Abstract

Directional heat treatment reduces the number of transverse grain boundaries in pure copper wires at suitable temperatures, thereby promoting the formation of columnar or even single-crystal structures. This process significantly enhances the electrical conductivity of the wires and has become a research focus. Fundamentally, directional heat treatment is a secondary recrystallization process, involving key microstructural evolutions such as grain growth and grain boundary migration. Investigating its mechanism in pure copper wires is essential for optimizing their conductive performance. In this study, pure copper wires were subjected to directional heat treatment and systematically characterized using electron backscatter diffraction (EBSD). The effects of treatment on grain growth and boundary migration were analyzed, clarifying the evolution of grain boundary structures and crystallographic textures during columnar grain development. It was revealed that grains with a <112> orientation preferentially develop into columnar structures, with most inter-columnar grain boundaries being low-energy ∑ 3 and ∑ 9 types. The novelty of this work lies in revealing the mechanism of directional grain boundary migration in pure copper wires and elucidating the formation mechanism of island grains after directional heat treatment.

1. Introduction

The trend toward greater precision and miniaturization in electrical equipment and electronic components is becoming increasingly evident, placing higher demands on the electrical performance of transmission conductors. The development of high-fidelity transmission wires, high-frequency cables, and ultra-fine conductors for miniature devices not only meets the technical requirements of fields such as national defense, aerospace, marine engineering and rail transportation, but also finds broad applications in civilian networks, electronic communications and audio-visual systems. As the most widely used conductive material, copper plays a pivotal role, and enhancing the electrical performance of pure copper conductors is therefore of great significance [1].

Theoretical research show that defects in metallic conductors, including impurities, solute atoms and grain boundaries, especially transverse grain boundaries perpendicular to the transmission direction, cause strong attenuation of signal transmission [2,3,4]. Currently, there are two methods to improve the signal transmission quality of conductor materials: one is to increase the purity of the conductor material to reduce the impact of impurities on its electrical properties; the other is to reduce the number of transverse grain boundaries in the conductor material, thereby weakening or eliminating the scattering effect of grain boundaries on electrons [5]. The purification method has reached its limit, so reducing transverse grain boundaries in conductors has become a major focus of research.

Japan’s Ohno Continuous Casting (O.C.C.) technology has successfully produced metallic wires with a perfect single-crystal structure. However, the as-cast wires obtained through this process still exhibit diameters larger than industrial application standards (e.g., ultrafine copper wires typically require diameters below 0.05 mm). Consequently, like all conventional wires, they must undergo wire drawing processes to achieve the target dimensions [6,7,8,9,10,11]. This creates a fundamental contradiction: the O.C.C. wire, designed to achieve a perfect single-crystal structure, inevitably suffers damage to its initial crystalline integrity during the essential subsequent wire-drawing deformation process. This introduces defects such as grain boundaries, consequently leading to the degradation of its superior electrical performance [12,13,14,15]. Therefore, finding new methods to reduce the number of transverse grain boundaries within the wire is critically important.

Directional heat treatment is an effective method. When wires are heat treated at suitable temperatures to form columnar or single-crystal structures, markedly improving its electrical performance. This process proceeds through grain-boundary migration and grain growth. Mao et al. conducted high-temperature short-time annealing on as-drawn T2 pure copper wires at 850 °C for 40 s. After this treatment, both the tensile strength and elongation after fracture of the wires increased, and the electrical conductivity was approximately 5.2% higher than that of the as-drawn state. Both the comprehensive performance and annealing efficiency are better than those of the low-temperature long-time annealing process at 400 °C for 60 min [16]. Fan et al. pointed out that simultaneously enhancing the strength and electrical conductivity of metal conductors is crucial, yet the mutual constraint between these two properties remains a significant challenge. This study proposes a strategy utilizing “<111>-oriented ultra-high aspect ratio fibrous crystals” to overcome this performance trade-off in copper wires. This approach leverages the unique spatial distribution and highly consistent hard orientation of grain boundaries, enabling the material to separately optimize strength and conductivity by assigning distinct roles during load-bearing and electrical conduction. Through a processing route combining directional solidification with severe wire drawing, fibrous crystal structures with an aspect ratio of 596.7 and a <111> texture fraction exceeding 97% were successfully fabricated, achieving excellent copper wires with a yield strength of 482.3 MPa and an electrical conductivity of 101.63% IACS. The formation mechanisms underlying the high strength and high conductivity are further quantitatively analyzed [17]. Jia investigated the heat treatment of copper and copper-silver alloy wires under varying annealing times at constant temperatures. Performance tests revealed that after 4 s of annealing, the elongation of copper wires with 14% and 28% deformation increased by 19.5 and 19.7 times, respectively, while resistivity decreased by 4.2% and 4.7%. After 2.77 s of annealing, copper wires drawn at 200 m/min and 800 m/min showed elongation improvements of 10.9 and 13.5 times, with resistivity reductions of 7.1% and 7.9%, respectively. Systematic comparison determined the optimal annealing time ranges to be 2.77–4 s for single crystal copper wires and 5.14–7.2 s for copper-silver alloy wires. The heat treatment effectively enhanced ductility, plasticity, and electrical conductivity while relieving internal residual stresses and mitigating work hardening, thus providing valuable process guidance for high-performance bonding wire fabrication [18]. Mao et al. successfully fabricated copper wires with axial fiber texture through rotary swaging, overcoming the conventional strength-conductivity trade-off. The as-prepared material achieves 97% IACS electrical conductivity, over 450 MPa yield strength, and excellent thermal stability (573 K for 1 h). After annealing, the conductivity further increases to 103% IACS while maintaining a yield strength above 380 MPa. The underlying mechanism involves axial elongated grains providing conduction channels for electrons, while low-angle grain boundaries between ultrafine grains simultaneously hinder dislocation slip and crack propagation while suppressing grain boundary migration [19].

The microstructural evolution of deformed materials primarily involves grain boundary migration, and an important factor affecting grain boundary migration is the grain boundary structure. By definition, Grain boundaries with misorientation angles below 15° are low-angle boundaries whose energy increases monotonically with angle. Those above 15° are high-angle boundaries; their energy-misorientation relationship is more complex and is described by the Coincident Site Lattice (CSL) model. A smaller Σ value indicates a higher density of coincident lattice sites. CSL boundaries with Σ ≤ 29 are termed special boundaries, while those with Σ > 29 are general boundaries [20]. Σ 1 corresponds to low-angle grain boundaries, and Σ 3 grain boundaries include coherent, incoherent twins, as well as asymmetric tilt, twist and irregular interfaces [21]. Generally, the grain-boundary energy of special boundaries is lower than that of random high-angle boundaries. Currently, researchers generally accept that small-angle grain-boundary migration occurs through dislocation climb and glide [22], high-angle grain-boundary migration is governed by atomic transfer across the boundary. In addition to boundary structure, migration is influenced by point defects such as impurities, solutes and vacancies, as well as textures [23]. The key external factors influencing the process include, but are not limited to, temperature and pressure.

During annealing, deformed materials primarily undergo processes of recovery, recrystallization and grain growth. During recovery, vacancies annihilate and dislocations rearrange via slip and climb; low-angle grain boundaries migrate, whereas high-angle boundaries remain stationary. During recrystallization, new nuclei form and subsequently migrate as grain boundaries, driven by stored energy. Zasadzińsk et al. investigated the work hardening and recrystallization kinetics of ETP and OF copper. The study covered an extensive strain hardening range (true strain ≈ 5) characteristic of micro-fine wire manufacturing, along with recrystallization temperatures and time ranges corresponding to actual industrial processing conditions in advanced micro-wire production technologies. The results demonstrated that the recrystallization temperature of ETP copper remains lower than that of OF copper regardless of recrystallization time. However, irrespective of copper grade, the recrystallization effect can be achieved within approximately 10–30 s [24]. Grain growth begins after primary recrystallization, with grain-boundary migration reducing the system’s free energy through the elimination of interfacial area. Grain growth is divided into normal grain growth (continuous growth) and abnormal grain growth (secondary recrystallization). Normal grain growth exhibits a uniform grain size, whereas abnormal grain growth shows a sudden increase in grain size and occurs when normal growth is inhibited [25]. Generally, abnormal growth is driven by the reduction in interfacial energy [26]. Rios et al. proposed that abnormally growing grains possess an initial size advantage over the matrix grains [27,28]. Two main explanations for secondary recrystallization are currently proposed. One emphasizes the significant influence of grain boundary type on abnormal grain growth, for instance, in oriented silicon steel, abnormal grain growth is determined by Σ 5, Σ 7 and Σ 9 grain boundaries; the other holds that high-energy grain boundaries with 20–45° misorientations dominate secondary recrystallization [29,30], these high-energy grain boundaries exhibit high mobility.

Directional heat treatment is widely used to produce oriented microstructures [31,32,33,34,35,36,37]. Zhu et al. through annealing treatment at 550 °C for 15 min, increased the proportion of Σ 3 grain boundaries in industrial pure copper wires to 49.80%, and the proportion of special grain boundaries reached 57.59%. The electrical conductivity significantly increased to 59.29% IACS (2.56 times that before annealing), confirming that the improvement in electrical conductivity is positively correlated with the proportion of Σ 3 grain boundaries, but has no correlation with grain size [38]. Liu et al. obtained the best comprehensive performance when the deformation amount was 60% after multiple passes of drawing and annealing treatment on pure copper wires: tensile strength of 244.9 MPa, elongation of 51%, and conductivity of 99.4% IACS [39]. Lei et al. employed a novel continuous casting-compositing and drawing process to fabricate brass-clad pure copper strands. After annealing at 300–350 °C for 1 h, the strands achieved optimal comprehensive performance: the elongation after fracture increased from 3% (as-drawn state) to approximately 40%, with the interfacial diffusion layer thickness controlled within 4.3–7.2 μm. The fracture mode of the brass cladding transitioned from cleavage to ductile fracture, significantly enhancing the service safety and lifespan of the ground wire [40]. Banganayi et al. showed through annealing curve analysis that oxygen-free copper (Cu-OF) has greater ductility potential than tough-pitch copper (Cu-ETP). Moreover, the process parameters needed to achieve basic ductility are unaffected by equipment speed or material type [41]. Cao et al. systematically investigated the effects of drawing and annealing processes on the properties of single-crystal copper wires. The study revealed that after 14% single-pass drawing, grains elongated along the drawing direction, with tensile strength increasing from 500.83 MPa to 615.5 MPa and resistivity slightly decreasing. When the drawing speed was increased to 500 m/min, tensile strength further rose to 660.26 MPa. Annealing experiments demonstrated that at 400 °C, the tensile strength of Φ0.08 mm copper wires decreased to 224.7 MPa while elongation after fracture significantly improved to 19.87%. However, after annealing at 550 °C, mechanical properties deteriorated, with tensile strength and elongation measuring 214.4 MPa and 12.18%, respectively [42].

In summary, the use of directional heat treatment to produce high-aspect-ratio columnar grains or even single-crystal copper wires is of significant importance for fundamental studies on grain boundary migration and grain growth in pure copper wires.

This paper systematically studies the effects of directional heat treatment on grain growth and boundary migration in pure copper wires by employing EBSD, aiming to elucidate changes in grain boundary structure and crystallographic texture during columnar grain growth and thus reveal the mechanism of directional boundary migration.

2. Materials and Methods

The experimental raw material was T1M20 copper wire rod (99.99% purity, 8 mm initial diameter) was directly supplied by Jiangsu Baojielong Electromagnetic Wire Co., Ltd., Yangzhou, China. Its composition is shown in Table 1. Through drawing, the drawing process was performed on an FR-16 horizontal hydraulic drawing machine. copper wires with diameters of 1 mm, 0.85 mm and 0.7 mm were obtained, with deformation amount of 87%, 89% and 91%, respectively.

Table 1.

Impurity Composition of Raw Materials (wt.%).

Directional heat treatment was performed in a high-frequency induction directional solidification furnace, manufactured by Zhengzhou Hengtong Furnace Industry Co., Ltd., in Zhengzhou, China. The chamber was connected to a mechanical pump and molecular pump to achieve a vacuum of 10−3 Pa, a high-frequency induction heating power supply was used, with heating temperature controlled by adjusting the current, temperature was monitored with a K-type thermocouple from Shanghai Wolan Instruments Co., Ltd., Shanghai, China. The chamber contained a cooling crystallizer filled with Ga-In-Sn alloy coolant, the temperature gradient ahead of the hot zone was controlled by adjusting the liquid level height. The sample was moved upwards at a constant rate via a pulling rod controlled by PLC.

To study the microstructure, the samples were sequentially ground with 240, 400, 600, 800 and 1200-grit abrasive paper and subsequently polished with 0.5 μm and 0.05 μm Al2O3 suspensions. They were then etched for 3–5 s in a solution composed of 10 g FeCl3, 100 mL HCl and 200 mL H2O. Microstructural observation was carried out using a optical microscope (OM) from Leica Microsystems in Wetzlar, Hesse, Germany, the specific model was DM6M. Scanning electron microscopy (SEM) was performed with Auriga FIB/SEM dual-beam system from Zeiss company, Oberkochen, Germany. For electron backscatter diffraction (EBSD) analysis, also from Zeiss company, Oberkochen, Germany. the sample was tilted to 70°, with an accelerating voltage of 20 kV and a working distance of 18 mm. The acquired data were processed using version 4.4 of the Channel 5 software package from HKL.

3. Results and Discussion

3.1. Crystallographic Texture of Initial Microstructure in Pure Copper Wire

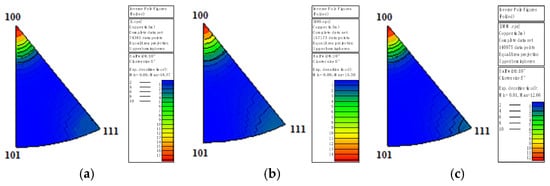

Figure 1 shows that pure copper wires with different degrees of deformation all exhibit a strong <100> texture. The <100> texture is strongest in the pure copper wire with 91% deformation, weakest in the wire with 87% deformation, and the <111> texture also appears in the latter. This is in agreement with the experimental findings of Yang et al., who reported that with increasing strain, the volume fraction of the <111> texture first increased and then decreased, whereas that of the <100> texture rose [43].

Figure 1.

Inverse pole figures along the drawing direction for the initial microstructures of pure copper wires with different deformation degrees: (a) 91%; (b) 89%; (c) 87%.

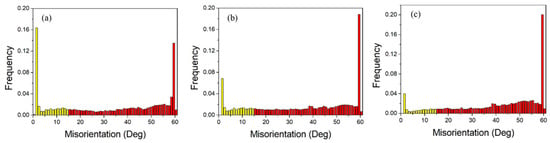

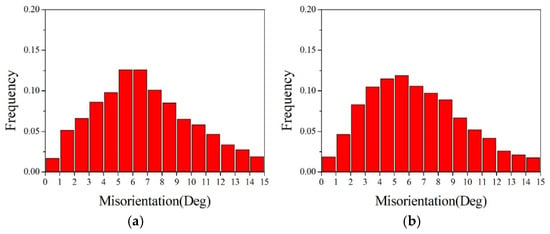

Figure 2 shows the statistical distribution of grain boundary misorientation angles in pure copper wires for three different deformation levels, where low-angle grain boundaries (LAGBs) and high-angle grain boundaries (HAGBs) are colored in yellow and red, respectively. The results indicate that HAGBs are predominant. The misorientation angle distribution is bimodal, with the first peak at approximately 2° and the second at around 60°, suggesting that 2° LAGBs and 60° HAGBs are the most prevalent types.

Figure 2.

Statistics of grain boundary angles in the initial microstructure of pure copper wires with different deformation amounts: (a) 91%; (b) 89%; (c) 87%.

As deformation increases, the first peak grows while the second diminishes, indicating a higher proportion of LAGBs and fewer HAGBs. According to statistical data, at 91% deformation, LAGBs account for 30.9%, while at 89% and 87% deformation, they account for 22.3% and 13.1%, respectively. As the deformation decreases, 2° LAGBs drop from 16.2% to 6.8% and 4.1%, while 60° HAGBs rise from 13.6% to 18.5% and 20.2%.

The 91% deformed pure copper wire yielded results similar to the 89% sample—both exhibited a strong <100> texture, were prone to secondary recrystallization, and could develop columnar grains with a high aspect ratio under appropriate directional heat treatment conditions. In contrast, the 87% deformed sample behaved distinctly. Therefore, the 89% and 87% deformed samples were selected as representative cases for subsequent comparative analysis.

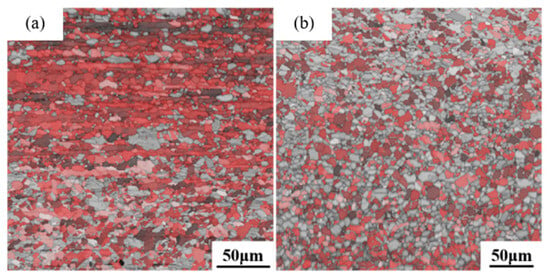

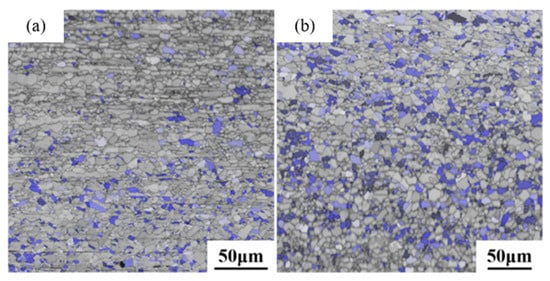

Figure 3 and Figure 4 show the initial microstructure texture distribution maps of pure copper wires with deformation amounts of 89% and 87%. Red grains represent <100> oriented grains, blue grains represent <111> oriented grains, and darker colors indicate closer proximity to the ideal orientation.

Figure 3.

Distribution map of <100> texture in the initial microstructure of pure copper wires with different deformation amounts: (a) 89%; (b) 87%.

Figure 4.

Distribution map of <111> texture in the initial microstructure of pure copper wires with different deformation amounts: (a) 89%; (b) 87%.

As shown in Figure 3, it is evident that the <100> grain orientation is significantly more concentrated and prevalent in the 89% deformed pure copper wire, constituting 63.3% of all grains. In comparison, the 87% deformed pure copper wire contains a considerably lower proportion of this orientation, representing only 42.1% of all grains.

As shown in Figure 4, the <111> texture is more prevalent in the pure copper wire with 87% deformation, accounting for 23.2% of all grains, despite its relatively scattered distribution. whereas the <111> oriented grains in the pure copper wire with 89% deformation account for 17.8% of all grains.

Figure 5 and Figure 6 quantitatively analyze the deviation from ideal texture in two deformation amounts of pure copper wires. We consider grains with orientation deviations within 15° from the ideal orientation as having <100> or <111> orientations. Figure 5 shows that in pure copper wires with different deformation amounts, the <100> texture mostly deviates from the ideal orientation by 5°~8°. Compared with Figure 6, it is evident that compared to the deformation amount of 89%, the <111> texture in pure copper wires with a deformation amount of 87% exhibits more uniform deviation.

Figure 5.

Statistical diagram of deviations from ideal <100> texture in the initial microstructure of pure copper wires with different deformation amounts: (a) 89%; (b) 87%.

Figure 6.

Statistical diagram of deviations from ideal <111> texture in the initial microstructure of pure copper wires with different deformation amounts: (a) 89%; (b) 87%.

Based on the quantitative analysis, the fraction of the <100> texture in the 89% deformed pure copper wire is 50% higher than in the 87% deformed wire, and the number of LAGBs is 70% higher. LAGBs, particularly those with very small misorientation angles, possess lower energy and consequently lower grain boundary mobility, whereas random HAGBs have higher energy and greater mobility. Texture pins most grain boundaries and thereby suppresses grain growth; only unpinned boundaries allow a few grains to grow rapidly. As deformation increases, texture strengthening enhances this pinning effect, grain-growth anisotropy becomes more pronounced, and secondary recrystallization is promoted. The 89% deformed pure copper wire develops a strong <100> texture accompanied by a high density of low-angle grain boundaries, resulting in significant texture pinning. During annealing, this pinning effect limits secondary recrystallization to a very small population of grains in optimal orientations. When a sufficient temperature gradient is applied, these abnormal grains continue to grow preferentially along the gradient, ultimately forming a columnar grain structure after directional heat treatment. The 87% deformed pure copper wire has a relatively weak texture, resulting in an inadequate grain boundary pinning effect. Consequently, even if secondary recrystallization occurs, the growth of abnormal grains is hindered, making it difficult to obtain a columnar grain structure through directional heat treatment.

3.2. Grain Boundary Structure and Crystallographic Texture After Directional Heat Treatment

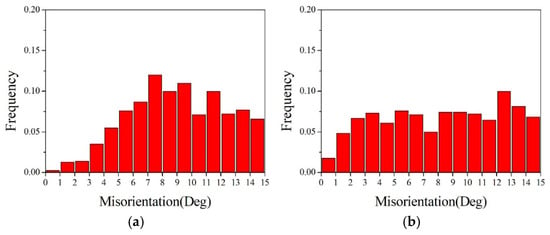

Figure 7 shows the grain boundary reconstruction maps of directional heat-treated structures under different drawing speeds at a heat treatment temperature of 550 °C. At 3 μm s−1, When the specimen remains in the hot zone for an extended duration, grain boundaries have sufficient time to undergo isotropic migration, thereby leading to the formation of equiaxed grains. At 5 μm s−1, columnar grain structures were successfully achieved when the hot zone translation rate was matched with the preferential growth rate of specific oriented grains. The prominent presence of annealing twin boundaries (red lines) in the figure, particularly their frequent occurrence within grain interiors, indicates extensive annealing twinning during the directional heat treatment process. This phenomenon is commonly associated with grain boundary migration mechanisms in face-centered cubic metals during recrystallization, where twin boundary formation effectively reduces the total interfacial energy of the system.

Figure 7.

Grain boundary reconstruction maps of directional heat-treated structures under different drawing speeds at a heating temperature of 550 °C: (a) 3 μm s−1; (b) 5 μm s−1.

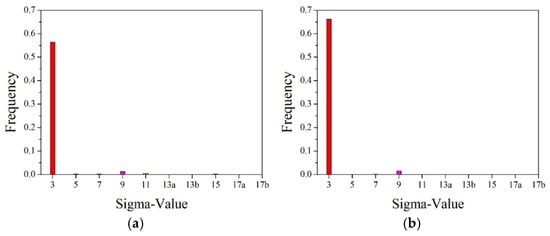

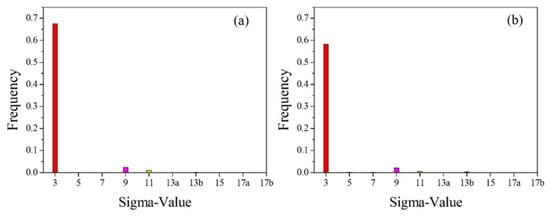

Figure 8 shows the corresponding special grain boundary statistics diagram, among them, Σ 3 twin boundaries predominate, followed by Σ 9 boundaries. These special boundaries have low energy, are relatively stable, and migrate only with difficulty. This indicates that high-mobility general high-angle grain boundaries are consumed or transformed into low-energy special boundaries during directional migration. The resultant grain boundary structure, dominated by low-Σ 3 boundaries, effectively reduces the overall driving force for grain boundary migration, leading to enhanced microstructural stability after heat treatment.

Figure 8.

Special grain boundary statistics of directional heat-treated microstructure at a heating temperature of 550 °C under different drawing rate conditions: (a) 3 μm s−1; (b) 5 μm s−1.

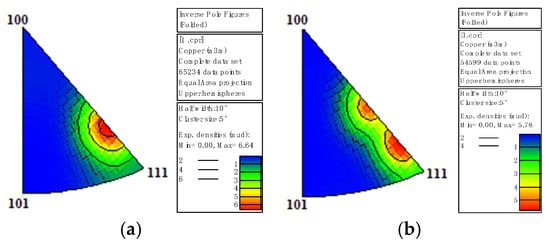

Figure 9 shows the inverse pole figures along the drawing direction of the directional heat-treated microstructure at a heating temperature of 550 °C under different withdrawal rates. As clearly shown in the figure, significant crystallographic texture changes occurred in the samples after directional heat treatment. Particularly under the condition with a pulling rate of 5 μm s−1, a <112> texture developed. This indicates that grains with <112> orientation exhibited a distinct growth advantage during the directional heat treatment process, enabling them to preferentially grow along the direction of heat flow and gradually form a columnar grain structure.

Figure 9.

Inverse pole figures along the drawing direction of the directional heat-treated microstructure under different drawing rates at a heating temperature of 550 °C: (a) 3 μm s−1; (b) 5 μm s−1.

3.3. Columnar Grain Orientation and Grain Boundary Structure

3.3.1. Columnar Grain Orientation

Figure 10 shows the orientation distribution of the directional heat-treated microstructure under heating temperatures of 650 °C and draw rates of 10 μm s−1 and 15 μm s−1, both exhibiting distinct columnar grains. The crystallographic orientations of ten representative columnar grains were analyzed, and the results are summarized in Table 2.

Figure 10.

Orientation distribution maps of the microstructure after directional heat treatment at a heating temperature of 650 °C under different drawing speeds: (a) 10 μm s−1; (b) 15 μm s−1.

Table 2.

Statistical Table of Columnar Grain Orientation after Directional Heat Treatment at 650 °C under Different Drawing Rates.

Half of the columnar grains have a <112> orientation, such as grains 1, 3, 4, 7 and 9 in Figure 10. Some columnar grains have a <111> orientation, such as grains 2 and 6. Therefore, it can be considered that grains with a <112> orientation are more likely to grow into columnar grains during directional heat treatment, while the <112> orientation is the secondary recrystallization texture of pure copper wires. Our results are similar to those of Li et al., who observed that columnar grains in directionally heat-treated, 90% cold-rolled pure nickel develop a typical secondary recrystallization texture. This texture in pure nickel is characterized by the {124} <21-1> orientation [44]. Kang et al. investigated the alloy and found that after heat treatment, the texture significantly reverted from the cold-rolled Copper and Brass deformation components to a Cube-dominated recrystallization texture, achieving peak hardness at the T4 condition of 390 °C × 2 h [45].

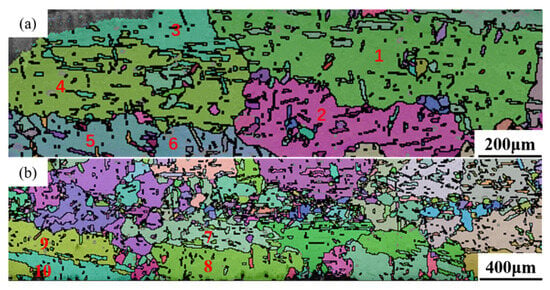

3.3.2. Grain Boundary Structure Between Columnar Crystals

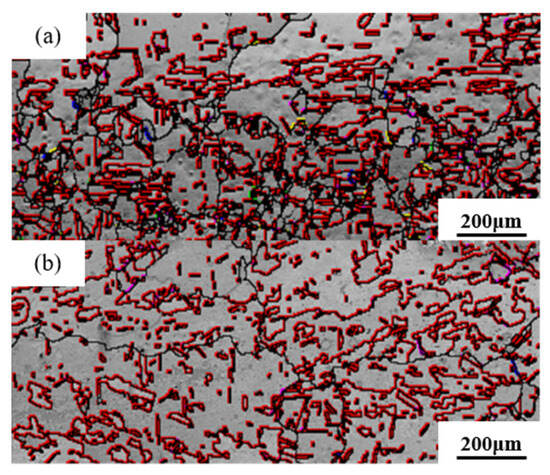

Figure 11 shows grain boundary reconstruction maps of microstructures after directional heat treatment at 650 °C under drawing rates of 10 μm s−1 and 15 μm s−1, while Figure 12 shows the corresponding special grain boundary statistics. Among the special grain boundaries, Σ 3 boundaries predominate, followed by Σ 9 boundaries. Σ 3 boundaries constitute 67% of the total, with most twin boundaries located within the columnar grains. It is worth noting that in the grain boundary reconstruction diagram in Figure 11, some colored lines marked with rectangular boxes can be seen, indicating that a considerable portion of the grain boundaries between columnar crystals are special grain boundaries.

Figure 11.

Grain boundary reconstruction diagram of directional heat treatment microstructure under different drawing rates at a heating temperature of 650 °C: (a) 10 μm s−1; (b) 15 μm s−1.

Figure 12.

Statistical diagram of special grain boundaries in directional heat treatment microstructure under different drawing rates at a heating temperature of 650 °C: (a) 10 μm s−1; (b) 15 μm s−1.

In Figure 11a, a pink secondary twin boundary is visible between columnar grains 1 and 2, while a red twin boundary can be observed between grains 3 and 4. Figure 11b also shows twin boundaries between columnar grains 6 and 7, as well as between grains 8 and 9. These special HAGBs possess relatively low energy and mobility, thereby reducing the overall system energy. Zhang et al., in their study on directional heat treatment of cold-rolled pure iron, found that grain boundaries between columnar grains tend to form low-energy boundaries, such as twin boundaries [46], which is similar to the results of this experiment.

3.3.3. Grain Boundary Structure Between Columnar Crystals and Their Front Equiaxed Crystals

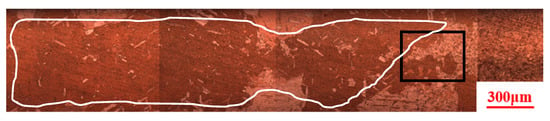

When the heating temperature is 750 °C and the drawing rate is 20 μm s−1, the microstructure at the interface between the columnar grains and their leading equiaxed grains in the directional heat-treated structure is shown in Figure 13. The white curve represents the columnar crystal structure, and the black square represents the front interface of the columnar crystal. With a pulling direction from right to left, continuously grown columnar grains approximately 2.5 mm in length are observed on the left, while fine equiaxed grains with an average size of about 5 μm are present on the right.

Figure 13.

Columnar grain front interface in the directional heat treatment microstructure at a heating temperature of 750 °C and a drawing rate of 20 μm s−1.

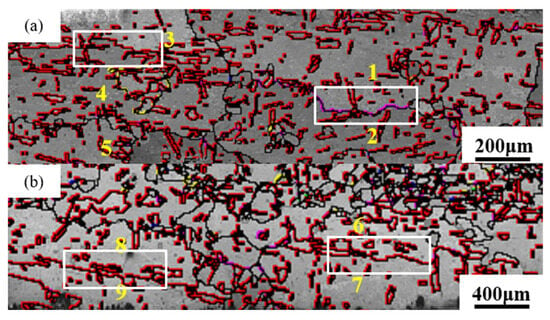

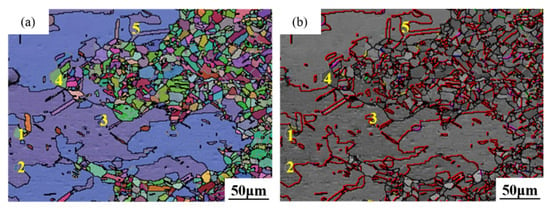

Figure 14a shows the grain orientation distribution at the interface within the rectangular frame in Figure 13, and Figure 14b shows the corresponding grain boundary reconstruction diagram. In the grain boundary reconstruction diagram, the types of grain boundaries at the interface are distinguished by color: general high-angle boundaries are represented in black, special high-angle boundaries in color, and low-angle boundaries in gray.

Figure 14.

(a) Orientation distribution map and (b) grain boundary reconstruction map of the front-end interface of columnar grains.

During directional heat treatment, the high-energy grain boundaries migrate rapidly, continuously consuming the slower-growing finer grains ahead of them. The mobility of these newly formed boundaries often dictates whether directional growth can be sustained. For example, the grain boundaries between <112> orientation grains and <100> orientation grains migrate rapidly during directional heat treatment, after <112> oriented grains consume the surrounding <100> oriented grains, they establish new boundaries with the remaining grains, if these new grain boundaries can also migrate rapidly during the migration process, they can maintain their advantage and continue to move forward, resulting in the continuous growth of columnar grains, this behaviour typically occurs at the general high-angle boundaries shown in black in Figure 14b.

LAGBs or twin boundaries, having low energy, therefore hinder the forward migration of grain boundaries. If the grains that form twin or low-angle boundaries with the columnar grains are small, their pinning effect is limited. Boundaries with higher mobility can bypass these grains, leaving them as isolated “island grains” within the columnar structure, as illustrated by grains 1, 2 and 3 in Figure 14. If the small-angle grain boundaries or twin boundaries are relatively long, they exert a stronger pinning force on migrating boundaries. The pinned section arrests, while the unpinned segment continues to advance, as seen for grains 4 and 5 in Figure 14.

3.4. Mechanism of Directional Heat Treatment in Pure Copper Wires

The initial grain boundary structure and crystallographic texture dictate the final microstructure after the directional heat treatment of cold-drawn pure copper wires. A strong initial texture leads to a pronounced pinning effect, selectively enabling only a few grains to undergo rapid growth. Under optimized process conditions, this can result in columnar grains. Consequently, the 89% deformed pure copper wire, with its strong <100> texture, is capable of forming a columnar grain structure upon directional heat treatment.

Under the cooling effect of the alloy melt, the temperature gradient at the front end of the hot zone along the drawing direction is large. During the directional heat treatment of pure copper wires, the growth of most grains at the front end of the hot zone is suppressed. A few <112> oriented grains with a growth advantage continuously consume the fine grains ahead along the heat flow direction, eventually forming columnar grains.

If the heating temperature is held constant with a relatively slow drawing rate, the prolonged heating time allows even the slower grain boundaries to migrate, despite the initial advantage of the <112> oriented grains, ultimately leading to an equiaxed structure. Conversely, an excessively fast drawing rate provides insufficient time for dominant boundaries to develop columnar grains, even if they possess a mobility advantage. Therefore, columnar grain formation requires an optimal match between the drawing rate and the grain boundary migration rate.

During the growth of columnar grains, a variety of boundary structures exist between the hot-zone front and the fine grains ahead. General HAGBs, possessing high energy and mobility, allow the boundary to propagate forward, forming new interfaces. Conversely, low-energy boundaries such as twins or LAGBs migrate with difficulty, exerting a pinning effect that hinders columnar grain growth.

If these low-energy interfaces are short, the hindrance effect is small and insufficient to stop the growth of the columnar crystal, the migrating interface will bypass the grains with low-energy interfaces, turning them into “island grains” inside the columnar grain; if these low-energy interfaces are longer, the hindrance effect is greater, causing part of the migrating interface to stop moving forward while another part can continue migrating; if these low-energy interfaces are very long, the migrating interface will be blocked and the columnar crystal will stop growing.

4. Conclusions

The following conclusions can be drawn:

- The 89% deformed pure copper wire exhibits a stronger and more concentrated <100> texture along the drawing direction than the 87% deformed wire. The increased stored energy induced by greater deformation facilitates enhanced grain rotation and alignment, which in turn leads to a stronger <100> fiber texture.

- Grains with a <112> orientation possess a distinct growth advantage, enabling them to evolve into columnar grains during directional heat treatment. The competitive growth of <112>-oriented grains is driven by their high-mobility boundaries with the <100>-textured matrix under the applied temperature gradient, enabling rapid consumption of surrounding equiaxed grains.

- The columnar grain boundaries in oriented pure copper wires are low-energy Σ 3 and Σ 9 grain boundaries. The preferential retention of Σ 3 and Σ 9 boundaries in the final columnar structure results from their low energy nature, which minimizes system energy during abnormal grain growth.

- Large columnar grains in pure copper wires contain “island grains.” Before directional heat treatment, there are small grains with low-angle grain boundaries or twin boundaries in pure copper wires. Since low-angle grain boundaries and twin boundaries are relatively stable and difficult to migrate, these small grains are bypassed by the directional migration interface, forming isolated “island grains” within the columnar grains. Due to their negligible mobility, low-energy boundaries pin small grains, causing the migration front to detour and selectively envelop them as “island grains” within the growing columnar crystal.

- During the directional migration of grain boundaries, large-angle grain boundaries at the leading edge of the interface, which generally migrate faster, promote the continuous growth of columnar crystals, while longer low-angle grain boundaries or twin boundaries at the leading edge hinder the interface from continuing to migrate forward. The migration rate of grain boundaries is governed by their energy: high-energy boundaries enable continuous columnar growth through rapid migration, whereas extensive low-energy boundaries act as potent pinning sites that impede microstructural development.

Author Contributions

Conceptualization, G.C.; Methodology, H.X.; Validation, X.D.; Investigation, X.D.; Resources, H.X., G.Z. and G.C.; Data curation, X.D. and H.R.; Writing—original draft, H.X. and H.R.; Writing—review & editing, G.Z.; Supervision, H.X., G.Z. and G.C.; Project administration, H.X.; Funding acquisition, H.X. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the National Natural Science Foundation of China (Grant No. 52201125), the Natural Science Foundation of Jiangsu Province (Grant No. BK20220961), and the Fundamental Research Funds for the Central Universities (Grant No. 30925010212).

Data Availability Statement

All relevant data are presented within this paper.

Acknowledgments

The author is sincerely grateful to all co-authors for their invaluable theoretical contributions and steadfast support throughout this work.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Alaraji, N.; Altamimi, M.H.; Alshammari, T.W. The role of cold drawing on electrical and mechanical properties of copper cables. Int. J. Adv. Technol. Eng. Explor. 2015, 2, 122. [Google Scholar]

- Zhang, H.; Xie, X.J.; Wang, D.Z. Fabrication of pure copper rods containing continuous columnar crystals by continuous unidirectional solidification technology. J. Univ. Sci. Technol. B 2004, 11, 240–243. [Google Scholar]

- Ge, T.S. Fundamentals of Solid Internal Friction Theory—Grain Boundary Relaxation and Grain Boundary Structure; Science Press: Beijing, China, 2000. [Google Scholar]

- Tian, S.; Li, X.C.; Liu, Z.T. Metal Physical Properties; Aviation Industry Press: Beijing, China, 1994. [Google Scholar]

- Fan, X.H.; Yan, W. Research progress and application prospects of high-fidelity single-crystal metal wires. Ordnance Mater. Sci. Eng. 2000, 23, 62–65. [Google Scholar]

- Yan, C.; Hu, L.; Li, J.Y.; Li, W.L.; Xu, Y.H.; Chen, A.H. Microstructure and Mechanical Property Evolution in Cold-Drawn Copper Wire. World Nonferrous Met. 2020, 15, 177–178. [Google Scholar]

- Soda, H.; McLean, A.; Motoyasu, G. A note on casting speed of Ohno continuous casting process. Mater. Sci. Technol. 2010, 26, 1015–1016. [Google Scholar] [CrossRef]

- Rao, L.; Zhu, B.L.; Hu, Y.Q. Microstructure morphology evolution of single crystal copper rod by Ohno continuous casting in copper manufacturing system. Appl. Mech. Mater. 2012, 252, 360–363. [Google Scholar] [CrossRef]

- Gan, L.G.; Liu, F.X.; Xie, X.J. Room temperature tensile property and fracture behavior of CuNi10Fe1Mn alloy rods produced by O.C.C. process. Mater. Sci. Technol. 2013, 29, 374–377. [Google Scholar] [CrossRef]

- Guo, P.Y.; Guo, H.X.; Deng, P.J. Study on the mechanical properties of single crystal aluminum by Ohno continuous casting. Mater. Sci. Forum 2014, 809, 358–362. [Google Scholar] [CrossRef]

- Hu, W.; Wang, H.Y.; Zhao, J.X. Preparation of aluminum wire by Ohno continuous casting and its microstructure and properties. Chin. J. Nonferrous Met. 2015, 25, 1882. [Google Scholar]

- Feng, L.C.; Fan, X.G.; Qiu, L.S. Development and application of horizontal Ohno continuous casting equipment. Spec. Cast. Nonferrous Alloys 2015, 35, 737. [Google Scholar]

- Chen, J.; Yan, W.; Li, W.; Miao, J.; Fan, X.H. Texture evolution and its simulation of cold drawing copper wires produced by continuous casting. Tran. Nonferrous Met. Soc. China 2011, 21, 152–158. [Google Scholar] [CrossRef]

- Chen, J.; Yan, W.; Wang, Y.X.; Fan, X.H. Microstructure evolution of single crystal copper wires in cold drawing. Sci. China Ser. E Technol. Sci. 2007, 50, 736–748. [Google Scholar] [CrossRef]

- Wang, H.Y.; Xiao, R.L.; Zhao, J.X. Microstructure and mechanical properties of columnar-grained copper produced by the Ohno continuous casting technique. Mater. Sci. Eng. 2015, 639, 122–130. [Google Scholar] [CrossRef]

- Mao, X.Q.; Xiao, Q.L.; Ou, M.G.; Liang, Y.; Long, W. Effect of annealing process on microstructure and properties of pure copper wire T2. Heat Treat. Met. 2020, 45, 7–11. [Google Scholar]

- Fan, X.Y.; Hou, J.P.; Wang, S.; Liu, Z.Q.; Gong, B.S.; Zhou, X.H.; Duan, Q.Q.; Zhang, Z.J.; Zhang, Z.F. Achieving extraordinary strength and conductivity in copper wire by constructing highly consistent hard texture and ultra-high aspect ratio. J. Mater. Sci. Technol. 2025, 220, 14–22. [Google Scholar] [CrossRef]

- Jia, H.W. Effect of Heat Treatment on the Microstructure and Properties of Copper-Based Micro-Fine Wires with Different Deformation Behaviors; Henan Polytechnic University: Jiaozuo, China, 2024. [Google Scholar]

- Mao, Q.Z.; Zhang, Y.S.; Guo, Y.Z.; Zhao, Y.H. Enhanced electrical conductivity and mechanical properties in thermally stable fine-grained copper wire. Commun. Mater. 2021, 2, 46. [Google Scholar] [CrossRef]

- Randle, V. The coincidence site lattice and the ‘sigma enigma’. Mater. Charact. 2001, 47, 411–416. [Google Scholar] [CrossRef]

- Randle, V. Twinning-related grain boundary engineering. Acta Mater. 2004, 52, 4067–4081. [Google Scholar] [CrossRef]

- Humphreys, J.F.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier Science Ltd.: Oxford, UK, 2004. [Google Scholar]

- Zhou, Z.Q. Influence of grain boundary structure on grain boundary migration. Ordnance Mater. Sci. Eng. 1998, 21, 3–8. [Google Scholar]

- Zasadzińska, M.; Knych, T.; Strzępek, P.; Jurkiewicz, B.; Franczak, K. Analysis of the strengthening and recrystallization of electrolytic copper (Cu-ETP) and oxygen free copper (Cu-OF). Arch. Civ. Mech. Eng. 2019, 19, 186–193. [Google Scholar] [CrossRef]

- Kim, N.B. Atomic jump model for migration of curved grain boundary. Scr. Mater. 1997, 8, 1111–1116. [Google Scholar] [CrossRef]

- Straumal, B.B.; Gust, W.; Dardinier, L. Abnormal grain growth in A1 of different purity. Mater. Des. 1997, 18, 293–295. [Google Scholar] [CrossRef]

- Rios, R.P. Abnormal grain growth in materials containing particles. Acta Mater. 1994, 42, 839. [Google Scholar] [CrossRef]

- Rios, R.P. Abnormal grain growth development from uniform grain size distribution in the presence of stable particales. Scr. Mater. 1998, 39, 1725–1730. [Google Scholar] [CrossRef]

- Rajmohan, N.; Szpunar, A.J. An analytical method for characterizing grain boundaries around growing Goss grains during secondary recrystallization. Scr. Mater. 2001, 44, 2387–2392. [Google Scholar] [CrossRef]

- Hayakawa, Y.; Szpunar, A.J. A new model of Goss texture development during secondary recrystallization of electrical steel. Acta Mater. 1997, 45, 4713–4720. [Google Scholar] [CrossRef]

- Yang, C.; Baker, I. Effect of solute on microstructural evolution during directional recrystallization. J. Alloys Compd. 2019, 815, 152358. [Google Scholar] [CrossRef]

- Yang, C.; Baker, I. Effect of soluble particles on microstructural evolution during directional recrystallization. Acta Mater. 2020, 188, 288–301. [Google Scholar] [CrossRef]

- Yang, C.; Baker, I. Breakdown of growth front at elevated drawing velocity during directional recrystallization. J. Philos. Mag. Lett. 2019, 99, 167–172. [Google Scholar] [CrossRef]

- Yang, C.; Baker, I. Elevated temperature directional recrystallization of high-purity nickel. J. Philos. Mag. 2019, 99, 1057–1078. [Google Scholar] [CrossRef]

- Ukai, S.; Taya, K.; Nakamura, K.; Aghamiri, M.S.; Oono, N.; Hayashi, S.; Okuda, T. Directional recrystallization by zone annealing in a Ni-based ODS superalloy. J. Alloys Compd. 2018, 744, 204–210. [Google Scholar] [CrossRef]

- Sugino, Y.; Ukai, S.; Hayashi, S.; Tang, Q.X.; Leng, B. Directional recrystallization of ODS alloys by means of zone annealing. J. Nucl. Mater. 2011, 417, 171–175. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Liu, Y.H.; Song, K.X.; Li, S.L.; Feng, C.L.; Zhu, Q.Q.; Peng, X.W.; Yang, S.D.; Li, X.; Zhang, P.F. Mechanisms for high strength and ultra-high electrical conductivity of Cu-3.5wt.%Ag alloy prepared by thermomechanical treatment. Mater. Today Commun. 2022, 33, 104819. [Google Scholar] [CrossRef]

- Zhu, T.; Lu, X.; Yang, S. Effect of annealing on grain boundary characteristics distribution and conductivity of copper wire. Heat Treat. Met. 2021, 46, 85–90. [Google Scholar]

- Liu, R.X.; Mao, X.Q.; Ou, G.M.; Liang, Y.; Xiao, Q.L. Effect of Cold Drawing Deformation on the Microstructure and Properties of Pure Copper. J. Nonferrous Met. Sci. Eng. 2022, 13, 67–75. [Google Scholar]

- Lei, Y.; Li, Y.S.; Jiang, Y.B.; Zhao, F.; Liu, X.H.; Xie, J.X. Effects of Annealing on the Microstructure and Mechanical Properties of Brass-Clad Pure Copper Strands. Chin. J. Nonferrous Met. 2023, 33, 702–714. [Google Scholar]

- Banganayi, C.; Nyembwe, K.; Mageza, K. Annealer curve characteristics of electrolytically refined tough pitch copper (Cu-ETP) and oxygen free up-cast copper (Cu-OF) for electrical cable wires. Results Mater. 2020, 8, 100146. [Google Scholar] [CrossRef]

- Cao, J.; Wu, X.F.; Su, C.H.; Jia, H.W.; Sun, Y.Z. Processing and Properties of Single-Crystal Copper Wire. Micromachines 2023, 14, 2080. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Dong, L.M.; Cai, L.; Wang, L.F.; Xie, Z.H.; Fang, F. Effect of cold drawing strain on the microstructure, mechanical properties and electrical conductivity of low-oxygen copper wires. Mater. Sci. Eng. A 2021, 818, 141348. [Google Scholar] [CrossRef]

- Li, J.; Baker, I. An EBSP study of directionally recrystallized cold-rolled nickel. Mater. Sci. Eng. 2005, 392, 8. [Google Scholar] [CrossRef]

- Kang, X.; Li, Z.L.; Cen, S.D.; Bao, X.R.; Zhang, J.F.; Ding, G. Effect of Cold Rolling and Heat Treatment on the Texture and Hardness of a Spray-Deposited Al-Cu-Mg Alloy. Heat Treat. Met. 2025, 50, 99–108. [Google Scholar]

- Zhang, Z.W. Study on Oriented Recrystallization and Its Kinetics. Ph.D. Thesis, Nanjing University of Science and Technology, Nanjing, China, 2008. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).