Interfacial Characteristics of Dissimilar Ti6Al4V/AA6060 Lap Joint by Pulsed Nd:YAG Laser Welding

Abstract

:1. Introduction

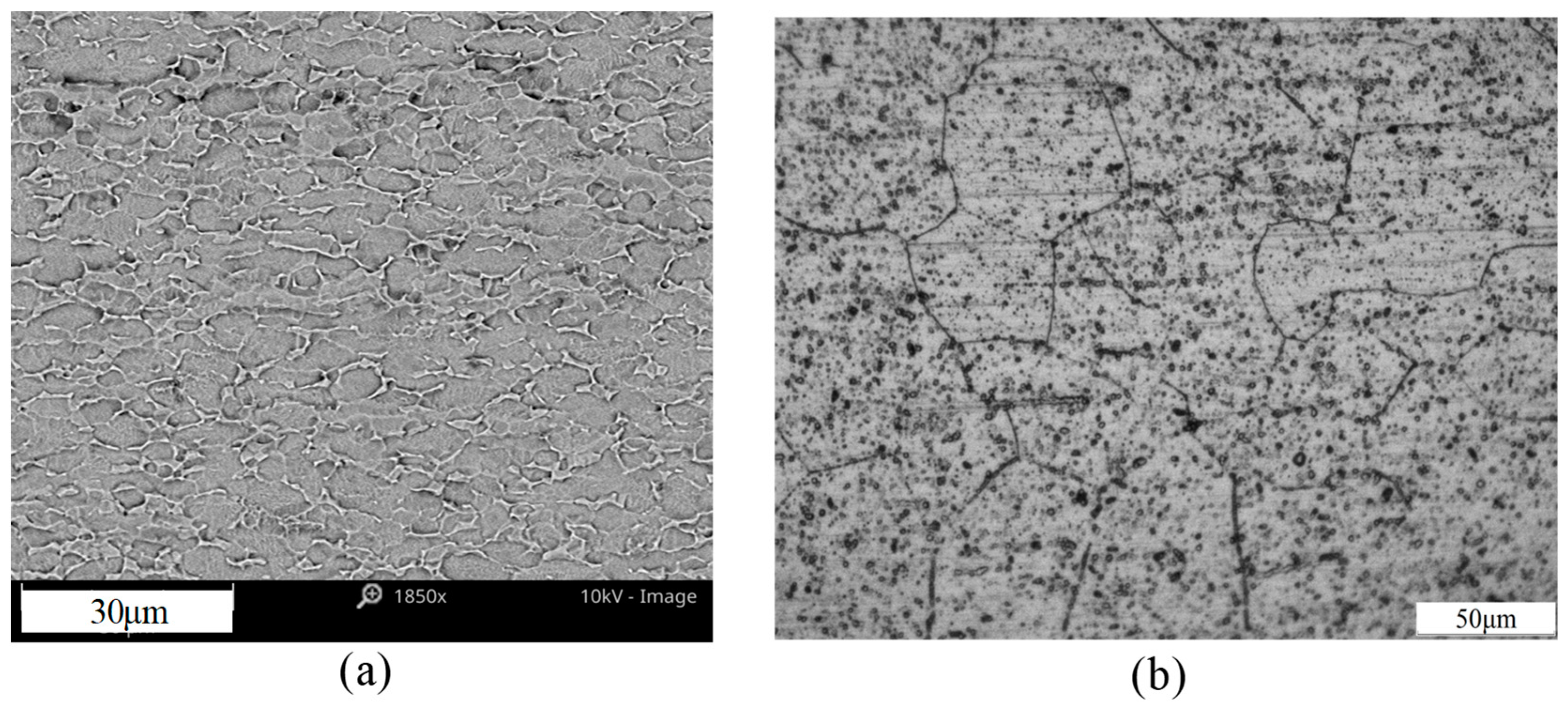

2. Base Materials

3. Experimental Procedures

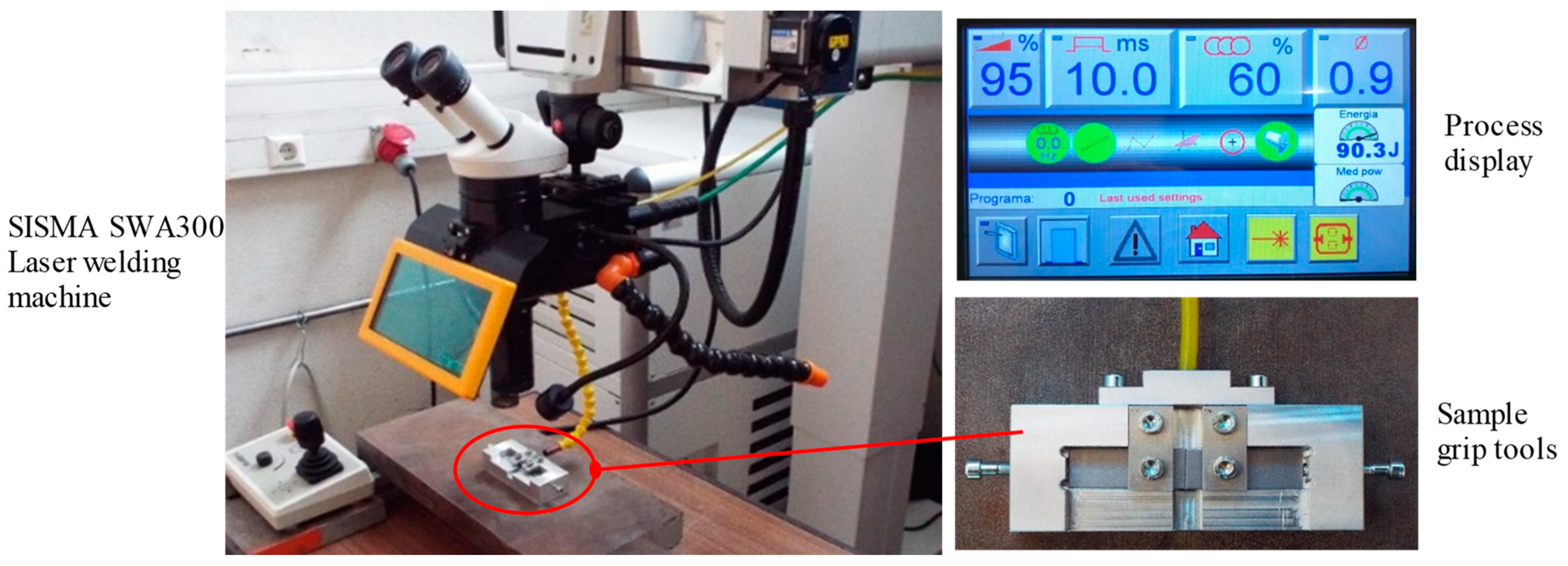

3.1. Pulsed Nd:YAG Laser Welding

3.2. Interface Characterizations

3.3. Mechanical Test

4. Results and Discussions

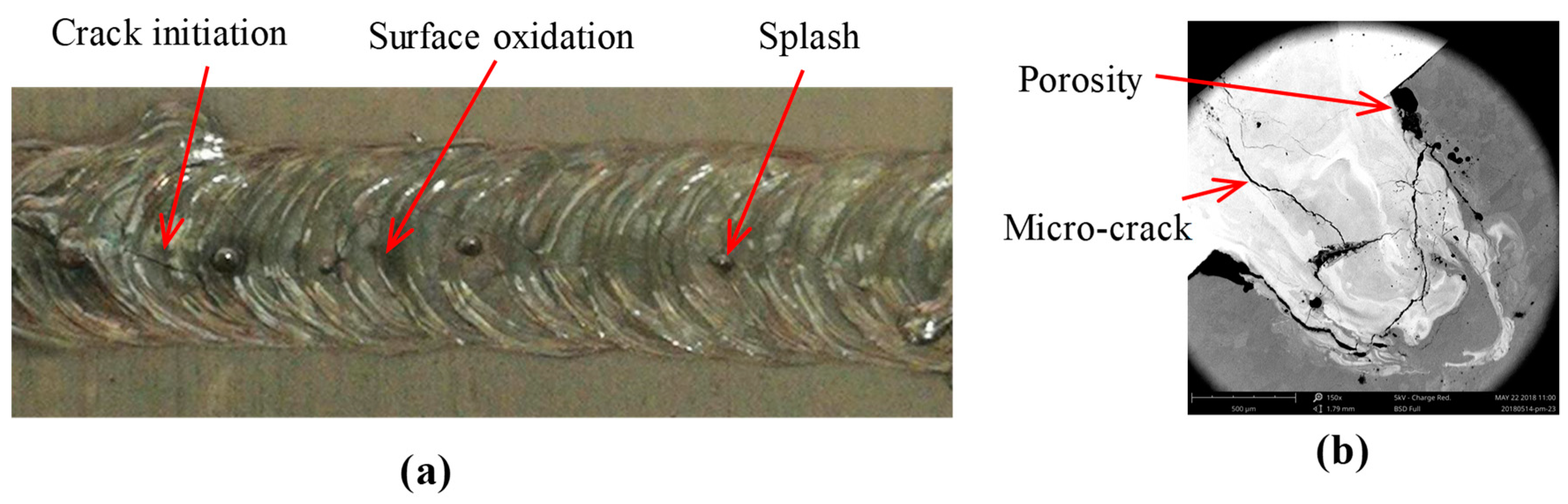

4.1. Influence of Pulsed Nd:YAG Laser Parameters on Tensile Shear Strength

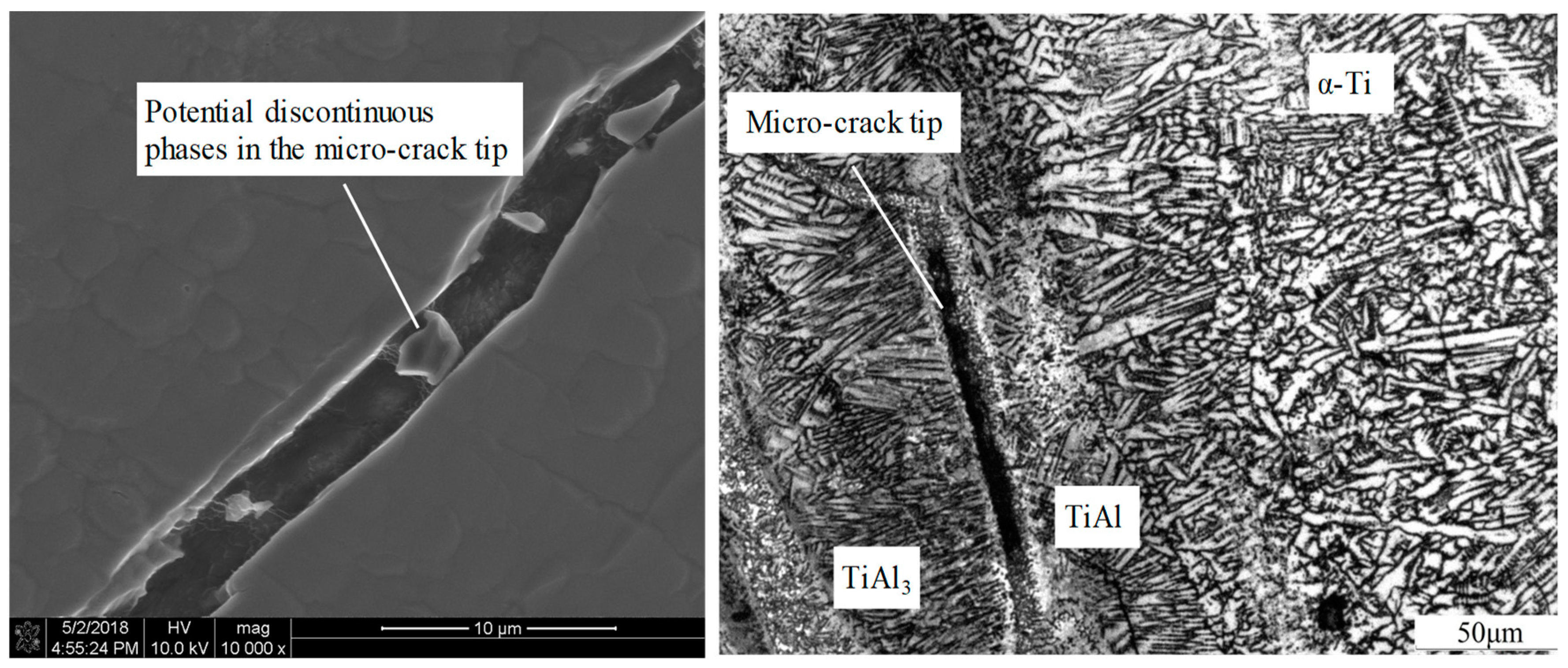

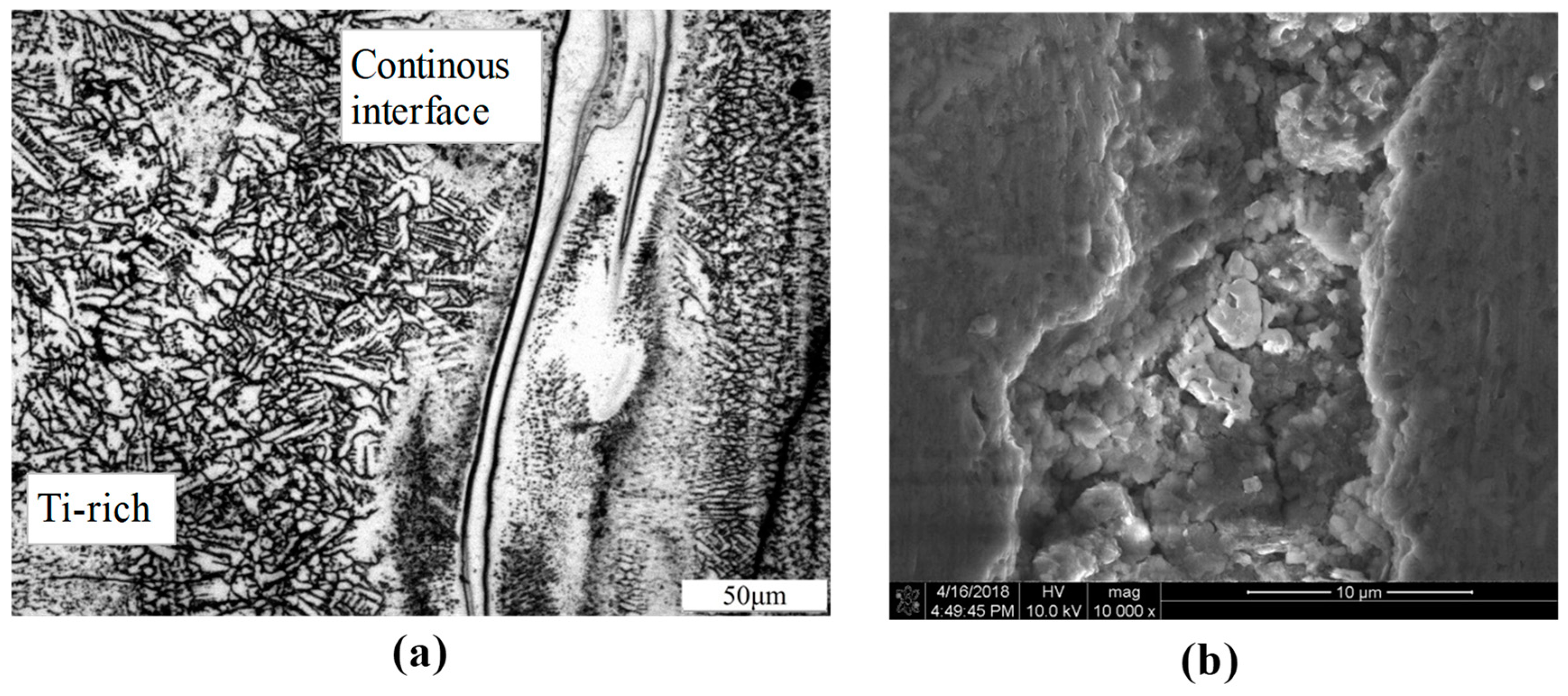

4.2. Estimation of Interfacial Crack Initiation of Dissimilar Ti6Al4V/AA6060 Lap Joint

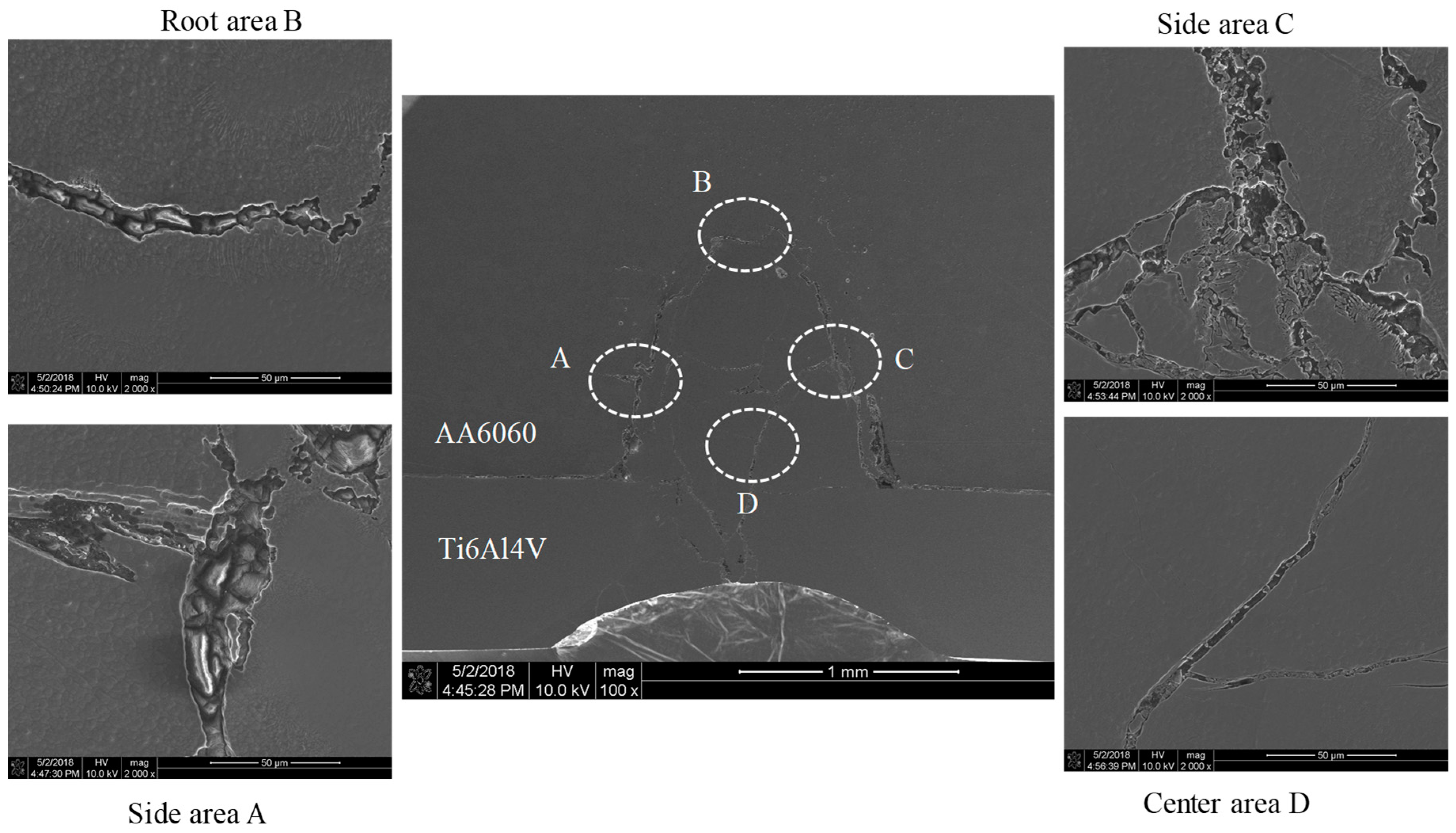

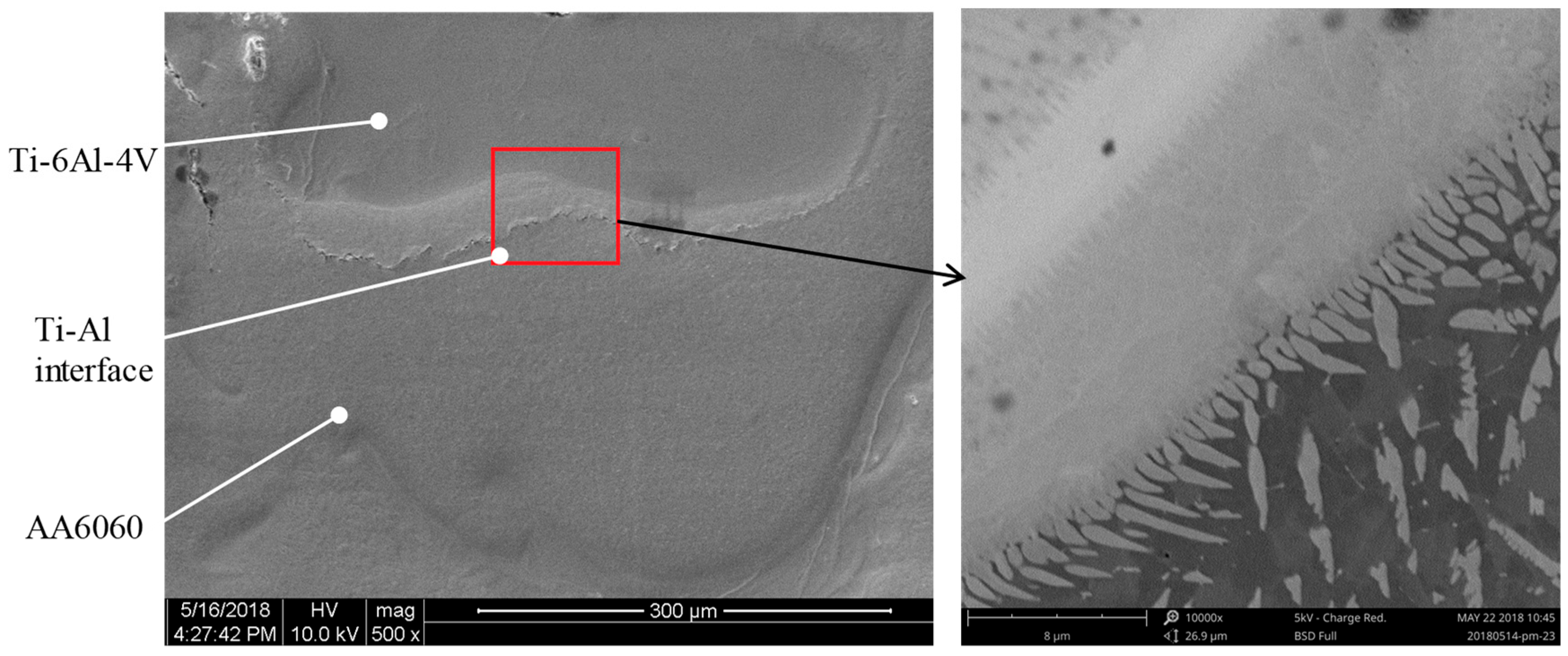

4.3. Interface Microstructural Characterizations of Dissimilar Ti6Al4V/AA6060 Lap Joint

5. Conclusions

- (1)

- By using the orthogonal experimental design method, the sensitivity order of the selected key process parameters on peak shear strength was: overlap, duration, laser beam diameter and power percent. One group of relatively optimal process parameters was: 90% power, 9 ms duration, 50% overlap and 1.0 mm laser beam diameter.

- (2)

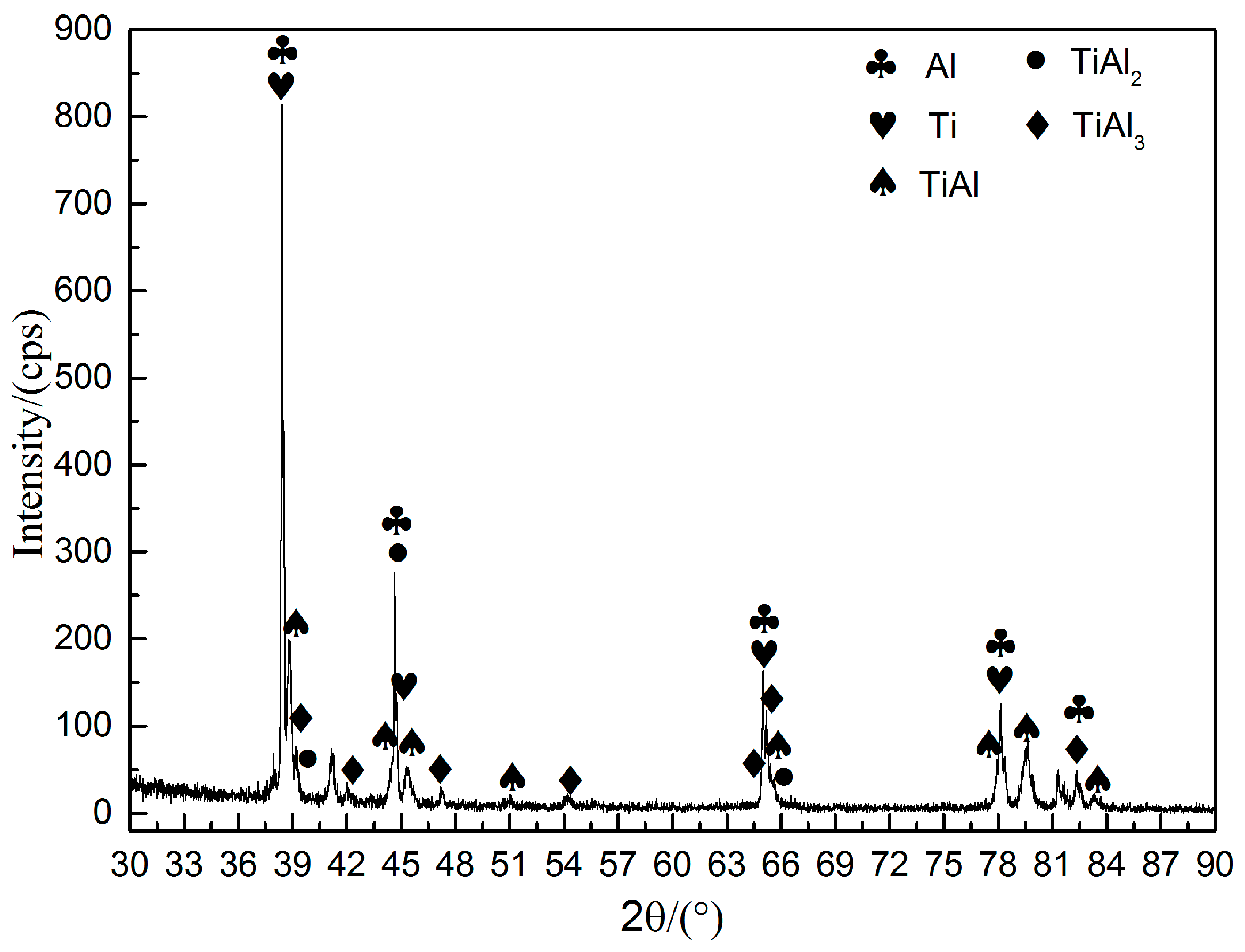

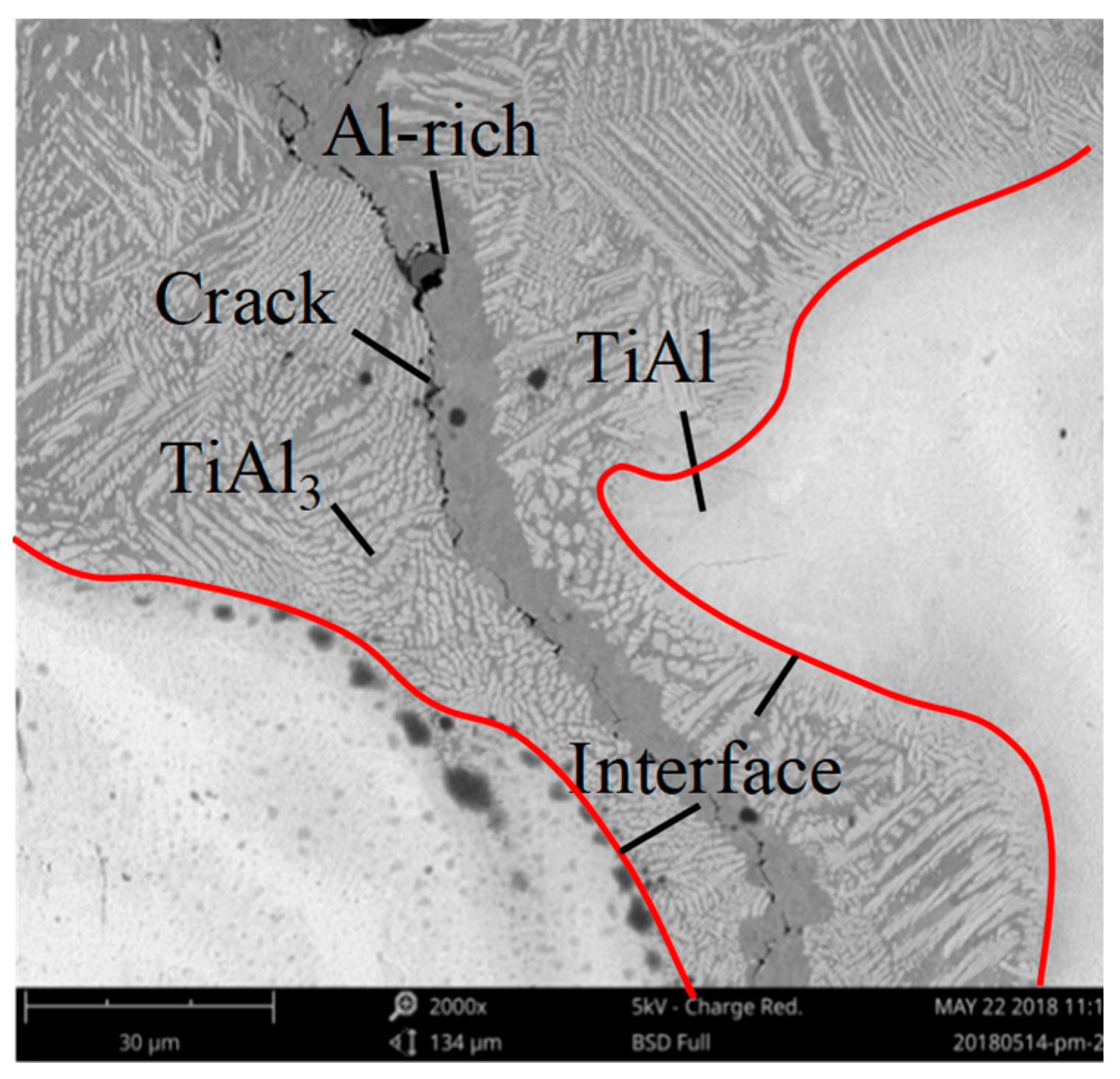

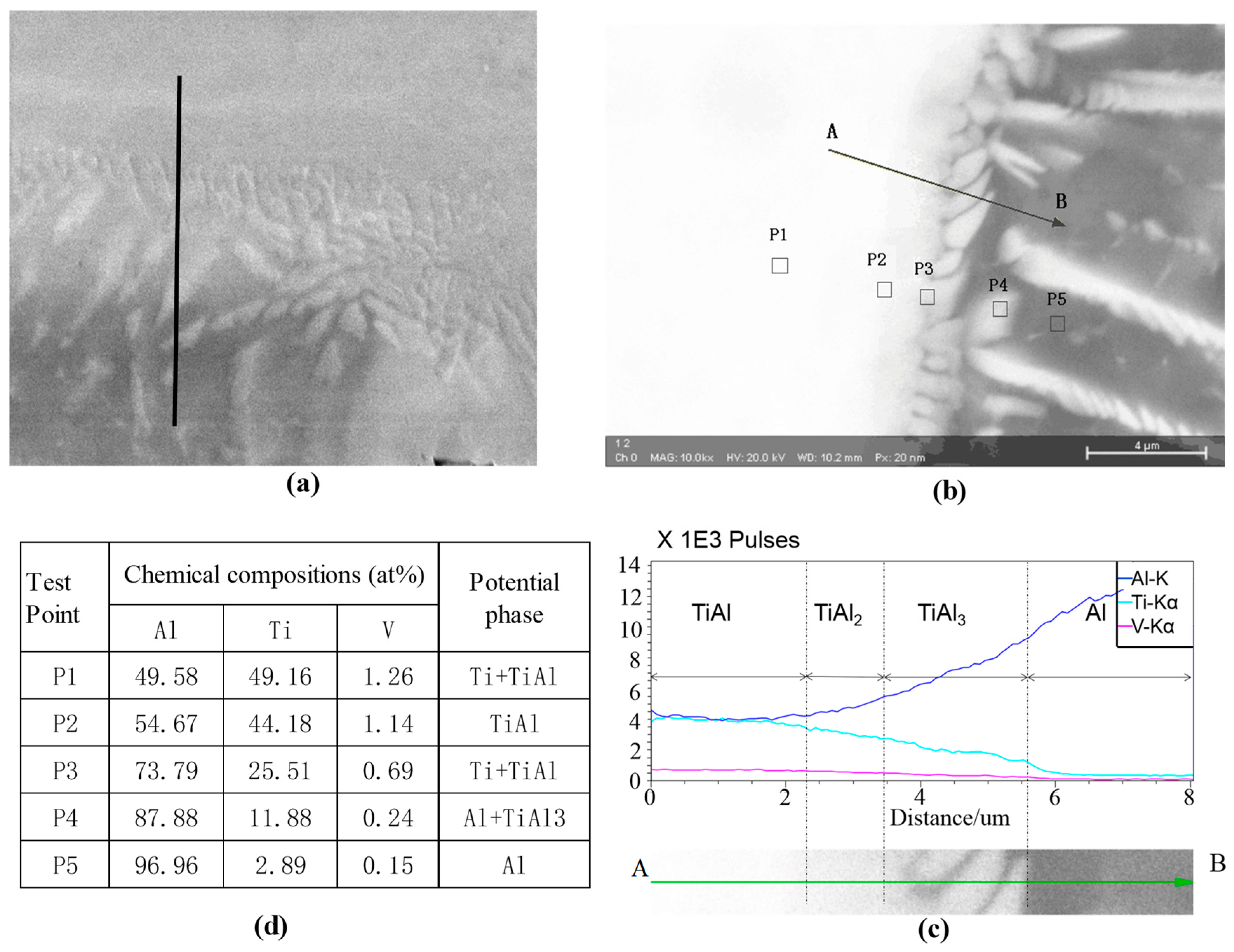

- The potential phases TiAl, TiAl2, and TiAl3 were observed near the Ti/Al interface. The phase change was situated mainly in Al-rich melted zone. However, sometimes it crosses interface and even touches Ti-rich melted zone as some quantities of intermetallic phase were also present. The estimation of interfacial crack initiation was analyzed and discussed in detail.

- (3)

- The discontinuous potential phases in the micro-crack tip can lead to mitigating the mechanical strength or performance of the welded joint, and a better jointing performance under pulsed Nd:YAG laser welding process may be obtained with the formation of continuous intermetallic layer.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, S.; Li, L.; Chen, Y.; Huang, J. Improving interfacial reaction nonhomogeneity during laser welding-brazing aluminum to titanium. Mater. Des. 2011, 32, 3913–3919. [Google Scholar] [CrossRef]

- Suhuddin, U.F.H.; Fischer, V.; Kostka, A.; Santos, J.F. Microstructure evolution in refill friction stir spot weld of a dissimilar Al–Mg alloy to Zn-coated steel. Sci. Technol. Weld. Join. 2017, 22, 658–665. [Google Scholar] [CrossRef]

- Ege, E.S.; Inal, O.T. Stability of interfaces in explosively welded aluminium titanium laminates. J. Mater. Sci. Lett. 2000, 19, 1533–1535. [Google Scholar] [CrossRef]

- Song, Z.; Nakata, K.; Wu, A.; Liao, J. Interfacial microstructure and mechanical property of Ti6Al4V/AA6061 dissimilar joint by direct laser brazing without filler metal and groove. Mater. Sci. Eng. A 2013, 560, 111–120. [Google Scholar] [CrossRef]

- Yang, J.; Yu, Z.S.; Li, Y.L.; Zhang, H.; Guo, W.; Zhou, N. Influence of alloy elements on microstructure and mechanical properties of Al/steel dissimilar joint by laser welding/brazing. Weld. World 2018, 62, 427–433. [Google Scholar] [CrossRef]

- Wang, T.H.; Shivakant, S.; Frank, M.; Mishra, R.S. Evolution of bond formation and fracture process of ultrasonic spot welded dissimilar materials. Sci. Technol. Weld. J. 2019, 24, 171–177. [Google Scholar] [CrossRef]

- Tang, J.M.; Shen, Y.F. Effects of preheating treatment on temperature distribution and material flow of aluminum alloy and steel friction stir welds. J. Manuf. Process. 2017, 29, 29–40. [Google Scholar] [CrossRef]

- Sambasiva Rao, A.; Madhusudhan Reddy, G.; Satya Prasad, K. Microstructure and tensile properties of dissimilar metal gas tungsten arc welding of aluminium to titanium alloy. Mater. Sci. Technol. 2011, 27, 65–70. [Google Scholar] [CrossRef]

- Chang, S.Y.; Tsao, L.C.; Lei, Y.H.; Mao, S.M.; Huang, C.H. Brazing of 6061aluminum alloy/Ti6Al4V using Al–Si–Cu–Ge filler metals. J. Mater. Process. Technol. 2012, 212, 8–14. [Google Scholar] [CrossRef]

- Vaidya, W.V.; Horstmann, M.; Ventzke, V.; Pertovski, B.; Kocak, M.; Kocik, R.; Tempus, G. Improving interfacial properties of a laser beam welded dissimilar joint of aluminum AA6056 and titanium Ti6Al4V for aeronautical applications. J. Mater. Sci. 2010, 45, 6242–6254. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Chen, Y.; Huang, J. Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process. J. Alloys Compd. 2011, 509, 891–898. [Google Scholar] [CrossRef]

- Majumda, B.; Galun, R.; Weisheit, A.; Mordike, B.L. Formation of crack-free joint between Ti-alloy and Al alloy by using a high-power CO2 laser. J. Mater. Sci. 1997, 32, 6191–6200. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Robson, J.D.; Prangnell, P.B. Dissimilar ultrasonic spot welding of aerospace aluminum alloy AA2139 to titanium alloy TiAl6V4. J. Mater. Process. Technol. 2016, 231, 382–399. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Peyre, P. Yb–YAG laser offset welding of AA5754 and T40 butt joint. J. Mater. Process. Technol. 2015, 223, 139–149. [Google Scholar] [CrossRef]

- Fabbro, R. Developments in Nd–Yag laser welding. In Handbook of Laser Welding Technologies; Katayama, S., Ed.; Woodhead Publishing Limited: Oxford, UK, 2013; pp. 47–72. [Google Scholar]

- Ren, J.W.; Li, Y.J.; Feng, T. Microstructure characteristics in the interface zone of Ti/Al diffusion bonding. Mater. Lett. 2002, 56, 647–652. [Google Scholar]

- Tomashchuk, I.; Sallamand, P.; Jouvard, J.M.; Grevey, D. The simulation of morphology of dissimilar copper–steel electron beam welds using level set method. Comput. Mater. Sci. 2010, 48, 827–836. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Andrzejewski, H.; Grevey, D. The formation of intermetallics in dissimilar Ti6Al4V/copper/AISI 316 L electron beam and Nd:YAG laser joints. Intermetallics 2011, 19, 1466–1473. [Google Scholar] [CrossRef]

- Oliveira, A.C.; Moreira, A.F.R.; Mello, C.B.; Riva, R.; Oliveira, R.M. Influence of Si coating on interfacial microstructure of laser joining of titanium and aluminium alloys. Mater. Res. 2018, 21, e20161109. [Google Scholar] [CrossRef]

- Xue, X.; Liao, J.; Vincze, G.; Pereira, A.B. Control strategy of twist springback for aluminium alloy hybrid thin-walled tube after mandrel-rotary draw bending. Int. J. Mater. Form. 2018, 11, 311–323. [Google Scholar] [CrossRef]

- He, P.G.; Chen, K.; Yu, B.; Yue, C.Y.; Yang, J.L. Surface microstructures and epoxy bonded shear strength of Ti6Al4V alloy anodized at various temperatures. Compos. Sci. Technol. 2013, 82, 15–22. [Google Scholar] [CrossRef]

- Squillace, A.; Prisco, U.; Ciliberto, S.; Astarita, A. Effect of welding parameters on morphology and mechanical properties of Ti6Al4V laser beam welded butt joints. J. Mater. Process. Technol. 2012, 212, 427–436. [Google Scholar] [CrossRef]

- Vaithilingam, J.; Goodridge, R.D.; Richard, J.M.; Hague, R.J.M.; Christie, S.D.R.; Edmondson, S. The effect of laser remelting on the surface chemistry of Ti6Al4V components fabricated by selective laser melting. J. Mater. Process. Technol. 2016, 232, 1–8. [Google Scholar] [CrossRef]

- Louvis, E.; Fox, P.; Christopher, J.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Moller, F.; Grden, M.; Thomy, C.; Vollertsen, F. Combined laser beam welding and brazing process for aluminium titanium hybrid structures. Phys. Procedia 2011, 12, 215–223. [Google Scholar] [CrossRef]

- Saida, K.; Ohnishi, H.; Nishimoto, K. Laser brazing of TiAl intermetallic compound using precious brazing filler metals. Weld. World 2015, 59, 9–22. [Google Scholar] [CrossRef]

- Cam, G.; Koçak, M. Progress in joining of advanced materials Part 2: Joining of metal matrix composites and joining of other advanced materials. Sci. Technol. Weld. Join. 1998, 3, 159–175. [Google Scholar] [CrossRef]

- Kanazawa, H. Welding performance of high power YAG lasers in aluminium alloys. J. Light Met. Weld. Constr. 1997, 35, 10–15. [Google Scholar] [CrossRef]

- Ion, J.C. Laser beam welding of wrought aluminium alloys. Sci. Technol. Weld. Join. 2013, 5, 265–276. [Google Scholar] [CrossRef]

- Eisazadeh, H.; Bunn, J.; Coules, H.E.; Achuthan, A.; Goldak, J.; Aidun, D.K. A residual stress study in similar and dissimilar welds. Weld. J. 2016, 95, 111–119. [Google Scholar]

- Liu, F.; Liu, Y.; Wu, Y.C. Effect of lattice matching degree and intermetallic compound on the properties of Mg/Al dissimilar material welded joints. Sci. Technol. Weld. Join. 2017, 22, 719–725. [Google Scholar] [CrossRef]

| Ti6Al4V | Al | V | Fe | O | Si | C | N | H | Other Elements | Ti |

| 5.5–6.8 | 3.5–4.5 | 0.3 | 0.2 | 0.15 | 0.10 | 0.05 | 0.01 | 0.5 | Balance | |

| AA6060 | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | |

| Balance | 0.3–0.6 | 0.1–0.3 | ≤0.10 | ≤0.10 | 0.35–0.6 | ≤0.05 | ≤0.15 | ≤0.10 |

| Material | Density (Kg/m3) | Melting Point (°C) | Specific Heat (J/Kg·°C) | Thermal Conductivity W/(M·K) | Thermal Expansion Coefficient (°C) | Shear Strength (Mpa) |

|---|---|---|---|---|---|---|

| Ti6Al4V | 4.44 × 103 | 1660 | 610 | 7.955 | 8.6 × 10−6 | 760 |

| AA6060 | 2.70 × 103 | 657 | 934.8 | 167 | 23.4 × 10−6 | 56 |

| No. | Process Configurations | Parameters |

|---|---|---|

| 1 | Source type | Nd:YAG (flash lamp) |

| 2 | Laser beam transport | Fiber-coupled |

| 3 | Average laser power | 300 W |

| 4 | Peak laser power | 12 kW |

| 5 | Wave length | 1064 nm |

| 6 | Spot diameter | 0.6–2.0 mm |

| 7 | Maximum pulse energy | 100 J |

| 8 | Pulse range | 0.2–25 ms |

| 9 | Argon shielding gas purity | 99.99% |

| 10 | Maximum focusing optics | 120 mm |

| Sample No. | Power Percent (%) | Duration (ms) | Overlap (%) | Laser Beam Diameter (mm) | Peak Shear Strength (MPa) |

|---|---|---|---|---|---|

| TA1 | 80 | 8 | 50 | 0.8 | 35.87 |

| TA2 | 80 | 9 | 60 | 0.9 | 37.25 |

| TA3 | 80 | 10 | 70 | 1.0 | 32.06 |

| TA4 | 90 | 8 | 60 | 1.0 | 37.81 |

| TA5 | 90 | 9 | 70 | 0.8 | 35.27 |

| TA6 | 90 | 10 | 50 | 0.9 | 37.44 |

| TA7 | 95 | 8 | 70 | 0.9 | 29.74 |

| TA8 | 95 | 9 | 50 | 1.0 | 43.43 |

| TA9 | 95 | 10 | 60 | 0.8 | 34.52 |

| K1 | 35.060 | 34.473 | 38.913 | 35.220 | |

| K2 | 36.840 | 38.650 | 36.527 | 34.810 | |

| K3 | 35.897 | 34.673 | 32.357 | 37.767 | |

| Variation Range (R) | 1.780 | 4.177 | 6.556 | 2.957 | |

| Sensitivity Order | 4 | 2 | 1 | 3 | |

| Optimal Value | 90 | 9 | 50 | 1.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, X.; Pereira, A.; Vincze, G.; Wu, X.; Liao, J. Interfacial Characteristics of Dissimilar Ti6Al4V/AA6060 Lap Joint by Pulsed Nd:YAG Laser Welding. Metals 2019, 9, 71. https://doi.org/10.3390/met9010071

Xue X, Pereira A, Vincze G, Wu X, Liao J. Interfacial Characteristics of Dissimilar Ti6Al4V/AA6060 Lap Joint by Pulsed Nd:YAG Laser Welding. Metals. 2019; 9(1):71. https://doi.org/10.3390/met9010071

Chicago/Turabian StyleXue, Xin, António Pereira, Gabriela Vincze, Xinyong Wu, and Juan Liao. 2019. "Interfacial Characteristics of Dissimilar Ti6Al4V/AA6060 Lap Joint by Pulsed Nd:YAG Laser Welding" Metals 9, no. 1: 71. https://doi.org/10.3390/met9010071

APA StyleXue, X., Pereira, A., Vincze, G., Wu, X., & Liao, J. (2019). Interfacial Characteristics of Dissimilar Ti6Al4V/AA6060 Lap Joint by Pulsed Nd:YAG Laser Welding. Metals, 9(1), 71. https://doi.org/10.3390/met9010071