Synergistic Effect of Pre-Aging and Nitriding on the Microstructure and Wear Resistance of L-PBF Manufactured 18Ni300

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methodology

2.3. Sample Characterization

3. Results and Analysis

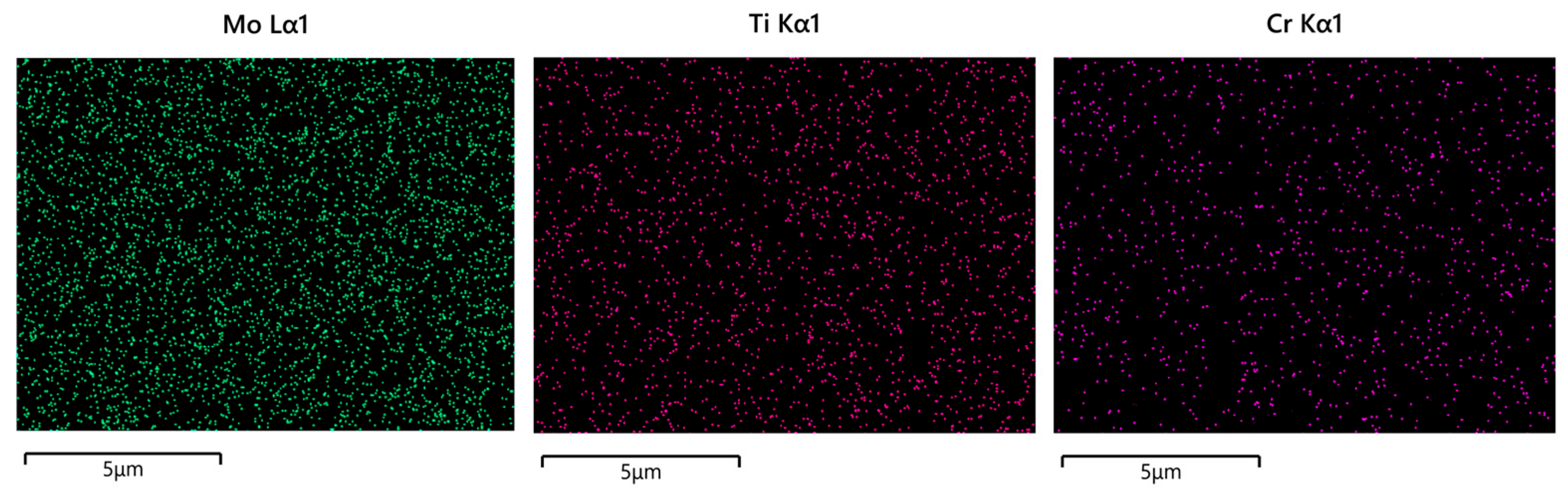

3.1. Microstructure

3.1.1. Microstructure of the Non-Aged Specimen

3.1.2. Microstructure of the Pre-Aged Specimen

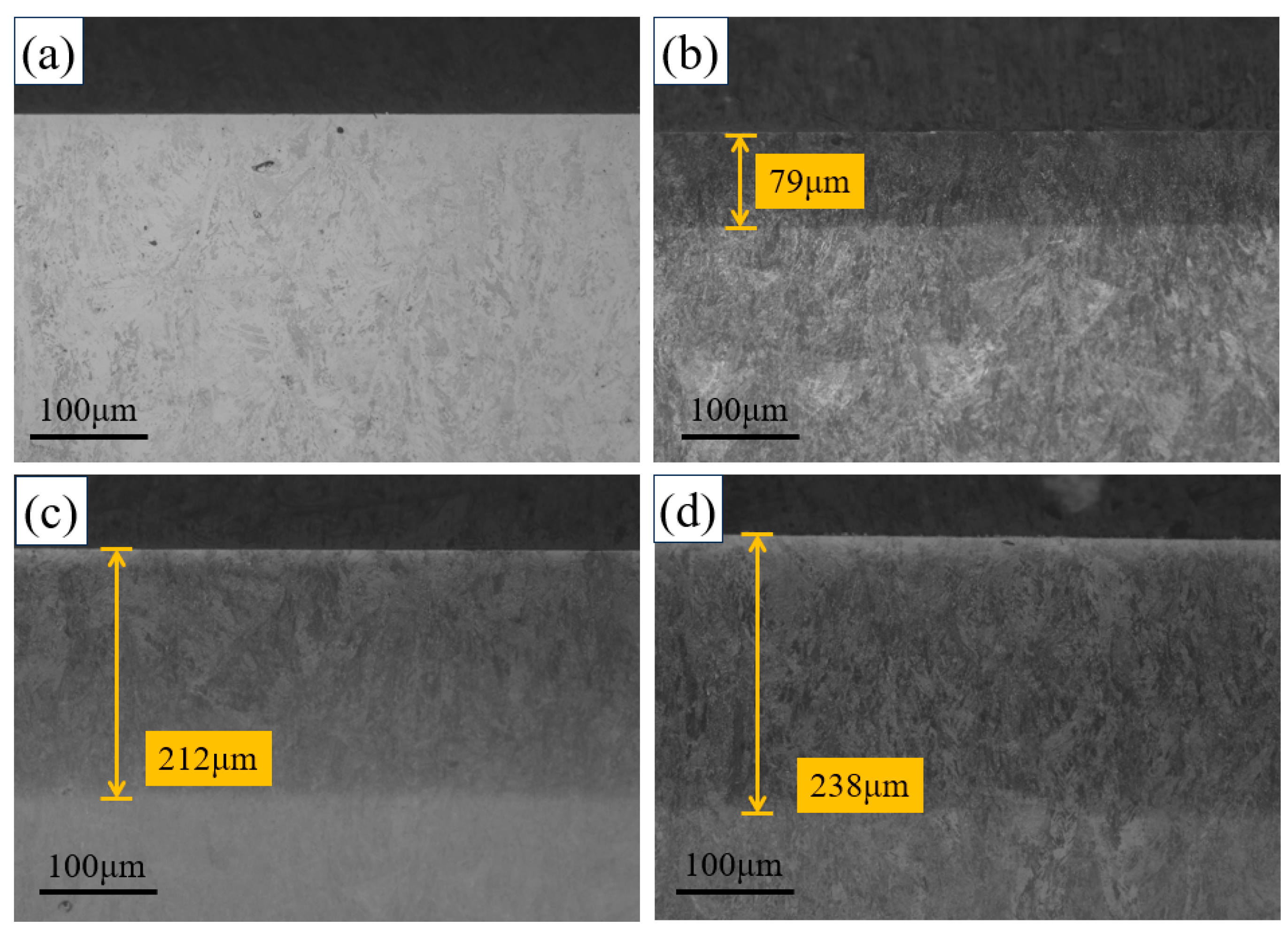

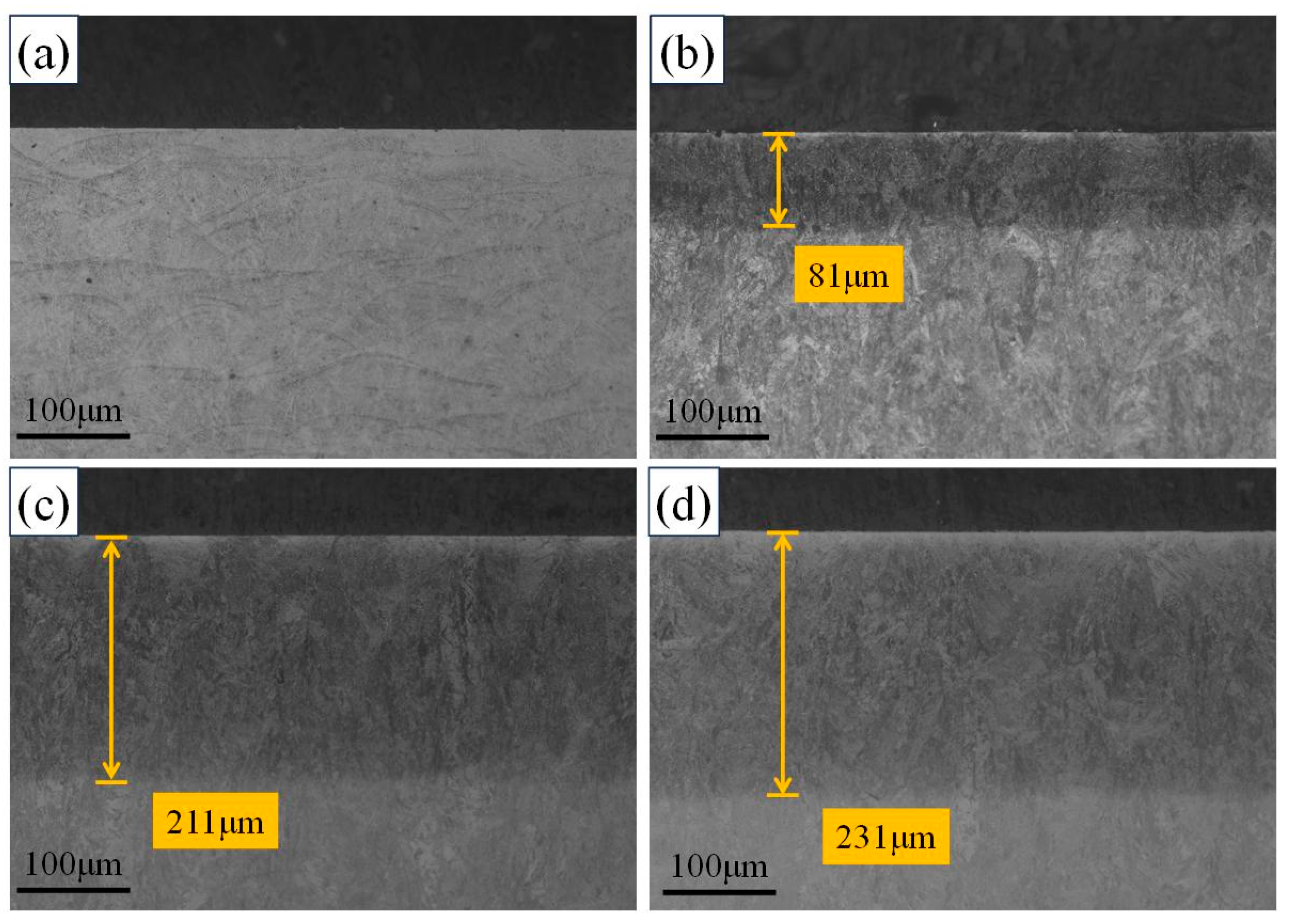

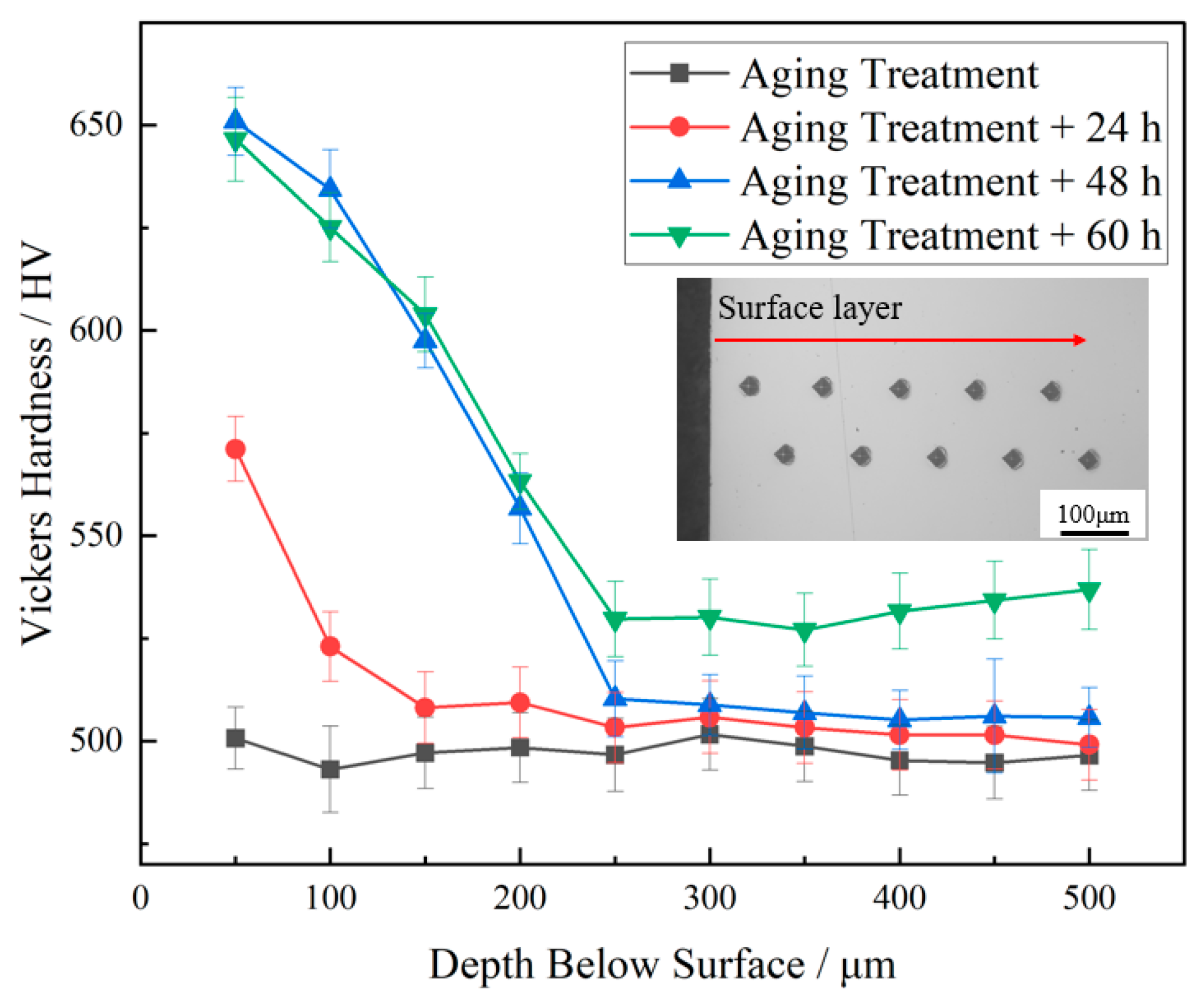

3.2. Cross-Sectional Hardness

3.2.1. Cross-Sectional Hardness of Non-Aged Specimen

3.2.2. Cross-Sectional Hardness of Pre-Aged Specimen

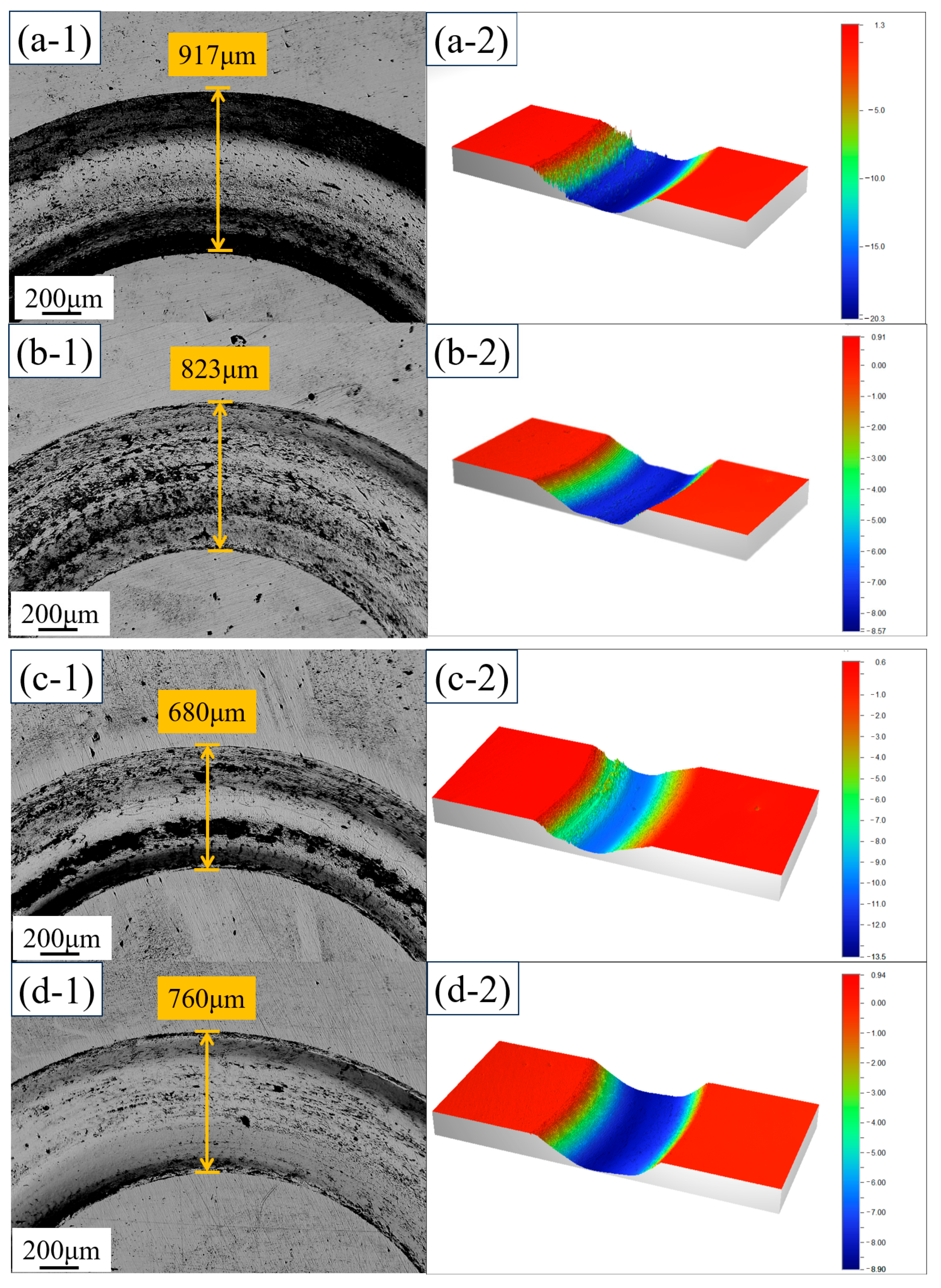

3.3. Wear Resistance

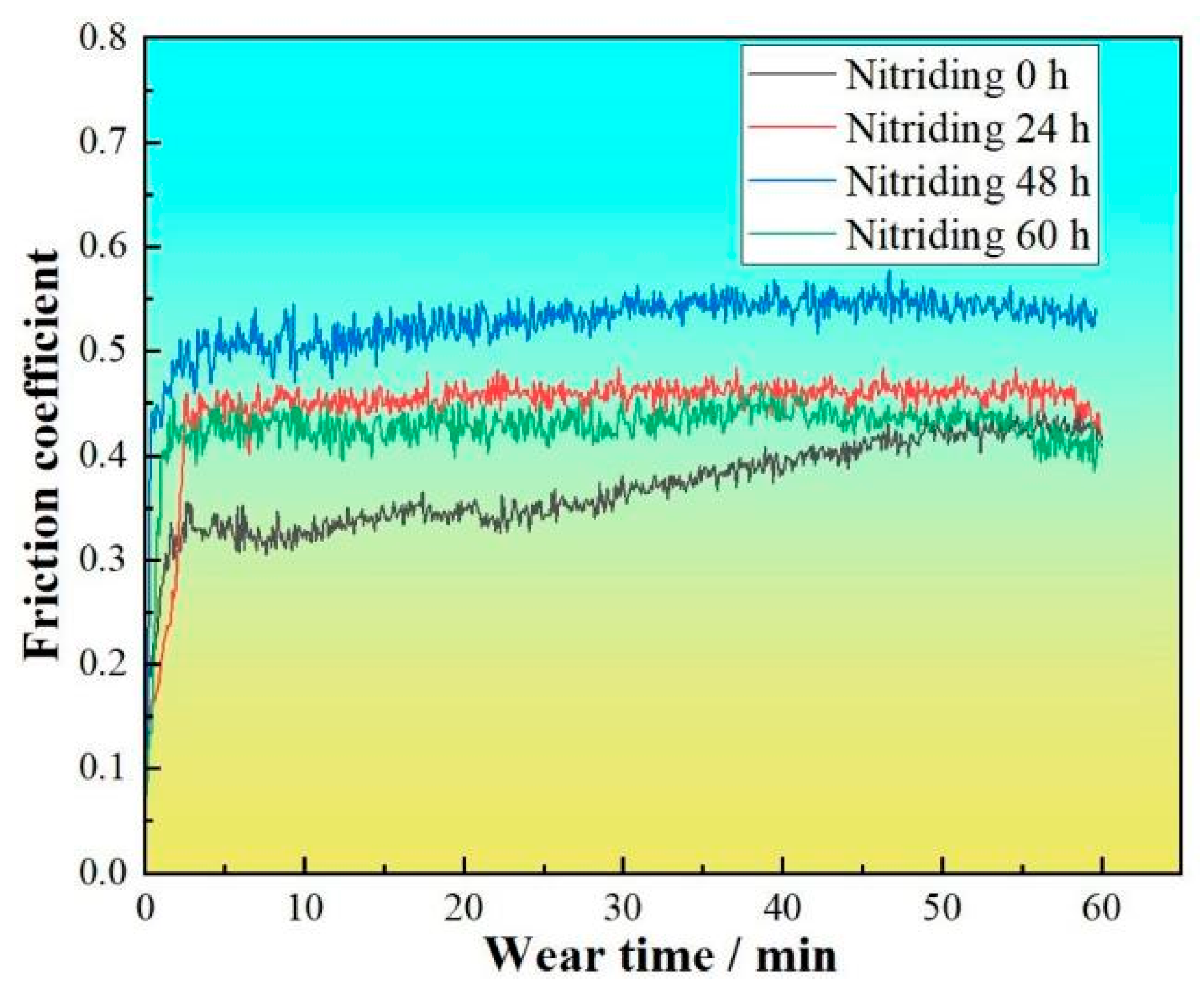

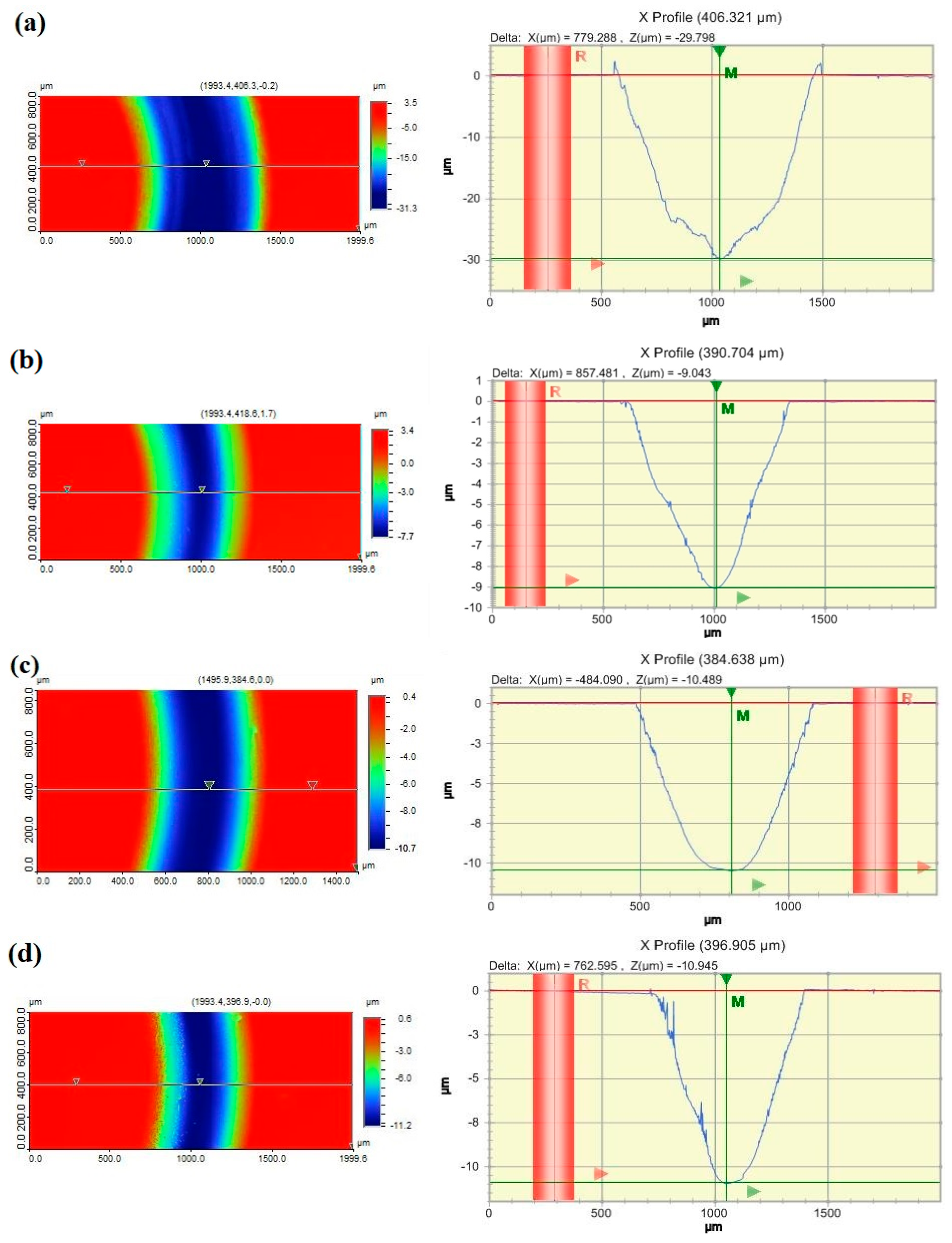

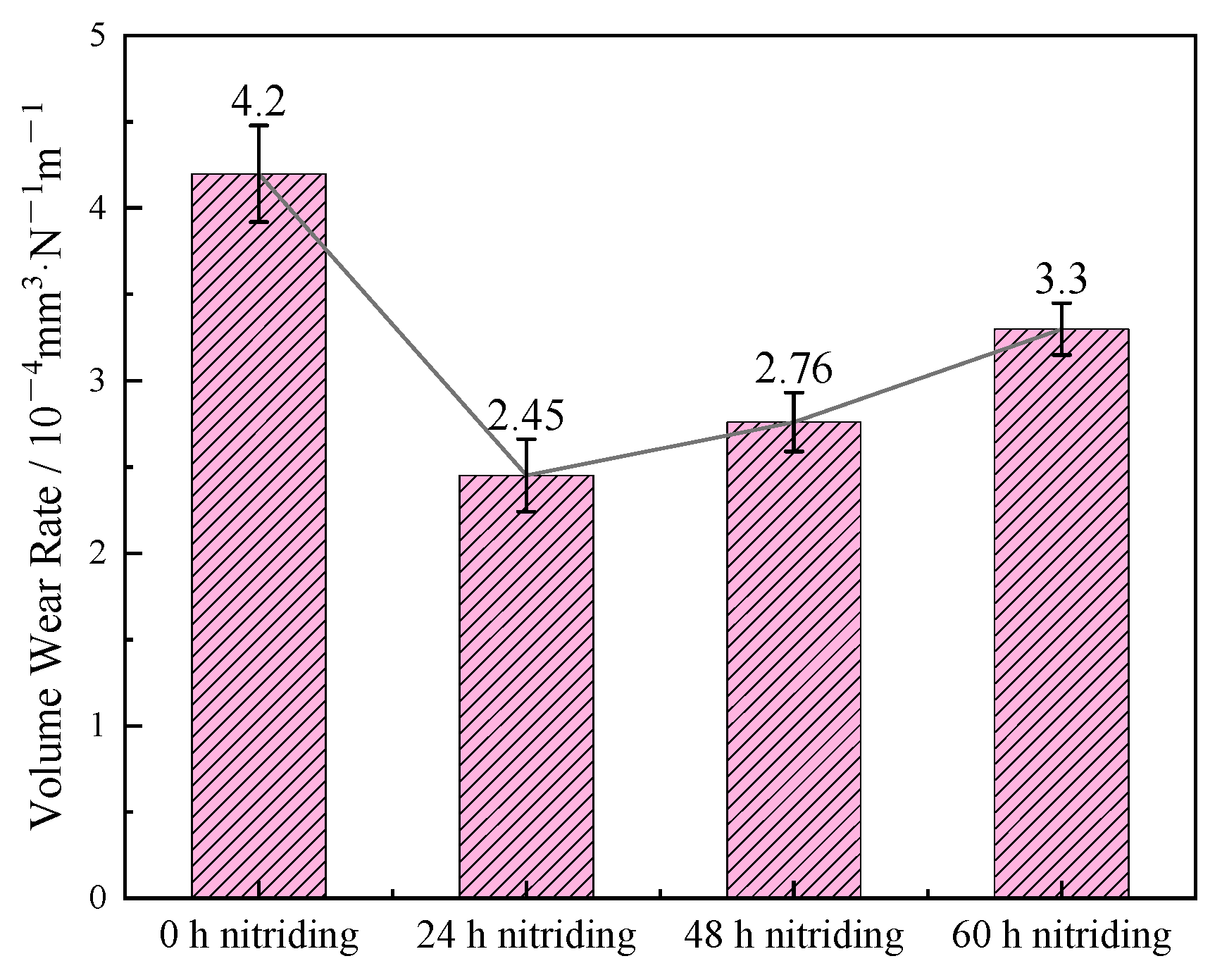

3.3.1. Wear Resistance of Non-Aged Specimen

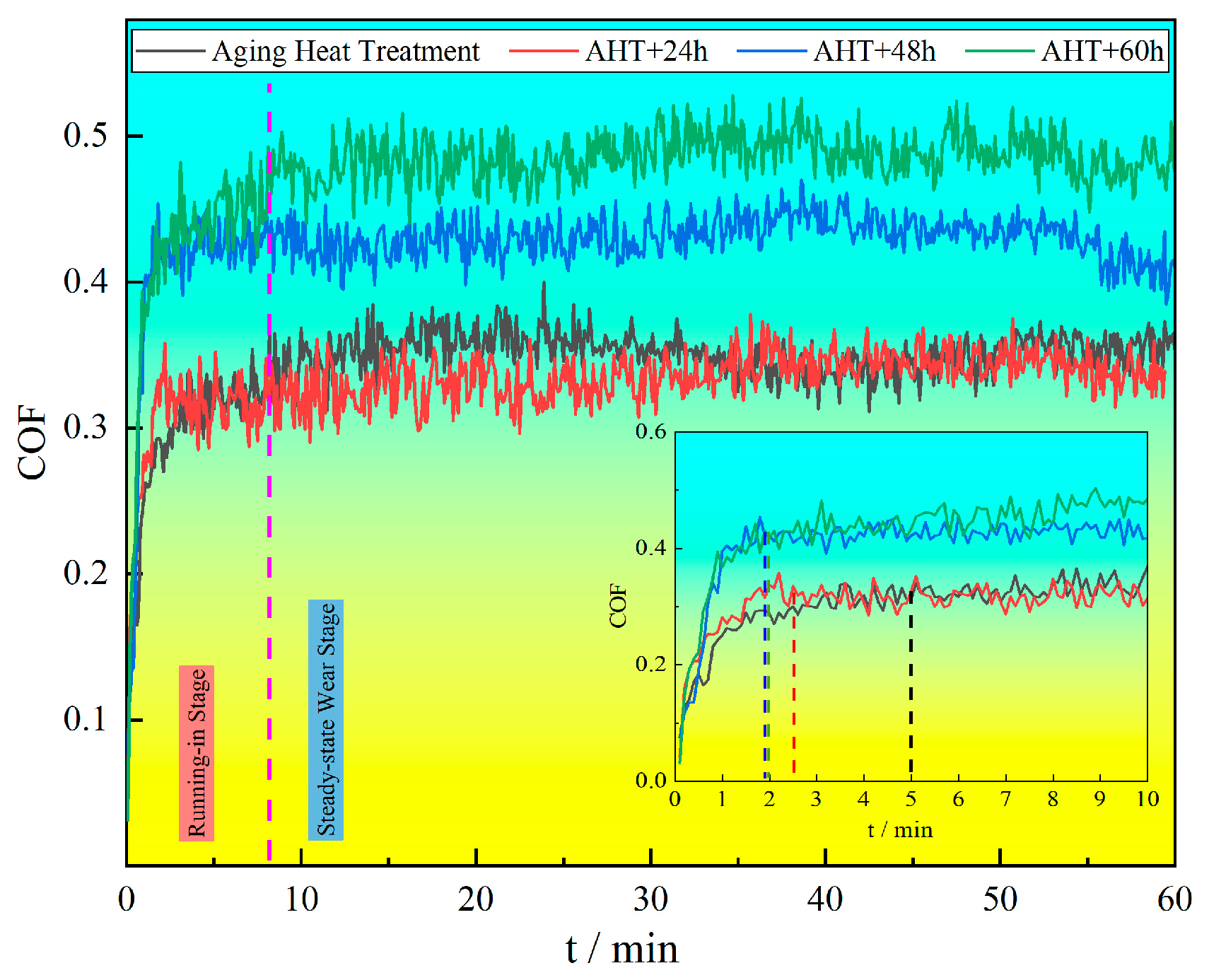

3.3.2. Wear Resistance of Pre-Aged Specimen

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Wang, F.; Xue, C. Microstructure and mechanical properties of 3D printing 18Ni300 die stee. Phys. Test Chem. Anal. Part A Phys. Test. 2016, 52, 243–246. [Google Scholar]

- XU, D.; CHEN, Y.; XU, H.; Xu, C.; Pu, C. Research progress of ultra-high strength maraging stee. J. Netshape Form. Eng. 2021, 13, 100–108. [Google Scholar]

- Gu, D.; Zhang, H.; Chen, H.; Zhang, H.; Xi, L. Laser additive manufacturing of high-performance metallic aerospace components. Chin. J. Lasers 2020, 47, 32–55. [Google Scholar] [CrossRef]

- Gu, D.; Meiners, W.; Wissenbach, K. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Cuesta, E.; Alvarez, B.J.; Zapico, P. Analysis of post-processing influence on the geometrical and dimensional accuracy of selective laser melting parts. Rapid Prototyp. J. 2020, 26, 1713. [Google Scholar] [CrossRef]

- Li, X. Investigation on the SLM Forming Mechanism and Super Hydrophobicity of the FeCrMoCBSiS Amorphous Alloy. Master’s Thesis, Jilin University, Changchun, China, 2023. [Google Scholar]

- Tan, C.L.; Zhou, K.S.; Ma, W.Y. Microstructural evolution, nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 maraging steel. Mater. Des. 2017, 134, 23–34. [Google Scholar] [CrossRef]

- Zhong, L.; Wang, S.; Men, X. Research on plasma nitriding process of 38CrMoAl Steel with Ti Catalyst. Surf. Technol. 2021, 50, 159–166. [Google Scholar]

- Karliński, W.; Tacikowski, J.; Wojtyra, K. Fatigue strength of nitrided 18Ni250 and 18Ni300 grade maraging steels. Surf. Eng. 1999, 15, 483–489. [Google Scholar] [CrossRef]

- Tsyrliné, S. Nitriding of maraging steel N18K9M5T. Met. Sci. Heat Treat. 1971, 13, 289–292. [Google Scholar] [CrossRef]

- Hu, N. The Effect of Nitriding Process on the Mechanical Properties of 18Ni Maraging Steel. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2017. [Google Scholar]

- Bai, Y.C.; Wang, D.; Yang, Y.Q. Effect of heat treatment on the microstructure and mechanical properties of maraging steel by selective laser melting. Mater. Sci. Eng. A 2019, 760, 105–117. [Google Scholar] [CrossRef]

- Men, Z. Effect of heat treatment on the microstructure and mechanical properties of 18Ni300 stainless steel melted by laser selective melting. Appl. Laser 2022, 42, 29–36. [Google Scholar]

- Dong, F.; Zhang, M.; Hou, J. Effect of aging time on microstructure and mechanical properties of SLM 18Ni300 maraging steel. Heat Treat. Met. 2021, 46, 88–91. [Google Scholar]

- Han, L.; Zhao, C. Study on fast plasma nitriding technology of 40Cr steel with nitrogen-rich layer. Trans. Mater. Heat Treat. 2009, 30, 124–128. [Google Scholar]

- Bai, J.; Men, Z.; Su, Y. Effects of aging heat treatment on friction and wear behaviors of selective laser-melted 18Ni300. J. Netshape Form. Eng. 2023, 15, 164–172. [Google Scholar]

- Chen, C.; Men, Z.; Ma, Y. Friction and wear characteristics of 18Ni300 prepared by selective laser melting. Appl. Laser 2022, 42, 72–80. [Google Scholar]

- Xiao, L.; Gao, C. Nitriding of Steel; China Machine Press: Beijing, China, 1989. [Google Scholar]

- Geng, Y.; Tang, H.; Xu, J. Formability and mechanical properties of high-strength Al-(Mn, Mg)-(Sc, Zr) alloy produced by selective laser melting. Acta Metall. Sin. 2022, 58, 1044–1054. [Google Scholar]

- Xue, J.; Sun, K.; Fang, L. Friction and wear characteristics of 30CrMnSiNi2A steel at dry sliding condition. Tribology 2016, 36, 614–621. [Google Scholar]

| Element | Ni | Co | Mo | Ti | Al | C | Mn | Si | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Content | 17.7 | 9.05 | 4.79 | 0.72 | 0.077 | 0.007 | 0.022 | 0.025 | 0.031 | 67.578 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Chen, C.; Men, Z.; Kang, Q.; Jia, Z. Synergistic Effect of Pre-Aging and Nitriding on the Microstructure and Wear Resistance of L-PBF Manufactured 18Ni300. Metals 2025, 15, 1200. https://doi.org/10.3390/met15111200

Gao X, Chen C, Men Z, Kang Q, Jia Z. Synergistic Effect of Pre-Aging and Nitriding on the Microstructure and Wear Resistance of L-PBF Manufactured 18Ni300. Metals. 2025; 15(11):1200. https://doi.org/10.3390/met15111200

Chicago/Turabian StyleGao, Xi, Cheng Chen, Zhengxing Men, Quan Kang, and Zhi Jia. 2025. "Synergistic Effect of Pre-Aging and Nitriding on the Microstructure and Wear Resistance of L-PBF Manufactured 18Ni300" Metals 15, no. 11: 1200. https://doi.org/10.3390/met15111200

APA StyleGao, X., Chen, C., Men, Z., Kang, Q., & Jia, Z. (2025). Synergistic Effect of Pre-Aging and Nitriding on the Microstructure and Wear Resistance of L-PBF Manufactured 18Ni300. Metals, 15(11), 1200. https://doi.org/10.3390/met15111200