Abstract

The residue from desulfurization and denitrification of exhaust gas treatment process with pyrolusite ore as absorbent is regarded as a potential source of iron and manganese. In this study, an extraction process is proposed for recovery of iron and manganese with ammonium sulphate roasting followed by sulphuric acid leaching. Firstly, the conversion mechanism was analyzed through mineral phase analysis of roasting products at different roasting temperature by means of X-ray diffraction (XRD) technology. Then, the parameters of the roasting procedure such as roasting temperature and time, ammonium sulphate dosage, leaching temperature, leaching time, and sulphuric acid concentration are examined. The results implicate that the iron oxide and manganese dioxide in the residue are firstly converted into the water-soluble and at 200–350 °C, and then the more stable and are formed, at temperature higher than 350 °C. Under optimum conditions, 95.2% Fe and 97.0% Mn can be extracted. Reactant diffusion through inert layer of silicon dioxide was considered as the rate-limiting step for iron extraction with an activation energy of 20.56 kJ/mol, while, the recovery process of Mn was controlled by both reactant diffusion and chemical reaction with an activation energy of 29.52 kJ/mol.

1. Introduction

SO2 and NOx emission from combustion of coal, fuel oils and waste have brought significantly important effects on environment and human health. Various kinds of technologies [1,2] have been developed to control and reduce SO2 and NOx emissions worldwide. Among these methods, pyrolusite ore adsorption has been regarded as one of the most promising technologies [2,3]. This is because it can successfully combine the removal of pollutants from flue gas, together with the manganese extraction from poor-grade pyrolusite ore [2,4]. Pyrolusite is a manganese oxide ore with manganese dioxide as its main component [5], which can oxidize the SO2 and NO, NO2 in the exhaust gas into and , respectively. These reactions can be written as the following:

Our previous studies [2,3] implicated that the removal efficiency of SO2 and NOx reached about 90% and 82% respectively, and the extraction efficiency of manganese can be maintained at 80~86%, with a pulp density of 500 g/L and a leaching temperature of 25 °C. The recovery products () meeting the national standard (HG/T 3817-2006) can be obtained through the further treatment of the absorption liquid, such as the removal of iron and heavy metal ions [6]. Unavoidably, the pyrolusite absorption residue (PAR) was produced in the process of desulfurization and denitrification using pyrolusite ore. The PAR is featured by high iron content, silicon dioxide and remaining manganese dioxide, and it also contains some heavy metal ions, such as cobalt, nickel, barium and calcium ions [7]. However, there are limited investigations on how to deal with these residues in order to reduce the risks of polluting environment. The PAR used to be an adsorbent for the treatment of Congo red and dyeing waste water, and satisfying removal efficiency were reported [8,9,10]. Lang et al. [11] pointed out that after adding limestone and bauxite, the residue can be used to generate sulphoaluminate cement. On the other hand, more than 45% iron oxide and 4% manganese dioxide were enriched in the PAR, which also can be regarded as a secondary source for iron and manganese.

In the past few decades, many methods have been developed to recover iron and manganese from various mineral [12], wastes [13] and residues [14,15]. The reduction roasting-magnetic separation is widely used for iron recovery from red mud using coal [16], sodium carbonate [14] and pyrite [17] as reducing agent at 600–1300 °C and the iron recovery efficiency is generally over 85%. Oxalate also was adopted for iron leaching with the advantages of fast leaching rate, high extraction efficiency, attributing its higher chelate ability [18,19]. Manganese recovery can be realized from low-grade pyrolusite ore by roasting, using elemental sulphur at 350–500 °C [20] or SO2 at 500 °C [21] followed by sulphuric acid or water leaching; also by hydrometallurgical treatment processes including aqueous SO2 [15,22], FeSO4 [23], and biomass [24] However, these methods do not meet the requirements for the simultaneous recovery of iron and manganese. Rolf R.F [25] presented their work that 97% manganese and 47% iron can be extracted at the same time by firstly reducing with gaseous hydrogen, carbon monoxide or mixtures at 550~800 °C a then leached with ammonium sulphate solutions. Although the high recovery efficiency of both Mn and Fe were obtained, this process consumes more energy and used hazardous gases (H2, CO) as reducing gases.

Recently, our group has found that ammonium sulphate, a widely available, low-cost, recyclable chemical agent can be used for extracting various metals containing Co, Ni, Mn and Al from low-grade nickel ore [26], zinc leaching residues [27], mine residues [28] and coal fly ash [29]. The extraction efficiency of manganese from the above minerals can achieve satisfying results i.e., higher than 80%. However, the iron leaching rate is lower, generally less than 50%. It is surprising that the iron recovery efficiency from ilmenite ore [30] and high-iron bauxite ore [31] could yield higher than 85%. The discrepancy of iron leaching efficiency obtained among these literatures [13,26,29,30,31] may be attributed to the different purpose of metal recovery; iron was generally regarded as impurities in these reports so that it was restricted to be extracted out. However, research aimed at simultaneous recovery of iron and manganese from minerals or other waste residue using ammonium sulfate as extracting agent has not been reported in literatures.

In this paper, the feasibility of sulphating roasting of PAR with ammonium sulphate was comprehensively investigated. The role that ammonium sulphate plays in the sulphating roasting process and corresponding reaction mechanism are discussed. The roasting kinetics were analysed to elucidate the extraction characteristics of manganese and iron. The effect of ammonium sulphate-to-PAR ratio, roasting temperature, roasting time, leaching temperature, leaching time, and sulphuric acid concentration on the extraction behavior have been studied.

2. Materials and Methods

2.1. Materials

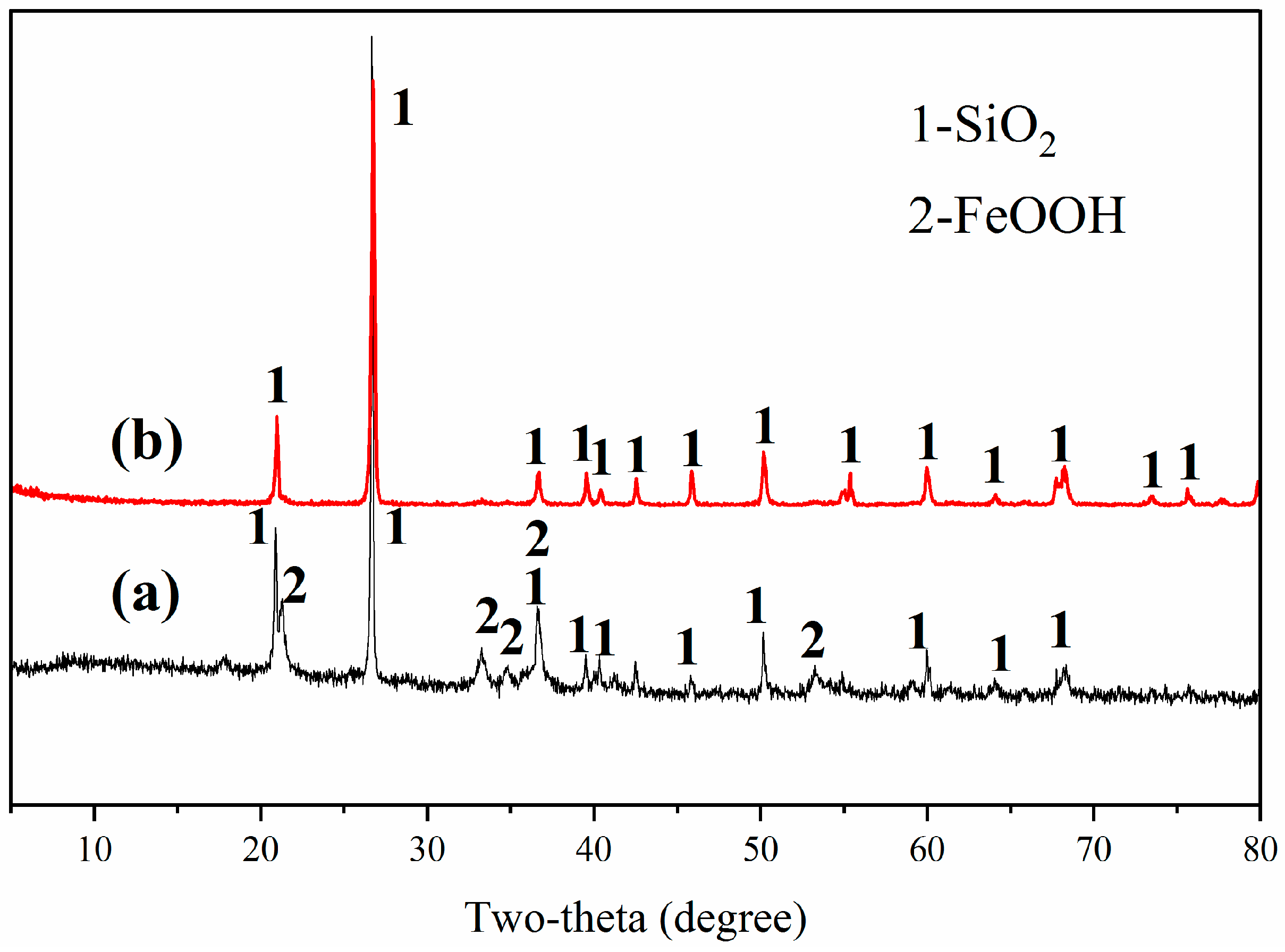

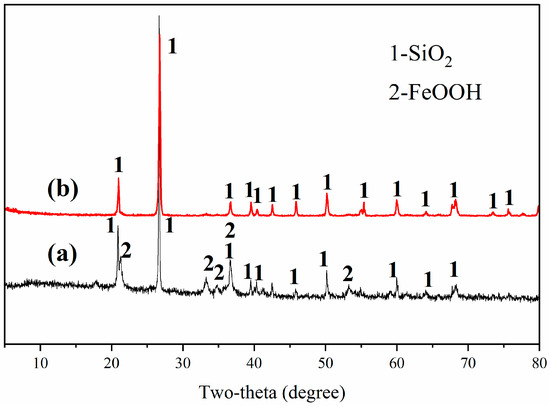

The Pyrolusite Absorption Residue (PAR) was generated during the flue gas desulfurization process using iron-rich pyrolusite ore as desulfurizer. The obtained residue was washed with distilled water and milled to a size of 200 mesh after dried at 80 °C for 3 h prior to experiments. The chemical composition of this residue is shown in Table 1. The average iron and manganese contents were 30.1% and 4.03%, respectively. The main minerals, which are evident from the X-ray diffraction pattern (Figure 1), are goethite (FeOOH) and silicon dioxide (SiO2). The analysis grade ammonium sulphate () was used in all experiments.

Table 1.

Chemical composition (metal content) of the pyrolusite absorption residue (PAR) used for experiments.

Figure 1.

The X-ray diffraction of pattern of (a) the PAR; (b) the leaching residue after roasting-acid leaching.

2.2. Methods and Procedure

Roasting experiments were conducted in a fixed horizontal electric tube furnace (SK-G04123K Tianjin Zhonghuan Lab Furnace Co., Ltd., Tianjin, China). The experimental apparatus is presented in Figure S1. As the tube is heated the required temperature at a rate of 10 °C /min, then a corundum crucible loading mixture of PAR and ammonium sulphate was sent into the roasting zone. At the end of the tube, the exhaust gas (NH3) was collected by NaOH solution. After each roasting experiment, the roasted PAR was leached by water and diluted sulphuric acid to transfer soluble sulphate salt into solution. The leaching slurry was filtered with 0.45 μm membrane, and the filtrate and residue then were separated. The leaching liquid was collected to determine the recovery percentage of manganese and iron. The influence of different parameters including: ammonium sulphate dosage, roasting temperature, and roasting time, as well as leaching temperature, time, and leaching acidity were studied in the way that one parameter was tested while keeping other parameters constant.

2.3. Product Analysis

Spectrophotometry was employed for Fe analysis using MAPADA V-1200 VIS spectrophotometer. Manganese was determined by ICP-MS (NEXION 300X, PERKINELMER, San Diego, MA, USA) equipped with an auto sampler (SC2 DX, ESI, PERKINELMER, San Diego, MA, USA). A X-ray diffraction (XRD) equipment (EMPYREAN, PANalytical, Almelo, The Netherlands) was used to identify the solid components of the PAR and roasting products.

3. Results and Discussion

3.1. Reaction Mechanisms

3.1.1. Reaction between PAR and Ammonium Sulphate

In order to understand the roasting process of thermochemical treatment of the absorption residue (PAR) with ammonium sulphate, it is important to gain insight in the thermal decomposition of pure over the temperature range studied, since it will affect greatly the thermochemical process. The published literatures revealed disagreement as to the nature of the intermediate species formed during thermal decomposition of ammonium sulphate. Nevertheless, a general consensus [30,32,33,34] is that the decomposition mechanism may involve the following steps:

KiyouraandUrano [33] confirmed the thermal decomposition of ammonium sulphate to ammonium bisulphate (Equation (4)) at temperature higher than 100 °C through release of ammonia, however, that is not being detected by X-ray diffraction method. This is because of the rapid reaction between ammonium sulphate and ammonium bisulphate to form triammonium hydrogen sulphate () (Equation (5)). Meantime, sulphamic acid is formed by release of H2O at 170 °C (Equation (6)), which would further decompose into various gases including NH3, SO2, N2, and H2O (Equation (7)) [33]. Dixo [32] pointed out that the ammonium pyrosulphate ( from the reactions (Equations (8) and (9)) accounts for 90% of the products of ammonium sulphate during the thermal decomposition at 400 °C. But this is not consistent with the results in this article, where only triammonium hydrogen sulphate was detected by XRD. This may due to the formation of from the dehydration of .

Studies [26,27,33] on the sulfation of iron oxides and MnO2 by ammonium sulphate at 300~500 °C, have shown the major products to be , , , , and , and . Based on these reaction products, the chemical reactions taking place during the thermochemical treatment PAR in air atmosphere may be considered as follows:

3.1.2. Characterization of Roasting Product

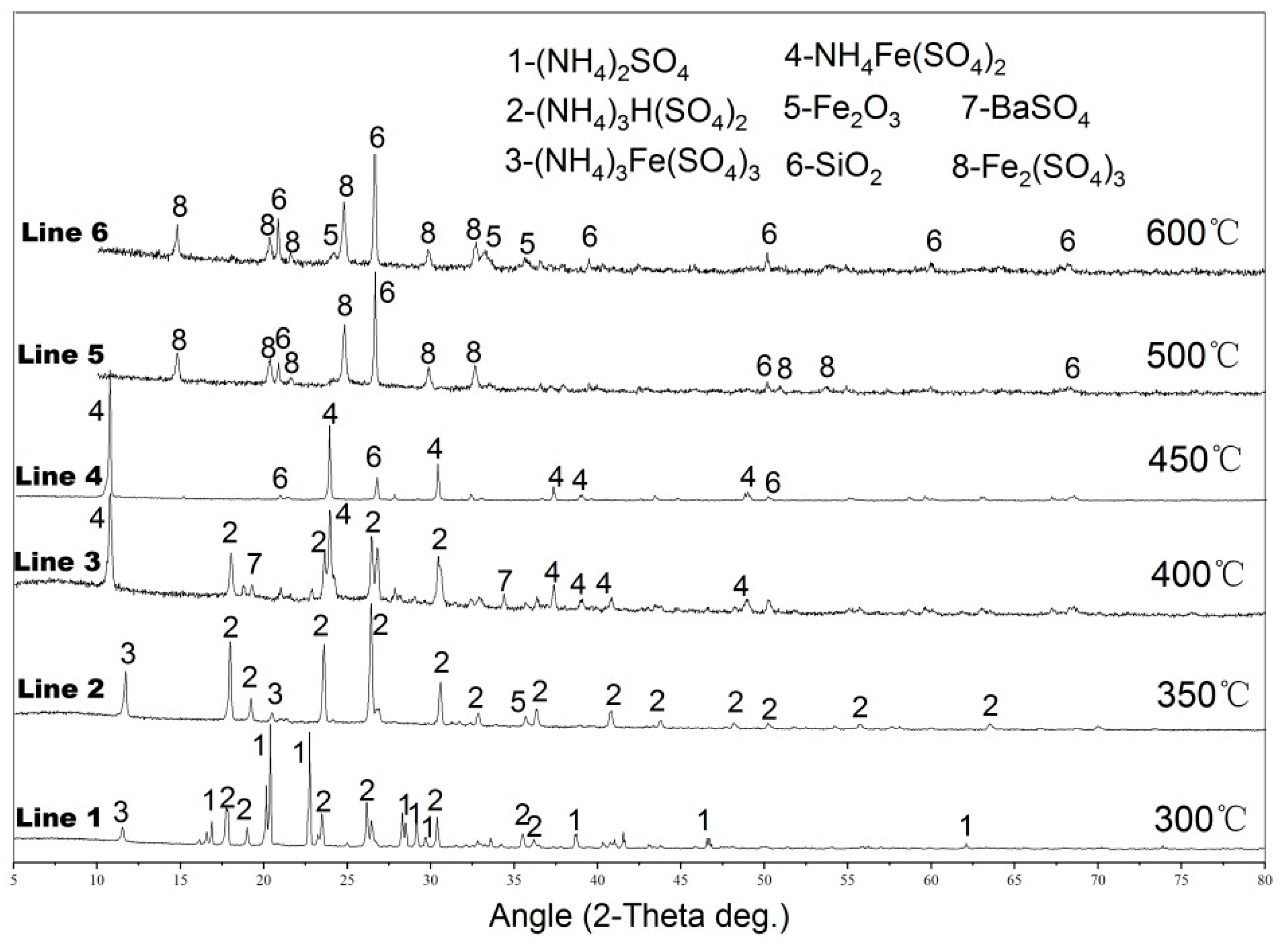

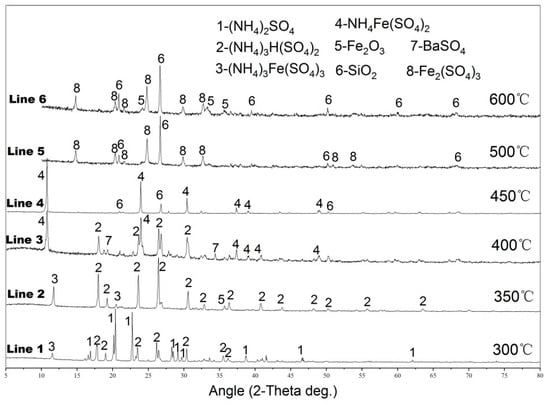

The roasting products of pyrolusite absorption residue (PAR) with ammonium sulphate at temperature of 300–600 °C were analyzed by XRD to study the roasting mechanism. The results are presented in Figure 2.

Figure 2.

X-ray patterns of the roasting products at different temperatures.

Compared with the XRD pattern of the residue (Figure 1), the XRD diagram of the product roasted at 300 °C, shown in Figure 2, indicates that some new diffraction peaks appeared after calcination, but the change of the mineral phase was not obvious at 300 °C. With respect to the analysis result, the new materials are mainly , and the peaks are weak and unobvious (Equation (12)). In disagreement with line 1, the peaks of new products were more obvious than before with increasing roasting temperature, indicating that more iron oxide was sulphated. At the same time, the hematite peak was also observed, suggesting that the goethite in the PAR was dehydrated at 350 °C to form a more stable hematite (Equation (19)).

As the calcination temperature continues to increase to 400 °C, the diffraction peak formed on lines 1–2 disappears, and a new peak is formed in line 3. This peak is considered as , which is a more stable ferric sulphate ammonium salt formed from the reaction between and (Equation (13)). When the roasting temperature is increased up to 450 °C, more was produced, because both the correspondent diffraction peak and intensity increase. And the diffraction peaks of have disappeared, indicating that it has been decomposed completely at 500 °C, and the peak of ferric sulphate is observed, indicating the occurrence of Equation (14). When the roasting temperature continues to increase to 600 °C, the peak of can be detected, which indicates that some of the ferric sulfate occurs to decompose.

Owe to the low manganese content in the PAR, it is difficult to examine the phase conversion of manganese dioxide during the roasting process by X-ray diffraction (XRD) technology. However, the roasting mechanism of manganese dioxide with ammonium sulphate can be analyzed on the basis of the extraction data from Figure 3b. It can be seen from Figure 3b that 56.4% Mn was extracted at roasting temperature of 300 °C and roasting time of 240 min, which implicated that the manganese dioxide has been reduced into the water-soluble . The following paper [27,30] examine the decomposition gas of ammonium sulphate, and the results show that the NH3 is the main gas when the temperature is below 380 °C, while, SO2 and H2O were mainly generated at 520 °C. Therefore, the sulfation-roasting process of manganese dioxide at lower temperature can be described through Equation (13). And this small amount of SO2 gas in Equation (16) was produced from the decomposition of sulphamic acid ( (Equation (7)). At a higher temperature, more SO2 was generated by Equation (11), which can directly react with manganese dioxide and form manganese sulphate (Equation (18)) [21].

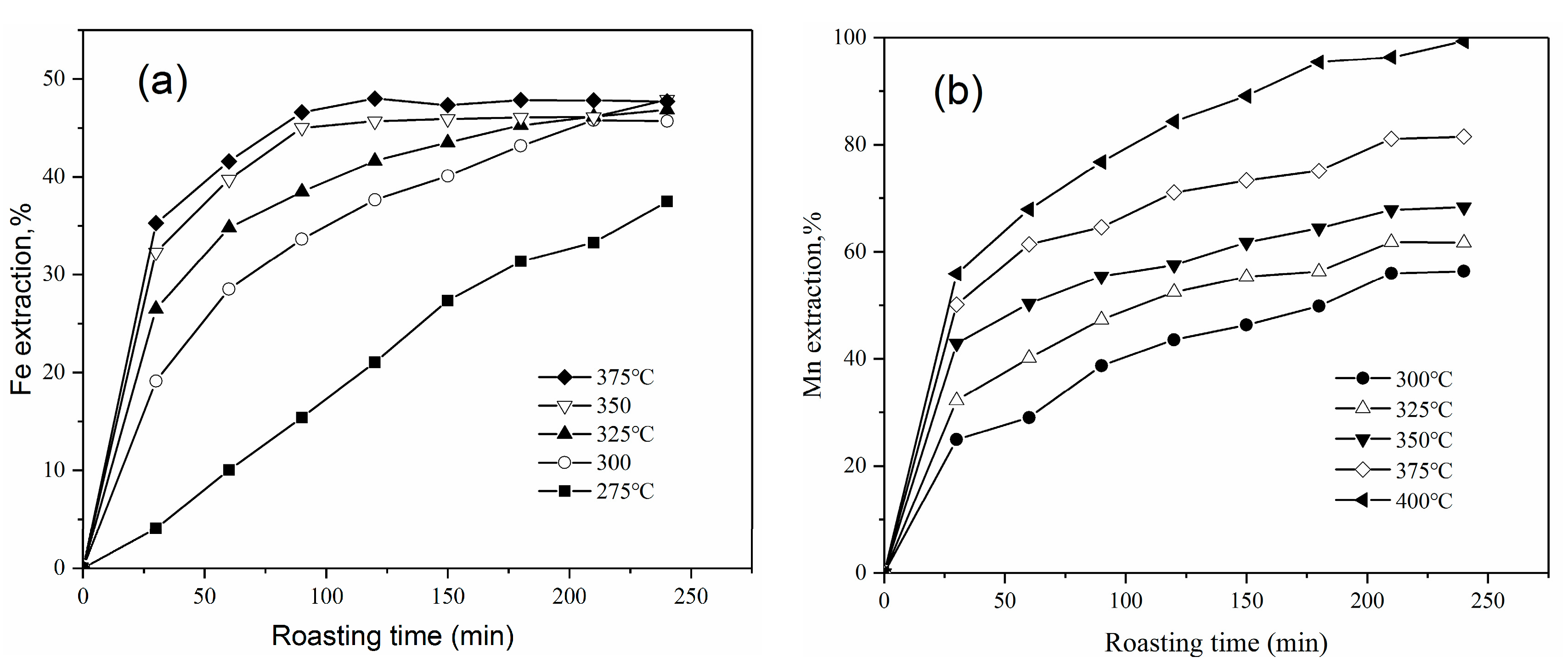

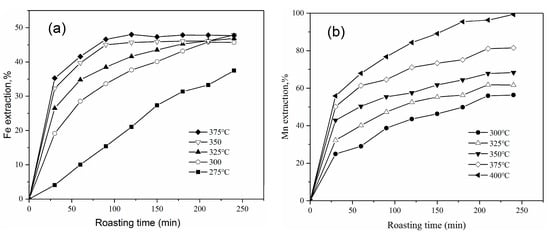

Figure 3.

The effect of roasting temperature on (a) iron and (b) manganese with sulphating roasting-water leaching.

3.2. Roasting Kinetics

The roasting kinetics of PAR with ammonium sulphate was studied by water leaching in the temperature range of 275–400 °C. Other conditions were: 12 of ammonium sulphate-to-PAR ratio, 60 °C of leaching temperature, and 120 min of leaching time. The effects of roasting temperature and time on manganese and iron extraction are shown in Figure 2a. With increasing roasting temperature, the proportion of manganese and iron leached from the PAR increase. As for the iron roasting process, the extracted amount increased linearly at a roasting temperature of 275 °C. However, the maximum efficiency of Fe extracted was reached at roasting temperature of 300–375 °C, within the roasting time studied.

Increasing the roasting temperature has little effect on further increasing the extraction efficiency of iron. Table S1 shows the iron extraction from various minerals, such as mine tailings [28], nickel laterite [26,35] and ilmenite [30], using ammonium sulfate as a roasting agent. These results implicate that the iron extraction efficiency is either lower or higher. This situation may be related to the content of silica in the ore, which may retard the diffusion of ammonium sulphate through the ash layer from the surface to the center of the PAR. When the silica is high, the recovery rate of iron is low [26,28,35], and vice versa the recovery rate of iron is high when the content of silicon is low [30,31]. About 95.6% Fe can be extracted from the roasting product of pure FeOOH under the same conditions, which further verify the above-mentioned mechanism that the iron roasting is greatly influenced by the content of silicon dioxide. Water leaching process after ammonium sulphate roasting in these literatures [26,28,35] is an important factor resulting low iron recovery. The results demonstrate that it is necessary to adopt acid leaching after ammonium sulphate roasting in order to improve the iron recovery efficiency.

It is indicated from Figure 3b that the extraction of manganese increases with roasting temperature. The leaching efficiency of manganese rises from 56.4% to 99.3% as the roasting temperature increases from 300 °C to 400 °C at a roasting time of 240 min. The leaching behavior of manganese differs greatly from that of iron during the roasting process, which seems not to be affected by the content of SiO2 in the residue. The insensitivity of manganese roasting process to SiO2 layer can be ascribed to the fact that the manganese dioxide was sulphated into soluble manganese sulphate by SO2 gas generated from the reactions (Equations (7) and (11)). Compared with the liquid ammonium sulphate in the roasting process, SO2 gas more easily diffused through SiO2 layer into the unreacted residue surface.

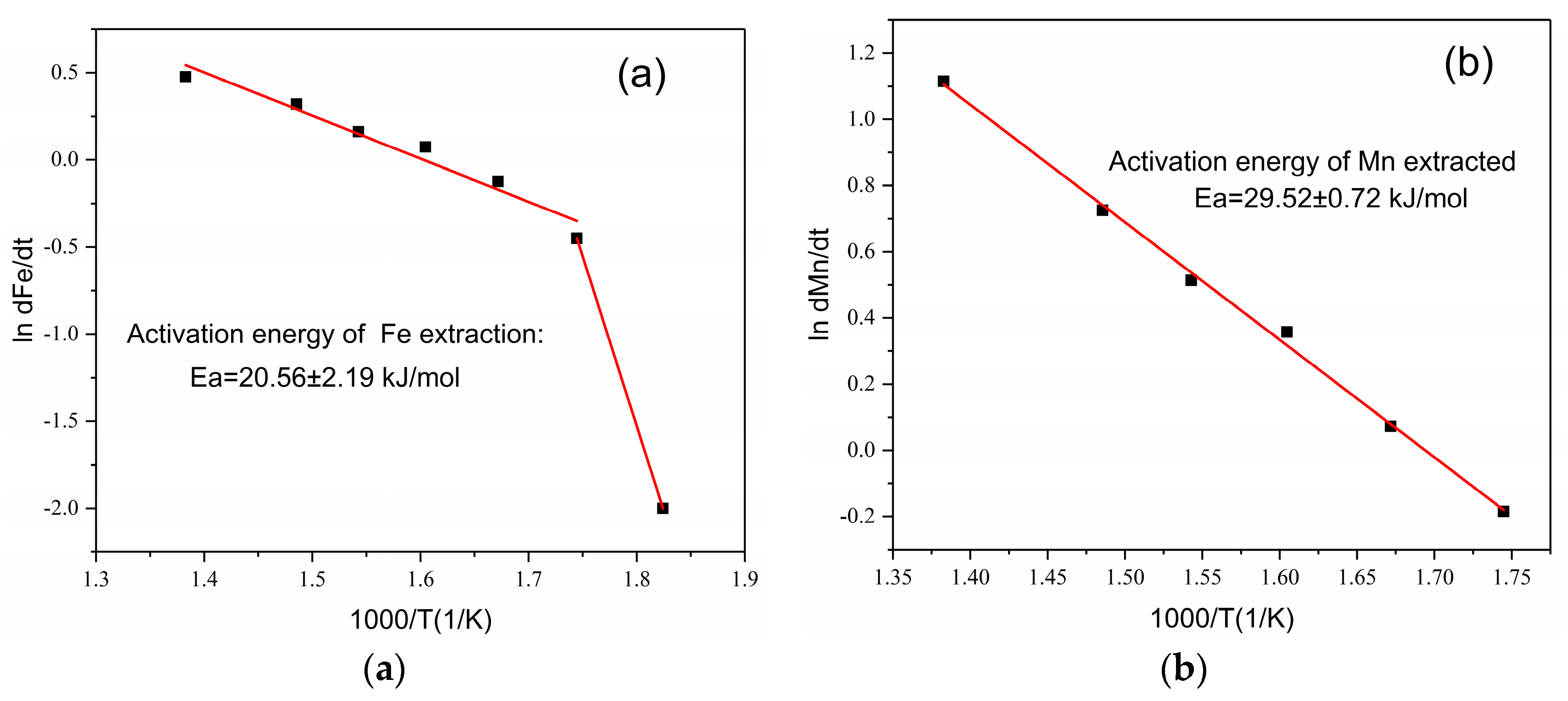

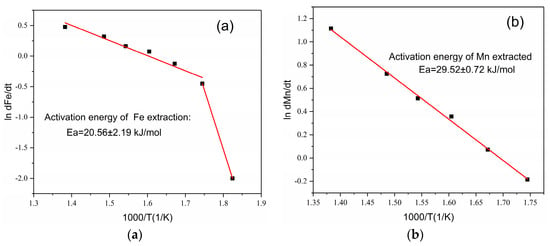

The extraction process of iron and manganese from pyrolusite adsorbent residue (PAR) with ammonium sulphate as a roasting agent can be simulated by so-called a shrinking model. The simulation results of iron are shown in Figure S2, showing that the iron extraction process is controlled by the chemical reaction on the PAR surface at the roasting temperature of 275 °C, and is controlled by the diffusion of the reactants through the inert or product layer at 300–375 °C. The apparent activation energy was estimated as 20.56 kJ/mol (Figure 4), supporting the diffusion mechanism for iron extraction. Figure S3 shows the simulation results of the manganese extraction process. From Figure S3, the manganese leaching process is controlled by both reactant diffusion and surface chemical reaction at a roasting temperature of 300–375 °C. When the temperature is increased to 400 °C, the manganese extraction rate is limited by SO2 diffusion though the inert layer. From the Figure 4, the apparent activation energy of manganese recovery was determined as 29.52 kJ/mol.

Figure 4.

The determination of apparent activation energy of (a) iron and (b) manganese.

3.3. Effect of Conditions Applied for Roasting and Acid Leaching

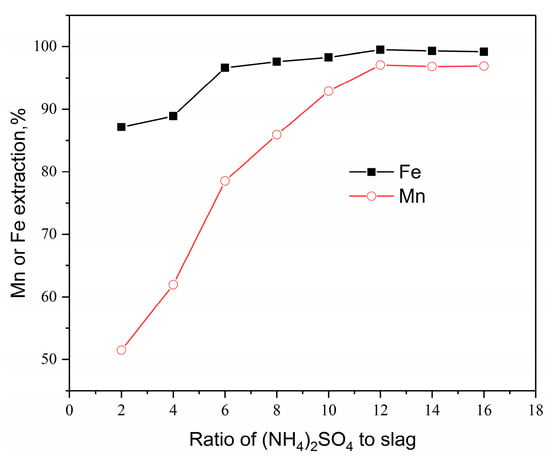

3.3.1. Effect of Ammonium Sulphate: PAR Mass Ratio

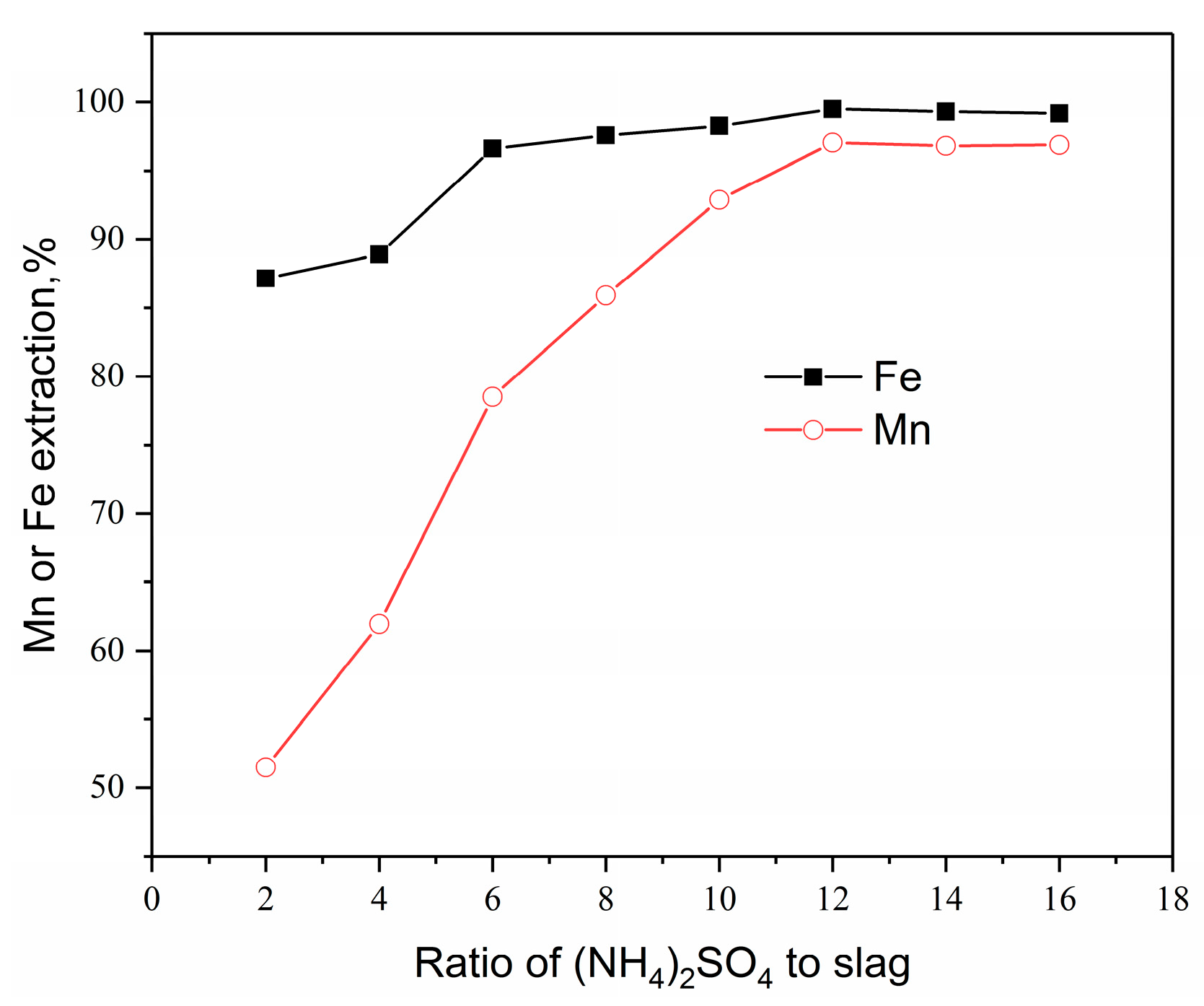

The dosage of ammonium sulphate is the essential factor for the roasting process to obtain higher manganese and iron recovery efficiency. The effect of : PAR mass ratio on the manganese and iron extraction rate is shown in Figure 5. Other conditions were as follows: 450 °C of roasting temperature, 30 min of roasting time, 90 °C of leaching temperature, 60 min of leaching time, and sulphuric acid concentration of 0.5 M.

Figure 5.

The effect of ammonium-to-sulphate ratio on the extraction of iron and manganese from PAR.

It can be seen from Figure 5, the iron extraction increased with increasing the ammonium sulphate dosage. This is because increasing the amount of ammonium sulphate enhanced the drive force of the diffusion of through the inert layer. As the ratio of ammonium sulphate to PAR is over 6:1, the extracted iron increase slowly, and about 97.6% Fe has been extracted. Manganese extraction seems to be greatly influenced by the ammonium sulphate-to-PAR ratio. The leaching efficiency increased from 51.5% to about 97.0%, when the ratio is increased from 2:1 to 12:1. Continuing increase in ammonium sulphate: PAR ratio over 12:1 does not result in obvious improvement upon manganese leaching. The strong dependence of manganese extraction upon the dosage of ammonium sulphate can be attributed to more SO2 gas generated by decomposition of (Equation (11)). It can be seen from Figure 2 that ammonium sulphate has decomposed completely at 450 °C producing various gases including SO2 gas according to Equation (11), as the diffraction peak of has not been observed. It has been demonstrated that manganese dioxide (MnO2) can be sulfated to produce manganese sulphate with SO2 gas at roasting temperature of 200–550 °C (Equation (18)) [21]. So, the SO2 gas resulted from decomposition of ammonium sulphate would react with manganese dioxide in the PAR to form water-soluble manganese sulfate. Increasing amounts of ammonium sulphate increases the yield of SO2 gas. To sum up, an ammonium sulfate-to-PAR ratio of 12:1 is recommended for sulfating-roasting process.

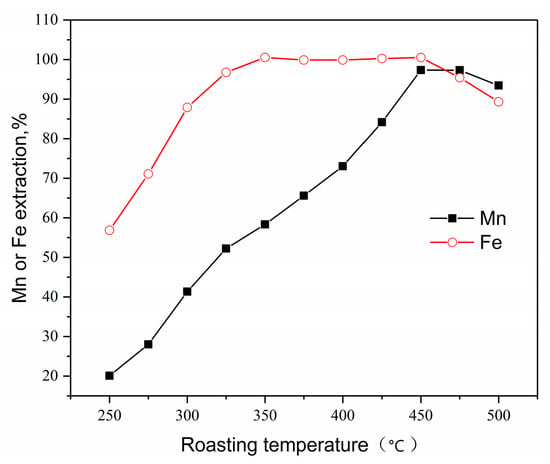

3.3.2. Effect of Roasting Temperature

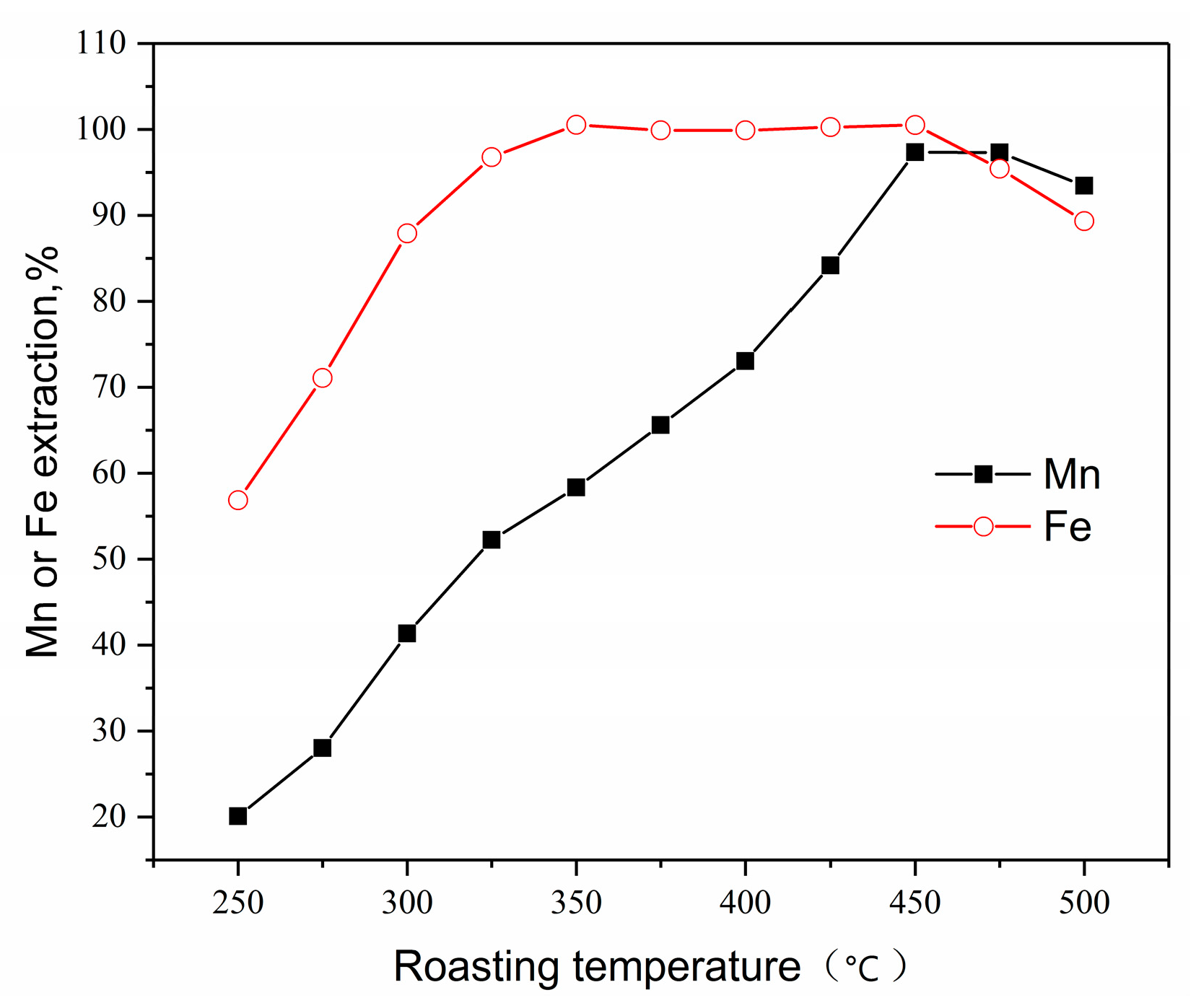

The effects of roasting temperature in the range chosen 250500 °C on the iron and manganese extraction efficiency have been investigated at ammonium sulphate-to-PAR ratio of 12:1, roasting time of 30 min, leaching temperature of 90 °C, and leaching time of 60 min. The results are shown in Figure 6.

Figure 6.

The effect of roasting temperature on the extraction of iron and manganese from PAR.

Figure 6 shows that roasting temperature has a significantly effect on roasting reaction. With an increase of roasting temperature from 250 to 325 °C, the proportion of Fe leached from the PAR increase significantly. When the roasting temperature was increased from 325 °C to 450 °C, it was found that the iron leaching efficiency have reached maximum, because the whole iron oxide in the ore are essentially extracted out. This is in agreement with the results presented in Figure 3a showing that iron extraction is no longer increased when roasting temperature is higher than 325 °C. The iron dissolution of the unreacted iron oxide during the roasting process was caused by the subsequent sulphuric acid leaching step. When roasting temperature is higher than 450 °C, it was found that the iron leaching decreased slightly, which may be owing to the occurrence of reaction (Equation (15)) which produced the insoluble iron oxide ().

It can be observed that roasting temperature had a more profound influence on manganese extraction compared to that of iron. For example, the extraction of manganese rises from 20.1% to about 97.33% when roasting temperature increases from 250 °C to 450 °C. The manganese extraction occurs to decrease as roasting temperature is beyond 450 °C. This may be related to the following reasons: (1) the more rapid decomposition of ammonium sulphate resulting in loss of SO2 before reacting with MnO2; (2) the decomposition of MnO2 producing Mn3O4, whose reactivity with SO2 is lower than MnO2. In conclusion, the roasting temperature of 450 °C was selected to obtain higher iron and manganese recovery.

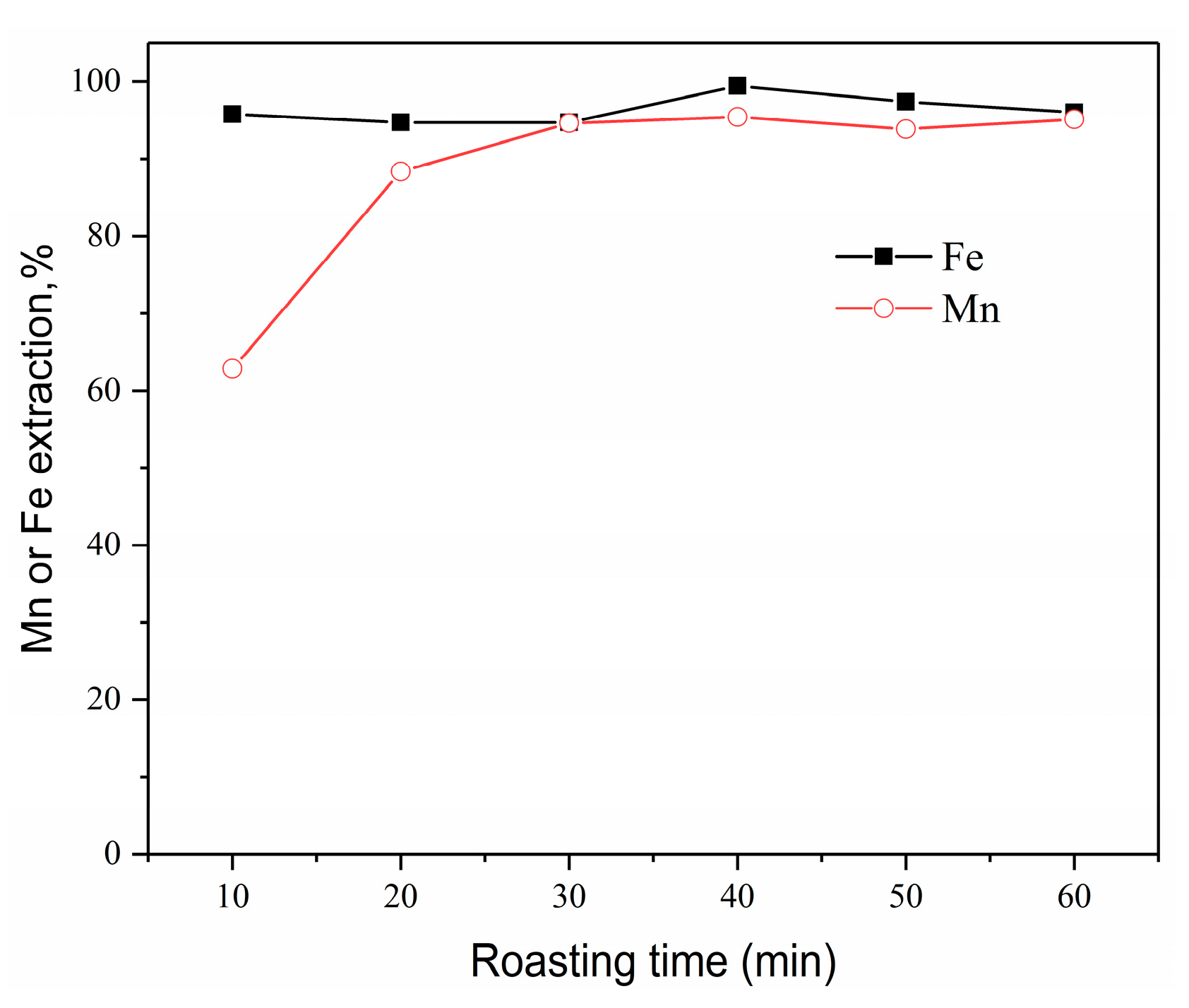

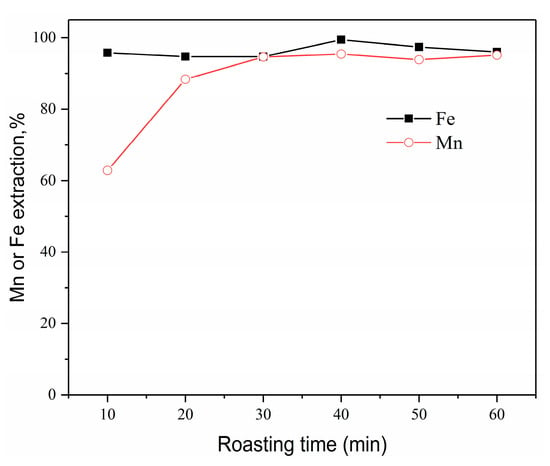

3.3.3. Effect of Roasting Time

To investigate the effect of roasting time on the recovery of Fe and Mn from PAR, a series of experiments were conducted at constant ammonium sulfate-to-PAR mass ratio of 12:1, roasting temperature of 450 °C, leaching temperature of 90 °C, and leaching time of 60 min. The results are presented in Figure 7.

Figure 7.

The effect of roasting time on the extraction of iron and manganese from PAR.

It was found that roasting time has a slight influence on Fe leaching. Only within 10 min, iron extraction efficiency reaches the maximum values. The insensitivity of iron leaching to calcination time is mainly be ascribed to the fact that rapid conversion of iron oxide on the residue surface to soluble ammonium iron sulphate takes place at the roasting temperature of 450 °C, then the left over iron oxide in the slag is subjected to acid dissolution under leaching conditions of 90 °C, 0.5 M H2SO4 and 180 min. Within the roasting time of 30 min, the manganese extraction rate reached its maximum. The increased manganese leaching with increasing roasting time is because of the reaction between ammonium sulphate and MnO2 in the residue. Thus, the roasting time of 30 min was chosen as the optimal value to minimize energy consumption.

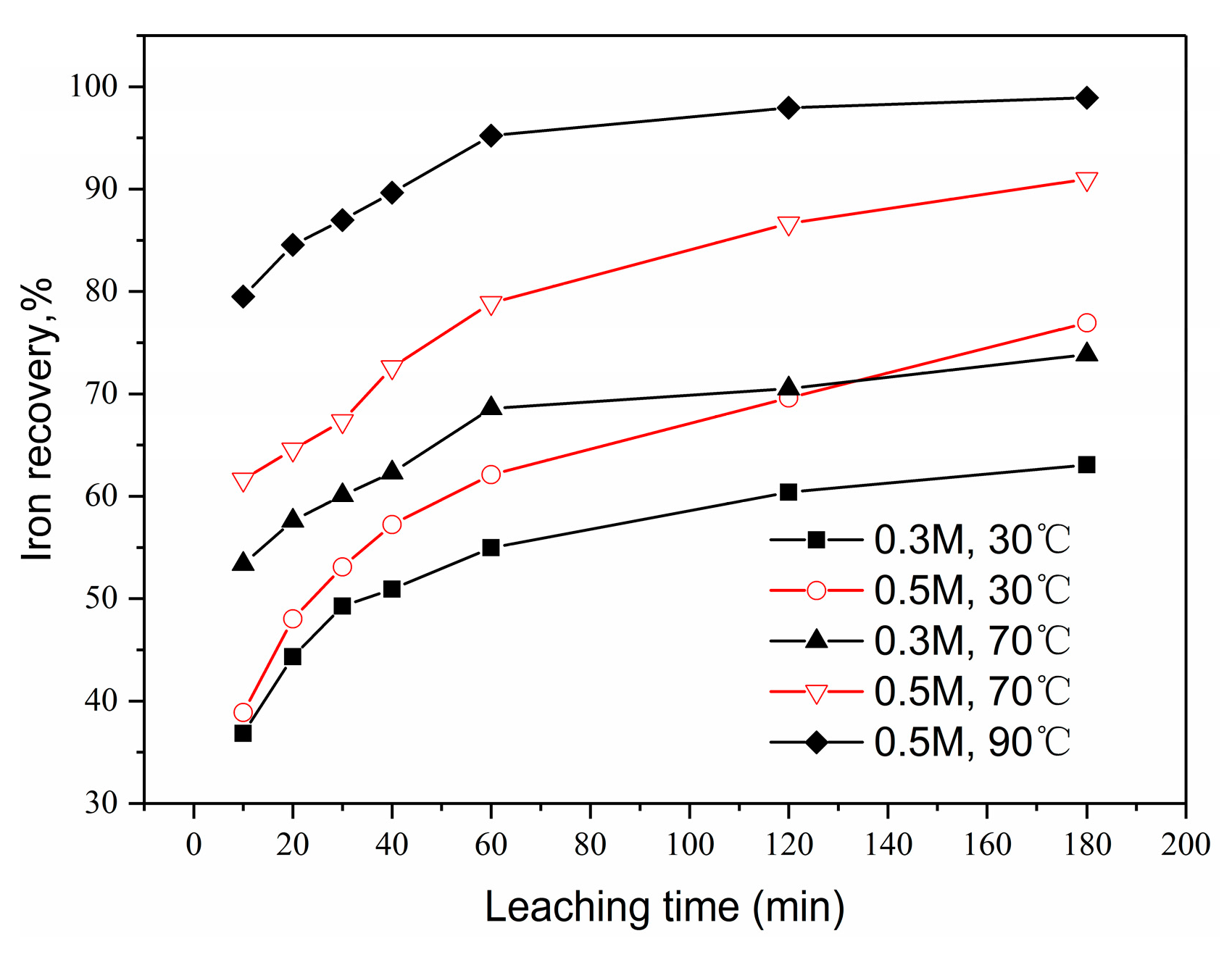

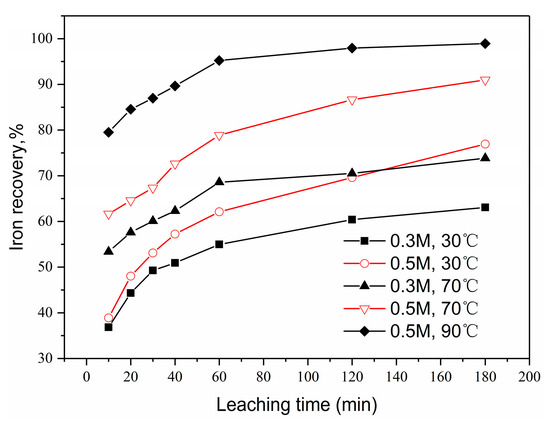

3.3.4. Effect of Leaching Temperature and Acidity

The effect of leaching temperature and time on iron extraction from the residue (PAR) was investigated and is shown in Figure 8, at a constant ammonium sulphate-to-PAR mass ratio of 12:1, roasting temperature of 450 °C, and roasting time of 30 min. It can be seen that leaching temperature and sulphuric acid concentration have an important influence on iron extraction. Iron leaching efficiency increase with increasing leaching temperature and sulphuric acid concentration. Only 73.8% iron was leached out as the leaching conditions were set at 30 °C, 0.5 M sulphuric acid, and leaching time of 180 min, which further illustrated that there are parts of iron oxide still present the form of goethite or hematite in the roasting process. So, it is necessary to optimize reaction temperature and acid concentration to gain satisfying iron recovery efficiency. From the results in Figure 8, it becomes evident that the iron leaching amount could be increased to 90.9%, as leaching temperature was elevated 70 °C, at 0.5 M sulphuric acid and 180 min. However, increasing temperature up to 90 °C greatly shorten the leaching time to obtain the higher iron leaching efficiency over 90%. For example, 95.2% iron was extracted at 60 min leaching time. Acid concentration is also vital factor to the dissolution of the remaining iron oxide. For example, the iron recovery efficiency increase from 63.1% to 76.9%, 73.8% to 90.9% while sulfuric acid concentration increase from 0.3 M to 0.5 M at 30 °C and 50 °C respectively. Although high iron extraction efficiency can be obtained by increasing either leaching temperature or sulfuric acid concentration, it is better to improve reaction temperature rather than to increase sulfuric acid concentration. This is because the leaching solution with high acidity would cause problems in the subsequent recovery of Mn and Fe. Therefore, the selected optimum leaching conditions are: leaching temperature of 90 °C, sulphuric acid concentration of 0.5 M and leaching time of 60 min.

Figure 8.

The effect of leaching temperature, sulphuric acid concentration and leaching time on the extraction of iron and manganese.

4. Conclusions

In this study, the process of ammonium sulphate roasting followed by sulphuric acid leaching was developed to recover iron and manganese from pyrolusite absorption residue (PAR). The experimental results reveal that high recovery efficiency of manganese and iron were simultaneously obtained, compared to the methods reported in literatures posing importance only on recovery of manganese, igoring iron extraction. In this roasting reaction, ammonium sulphate mainly reacts with goethite and manganese dioxide in the PAR and produce and at 200–350 °C, which can be converted to the thermochemically stable and MnSO4, at higher roasting temperature. The sulfation of iron oxide process is controlled by reactant diffusion through the surface ash layer with an activation energy of 20.56 kJ/mol. Manganese extraction was limited by both of the diffusion rate and the chemical reaction with an activation energy of 29.52 kJ/mol. The maximum recovery rates of Mn and Fe were 97.0% and 95.2%, respectively, at an ammonium sulphate-PAR mass ratio of 12:1, roasting temperature of 450 °C, roasting time of 30 min, leaching temperature of 90 °C, leaching time of 60 min, and leaching acidity of 0.5 M H2SO4.

Supplementary Materials

The following are available online at http://www.mdpi.com/2075-4701/8/1/38/s1, Figure S1: Schematic diagram of the sulfation roasting equipment, Figure S2: The simulation results for iron roasting process, Figure S3: The simulation results for manganese roasting process, Table S1: Iron extraction from ores using ammonium sulphate roasting data reported in literatures.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (NSFC-51304140 and NSFC-51374150) and Science and Technology Plan Projects of Sichuan Province, China (Grant No. 2015HH0067).

Author Contributions

Wei-Yi Sun and Shi-Jun Su provided research ideas; Lin Deng conducted a literature survey; Sang-Lan Ding conducted experimental design; Lin Deng and Bing Qu conducted experimental operations and data analysis; Lin Deng wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gui, Y.L.; Yan, Q.C.; Yan, Y.K.; Song, C.Y. Chemical Reaction Mechanism of Sintering Flue Gas Desulphurization with Pyrolusite Slurry. In Applications of Engineering Materials, Pts 1–4. Advanced Materials Research; Bu, J.L., Wang, P.C., Ai, L., Sang, X.M., Li, Y.G., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Swizerland, 2011; Volume 287–290, pp. 2937–2940. [Google Scholar]

- Sun, W.-Y.; Ding, S.-L.; Zeng, S.-S.; Su, S.-J.; Jiang, W.-J. Simultaneous absorption of NOx and SO2 from flue gas with pyrolusite slurry combined with gas-phase oxidation of NO using ozone. J. Hazard. Mater. 2011, 192, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.-Y.; Wang, Q.-Y.; Ding, S.-L.; Su, S.-J. Simultaneous absorption of SO2 and NOx with pyrolusite slurry combined with gas-phase oxidation of NO using ozone: Effect of molar ratio of O2/(SO2 + 0.5NOx) in flue gas. Chem. Eng. J. 2013, 228, 700–707. [Google Scholar] [CrossRef]

- Naik, P.K.; Sukla, L.B.; Das, S.C. Aqueous SO2 leaching studies on Nishikhal manganese ore through factorial experiment. Hydrometallurgy 2000, 54, 217–228. [Google Scholar] [CrossRef]

- An Introduction of Pyrolusite Ore. Available online: https://en.wikipedia.org/wiki/Pyrolusite (accessed on 3 November 2017).

- Sun, W.-Y.; Wang, Q.-Y.; Ding, S.-L.; Su, S.-J.; Jiang, W.-J.; Zhu, E.-G. Reaction mechanism of NOx removal from flue gas with pyrolusite slurry. Sep. Purif. Technol. 2013, 118, 576–582. [Google Scholar] [CrossRef]

- Sun, W.-Y.; Shen, W.; Wang, Q.Y.; Ding, S.L.; Su, S.-J. Adorption of chromium from aqueous solution onto aluminum pillared pyrolusite leaching residue. Fresen. Environ. Bull. 2013, 22, 2645–2650. [Google Scholar]

- Liao, B.; Shen, W.; Sun, W.; Wu, B.; Su, S.; Ding, S. Adsorption of methylene blue from aqueous solution onto pyrolusite leaching residue and degradation in H2O2/H2SO4 system. Fresen. Environ. Bull. 2014, 23, 1618–1625. [Google Scholar]

- Shen, W.; Liao, B.; Sun, W.; Su, S.; Ding, S. Adsorption of Congo red from aqueous solution onto pyrolusite reductive leaching residue. Desalination Water Treat. 2014, 52, 3564–3571. [Google Scholar] [CrossRef]

- Li, C.; Zhong, H.; Wang, S.; Xue, J.; Zhang, Z. Removal of basic dye (methylene blue) from aqueous solution using zeolite synthesized from electrolytic manganese residue. J. Ind. Eng. Chem. 2015, 23, 344–352. [Google Scholar] [CrossRef]

- Lang, T.; Xu, D.D.; Yi, M.Y.; Sun, W.Y.; Shen, W.; Su, S.J. Preparation of sulphoaluminate cement clinkers from pyrolusite flue desulfurization slag. Environ. Eng. 2014, 32, 108–112. [Google Scholar]

- Zhang, Y.; Du, M.; Liu, B.; Su, Z.; Li, G.; Jiang, T. Separation and recovery of iron and manganese from high-iron manganese oxide ores by reduction roasting and magnetic separation technique. Sep. Sci. Technol. 2017, 52, 1321–1332. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, H.; Xue, X.-X.; Yuan, S. Separation and Recovery of Iron and Rare Earth from Bayan Obo Tailings by Magnetizing Roasting and (NH4)(2)SO4 Activation Roasting. Metals 2017, 7, 195. [Google Scholar] [CrossRef]

- Zhu, D.-Q.; Chun, T.-J.; Pan, J.; He, Z. Recovery of Iron from High-Iron Red Mud by Reduction Roasting with Adding Sodium Salt. J. Iron Steel Res. Int. 2012, 19, 1–5. [Google Scholar] [CrossRef]

- Zhang, W.; Cheng, C.Y. Manganese metallurgy review. Part I: Leaching of ores/secondary materials and recovery of electrolytic/chemical manganese dioxide. Hydrometallurgy 2007, 89, 137–159. [Google Scholar] [CrossRef]

- Liu, W.; Yang, J.; Xiao, B. Application of Bayer red mud for iron recovery and building material production from alumosilicate residues. J. Hazard. Mater. 2009, 161, 474–478. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhao, B.; Tang, Y.; Wan, P.; Chen, Y.; Lv, Z. Recycling of iron from red mud by magnetic separation after co-roasting with pyrite. Thermochim. Acta 2014, 588, 11–15. [Google Scholar] [CrossRef]

- Yu, Z.-L.; Shi, Z.-X.; Chen, Y.-M.; Niu, Y.-J.; Wang, Y.-X.; Wan, P.-Y. Red-mud treatment using oxalic acid by UV irradiation assistance. Trans. Nonferr. Met. Soc. 2012, 22, 456–460. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, X.; Wang, M.; Wang, H.; Xian, P. Recovery of iron from red mud by selective leach with oxalic acid. Hydrometallurgy 2015, 157, 239–245. [Google Scholar] [CrossRef]

- Zhang, Y.; You, Z.; Li, G.; Jiang, T. Manganese extraction by sulfur-based reduction roasting-acid leaching from low-grade manganese oxide ores. Hydrometallurgy 2013, 133, 126–132. [Google Scholar] [CrossRef]

- You, Z.; Li, G.; Zhang, Y.; Peng, Z.; Jiang, T. Extraction of manganese from iron rich MnO2 ores via selective sulfation roasting with SO2 followed by water leaching. Hydrometallurgy 2015, 156, 225–231. [Google Scholar] [CrossRef]

- Freitas, L.R.; Amaral, J.C.; Mendonca, C.F. Sulphation of Carajas manganese ore with gaseous SO2. Trans. Inst. Min. Metall. Sect. C 1993, 102, 130–131. [Google Scholar]

- Vu, H.; Jandová, J.; Lisá, K.; Vranka, F. Leaching of manganese deep ocean nodules in FeSO4–H2SO4–H2O solutions. Hydrometallurgy 2005, 77, 147–153. [Google Scholar] [CrossRef]

- Yi, A.-F.; Wu, M.-N.; Liu, P.-W.; Feng, Y.-L.; Li, H.-R. Reductive leaching of low-grade manganese ore with pre-processed cornstalk. Int. J. Miner. Metall. Mater. 2015, 22, 1245–1251. [Google Scholar] [CrossRef]

- Rolf, R.F. Process for the Selective Recovery of Manganese and Iron. U.S. Patent 3471285DA, 7 October 1969. [Google Scholar]

- Li, J.; Chen, Z.; Shen, B.; Xu, Z.; Zhang, Y. The extraction of valuable metals and phase transformation and formation mechanism in roasting-water leaching process of laterite with ammonium sulfate. J. Clean. Prod. 2016, 140, 1148–1155. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H.; Peng, B.; Min, X.; Hu, M.; Peng, N.; Yuang, Y.; Lei, J. Study on separating of zinc and iron from zinc leaching residues by roasting with ammonium sulphate. Hydrometallurgy 2015, 158, 42–48. [Google Scholar] [CrossRef]

- Mohamed, S.; Merwe, E.M.V.D.; Altermann, W.; Doucet, F.J. Process development for elemental recovery from PGM tailings by thermochemical treatment: Preliminary major element extraction studies using ammonium sulphate as extracting agent. Waste Manag. 2016, 50, 334–345. [Google Scholar] [CrossRef] [PubMed]

- Doucet, F.J.; Mohamed, S.; Neyt, N.; Castleman, B.A.; van der Merwe, E.M. Thermochemical processing of a South African ultrafine coal fly ash using ammonium sulphate as extracting agent for aluminium extraction. Hydrometallurgy 2016, 166, 174–184. [Google Scholar] [CrossRef]

- Lee, C.T.; Sohn, H.Y. Recovery of synthetic rutile and iron oxide from ilmenite ore by sulfation with ammonium sulfate. Ind. Eng. Chem. Res. 1989, 28, 1802–1808. [Google Scholar] [CrossRef]

- Xin, H.X.; Wu, Y.; Liu, S.M.; Zhai, Y.C. Recovery of aluminum and iron from high-iron bauxite by roasting method using ammonium sulfate. Conserv. Util. Miner. Resour. 2013, 37, 37–40. [Google Scholar] [CrossRef]

- Dixo, P. Formation of sulphamic acid during the thermal decomposition of ammonium sulphate. Nature 1944, 154, 706. [Google Scholar] [CrossRef]

- Kiyoura, R.; Urano, K. Mechanism, Kinetics, and Equilibrium of Thermal Decomposition of Ammonium Sulfate. Ind. Eng. Chem. Process Des. Dev. 1970, 9, 489–494. [Google Scholar] [CrossRef]

- Chen, Y.-Z.; Li, G.-G.; Bi, C.-M.; Wang, B.; Li, R.-G. Research on the preparation of cementitious material using slag, desulfuration residue and cinder. J. Wuhan Univ. Technol. 2010, 32, 6–10. [Google Scholar] [CrossRef]

- Liu, X.-W.; Feng, Y.-L.; Li, H.-R.; Yang, Z.-C.; Cai, Z.-L. Recovery of valuable metals from a low-grade nickel ore using an ammonium sulfate roasting-leaching process. Int. J. Miner. Metall. Mater. 2012, 19, 377–383. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).