Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel

Abstract

1. Introduction

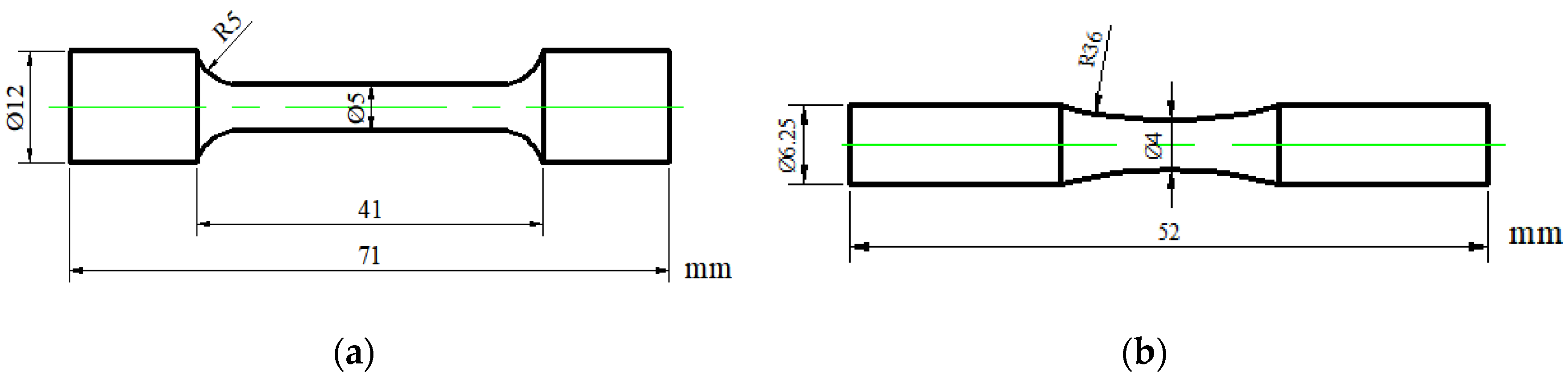

2. Experimental Procedure

3. Results and Discussion

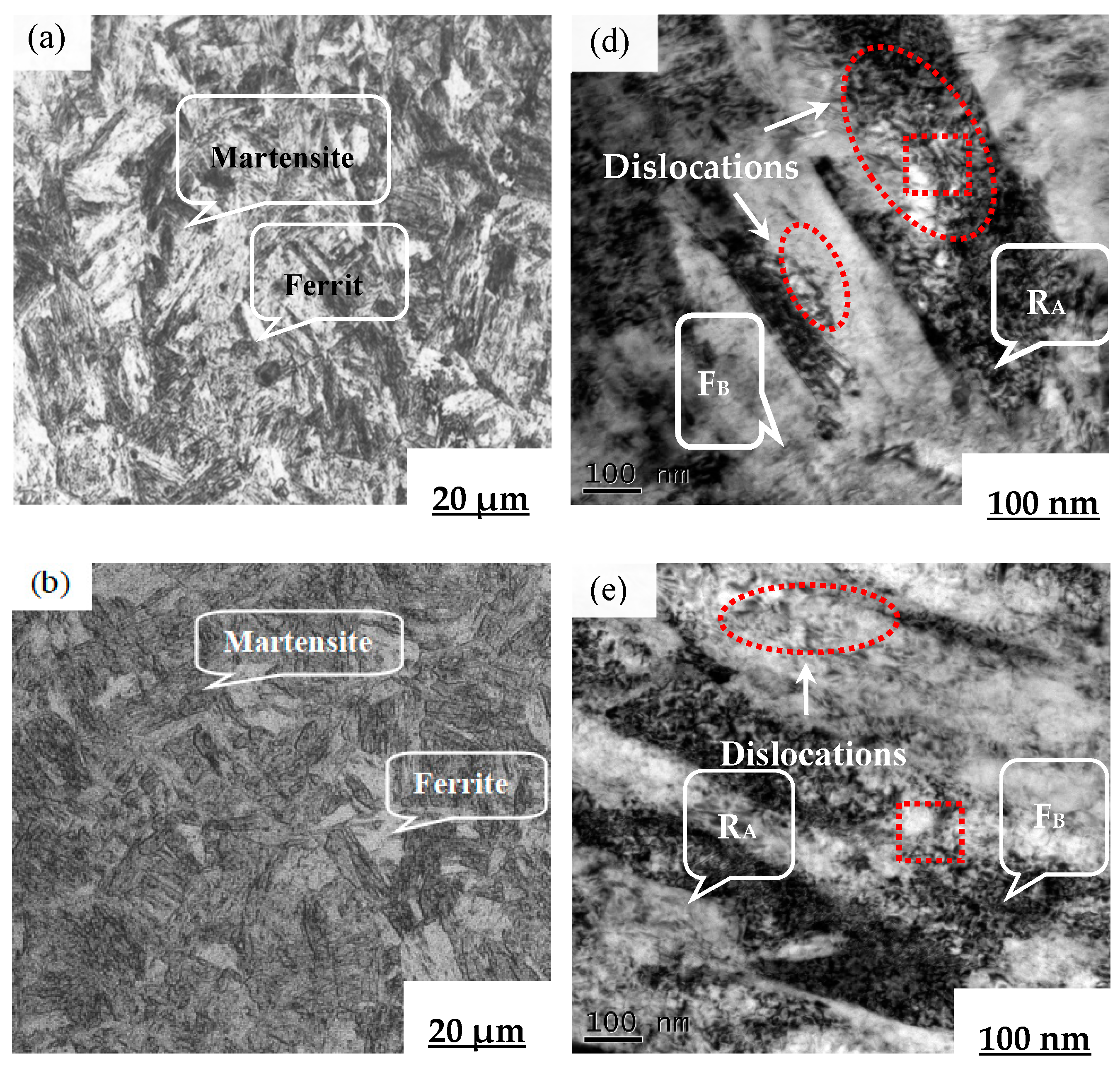

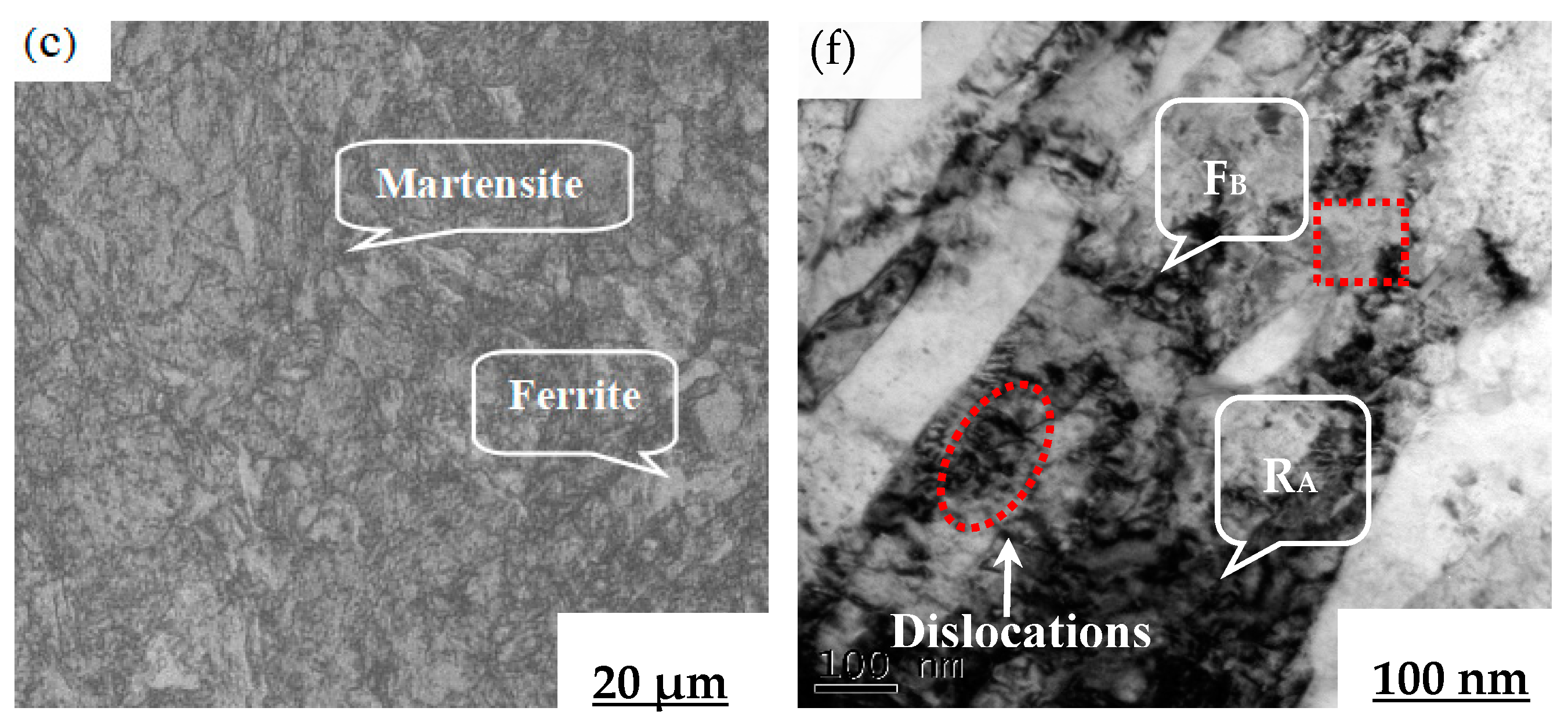

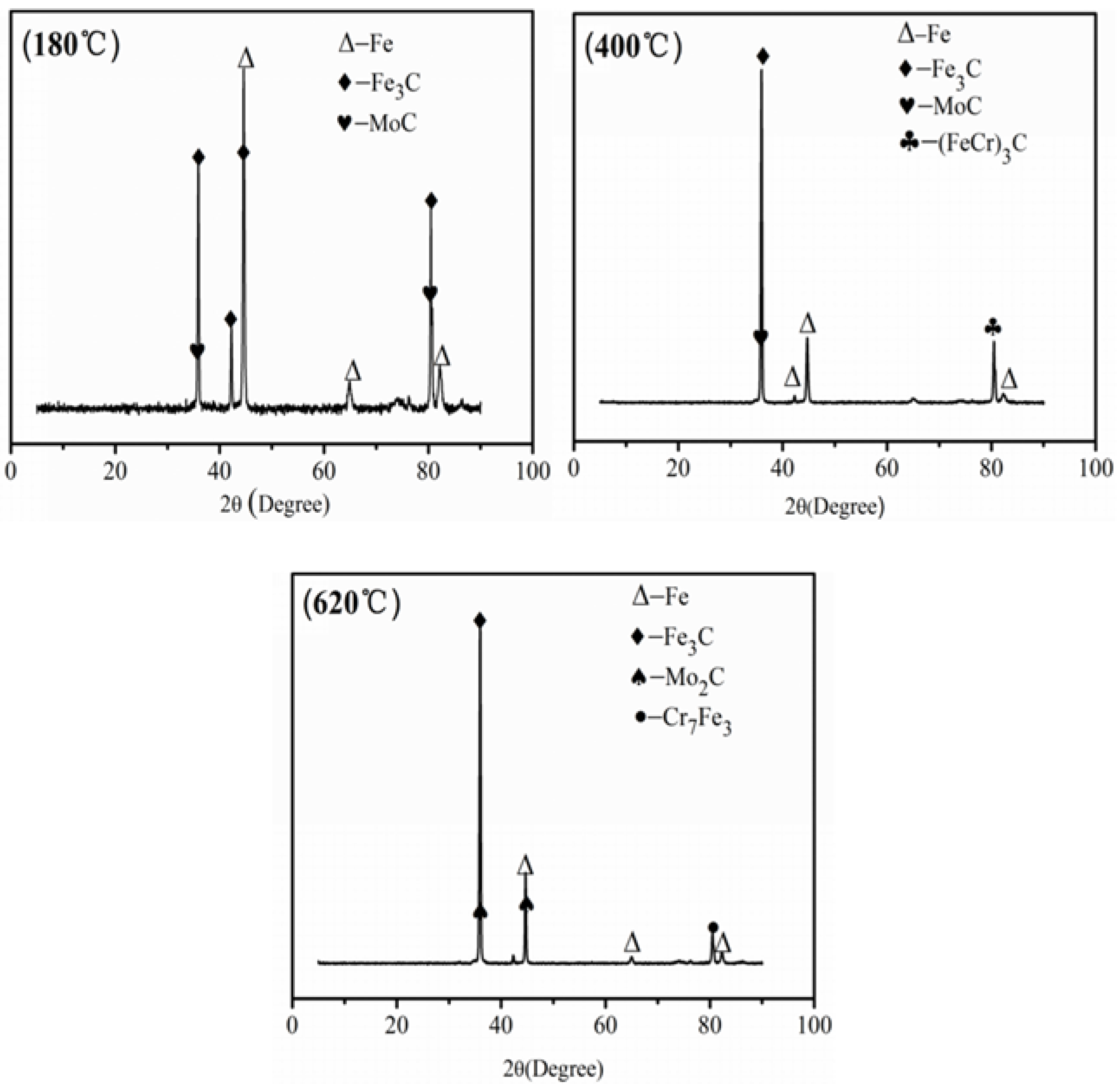

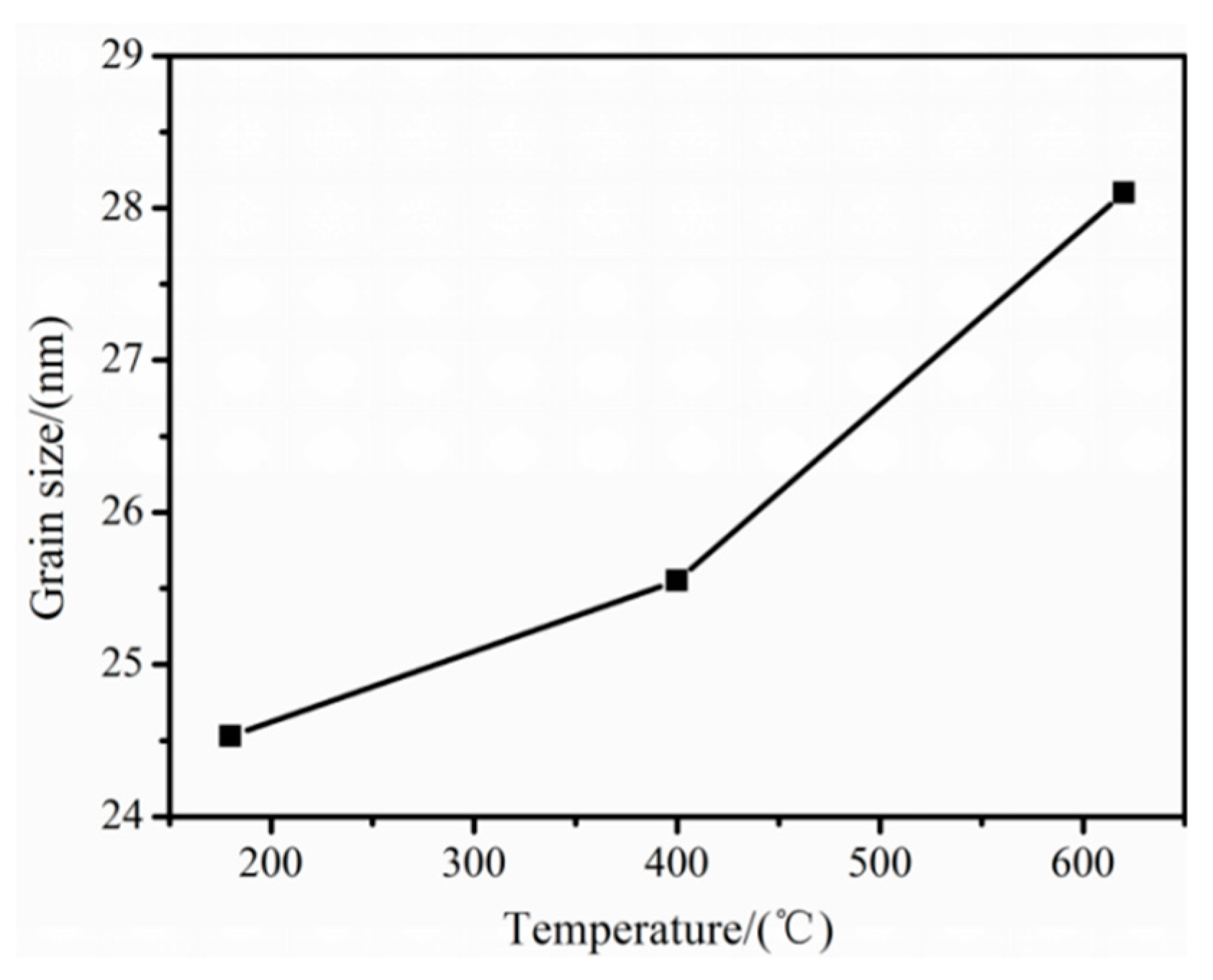

3.1. Microstructural Characterization

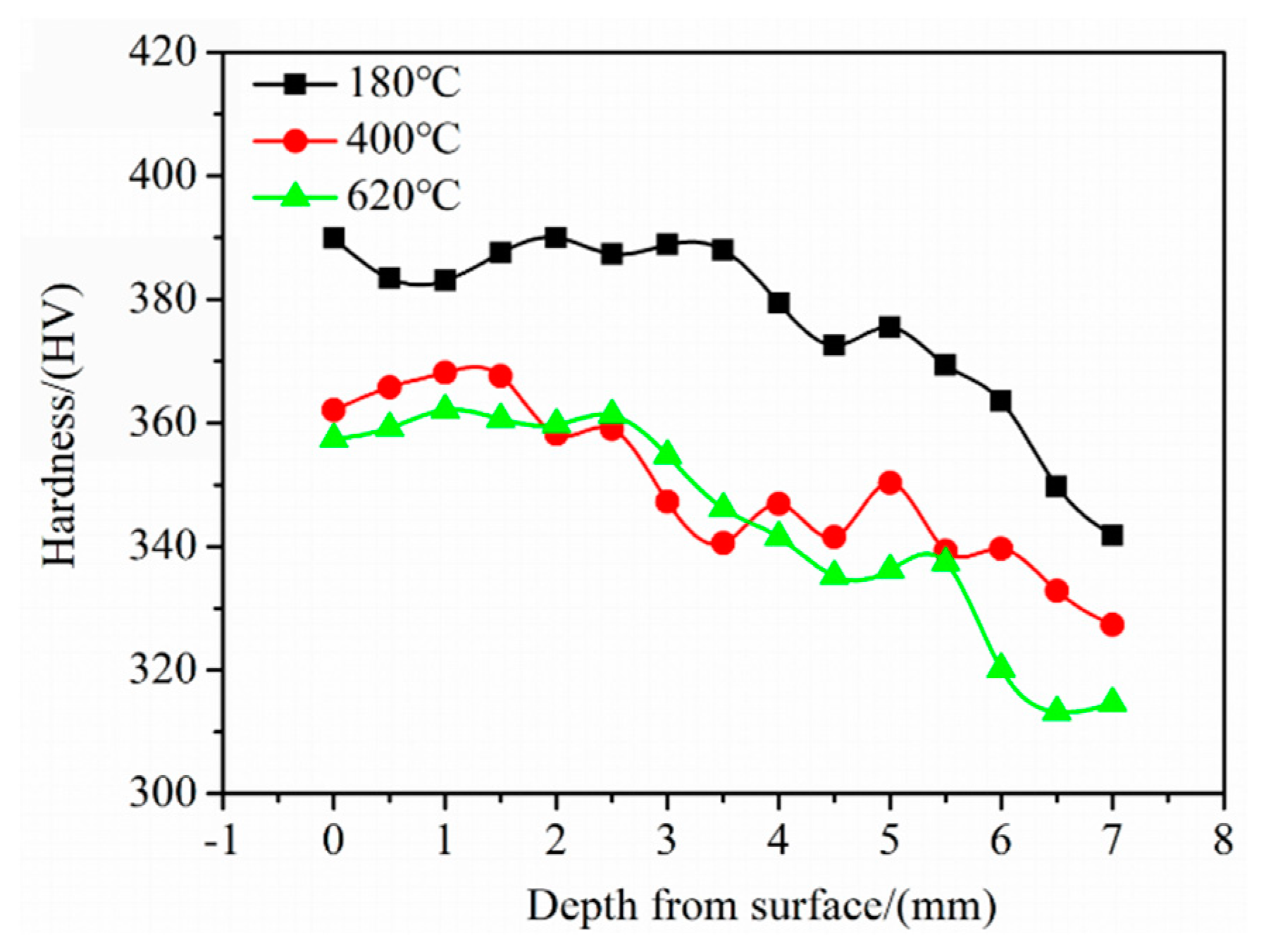

3.2. Hardness

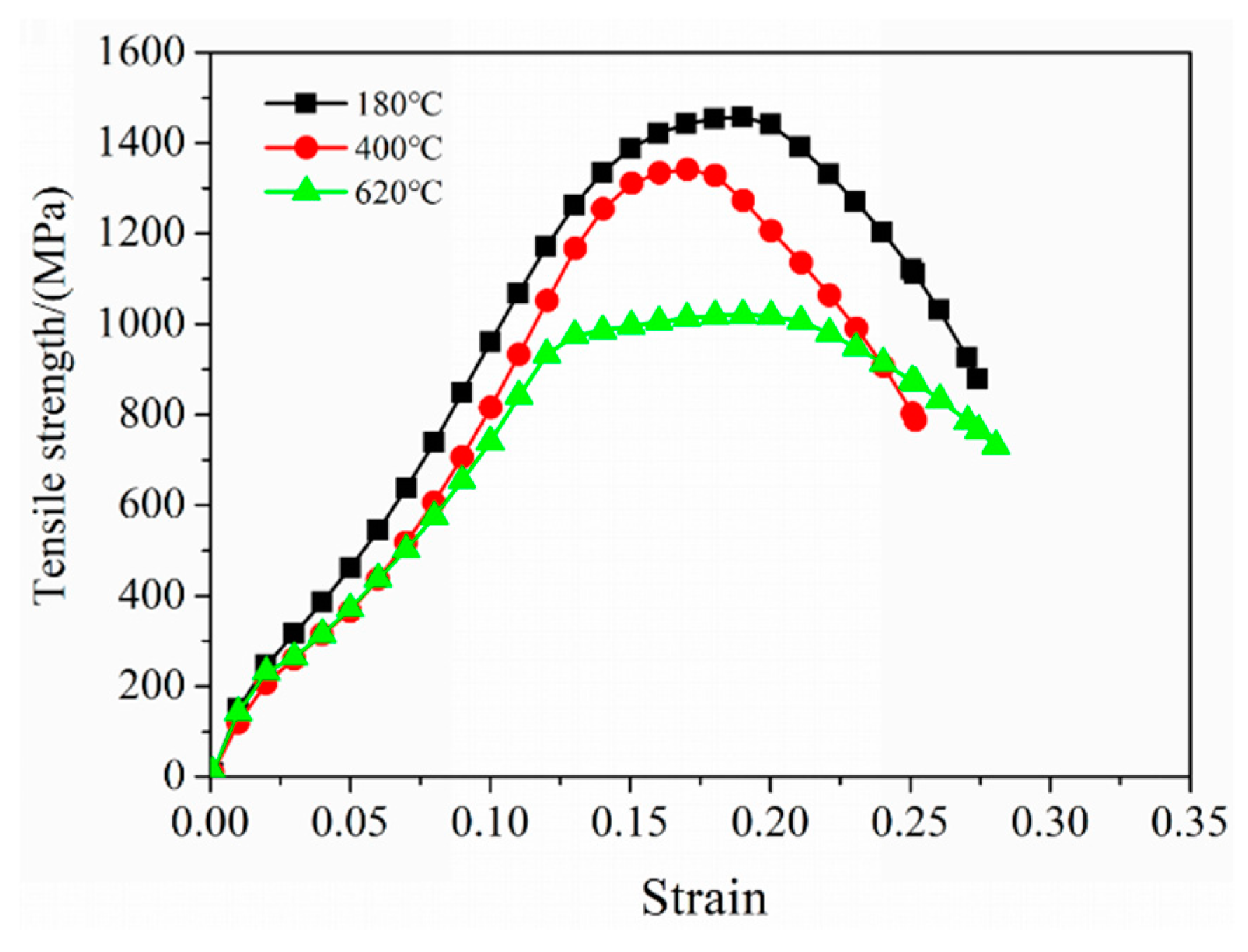

3.3. Tensile Properties

3.3.1. Tensile Strength

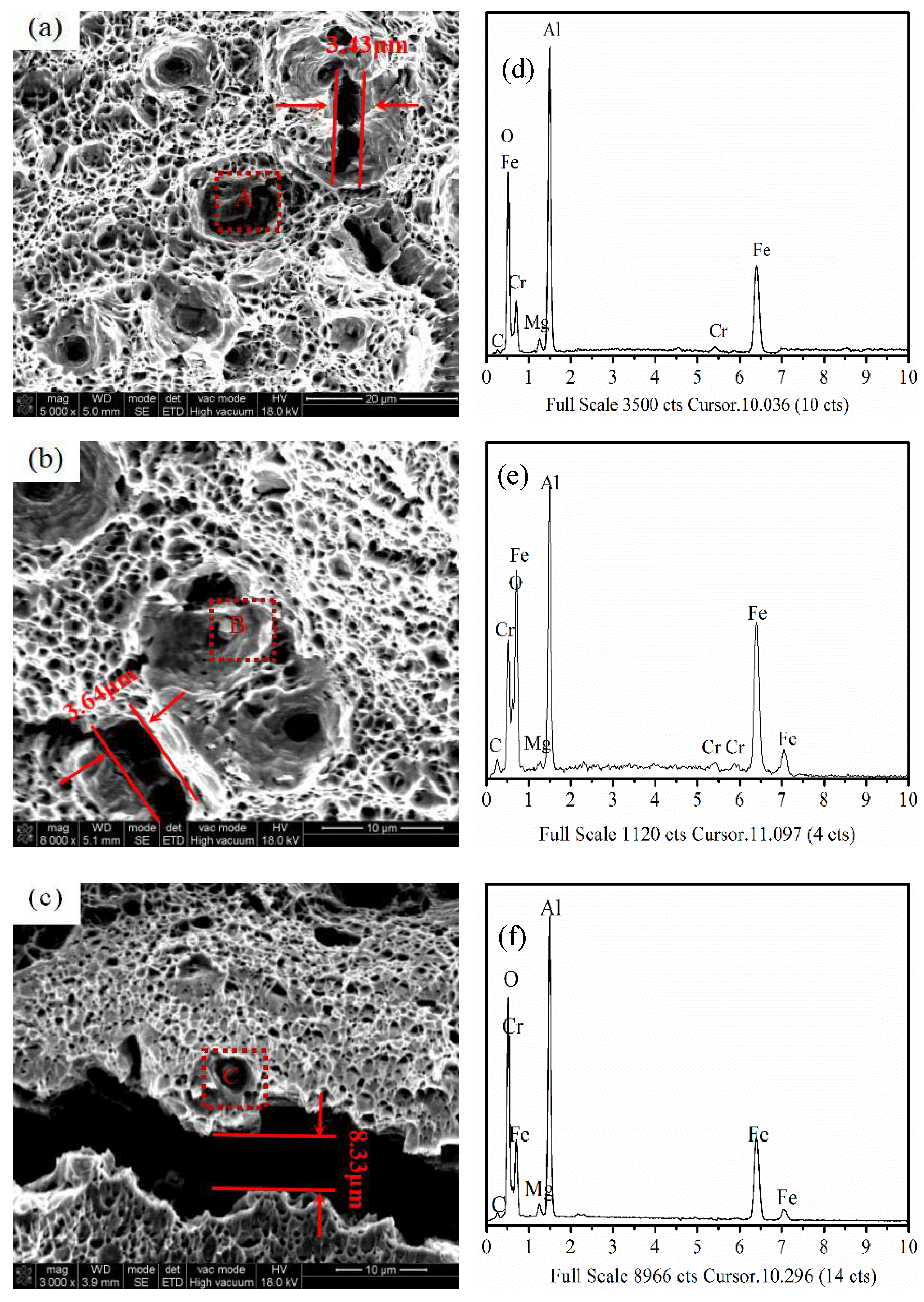

3.3.2. Fracture Analysis

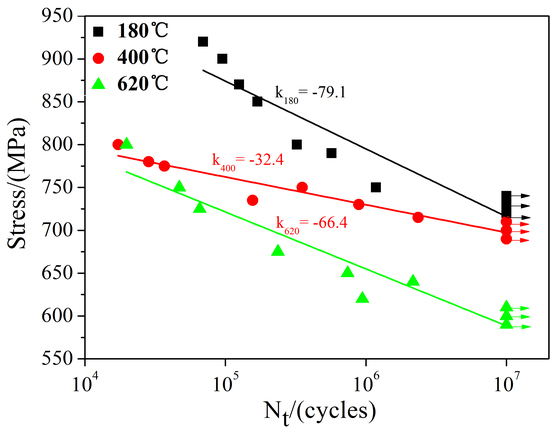

3.4. Fatigue Characteristics

3.4.1. S-N Curve

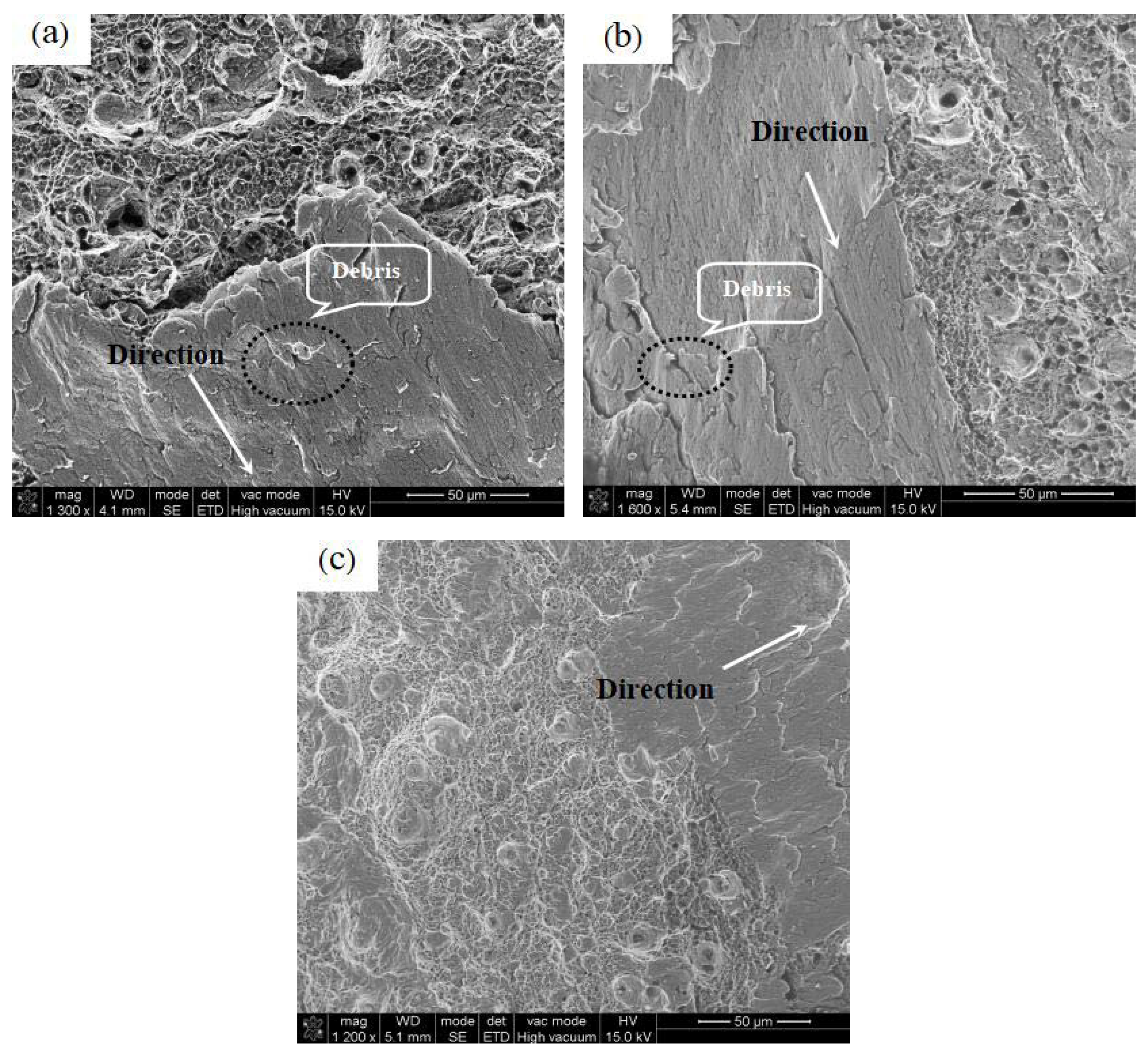

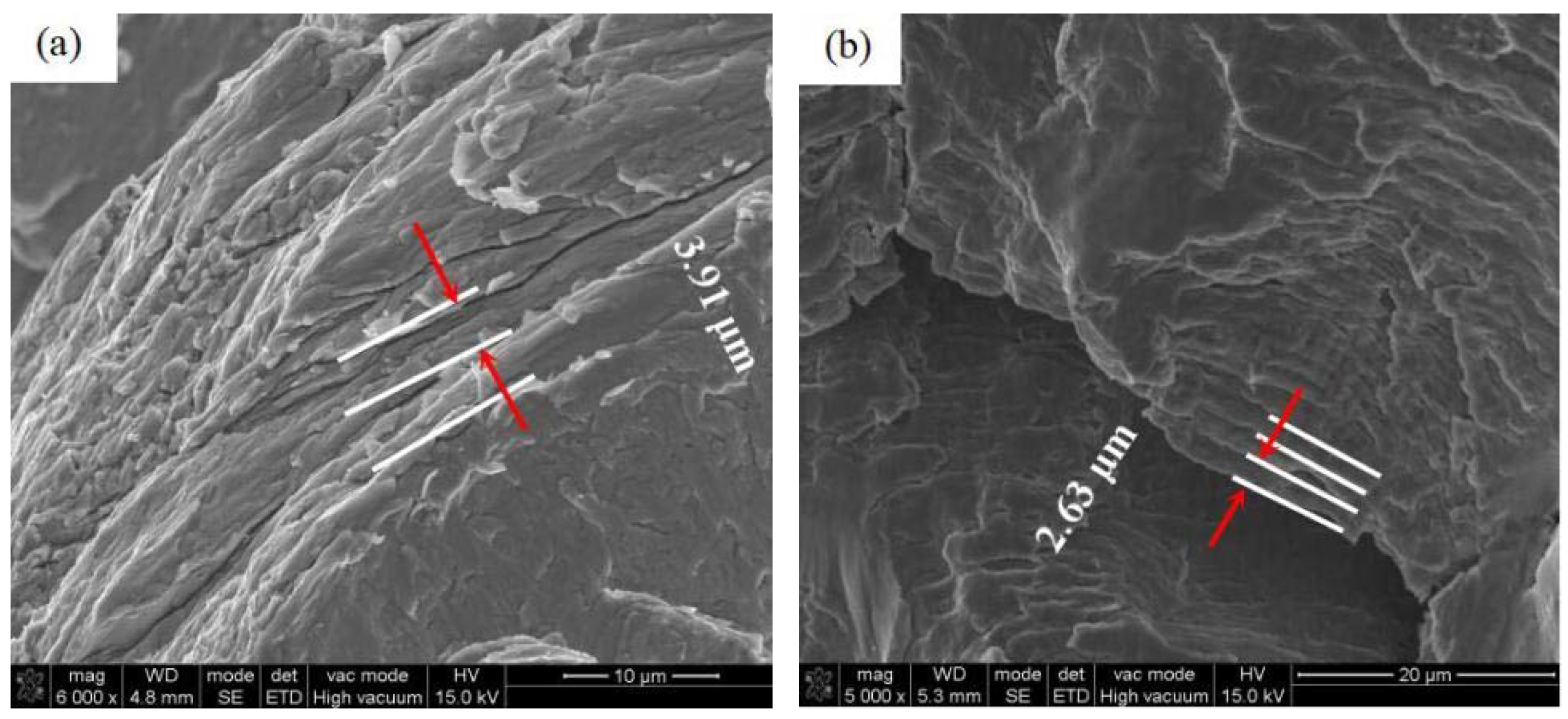

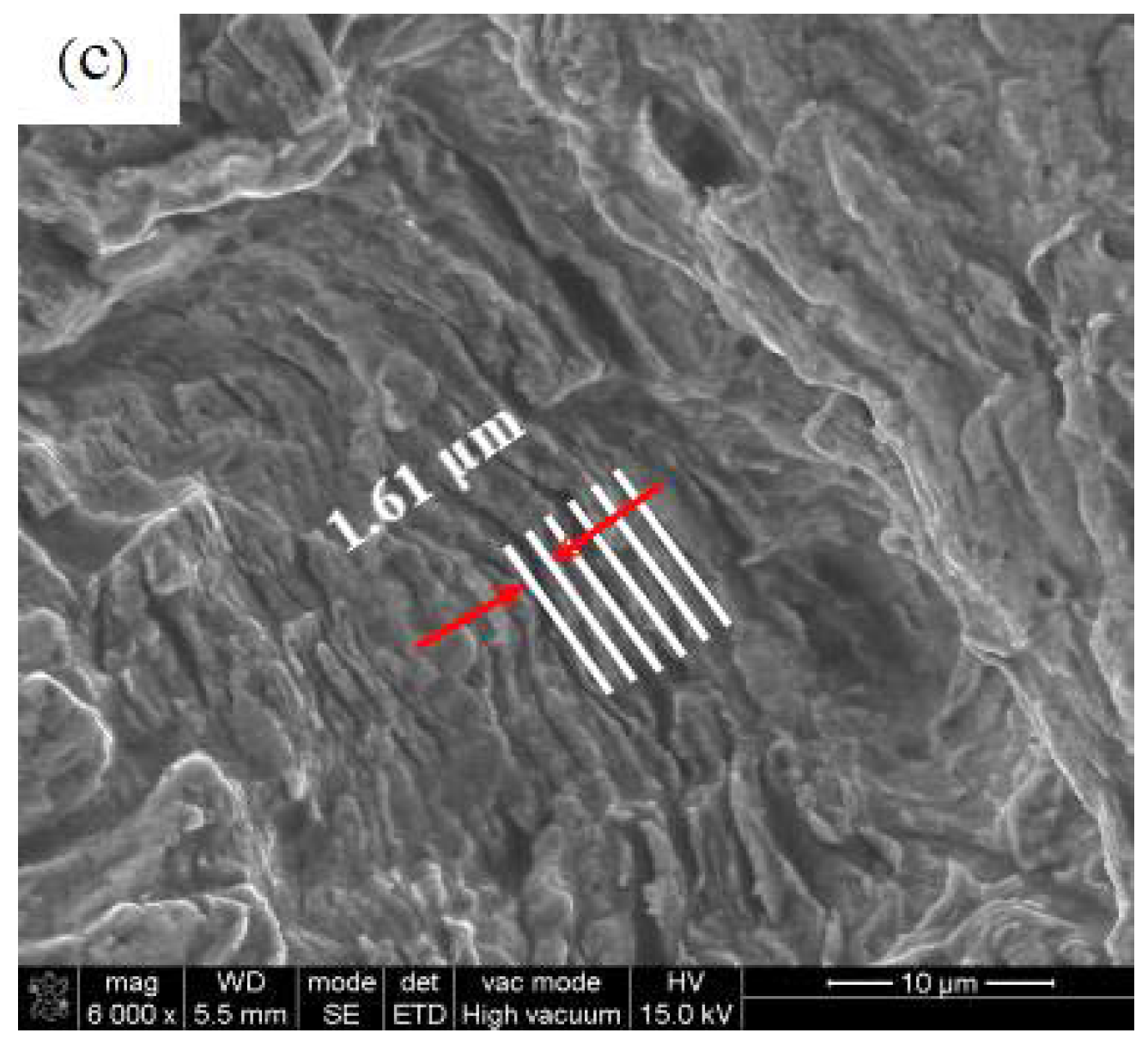

3.4.2. Fractography

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, Y.H.; Wang, M.Q.; Chen, J.C.; Dong, H. Microstructure and mechanical properties of gear steels after high temperature carburization. J. Iron Steel Res. Int. 2013, 20, 140–145. [Google Scholar] [CrossRef]

- Gurudas, M.; Kumar, T.N.; Kumar, G.S. Enhancement of mechanical properties in bainitic steel processed from different austenitization temperatures. Steel Res. Int. 2017, 2, 87–92. [Google Scholar]

- Morave, J.M.; Mantovani, D. Biodegradable metals for cardiovascular stent application: Interests and new opportunities. Int. J. Mol. Sci. 2011, 12, 4250–4270. [Google Scholar] [CrossRef] [PubMed]

- Schinhammer, M.; Hänzi, A.; Löffle, J.; Uggowitzer, P.J. Design strategy for biodegradable Fe-based alloys for medical applications. Acta Biomater. 2010, 6, 1705–1713. [Google Scholar] [CrossRef] [PubMed]

- Francis, A.; Yang, Y.; Virtanen, S.; BoccacciniIron, A.R. Iron and iron-based alloys for temporary cardiovascular applications. J. Mater. Sci. Mater. Med. 2015, 26, 138–154. [Google Scholar] [CrossRef] [PubMed]

- Pereloma, E.V.; Scott, R.I.; Smith, R.M. Effect of Cr on strain ageing behaviour of low carbon steel. Mater. Sci. 2007, 24, 539–543. [Google Scholar]

- Yang, Z.; Cong, D.Y.; Sun, X.M.; Nie, Z.H.; Wang, Y.D. Enhanced cyclability of elastocaloric effect in boron-microalloyed NiMn-In magnetic shape memory alloys. Acta Mater. 2017, 127, 33–42. [Google Scholar] [CrossRef]

- Wang, Q.W.; Li, C.S.; Chen, J.; Tu, X.Y. Effects of heat input on microstructure and mechanical properties of Fe-2Cr-Mo-0.12C steel. Mater. Sci. Technol. 2018, 34, 538–546. [Google Scholar] [CrossRef]

- Wang, M.Q.; Jie, S.; Han, D. Microstructure and mechanical properties of V-Nb microalloyed steel for heavy-duty gear. Trans. Mater. 2007, 28, 18–23. (In Chinese) [Google Scholar]

- Xiao, F.R.; Cao, Y.B.; Qiao, G.Y.; Zhang, X.B.; Bo, L. Effect of Nb solute and NbC precipitates on dynamic or static recrystallization in Nb steels. J. Iron Steel Res. Int. 2012, 19, 52–56. [Google Scholar] [CrossRef]

- Chen, S.L.; Geng, K. Effect of heat treatment on mechanical properties of Cr-Ni-Mo carburized gear steel. Spec. Steel 2002, 23, 20–22. (In Chinese) [Google Scholar]

- Wu, D.; Wang, F.M.; Cheng, J.; Li, C.R. Effects of Nb and tempering time on carbide precipitation behavior and mechanical properties of Cr-Mo-V Steel for brake discs. Steel Res. Int. 2018, 89. [Google Scholar] [CrossRef]

- Hong, Y.S.; Lei, Z.Q.; Sun, C.Q.; Zhao, A.G. Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels. Int. J. Fatigue 2014, 58, 144–152. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Trans. A 1991, 7, 1545–1558. [Google Scholar] [CrossRef]

- Mohammad, J.K.; Mohammad, A. Evaluation of high-cycle bending fatigue and fracture behaviors in EN-GJS700-2 ductile cast iron of crankshafts. Eng. Fail. Anal. 2018, 85, 189–200. [Google Scholar]

- Shendy, B.R.; Yoozbashi, M.N.; Avishan, B.; Yazdani, S. An investigation on rotating bending fatigue behavior of nanostructured low-temperature bainitic steel. Acta Metall. 2014, 27, 233–238. [Google Scholar] [CrossRef]

- Swarr, T.; Krauss, G. The effect of structure on the deformation of as-quenched and tempered martensite in a Fe-0.2 pct C alloy. Metall. Trans. A 1976, 7, 41–48. [Google Scholar] [CrossRef]

- Tomita, Y.; Okabayashi, K. Effect of microstructure on strength and toughness of heat-treated low alloy structural steels. Matall. Trans. A 1986, 17, 1203–1207. [Google Scholar] [CrossRef]

- Stasko, R.; Adrian, H.; Adrian, A. Effect of nitrogen and vanadium on austenite grain groeth of a low alloy steel. Mater. Charact. 2006, 5, 340–347. [Google Scholar] [CrossRef]

- Long, S.L.; Liang, Y.L.; Jiang, Y.; Liang, Y.; Yang, M. Effect of quenching temperature on martensite multi-level microstructures and properties of strengh and toughness in 20CrNi2Mo steel. Mater. Sci. Eng. A 2016, 676, 38–47. [Google Scholar] [CrossRef]

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The morphology and crystallography of lath martensite in Fe-C. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Chang, Y.L.; Chen, P.Y.; Tsai, Y.T.; Yang, J.R. Crystallographic analysis of lenticular martensite in Fe-1.0C-17Cr stainless steel by electron backscatter diffraction. Mater. Charact. 2016, 113, 17–25. [Google Scholar] [CrossRef]

- Wang, C.F.; Wang, M.Q.; Dong, H. In-situ observation of deformation and fracture process for lath martensite steel. J. Iron Steel Res. 2012, 24, 38–43. (In Chinese) [Google Scholar]

- Li, Y.Q. Microstructure and strain fatigue dislocation structure of 7075 RRA Aluminum alloy. Rare Met. 2001, 20, 52–57. [Google Scholar]

- Phung, N.L.; Favier, V.; Ranc, N.; Valès, F.; Mughrabi, H. Very high cycle fatigue of copper: Evolution, morphology and locations of surface slip markings. Int. J. Fatigue 2014, 3, 63–68. [Google Scholar] [CrossRef]

- Neumann, P. Coarse slip model of fatigue. Acta Metall. 1969, 17, 1219–1225. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Al | Cu | Mo | V | Nb | Mg | S | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.188 | 0.015 | 0.40 | 1.83 | 1.63 | 0.048 | 0.01 | 0.31 | 0.093 | 0.059 | 0.007 | 0.001 | 0.009 |

| Samples Label | Quenching Temperature | Quenching Method | Tempering Temperature | Tempering Method |

|---|---|---|---|---|

| 1 | 860 °C × 1 h | oil | 180 °C × 2 h | water |

| 2 | 860 °C × 1 h | oil | 400 °C × 2 h | water |

| 3 | 860 °C × 1 h | oil | 620 °C × 2 h | water |

| Sample Label | Temperature (°C) | 2% YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|---|

| 1 | 180 | 1362 | 1456 | 13.76 |

| 2 | 400 | 1288 | 1341 | 12.48 |

| 3 | 620 | 964 | 1019 | 14.8 |

| Element | Weight % | ||

|---|---|---|---|

| A | B | C | |

| C | 7.81 | 4.99 | 2.41 |

| O | 19.23 | 32.54 | 33.45 |

| Mg | 0.63 | 1.15 | 1.21 |

| Al | 21.2 | 24.66 | 25.34 |

| Cr | 1 | 1.47 | 1.62 |

| Fe | 50.13 | 35.19 | 35.97 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, S.-G.; Zhang, Y.-L.; Lai, F.-Q.; Li, X.-Q. Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel. Metals 2018, 8, 507. https://doi.org/10.3390/met8070507

Qu S-G, Zhang Y-L, Lai F-Q, Li X-Q. Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel. Metals. 2018; 8(7):507. https://doi.org/10.3390/met8070507

Chicago/Turabian StyleQu, Sheng-Guan, Ya-Long Zhang, Fu-Qiang Lai, and Xiao-Qiang Li. 2018. "Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel" Metals 8, no. 7: 507. https://doi.org/10.3390/met8070507

APA StyleQu, S.-G., Zhang, Y.-L., Lai, F.-Q., & Li, X.-Q. (2018). Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel. Metals, 8(7), 507. https://doi.org/10.3390/met8070507