPC cured at 0 °C and 20 °C increase first and then decreased with the increase in fly ash content. In other words, MPC cured at 0 °C still has appropriate mechanical properties and water resistance.

- (3)

- The linear shrinkage rate of MPC repair mortar cured at 0 °C is higher than that cured at 20 °C because of the difference in curing humidity under the same fly ash content. The linear shrinkage rate of MPC repair mortar cured at 0 °C and 20 °C decreases first and then increases with the increase in fly ash content, which is the lowest when the fly ash content is 15 wt%.

- (4)

- The section of fly ash-modified MPC contains visible struvite, MgO, fly ash particles, and glass beads. The fly ash refines the struvite and increases the compactness of MPC, so its water resistance is improved. Meanwhile, with the increase in fly ash content, the crystallinity and continuity of struvite decrease, which leads to a decrease in its mechanical properties.

Author Contributions

Conceptualization, J.L.; Methodology, J.L. and M.Y.; Investigation, J.L., M.Y., A.L. and J.Z.; Writing—original draft preparation, J.L. and M.Y.; Writing—review and editing, R.H. and F.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Independent Innovation Application Research Project of the Zhongyuan University of Technology (No. K2020YY013).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Wang, Y.; Dai, J. Use of magnesia sand for optimal design of high performance magnesium potassium phosphate cement mortar. Constr. Build. Mater. 2017, 153, 385–392. [Google Scholar] [CrossRef]

- Li, T.; Chen, G.; Yang, J.; Chong, L.; Hu, X. Influence of curing conditions on mechanical properties and microstructure of magnesium potassium phosphate cement. Case. Stud. Constr. Mat. 2022, 17, e01264. [Google Scholar] [CrossRef]

- Wang, Y.; Dai, J.; Ding, Z.; Xu, W. Phosphate-based geopolymer: Formation mechanism and thermal stability. Mater. Lett. 2017, 190, 209–212. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Li, L.; Ma, C.; Wang, S. Basic properties and mechanism of high activity phosphate-based slurry for dynamic water blocking-A feasibility research. Constr. Build. Mater. 2021, 275, 122040. [Google Scholar] [CrossRef]

- Jia, X.; Li, J.; Wang, P.; Qian, J.; Tang, M. Preparation and mechanical properties of magnesium phosphate cement for rapid construction repair in ice and snow. Constr. Build. Mater. 2019, 229, 116927. [Google Scholar] [CrossRef]

- Xu, B.; Winnefeld, F.; Ma, B.; Rentsch, D.; Lothenbach, B. Influence of aluminum sulfate on properties and hydration of magnesium potassium phosphate cements. Cement. Concrete. Res. 2022, 156, 106788. [Google Scholar] [CrossRef]

- Jin, B.; Chen, L.; Chen, B. Factors assessment of a repair material for brick masonry loaded cracks using magnesium phosphate cement. Constr. Build. Mater. 2020, 252, 119098. [Google Scholar] [CrossRef]

- Hall, D.; Stevens, R.; El-Jazairi, B. The effect of retarders on the microstructure and mechanical properties of magnesia–phosphate cement mortar. Cement. Concrete. Res. 2001, 31, 455–465. [Google Scholar] [CrossRef]

- Jiang, Z.; Qian, C.; Chen, Q. Experimental investigation on the volume stability of magnesium phosphate cement with different types of mineral admixtures. Constr. Build. Mater. 2017, 157, 10–17. [Google Scholar] [CrossRef]

- Seehra, S.; Gupta, S.; Kumar, S. Rapid setting magnesium phosphate cement for quick repair of concrete pavements—Characterisation and durability aspects. Cement. Concrete. Res. 1993, 23, 254–266. [Google Scholar] [CrossRef]

- Yang, Q.; Wu, X. Factors influencing properties of phosphate cement-based binder for rapid repair of concrete. Cement. Concrete. Res. 1999, 29, 389–396. [Google Scholar] [CrossRef]

- Wang, Q.; Qian, J.; Qin, J.; You, C.; Wang, H. Effect of Ambient Temperature on Setting Time and Strength Development of Magnesia-phosphate Cement. J. Chin. Ceram. Soc. 2013, 41, 6. (In Chinese) [Google Scholar]

- You, C.; Qian, J.; Qin, J.; Wang, H.; Wang, Q.; Ye, Z. Effect of early hydration temperature on hydration product and strength development of magnesium phosphate cement (MPC). Cement. Concrete. Res. 2015, 78, 179–189. [Google Scholar] [CrossRef]

- Yang, N.; Shi, C.; Yang, J.; Chang, Y. Research Progresses in Magnesium Phosphate Cement–Based Materials. J. Mater. Civil. Eng. 2014, 26, 04014071. [Google Scholar] [CrossRef]

- Li, Y.; Chen, B. Factors that affect the properties of magnesium phosphate cement. Constr. Build. Mater. 2013, 47, 977–983. [Google Scholar] [CrossRef]

- Popovics, S.; Rajendran, N. Early age properties of magnesium phosphate-based cements under various temperature conditions. In Proceedings of the 66th Annual Meeting of the Transportation Board, Washington, DC, USA, 12–15 January 1987. [Google Scholar]

- Wang, H. Study on the High Performance Magnesia-Phosphate Cement Based Composites; Chongqing University: Chongqing, China, 2006. [Google Scholar]

- Liao, W.; Ma, H.; Sun, H.; Huang, Y.; Wang, Y. Potential large-volume beneficial use of low-grade fly ash in magnesia-phosphate cement based materials. Fuel 2017, 209, 490–497. [Google Scholar] [CrossRef]

- Gardner, L.; Bernal, S.; Walling, S.; Corkhill, C.; Provis, J.; Hyatt, N. Characterisation of magnesium potassium phosphate cements blended with fly ash and ground granulated blast furnace slag. Cement. Concrete. Res. 2015, 74, 78–87. [Google Scholar] [CrossRef]

- Lu, X.; Chen, B. Experimental study of magnesium phosphate cements modified by metakaolin. Constr. Build. Mater. 2016, 123, 719–726. [Google Scholar] [CrossRef]

- Zheng, D.; Ji, T.; Wang, C.; Sun, C.; Lin, X.; Hossain, K. Effect of the combination of fly ash and silica fume on water resistance of Magnesium–Potassium Phosphate Cement. Constr. Build. Mater. 2016, 106, 415–421. [Google Scholar] [CrossRef]

- Xu, B.; Lothenbach, B.; Winnefeld, F. Influence of wollastonite on hydration and properties of magnesium potassium phosphate cements. Cement. Concrete. Res. 2020, 131, 106012. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Z.; Chen, B. Experimental research on magnesium phosphate cements modified by red mud. Constr. Build. Mater. 2020, 231, 117131. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, Y.; Huang, X.; Luo, H. Effect of raw materials and proportion on mechanical properties of magnesium phosphate cement. J. Roa. Eng. 2022, 2, 243–251. [Google Scholar] [CrossRef]

- Jia, X.; Luo, J.; Zhang, W.; Tang, M.; Qian, J.; Wang, P.; Li, J. Reaction characteristics and compressive strength of magnesia-phosphate cement at negative temperatures. Constr. Build. Mater. 2021, 305, 124819. [Google Scholar] [CrossRef]

- Feng, H.; Nie, S.; Guo, A.; Lv, L.; Chu, L.; Yu, J. Fresh properties and compressive strength of MPC-based materials with blended mineral admixtures. Case. Stud. Constr. Mat. 2022, 17, e01201. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Zhang, M.; Hai, R. Research progress on magnesium phosphate cement modified by mineral admixtures. Inorg. Chem. Ind. 2022, 54, 18–23. (In Chinese) [Google Scholar] [CrossRef]

- JGJ/T 70-2009; Standard for Test Method of Basic Properties of Construction Mortar. China Architecture and Building Press: Beijing, China, 2009.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). China Standards Press: Beijing, China, 2021.

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2009.

- JC/T 603-2004; Standard Test Method for Drying Shinkage of Mortar. ASTM International: West Conshohocken, PA, USA, 2004.

- Wagh, A. (Ed.) Chemically Bonded Phosphate Ceramics, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 17–34. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, B.; Dong, B.; Wang, Y.; Xing, F. Influence mechanisms of fly ash in magnesium ammonium phosphate cement. Constr. Build. Mater. 2022, 314, 125581. [Google Scholar] [CrossRef]

- Qin, Z.; Ma, C.; Zheng, Z.; Long, G.; Chen, B. Effects of metakaolin on properties and microstructure of magnesium phosphate cement. Constr. Build. Mater. 2020, 234, 117353. [Google Scholar] [CrossRef]

- Feng, L.; Chen, X.; Wen, X.; Zhang, Z.; Shou, L. Investigating and optimizing the mix proportion of sustainable phosphate-based rapid repairing material. Constr. Build. Mater. 2019, 204, 550–561. [Google Scholar] [CrossRef]

- Wang, H.; Xue, M.; Cao, J. Research on the Strength Properties of the Magnesium Phosphate Cement (MPC) under the Sub-Zero Temperature Environment. Adv. Mat. Res. 2010, 150–151, 1517–1520. [Google Scholar] [CrossRef]

- Lu, K.; Wang, B.; Han, Z.; Ji, R. Experimental study of magnesium ammonium phosphate cements modified by fly ash and metakaolin. J. Build. Eng. 2022, 51, 104137. [Google Scholar] [CrossRef]

- Wu, J.; Lai, Z.; Deng, Q.; Liu, M. Effects of various curing conditions on volume stability of magnesium phosphate cement. Adv. Mater. Sci. Eng. 2021, 2021, 6652363. [Google Scholar] [CrossRef]

- Chong, L.; Yang, J.; Shi, C. Effect of curing regime on water resistance of magnesium–potassium phosphate cement. Constr. Build. Mater. 2017, 151, 43–51. [Google Scholar] [CrossRef]

- Ding, Z.; Dong, B.; Xing, F.; Han, N.; Li, Z. Cementing mechanism of potassium phosphate based magnesium phosphate cement. Ceram. Int. 2012, 38, 6281–6288. [Google Scholar] [CrossRef]

- Walling, S.; Provis, J. Magnesia-based cements: A journey of 150 years, and cements for the future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).