Ultrafast Heating and Initial Microstructure Effect on Phase Transformation Evolution of a CrMo Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Compositions of the Experimental Steels

2.2. Heat Treatment

2.3. Microstructural Characterization

2.4. Modelling of the Microstructure

3. Results

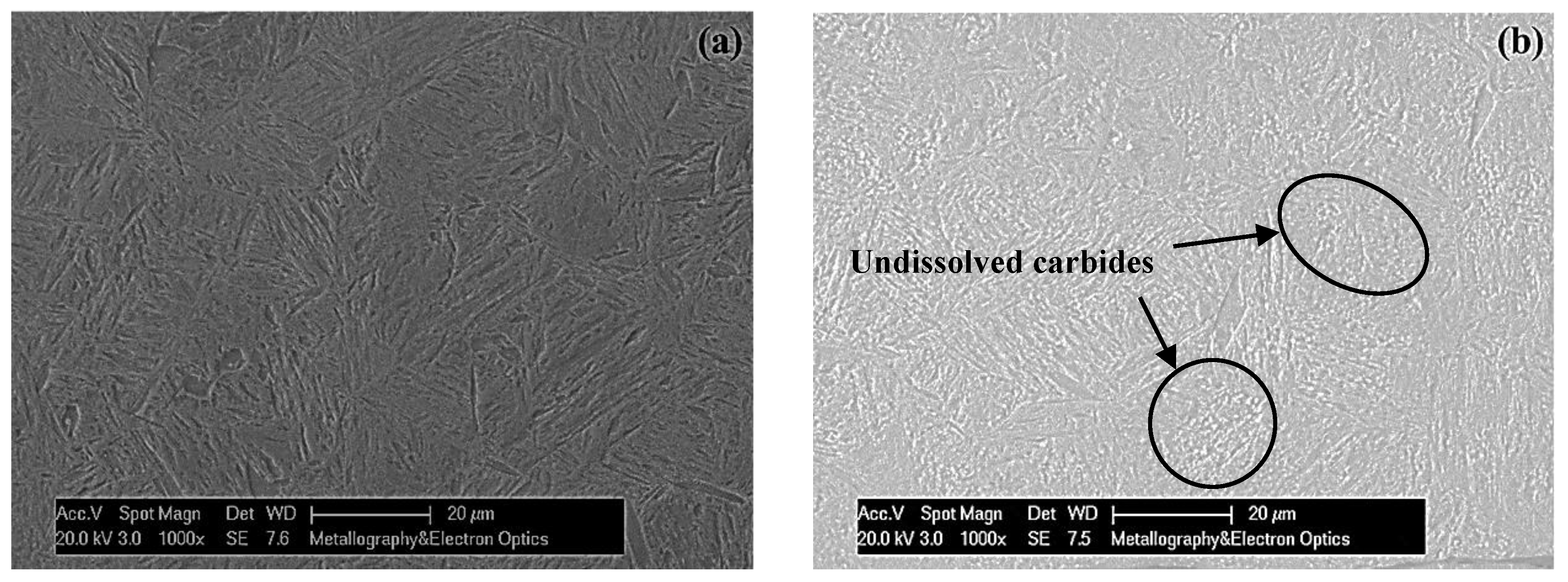

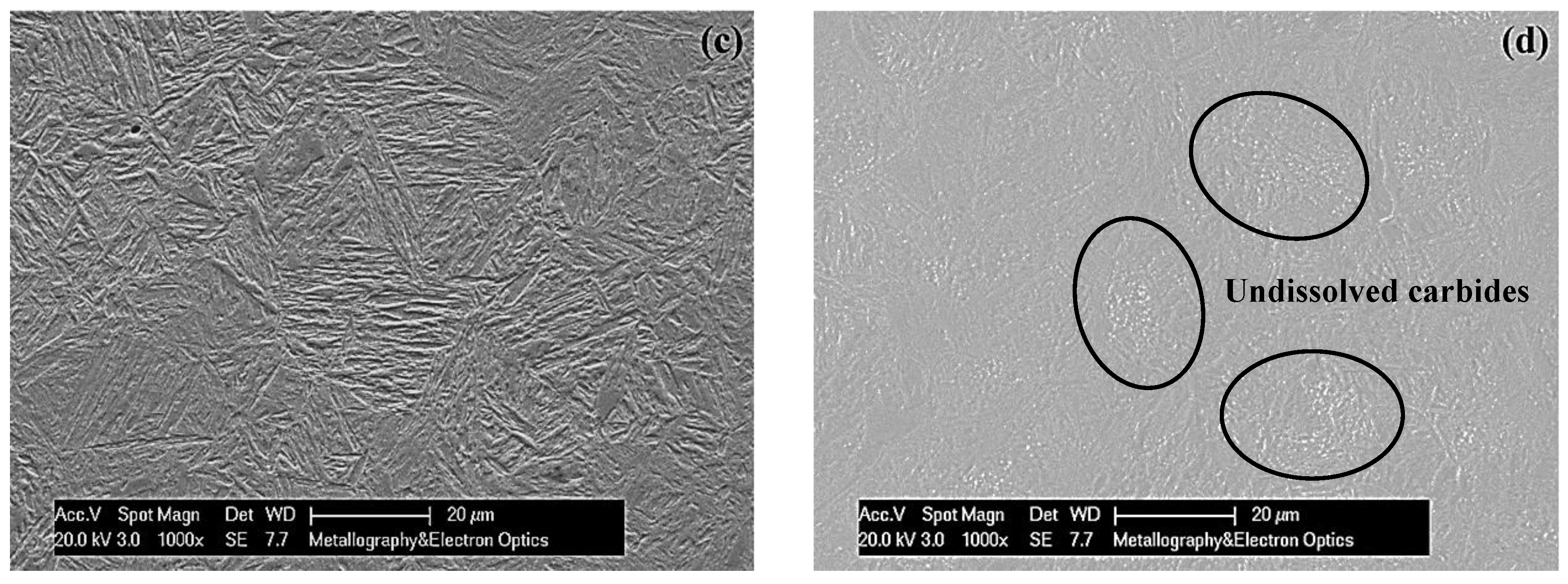

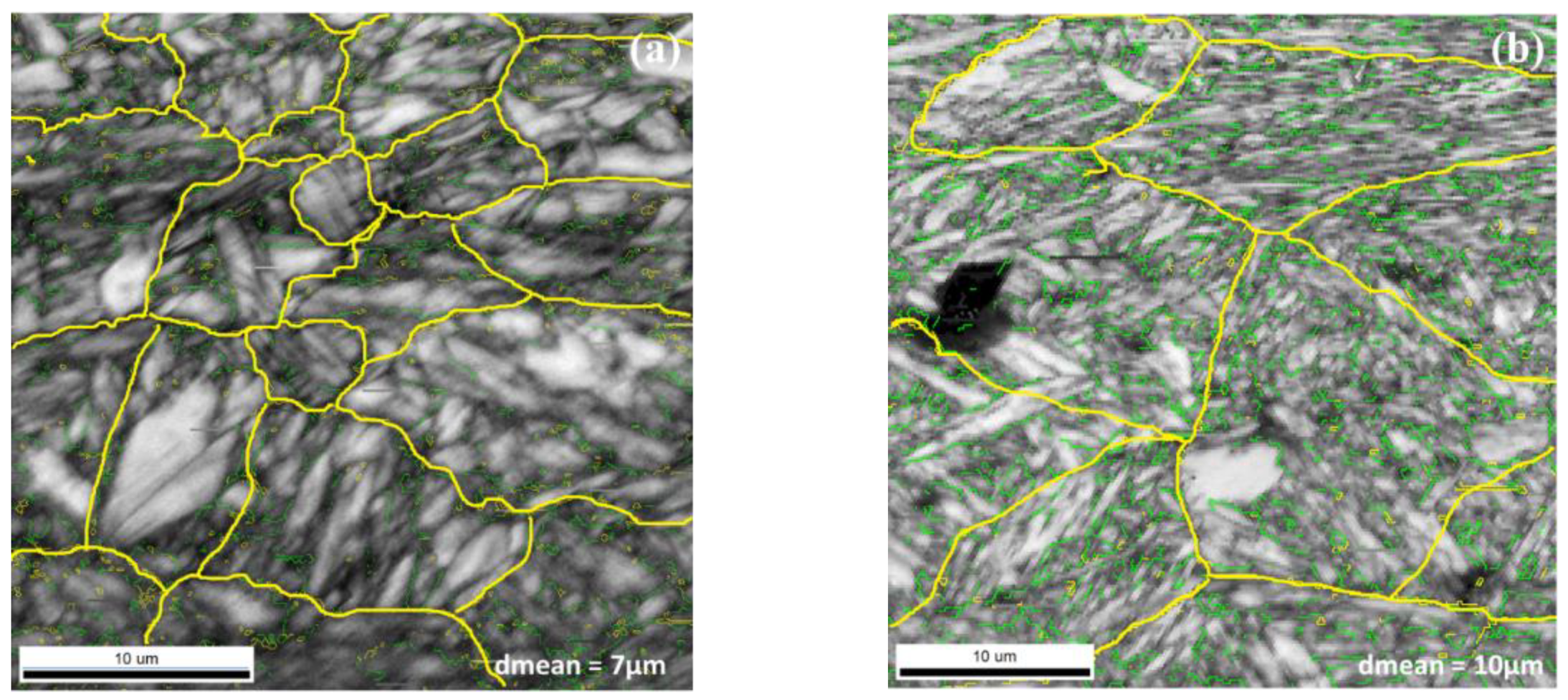

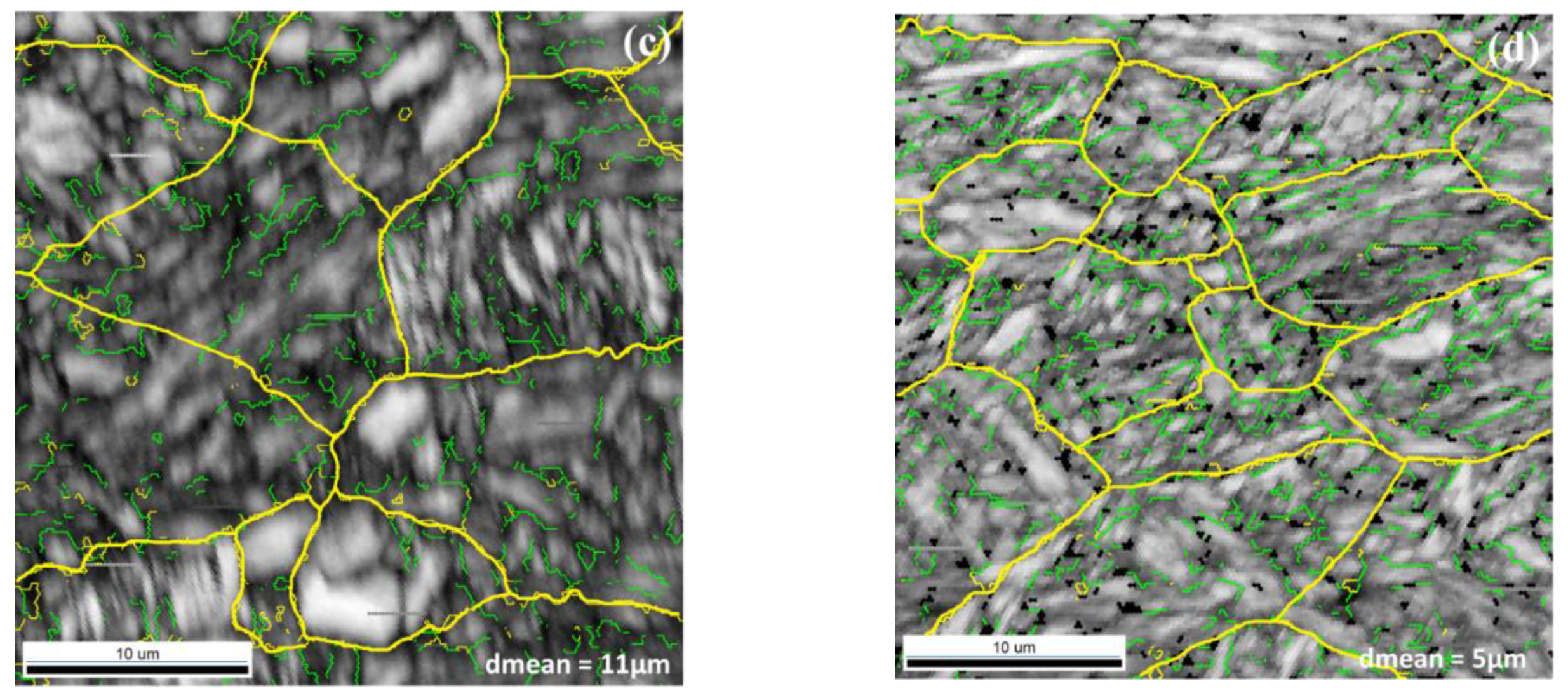

3.1. Microstructural Analysis

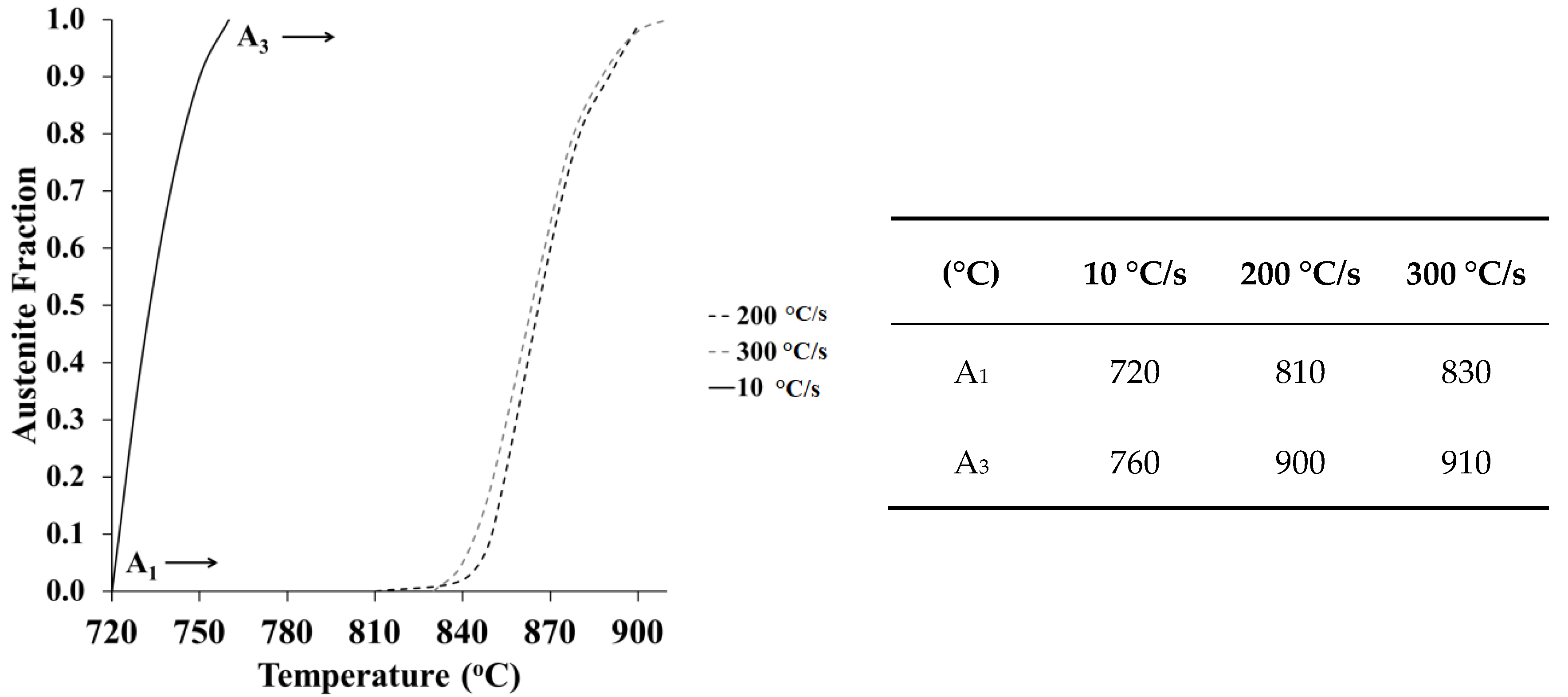

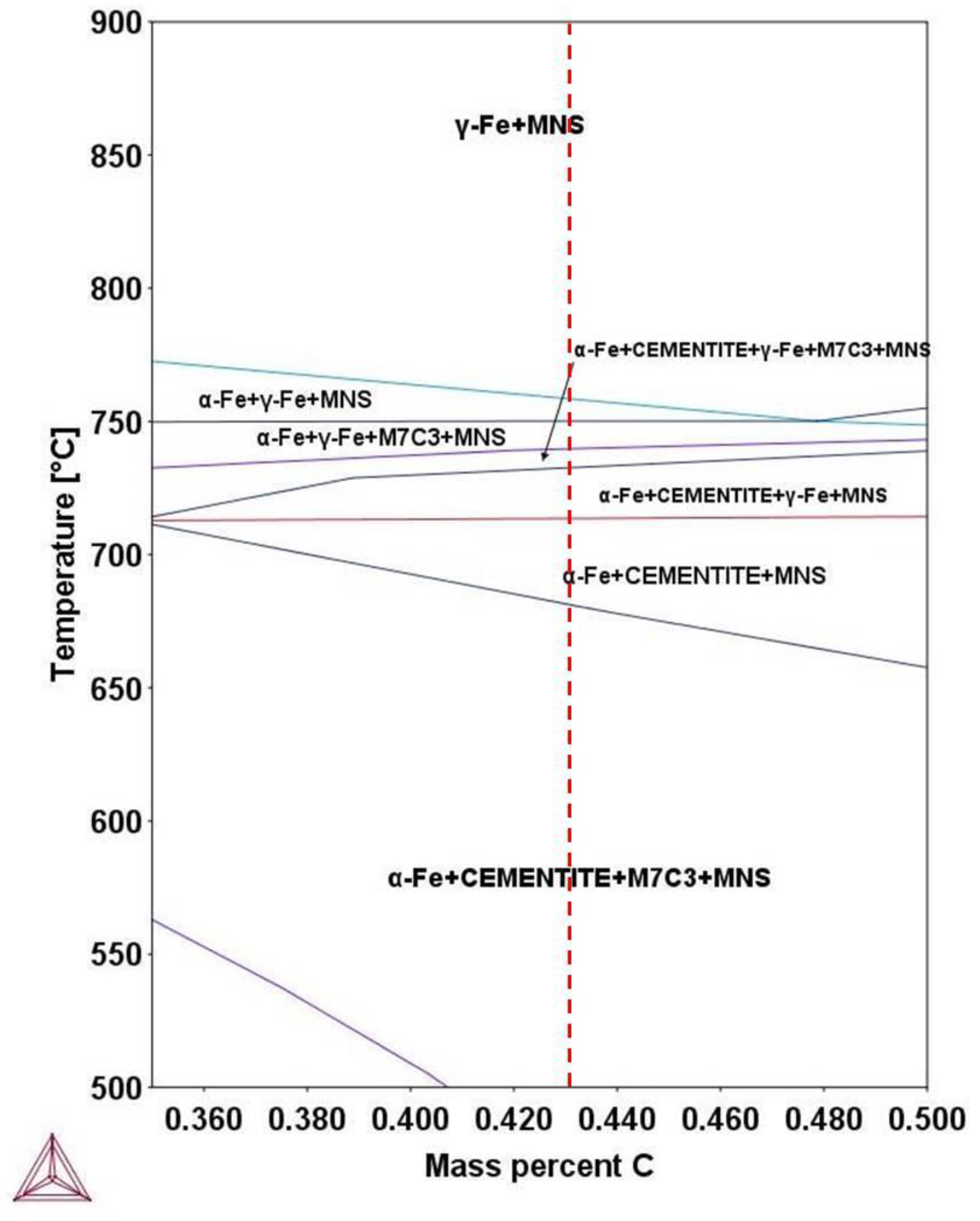

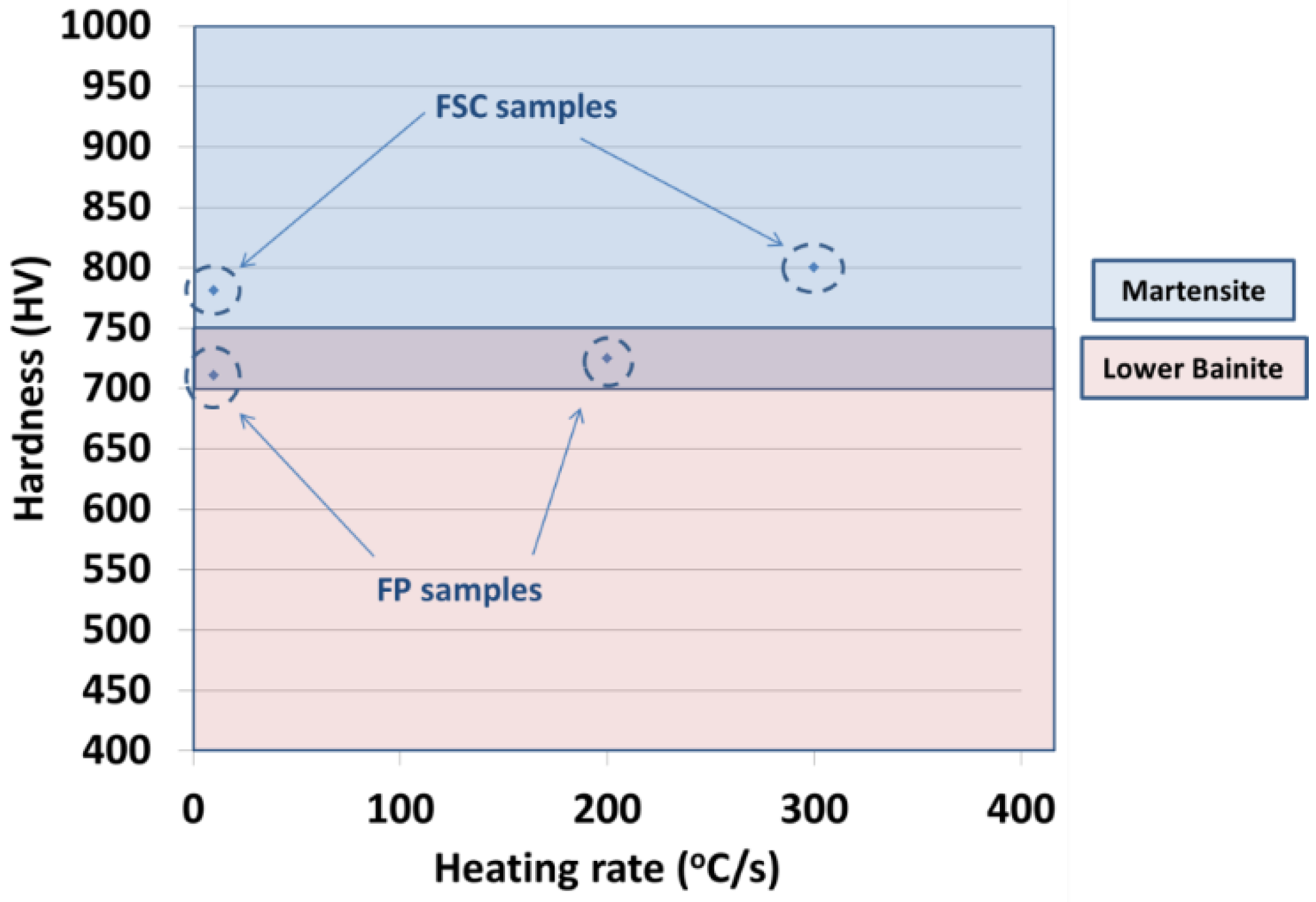

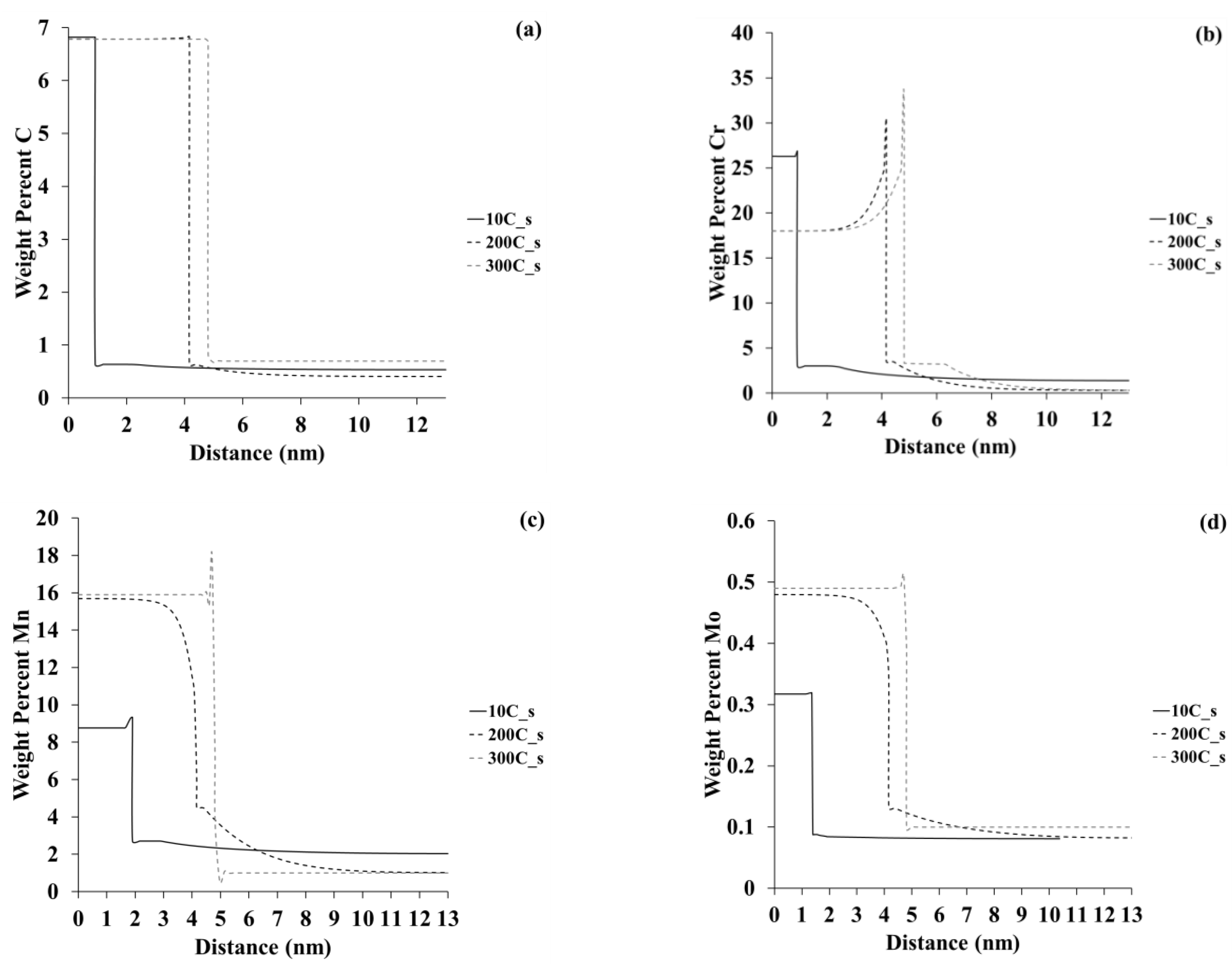

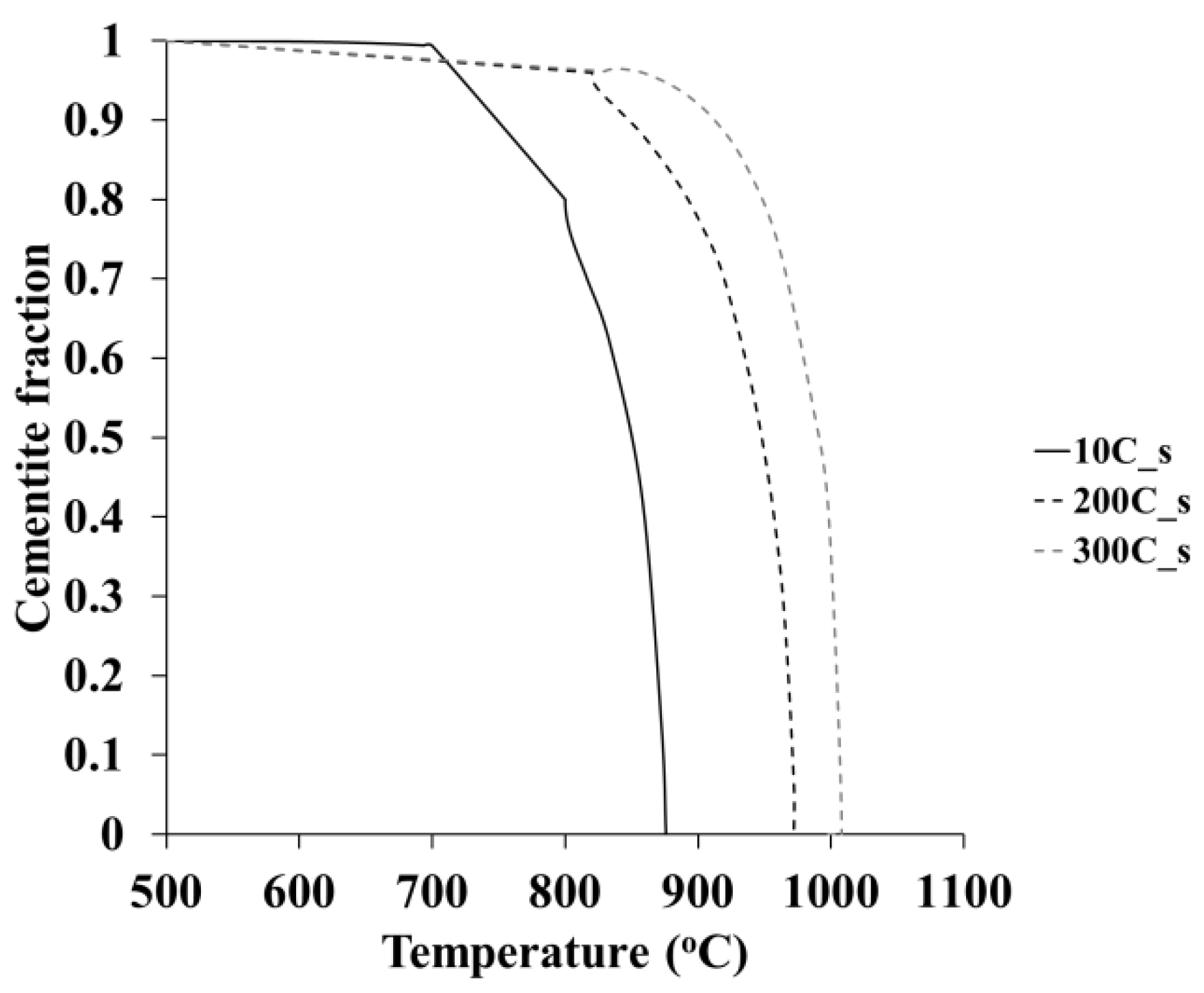

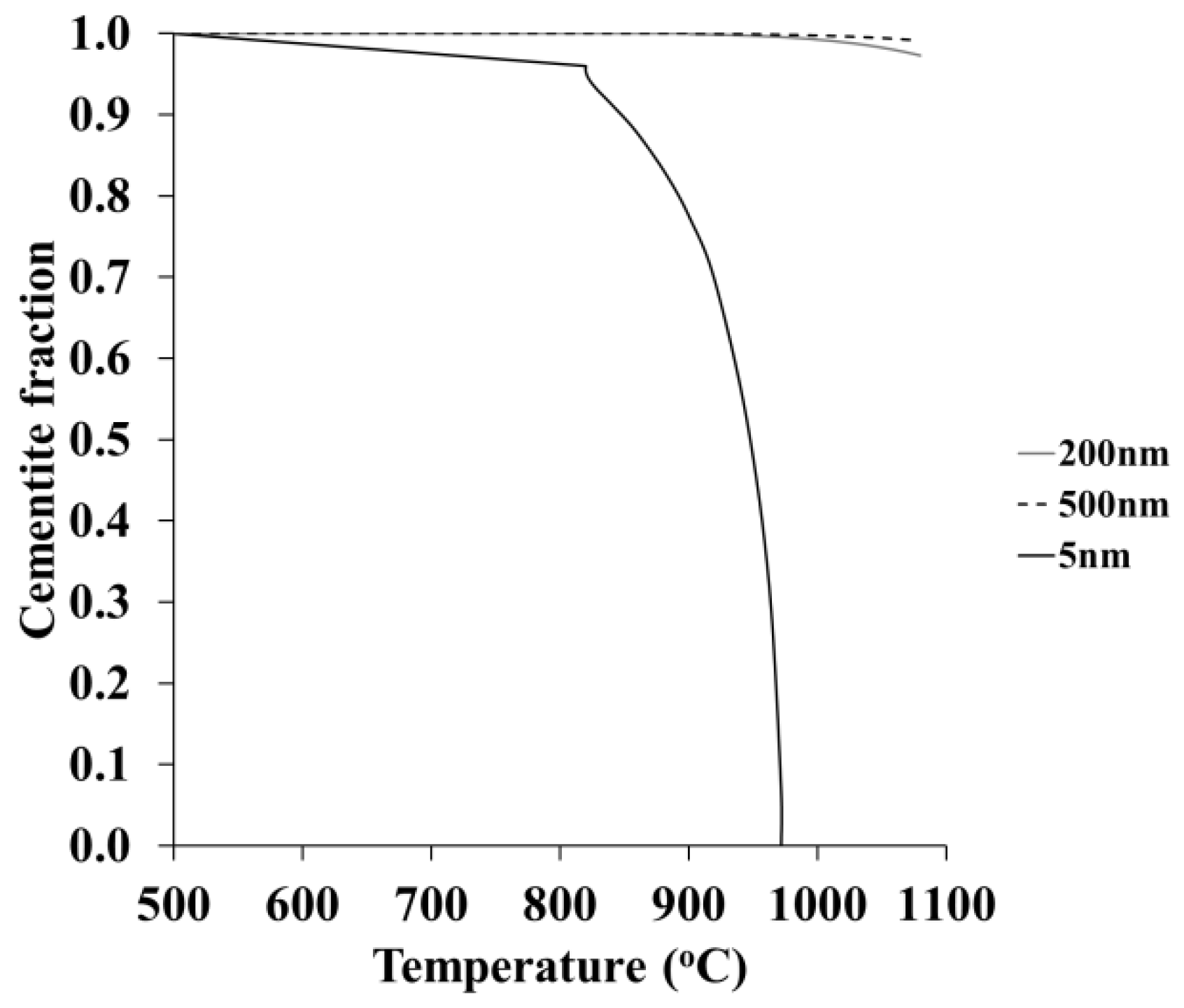

3.2. Modelling Results

4. Discussion

4.1. Effect of Rapid Heating on the Phase Transformation Evolution

4.2. Effect of Initial Microstructure

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lolla, S.V.T. Understanding Microstructure Evolution in Rapid Thermal Processing of AISI 8620 Steel. Ph.D. Dissertation, The Ohio State University, Columbus, OH, USA, 2009. [Google Scholar]

- Lolla, T.; Alexandrov, B.; Babu, S.; Cola, G. Towards understanding the microstructure development during heating and cooling of steels. In Proceedings of the THERMEC ’09, Berlin, Germany, 25–29 August 2009. [Google Scholar]

- Lolla, T.; Cola, G.; Narayanan, B.; Alexandrov, B.; Babu, S.S. Development of rapid heating and cooling (flash processing) process to produce advanced high strength steel microstructures. Mater. Sci. Technol. 2011, 27, 863–875. [Google Scholar] [CrossRef]

- Papaefthymiou, S. A New Opportunity for the Design of Advanced High Strength Steels with Heterogeneous-Phase Microstructures via Rapid Thermal Processing. J. Nanosci. Adv. Tech. 2017, 2, 20–23. [Google Scholar] [CrossRef]

- Cola, G. Properties of bainite nucleated by water quenching in 80 ms. In 1st International Symposium on Steel Science; Iron and Steel Institute of Japan: Tokyo, Japan, 2007. [Google Scholar]

- Zhao, J.; Jiang, Z. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, R.; Zhang, M.; Liu, R.; Wei, X.; Li, L. Bake hardening behaviour of TRIP and DP steels. J. Univ. Sci. Technol. Beijing 2008, 15, 132–137. [Google Scholar] [CrossRef]

- Dong, H.; Hao, X.; Deng, D. Effect of Welding Heat Input on Microstructure and Mechanical Properties of HSLA Steel Joint. Metallogr. Microstruct. Anal. 2014, 3, 138–146. [Google Scholar] [CrossRef]

- Li, H.; Liu, D.; Yan, Y.; Guo, N.; Liu, Y.; Feng, J. Effects of heat input on arc stability and weld quality in underwater wet flux-cored arc welding of E40 steel. J. Manuf. Process. 2018, 31, 833–843. [Google Scholar] [CrossRef]

- Bleck, W.; Papaefthymiou, S.; Frehn, A. Microstructure and Tensile Properties in Dual Phase and Trip Steels. Steel Res. Int. 2004, 75, 704–710. [Google Scholar] [CrossRef]

- Zhang, H.; Ponge, D.; Raabe, D. Designing quadplex (four-phase) microstructures in an ultrahigh carbon steel. Mater. Sci. Eng. A 2014, 612, 46–53. [Google Scholar] [CrossRef]

- Adamczyk, J.; Opiela, M. Influence of the thermo–mechanical treatment parameters on the inhomogeneity of the austenite structure and mechanical properties of the Cr–Mo steel with Nb, Ti and B microadditions. J. Mater. Process. Technol. 2004, 157, 456–461. [Google Scholar] [CrossRef]

- Rudnev, V.; Loveless, D.; Cook, R. Handbook of Induction Heating; Marcell Dekker Inc.: New York, NY, USA, 2003. [Google Scholar]

- Zinn, S.; Semiatin, S. Elements of Induction Heating: Design, Control, and Applications; EPRI, ASM International: Metals Park, OH, USA, 1988. [Google Scholar]

- De Knijf, D.; Puype, A.; Föjer, C.; Petrov, R. The influence of ultra-fast annealing prior to quenching and partitioning on the microstructure and mechanical properties. Mater. Sci. Eng. A 2015, 627, 182–190. [Google Scholar] [CrossRef]

- Cerda, F.M.C.; Goulas, C.; Sabirov, I.; Papaefthymiou, S.; Monsalve, A.; Petrov, R. Microstructure, texture and mechanical properties in a low carbon steel after ultrafast heating. Mater. Sci. Eng. A 2016, 672, 108–120. [Google Scholar] [CrossRef]

- Cerda, F.M.C.; Kestens, L.; Monsalve, A.; Petrov, R. The Effect of Ultrafast Heating in Cold-Rolled Low Carbon Steel: Recrystallization and Texture Evolution. Metals 2016, 6, 288. [Google Scholar] [CrossRef]

- Kaluba, W.; Taillard, R.; Foct, J. The bainitic mechanism of austenite formation during rapid heating. Acta Mater. 1998, 46, 5917–5927. [Google Scholar] [CrossRef]

- Cerda, F.C.; Sabirov, I.; Goulas, C.; Sietsma, J.; Monsalve, A.; Petrov, R. Austenite formation in 0.2% C and 0.45% C steels under conventional and ultrafast heating. Mater. Des. 2017, 116, 448–460. [Google Scholar] [CrossRef]

- Cerda, F.M.C.; Schulz, B.; Papaefthymiou, S.; Artigas, A.; Monsalve, A.; Petrov, R.H. The Effect of Ultrafast Heating on Cold-Rolled Low Carbon Steel: Formation and Decomposition of Austenite. Metals 2016, 6, 321. [Google Scholar] [CrossRef]

- Papaefthymiou, S.; Goulas, C.; Cerda, F.M.C.; Geerlofs, N.; Petrov, R. The Effect of Heating Rate on the Microstructure of a Soft-Annealed Medium Carbon Steel. Steel Res. Int. 2017, 88, 1700158. [Google Scholar] [CrossRef]

- Cerda, F.M.C.; Vercruysse, F.; Goulas, C.; Schulz, B.; Petrov, R.H. ‘Flash’ Annealing in a Cold-Rolled Low Carbon Steel Alloyed With Cr, Mn, Mo and Nb: Part I—Continuous Phase Transformations. Steel Res. Int. 2018. [Google Scholar] [CrossRef]

- Papaefthymiou, S.; Bouzouni, M.; Petrov, R.H. Study of Carbide Dissolution and Austenite Formation during Ultra–Fast Heating in Medium Carbon Chromium Molybdenum Steel. Metals 2018, 8, 646. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Considerations of solute-drag in relation to transformations in steels. J. Mater. Sci. 1983, 18, 1473–1481. [Google Scholar] [CrossRef]

- Ghosh, G.; Olson, G.B. Simulation of paraequilibrium growth in multicomponent systems. Metall. Mater. Trans. A 2001, 32, 455–467. [Google Scholar] [CrossRef]

- Miyamoto, G.; Usuki, H.; Li, Z.-D.; Furuhara, T. Effects of Mn, Si and Cr addition on reverse transformation at 1073K from spheroidized cementite structure in Fe–0.6 mass% C alloy. Acta Mater. 2010, 58, 4492–4502. [Google Scholar] [CrossRef]

- Ollat, M.; Militzer, M.; Massardier, V.; Fabrègue, D.; Buscarlet, E.; Keovilay, F.; Perez, M. Mixed-mode model for ferrite-to-austenite phase transformation in dual-phase steel. Comput. Mater. Sci. 2018, 149, 282–290. [Google Scholar] [CrossRef]

- Qiu, C.; Zurob, H.; Hutchinson, C.; Hutchinson, C. The coupled solute drag effect during ferrite growth in Fe–C–Mn–Si alloys using controlled decarburization. Acta Mater. 2015, 100, 333–343. [Google Scholar] [CrossRef]

- Yamashita, T.; Enomoto, M.; Tanaka, Y.; Matsuda, H.; Nagoshi, M. Analysis of Carbon Partitioning at an Early Stage of Proeutectoid Ferrite Transformation in a Low Carbon Mn–Si Steel by High Accuracy FE-EPMA. ISIJ Int. 2018, 58, 1079–1085. [Google Scholar] [CrossRef]

- Aranda, M.; Rementeria, R.; Poplawsky, J.; Urones-Garrote, E.; Capdevila, C. The role of C and Mn at the austenite/pearlite reaction front during non-steady-state pearlite growth in a Fe–C–Mn steel. Scr. Mater. 2015, 104, 67–70. [Google Scholar] [CrossRef]

- Zhang, G.-H.; Chae, J.-Y.; Kim, K.-H.; Suh, D.W. Effects of Mn, Si and Cr addition on the dissolution and coarsening of pearlitic cementite during intercritical austenitization in Fe-1mass%C alloy. Mater. Charact. 2013, 81, 56–67. [Google Scholar] [CrossRef]

- Lupton, D.F.; Warrington, D.H. The Influence of Deformation on the Spheroidization and Coarsening of Pearlite. Met. Sci. J. 1972, 6, 200–204. [Google Scholar] [CrossRef]

- Eggbauer, A.; Lukas, M.; Prevedel, P.; Panzenböck, M.; Ressel, G.; Ebner, R. Effect of Initial Microstructure, Heating Rate and Austenitizing Temperature on the Subsequent Formation of Martensite and Its Microstructural Features in a QT Steel. Steel Res. Int. 2018. [Google Scholar] [CrossRef]

- Andersson, J.-O.; Ågren, J. Models for numerical treatment of multicomponent diffusion in simple phases. J. Appl. Phys. 1992, 72, 1350–1355. [Google Scholar] [CrossRef]

- Hata, K.; Fujiwara, K.; Wakita, M.; Kawano, K. Development of a Reconstruction Method of Prior Austenite Microstructure Using EBSD Data of Martensite; Nippon Steel & Sumitomo Metal Corporation: Tokyo, Japan, 2017. [Google Scholar]

- Wang, X.; Zurob, H.S.; Xu, G.; Ye, Q.-B.; Bouaziz, O.; Embury, D. Influence of Microstructural Length Scale on the Strength and Annealing Behavior of Pearlite, Bainite and Martensite. Metall. Mater. Trans. A 2012, 44, 1454–1461. [Google Scholar] [CrossRef]

- Cahn, J.W. The impurity-drag effect in grain boundary motion. Acta Metall. 1962, 10, 789–798. [Google Scholar] [CrossRef]

- Offerman, S.; Van Wilderen, L.; Van Dijk, N.; Sietsma, J.; Rekveldt, M.; Van Der Zwaag, S. In-situ study of pearlite nucleation and growth during isothermal austenite decomposition in nearly eutectoid steel. Acta Mater. 2003, 51, 3927–3938. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Raabe, D. On the Effect of Manganese on Grain Size Stability and Hardenability in Ultrafine-Grained Ferrite/Martensite Dual-Phase Steels. Metall. Mater. Trans. A 2011, 43, 37–46. [Google Scholar] [CrossRef]

- Aaron, H.B.; Fainstein, D.; Kotler, G.R. Diffusion-Limited Phase Transformations: A Comparison and Critical Evaluation of the Mathematical Approximations. J. Appl. Phys. 1970, 41, 4404–4410. [Google Scholar] [CrossRef]

- Caballero, F.; Miller, M.K.; Garcia-Mateo, C.; Capdevila, C.; De Andrés, C.G. Phase transformation theory: A powerful tool for the design of advanced steels. JOM 2008, 60, 16–21. [Google Scholar] [CrossRef]

- Hillert, M.; Sundman, B. A treatment of the solute drag on moving grain boundaries and phase interfaces in binary alloys. Acta Metall. 1976, 24, 731–743. [Google Scholar] [CrossRef]

- Sharma, S.; Nanda, T.; Adhikary, M.; Venugopalan, T.; Kumar, R. A simulation study of pearlite to austenite transfromation kinetics in rapidly heated hot-rolled low carbon steel. Mater. Des. 2016, 107, 65–73. [Google Scholar] [CrossRef]

- Goulas, C.; Mecozzi, M.G.; Sietsma, J. Bainite Formation in Medium-Carbon Low-Silicon Spring Steels Accounting for Chemical Segregation. Metall. Mater. Trans. A 2016, 47, 3077–3087. [Google Scholar] [CrossRef]

- Hidalgo, J.; Santofimia, M.J.; Hidalgo-García, J. Effect of Prior Austenite Grain Size Refinement by Thermal Cycling on the Microstructural Features of As-Quenched Lath Martensite. Metall. Mater. Trans. A 2016, 47, 5288–5301. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | Cr | Mo | P | S |

|---|---|---|---|---|---|---|---|

| % | 0.43 | 1–1.43 | 0.3–0.4 | 1.1–1.23 | 0.1–0.25 | <0.040 | <0.040 |

| Samples | Thermal Cycles |

|---|---|

| FP_10 | Initial microstructure (as-rolled): ferrite-pearlite (FP), heating rate: 10 °C/s, Tpeak: 900 °C, isothermal holding: 5 min, quenching |

| FSC_10 | Initial microstructure (soft annealed): ferrite-spheroidized carbides (FSC), heating rate: 10 °C/s, Tpeak: 900 °C, isothermal holding: 5 min, quenching |

| FP_200 | Initial microstructure: ferrite-pearlite (FP), heating rate: 200 °C/s, Tpeak: 900 °C, isothermal holding: 5 min, quenching |

| FSC_300 | Initial microstructure: ferrite-spheroidized carbides (FSC), heating rates: 300 °C /s, Tpeak: 900 °C, isothermal holding: 5 min, quenching |

| Phases | C (wt.%) | Cr (wt.%) | Mn (wt.%) | Mo (wt.%) |

|---|---|---|---|---|

| Cementite | 6.67 | 9.17 | 9.69 | 0.17 |

| Ferrite | 0.0007 | 0.073 | 0.29 | 0.018 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papaefthymiou, S.; Karamitros, V.; Bouzouni, M. Ultrafast Heating and Initial Microstructure Effect on Phase Transformation Evolution of a CrMo Steel. Metals 2019, 9, 72. https://doi.org/10.3390/met9010072

Papaefthymiou S, Karamitros V, Bouzouni M. Ultrafast Heating and Initial Microstructure Effect on Phase Transformation Evolution of a CrMo Steel. Metals. 2019; 9(1):72. https://doi.org/10.3390/met9010072

Chicago/Turabian StylePapaefthymiou, Spyros, Vassilios Karamitros, and Marianthi Bouzouni. 2019. "Ultrafast Heating and Initial Microstructure Effect on Phase Transformation Evolution of a CrMo Steel" Metals 9, no. 1: 72. https://doi.org/10.3390/met9010072

APA StylePapaefthymiou, S., Karamitros, V., & Bouzouni, M. (2019). Ultrafast Heating and Initial Microstructure Effect on Phase Transformation Evolution of a CrMo Steel. Metals, 9(1), 72. https://doi.org/10.3390/met9010072