Thermomechanical Grain Refinement in AA6082-T6 Thin Plates under Bobbin Friction Stir Welding

Abstract

1. Introduction

1.1. Context

1.2. Background

1.3. Purpose and Approach

2. Materials and Methods

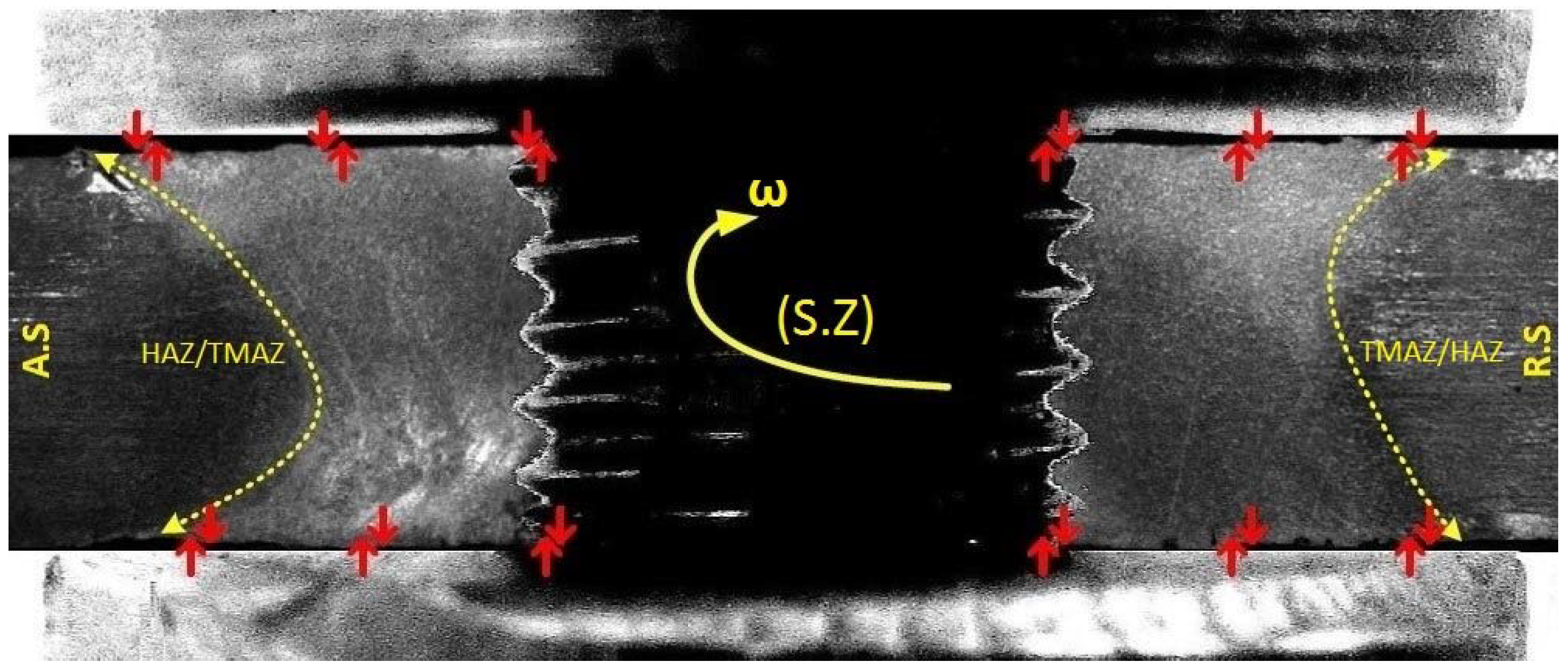

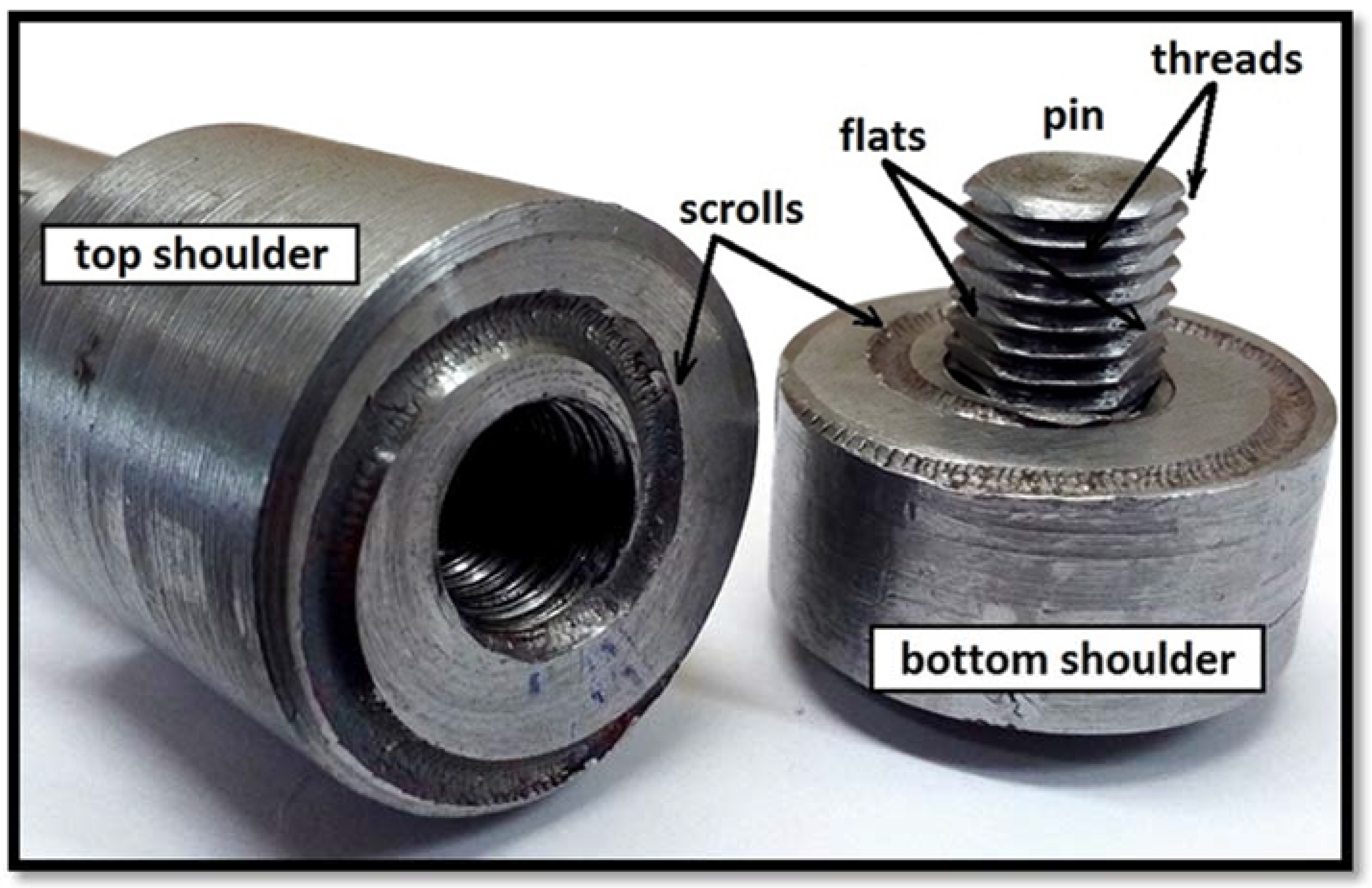

2.1. Welding Trials

2.2. Metallography

2.3. Electron Microscopy

3. Results and Findings

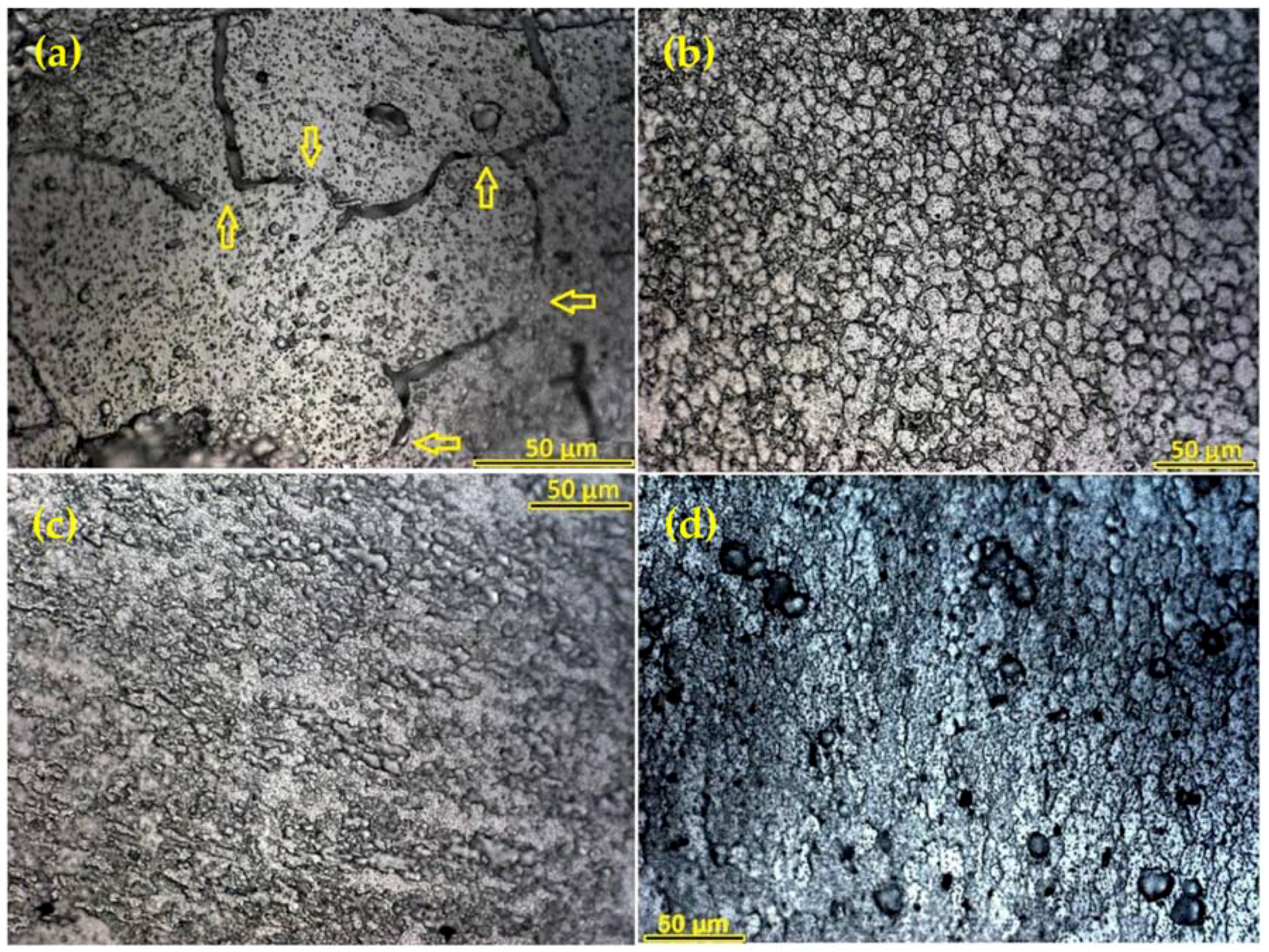

3.1. Optical Microscopy

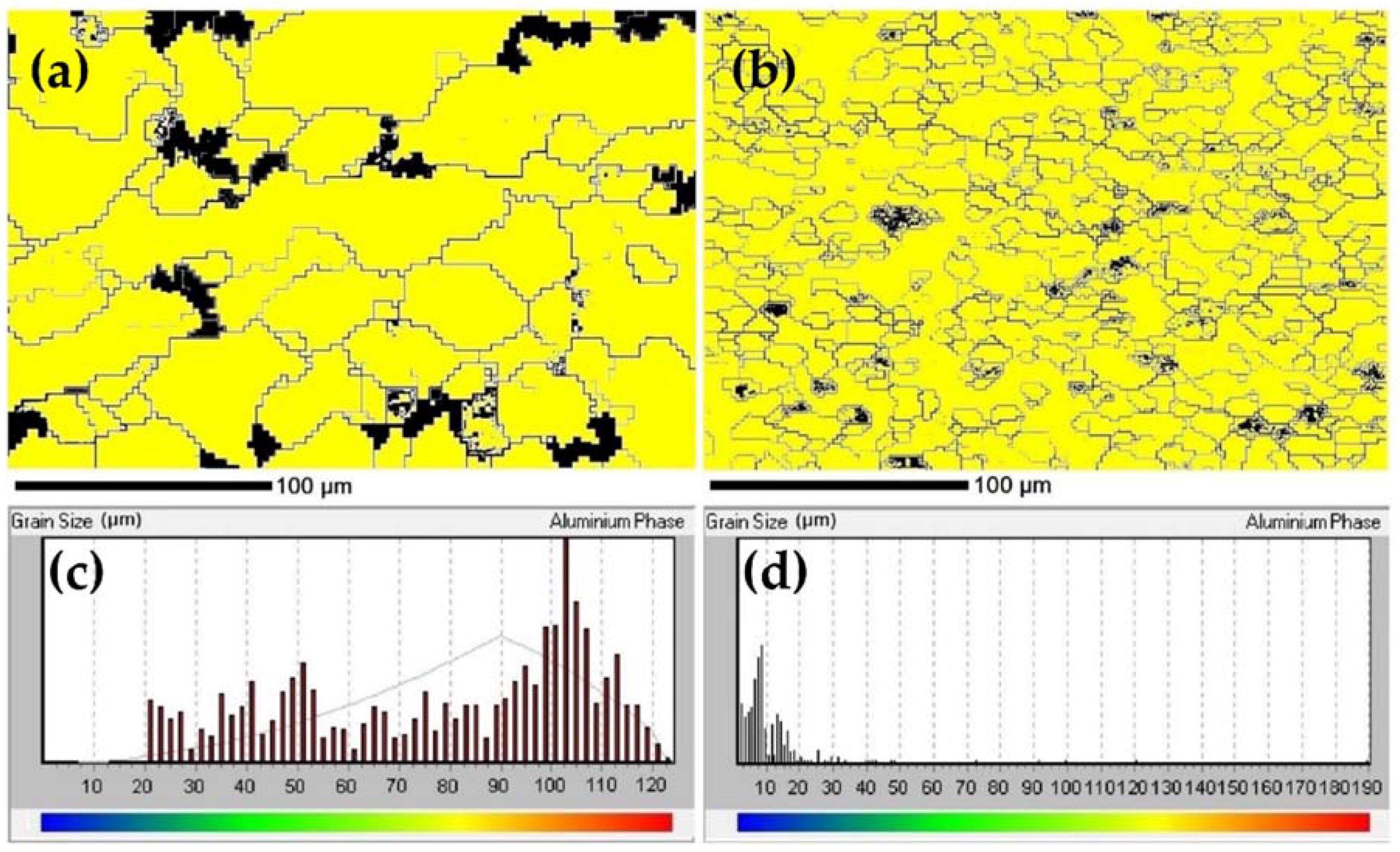

3.1.1. Grain Refinement

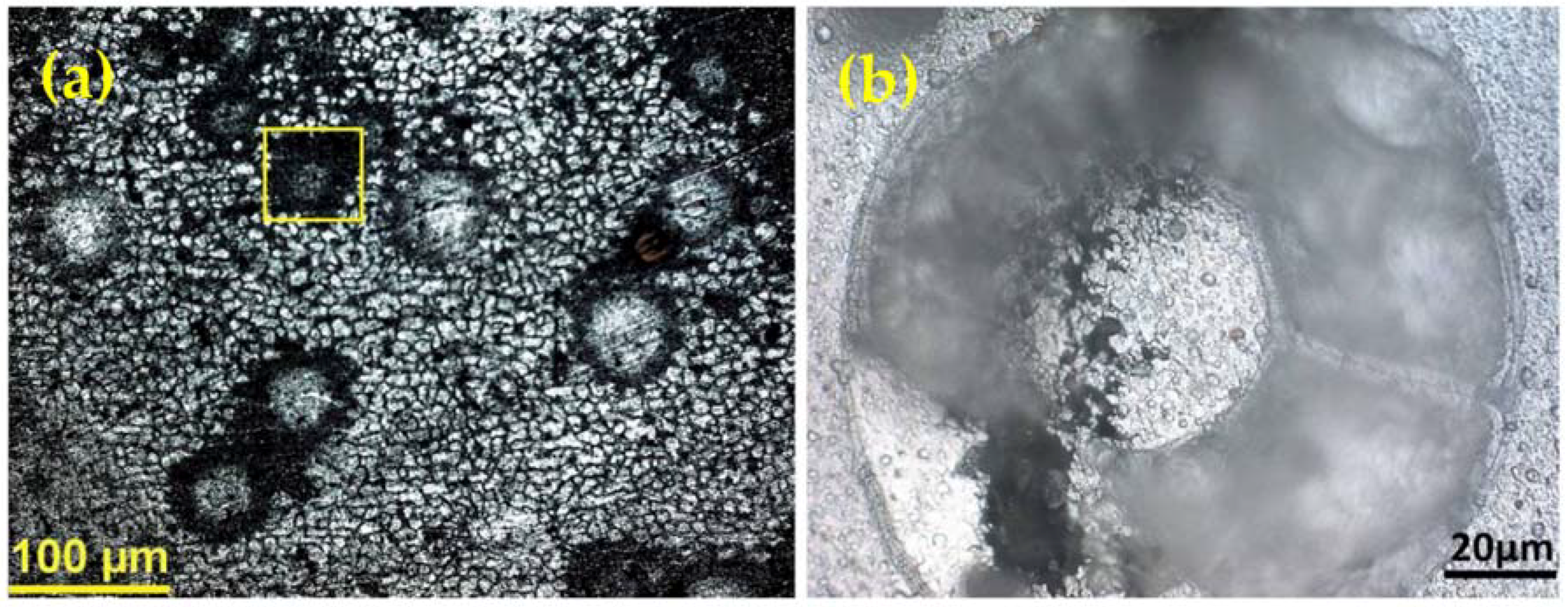

3.1.2. Glass-Metal Features

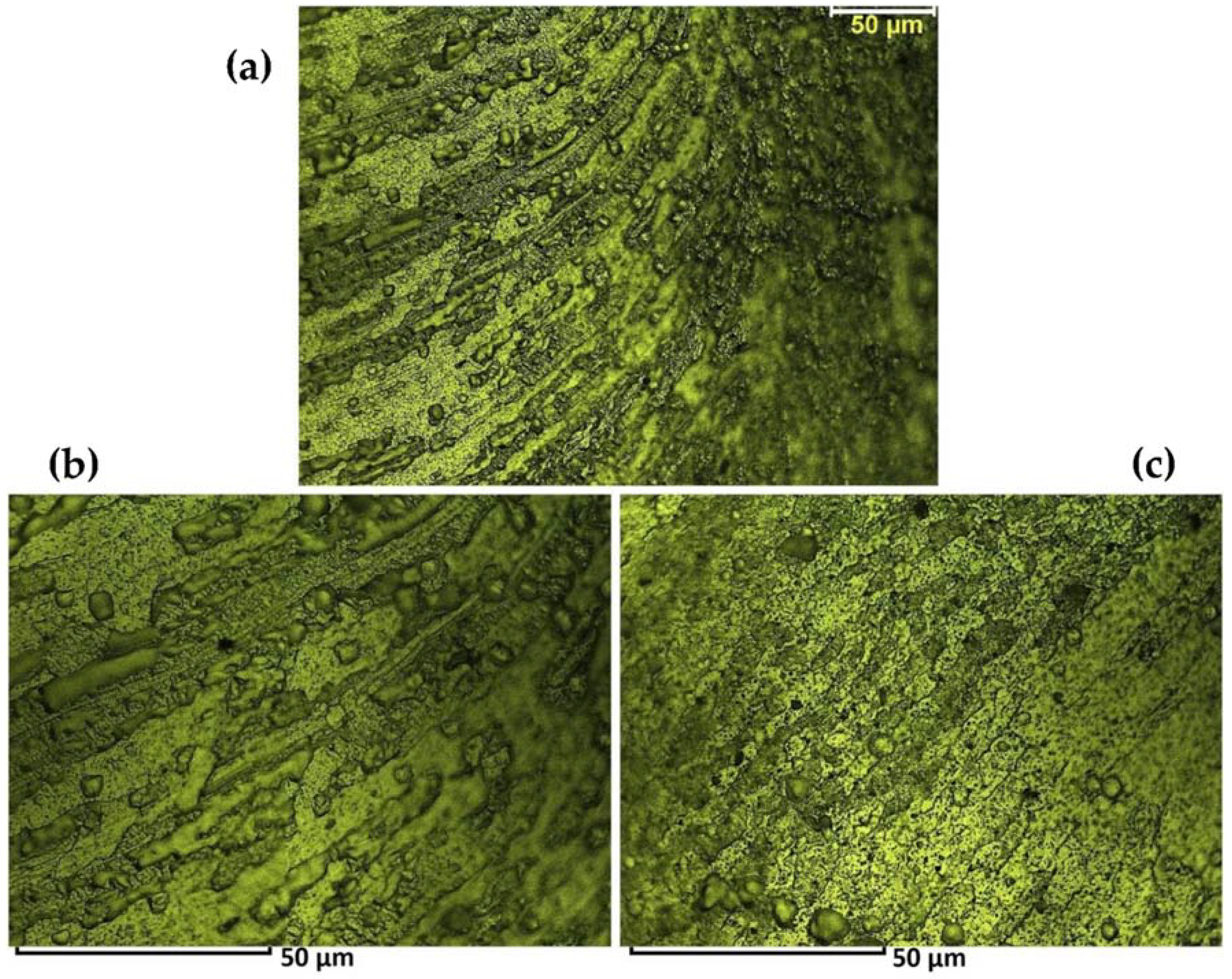

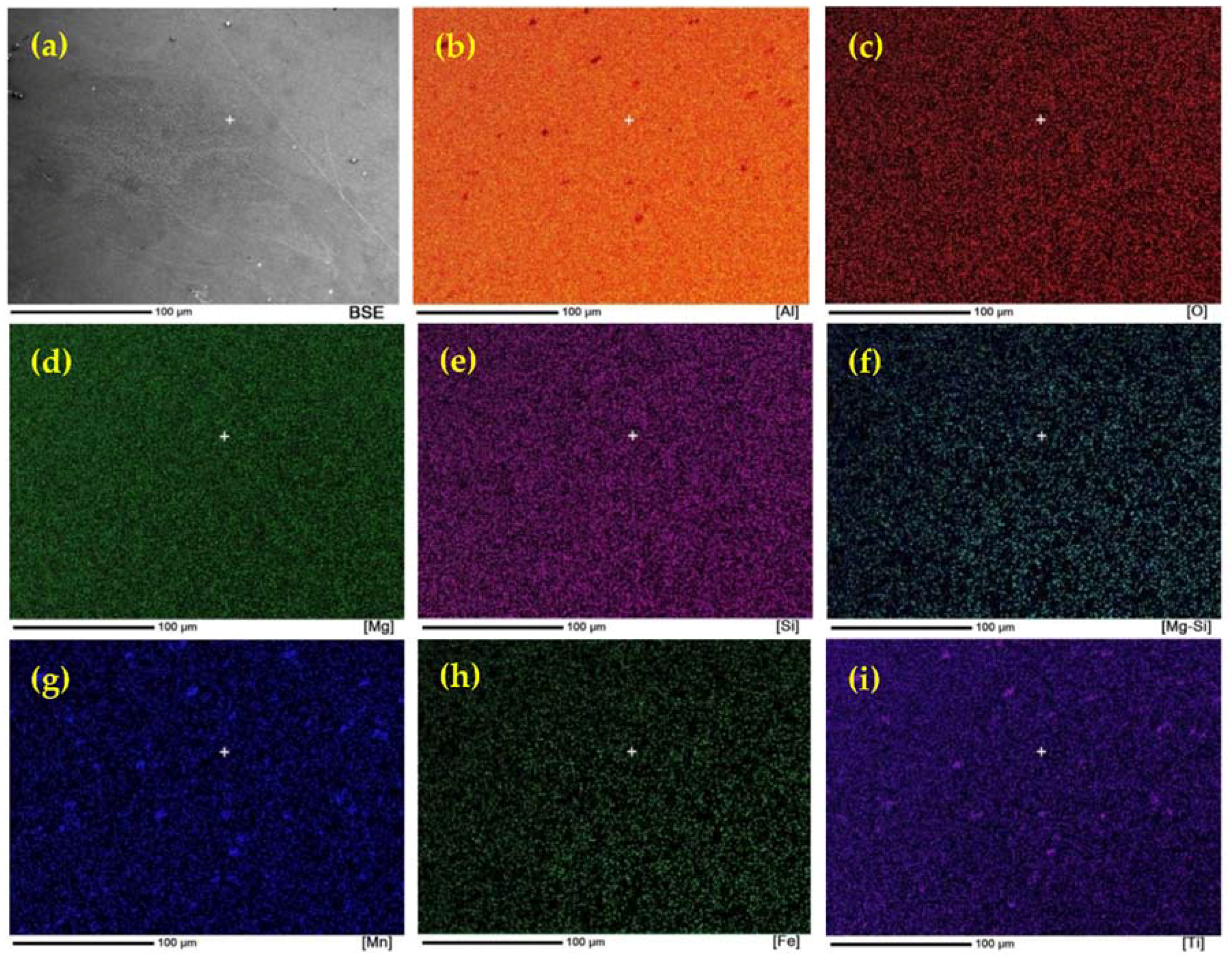

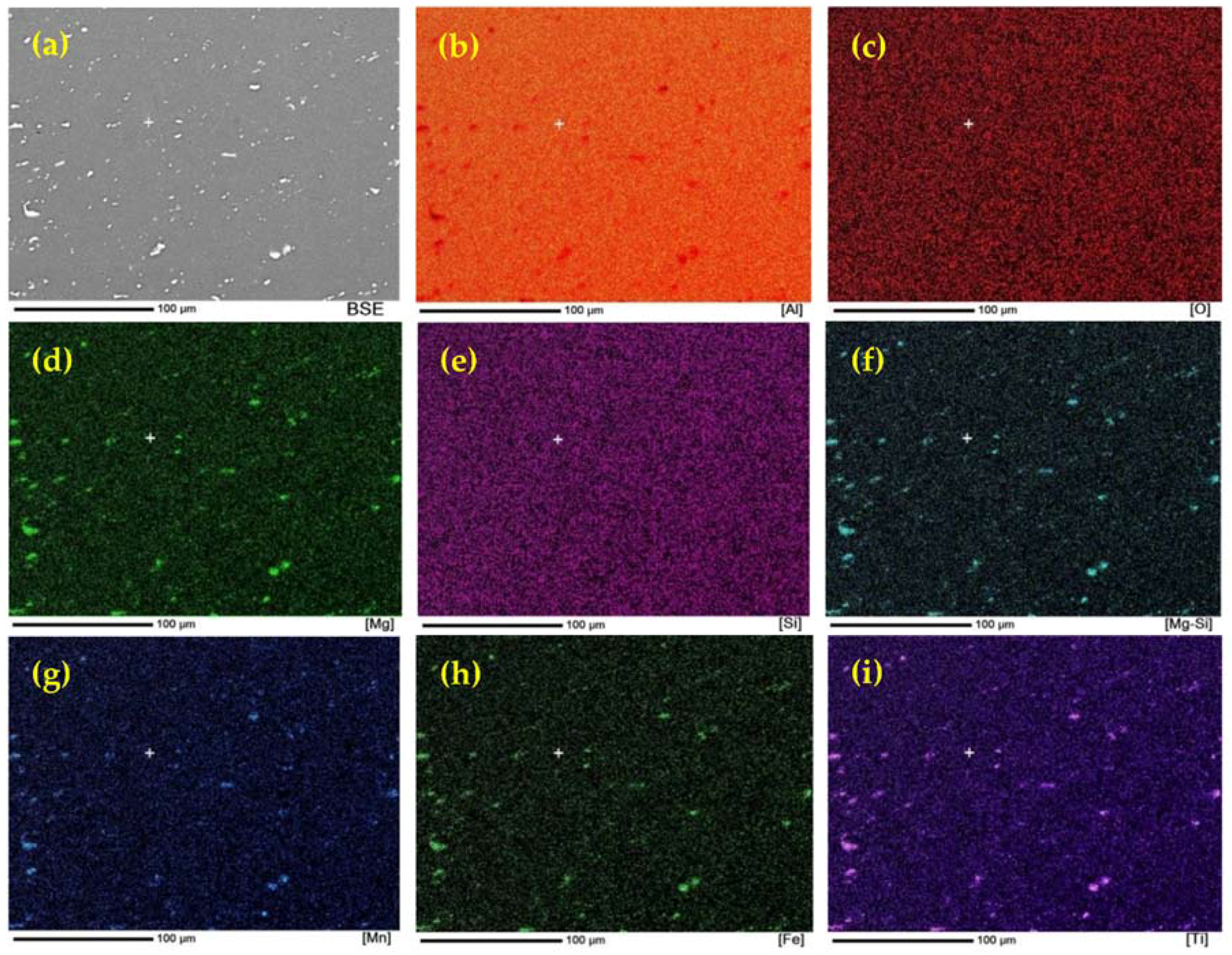

3.2. Electron Microscopy

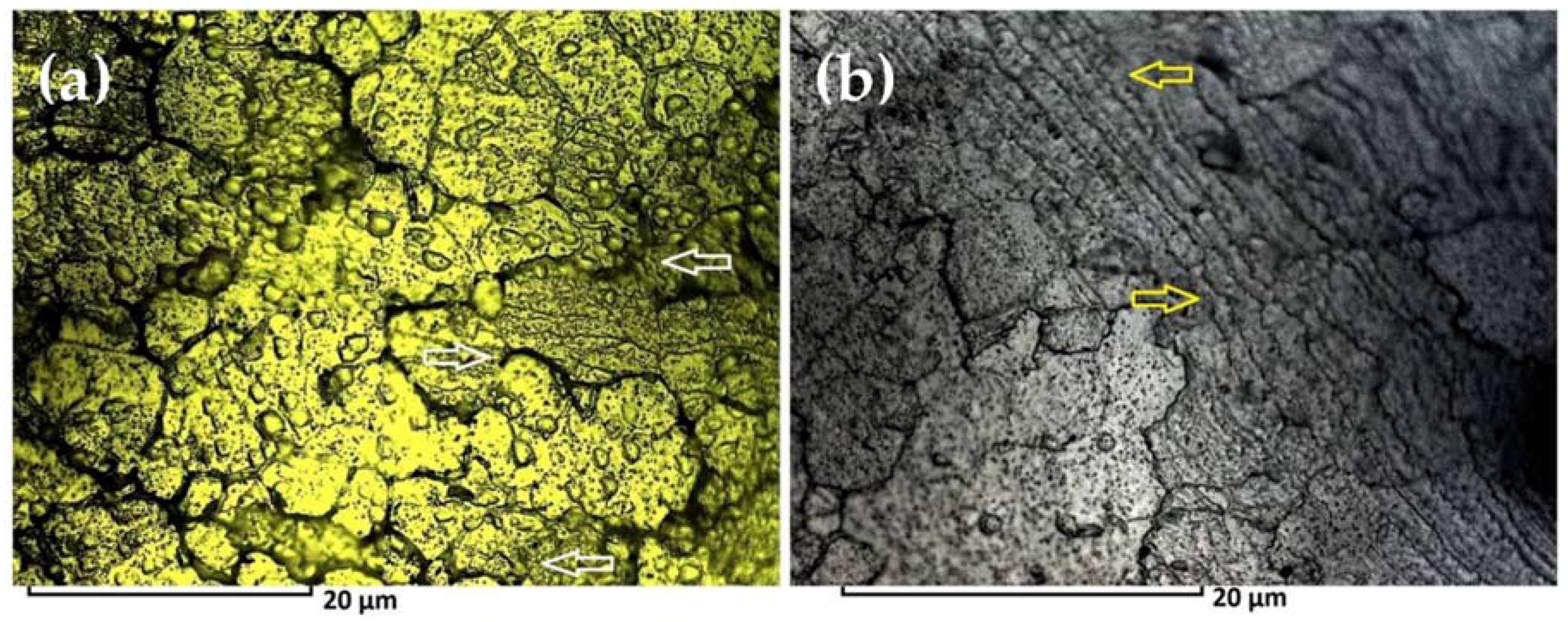

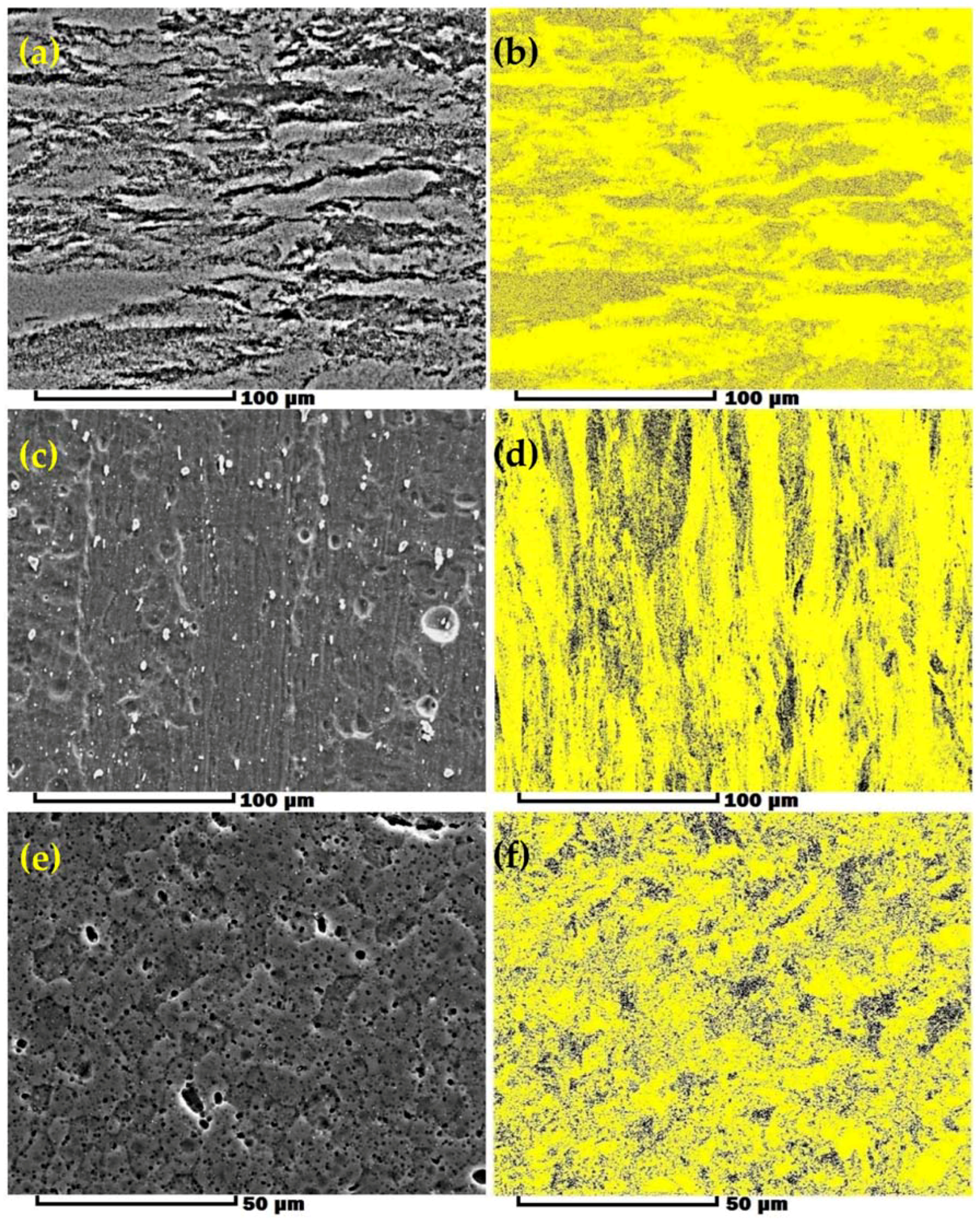

3.2.1. Dynamic Recrystallization

3.2.2. Precipitation

4. Discussion

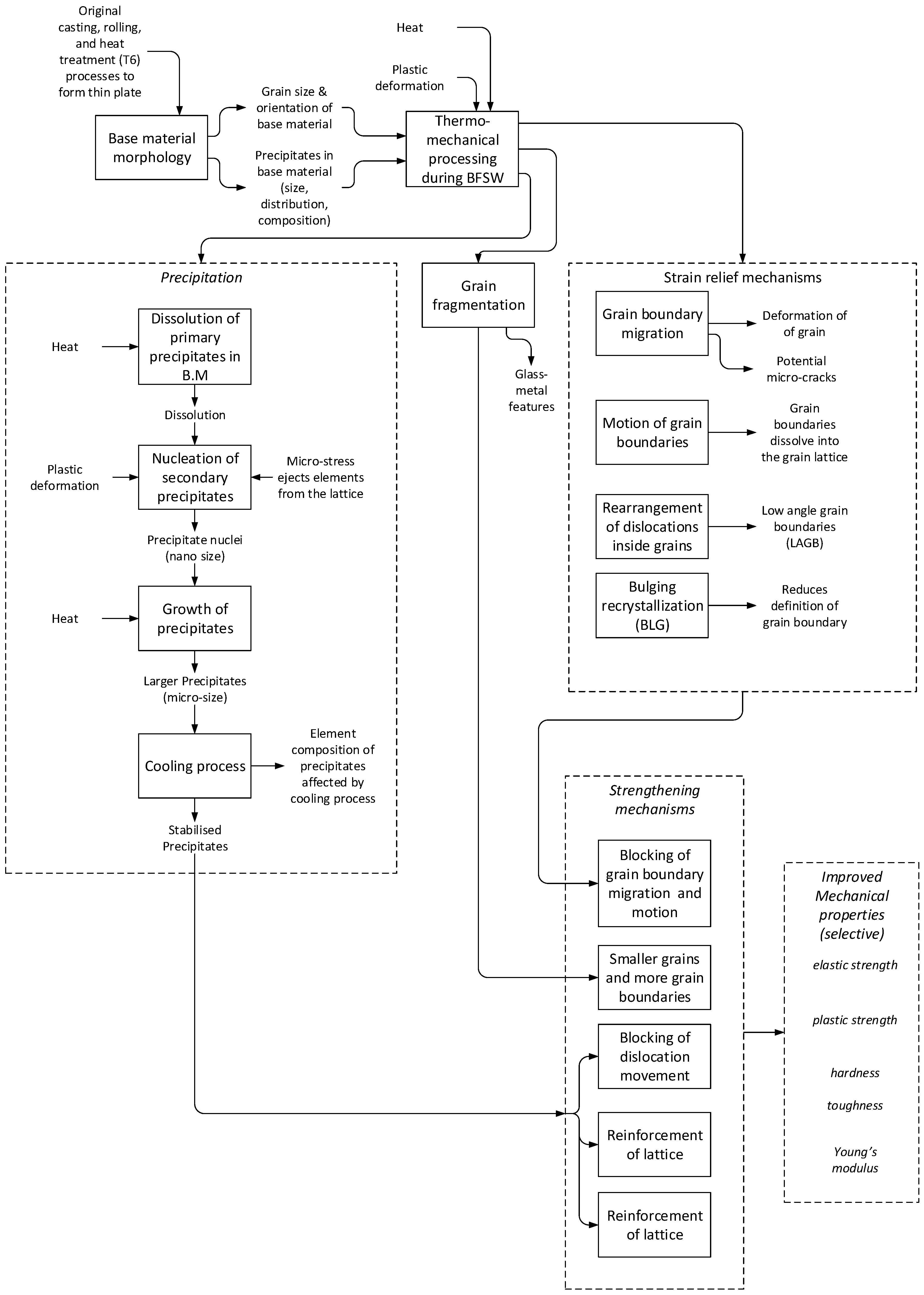

4.1. Model for Strengthening Mechanism

4.2. Original Contributions

4.3. Implications for Practitioners

4.4. Limitations and Implications for Future Research

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Thomas, W. Friction Stir Welding. International Patent Application No PCT/GB92/02203, 6 December 1991. [Google Scholar]

- Thomas, W.; Wiesner, C. Recent developments of FSW technologies: Evaluation of root defects, composite refractory tools for steel joining and one-pass welding of thick sections using self-reacting bobbin tools. In Proceedings of the 8th International Conference Trends in Welding Research, Callaway Gardens Resort, Pine Mountain, GA, USA, 1–6 June 2008; ASM International: Almere, The Netherlands, 2009; p. 25. [Google Scholar]

- Thomas, W.; Wiesner, C.; Marks, D.; Staines, D. Conventional and bobbin friction stir welding of 12% chromium alloy steel using composite refractory tool materials. Sci. Technol. Weld. Join. 2009, 14, 247–253. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Ahmed, M.; Martin, J.P.; Perrett, J.G.; Wynne, B.P. The Use of Bobbin Tools for Friction Stir Welding of Aluminium Alloys; Materials Science Forum; Trans Tech Publication: Zürich, Switzerland, 2010; pp. 1179–1184. [Google Scholar]

- Myhr, O.; Klokkehaug, S.; Grong, O.; Fjær, H.; Kluken, A. Modeling of microstructure evolution, residual stresses and distortions in 6082-T6 aluminum weldments. Weld. J. N. Y. 1998, 77, 286-s. [Google Scholar]

- McNelley, T.; Swaminathan, S.; Su, J. Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr. Mater. 2008, 58, 349–354. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H. Recent advances in friction-stir welding–process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Russell, M.; Shercliff, H. Analytical modelling of microstructure development in friction stir welding. In Proceedings of the 1st International Symposium On Friction Stir Welding, Oaks, CA, USA, 14–16 June 1999. [Google Scholar]

- Schmidt, H.; Hattel, J. A local model for the thermomechanical conditions in friction stir welding. Model. Simul. Mater. Sci. Eng. 2004, 13, 77. [Google Scholar] [CrossRef]

- Nandan, R.; Roy, G.; Debroy, T. Numerical simulation of three-dimensional heat transfer and plastic flow during friction stir welding. Metall. Mater. Trans. A 2006, 37, 1247–1259. [Google Scholar] [CrossRef]

- Thomas, W.; Nicholas, E. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar] [CrossRef]

- Sued, M.; Pons, D.; Lavroff, J. Compression ratio effects in bobbin friction stir welding. In Proceedings of the 10th International Friction Stir Welding Symposium, Beijing, China, 20–22 May 2014; pp. 1–19. [Google Scholar]

- Sued, M.K.; Pons, D.J. Dynamic interaction between machine, tool, and substrate in bobbin friction stir welding. Int. J. Manuf. Eng. 2016, 2016, 8697453. [Google Scholar] [CrossRef]

- Song, M.; Kovacevic, R. Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int. J. Mach. Tools Manuf. 2003, 43, 605–615. [Google Scholar] [CrossRef]

- Sofuoglu, H.; Rasty, J. Flow behavior of plasticine used in physical modeling of metal forming processes. Tribol. Int. 2000, 33, 523–529. [Google Scholar] [CrossRef]

- Kumar, K.; Kailas, S.V. The role of friction stir welding tool on material flow and weld formation. Mater. Sci. Eng. A 2008, 485, 367–374. [Google Scholar] [CrossRef]

- Sued, M.K. Fixed Bobbin Friction Stir Welding of Marine Grade Aluminium. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2015. [Google Scholar]

- Babu, G.R.; Murti, K.; Janardhana, G.R. An experimental study on the effect of welding parameters on mechanical and microstructural properties of aa 6082-T6 friction stir welded butt joints. ARPN J. Eng. Appl. Sci. 2008, 3, 68–74. [Google Scholar]

- Seidel, T.; Reynolds, A.P. Two-dimensional friction stir welding process model based on fluid mechanics. Sci. Technol. Weld. Join. 2003, 8, 175–183. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Development of metallographic etchants for the microstructure evolution of A6082-T6 BFSW welds. Metals 2017, 7, 423. [Google Scholar] [CrossRef]

- Sued, M.; Tamadon, A.; Pons, D. Material flow visualization in bobbin friction stir welding by analogue model. Proc. Mech. Eng. Res. Day 2017, 2017, 368–369. [Google Scholar]

- Vander Voort, G.; Manilova, E.P. Metallographic Etching of Aluminum and Its Alloys; Buehler Ltd., EUA: Lake Bluff, IL USA, 2009. [Google Scholar]

- Sasabe, S.; Matsumoto, T. Mechanical properties of A6082 welded joints with ND–yag laser. Weld. Int. 2012, 26, 351–359. [Google Scholar] [CrossRef]

- Schneider, J.; Nunes, A.C., Jr. Origins of Line Defects in Self-Reacting Friction Stir Welds and Their Impact on Weld Quality; NASA Marshall Space Flight Center: Huntsville, AL, USA, 2016.

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Formation mechanisms for entry and exit defects in bobbin friction stir welding. Metals 2018, 8, 33. [Google Scholar] [CrossRef]

- Xu, H.; Tang, H.; Liu, Z.; Xie, M.; Jiao, J. Microstructure and mechanical properties of 6082 aluminum alloy joints welded by MIG. Hot Work. Technol. 2010, 1, 42. [Google Scholar]

- Sued, M.; Pons, D.; Lavroff, J.; Wong, E.-H. Design features for bobbin friction stir welding tools: Development of a conceptual model linking the underlying physics to the production process. Mater. Des. (1980–2015) 2014, 54, 632–643. [Google Scholar] [CrossRef]

- Jata, K.; Semiatin, S. Continuous Dynamic Recrystallization during Friction stIr Welding of High Strength Aluminum Alloys; Air Force Research Lab Wright-Patterson AFB OH Materials and Manufacturing Directorate: Dayton, OH, USA, 2000. [Google Scholar]

- Waldron, D.J.; Roberts, R.W.; Dawes, C.J.; Tubby, P.J. Friction Stir Welding—A Revolutionary New Joining Method; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Zhang, H.; Wang, M.; Zhang, X.; Yang, G. Microstructural characteristics and mechanical properties of bobbin tool friction stir welded 2A14-T6 aluminum alloy. Mater. Des. (1980–2015) 2015, 65, 559–566. [Google Scholar] [CrossRef]

- Fonda, R.; Bingert, J. Precipitation and grain refinement in a 2195 Al friction stir weld. Metall. Mater. Trans. A 2006, 37, 3593–3604. [Google Scholar] [CrossRef]

- Fonda, R.; Bingert, J.; Colligan, K. Development of grain structure during friction stir welding. Scr. Mater. 2004, 51, 243–248. [Google Scholar] [CrossRef]

- Vander Voort, G.F.; Lampman, S.R.; Sanders, B.R.; Anton, G.J.; Polakowski, C.; Kinson, J.; Muldoon, K.; Henry, S.D.; Scott, W.W., Jr. Metallography and Microstructures. In ASM Handbook; ASM International: Almere, The Netherlands, 2004; Volume 9, pp. 40002–44073. [Google Scholar]

- Tamadon, A.; Ds, K.C.; Pons, D.; Sued, M.; Clucas, D.; Wong, E. Analogue modelling of bobbin tool friction stir welding. In Proceedings of the International Conference on Innovative Design and Manufacturing, Auckland, New Zealand, 14–16 September 2016. [Google Scholar]

- Czubayko, U.; Sursaeva, V.; Gottstein, G.; Shvindlerman, L. Influence of triple junctions on grain boundary motion. Acta Mater. 1998, 46, 5863–5871. [Google Scholar] [CrossRef]

- Wang, D.; Xiao, B.; Ma, Z.; Zhang, H. Friction stir welding of Zr55Cu30Al10Ni5 bulk metallic glass to Al–Zn–Mg–Cu alloy. Scr. Mater. 2009, 60, 112–115. [Google Scholar] [CrossRef]

- Fujii, H.; Sun, Y.; Inada, K.; Ji, Y.; Yokoyama, Y.; Kimura, H.; Inoue, A. Fabrication of Fe-based metallic glass particle reinforced Al-based composite materials by friction stir processing. Mater. Trans. 2011, 52, 1634–1640. [Google Scholar] [CrossRef]

- Sun, Y.; Ji, Y.; Fujii, H.; Nakata, K.; Nogi, K. Microstructure and mechanical properties of friction stir welded joint of Zr55Cu30Al10Ni5 bulk metallic glass with pure copper. Mater. Sci. Eng. A 2010, 527, 3427–3432. [Google Scholar] [CrossRef]

- Li, F.; Zhang, D.; Luo, Z.; Tan, C.; Lin, J. Microstructure and mechanical properties of friction stir welded joint of Zr46Cu46Al8 bulk metallic glass with pure aluminum. Mater. Sci. Eng. A 2013, 588, 196–200. [Google Scholar] [CrossRef]

- Sato, Y.S.; Yamashita, F.; Sugiura, Y.; Park, S.H.C.; Kokawa, H. Fib-assisted tem study of an oxide array in the root of a friction stir welded aluminium alloy. Scr. Mater. 2004, 50, 365–369. [Google Scholar] [CrossRef]

- Sato, Y.S.; Takauchi, H.; Park, S.H.C.; Kokawa, H. Characteristics of the kissing-bond in friction stir welded Al alloy 1050. Mater. Sci. Eng. A 2005, 405, 333–338. [Google Scholar] [CrossRef]

- Kobata, J.; Takigawa, Y.; Chung, S.; Tsuda, H.; Kimura, H.; Higashi, K. Nanoscale amorphous “band-like” structure induced by friction stir processing in Zr55Cu30Al10Ni5 bulk metallic glass. Mater. Lett. 2007, 61, 3771–3773. [Google Scholar] [CrossRef]

- Ogura, T.; Saito, Y.; Nishida, T.; Nishida, H.; Yoshida, T.; Omichi, N.; Fujimoto, M.; Hirose, A. Partitioning evaluation of mechanical properties and the interfacial microstructure in a friction stir welded aluminum alloy/stainless steel lap joint. Scr. Mater. 2012, 66, 531–534. [Google Scholar] [CrossRef]

- Zipperian, D.C. Metallographic Handbook; Chief Technical Officier PACE Technologies: Tucson, AZ, USA, 2011. [Google Scholar]

- Frøseth, A.G.; Høier, R.; Derlet, P.M.; Andersen, S.J.; Marioara, C.D. Bonding in mgsi and Al-Mg-Si compounds relevant to Al-Mg-Si alloys. Phys. Rev. B 2003, 67, 224106. [Google Scholar] [CrossRef]

| AA6082-T6 | Composition |

|---|---|

| Chemical Element | % Present |

| Silicon (Si) | (0.70–1.30) |

| Magnesium (Mg) | (0.60–1.20) |

| Manganese (Mn) | (0.40–1.00) |

| Iron (Fe) | (0.0–0.50) |

| Chromium (Cr) | (0.0–0.25) |

| Zinc (Zn) | (0.0–0.20) |

| Titanium (Ti) | (0.0–0.10) |

| Copper (Cu) | (0.0–0.10) |

| Other (Each) | (0.0–0.05) |

| Other (total) | (0.0–0.15) |

| Aluminium (Al) | Balance |

| Welding Parameters | Amount |

|---|---|

| DShoulder (mm) | 21 |

| DPin (mm) | 7 |

| DShoulder/DPin | 3 |

| Plate Thickness (mm) | 4 |

| Compression Ratio | 3.75% |

| Spindle rotational speed, ω (rpm) | 600 |

| Feed rate, V (mm/min) | 400 |

| Thread Pitch (mm) | 1 |

| Number of Threads | 4 |

| Name of Etchant | Pre-Etching | Etchant Composition |

|---|---|---|

| A | - | 0.5 g (NH4)2MoO4 + 3.0 g NH4Cl + 1 mL HF + 18 mL HNO3 + 80 mL H2O (90 s, 70 °C) |

| B | 20 g NaOH + 80 mL H2O (20 s, 50 °C), | Etchant A (60 s, 70 °C) |

| C | 20 g NaOH + 80 mL H2O (20 s, 50 °C), then: 30 mL H3PO4 + 70 mL ethanol (20 s, 50 °C) | 10 g CrO3 + 2 g Na2SO4 + 10 mL HNO3 + 10 mL CH3COOH + 1 mL HF + 80 mL H2O (60 s, 70 °C) |

| D | 20 g NaOH + 80 mL H2O (20 s, 50 °C), then: 30 mL H3PO4 + 70 mL ethanol (20 s, 50 °C) | Etchant C (60 s, 70 °C), then: 15 mL CH3COOH + 85 mL H2O (15 s, 70 °C), then: 15 mL H3PO4 + 85 mL H2O (15 s, 70 °C) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Thermomechanical Grain Refinement in AA6082-T6 Thin Plates under Bobbin Friction Stir Welding. Metals 2018, 8, 375. https://doi.org/10.3390/met8060375

Tamadon A, Pons DJ, Sued K, Clucas D. Thermomechanical Grain Refinement in AA6082-T6 Thin Plates under Bobbin Friction Stir Welding. Metals. 2018; 8(6):375. https://doi.org/10.3390/met8060375

Chicago/Turabian StyleTamadon, Abbas, Dirk J. Pons, Kamil Sued, and Don Clucas. 2018. "Thermomechanical Grain Refinement in AA6082-T6 Thin Plates under Bobbin Friction Stir Welding" Metals 8, no. 6: 375. https://doi.org/10.3390/met8060375

APA StyleTamadon, A., Pons, D. J., Sued, K., & Clucas, D. (2018). Thermomechanical Grain Refinement in AA6082-T6 Thin Plates under Bobbin Friction Stir Welding. Metals, 8(6), 375. https://doi.org/10.3390/met8060375