Abstract

Perforated cylindrical shaped metal plates are used with high efficiency in the manufacture of deflectors, components of cooling systems, wind tunnels, climatic chambers, filters, and cylindrical implants. This is particularly important for lightweight cylindrical structures, where even minor changes in stiffness can affect structural strength. One of the most important parameters determining the mechanical behavior of such structures is the effective elastic modulus of the perforated element which characterizes its resistance to deformation. The research involves plates made of stainless steel 304 alloy, where perforations were created using the laser-cutting method. The cylindrical shape of the samples with height 50 mm, thickness 1 mm, and diameter 48 mm of each specimen was obtained using metal rolling and welding techniques. To determine the effective elastic modulus, a non-destructive material property evaluation method was applied by solving an inverse problem. In this research, resonance frequencies were determined using a laser vibrometer and a full factorial experimental plan was developed. Physical samples were digitized into 3D models using 3D scanning technology. To evaluate the accuracy of the applied finite element numerical model, its convergence analysis was performed. Numerical results were approximated using the least-squares method, while the effective elastic modulus was calculated by formulating and minimizing the error functional between experimental and numerical eigenfrequencies. The results indicate that increasing the relative perforation area from 0% to 50.24% leads to a decrease in the effective elastic modulus from 184.76 GPa to 50.69 GPa, confirming that increasing the perforation area in a stainless steel 304 cylinder reduces its elastic properties. The observed reduction in resonance frequencies and elastic properties is primarily due to the stiffness decrease caused by the higher perforation volume.

1. Introduction

Perforated stainless steel is widely used for industrial and medical purposes. Key areas of use include filtration, separation, drying, as well as their utilization as components in various technical devices. In medicine, perforated stainless steel is used, for example, for bone regeneration [1]. The mechanical properties of the material, such as the effective elastic modulus, significantly influence the durability of implants and their adaptation to the applied load [2,3,4]. The presence of perforations alters the material’s structure, reduces its load-bearing capacity, and affects the stress distribution within the material [2]. To ensure an effective and biomechanically compatible implant design, it is crucial to understand the dependence of the effective elastic modulus on the relative perforation area in cylindrical structures. Measurements on perforated structures allow for the evaluation of their mechanical properties for specific applications, such as the manufacture of medical implants [3]. Recent work on thin, porous layers shows that standardized physical and mechanical assessment combining tensile response with light-permeability and breathing-resistance tests (EN 149 [5]) is decisive for discriminating performance-critical behavior in architected sheets [6]. One of the most significant challenges in implantology is the discrepancy between the elastic modulus of the implant and that of natural bone, which can lead to stress shielding. This phenomenon promotes bone resorption and may result in implant loosening [4,7,8,9,10]. Perforated materials are used in implants to reduce the weight of structures, ensure the circulation of bodily fluids, and promote tissue integration. Due to their high biocompatibility, they help to improve the healing process [7,11,12]. In medicine, perforated cylindrical elements are used as implants for the fixation and support of bone structures.

The use of cylindrical thin-walled structures reduces the implant’s mass, thereby decreasing the load on surrounding tissues. The perforated structure facilitates customization to the patient, as the implant features an adjustable height. The open architecture of the titanium mesh promotes bone ingrowth and optimizes osseointegration. Rings at the ends of the mesh ensure correct spinal alignment after rehabilitation [13]. In previous studies on flat perforated specimens, the influence of perforation on their mechanical properties and load-bearing capacity was analyzed [2]. The impact of geometric parameters and mechanical properties of perforated materials on their load-bearing capacity was investigated, with particular attention paid to stress distribution within the material, which significantly affects its strength and durability [2,14]. The relative perforation area is an important variable influencing the elastic response of cylindrical shells in this investigation since geometric configuration can independently regulate effective stiffness [15]. Numerical analyses indicate that material curvature and plastic properties influence stress, while mechanical testing of porous titanium alloys reveals structural changes under load [16]. Methodology with numerical modeling and inverse analysis, was used to determine the elastic modulus of electrospun nanofibrous mats by correlating their vibrational response with finite element simulations [15,17]. Studies on flat specimens have revealed that the elastic modulus decreases with an increasing perforation area; however, there is currently a lack of data to predict changes in the effective elastic modulus in perforated cylindrical implants [2,18].

This research analyzes the dependence of the effective elastic modulus on the relative perforation area in perforated, cylindrical stainless-steel specimens. The determination of their frequency characteristics and the visualization of the corresponding mode shapes were performed using a non-contact “Polytec PSV 500 3D” (Polytec GmbH, Waldbronn, Germany) laser vibrometer. The research was conducted at the Institute of High-Performance Materials and Structures of Riga Technical University. Finite element analysis was subsequently used to determine the effective elastic modulus of the stainless-steel material for these specimens [18,19]. Numerical analysis was previously developed for the determination of the elastic properties of composite materials [20] and was adopted for perforated steel cylinders. The manufacturing of cylindrical perforated implants enables the rehabilitation of tubular bone injuries. Although cylindrical implants are typically made from titanium, stainless steel is still used for temporary structures [21,22,23,24,25]. Due to its comparable properties and wide availability, stainless steel is also an economically advantageous alternative [26,27]. Stainless steel 304 was selected due to its established biocompatibility, corrosion resistance, and mechanical stability, which make it suitable for biomedical applications. In addition, stainless steel can serve as an alternative material in cases of allergy or intolerance to titanium alloys, offering a clinically viable option for implant design. No studies have been conducted to analyze the dependence of the effective elastic modulus on the relative perforation area for perforated stainless-steel cylinders, this work is aimed at uncovering this behavior.

2. Materials and Methods

2.1. Stainless Steel 304 Plates Perforation

Rectangular 304 stainless steel specimens were prepared for this study. Five plates were manufactured with a width of 150 mm, a length of 50 mm, and a thickness of 1 mm. The stainless steel used in this study was AISI 304, an austenitic stainless steel with a typical composition of approximately 18% Cr, 8% Ni, and the balance Fe, along with minor amounts of Mn, Si, C, and other trace elements as specified by the ASTM A240 standard [28]. Perforations in the specimens are created using the laser cutting method to perforate the 304 stainless steel plates [29,30]. This technology is particularly suitable for creating high-precision perforations, ensuring narrow kerf widths (typically 0.1–1 mm), which enables the production of diverse shapes with sharp and smooth edges without the need for additional processing [2,30]. The sample numbers are listed in Table 1; their assignment was based on ascending values of the relative perforation area. Perforation type was circular in a square arrangement. Circular perforations were chosen because they provide uniform stress distribution around the hole edges, minimize stress concentration compared to non-circular shapes, and are the most commonly used geometry in engineering and biomedical applications. This geometry also simplifies both manufacturing and numerical modeling, ensuring consistent comparison between experimental and computational results. Perforation area is calculated using Equation (1). In Equation (1) d is hole diameter and s is the pitch between holes [4].

Table 1.

Perforation parameters for the stainless steel 304 plates.

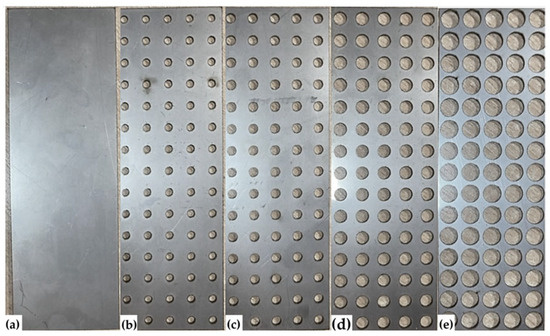

The laser cutting of the research specimens was performed in the laboratory facilities of the Rezekne Academy (RTU, LV), where a laser-cutting machine is available. After laser cutting, five stainless steel specimens were produced from a 1 mm thick metal sheet, with a length of 150 mm and a width of 50 mm, each with a different relative perforation area. Figure 1 illustrates the specimens created for the research, which have been assigned serial numbers.

Figure 1.

Perforated stainless steel samples with a width of 150 mm, a length of 50 mm, and a thickness of 1 mm, prepared using the laser-cutting method. (a) Aperf = 0%; (b) Aperf = 7.07%; (c) Aperf = 12.56%; (d) Aperf = 23.75%; and (e) Aperf = 50.24%.

The fixation of the manufactured deformed plate specimens was performed by laser welding; the result is illustrated in Figure 2.

Figure 2.

Laser-welded perforated stainless-steel sample.

The welding of the specimens was prepared at SIDRABE AS (Riga, Latvia), which possesses the necessary laser welding equipment. Argon was used as shielding gas during the welding process. The laser welding process was carried out using a direct current of 40 A per millimeter of material thickness, employing direct current electrode negative (DCEN) polarity, in which the torch was connected to the negative terminal. High-purity argon was used as the shielding gas at a flow rate of 8 l/min to protect the weld pool from oxidation. A tungsten electrode with a diameter of 1.6 mm, preferably containing 2% lanthanum, was used.

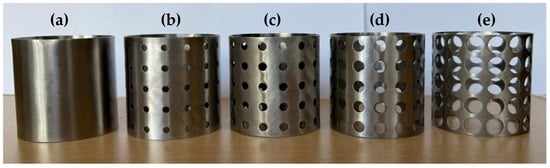

The diameter of each specimen was 48 mm. Figure 3 illustrates the finished cylindrical specimens.

Figure 3.

Cylindrical specimens with a height of 50 mm, a thickness of 1 mm, and a diameter of 48 mm, produced by metal rolling and laser-welding methods. (a) Aperf = 0%; (b) Aperf = 7.07%; (c) Aperf = 12.56%; (d) Aperf = 23.75%; and (e) Aperf = 50.24%.

2.2. Three-Dimensional Surface Scanning of the Perforated Stainless Steel 304 Cylindrical Specimen

To determine the effective elastic modulus of the specimens, a numerical method will be used, involving the analysis of properties from a 3D (three-dimensional) model. A 3D method was used to ensure the precise conformity of the specimen shape. After scanning the object, a model is obtained that is suitable for use in various computer programs. The scanning of the specimens was performed with a CRS07R model 3D scanner from the company “Creality” (Shenzhen, China). The “Creality CR-Scan Raptor” is a scanner that combines infrared and blue light technologies, providing an accuracy of up to 0.02 mm in the blue light mode and in the infrared mode. A working accuracy of 0.1 mm was adopted, as higher accuracy was not required due to slight surface deformations of the specimens. The final solid models for numerical analysis were obtained by merging the scanned geometry with the CAD model to ensure compatibility with ANSYS Mechanical APDL version 2024 R2 (2024.2.0 <20240501) and maintain geometric consistency. The scanning speed reaches up to 60 frames per second in the blue light mode and up to 20 frames per second in the infrared mode. The scanner supports the scanning of objects in a wide size range—from 5 × 5 × 5 mm to 2000 × 2000 × 2000 mm [31].

To ensure accurate scanning, a base equipped with reference markers was first prepared to enable accurate spatial orientation of the scanner. The specimen was then placed on this base, and the specimen was scanned with blue light from all sides.

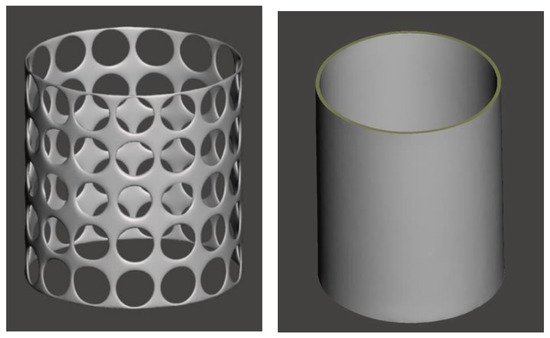

As a result, images of the specimen’s surface from all sides were obtained, which were combined in the “Creality Scan” software (V3.3.46) to create models of the studied specimens with an accuracy of up to 0.7 mm. Figure 4 shows the obtained 3D model of specimen Nr. 5 and Nr. 1.

Figure 4.

Three-dimensional model of sample Nr. 5 and Nr. 3 obtained using 3D scanning.

2.3. Determination of the Dynamic Properties of Perforated Stainless Steel 304 Cylindrical Specimens Using Laser Vibrometry

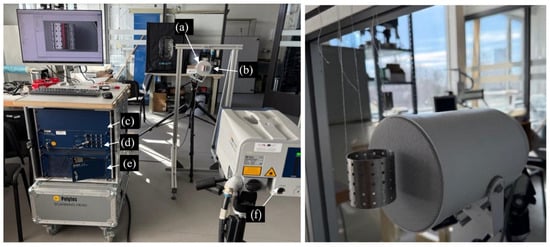

The determination of the resonance frequencies for the studied perforated stainless steel cylindrical specimens with a relative perforation area ranging from 0% to 50.24% was conducted in several steps. The determination of the specimens’ frequency characteristics, the determination of the corresponding characteristics, and the visualization of the corresponding mode shapes were performed using a non-contact laser vibrometer, the “Polytec PSV 500 3D”. Figure 5 shows the setup used to determine the resonance frequencies of the specimens.

Figure 5.

The “Polytec PSV 500 3D” setup is used for determining the frequency characteristics of the specimens. (a) Loudspeaker; (b) specimen; (c) controller; (d) distribution box; (e) PC; and (f) scanning head.

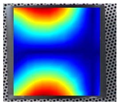

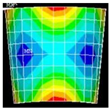

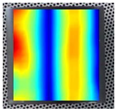

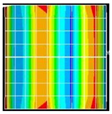

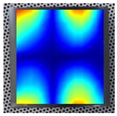

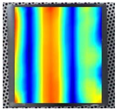

Initially, the specimen is suspended in a free state (free–free boundary conditions) to ensure its free oscillation. This arrangement helps to minimize boundary effects that could influence the vibration behavior. A loudspeaker, positioned on the back of the specimen, is used to excite vibrations by generating acoustic waves over a broad frequency range. The research employed an excitation frequency range from 0 to 15 kHz. A laser beam is focused onto the specimen’s surface, each scan of the specimen surface was performed at 169 points, which were evenly distributed across its length and width. During vibration, the motion of the specimen induces a frequency shift in the reflected laser beam, which is directly related to the surface velocity. The laser vibrometer detects this frequency shift and converts it into data representing the oscillation velocity and amplitude. The acquired data are analyzed to identify the specimen’s resonance frequencies [18,19,29]. Figure 6 shows an example of the 4th resonance frequency and the corresponding mode shape for specimen Nr. 3.

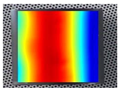

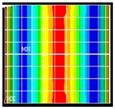

Figure 6.

An example of the obtained 4th resonance frequency and the corresponding mode shape for the studied specimen Nr. 3.

Subsequently, the resonance frequencies and their corresponding mode shapes are used to calculate the material’s elastic properties [18,19,29]. The excitation of the specimens is performed using a non-contact method, which does not influence the specimen’s vibrations nor alter its elastic properties.

2.4. Development of a Full Factorial Experimental Plan

A full factorial experimental design involves conducting experiments with every possible combination of factor levels. Each factor is assigned levels, for example, minimum and maximum, or a larger number of levels [29]. The number of experiments is calculated according to Equation (2).

N = Lk

N is several experiments, and Lk is several factor levels. First, the limits of the factors were set, next, the factor levels that ensure the optimal value of the response variable were determined. Such experiments are applied to solve optimization problems. Next, a mathematical model is developed to describe the dependence of the response variable on the factors. This model also allows predictions beyond the performed experiments. The development of a full factorial design follows several principles. The factors under research are selected, and levels are assigned to each of them [32]. A matrix is then constructed that includes all possible combinations of factor levels.

Each experiment is carried out according to the design, with results recorded for every combination of factor levels. After conducting experiments, a mathematical model is constructed, typically in the form of square regression. Once the above steps are completed, the obtained data is analyzed.

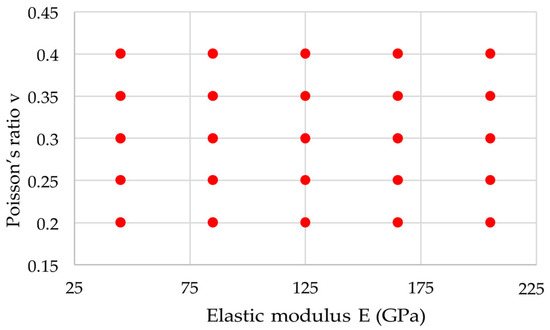

In this research, a full factorial experimental design was developed based on two independent elastic constants characterizing the material—the elastic modulus E and Poisson’s ratio ν [18,19]. The required number of experiments was calculated according to relation 2. Two factors were considered—the elastic modulus and Poisson’s ratio—with five levels assigned to each. As a result, 25 numerical experiments were performed for each sample model, and a total of 125 experiments were carried out for all samples. For numerical experiments, the following ranges of elastic constants were adopted as 45 GPa ≤ E ≤ 205 GPa and 0.2 ≤ ν ≤ 0.4 [18,19].

In the research, an isotropic material model was adopted, which is characterized by three elastic constants: Young’s modulus E, shear modulus G, and Poisson’s ratio ν. These three constants are interrelated by Equation (3).

G is the shear modulus, E is Young’s modulus, and ν is Poisson’s ratio. According to the given relationship, two of the constants are independent, while the third, dependent variable can be calculated. For isotropic materials, Poisson’s ratio has strict and well-defined limits. When designing a uniform experimental plan based on E and G, the resulting ν could fall outside the permissible range of values for an isotropic model. For this reason, the experimental plan was designed based on E and ν. Figure 7 illustrates the experimental design used for the finite element method analysis.

Figure 7.

Explanation of the experimental plan.

The selection of five factor levels ensures a more detailed analysis of the response surface, allowing for a more precise determination of potential optimal property combinations for each sample.

2.5. Numerical Experiment on Elastic Properties Determination of Perforated Stainless Steel 304 Cylindrical Specimens

To determine the numerical model’s resonance frequencies and corresponding resonant mode shapes, a modal analysis using the Lanczos algorithm is employed. The Lanczos algorithm is a computational method that utilizes only matrix multiplication with long, narrow matrices [33]. In the experiment, the geometric parameters of the outer surface shape and dimensions-obtained from 3D-scanned models were used to create the numerical models. The thickness of the specimen material (1 mm) was assigned to the outer surface geometry of the models obtained by the scanner, so that the numerical model would correspond to the physical specimen. The density of these models corresponds not to the theoretical density of stainless steel, but to the equivalent density of each physical specimen. The equivalent density ρ of each specimen was calculated by weighing each specimen and determining its geometric dimensions, using Equation (4).

In Equation (4), ρ is the equivalent density of the specimen, m is the mass of the specimen, V is the volume of the specimen, l is the length of the specimen, w is the width of the specimen, and h is the thickness of the specimen material. The specimen dimensions, masses, and calculated equivalent densities are summarized in Table 2.

Table 2.

Physical, geometric, experimental, and calculated data of perforated stainless-steel 304 samples.

When creating the numerical models, the scanned surfaces of the specimens without perforations were used, as this allows for the determination of the specimen’s resonance frequencies. In the case of modeling perforated specimens, the resulting values would characterize the elastic properties of stainless steel, which are already known.

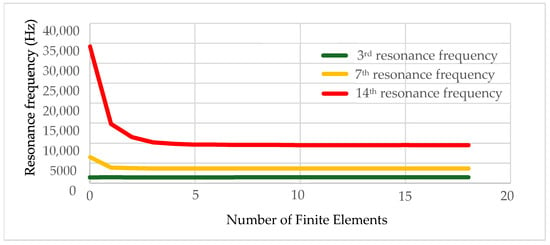

Based on the results shown in Table 3, an 8 × 24 mesh was selected for the model of specimen 1, as increasing the number of elements from 7 × 21 to 8 × 24 elements did not significantly alter the calculated frequencies. The resonance frequency values changed within a range of 0.5%. This indicates a stable model and that the resonance frequencies of the finite element models were determined with 0.5% accuracy.

Table 3.

Finite element model convergence checks for the model of specimen Nr. 1.

The resonance frequencies of the three-dimensional models were calculated using the finite element method. The finite element analysis was performed in ANSYS Mechanical APDL. The three-dimensional geometries of the scanned specimens were imported in IGES format and verified for dimensional accuracy using keypoint distance queries to confirm the correct scale in meters. Prior to meshing, the geometry was simplified by removing unnecessary solid regions, leaving only the thin shell surface representing the cylindrical wall of each specimen. The SHELL181 element type was selected as it provides reliable performance for thin-walled, curved structures under modal analysis conditions. Material properties, namely the elastic modulus, Poisson’s ratio, and effective density were defined for each simulation according to the experimental plan, using measured specimen mass and geometric parameters to calculate equivalent density. The shell thickness was assigned as 1 mm, corresponding to the physical specimen. Mesh density was determined based on the convergence analysis described earlier; a uniform mapped mesh was generated to achieve stable resonance frequency results. The modal analysis was configured using the Block Lanczos solver with 30 natural modes requested to ensure that the frequency range covered all experimentally observed resonances. After solving, the obtained eigenfrequencies and mode shapes were compared with experimental data to verify numerical accuracy. The APDL environment was chosen over Workbench because it enables direct command-level control, parameter scripting, and efficient batch processing of multiple models, which is essential for full factorial simulation runs and subsequent parameter identification. When a case is reached where the sequences of resonance frequencies from the physical experiments and the numerical calculations coincide, it can be concluded that the properties corresponding to the elastic properties of the physical specimens have been found. The solution to the problem involved analyzing the coincidence of the first fifteen resonance frequencies. The correct identification of the resonance sequence was confirmed by comparing the mode shapes from both the experiments and the numerical calculations. This comparison allowed for a double-check and ensured the correct identification of the elastic properties. Furthermore, solving the inverse problem in conjunction with the numerical method provides the opportunity to conduct research in a non-invasive environment, preserving the specimens for future experiments, which cannot be said for mechanical tests.

The application of the inverse problem facilitated the achievement of the stated research objective, thereby helping to reveal the effective elastic properties of the studied specimens.

2.6. Approximation of Experimental Data Using the Least-Squares Method

Approximation allows for obtaining a general description of a function that better fits noisy or incomplete data. Approximation methods are applied in physics and engineering to characterize complex processes and experimentally obtained data that cannot be described by simple functions. The approximation of the numerically obtained resonance frequencies was carried out using the least-squares method implemented in Python version 3.12.7 (Visual Studio Code version 1.105.1).

The least-squares method is one of the most popular and widely used approaches for performing approximation. Its fundamental principle is to find a function that minimizes the error between the initial data and the approximated function [34]. More precisely, the least squares method optimizes the function to reduce the squared deviations between the observed data and the approximated value shown in Equation (5).

S = ∑ni=1(yi − g(xi))2

S is the error function that is minimized, n is several specific values, yi is an experimentally determined values and g(xi) is approximate value.

The least-squares method was used to formulate a regression equation expressed as a second-order polynomial. Approximation with a polynomial is employed to mathematically describe the relationship between variables using a polynomial function that provides the best possible fit to the experimental data. A second-order polynomial is one of the most used regression models, as it can represent both linear and nonlinear relationships between variables [35]. In its general form, a second-order polynomial is expressed as follows, shown in Equation (6).

y = a0 + a1x + a2x2,

y is the dependent variable (result), x is the independent variable (input parameters), and a0, a1, and a2 are polynomial coefficients. Such a regression equation is applied in situations where the relationship between input and output data is not linear and more accurate data modeling is required than in the case of linear regression. The least-squares method is used to determine the second-order polynomial so that the function fits the experimental data as closely as possible. The fundamental principle of this method is to minimize the error between the experimentally obtained values and the values of the approximation function. Mathematically, this is described by Equation (7).

where yk is the target value, xk is the independent variable value, m is the number of experimental data points, and S is the function that calculates the total square error.

The formulation of the approximating polynomial involves several steps. First, experimental data to be approximated are obtained. Subsequently, a system of equations is established, corresponding to a solution by the least-squares method. This system of equations is solved, resulting in the calculation of the regression equation coefficients [35]. As a result, a regression equation expressed as a second-order polynomial with appropriately determined coefficients is obtained.

After calculating the coefficients of the regression equation, it is possible to construct a response surface. A response surface is a mathematical modeling method used to visually analyze how different factors influence the outcome [36]. Numerical experiments were conducted based on experimental design. Following the application of the finite element method, the numerically obtained results were approximated using the least-squares method. In the numerical experiment, sequences of resonance frequencies were obtained for various combinations of elastic parameters. For each combination, the sequence of the first 15 resonance frequencies was determined, the agreement of which was confirmed by visualizing the mode shapes and comparing them with the resonance sequences obtained from physical experiments. A second-order regression equation, shown in Equation (8), was applied to approximate the results of the numerical experiment [18,19].

fi = b0i + b1i × E + b2i × v + b12i × E × v + b11i × E2 + b22i × v2

fi is the i-th order resonance frequency, E is the modulus of elasticity, v is Poisson’s ratio, and b0i, b1i, b2, b12i, b11i, and b22i are the coefficients of the second-order regression function.

2.7. Formulation and Optimization of the Inverse Problem for Elastic Property Identification

In the research, the inverse problem was applied to determine the effective elastic properties of the specimens. During the physical experiments, the resonance frequencies of the specimens were determined, and the corresponding mode shapes were visualized. However, the initial data regarding the elastic properties of the specimens were not known from the experiment. The inverse problem was formulated to identify the effective elastic properties by minimizing the discrepancy between experimentally measured and numerically predicted resonance frequencies.

Following the approximation of numerical results using the least-squares method, the construction of a second-order regression equation, and the generation of response surfaces, the error functional was formulated. The error functional (also referred to as an error function or loss function) is a mathematical expression that quantifies the discrepancy between model predicted and experimentally measured values [37,38,39]. Mathematically it represents the relationship between the error and the unknown parameters with the goal of minimizing this discrepancy to obtain the most accurate solution. The construction of the error functional involves several sequential steps. First, a target function describing the relationship between input and output parameters is defined. Next, the error functional is formulated to evaluate how closely the model corresponds to the experimental data. Once the functional is defined, minimization is performed to identify the optimal parameter values [37,40,41]. In the case of elastic property identification, the error functional describing the differences between experimental and numerical resonance frequencies can be expressed as Equation (9) [18,19]:

are the experimentally determined resonance frequencies, are the regression-based functions obtained from the numerical experiment using the response surface method, and I is the number of resonance frequencies used in the identification procedure. After formulation of the error functional, minimization was carried out. Error functional minimization is a mathematical procedure aimed at finding optimal model parameters by reducing the differences between experimentally measured values and model predictions. This approach is widely applied in numerical modeling and engineering because it ensures improved model consistency with real observations [37,42]. In this study, the minimization procedure was implemented in Python within the Visual Studio Code environment. The research problem required a method capable of locating the global minimum rather than a local one since the optimization landscape was nonlinear and included multiple local extrema.

For this research the Differential Evolution algorithm was chosen. This global optimization method prevents stagnation at local minima (as may occur with, for example, the Basinhopping algorithm) and is particularly effective for nonlinear optimization tasks with multiple local extrema. Since the identification problem involved two variables (Poisson’s ratio and Elastic modulus), Differential Evolution was the most suitable approach.

Upon completion of the error functional minimization, the identification of the effective material properties of the tested specimens was performed in accordance with Equation (9). The analysis of the obtained results demonstrated that the maximum relative deviation between experimental and numerical resonance frequencies did not exceed 2% for all specimens, confirming the high accuracy of the identification procedure [18,19].

The chosen minimization strategy, based on the differential evolution algorithm, ensured improved numerical precision by reducing discrepancies between theoretical and experimental data. The Differential Evolution algorithm was effective for locating the global minimum of the error functional in a nonlinear problem setting.

3. Results

The determination of the dependence of the effective elastic modulus on the relative perforation area begins with obtaining the resonance frequency sequence and corresponding mode shapes for each physical specimen. Table 4 summarizes the results of the physical experiments and numerical experiment for specimen Nr. 1.

Table 4.

The obtained resonance frequency sequence and corresponding mode shapes for specimen Nr. 1, obtained by numerical and physical experiment.

As can be seen from Table 4, specimen Nr. 1 exhibits various characteristic mode shapes, which change depending on the vibration order. The resonance frequencies gradually increase, starting from 1116 Hz (physical experiment) and 1113 Hz (numerical experiment), up to 10,332 Hz (physical experiment) and 10,314 Hz (numerical experiment).

Prior to performing the finite element analysis, a convergence check was conducted for each model. Table 4 shows an example of the convergence check for a model with a diameter of 47.7 mm, a height of 50 mm, and a thickness of 1 mm. For all models during the check, a density of 7850 kg/m3 was assumed, corresponding to the density of the studied material. The evaluation utilized the first 15 determined resonance frequency values, analyzing the influence of mesh density within the range of 1 × 3 to 22 × 66 finite element distribution.

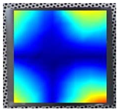

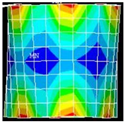

Figure 8 demonstrates the stability of the convergence result for the 3rd, 7th, and 14th order resonance frequencies of specimen Nr. 1.

Figure 8.

Stabilization of resonance frequencies for the 1st studied sample.

As can be seen from Figure 7, the resonance frequencies converge depending on the number of finite elements used. Thus, the selected mesh density for each model does not affect the accuracy of the numerical calculations, ensuring reliable modeling results. This analysis allowed for the selection of the most appropriate mesh density for each model, maintaining high computational accuracy and avoiding unnecessary consumption of computational resources. It can also be observed that higher-order resonance frequencies (such as the 14th resonance frequency) are more sensitive to mesh refinement and require a larger number of finite elements to achieve stabilization. In contrast, lower-order modes converge faster, resulting in smaller deviations and reduced numerical error even with coarser meshes. After the convergence check of the final models, the finite element method was performed, and the obtained results were approximated using a second-order regression function.

A separate second-order regression function was fitted for each resonance frequency, which allowed for detailed modeling of the dependence of these frequencies on the elastic modulus E and Poisson’s ratio. The regression coefficients were determined using the least-squares method and are listed in Table 5.

Table 5.

Coefficients of the approximation function for specimen Nr. 1.

Regression coefficients provide the ability to evaluate the influence of each parameter on the resonance frequency. The regression function coefficients b1i and b2 characterize the direct dependence on E and v, while the coefficients b12i, b11i, and b22i reflect the mutual interaction of the parameters. Based on the obtained coefficients, response surfaces were created. Surfaces visualize the variation in each resonance frequency depending on the selected material parameters. Response surfaces were used to perform approximation for the entire set of experiments, thereby ensuring that no errors were introduced during the input of the numerical experimental data.

To verify the quality of the approximation, a comparison was made between the numerical and approximated frequencies. The average and maximum relative errors, as well as the coefficients of determination, were calculated for each of the 15 resonance frequency series. The average relative error was calculated using Equation (10).

MRPE is a mean relative percentage error, N is a number of resonance frequencies used in the identification procedure, yi is a resonance frequency value obtained from the numerical experiment, and ŷi is an approximated resonance frequency value.

Using the built-in “max” function in Microsoft Excel, the maximum relative error value was determined for each frequency. After calculating the average and maximum relative error values, the coefficient of determination R2 was determined for each frequency using Equation (11).

R2 is a coefficient of determination, ŷi is a resonance frequency value obtained from the numerical experiment, is an approximated resonance frequency value, and ȳ is a mean value of the approximated frequencies.

Below is an example of the coefficient of determination calculation for the 6th resonance frequency of sample Nr. 1. To simplify the calculation, the numerator of the expression was computed first, followed by the mean value of the approximated resonance frequency for the given order frequency, and then the denominator.

Table 6 presents the average and maximum relative errors, as well as the coefficient of determination values, for all 15 frequency series of sample Nr. 1.

Table 6.

Verification of approximation quality for each resonance frequency series of sample Nr. 1.

The values of the effective elastic modulus and the effective shear modulus were determined for each sample and are summarized in Table 7. The experimentally and numerically obtained resonance frequencies and elastic property values for all samples are also presented.

Table 7.

The calculated results for the samples: effective elastic modulus and effective shear modulus.

After processing the results and determining the optimal effective elastic modulus values for each sample, it became possible to evaluate the dependence of the effective elastic modulus of the perforated cylinder on the relative perforation area.

4. Discussion

The main goal of this research is to investigate the dependence of the effective elastic modulus of a perforated stainless-steel cylinder on the relative perforation area. Microsoft Excel software was used to process the results of the dependence of the effective elastic modulus values of cylindrical specimens on the relative perforation area. The software was utilized to compile results in Table 8 from the obtained data and to create a graph of the studied dependencies (Figure 8 and Figure 9). The research determined the effective elastic modulus values of a grade 304 stainless-steel cylinder, as well as obtained the effective shear modulus values for cylinders with a relative perforation area ranging from 0% to 50.24%. The experimentally obtained data are presented in Table 8.

Table 8.

The calculated results of the specimens investigated are presented.

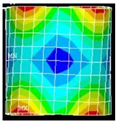

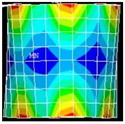

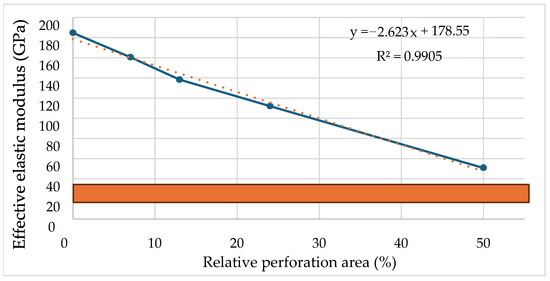

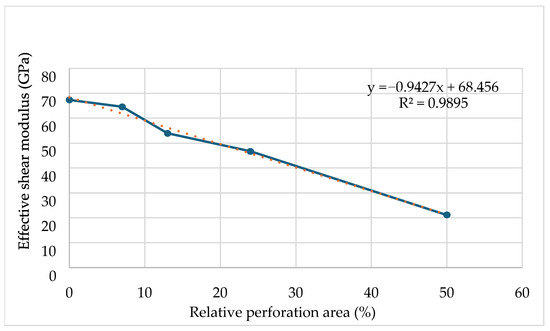

Figure 9.

Dependence of the effective elastic modulus on the relative perforation area.

The Table 8 specifies the sample number, perforation diameter, relative perforation area, and the values of the effective elastic and shear moduli. The data from the Table 8 shows that an increase in the relative perforation area from 0% to 50.24% causes a decrease in the elastic modulus from 184.76 GPa to 50.69 GPa, indicating a deterioration in the stiffness properties of the material studied. This reduction can be explained by the fact that as the relative perforation area increases, the effective cross-sectional area of the material capable of bearing the load decreases, leading to elevated stress concentrations around the perforations.

The data presented in the table also indicate a similar trend for the effective shear modulus. As the relative perforation area increases, the effective shear modulus decreases from 67.34 GPa to 21.12 GPa. This parameter is used to determine the material’s ability to resist shear deformation. The shear modulus is another important factor considered during implant manufacturing, as it indicates the mechanical strength and stability of the material used.

Based on the obtained results, it can be concluded that an increase in the relative perforation area leads to a deterioration of the elastic properties in stainless steel, while simultaneously making it mechanically closer to the properties of human bone.

Figure 9 illustrates the dependence of the effective elastic modulus on the relative perforation area. The graph demonstrates that an increase in the relative perforation area leads to a reduction in the effective elastic modulus. The elastic modulus describes a material’s ability to resist elastic deformation. For grade 304 stainless steel, the elastic modulus value without perforations typically ranges from 190 GPa to 203 GPa.

In the studied cylinder without perforations, the effective elastic modulus was 184.76 GPa. Introducing perforations with a diameter of 3 mm, resulting in a relative perforation area of 7.07%, reduced the elastic modulus to 160.47 GPa. Increasing the relative perforation area to 12.56% further decreased the effective elastic modulus to 138.25 GPa. At a relative perforation area of 23.75%, the effective elastic modulus reached 112.02 GPa. When the relative perforation area increased to 50.24%, the effective elastic modulus decreased to 50.69 GPa. The reduction of the relative perforation area from 0% to 50.24% resulted in a sharp decline in the effective elastic modulus. The numerical decrease was 134 GPa, representing a percentage difference of 73%. The graph shows that increasing the relative perforation area from 0% to 20% reduces the effective elastic modulus by 60 GPa, resulting in a relative difference of 34%. Further increasing the perforation area from 20% to 40% reduces the effective elastic modulus by approximately 45 GPa, corresponding to a relative difference of 37.5%. The increase in perforation diameter and the reduction in ligament width between holes lead to a decrease in the effective elastic modulus, as the reduced load-bearing cross-sectional area and stress concentration around the perforation edges diminish the material’s overall stiffness. This tendency agrees well with earlier research findings, which also demonstrated that increasing perforation size or density leads to a reduction in the effective stiffness of the structure [30].

Based on this analysis, it can be concluded that the effective elastic modulus decreases linearly and uniformly. The graph reveals a linear decreasing trend, described by a regression function with a very high coefficient of determination (R2 = 0.9905). This high R2 value indicates that the chosen regression curve accurately reflects the observed relationship between the effective elastic modulus and the relative perforation area. The studied dependence can be mathematically described by Equation (12).

E = −2.623 ∗ RP + 178.55

E is an effective elastic modulus and RP is a relative perforation area. This regression function allows for the prediction of elastic modulus values even beyond the experimentally obtained data points within a defined range. The function also indicates that as the perforation area increases, the effective elastic modulus decreases almost uniformly.

The elastic modulus values of human bone fall within the range of 10 GPa to 30 GPa, which is highlighted in orange in Figure 8. Based on the results obtained in this research, the closest approximation to human bone is sample Nr. 5, with an effective elastic modulus of 50.69 GPa, as its value is the lowest compared to the other samples. Despite having the smallest difference in elastic modulus, there remains a high risk of bone resorption, which could lead to implant loosening. Therefore, to achieve even greater similarity to the elastic properties of human bone, it would be necessary to investigate the effective elastic modulus values of perforated stainless-steel cylinders with a relative perforation area exceeding 50%. In the author’s opinion, it would also be useful to study the influence of the perforated cylinder’s diameter on the effective elastic modulus value, as there may be a correlation that causes this value to increase or decrease.

Within the framework of the research, the values of the effective shear modulus were also determined for each sample, as indicated in Figure 10. The shear modulus characterizes the material’s ability to resist shear deformation. Similarly to the elastic modulus, a pronounced decrease is observed for the effective shear modulus. For the sample without perforations, the obtained effective shear modulus value was 67.34 GPa, whereas for the sample with the largest relative perforation area, this value decreased to 21.12 GPa. Such a reduction in the effective shear modulus significantly impacts the material’s ability to resist shear deformation, which is important to consider when developing biomechanical implants.

Figure 10.

Dependence of the effective shear modulus on the relative perforation area.

The research results also indicate a decrease in the sequence of resonance frequencies with an increase in the relative perforation area. The first resonance frequency of sample Nr. 1 is 1116 Hz, and the highest is 10,332 Hz, while for sample Nr. 5, the first frequency is already 827 Hz and the last is 7889 Hz. This confirms that, alongside the deterioration of the material’s effective cross-section and stiffness, the resonance frequencies across the system also decrease. The presence of larger or more closely spaced perforations lowers the effective shear modulus due to the reduced number of shear load paths and the concentration of local shear strains within the thin ligaments between perforations.

The average error between the experimentally and numerically determined resonance frequencies increases with the perforation area, mainly due to higher stress concentration, reaching a maximum average error of 1.01% at a 50.24% relative perforation area. According to the data provided in the table, the maximum relative error between experimentally and numerically determined frequencies reached 1.97%. These errors are associated with the approximation process, which utilizes the least-squares method and error functional minimization. It should be noted that numerical frequency values were obtained using the finite element method. The precision of the numerical model played a significant role in this process, as mentioned earlier-the 3D scanner ensured geometric model accuracy up to 1.5%. The accuracy of the numerical frequencies could also be influenced by the discretization of the numerical model into finite elements, whose mesh convergence was selected with an accuracy of up to 0.5%. Therefore, in the author’s opinion, the effective elastic modulus values were determined with a maximum relative error between the experimental and numerical resonance frequencies reached 1.97%, which may result from slight inaccuracies in boundary conditions and geometric simplifications in the numerical model, but the obtained numerical frequency values could also be influenced by other applied methods. The total result error could reach up to 5%, mainly due to combined uncertainties in material properties, geometry, and experimental measurements.

Recent advances in materials science have shown that geometric structuring can be used not only to adjust stiffness but also to induce unusual deformation characteristics, such as a negative Poisson’s ratio (auxetic behavior) [43,44]. Perforation-based design approaches therefore provide a versatile route to tailoring mechanical response, combining light weight with adjustable elastic properties. This concept is of particular interest for biomedical implants, where local compliance and energy absorption are critical.

The results of this study demonstrate that the geometric configuration of perforations significantly influences the elastic and shear properties of cylindrical structures. This geometry-driven behavior aligns with the concept of mesoscale architecture, where structural design is used to control macroscopic mechanical response. Recent research on mechanical metamaterials confirms that periodic geometric modifications can enable tunable stiffness and functional adaptability [45,46]. The present work thus provides a practical example of geometry-based optimization of mechanical performance and contributes to the broader understanding of architectured material design. These findings may also support future developments in biomedical and lightweight engineering applications, where mechanical efficiency and functionality are equally important [43].

5. Conclusions

This research successfully applied a non-destructive method for determining the effective elastic modulus of perforated 304 stainless-steel cylinders. The method was based on determining the resonance frequencies of physical specimens using a non-contact vibrometer and solving an inverse problem for numerical models utilizing the finite element method, approximation via the least-squares method, second-order regression functions, as well as the formulation and minimization of an error functional.

The results show that as the relative perforation area increases, the elastic properties of perforated 304 stainless-steel cylinders significantly decrease. With an increase in the relative perforation area from 0% to 50.24%, the effective elastic modulus decreased from 184.76 GPa to 50.69 GPa.

A high degree of agreement was observed between the experimentally and numerically obtained resonance frequency values. The average relative error for all specimens did not exceed 1.01%, while the maximum relative error was less than 2%.

An increase in the relative perforation area leads to a decrease in resonance frequencies—the smaller the perforation area, the higher the frequencies, whereas as the perforation area increases, the frequency values gradually decrease. A larger perforation volume lowers resonance frequencies by reducing stiffness.

The decrease in the effective elastic modulus values affects the material’s mechanical properties. For future studies, it is recommended to also investigate the strength and fatigue properties of perforated 304 stainless-steel cylinders to more thoroughly identify the factors causing the deterioration of the material’s mechanical properties with increasing relative perforation area.

To identify the deeper causes of the perforation-induced reduction in elastic properties, it is recommended to analyze internal changes in the material at the microscopic level. This investigation will help determine whether and how perforations cause local changes in the material’s structure that affect its mechanical behavior.

In future studies we recommend defining optimal parameters for practical applications, especially in medical implant design. This would allow defining optimal parameters for practical applications, particularly in the development of medical implants. Also, future studies should consider a more detailed numerical representation of the perforation geometry to better capture local stress effects and improve the accuracy of elastic property evaluation.

Therefore, future studies should focus on a more detailed analysis of these geometric factors, especially on perforation areas lower than 50%, to establish predictive relationships between perforation geometry and the effective elastic properties of such structures.

Author Contributions

Conceptualization, P.A., A.S. (Anastasija Sirotkina), M.O. and V.M.; methodology, A.S. (Anastasija Sirotkina), V.M. and P.A.; software, P.A. and A.S. (Anastasija Sirotkina); investigation, A.S. (Anastasija Sirotkina), V.M., P.A. and M.O.; data curation, A.S. (Anastasija Sirotkina), V.M., P.A. and M.O.; writing—original draft preparation, A.S. (Anastasija Sirotkina), M.O., visualization, A.S. (Anastasija Sirotkina), P.A. and M.O.; project administration, V.M., M.O., A.S. (Anastasija Sirotkina), I.L. and A.S. (Andris Skromulis). writing—review and editing, M.O., A.S. (Anastasija Sirotkina), V.M., P.A. and I.L. All authors have read and agreed to the published version of the manuscript.

Funding

The study was supported by research and development grant No RTU-PA-2024/1-0091 under the EU Recovery and Resilience Facility funded project No. 5.2.1.1.i.0/2/24/I/CFLA/003 “Implementation of consolidation and management changes at Riga Technical University, Liepaja University, Rezekne Academy of Technology, Latvian Maritime Academy and Liepaja Maritime College for the progress towards excellence in higher education, science, and innovation”.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hunt, P.; Unterhauser, F.N.; Strobel, M.J.; Weiler, A. Development of a perforated biodegradable interference screw. Arthroscopy 2005, 21, 258–265. [Google Scholar] [CrossRef]

- Ahmed, M.S. Numerical Analysis of the Perforated Steel Sheets Under Uni-Axial Tensile Force. Metals 2019, 9, 632. [Google Scholar] [CrossRef]

- Chentsov, A.V.; Goldstein, R.V.; Mokryakov, V.V.; Andreev, A.O.; Petrovskii, V.N.; Gleser, A.M.; Libman, M.A. Experimental measurements of the effective elastic modulus of steel specimens containing lattices of circular holes. In Proceedings of the 17th International Conference on Experimental Mechanics (ICEM 17), Rhodes, Greece, 3–7 July 2016. [Google Scholar] [CrossRef]

- Singh, D.; Sinha, S.; Singh, H.; Jagetia, A.; Gupta, S.; Gangoo, P.; Tandon, M. Use of Nitinol Shape Memory Alloy Staples (Niti Clips) after Cervical Discoidectomy: Minimally Invasive Instrumentation and Long-Term Results. Minim. Invasive Neurosurg. 2011, 54, 172–178. [Google Scholar] [CrossRef] [PubMed]

- EN 149:2001+A1:2009; Respiratory Protective Devices—Filtering Half Masks to Protect Against Particles—Requirements, Testing, Marking. European Committee for Standardization: Brussels, Belgium, 2009.

- Cheng, Y. Architectural applications of perforated metal panels: Structural and aesthetic considerations. J. Archit. Eng. 2022, 28, 04022016. [Google Scholar]

- Cossetto, D.J.; Gouda, A.D. Uncemented tibial fixation total knee arthroplasty. J. Arthroplast. 2009, 26, 41–42. [Google Scholar] [CrossRef] [PubMed]

- Murphy, W.; Black, J.; Hastings, G. (Eds.) Handbook of Biomaterial Properties, 2nd ed.; Springer: New York, NY, USA, 2016; 676p, ISBN 978-1493933037. [Google Scholar]

- Brunette, D.M.; Tengvall, P.; Textor, M.; Thomsen, P. (Eds.) Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications, 1st ed.; Springer: Berlin, Heidelberg; New York, NY, USA, 2001; 1019p, ISBN 3540-66936-1. [Google Scholar]

- Grigoriev, S.; Sotova, C.; Vereschaka, A.; Uglov, V.; Cherenda, N. Modifying coatings for medical implants made of titanium alloys. Metals 2023, 13, 718. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P. Ti–6Al–4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J. Mech. Behav. Biomed. Mater. 2015, 51, 61–73. [Google Scholar] [CrossRef]

- Shi, J.; Liang, H.; Jiang, J.; Tang, W.; Yang, J. Design and performance evaluation of porous titanium alloy structures for bone implantation. Math. Probl. Eng. 2019, 2019, 5268280. [Google Scholar] [CrossRef]

- 3-Point Bend Testing. Available online: https://www.bruker.com/es/products-and-solutions/test-and-measurement/tribometers-and-mechanical-testers/3-point-bend-testing.html (accessed on 29 August 2025).

- Dewidar, M.; Khalil, A.; Lim, J. Processing and mechanical properties of porous 316L stainless steel for biomedical applications. Trans. Nonferrous Met. Soc. 2006, 16, 468–473. [Google Scholar] [CrossRef]

- Sanchaniya, J.V.; Rengasamy Kannathasan, K.; Vejanand, S.R.; Joshi, J.; Lasenko, I. Effect of Infill Pattern Design on Tensile Strength of Fused Deposition Modelled Specimens. In Proceedings of the 16th International Scientific and Practical Conference “Environment. Technology. Resources”, Rezekne, Latvia, 19–20 June 2025; Volume IV, pp. 375–382. [Google Scholar] [CrossRef]

- Mukanov, G. Evaluation of the Elastic Modulus of Cellular Titanium Implants by Finite Element Modeling. Ph.D. Thesis, Ural Federal University, Yekaterinburg, Russia, 2018. [Google Scholar]

- Sanchaniya, J.V.; Lasenko, I.; Vijayan, V.; Smogor, H.; Gobins, V.; Kobeissi, A.; Goljandin, D. A Novel Method to Enhance the Mechanical Properties of Polyacrylonitrile Nanofiber Mats: An Experimental and Numerical Investigation. Polymers 2024, 16, 992. [Google Scholar] [CrossRef]

- Barkanov, E.N.; Wesolowski, M.; Akishin, P.; Mihovski, M. Techniques for Non-destructive Material Properties Characterisation. In Non-destructive Testing and Repair of Pipelines. Engineering Materials; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 191–207. [Google Scholar] [CrossRef]

- Bhaduri, A. Mechanical Properties and Working of Metals and Alloys; Springer: Singapore, 2018; 748p, ISBN 978-981-10-7208-6. [Google Scholar]

- Gluhih, S.; Kovalov, A.; Tishkunov, A.; Akishin, P.; Chate, A.; Auzins, E.; Kalnins, M. Identification of the elastic modulus of polymeric materials by using thin-walled cylindrical specimens. Mech. Compos. Mater. 2012, 48, 57–64. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J. Finite element analysis of stress concentration in perforated titanium rings for orthopedic implants. Mater. Sci. Eng. C 2023, 142, 113123. [Google Scholar]

- Hussain, M.; Rizvi, S.H.A.; Abbas, N.; Sajjad, U.; Shad, M.R.; Badshah, M.A.; Malik, A.I. Recent Developments in Coatings for Orthopedic Metallic Implants. Coatings 2021, 11, 791. [Google Scholar] [CrossRef]

- Nouri, A.; Wen, C. Stainless steels in orthopedics. In Structural Biomaterials: Properties, Characteristics and Selection; Woodhead Publishing: Cambridge, UK, 2021; Volume 3, pp. 67–101. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, G. Biomaterials and their applications. AIP Conf. Proc. 2018, 1953, 080041. [Google Scholar] [CrossRef]

- Newson, T. Stainless steel—A family of medical device materials. In Business Briefing: Medical Device Manufacturing & Technology; World Markets Research Centre: London, UK, 2002; Available online: https://bssa.org.uk/wp-content/uploads/2021/11/Tony-Newson-Medical-Device-Materials.pdf (accessed on 5 September 2025).

- Čapek, J.; Stehlíková, K.; Michalcová, A.; Msallamová, Š.; Vojtěch, D. Microstructure, mechanical and corrosion properties of biodegradable powder metallurgical Fe–2 wt% X (X = Pd, Ag and C) alloys. Mater. Chem. Phys. 2016, 181, 501–511. [Google Scholar] [CrossRef]

- Rajan, A.B.S.; Mary, S.K.S.; Kumar, S.R.R. A systematic review of the use of titanium versus stainless steel implants in orthopedic surgery. J. Orthop. Surg. Res. 2021, 16, e138. [Google Scholar] [CrossRef]

- ASTM A240; Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications. ASTM International: West Conshohocken, PA, USA, 2024.

- Abd-Elaziem, W.; Darwish, M.A.; Hamada, A.; Daoush, W.M. Titanium-based alloys and composites for orthopedic implants applications: A comprehensive review. Mater. Des. 2024, 241, 112850. [Google Scholar] [CrossRef]

- Mironovs, V.; Osipova, M.; Akishin, P.; Zemchenkovs, V.; Serdjuks, D. Methods for evaluating the elastic properties of stainless steel perforated plates. Metals 2025, 15, 711. [Google Scholar] [CrossRef]

- 3D-Scaner Creality CR-Scan Raptor 4008050049 CRS07R. Available online: https://domtehno.com/p2261343781-skaner-creality-scan.html (accessed on 22 August 2025).

- Ahmad, N.; Janahiraman, T.V. A study on regression model using response surface methodology. Appl. Mech. Mater. 2014, 619, 341–345. [Google Scholar] [CrossRef]

- Pearson, C.; Ginsburg, B. Deep Learning. In Programming Massively Parallel Processors, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 355–389. [Google Scholar] [CrossRef]

- Golub, G.; Van Loan, C. Matrix Computations, 4th ed.; Johns Hopkins University Press: Baltimore, MD, USA, 1996; 780p, ISBN 978-1-4214-0794-4. [Google Scholar]

- Uhlmann, G. Inverse problems: Seeing the unseen. Bull. Math. Sci. 2014, 4, 209–279. [Google Scholar] [CrossRef]

- Cherednik, V. Regression Analysis. Practicum, N.I., Ed.; Lobachevsky State University of Nizhny Novgorod: Nizhny Novgorod, Russia, 2009; 17p. [Google Scholar]

- Denisiewicz, A.; Socha, T.; Kula, K.; Błażejewski, W.; Wyjadłowski, M. Numerical Analysis of the Load-Bearing Capacity of a Thin-Walled Perforated Beam Cooperating with Chipboard Panels in a Structural System. Materials 2025, 18, 2208. [Google Scholar] [CrossRef]

- Barkanov, E.; Chate, A.; Ručevskis, S.; Skukis, E. Characterisation of composite material properties by an inverse technique. Key Eng. Mater. 2007, 345–346, 1319–1322. [Google Scholar]

- Wesolowski, M.; Barkanov, E.; Rucevskis, S.; Chate, A.K.; la Delfa, G. Characterisation of elastic properties of laminated composites by non-destructive techniques. In Proceedings of the ICCM International Conferences on Composite Materials, Vancouver, BC, Canada, 19–24 July 2009. [Google Scholar]

- Kovalovs, A.; Rucevskis, S. Identification of elastic properties of composite plate. IOP Conf. Ser. Mater. Sci. Eng. 2011, 23, 012034. [Google Scholar] [CrossRef]

- Vovk, S. Methods of Numerical Minimization of the Quasi-Extension Functional. Syst. Technol. 2019, 5, 18–32. [Google Scholar] [CrossRef]

- Kovalovs, A.; Barkanov, E.; Vodka, O. Identification procedure of functionally graded material in sandwich beam. In Proceedings of the 23rd International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 27–29 May 2024. [Google Scholar] [CrossRef]

- Kulagin, R.; Beygelzimer, Y.; Estrin, Y.; Schumilin, A.; Gumbsch, P. Architectured Lattice Materials with Tunable Anisotropy: Design and Analysis of the Material Property Space with the Aid of Machine Learning. Adv. Eng. Mater. 2020, 22, 2001069. [Google Scholar] [CrossRef]

- Lakes, R.S. Foam Structures with a Negative Poisson’s Ratio. Science 1987, 235, 1038–1040. [Google Scholar] [CrossRef] [PubMed]

- Jiao, P.; Mueller, J.; Raney, J.R.; Zheng, X.R.; Alavi, A.H. Mechanical Metamaterials and Beyond. Nat. Commun. 2023, 14, 6208. [Google Scholar] [CrossRef] [PubMed]

- Estrin, Y.; Bréchet, Y.; Dunstan, D.J.; Brechet, Y. Architecturing Materials at Mesoscale: Some Current Trends. Mater. Res. Lett. 2021, 9, 129–147. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).