Abstract

High specific modulus materials are considered excellent for the aerospace industry. The system Ti-TiAl-B4C is presented herein as an alternative material. Secondary phases formed in situ during fabrication vary depending on the processing conditions and composition of the starting materials. The final behaviors of these materials are therefore difficult to predict. This research focuses on the study of the system Ti-TiAl-B4C, whereby relations between microstructure and properties can be predicted in terms of the processing parameters of the titanium matrix composites (TMCs). The powder metallurgy technique employed to fabricate the TMCs was that of inductive hot pressing (iHP) since it offers versatility and flexibility. The short processing time employed (5 min) was set in order to test the temperature as a major factor of influence in the secondary reactions. The pressure was also varied. In order to perform this research, not only were X-Ray Diffraction (XRD) analyses performed, but also microstructural characterization through Scanning Electron Microscopy (SEM). Significant results showed that there was an inflection temperature from which the trend to form secondary compounds depended on the starting material used. Hence, the addition of TiAl as an elementary blend or as prealloyed powder played a significant role in the final behavior of the TMCs fabricated, where the prealloyed TiAl provides a better precursor of the formation of the reinforcement phases from 1100 °C regardless of the pressure.

1. Introduction

High specific modulus materials are required in the aerospace sector. Although titanium and its alloys offer excellent properties desired in this sector [1,2], demands for an increase in their specific modulus promoted the use of these alloys in the development of titanium matrix composites (TMCs). Therefore, the low density of the titanium-based matrices combined with the effect of reinforcement stiffness meet the needs of the aerospace industry.

Among the different types of reinforcement materials employed to produce TMCs, recent studies present several ceramic materials (TiB, TiB2, and TiC) as suitable candidates due to their high elastic modulus and hardness, similar thermal expansion coefficients, and density with the titanium matrix [3,4,5,6]. The in situ synthesis technology constitutes one of the most promising approaches towards fabricating the particulate-reinforced titanium-based composite with mechanical properties elevated by the hard phases formed in situ [7,8,9]. It is well known that there are reaction paths between Ti and B4C, which result in the formation of TiB, TiB2, and TiC. Therefore, the Ti/B4C system has been extensively studied by many authors in the last decade [10,11,12,13,14,15].

In addition to B4C particles as starting reinforcement materials, the stiffness effect of the titanium matrix has been raised through the incorporation of aluminum into the matrix by other authors. In this way, the formation of intermetallic compounds (Al-Ti) leads to the improvement of the properties [16] either with the formation of intermetallic compounds from elementary Ti and Al powder or directly by the incorporation of prealloyed powder to the blending of the starting material. The influence of TiAl as an elementary blend or as a prealloyed powder as starting material has yet to be widely studied in the properties of the final specimens. The novelty of the present research work is to determine possible differences between both systems (Ti matrix-B4C-Ti powder-Al powder vs. Ti matrix-B4C-TiAl prealloyed powder) in the final properties.

In accordance with the aforementioned, there are a limited number of reports regarding the microstructural evolution and reaction mechanism of the Ti-B4C system under solid-state sintering, although it is one of the most popular methods for the preparation of TMCs [10,11,12,13,14,15]. Furthermore, the incorporation of Ti-Al as a precursor of intermetallic compounds presents a further aspect to be taken into account in this work, since the influence of the intermetallic compounds in the formation of TiB and TiC remains unclear [13].

In this paper, experiments have been carried out to clarify the behavior of the in situ reaction of the Ti-B4C-TiAl system under solid-state sintering while varying processing parameters and the raw materials. The importance of determining whether there is any significant influence of the raw materials on the final properties, in addition to evaluating the behavior of the different specimens while varying their processing parameters, constitute the motivation points of the present research work. Concluding, it is pursued to have greater control of the final properties depending on the composition and manufacturing parameters, and further develop the knowledge of the Ti-B4C system, by the addition of intermetallic: Ti-Al blended, and prealloyed TiAl.

2. Materials and Methods

2.1. Materials

From the raw materials point of view, both the size and morphology of the starting powders have been studied in this research as influence factors in the final properties of composites. To this end, a detailed study has been carried out. A spherical titanium matrix powder (grade 1), manufactured by TLS GmbH (Bitterfeld, Germany), was used. In order to trigger the formation of secondary phases formed in situ, boron carbide particles were selected (manufactured by ABCR GmbH & Co KG, Karlsruhe, Germany). The innovation of this investigation lies in the use of two types of Ti-Al powders. On one hand, in situ TixAly-based intermetallic compounds from elementary aluminum and fine titanium powder were used. In this way, these blendings of raw powder led to an expected Ti-Al intermetallic compound (Ti powder manufactured by TLS GmbH, and Al powder by NMD GmbH, Heemsen, Germany) [17]. On the other hand, prealloyed powder Ti-Al was used (TiAl* by TLS GmbH).

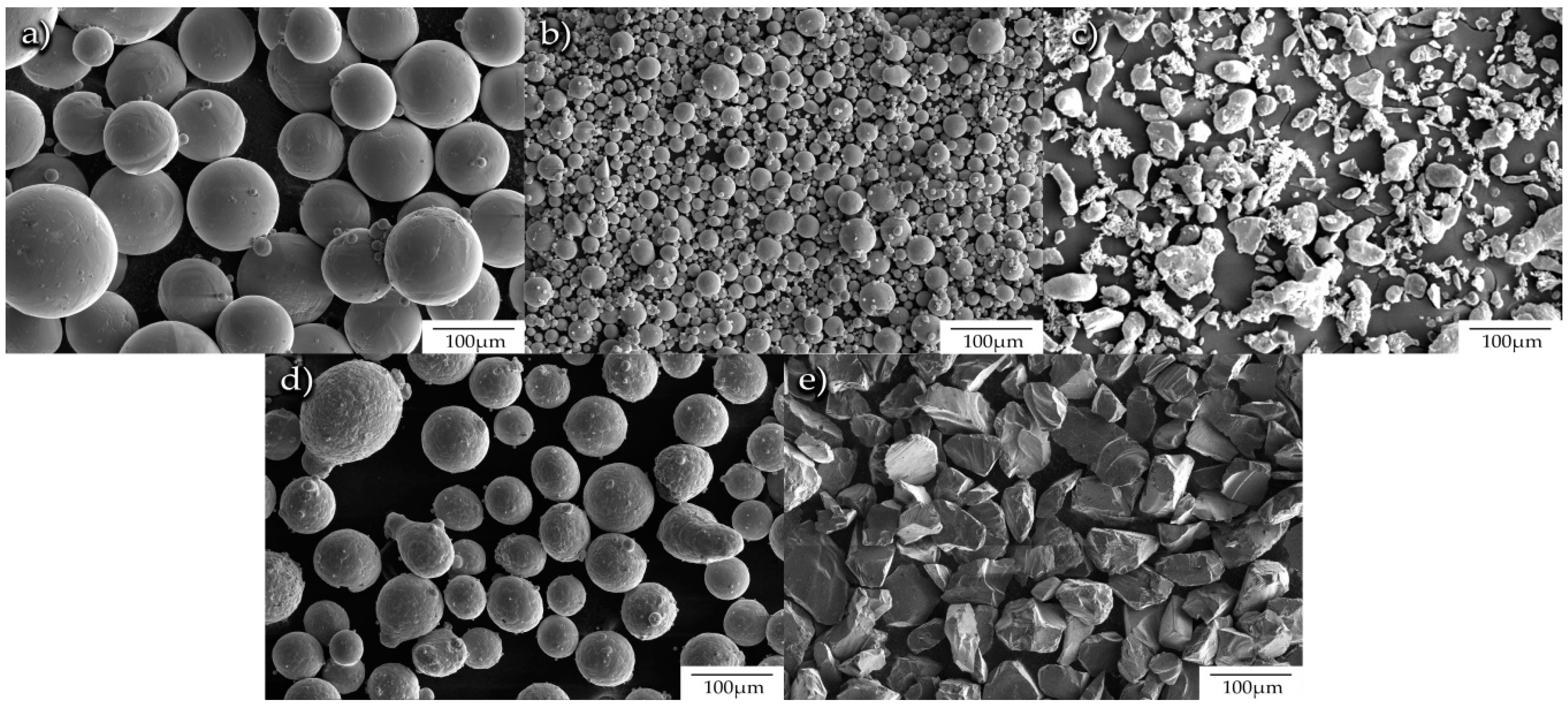

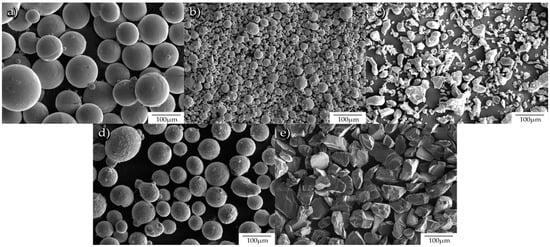

By means of the selection of the elementary powder blending and prealloyed powder, a significant variation in the behavior of the TMCs may be expected. A characterization of all the raw materials was performed to verify the information supplied by the manufacturers regarding the size and morphology of powders. Mastersizer 2000 (Malvern Instruments, Malvern, UK) equipment was employed to verify the average particle size. The results obtained are listed in Table 1. Moreover, Scanning Electron Microscopy (SEM) images of the powders showed the morphologies of the starting materials employed in the fabrication of the TMCs. As observed in Figure 1, the prealloyed TiAl (named TiAl*) and the elementary blend of Ti-Al (named TiAl) present different particle sizes.

Table 1.

Particle-size distribution of the raw materials.

Figure 1.

Scanning Electron Microscope (SEM) images of the raw powders: (a) spherical titanium matrix powder morphology; (b) fine titanium; (c) aluminium particles; (d) prealloyed TiAl powder; (e) faceted B4C particles.

In Figure 1, the SEM images (FEI Teneo, Hillsboro, OR, USA) reflect the spherical morphologies of the two types of Ti powders and the TiAl prealloyed powder. The fine Al powder presents an irregular-nodular morphology. Furthermore, B4C particles show a faceted shape.

2.2. Experimental Procedure

The various stages of the experimental procedure are described in this section. Firstly, the material preparation took place. The consolidation of the specimens was then carried out via inductive hot pressing. In order to investigate the relation between the starting materials in terms of processing parameters and TMCs behaviors, a detailed characterization was developed for all specimens fabricated. Analyses were performed by X-ray diffraction (XRD) (Bruker D8 Advance A25, Billerica, MA, USA) and SEM to examine the evolution of their microstructure versus variations of the influence factors: (i) starting materials; (ii) processing temperature; and (iii) consolidation pressure. Furthermore, density, Young’s Modulus, and the hardness of samples were also measured.

2.2.1. Preparation of the Powders

The powder preparation was carried out in various steps. The first stage involved the mixing of the elementary blend of Ti-Al. This was made of 64% weight of fine titanium powder and 36% weight of aluminum powders. It was developed according to the atomic ratio Ti:Al. A Sintris mixer (Sintris Macchine S.R.L., Piacenza, Italy) was employed for this first powder mixing, for 12 h using ZrO2 balls (Ø 3 mm) in cyclohexane. The weight ratio of the ceramic balls and powder was 10:1. After drying, the Ti-Al was mixed in a vacuum oven at 100 °C for 8 h to evaporate the solvent, and powders were blended for 2 h. This type of Ti-Al powder was prepared for its combination with the raw matrix powder and the B4C particles. A similar content of TiAl blending powder or prealloyed TiAl powder was incorporated to determine the starting powder mixtures. All these particulate materials were also blended in a Sintris mixer for 2 h. These mixing processes were employed in previous studies and obtained the optimal dispersion result of the particles [17].

To summarize, Table 2 shows the tested starting materials under various processing parameters. It is important to note that pressure was varied to obtain better values of densification in the TMCs produced from Ti-B4C-TiAl raw materials. Furthermore, to define in a specific way how the intermetallic (TiAl) compounds could contribute towards blocking the formation of secondary phases (TiB and TiC), the system Ti matrix with TiAl* (prealloyed powder) and Ti matrix with Ti-Al elementary blend without B4C particles had to be studied. To this end, additional specimens were fabricated as indicated in Table 2.

Table 2.

Starting composition 1 of titanium matrix composites (TMCs) and the fabrication parameters (by iHP).

2.2.2. Inductive Hot-Pressing Consolidation Process

A self-made hot pressing machine, inductive Hot Pressing (iHP) equipment of RHP-Technology GmbH & Co. KG (Seibersdorf, Austria), was employed to perform the consolidation of the specimens. This equipment enables the time of the operational cycles to be reduced thanks to its advantageous high heating rate, which in turn is due to its special inductive heating set up. A graphite die was used for all the iHP cycles (punch Ø 20 mm). The same procedure to fill the die was carried out for the consolidation of each of the specimens. The die was lined with thin graphite paper with a protective coating of boron nitride (BN). As mentioned earlier, Table 2 shows the operational parameters tested in this work. The vacuum and the heating rate were fixed in all the iHP cycles: heating rate (50 °C·min−1) and vacuum conditions (5×10−4 bar). This vacuum value was the maximum that the equipment would allow.

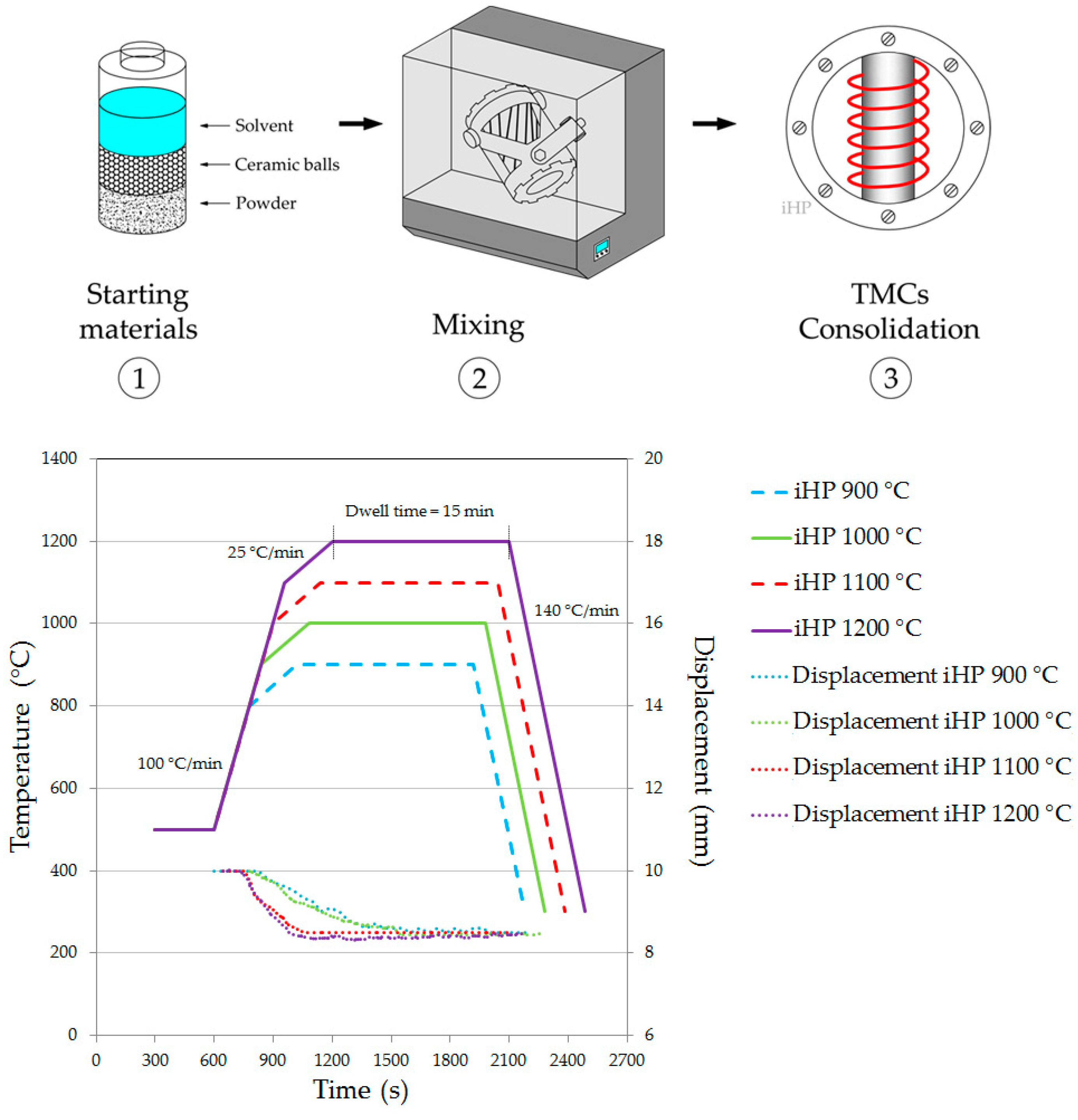

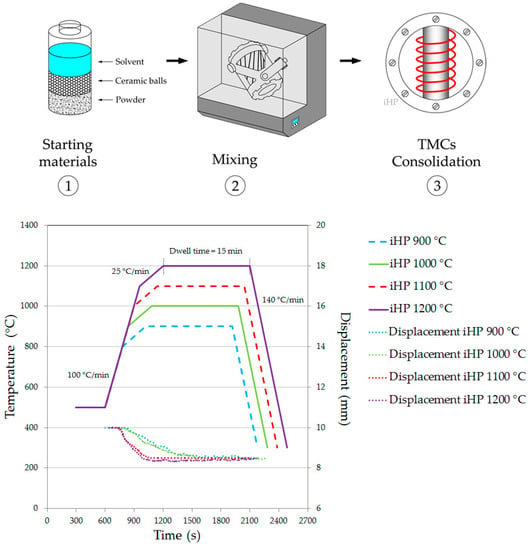

To graphically represent the development of the TMC fabrication process, Figure 2 shows a sketch of the equipment and the different manufacturing steps: (i) Preparation of starting materials; (ii) Mixing; and (iii) Hot Consolidation.

Figure 2.

Sketch of the manufacturing process of the TMCs.

2.2.3. Specimen Characterization

After the manufacture of the specimens, their characterization was carried out. Compacts were removed from the die and then sand-blasted cleaned to remove the graphite paper residue from the surfaces. Firstly, a microstructural study was performed, after a thorough metallographic preparation. The microstructure was studied by means of optical microscopy (OM), using Nikon Model Epiphot 200 (Tokyo, Japan), and by SEM, using JEOL 6460LV (Tokyo, Japan) and FEI Teneo (Hillsboro, OR, USA). Moreover, an XRD study was carried out on the Bruker D8 Advance A25 (Billerica, MA, USA) to identify and evaluate the diverse crystalline phases in the composites. Archimedes’ method (ASTM C373-14) was set for the determination of the density. The results obtained were compared to the measurements performed with other control techniques such as geometrical density (ASTM B962-13). On the polished cross-section of the specimens, the hardness measurements were carried out. Eight indentations were performed on each specimen, avoiding B4C particles. A tester model, Struers-Duramin A300 (Ballerup, Denmark), was used to ascertain the Vickers hardness (HV10). To complete the characterization of the specimens, an ultrasonic method (Olympus 38 DL, Tokyo, Japan) was used to calculate Young’s Modulus by measuring longitudinal and transverse propagation velocities of acoustic waves [18].

3. Results and Discussion

3.1. XRD Analysis

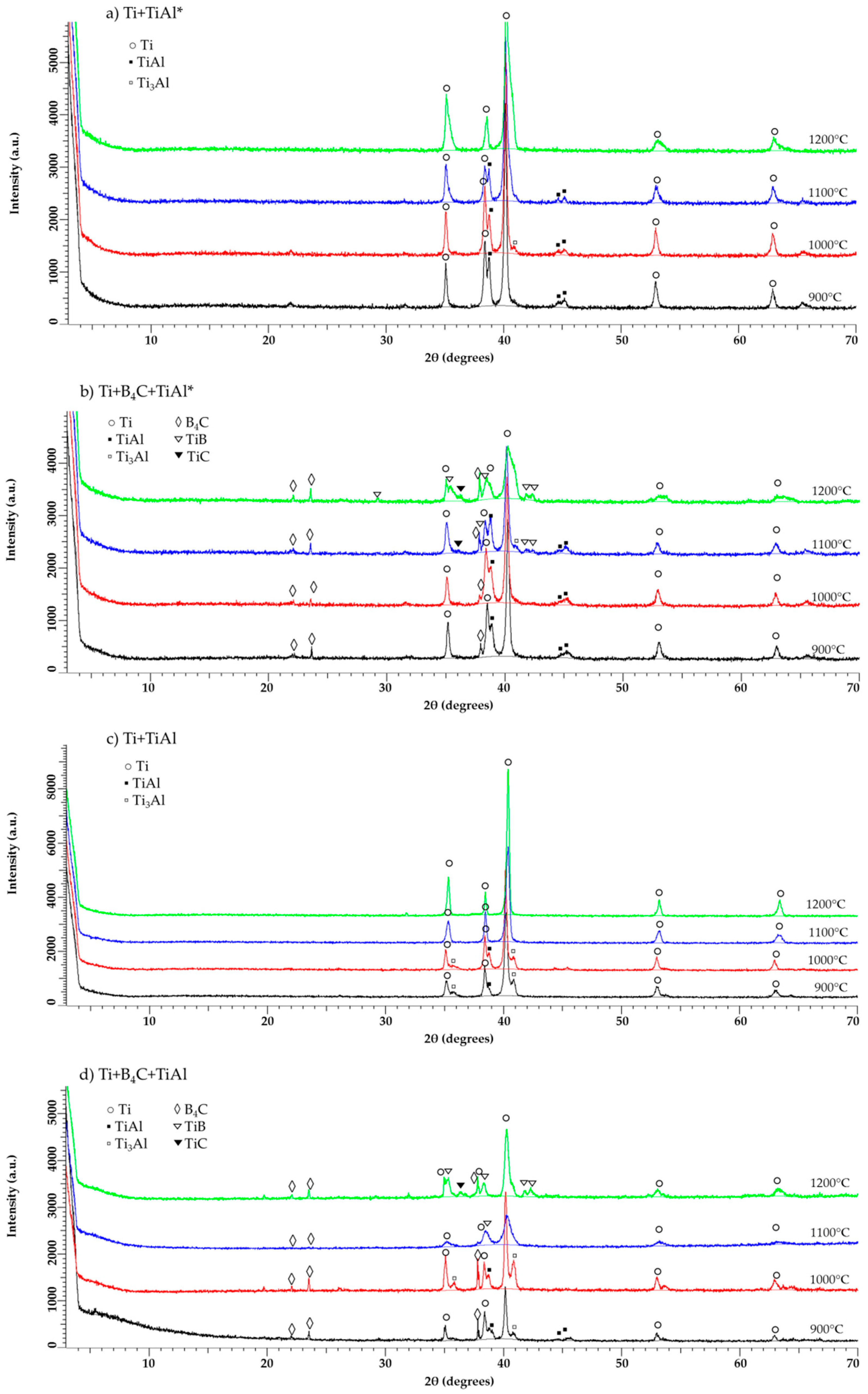

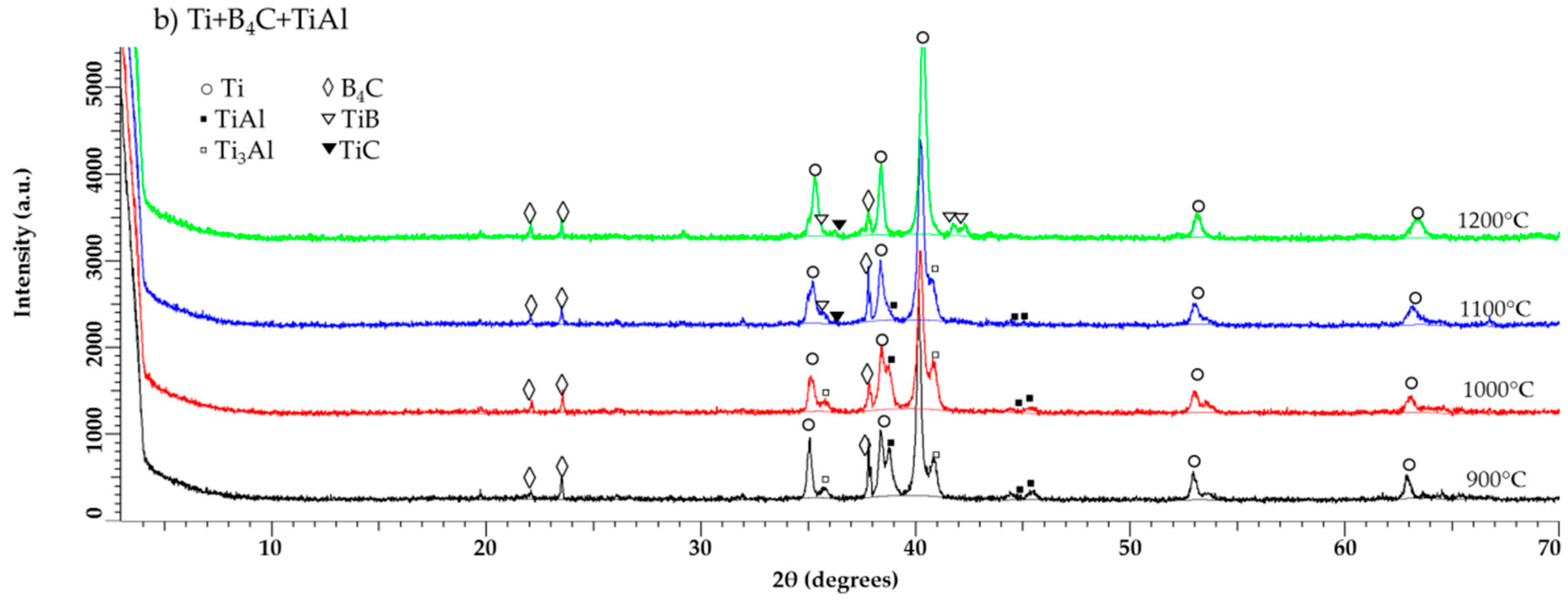

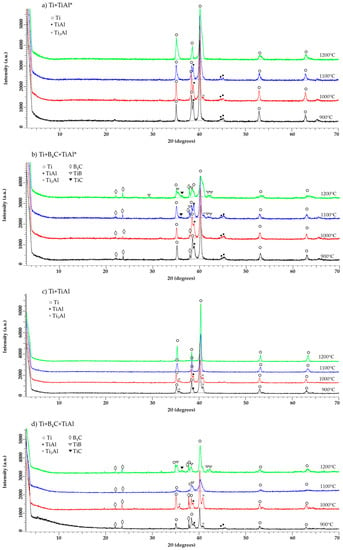

The X-ray diffraction analysis was employed to identify the phase transformations and probable reactions during the sintering process. The obtained results were evaluated, compared, and discussed taking into account the effect caused by variation of the starting materials (Ti-Al, TiAl* and B4C) and of the processing parameters (temperature (900, 1000, 1100 and 1200 °C) and pressure (40 and 80 MPa)). Figure 3 shows the XRD patterns of the TMCs processed at different temperatures from the four blends of raw powders, consolidated under 40 MPa for 5 min.

Figure 3.

X-ray diffraction (XRD) patterns of the TMCs processed under 40 MPa for 5 min, from the starting materials: (a) Ti matrix with TiAl* (prealloyed powder); (b) Ti matrix with Ti-Al (Ti-Al blend); (c) Ti matrix with TiAl* and B4C particles; (d) Ti matrix with TiAl and B4C particles.

It should be borne in mind that Figure 3a,c show the patterns of specimens from Ti and TiAl powders without the B4C phase. By excluding the Ti peaks, there are crystalline phases related to the starting materials (TiAl prealloyed or blend powders). The effect of the temperature and the starting materials are reflected in the pattern of these specimens. It seems that in the specimens from Ti powder mixed with Ti-Al blend, peaks of Ti3Al and TiAl are appreciated only below 1000 °C. When prealloyed TiAl powder is used, peaks of TiAl phase are clearly observed even up to 1100 °C. These results suggest that this is due to the prealloyed powder being less reactive than the aluminum from the blend powder. Moreover, aluminum has a tendency to diffuse into the crystalline structure of Ti: it happens from 1200 °C if the raw powder is prealloyed, and from 1100 °C if the starting particles come from the blend Ti-Al. This means that, from 1100 °C, there are only peaks of titanium alpha phase in specimens whose starting powder was the Ti-Al blend; however, this phenomenon in specimens from Ti with prealloyed TiAl* takes place at 1200 °C.

Comparing Figure 3b,d, there are substantial differences between patterns of specimens made from prealloyed TiAl* and Ti-Al blended powders, with the B4C particles processed at the same temperature. As previously mentioned, the presence of the TiAl phase is only detected up to 1100 °C when TiAl* prealloyed powder is used in the starting materials of specimens. In this respect, the presence of the B4C did not affect the TiAl stability.

From the point of view of the phases formed in situ, the difference between patterns of specimens produced from TiAl* and Ti-Al blend powders are evident (see Figure 3b,d). Considering the study of phase changes based on variations of rising temperature, if prealloyed powder is used then the apparition of secondary phases is more notorious in general up to determinate temperatures. It can be found, when the consolidation temperature is lower than 1100 °C, that the compact only consists of alpha Ti, B4C and intermetallic phases. By hot pressing at 1100 °C under 40 MPa, a weak peak corresponding to TiC and two peaks of TiB phases appear, and their intensities increase with the increment of the operational temperature in specimens processed from TiAl*. The formation of TiC and TiB is detected at 1200 °C for both types of TMCs. It therefore seems to indicate that the presence of Al in the blend could act as a block in the secondary reaction at 1100 °C when the consolidation pressure is 40 MPa.

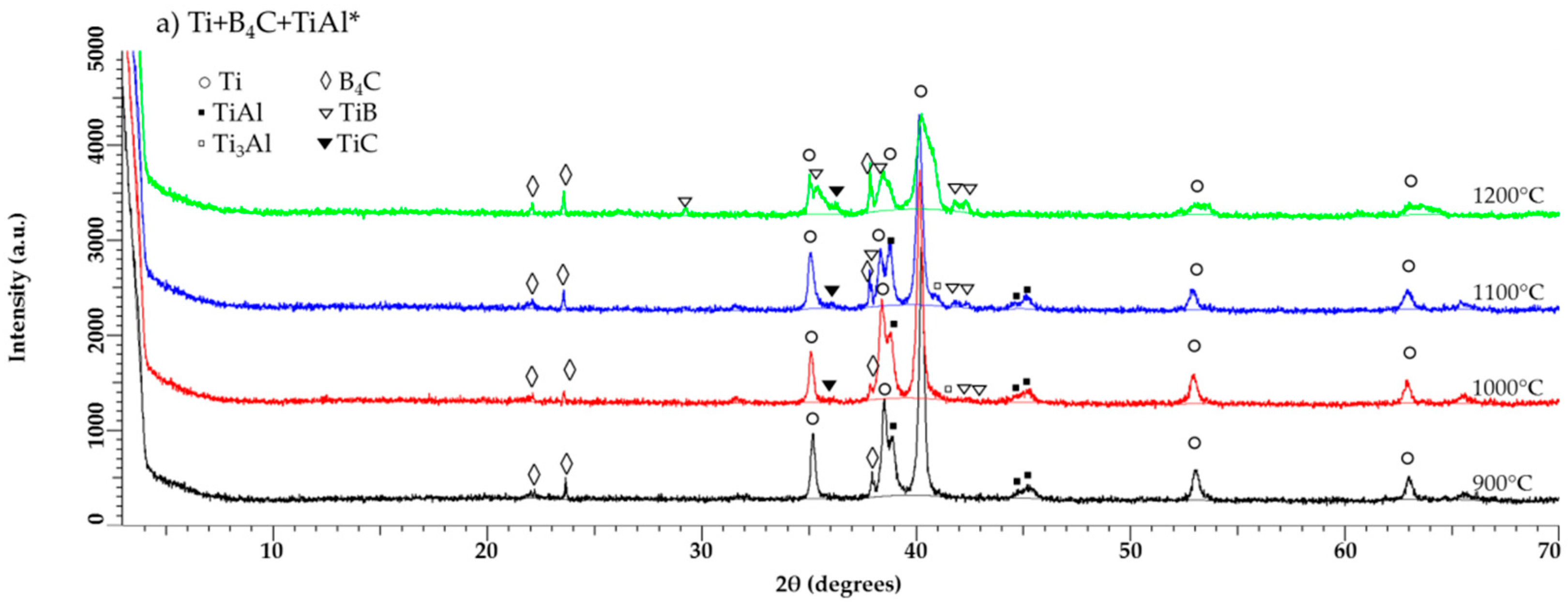

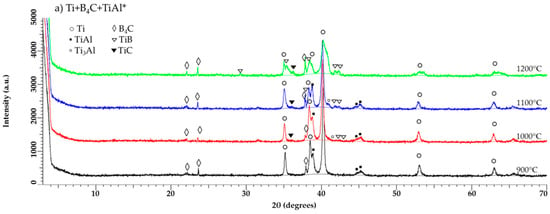

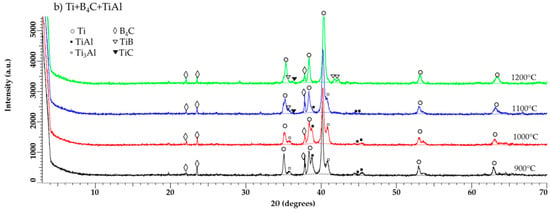

In order to evaluate whether a certain influence of the inductive pressure exists in the phases formed in situ, not only was 40 MPa tested as operational pressure, but also 80 MPa. A semi-quantitative analysis made by the Reference Intensity Ratio (RIR) method, shown in Table 3, was also performed. Results indicate that such variation contributes towards enhancing the content of the reinforcement when the specimens are hot-consolidated under 80 MPa. For that matter, at lower temperatures, peaks and semi-quantification of TiB and TiC can be observed in Figure 4a,b and Table 3. In the case where specimens are made from TiAl*, weak peaks of TiB and TiC phases appear at 1000 °C; while in specimens made from Ti-Al blend, the processing temperature to detect secondary phases ascends to 1100 °C. In this respect, this phenomenon has certain similitude with the aforementioned results as observed in Figure 3b,d. At 1100 °C, the formation of a small amount of intermetallic Ti3Al can be appreciated under 80 MPa, thanks to the decomposition of TiAl and the subsequent reactions inside the Ti matrix. Table 3 confirms these observations.

Table 3.

Reference Intensity Ratio (RIR) semi-quantification analysis of TMCs manufactured at 80 MPa and at different temperatures (by iHP).

Figure 4.

XRD patterns of the TMCs processed under 80 MPa for 5 min, from the starting materials: (a) Ti matrix with TiAl* and B4C particles; (b) Ti matrix with TiAl and B4C particles.

On concluding the XRD analysis of the specimens, in those produced at 1100 °C, patterns are slightly different; a transition can be observed with temperature. It is therefore necessary to delve into further depth regarding the phase evolution information by microstructure observation with SEM and optical microscopy.

3.2. Microstructural Characterization

The identification was performed on phases formed in situ and intermetallic compounds through a microstructural study of the specimens. In order to present the results of this study in a suitable way, several comparisons between diverse specimens are performed based on: (i) starting materials; (ii) consolidation pressure; and (iii) processing temperature.

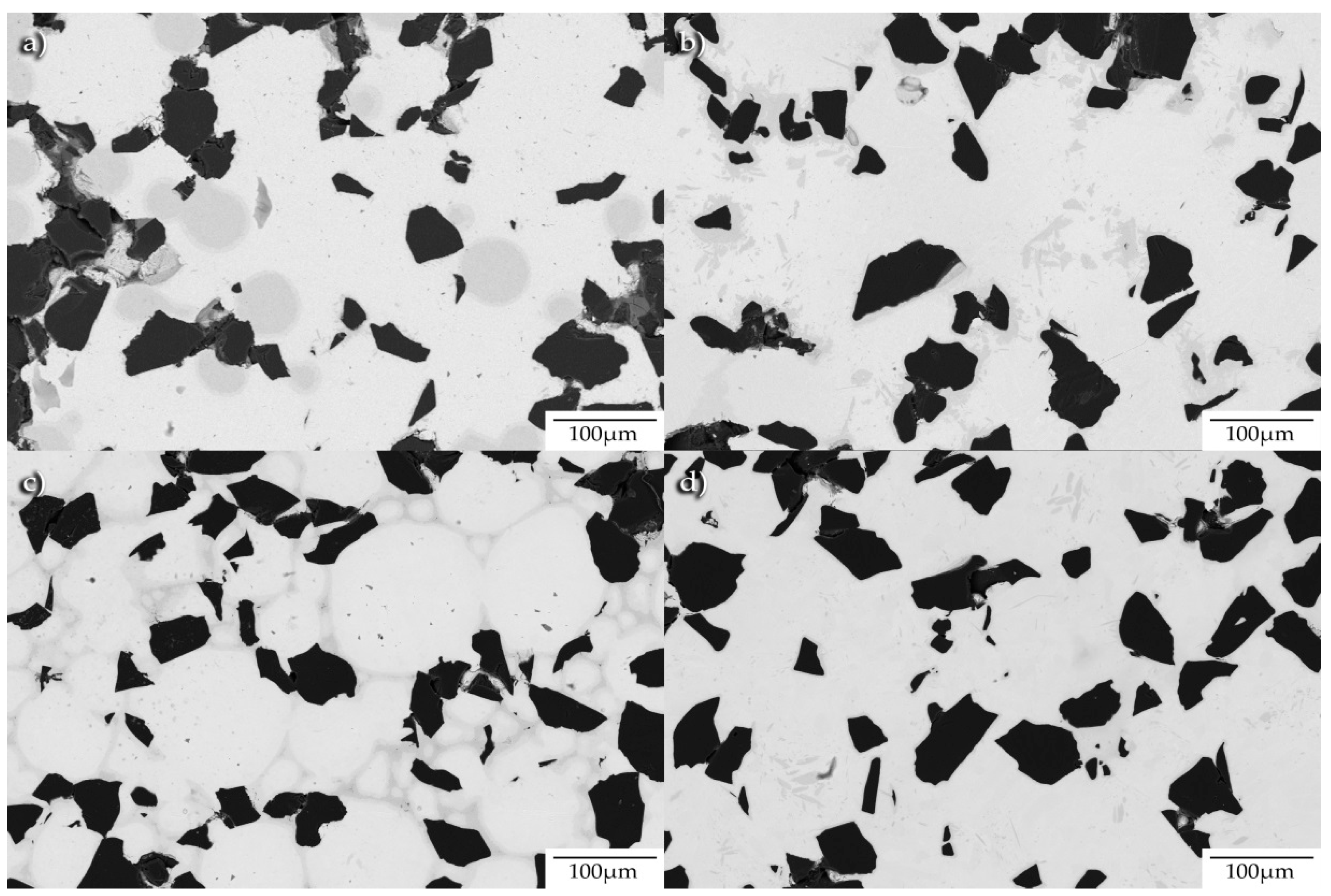

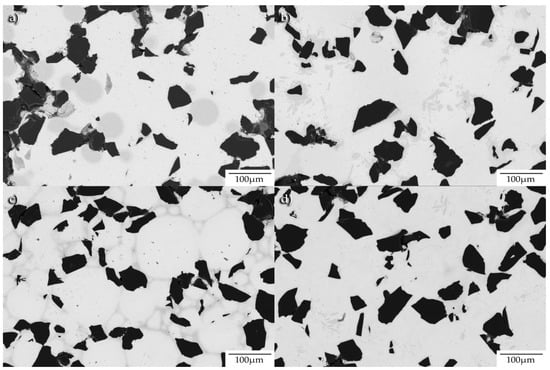

Regarding the powders used in the fabrication, a first comparison between TMCs processed from TiAl* and Ti-Al blend powder is carried out. Figure 5 shows microstructures of the specimens processed at two temperatures (1000 °C and 1200 °C), for 5 min and with pressure at 80 MPa, whereby the starting materials constitute the influence factor to be evaluated. By hot pressing at 1200 °C, no presence of TiAl or Ti3Al phases remains, for either TMCs made from TiAl* or Ti-Al blend. However, if the temperature of the hot pressing is 1000 °C, then intermetallic phases are observed (Figure 5a,c). The distribution in the Ti matrix of the TiAl-based phases depends on the starting materials employed. While the microstructure of the specimens with TiAl* shows the TiAl-based phases as nodular morphology into the matrix, the location and morphology of these phases in TMC made from Ti-Al blend is totally different. The equiaxial grain of the Ti matrix in TMCs from Ti-Al blend can be appreciated thanks to the location of the intermetallic compound at grain boundaries. This phenomenon was also studied in previous work by the authors [17]. Through the use of TiAl*, the grain boundaries are free to react with the B4C particles. For this reason, the presence of secondary phases at a lower temperature is observed, which means that TiB and TiC form first in these TMCs.

Figure 5.

SEM images of the TMCs processed under 80 MPa for 5 min, from the starting materials: (a) Ti matrix with TiAl* and B4C particles at 1000 °C; (b) Ti matrix with TiAl* and B4C particles at 1200 °C; (c) Ti matrix with Ti-Al and B4C particles at 1000 °C; (d) Ti matrix with Ti-Al blend and B4C particles at 1000 °C.

Figure 5b,d show the SEM micrographs of the TMCs compacted at the highest pressure (80 MPa) and the highest temperature (1200 °C). From the cross-section of the specimens, a uniform distribution of the reinforcing phases without porosity can be observed, which indicates that a well-bonded composite structure can be achieved by means of the inductive hot-pressing process under these conditions.

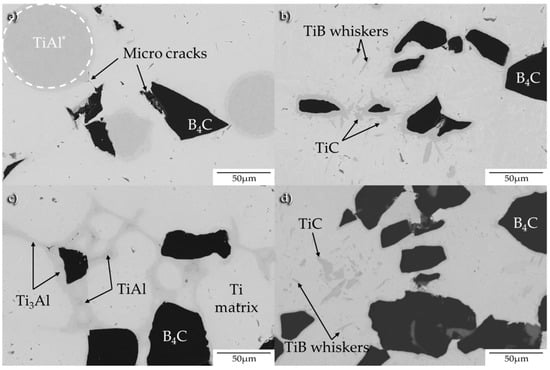

Figure 6 displays the evolution of the microstructures of the TMCs under the processing parameters of 40 MPa pressure and at temperatures of 1000 and 1200 °C. As commented previously for specimens processed under 80 MPa, the higher the temperature becomes, the more the secondary phases are formed. Regarding densification, certain cracks and porosity could be observed close to the B4C particles. In particular, there are micro cracks close to intermetallic phases at lower temperatures, as it can be observed in Figure 6a.

Figure 6.

SEM images of the TMCs processed under 40 MPa for 5 min, from the starting materials: (a) Ti matrix with TiAl* and B4C particles at 1000 °C; (b) Ti matrix with TiAl* and B4C particles at 1200 °C; (c) Ti matrix with Ti-Al and B4C particles at 1000 °C; (d) Ti matrix with Ti-Al blend and B4C particles at 1000 °C.

The interface zone between the matrix and B4C particles is clear. It can be observed from Figure 6b,d that TiC areas and TiB whiskers are tightly fixed to the Ti matrix and no microdefects appeared due to the clean reaction interface between the matrix and the phases formed in situ. When B4C dissolves in B and C elemental particles, carbon particles present higher diffusion than do boron particles in the matrix, and they form round dendritic TiC phases far from that of the original B4C. Boron particles stay close to B4C, surrounding the particles and forming TiB whiskers.

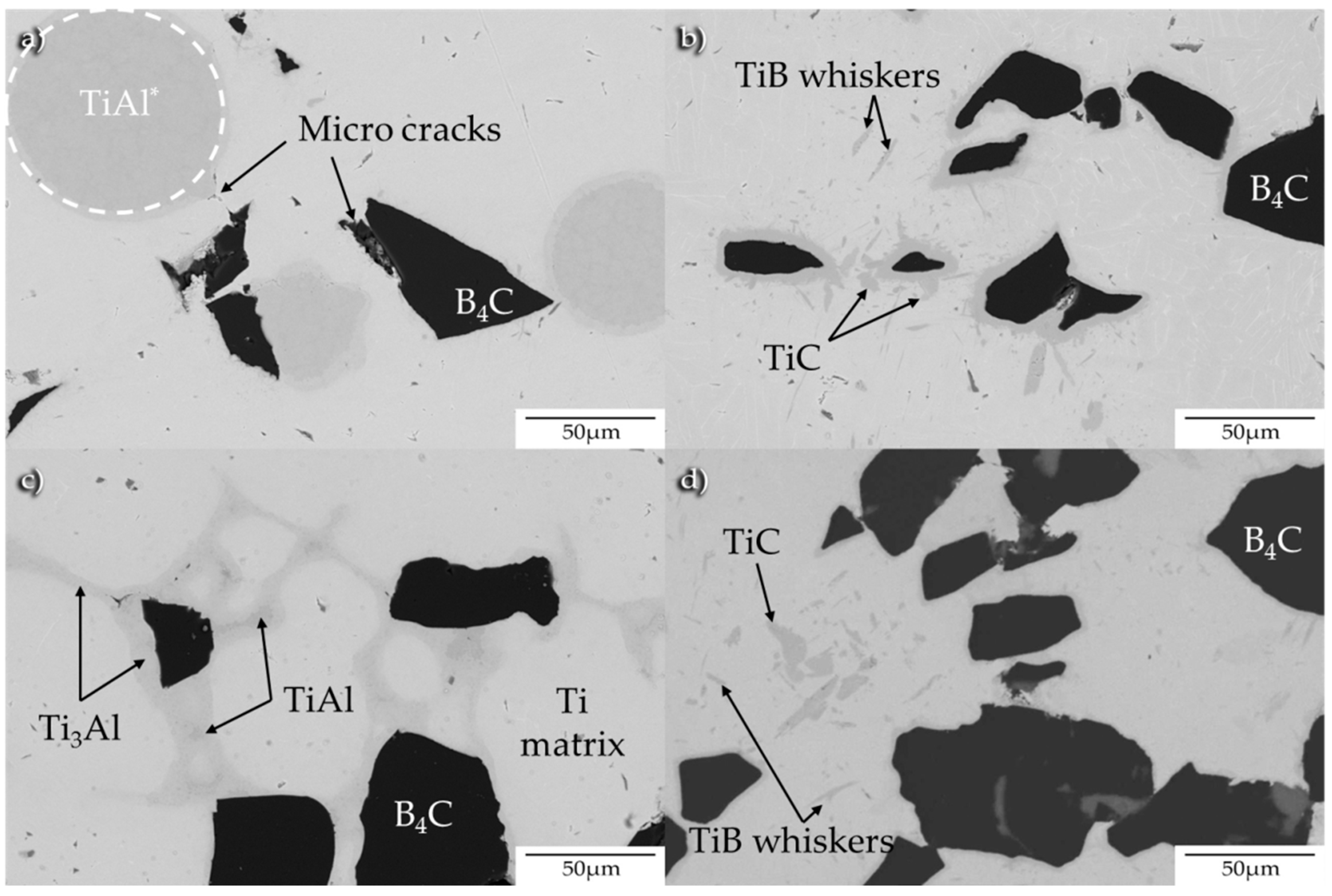

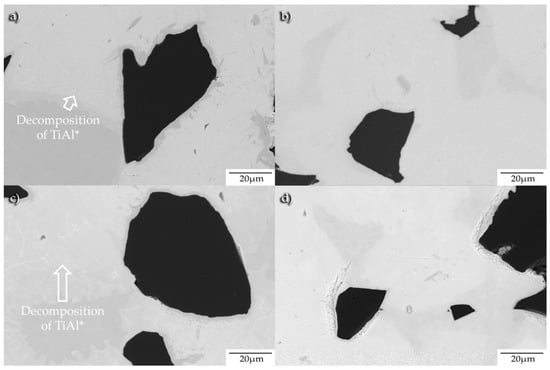

Figure 7 shows the effect of pressure at the transition temperature (1100 °C), and confirms the XRD results. Indeed, at the higher pressure of 80 MPa, both the bonding of TiAl* and the diffusion of aluminum in the Ti matrix improved.

Figure 7.

SEM images of the TMCs processed for 5 min, from the starting materials: (a) Ti matrix with TiAl* and B4C particles at 1100 °C under 40 MPa; (b) Ti matrix with TiAl and B4C particles at 1100 °C under 40 MPa; (c) Ti matrix with Ti-Al and B4C particles at 1100 °C under 80 MPa; (d) Ti matrix with Ti-Al blend and B4C particles at 1100 °C under 80 MPa.

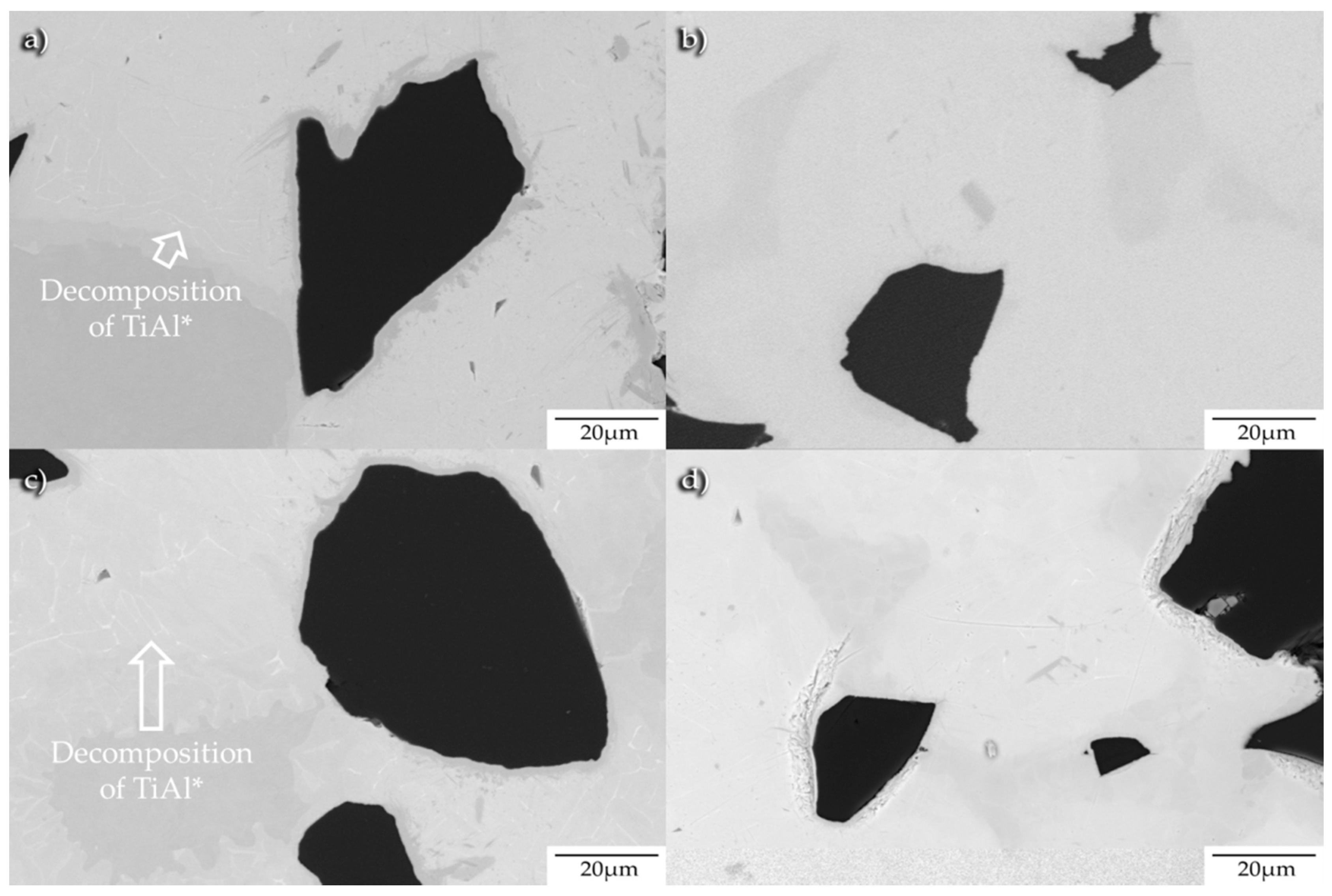

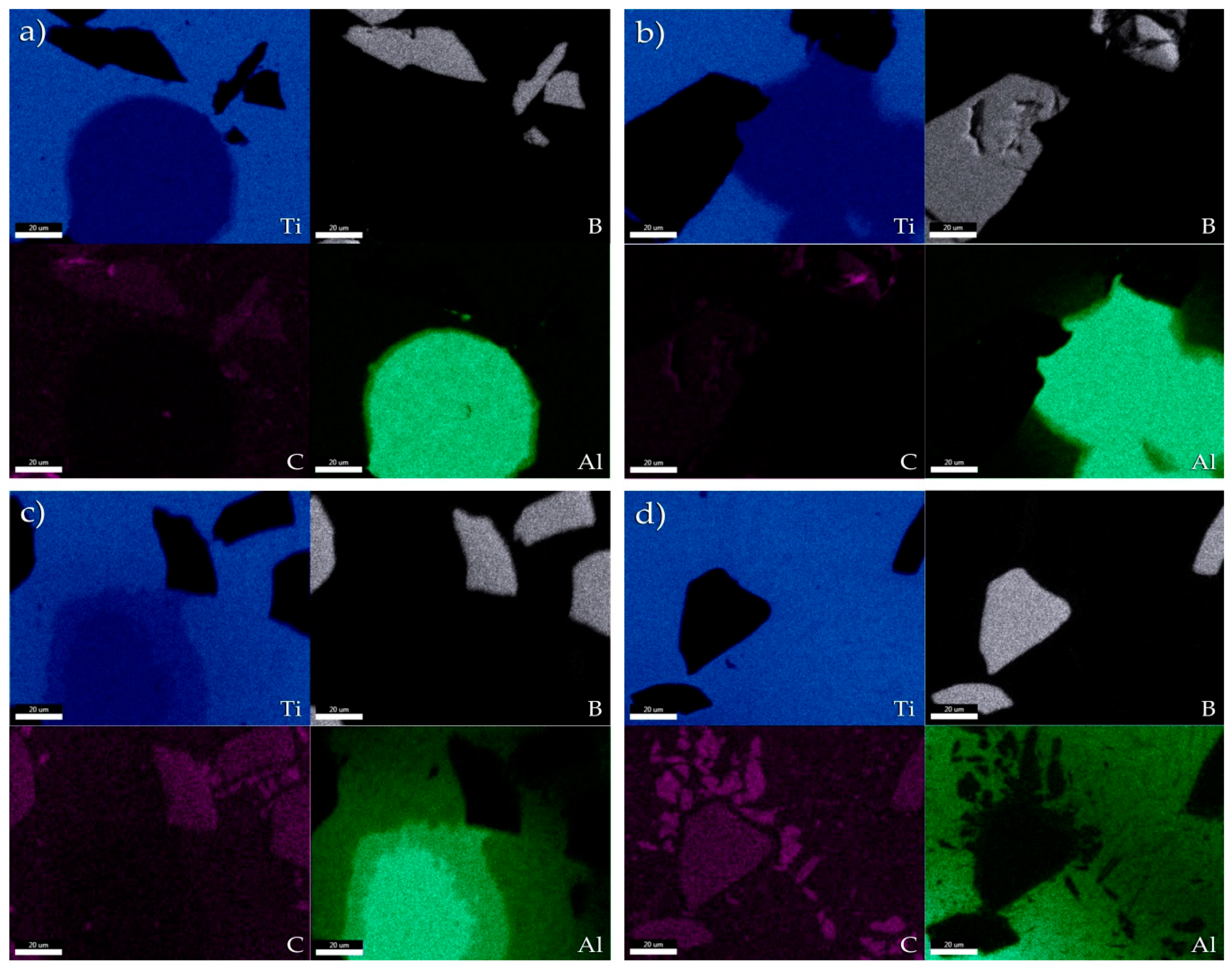

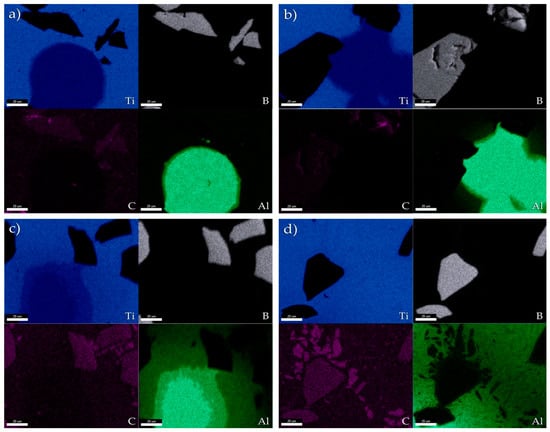

For the conclusion of the microstructural study, a compositional mapping of several elements (Ti, Al, C, and B) is carried out to determine the possible reactions of the constituents of the TMCs at the four processing temperatures tested (900 °C, 1000 °C, 1100 °C, and 1200 °C). The specimens studied are those of the TMCs with TiAl* under 80 MPa. The influence of the temperature in the microstructural evolution can be well appreciated in Figure 8. By hot pressing at 900 °C, there are clear areas corresponding to the intermetallic TiAl from the prealloyed powder (TiAl*), Ti matrix, and the B4C particles. As the temperature rises, through the diffusion and reaction of the elements, the in situ secondary phases appear. These reactions become more evident from 1100 °C. Additionally, the intermetallic compound begins to be more reactive. In this way, the aluminum diffusion into the matrix is more noticeable at 1100 °C as displayed in Figure 8c. Owing to the increment of the temperature up to 1200 °C, the decomposition and reaction of the intermetallic compounds become imminent. Furthermore, as demonstrated in previous research work and mentioned previously, the higher the processing temperature, the greater the content of TiB and TiC phases, and the lower the intermetallic-phase content.

Figure 8.

Mapping of the TMC processed by hot pressing for 5 min under 80 MPa, from the starting materials Ti matrix with TiAl* and B4C at the four processing temperatures: (a) 900 °C, (b) 1000 °C, (c) 1100 °C, and (d) 1200 °C.

3.3. Density, Hardness and Young’s Modulus

Density, hardness, and Young’s Modulus properties are three significant indicators that reflect the reliability of the inductive hot-pressing process and the veracity of the operational parameters employed. These properties are evaluated and compared in terms of whether the processing temperature and pressure are increased.

The use of the intermetallic compound in the form of prealloyed powder or Ti-Al blend powders involves variations in the microstructure of the specimens by the temperature as well as the addition of the B4C; it is therefore crucial to evaluate their effect on the final properties of the manufactured specimens.

In the specimens manufactured without B4C, if the temperature is rising from 900 °C to 1000 °C under 40 MPa, then the density of the specimens made from TiAl* increases by only 0.2% (4.364 and 4.374 g/cm3, respectively) and for specimens from the Ti-Al blend, this increase is 0.7% (4.371 and 4.339 g/cm3, respectively). These increments are negligible values. If the temperature rises from 1100 °C to 1200 °C, the densification increments of the specimens remain below 0.1%. This means that the densification is well performed even at the lowest temperature.

In general, with B4C particles at the lowest temperature (900 °C), the density of the specimens made from TiAl* presents lower values (3.400 g/cm3 at 40 MPa and 3.497 g/cm3 at 80 MPa) than the other specimens from Ti-Al blend powder (3.530 g/cm3 at 40 MPa and 3.606 g/cm3 at 80 MPa). This is in agreement with microstructures observed in Figure 6. The microcracks at the border of the intermetallic phase are visible in specimens processed at 900 °C and 40 MPa; however, under identical conditions, the specimens made from Ti-Al blend powder show no such microdefects. On increasing the pressure of the hot consolidation up to 80 MPa, these defects become slightly visible.

By raising the operational temperature from 900 °C to 1000 °C and from 1100 °C to 1200 °C under 40 MPa, the densification of the TMCs, whose starting powder has B4C particles and TiAl*, presented increments of 2.1% and 3.5%, respectively. The density therefore has a gradual tendency to increase in accordance with the temperature. Related to the specimens made from Ti-Al blend powder with B4C particles, the temperature influence is less significant. If the operational temperature increases from 900 °C to 1000 °C and from 1100 °C to 1200 °C, then there is an augmentation of 1.5% approximately of densification in both cases; however, from 1000 to 1100 °C the density remains constant. Furthermore, the phases formed in situ by the reactions eliminate the possible porosity in the matrix, thereby promoting bonding between the matrix and reinforcements. In this regard, density is promoted by temperature.

While evaluating the influence of the consolidation pressure at the same constant manufacturing temperature (1200 °C) for each type of powder, the increment in pressure from 40 MPa to 80 MPa involves increases in percentages of 2.7% (3.724 and 3.826 g/cm3, respectively) when TiAl* prealloyed powder is used and 1.4% (3.710 and 3.763 g/cm3, respectively) for Ti-Al blend powder.

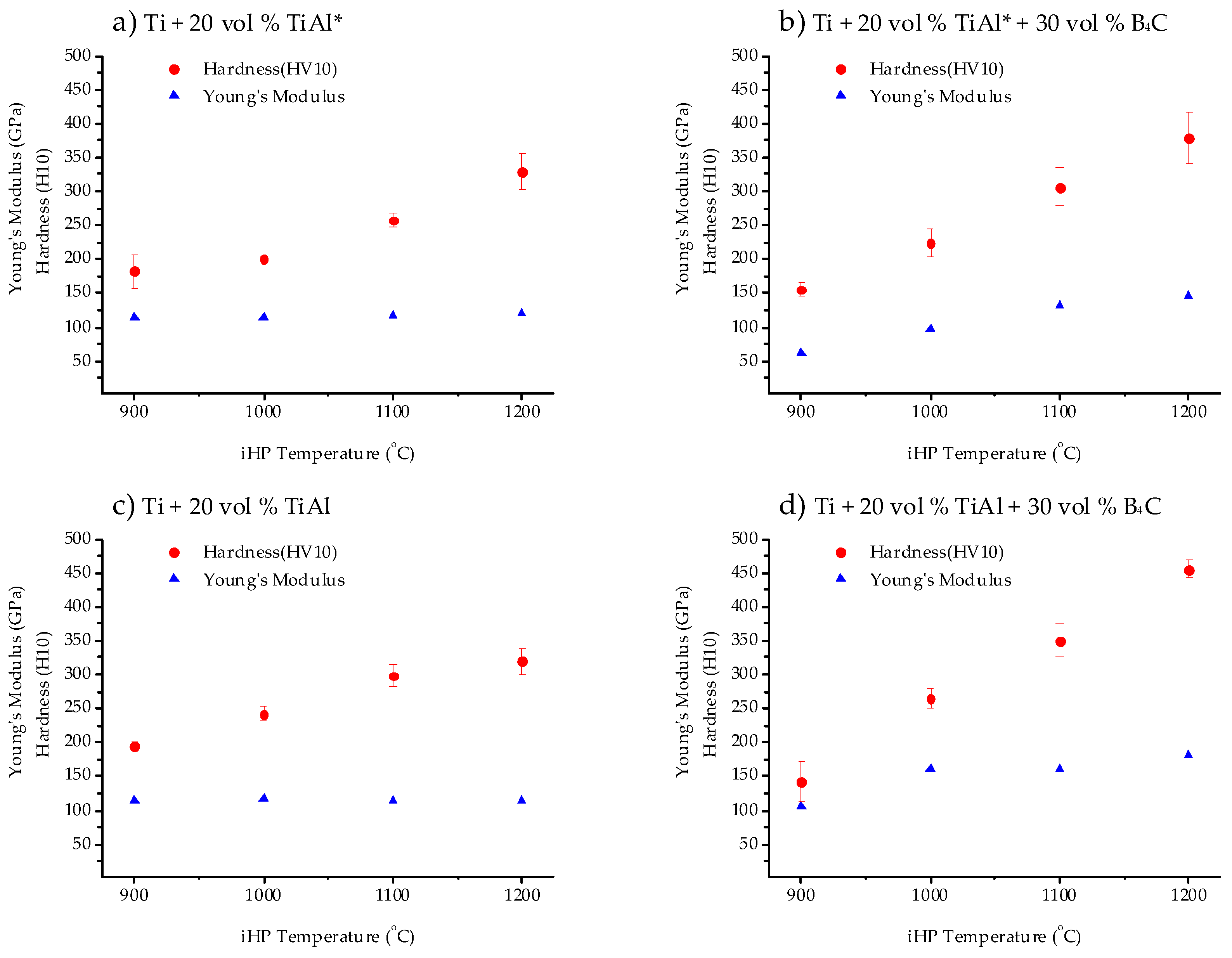

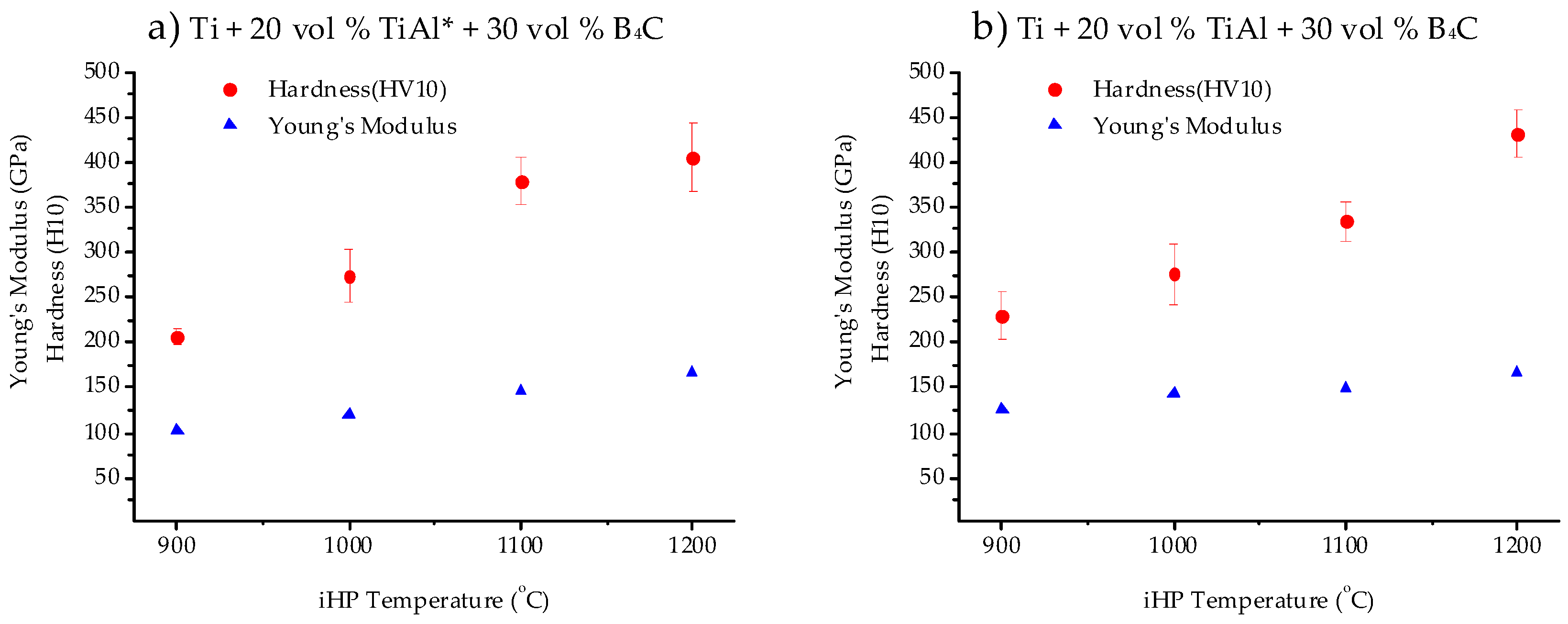

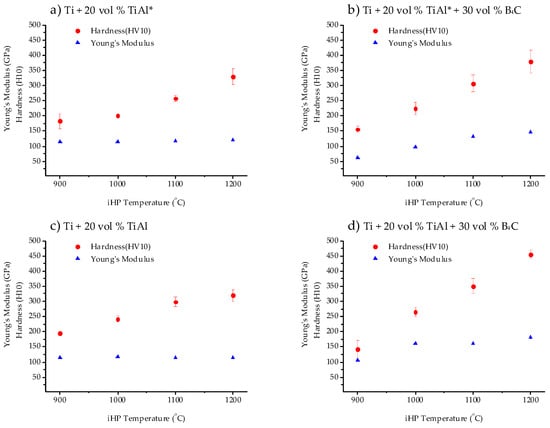

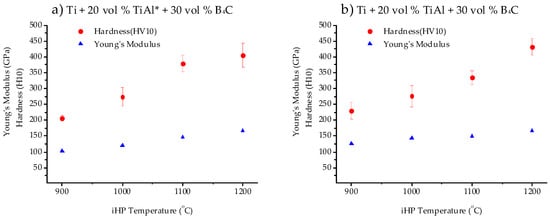

Hardness and Young’s Modulus properties of the specimens are displayed in Figure 9 and Figure 10; their measured values are shown while taking into account the starting materials and the pressure employed (40 MPa and 80 MPa).

Figure 9.

(All the specimens consolidated at 40 MPa). Processing temperature (°C) vs. hardness (HV10) and Young’s Modulus (GPa): (a) Ti + 20 vol % TiAl*; (b) Ti + 20 vol % TiAl* + 30 vol % B4C; (c) Ti + 20 vol % TiAl; (d) Ti + 20 vol % TiAl + 30 vol %B4C.

Figure 10.

(All the specimens consolidated at 80 MPa). Processing temperature (°C) vs. hardness (HV10) and Young’s Modulus (GPa): (a) Ti + 20 vol % TiAl* + 30 vol % B4C; (b) Ti + 20 vol % TiAl + 30 vol % B4C.

On one hand, Figure 9a,c show the behavior of specimens made from Ti with TiAl* and from Ti-Al blend without B4C particles, respectively. On the other hand, Figure 9b,d illustrate the properties of TMCs with B4C made from TiAl* and Ti-Al blend, respectively. All these specimens are consolidated at 40 MPa.

Hardness of the specimens is also compared on the basis of the process parameters. In specimens without B4C particles, the values of hardness are significantly affected by raising the temperature. By 900 °C hot pressing, the specimen from TiAl* (182 HV) presents lower hardness values than does the specimen from the Ti-Al blend (195 HV), as shown in Figure 9a,c. The homogeneous distribution of the intermetallic compound at the Ti grain boundaries of the matrix provides evidence of its improved strengthening effect. In the case of the specimens from TiAl*, at 900 °C, the microstructure study reveals a number of cracks close to the areas of the intermetallic TiAl compound. It could contribute towards reducing their hardness. In specimens made from TiAl*, Figure 9a, when the temperatures tested vary from 900 °C to 1000 °C, from 1000 °C to 1100 °C, and from 1100 °C to 1200 °C, then their hardness increases by 11%, 28%, and 28%, respectively. It can be observed in Figure 9c, that when temperature rises from 1100 °C to 1200 °C, there is only 7% of increment in hardness of specimens made from the Ti-Al blend. A possible explanation for this hardness increment may be related to the decomposition of the intermetallic compound into the Ti matrix. In the case of specimens from TiAl*, the intermetallic phases are observed in the matrix up to 1100 °C. However, in specimens from the Ti-Al blend, the intermetallic phases appear up to 1000 °C. The gain in hardness in general for the specimens made from TiAl* without B4C particles is of 80% when comparing specimens produced at 900 °C and 1200 °C. Under these same conditions, the increment of hardness in specimens from Ti-Al blend powder is of 64% (from 900 °C to 1200 °C). In spite of this, by means of 1200 °C hot pressing, the specimens’ hardnesses become 329.6 ± 25.6 HV and 319.8 ± 19.7; this makes sense, since at 1200 °C, in both cases, the Al is not as intermetallic and is located into the matrix, thereby reinforcing it.

When B4C particles are added to the starting materials of the TMCs, the variations of hardness account for the reactions between the matrix and B4C particles, as well as the intermetallic behavior. For these types of TMCs, not only could the temperature be evaluated as a factor of influence, but the pressure employed during the hot consolidation stage, 40 MPa and 80 MPa, could also be considered as a factor. By 900 °C hot pressing, specimens compacted under 80 MPa show greater hardness than specimens consolidated under 40 MPa, regardless of the starting materials (from TiAl* or Ti-Al blend with B4C). This trend occurs in general at all processing temperatures, and can be observed in Figure 9a,b,d. In the case of TMCs made from TiAl* at 1000 °C, the effect of the pressure is significant; the hardness measured in specimens compacted at 40 MPa and 80 MPa are 223.8 ± 19.6 HV and 274 ± 30 HV, respectively. This fact may be linked to the formation of the secondary phases. In the case of the TiAl* powder, there are reactions between the Ti matrix and the C and B from the B4C particles, even at lower temperatures, when the pressure applied is 80 MPa, as previously stated. At 1100 °C under this pressure, the hardness of the TMCs from TiAl* is greater than the hardness of specimens from Ti-Al blend powder.

In concluding the hardness study, the higher the pressure and temperature employed, the greater the hardness measured. In particular, at 1200 °C, the hardnesses of TMCs from TiAl* and Til-Al blend powder show values of 405.8 ± 38 HV and 456 ± 12 HV, respectively. These values are in agreement with the microstructure observed and the XRD analysis studied. The greater the content of the secondary phases, the greater the hardness.

In the framework of Young’s Modulus properties, specimens without B4C particles show values of approximately 115 GPa, regardless of whether they are made from TiAl* or Ti-Al blend power. Moreover, this value remains constant even when the operational temperature rises. In contrast, through the addition of B4C, the variations in the processing parameters contribute towards an increment in the Young’s Modulus of the specimens, independently of the starting powder (TiAl* or Ti-Al blend powder). At 900 °C, the specimens with B4C particles consolidated at 40 MPa showed lower Young’s Modulus values than did the specimens without B4C manufactured under similar conditions. This finding suggests that the incorporation of the B4C into the matrix could reduce Young’s Modulus. This is due to the existence of certain porosity close to the B4C particles, and to the absence of good bonding at this low temperature between the Ti matrix and the B4C phase. The increments of Young’s Modulus with rises in temperature reflect the formation of in situ phases. This trend occurs for TMCs consolidated under the two pressures tested (40 MPa and 80 MPa).

It can therefore be deduced that by varying the starting powder and parameters, the behavior of the TMCs are clearly affected.

4. Conclusions

The following conclusions can be drawn:

- The formation of secondary phases (TiB and TiC) is affected by the addition of TiAl in the starting blend. If the TiAl is prealloyed powder, more content of TiC and TiB was detected by XRD analysis at a lower temperature (1100 °C) than in the case of the starting blend made from elementary powders Ti-Al. Regarding the processing conditions, the higher the pressure, the more content of TiB and TiC at similar processing temperatures, regardless of the starting powder.

- The microstructure characterization reveals significant evolution of the secondary phases in the matrix by the temperature. The pressure influence confirms XRD results. The intermetallic compounds are located as nodular morphology in Ti matrix for TiAl* specimens and at grain boundaries in Ti-Al blend specimens. The secondary-phase morphologies are TiB whiskers and dendritic TiC. With pressure (80 MPa), decomposition of TiAl* takes place at lower temperature.

- Regarding the processing parameters effect on the density, hardness, and Young’s Modulus. In general, raising the temperature results in better values of density and higher values of hardness. If there are B4C particles in the starting materials then the effect of increasing pressure in parallel to the temperature promotes the strengthening of the TMCs by the phases formed in situ. However, Young’s Modulus remains constant if no particles of B4C are included in the starting powder blend. When B4C is added, Young’s Modulus rises with temperature, and is higher with TiAl than with TiAl*; this is due to the substitutive solution between Ti and Al.

- The higher the pressure becomes, the lower the temperature at which the in situ secondary phases are formed. The consolidation pressure has a slight influence on the density of specimens processed at the same temperature, whereby the higher the pressure becomes, the better the densification is achieved. Hardness and Young’s Modulus follow the same trend.

Author Contributions

All the authors have collaborated with each other to obtain high quality research work. I.M.-M. performed the materials selection, analyzed the data, and designed the structure of the paper. C.A. has been responsible for the microstructure characterization for specimens: optical and electron microscopy, and the relationship between processing parameters and material properties. E.M.P.-S. has performed the metallographic preparation, carried out the mechanical properties, and selected the references. M.K. has controlled the fabrication process. E.N. has optimized the equipment and applications.

Acknowledgments

We are grateful to the Microscopy and X-Ray Laboratory Services of CITIUS (University of Seville).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leyends, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications, 1st ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Yu, H.L.; Zhang, W.; Wang, H.M.; Ji, X.C.; Song, Z.Y.; Li, X.Y.; Xu, B.S. In-situ synthesis of TiC/Ti composite coating by high frequency induction cladding. J. Alloys Compd. 2017, 701, 244–255. [Google Scholar] [CrossRef]

- Cao, Z.; Wang, X.; Li, J.; Wu, Y.; Zhang, H.; Guo, J.; Wang, S. Reinforcement with graphene nanoflakes in titanium matrix composites. J. Alloys Compd. 2017, 696, 498–502. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Kakovkina, N.; Sherbakov, V. Graded layered titanium composite structures with TiB2 inclusions fabricated by selective laser melting. Compos. Struct. 2017, 169, 90–96. [Google Scholar] [CrossRef]

- Ma, F.; Zhou, J.; Liu, P.; Li, W.; Liu, X.; Pan, D.; Lu, W.; Zhang, D.; Wu, L.; Wei, X. Strengthening effects of TiC particles and microstructure refinement in in situ TiC-reinforced Ti matrix composites. Mater. Charact. 2017, 127, 27–34. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, Y.; Shi, L.; Yang, H.; Xi, M. Research on development of in situ titanium matrix composites and in situ reaction thermodynamics of the reaction systems. J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 2006, 13, 551–557. [Google Scholar] [CrossRef]

- Balaji, V.S.; Kumaran, S. Densification and microstructural studies of titanium-boron carbide (B4C) powder mixture during spark plasma sintering. Powder Technol. 2014, 264, 536–540. [Google Scholar] [CrossRef]

- Attar, H.; Prashanth, K.G.; Zhang, L.C.; Calin, M.; Okulov, I.V.; Scudino, S.; Yang, C.; Eckert, J. Effect of Powder Particle Shape on the Properties of In Situ Ti–TiB Composite Materials Produced by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 1001–1005. [Google Scholar] [CrossRef]

- Wang, M.; Lu, W.; Qin, J.; Ma, F.; Lu, J.; Zhang, D. Effect of volume fraction of reinforcement on room temperature tensile property of in situ (TiB + TiC)/Ti matrix composites. Mater. Des. 2006, 27, 494–498. [Google Scholar] [CrossRef]

- Ni, D.R.; Geng, L.; Zhang, J.; Zheng, Z.Z. Fabrication and tensile properties of in situ TiBw and TiCp hybrid-reinforced titanium matrix composites based on Ti–B4C–C. Mater. Sci. Eng. A 2008, 478, 291–296. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Vilar, R. Characterization of (TiB + TiC)/TC4 in situ titanium matrix composites prepared by laser direct deposition. J. Mater. Process. Technol. 2011, 211, 597–601. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J.M.; Cho, Y.H.; Kim, S.H.; Yu, H. Effect of the Ti/B4C mole ratio on the reaction products and reaction mechanism in an Al–Ti–B4C powder mixture. Mater. Chem. Phys. 2014, 147, 925–933. [Google Scholar] [CrossRef]

- Vadayar, K.S.; Rani, S.D.; Prasad, V.V.B. Effect of Boron Carbide Particle Size and Volume Fraction of TiB–TiC Reinforcement on Fractography of PM Processed Titanium Matrix Composites. Procedia Mater. Sci. 2014, 6, 1329–1335. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X.; Qin, J.; Zhang, D.; Lu, W. Microstructure and mechanical properties of investment casted titanium matrix composites with B4C additions. Mater. Sci. Eng. A 2015, 628, 366–373. [Google Scholar] [CrossRef]

- Tochaee, E.B.; Hosseini, H.R.M.; Reihani, S.M.S. On the fracture toughness behavior of in-situ Al–Ti composites produced via mechanical alloying and hot extrusion. J. Alloys Compd. 2016, 681, 12–21. [Google Scholar] [CrossRef]

- Arévalo, C.; Montealegre-Meléndez, I.; Ariza, E.; Kitzmantel, M.; Rubio-Escudero, C.; Neubauer, E. Influence of Sintering Temperature on the Microstructure and Mechanical Properties of In Situ Reinforced Titanium Composites by Inductive Hot Pressing. Materials 2016, 9, 919. [Google Scholar] [CrossRef] [PubMed]

- Davis, J.R. Nondestructive Evaluation and Quality Control. In ASM Handbook; ASM-International: Novelty, OH, USA, 1989. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).