Interface Structure and Mechanical Properties of 7075Al Hybrid Composite Reinforced with Micron Ti Metal Particles Using Pressure Infiltration

Abstract

1. Introduction

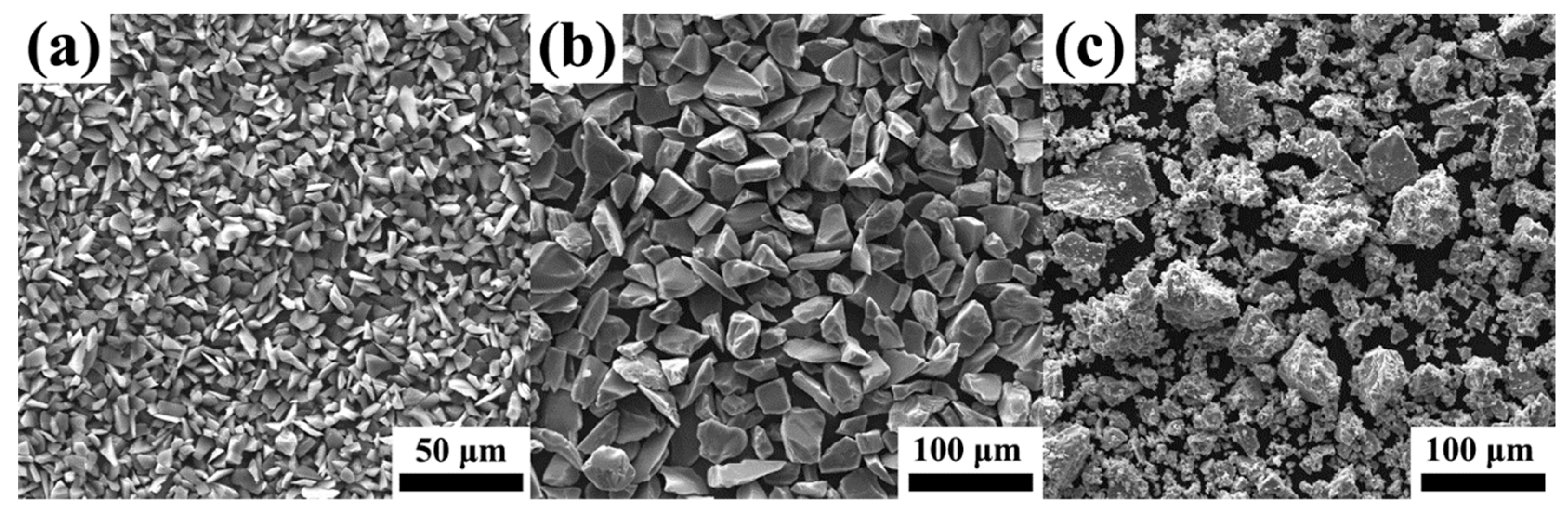

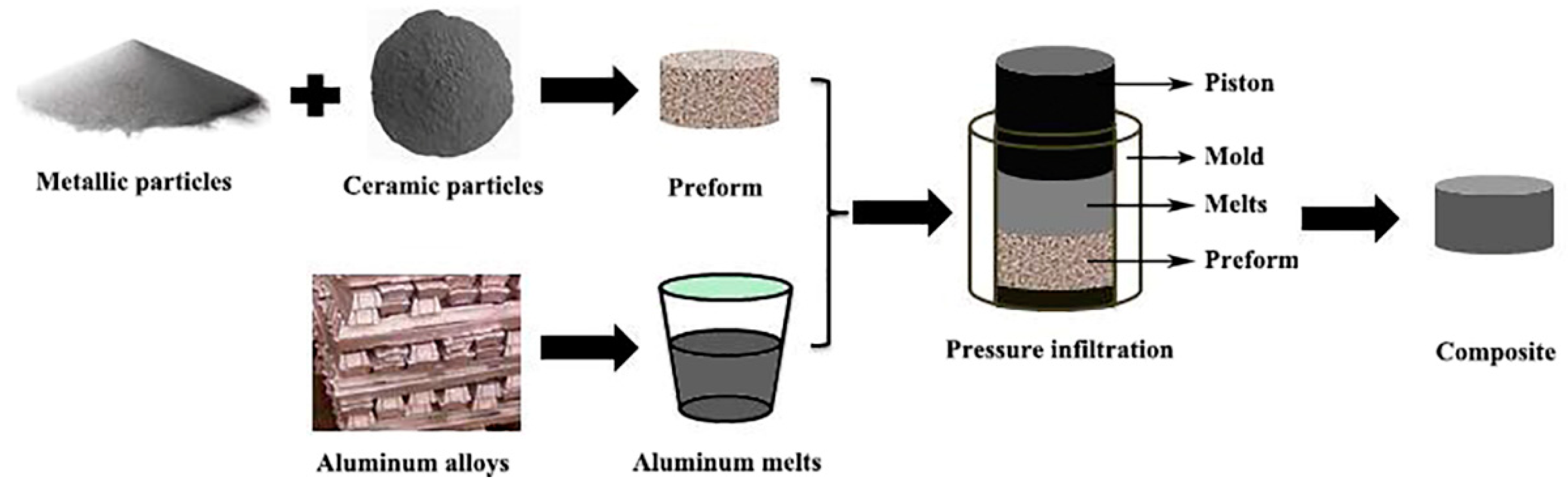

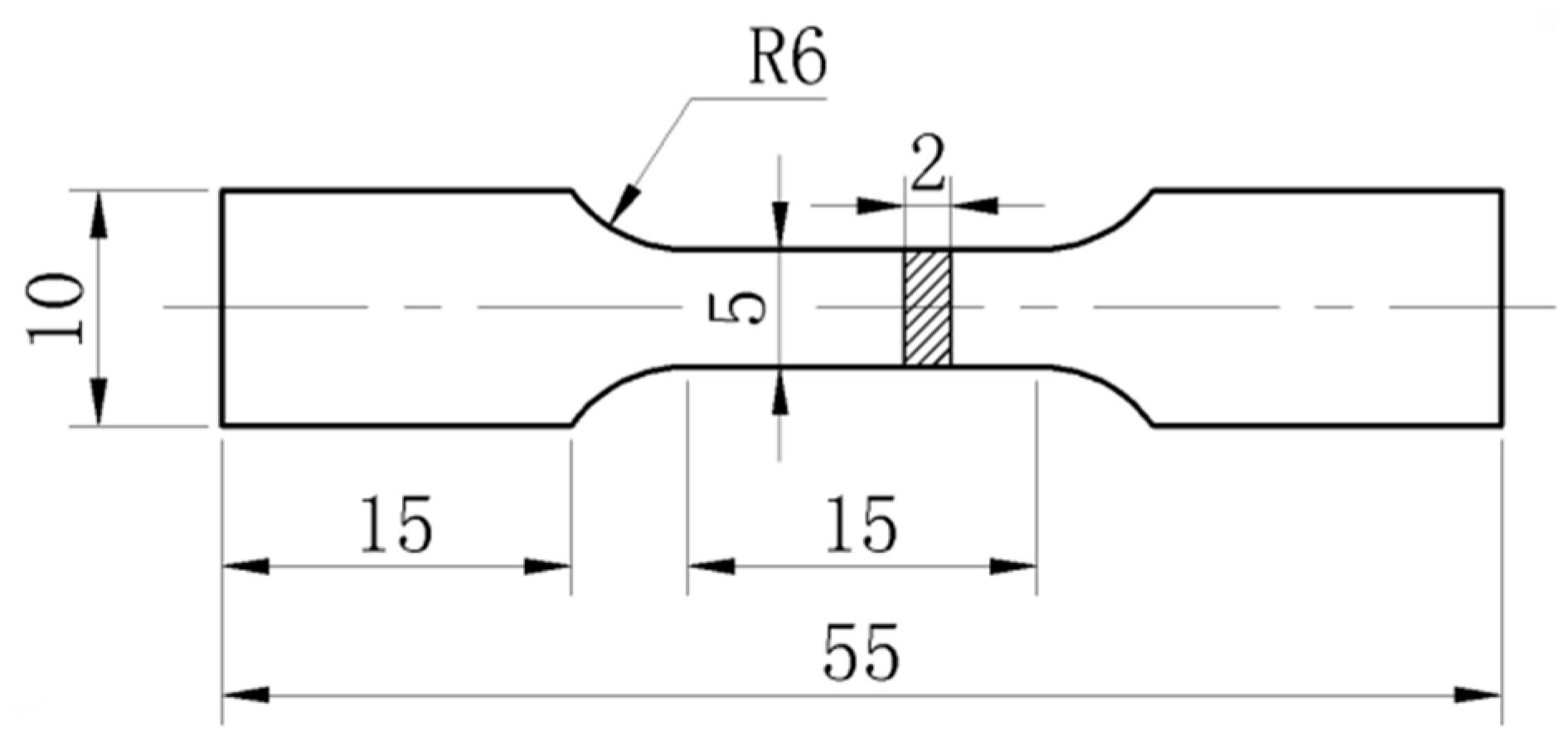

2. Methods and Experiments

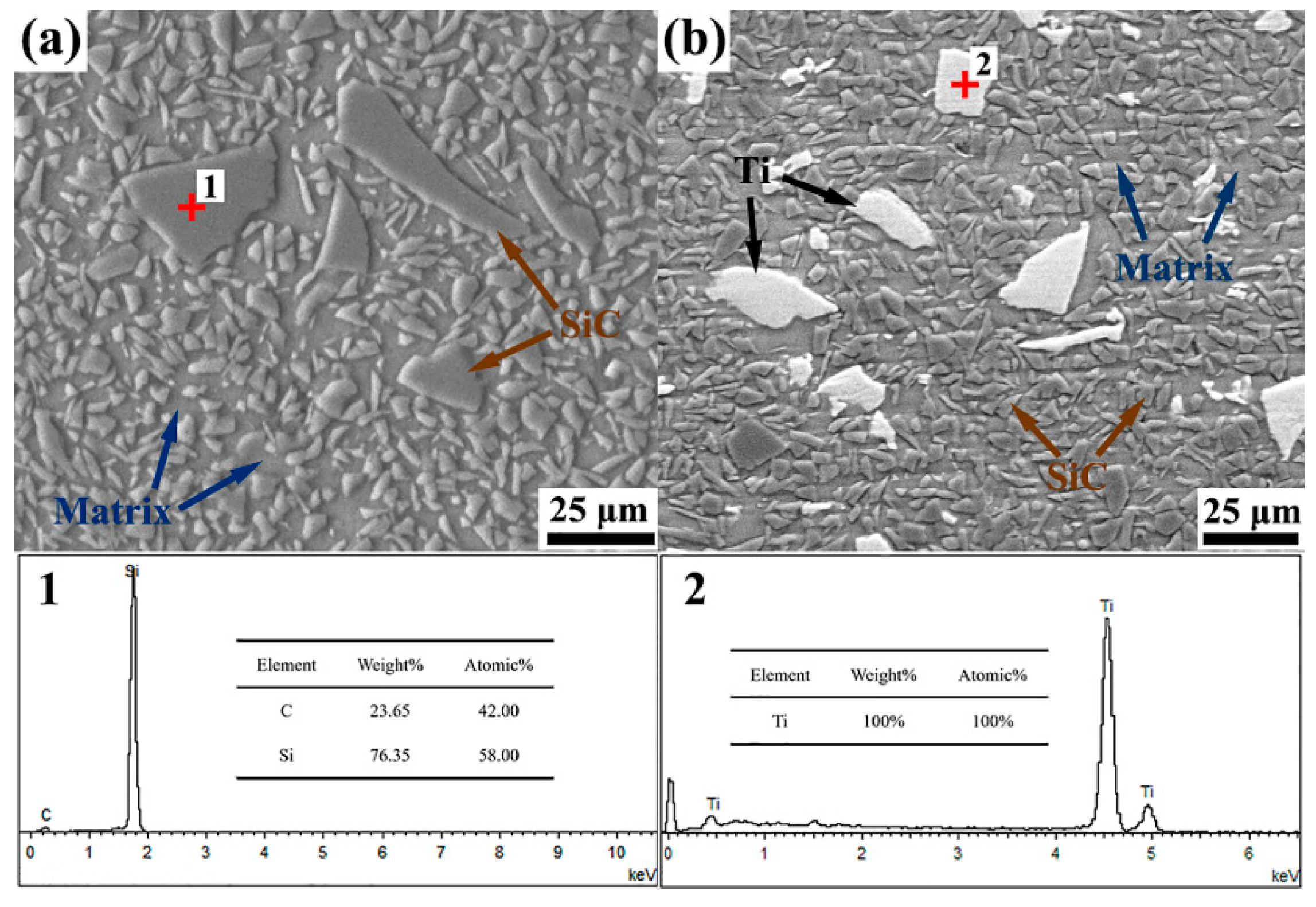

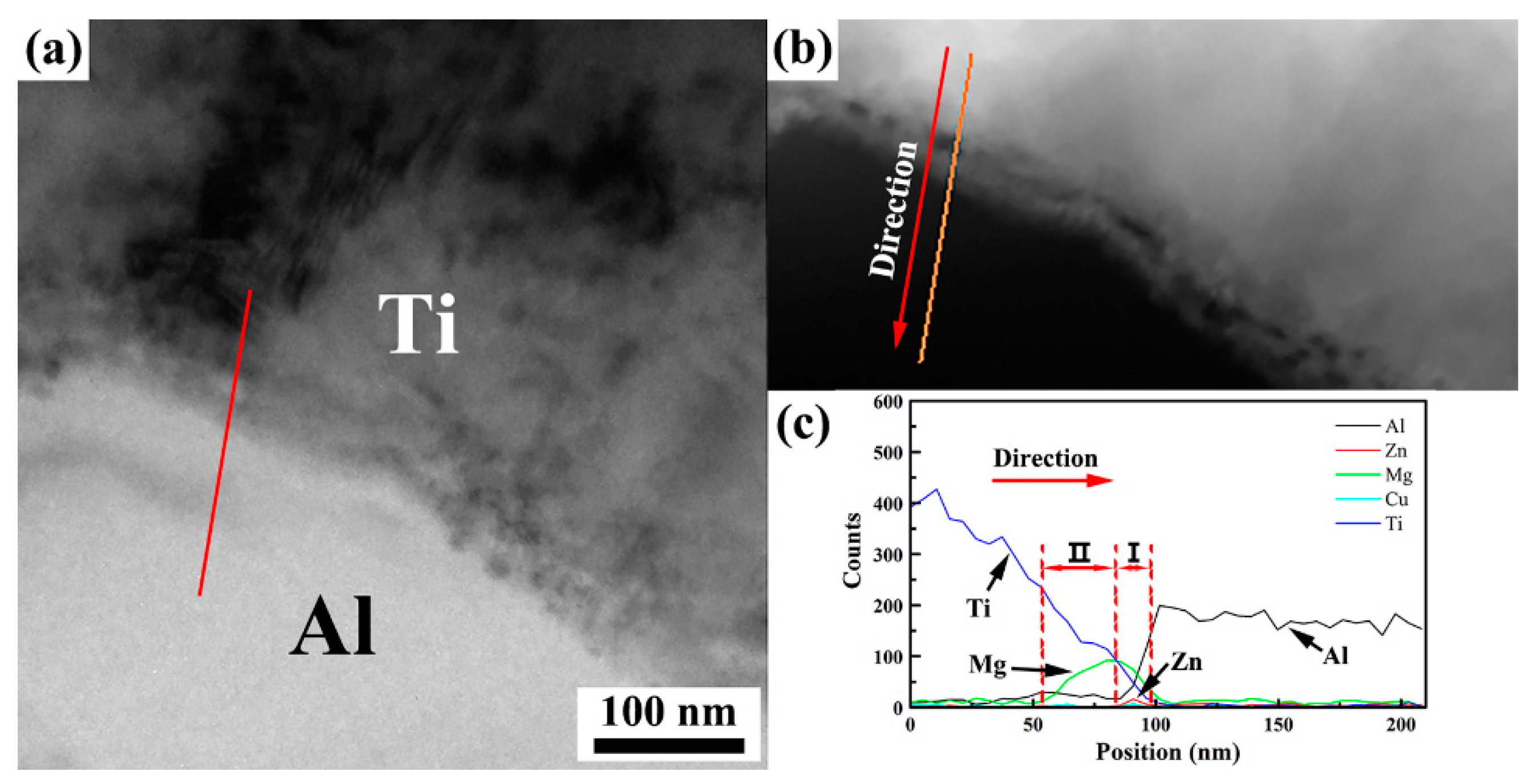

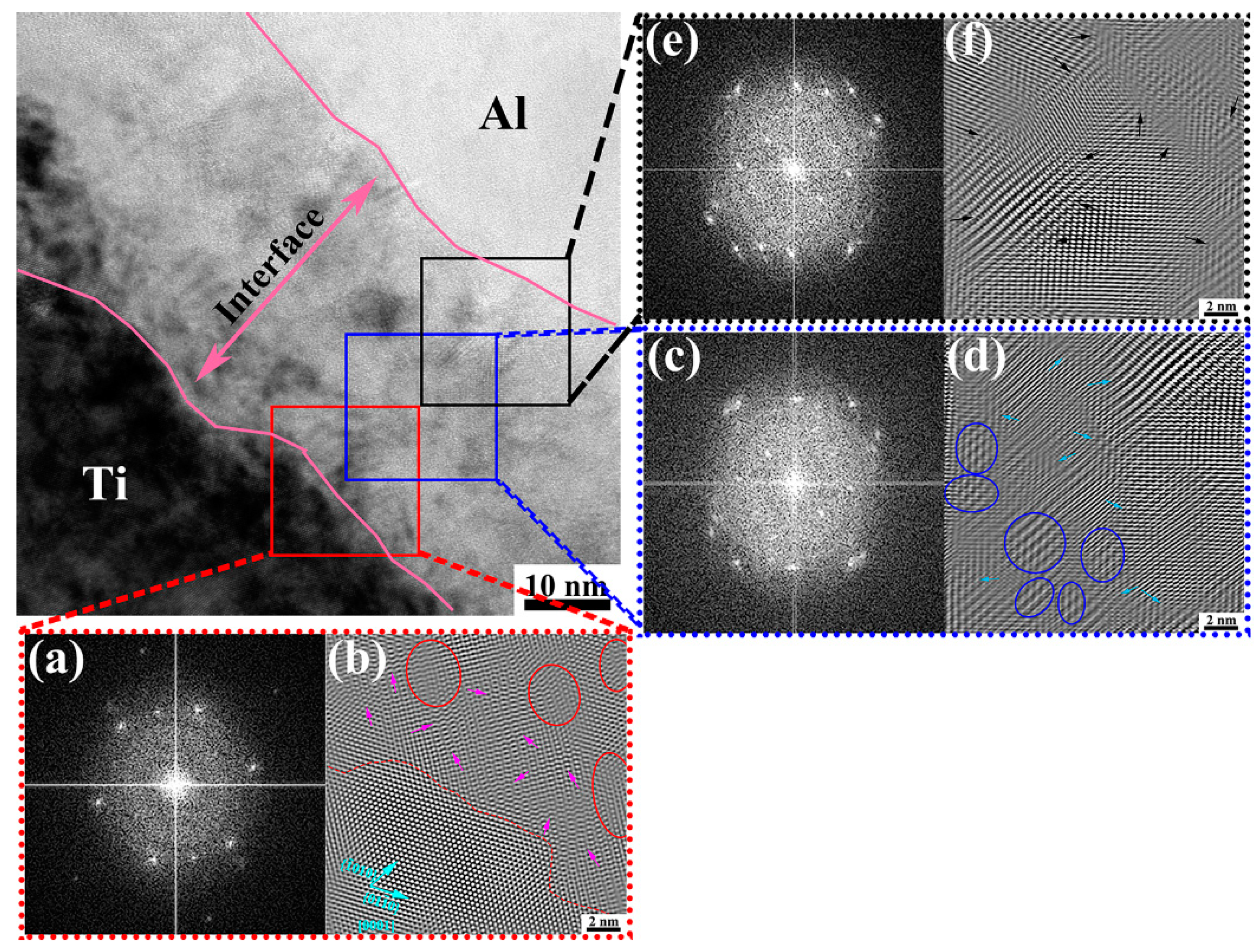

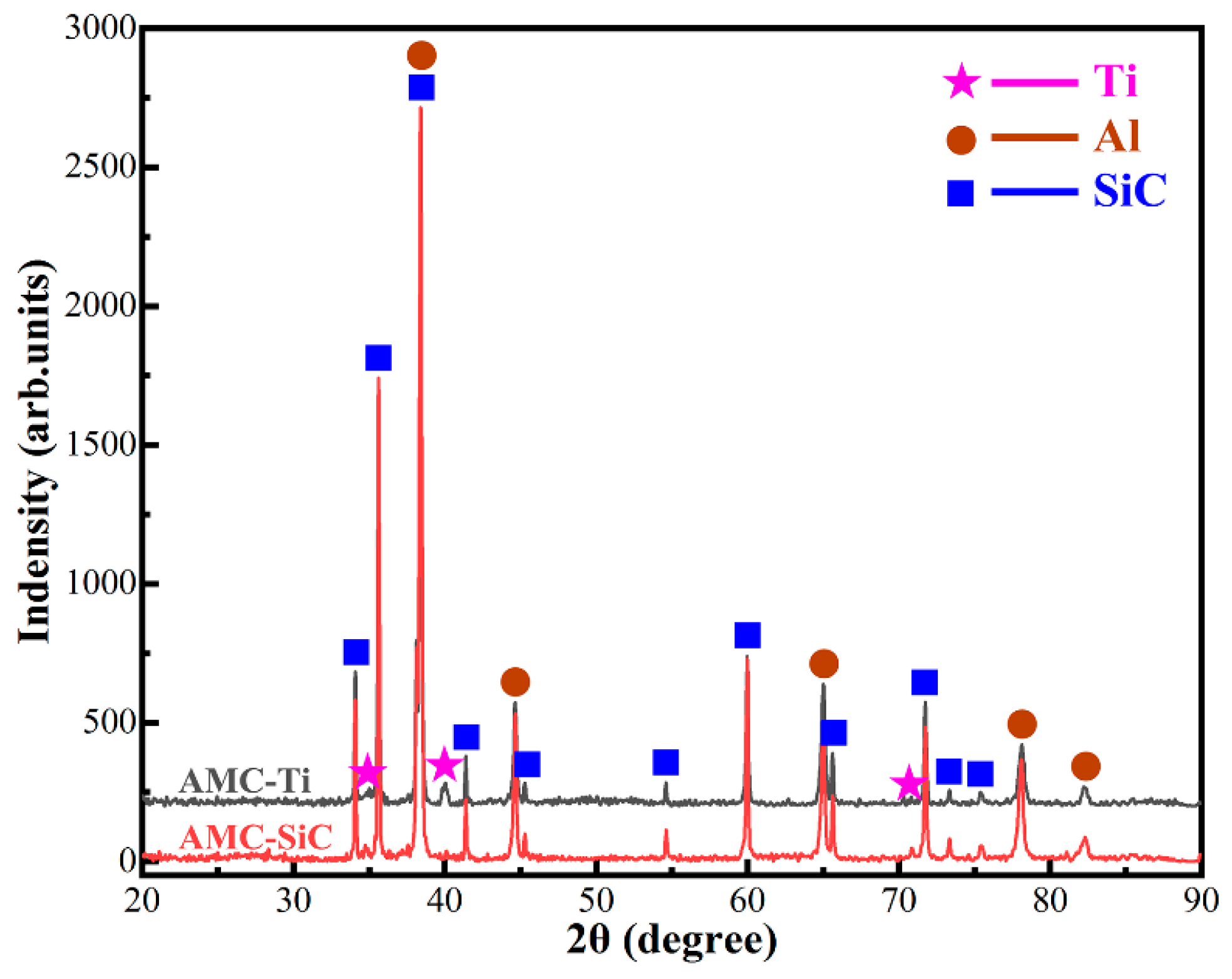

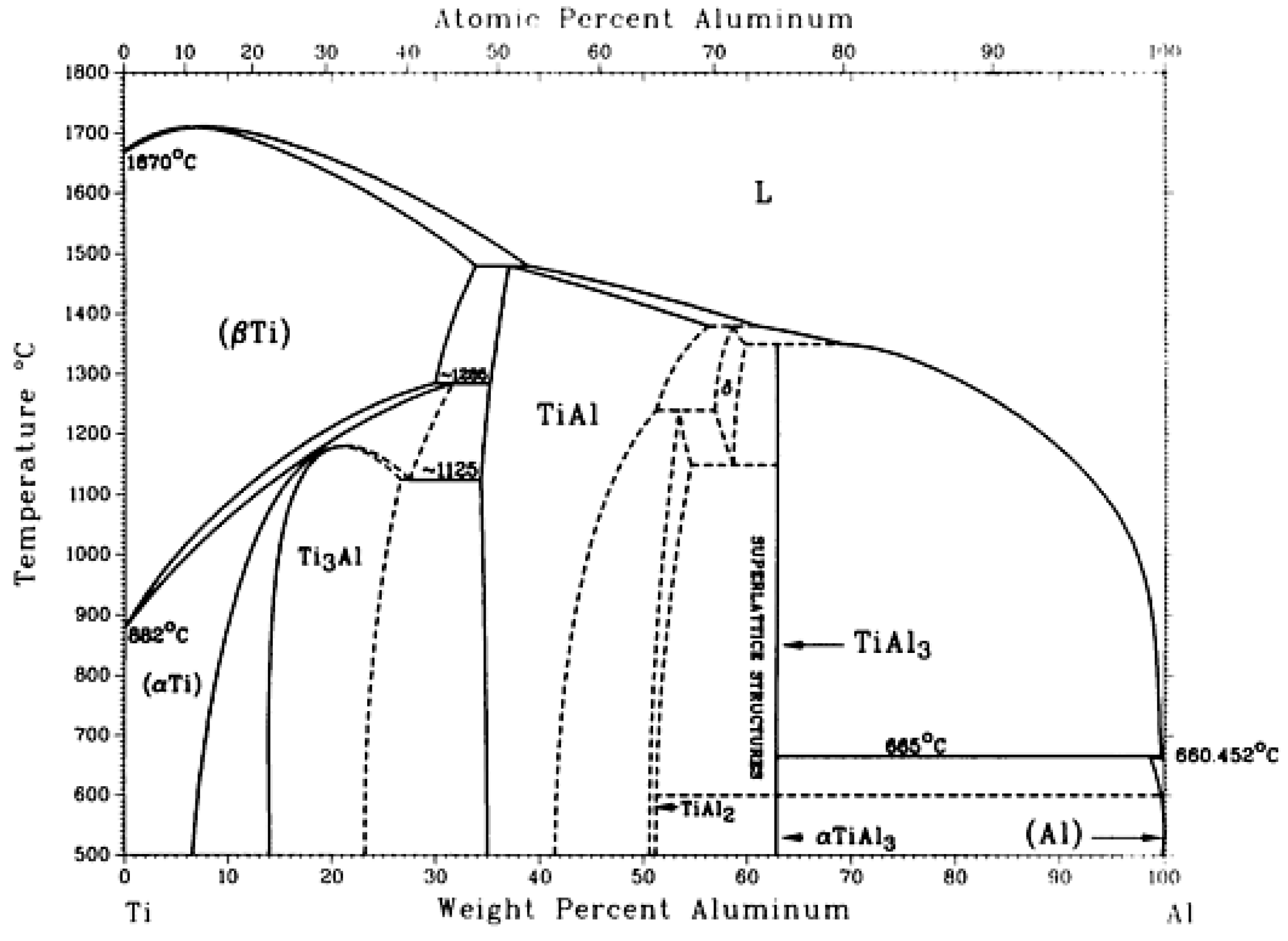

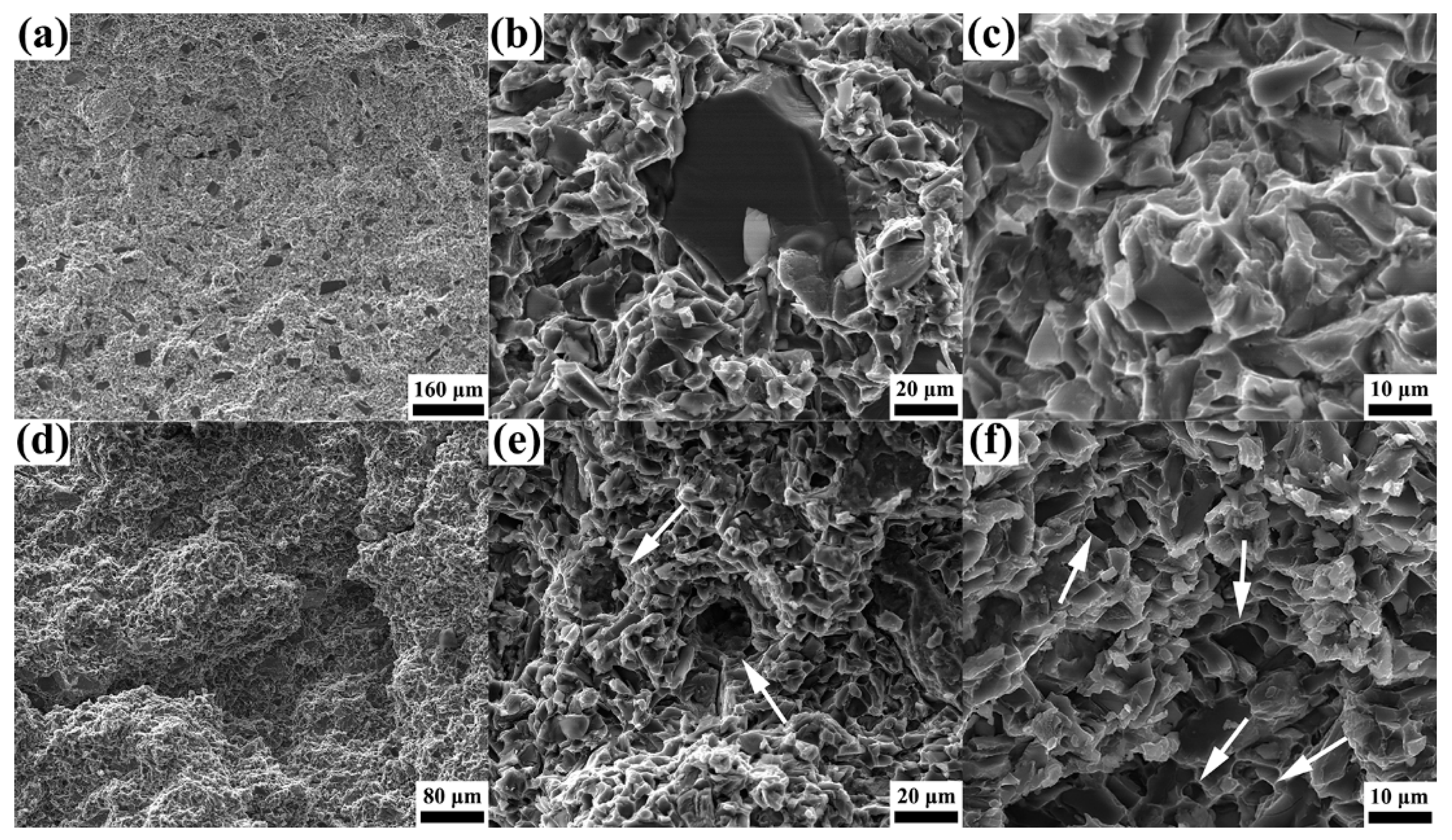

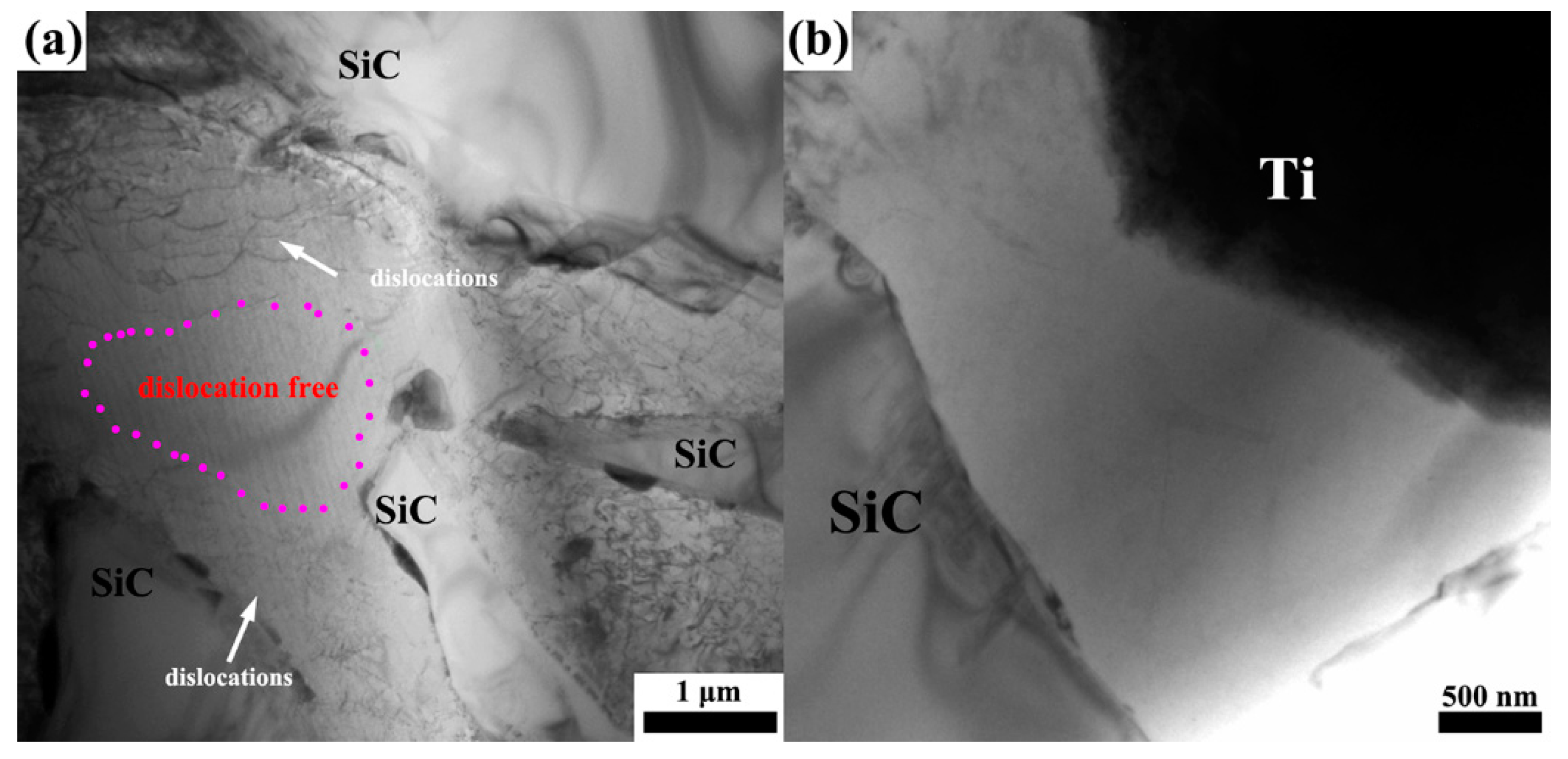

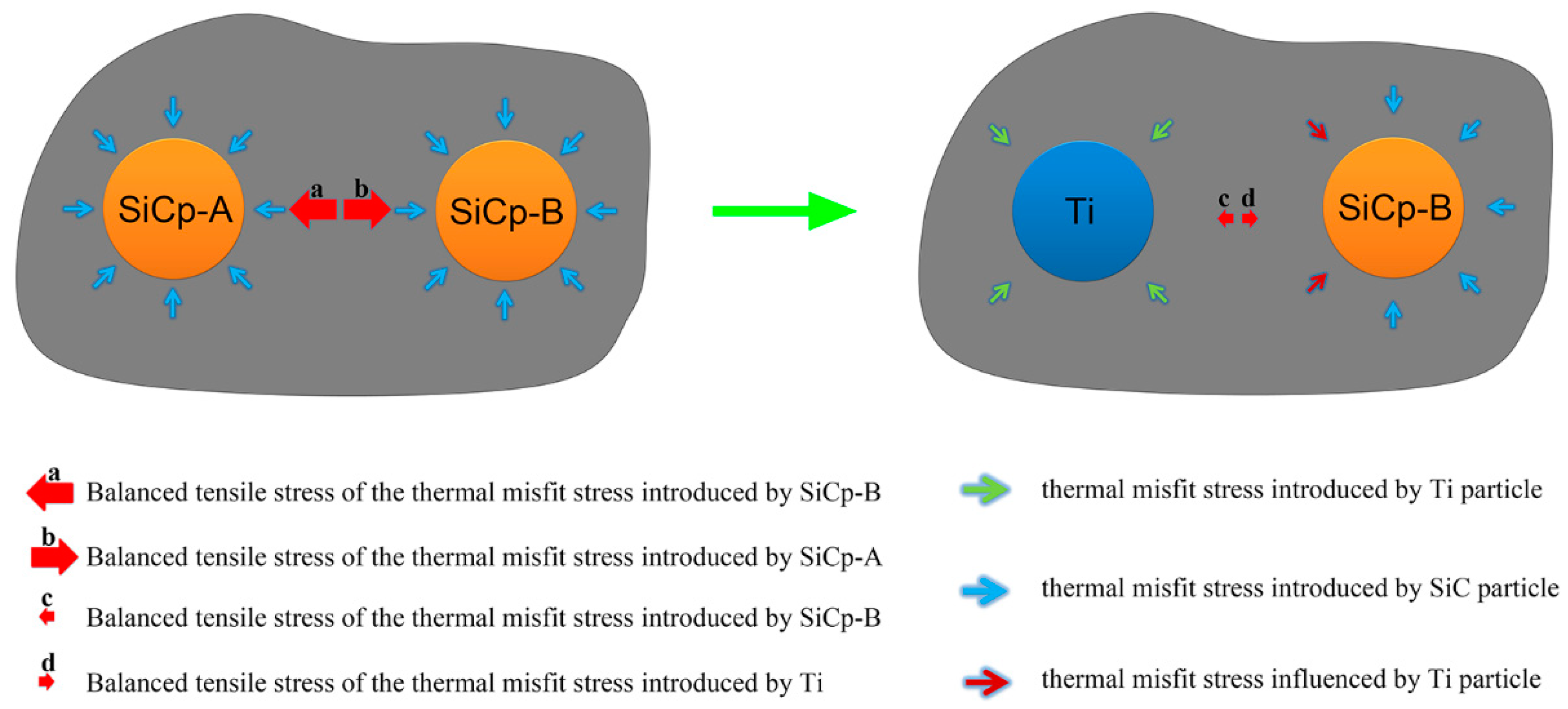

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, H.; Choi, J.H.; Jo, M.C.; Lee, D.; Shin, S.; Jo, I.; Lee, S.-K.; Lee, S. Effects of SiC particulate size on dynamic compressive properties in 7075-T6 Al-SiCp composites. Mater. Sci. Eng. A. 2018, 738, 412–419. [Google Scholar] [CrossRef]

- Xu, Q.; Ma, A.; Wang, J.; Sun, J.; Jiang, J.; Li, Y.; Ni, C. Development of high-performance SiCp/Al-Si composites by equal channel angular pressing. Metals 2018, 8, 738. [Google Scholar] [CrossRef]

- Hadian, M.; Shahrajabian, H.; Rafiei, M. Mechanical properties and microstructure of Al/(TiC+TiB2) composite fabricated by spark plasma sintering. Ceram. Int. 2019, 45, 12088–12092. [Google Scholar] [CrossRef]

- Zan, Y.N.; Zhou, Y.T.; Liu, Z.Y.; Ma, G.N.; Wang, D.; Wang, Q.Z.; Wang, W.G.; Xiao, B.L.; Ma, Z.Y. Enhancing strength and ductility synergy through heterogeneous structure design in nanoscale Al2O3 particulate reinforced Al composites. Mater. Des. 2019, 166, 107629. [Google Scholar] [CrossRef]

- Léger, A.; Weber, L.; Mortensen, A. Influence of the wetting angle on capillary forces in pressure infiltration. Acta Mater. 2015, 91, 57–69. [Google Scholar] [CrossRef]

- Alonso, A.; Narciso, J.; Pamies, A.; Garcia-Cordovilla, C.; Louis, E. Effect of K2ZrF6 coatings on pressure infiltration of packed SiC particulates by liquid aluminum. Scr. Metall. Mater. 1993, 29, 1559–1564. [Google Scholar] [CrossRef]

- Kouzeli, M.; San Marchi, C.; Mortensen, A. Effect of reaction on the tensile behavior of infiltrated boron carbide-aluminum composites. Mater. Sci. Eng. A. 2002, 337, 264–273. [Google Scholar] [CrossRef]

- Ali, F.; Scudino, S.; Liu, G.; Srivastava, V.C.; Mukhopadhyay, N.K.; Khoshkhoo, M.S.; Prashanth, K.G.; Uhlenwinkel, V.; Calin, M.; Eckert, J. Modeling the strengthening effect of Al-Cu-Fe quasicrystalline particles in Al-based metal matrix composites. J. Alloys Compd. 2012, 536, S130–S133. [Google Scholar] [CrossRef]

- Jang, J.S.C.; Li, T.H.; Jian, S.R.; Huang, J.C.; Nieh, T.G. Effects of characteristics of Mo dispersions on the plasticity of Mg-based bulk metallic glass composites. Intermetallics 2011, 19, 738–743. [Google Scholar] [CrossRef]

- Gao, M.; Chen, T.; Qin, H. Effects of mold temperature on the microstructure and tensile properties of Ti@(Al-Si-Ti)p/A356 composite prepared via powder thixoforming. Metals 2018, 8, 829. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, Y.; Zhang, G.; Wang, Z. Formation of nanoscale metallic glassy particle reinforced Al-based composite powders by high-energy milling. Metals 2017, 7, 425. [Google Scholar] [CrossRef]

- Rezaei, M.R.; Shabestari, S.G.; Razavi, S.H. Effect of ECAP consolidation temperature on the microstructure and mechanical properties of Al-Cu-Ti metallic glass reinforced aluminum matrix composite. J. Mater. Sci. Technol. 2017, 33, 1031–1038. [Google Scholar] [CrossRef]

- Kang, N.; Fu, Y.; Coddet, P.; Guelorget, B.; Liao, H.; Coddet, C. On the microstructure, hardness and wear behavior of Al-Fe-Cr quasicrystal reinforced Al matrix composite prepared by selective laser melting. Mater. Des. 2017, 132, 105–111. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, Q.; Tan, X.; Deng, S.; Shi, K.; Wang, C.; Wu, G. Fully-dense Mn3Zn0.7Ge0.3N/Al composites with zero thermal expansion behavior around room temperature. Materialia 2019, 6, 100289. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Li, Z.; Wang, X.; Fan, X.; Liu, J. Formation of transition layer and its effect on mechanical properties of AlCoCrFeNi high-entropy alloy/Al composites. J. Alloys Compd. 2019, 780, 558–564. [Google Scholar] [CrossRef]

- Rasouli, M.; Akhlaghi, F.; Ojo, O.O.; Paidar, M. Preparation and characterization of in-situ Al-AlXNiY composites via reactive infiltration. J. Alloys Compd. 2019, 780, 829–845. [Google Scholar] [CrossRef]

- Rezaei, A.; Madaah Hosseini, H.R. Evolution of microstructure and mechanical properties of Al-5wt% Ti composite fabricated by P/M and hot extrusion: Effect of heat treatment. Mater. Sci. Eng. A. 2017, 689, 166–175. [Google Scholar] [CrossRef]

- Yadav, D.; Bauri, R. Nickel particle embedded aluminium matrix composite with high ductility. Mater. Lett. 2010, 64, 664–667. [Google Scholar] [CrossRef]

- Pandey, A.B.; Majumdar, B.S.; Miracle, D.B. Effect of aluminum particles on the fracture toughness of a 7093/SiC/15p composite. Mater. Sci. Eng. A. 1999, 259, 296–307. [Google Scholar] [CrossRef]

- Markó, D.; Prashanth, K.G.; Scudino, S.; Wang, Z.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J. Al-based metal matrix composites reinforced with Fe49.9Co35.1Nb7.7B4.5Si2.8 glassy powder: Mechanical behavior under tensile loading. J. Alloys Compd. 2014, 615, S382–S385. [Google Scholar] [CrossRef]

- Lu, T.; Chen, W.; Xu, W.; Wang, P.; Mao, M.; Liu, Y.; Fu, Z. The effects of Cr particles addition on the aging behavior and mechanical properties of SiCp/7075Al composites. Mater. Charact. 2018, 136, 264–271. [Google Scholar] [CrossRef]

- Zhang, L.; Li, B.; Wu, H.; Wang, W.; Zhai, S.; Xu, J.; Niu, Z.; Wang, Y. Microstructure and property characterization of Al-based composites reinforced with CuZrAl particles fabricated by mechanical alloying and spark plasma sintering. Adv. Powder Technol. 2018, 29, 1695–1702. [Google Scholar] [CrossRef]

- Chen, G.; Jin, Y.; Zhang, H.; Han, F.; Chen, Q.; Xu, J.; Zhao, Z. Microstructures and mechanical properties of in-situ Al3Ti/2024Al composites after solution and subsequent aging treatment. Mater. Sci. Eng. A. 2018, 724, 181–188. [Google Scholar] [CrossRef]

- Du, Y.; Chang, Y.A.; Huang, B.; Gong, W.; Jin, Z.; Xu, H.; Yuan, Z.; Liu, Y.; He, Y.; Xie, F.Y. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng. A. 2003, 363, 140–151. [Google Scholar] [CrossRef]

- Köppers, M.; Herzig, C.; Friesel, M.; Mishin, Y. Intrinsic self-diffusion and substitutional Al diffusion in α-Ti. Acta Mater. 1997, 45, 4181–4191. [Google Scholar] [CrossRef]

- ASM International. ASM Handbook—Alloy Phase Diagrams; The Materials Information Company: New York, NY, USA, 1995; p. 327. [Google Scholar]

- Kelly, A.; Zweben, C.H. Comprehensive Composite Materials; Pergamon Press: New York, NY, USA, 2000; p. 35. [Google Scholar]

- Liu, Y.; Yang, C.; Chen, W.; Zhu, D.; Li, Y. Effects of particle size and properties on the microstructures, mechanical properties, and fracture mechanisms of 7075Al hybrid composites prepared by squeeze casting. J. Mater. Sci. 2014, 49, 7855–7863. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 7075Al | 0.046 | 0.109 | 1.333 | 0.027 | 2.085 | 0.225 | 5.614 | 0.009 | 0.038 | Balanced |

| Solute | Solvent | D0 (m2/s) | Q (KJ/mole) | Temperature Range (K) | Reference |

|---|---|---|---|---|---|

| Ti | Al | 4.29 × 10−7 | 36.3 | 850–1100 | [24] |

| Al | Ti | 6.6 × 10−3 | 329 ± 2 | 850–1100 | [25] |

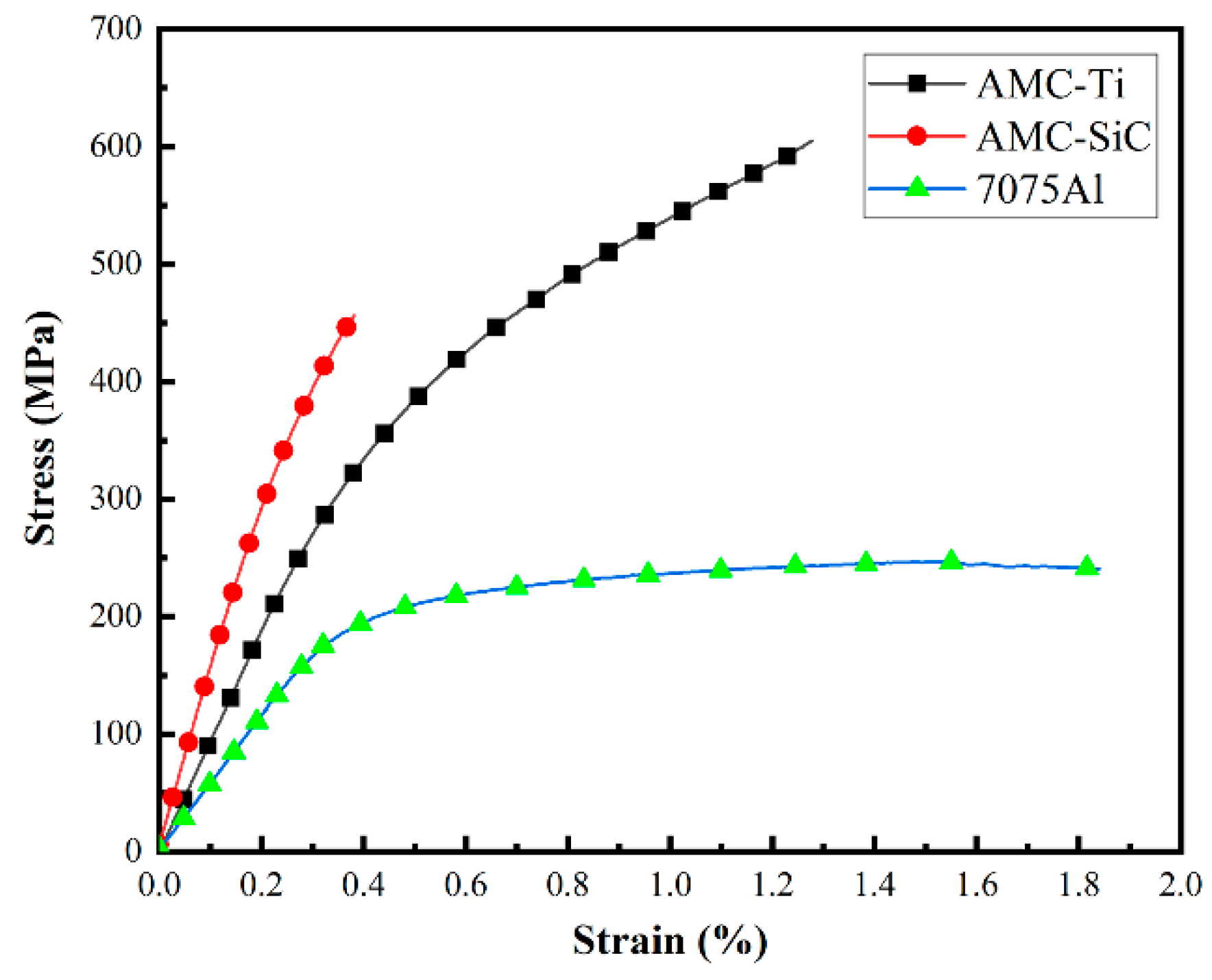

| Materials | E (GPa) | σy (MPa) | σmax (MPa) | εf (%) |

|---|---|---|---|---|

| AMC-SiC | 155 ± 10 | 423 ± 27 | 460 ± 19 | 0.39 ± 0.05 |

| AMC-Ti | 100 ± 13 | 488 ± 33 | 623 ± 17 | 1.20 ± 0.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zheng, Z.; Cao, G.; Zhu, D.; Yang, C.; Luo, M. Interface Structure and Mechanical Properties of 7075Al Hybrid Composite Reinforced with Micron Ti Metal Particles Using Pressure Infiltration. Metals 2019, 9, 763. https://doi.org/10.3390/met9070763

Liu Y, Zheng Z, Cao G, Zhu D, Yang C, Luo M. Interface Structure and Mechanical Properties of 7075Al Hybrid Composite Reinforced with Micron Ti Metal Particles Using Pressure Infiltration. Metals. 2019; 9(7):763. https://doi.org/10.3390/met9070763

Chicago/Turabian StyleLiu, Yixiong, Zhenxing Zheng, Genghua Cao, Dezhi Zhu, Chao Yang, and Mingqiang Luo. 2019. "Interface Structure and Mechanical Properties of 7075Al Hybrid Composite Reinforced with Micron Ti Metal Particles Using Pressure Infiltration" Metals 9, no. 7: 763. https://doi.org/10.3390/met9070763

APA StyleLiu, Y., Zheng, Z., Cao, G., Zhu, D., Yang, C., & Luo, M. (2019). Interface Structure and Mechanical Properties of 7075Al Hybrid Composite Reinforced with Micron Ti Metal Particles Using Pressure Infiltration. Metals, 9(7), 763. https://doi.org/10.3390/met9070763