Abstract

In order to improve the performance of welded joints in Al-Li alloys, butt joints consisting of 2 mm thick 2195-T8 Al-Li alloy plates are fabricated by laser beam welding with different filler wires in this paper. The joints welded by ER2319CT, ER4047, and without filler are investigated in the context of microstructure, the distribution of alloying elements, the burning loss of alloying elements, and tensile strength. From the fusion boundary to the center of the weld seam (WS), the crystal morphologies vary in the sequence of fine equiaxed grains, columnar dendrite, and equiaxed dendrite. The equiaxed grains and columnar dendrite disappear in certain areas of the WS by ER2319CT. The burning loss rates of Li and Cu in the WS by filler wires are higher than those by laser welding without filler. AlLiSi and Al2Cu are identified as the strengthening phases in the WS by ER4047, while Al2Cu, Al2CuLi, and Al6CuLi3 are the strengthening phases in the WS by ER2319CT. Compared with laser welding without filler wire, more strengthening phases improve the mechanical properties of the welded joints by filler wires. Both types of welding wires can improve the performance of welded joints, and ER2319CT is more effective.

1. Introduction

An Al-Li alloy is an ideal lightweight structural material with high strength, low density, and excellent weldability that is used in the aerospace field [1,2,3]. The 2195 Al-Li alloy is the third-generation Al-Li alloy that has been applied to spacecraft fuel and rocket tanks [4]. Riveting is the main joining technology in the manufacturing process, which is limited by low efficiency, inability to lose weight, and high cost. As a high-energy beam-connection method, laser-welding technology with high energy density, good welding quality, high precision, high production efficiency, and a good weight-reduction effect has focused on lightweight structural applications in aerospace and other fields [5,6]. It can solve the problems mentioned above well [7,8,9].

Nowadays, microstructure evolution, mechanical properties, softening, and hot-cracking sensitivity of laser-beam-welded joints were studied [10]. In order to improve the performance of the T-joint, Zhang [11] carried out two different post-weld heat treatments, namely solution treatment and artificial aging (STAA) and artificial aging (AA). In the case of STAA, the increased second phase in the matrix resulted in significant dispersion strengthening and enhanced strength. In the case of AA, alloy elements segregated towards the grain boundary, leading to grain boundary strengthening, and improved strength. The elongation of joints treated by STAA was superior to AA. Enz [12] et al. investigated the effect of chemical composition changed on the mechanical properties of weld seams of AA2190 and AA2198 Al-Li alloys. The uneven distribution of Li and the burning loss of Si greatly influenced the mechanical properties of the weld joint. The strengthening effect of alloying elements, such as Cu and Ag, on mechanical properties was less than that caused by hot cracks. Bing Han [13] et al. studied the effects of AA4047 and CW3 (Al-6.2Cu-5.4Si) welding wires on the T-joints of 2060/2099 Al-Li alloy aircraft panels by double-sided laser welding. The main intergranular precipitate within the EQZ was converted from the T (AlLiSi) phase to the T2 (Al6CuLi3) phase in the weld by CW3, which improved the mechanical properties of weld joints significantly. In addition, bridging caused by substructure dendrites within CW3 weld’s columnar zone resulted in lower hot-cracking susceptibility of the whole weld than AA4047. Lei [14] et al. used Al-Si welding wire to weld the T-joint of the 2195-T87 Al-Li alloy on both sides by laser swing welding. The results showed that laser swing welding (with high welding speed, low heat input, moderate swing amplitude, and frequency, which improved the forming quality of the weld surface) inhibited the formation of pores, refined the microstructure, and improved the mechanical properties. Chen [15] et al. found that Ni as a filler material can generate more Ni3Ti in laser-welded joints of NiTi/stainless steel (SS). As post-weld heat treatment increased, increased Ni3Ti and homogenization of the microstructure were observed in the joints, resulting in high micro-hardness and tensile strength. Cui [16] et al. observed EBSD on the structure of a 3 mm thick 5A90 Al-Li alloy laser weld seam. Compared with the base metal, the grain orientation in the weld seam was distributed randomly. Jun [17] et al. analyzed the influence of heat treatment on 1420 Al-Li alloy joints by laser–MIG hybrid welding. After heat treatment, all dendrites were transformed into the equiaxed structure, and the tensile strength was changed from 223 MPa to 267 MPa. Li [18] et al. investigated the effects of peak temperature on the grain morphology and mechanical properties of Inconel 625 alloys. After Gleeble thermal simulations, prominent equiaxed grains appeared. With the increasing peak temperature, the size of equiaxed grains increased and the mechanical properties were distinctly weakened. Liu [19] et al. focused on the mechanical properties and microstructure of 2A55 Al-Li alloy TIG-welded joints obtained by the 2A55 alloy and Al-8Cu filler wire. The weld grain was significantly refined by the filler wire with higher Zr and Ti content. After natural aging, the yield strength (YS) of the 2A55 joint increased by 24.1% compared with a 14.7% improvement in the Al-8Cu joint.

Welding wire could inhibit thermal cracks effectively in laser welding. Wang [20] et al. investigated the microstructure evolution of the joint and the influence of strain rate on the mechanical behavior of the joint by laser wire filling welding with AA4047 on the 2060 Al-Li alloy. No solidification cracking or liquation cracking was found in the fusion zone (FZ) and heat-affected zone (HAZ). In the partially melted zone (PMZ), a mount of eutectic liquids was observed to flow into the boundaries to refill the cavities made by insufficient grain boundary liquids and repair the liquation cracks. Lin [21] et al. used ER4047 welding wire to carry out laser filler welding of the 2198 Al-Li alloy to improve the fluidity of the molten pool and inhibit crack propagation. The result indicated that a higher welding speed caused the increase in the crack number and a lower wire feeding rate led to a higher cracking susceptibility. The average tensile strength reached 65.4% of the base material. An [22] et al. used 5087 Al-Mg-Si filler wire to weld a 2060-T8 Al-Li alloy and found that the crystal crack sensitivity of the weld seam alleviated with the decrease in laser power and welding speed. The weld porosity, cracking, and joint mechanical properties of the T-joint of the 2060-T8/2099-T83 Al-Li alloy were investigated [23]. The pores could be avoided by removing surface layers that are 0.15 mm thick. Hot cracking could be eliminated with filler wire of AlSi12 and an appropriate bevel design. The circumferential tensile strength of the seams can reach 82.5% of the base metal. Zhang [5,24] compared the microstructure and properties of the seam on a 2060-T8 Al-Li alloy welded by Al-Mg welding wire and Al-Si welding wire. The results showed that the seam strength welded by Al-Si welding wire was higher than that of Al-Mg welding wire.

The content and distribution of alloying elements in the Al-Li alloy influenced the properties of the weld seam. Zhou [25] et al. investigated the burning loss of magnesium during laser deep penetration welding of 5052 aluminum alloy, in which welding parameters greatly influenced the burning loss of magnesium. Sanchez-Amaya [26] et al. carried out surface treatment on aluminum alloy before welding, such as surface coating and sandblasting, which improved the corrosion resistance of weld seam and reduced the burning loss of Mg. Zhan [27] et al. studied the distribution of Mg in electron beam weld seams of a 6061 aluminum alloy. The characteristic isotherm and convection within the molten pool during EBW were the key factors that dominated the microstructure and magnesium distribution.

The aim of this paper was to study the influence of different filler wires on the properties of weld joints. Through the investigation of microstructure, element distribution, and the mechanical properties of welded joints, the microstructure evolution mechanism and mechanical properties were discussed preliminarily. This study provided useful information on the laser welding of a 2195 Al-Li alloy and facilitated the application of this new generation of Al-Li alloy in the aerospace field.

2. Materials and Methods

This study used rectangular sheets of laminated 2195-T8 Al-Li alloy (100 mm × 50 mm × 2 mm) for laser welding. Two filler wires with the same diameter of 1.2 mm were obtained from Shanghai Longshuo Welding Material Co., Ltd., in Shanghai, China. One was an eutectic alloy ER4047 with a certain amount of Si, and the other was a new kind of filler wire, namely ER2319CT with 2%TiC nanoparticles. Chemical compositions are shown in Table 1. The tensile strength of 2195 Al-Li alloy was 446 MPa. Element Si in ER4047 increased the fluidity of the welding pool and restrained hot cracks on weld joints effectively [28]. TiC particles can enhance the fusion between the welding wire and the base metal, promote the migration of alloying elements, improve the distribution of elements in the molten pool, and ultimately modify the microstructure of the welded joint [29].

Table 1.

Chemical compositions of base metal (BM) and filler wires (wt.%).

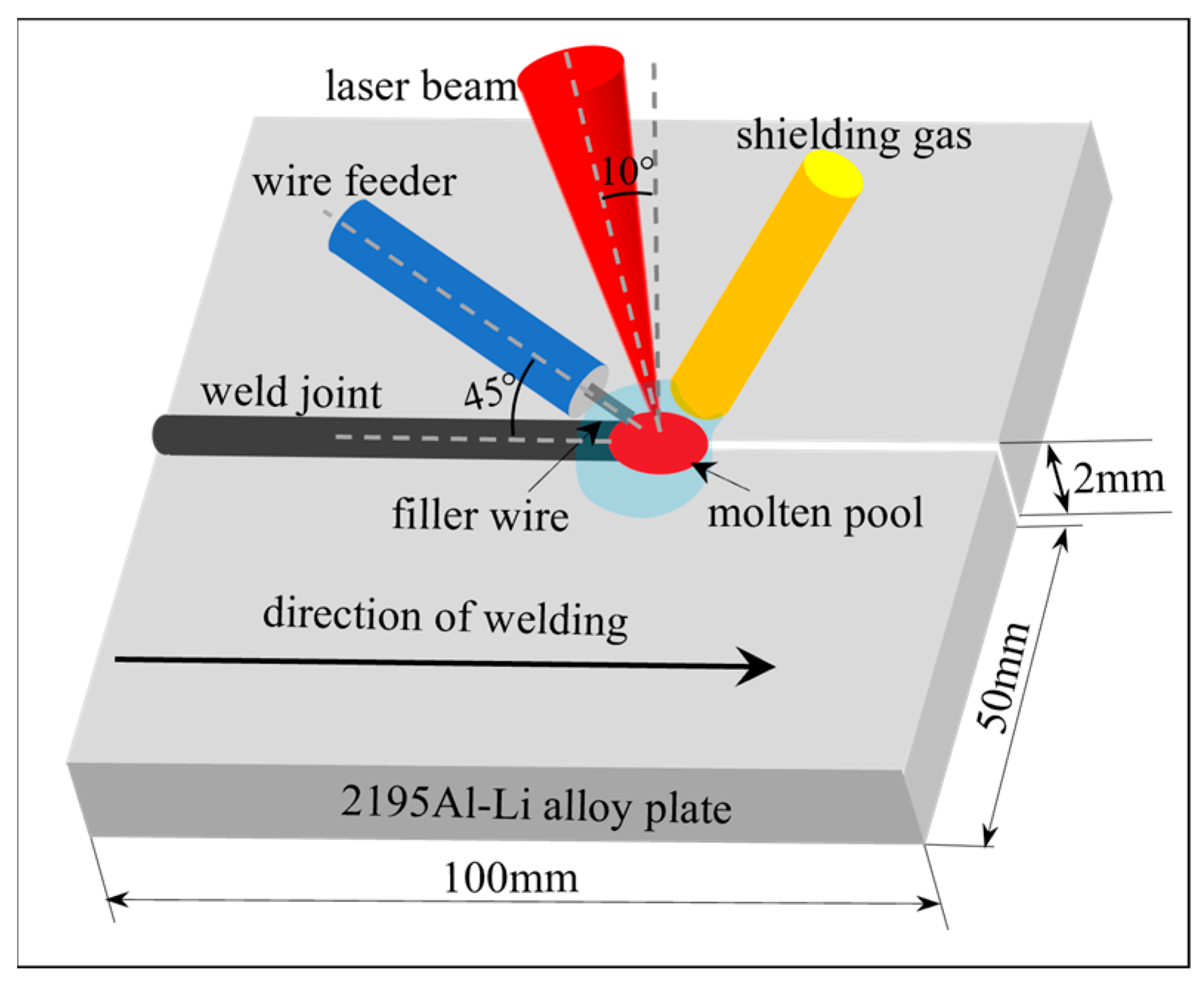

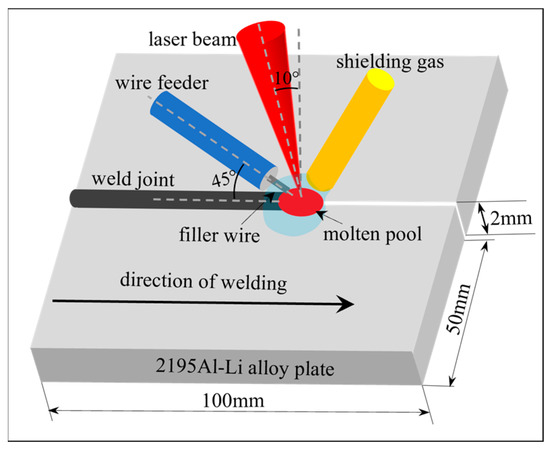

TruDisk-12003 disc was used in the experiment. The laser head, wire feeding catheter, and protective trachea were fixed on a KR60HA six-axis robot. The schematic diagram of laser welding is shown in Figure 1. The welding direction was parallel to the rolling direction of the Al-Li alloy. The wire feeder and the shielding gas nozzle were positioned at either side beyond the end of the welding site, respectively. The wire feeder and the shielding gas nozzle were located on the same plane to stabilize the welding process. The angle between the laser beam and the workpiece was fixed at 80° to reduce the adverse effect of harmful reflections. The angle between the wire feeder and the workpiece was fixed at 45°. Argon was used as shielding gas, whose flow rate was 15 L/min. In addition, there was a gap of 0.2 mm between the Al-Li alloy plates. The welding parameters, such as power, welding speed, and defocusing amount, were pre-tested and optimized. In the current work, the welding power was 2.5 KW, the welding speed was 1.8 m/min, and the defocusing amount was 0 mm. It is necessary to eliminate the oxide film on the aluminum alloy surface before welding. The oxide film and water vapor on the surface of samples were removed by polishing and drying, which helps to reduce laser reflectivity and inhibit welding defects (such as pores and cracks).

Figure 1.

Schematic diagram of laser butt welding.

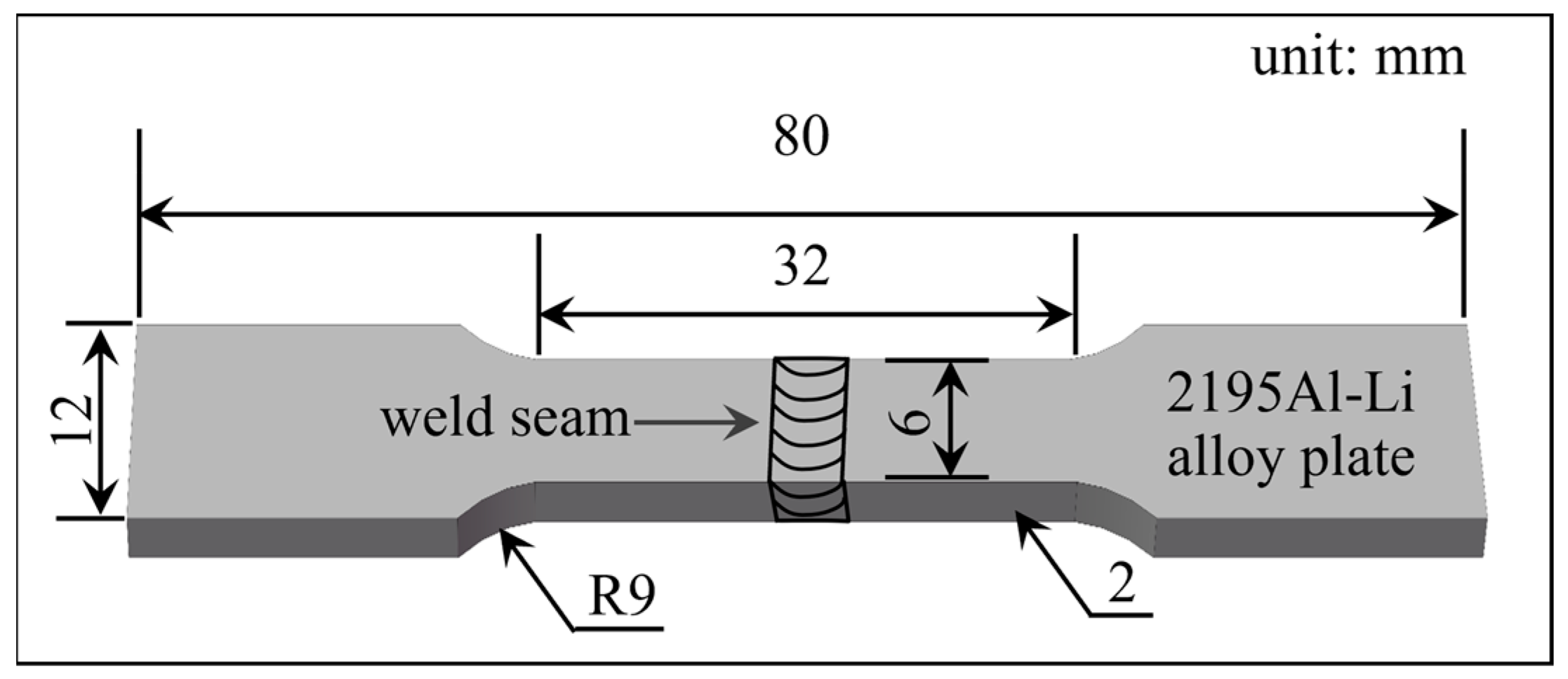

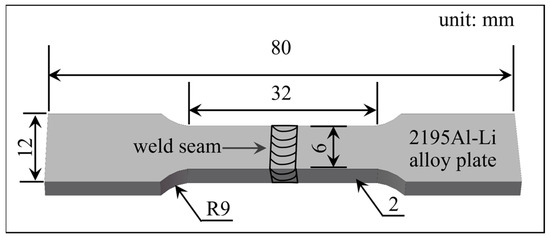

To observe the microstructure of the WSs, the metallographic specimens (5 mm × 20 mm × 2 mm) were cut from the weld joint using wire-cut electric-discharge machining. Each specimen was polished using emery paper and then polished with a 0.05 μm diamond paste until the surface was bright for observation. For microstructure exposure, chemical etching was performed using Keller solution (composed of 95% H2O + 2.5% HNO3 + 1.5% HCl + 1% HF) [19,30]. The etched samples were observed using an MR-5000 optical microscope. The polished samples and the fracture morphology were analyzed using a HitachiS-4800 scanning electron microscope. Energy-dispersive spectroscopy (EDS) and inductively coupled plasma mass spectrometry (ICP-MS) determined the content and distribution of alloying elements in the WSs. In order to obtain the tensile properties of the weld joint, CMT-5105 electronic universal testing machine with 1 mm/min loading speed was employed for tensile tests. The dimension of the tensile specimen is shown in Figure 2.

Figure 2.

The dimension of tensile specimen.

3. Results and Discussion

3.1. Microstructure of the Welded Joint Using Different Wires

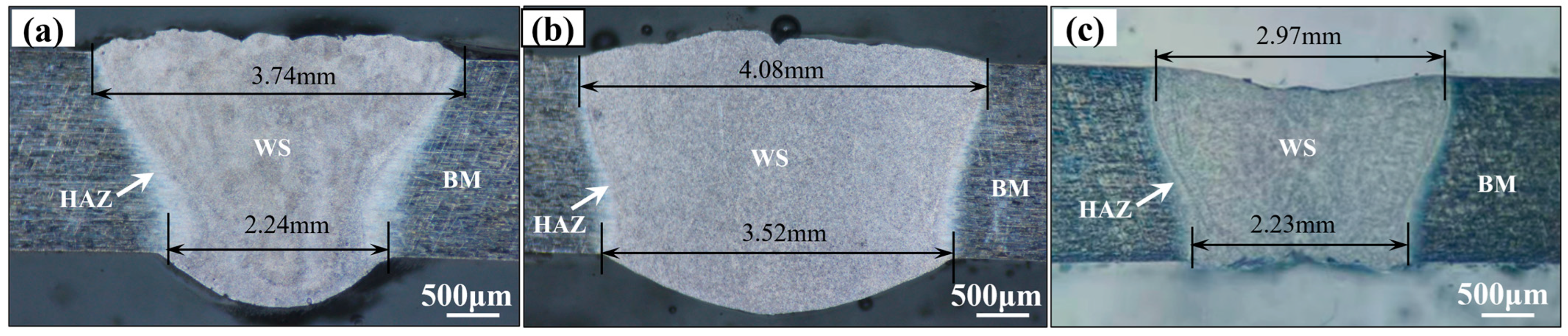

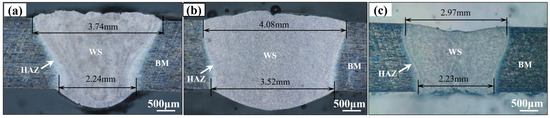

The metallographic cross-sections welded by different filler wires observed by an optical microscope are shown in Figure 3. The weld joints are welded thoroughly, approximately X-shaped, without pores and cracks. The liquid metal is affected by gravity during the solidification process. Filler wires flow into the molten pool, timely replenishing the burnt metal with high laser energy, resulting in an obvious root reinforcement in Figure 3a,b. However, the surface welded by laser welding without filler is collapsed in Figure 3c. In order to quantitatively characterize the cross-section of the WS, the width of the weld seam in the top surface and bottom surface of the three samples are measured. The largest width of the WS is welded by ER2319CT because the nanoparticles in ER2319CT enhance the fluidity of the molten pool, which helps more molten metals flow into the WS. The width of the WS by laser welding without filler is minimal due to the lack of supplements. Compared to the WS welded by ER4047, a more uniform microstructure and larger cross-section of the WS are obtained by ER2319CT. The high fluidity of the molten pool can melt the base metal and welding wire metal fully, refining the structure of the WS.

Figure 3.

Metallographic cross-section welded by different filler wires: (a) ER4047; (b) ER2319CT; (c) without filler.

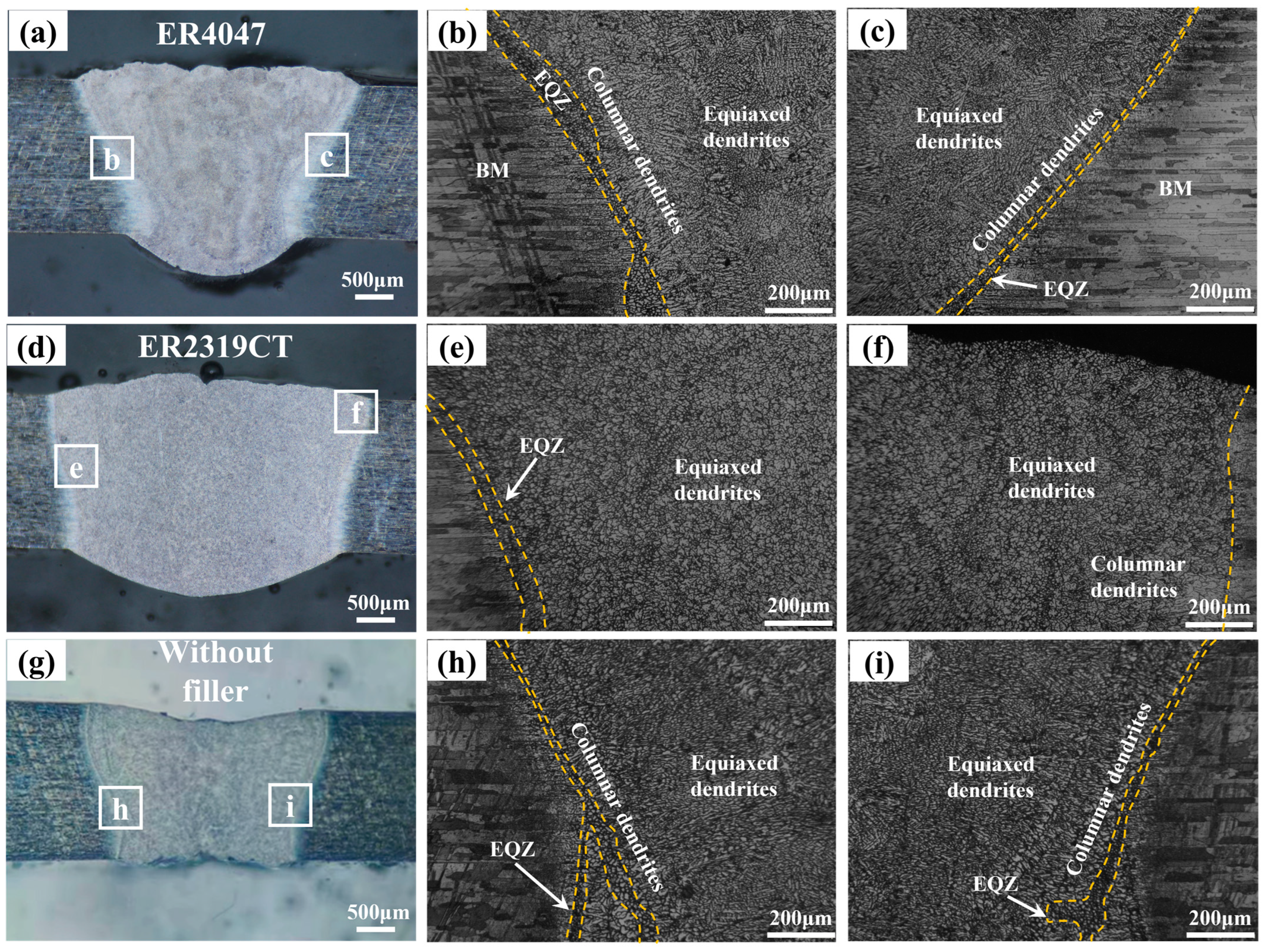

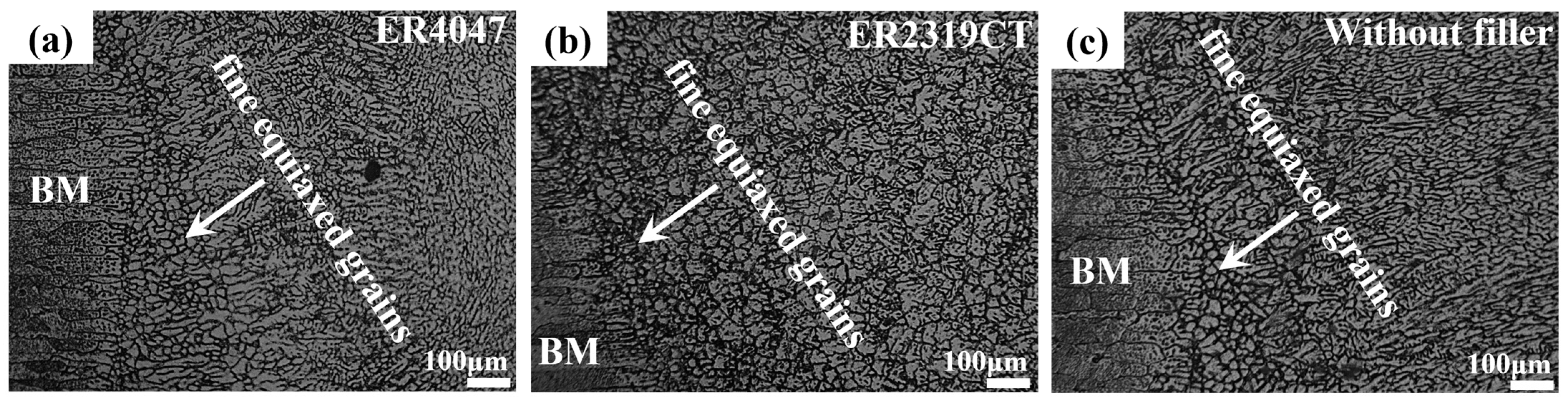

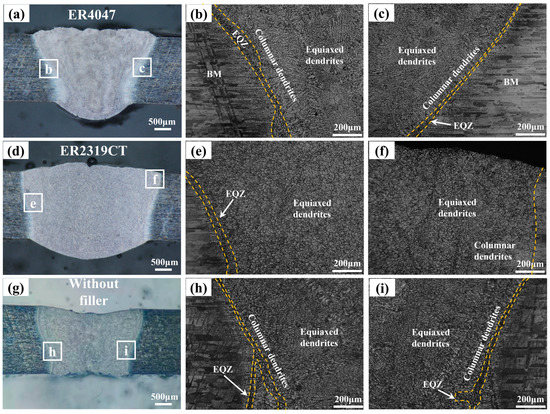

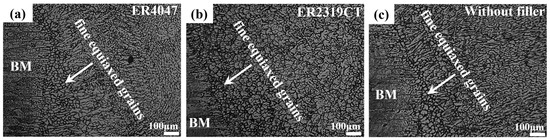

Figure 4 shows the microstructure of the WS by laser welding. The left side and right side of the WS near the fusion line are chosen to be observed in detail. As shown in Figure 4b,e,h, a zone of fine equiaxed grains, named the EQZ, is formed along the fusion line, and the enlarged image is shown in Figure 5. The fine equiaxed grains in the EQZ are thought to be formed by a heterogeneous nucleation mechanism aided by Al3Zr and Al3 (Li, Zr) precipitates [13]. Due to the high degree of undercooling, fine equiaxed grains transform to columnar dendrites, and the growth direction of columnar dendrites is vertical to the boundary of the EQZ, forming a certain columnar crystal zone (CZ). As the columnar crystal grows, the alloying elements at the solid–liquid interface are gradually pushed to the center of the WS. Then, many crystal nuclei are generated, which promote the growth of the fine-grained structure in the center of the weld. Coarse dendrites and fine-grained structures are alternately distributed in the center of the WS. Furthermore, some secondary dendrites appeared in the coarse dendrites. In Figure 4b,c,h,i, it is found that, from the fusion boundary into the center of WS, the crystal morphologies varied in the sequence of fine equiaxed grains, columnar dendrite, and equiaxed dendrite.

Figure 4.

Microstructure of 2195 Al-Li alloy WS by laser welding: (a,d,g) Macrographs of the weld joints; (b,e,h) left side of WS; (c,f,i) right side of WS.

Figure 5.

Fine equiaxed grains near the fusion line: (a) ER4047; (b) ER2319CT; (c) Without filler.

Simple dendrites are found in fine-grained structures which are distributed evenly in Figure 4e,f. In the upper right corner of the weld, the microstructure without the EQZ appears in the WS via ER2319 in Figure 4f. Figure 4e shows that the CZ disappears between the EQZ and the equiaxed dendrite zone (EDZ). For Al–Li alloys, the strengthening phases are mainly AlLiSi, Al2Cu, and Al2CuLi phases, which are dispersed in the matrix, grain boundaries, and dislocations. These dispersion phases pin the grain boundaries and hinder the movement of dislocations [31]. The precipitates are distributed uniformly in the molten pool by liquid metal with high velocity, which inhibits the EQZ [13]. It is considered that ER2319CT filler wire can adjust and refine microstructure uniformly.

3.2. Distribution of Elements

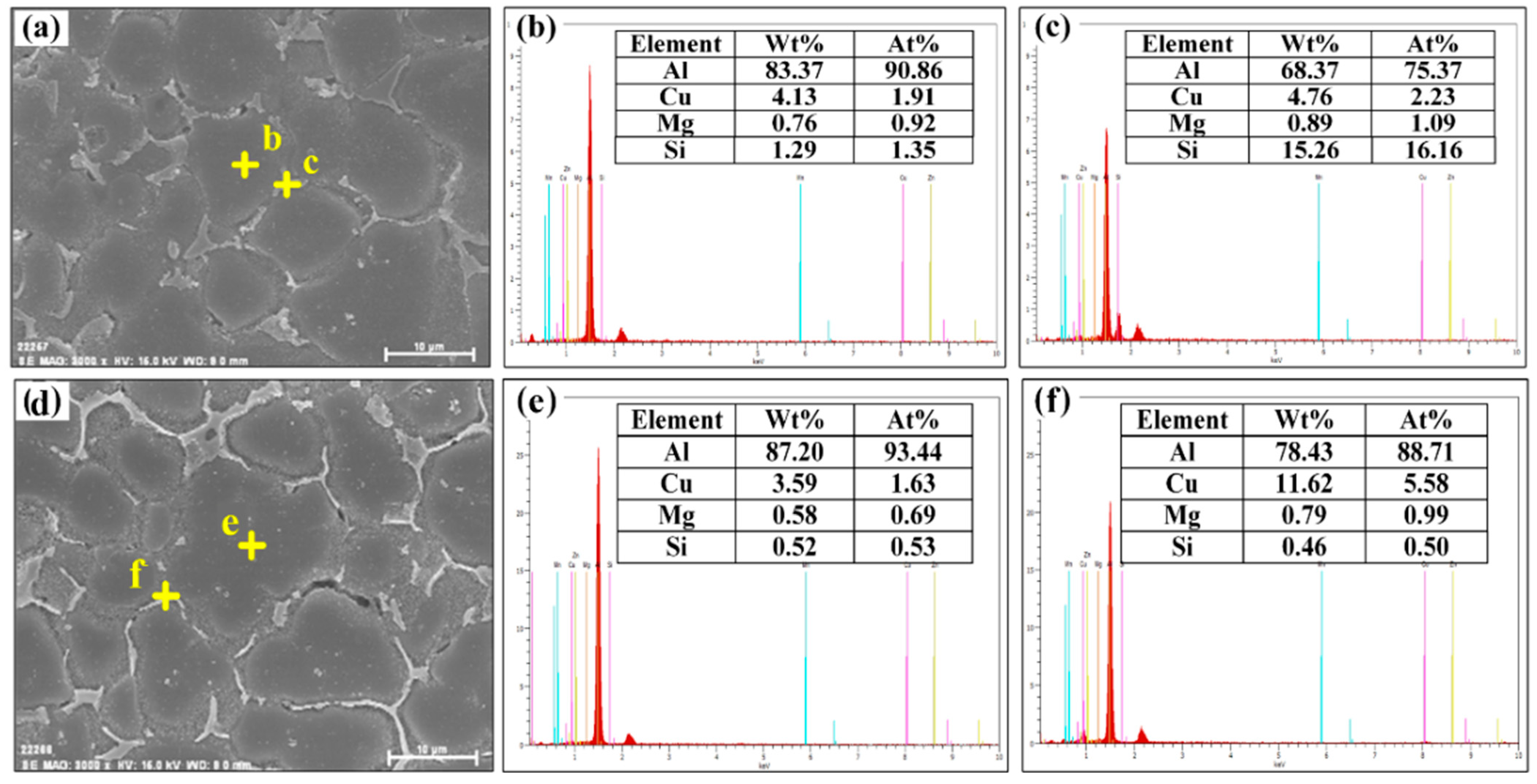

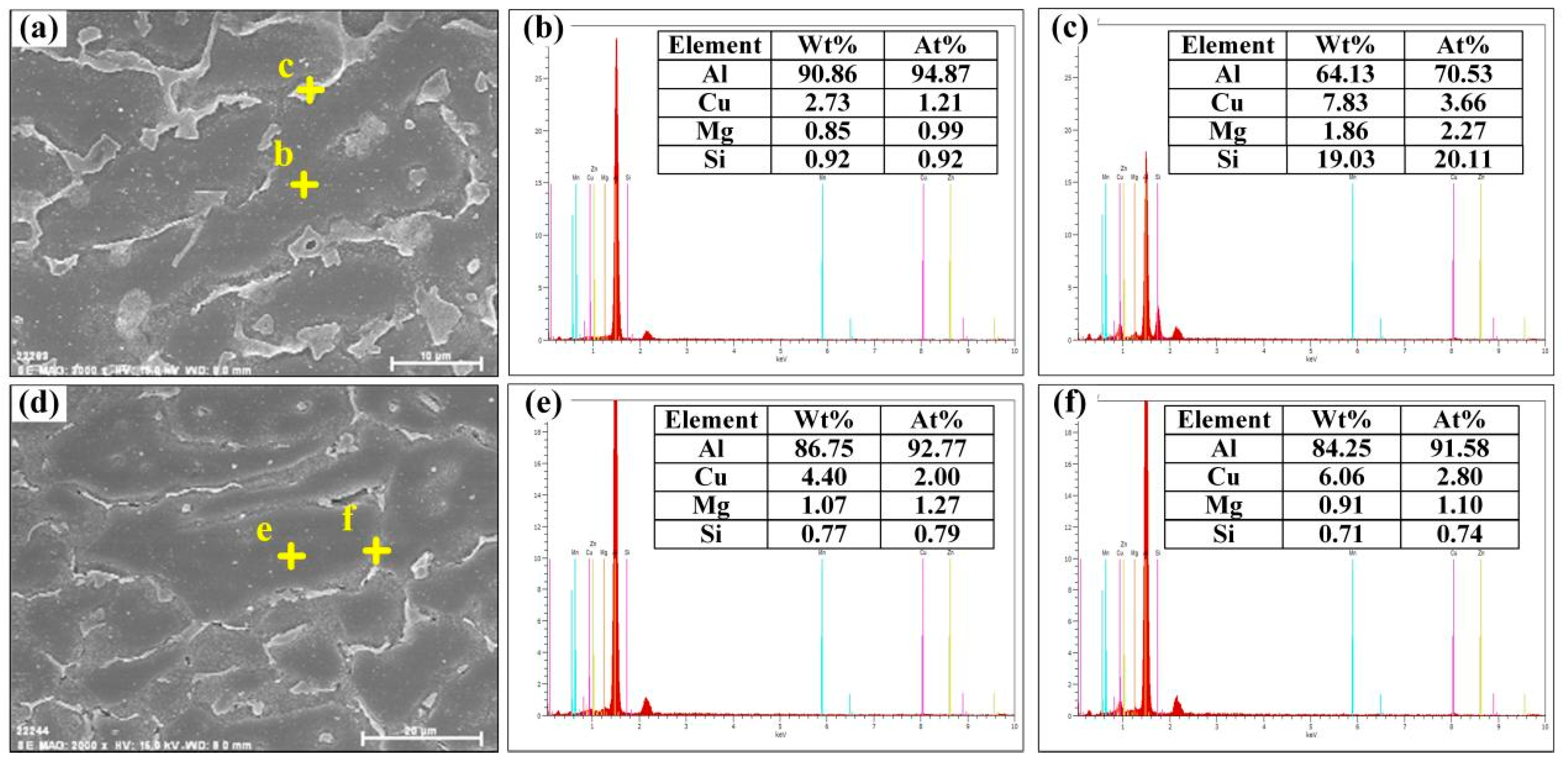

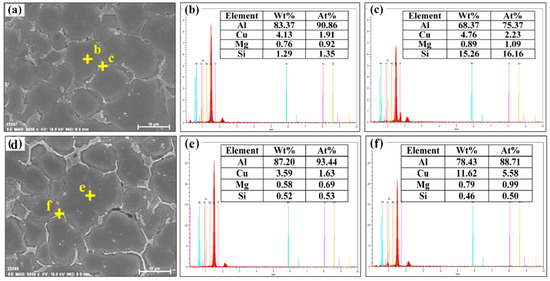

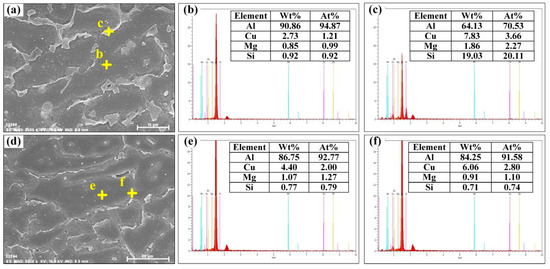

In the EQZ and CZ, eutectic products exist along the grain boundary, which indicates the segregation of alloying elements (existing in the base metal and added with the filler wires) at the grain boundary. In order to determine the precipitated phases in these typical regions, a scanning electron microscope and energy-dispersive spectrometer are used for semiquantitative analyses. The results are shown in Figure 6 and Figure 7.

Figure 6.

Element points scanning results of matrix and grain boundary in EQZ: (a–c) ER4047; (d–f) ER2319CT.

Figure 7.

Element points scanning results of matrix and grain boundary in CZ: (a–c) ER4047; (d–f) ER2319CT.

The grain boundaries of the EQZ and CZ are found to be enriched in Cu, Si, and Mg. Especially for Si in the WS by ER4047, its content (15.26 wt.% and 19.03 wt.% in EQZ and CZ, respectively) significantly exceeds the nominal composition in the base metal. This is due to the high content of elements from ER4047 filler wires. As shown in Figure 6c and Figure 7c, the eutectic products are rich in Si, and the tested mass ratio of Al/Si is about 4.5 and 3.3 in the EQZ and CZ, respectively, so these phases should be identified as T (LiAlSi) phase or binary eutectic of silicon. Therefore, the T phase is the main phase in the weld when using this kind of high Si-containing commercial filler [13]. On the other hand, the WS by ER2319CT content is 11.62 wt.% and 6.06 wt.% in the EQZ and CZ, respectively, and the tested mass ratio of Al/Si is about 6.8 to 13.9. As such, these phases should be identified as θ (Al2Cu), T1 (Al2CuLi), T2 (Al6CuLi3), and the compound of them. This conclusion is consistent with the analysis result of Han et al. [32].

Figure 7 shows the scanning result of the CZ. Compared to the matrix, the content of Mg, Si, and Cu is the explosion in grain boundary by ER4047, obtaining more precipitated phases, such as AlLiSi and Mg2Si. Cu content in precipitated phases is close to the matrix by ER2319CT, indicating that more Cu exists in the matrix and cannot be precipitated.

3.3. Element-Burning Loss

Alloy-element-burning loss has certain effects on the performance of welded joints. This paper investigates the burning loss of different alloy elements under various welding conditions.

As is well known, Li is too light to be detected by the EDS test. ICP-MS is used to measure the Li element content in this work. As shown in Table 2, the burning loss rate of Li in the WS by ER4047 is higher than that by ER2319CT, and the burning loss rate of both cases is higher than that by laser welding without filler. Lithium is not supplemented from the filler wires during laser welding.

Table 2.

The content (wt.%) and burning loss rate of Li (%).

The content, burning loss rate, and replenishment rate of Cu in the WS are shown in Table 3. The burning loss of Cu is 29.25% by ER4047. However, the content of Cu reaches 4.29% by ER2319CT. A lot of Cu is added to the seam by ER2319CT, resulting in higher Cu content in the weld joint than in the base metal.

Table 3.

The content (wt.%), burning loss rate (%), and replenishment of Cu (%).

Compared to the WS by filler wires, the burning loss rate of Cu and Li in the WS without filler is small. It may be because the filler wire is fused with the base metal in the weld seam during laser welding, leading to combustion and loss of alloy elements. In contrast, when laser welding has no filler wire, the contact area between the base metals is relatively small, and the heat distribution in the weld area is more uniform, resulting in a relatively lower burning of alloy elements.

3.4. Tensile Strength and Fracture Morphology

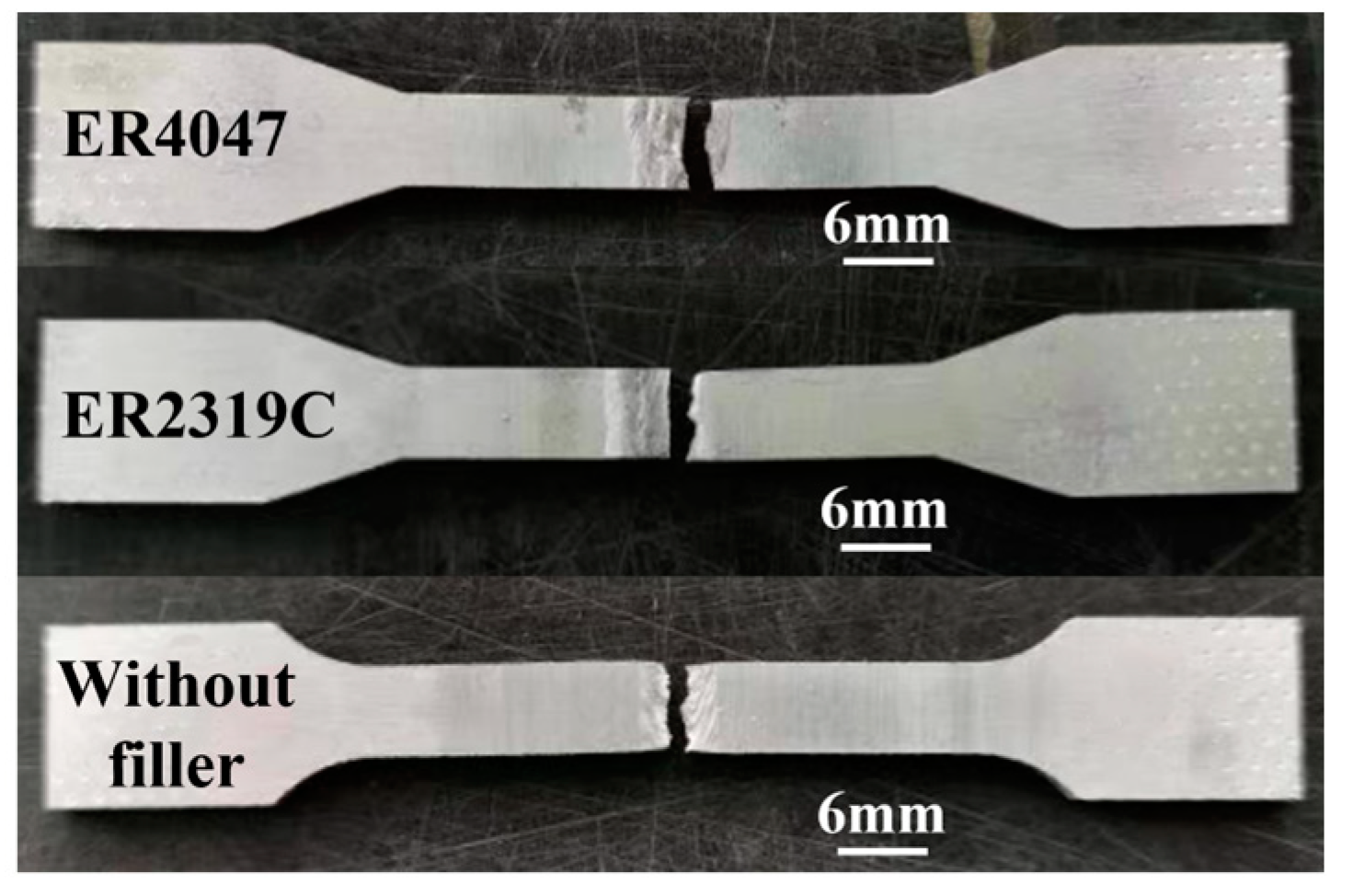

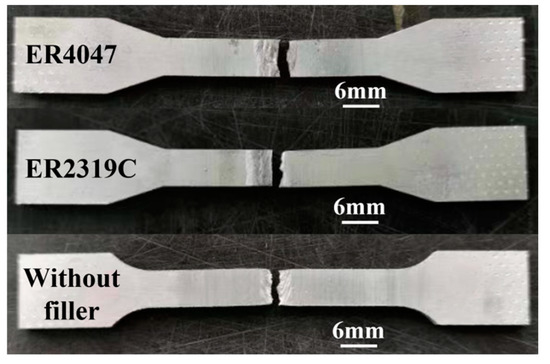

In order to characterize the mechanical properties of the joints, tensile tests of the weld joints are carried out at room temperature, and the tensile specimen and the fracture position are shown in Figure 8. According to the GB/T 2651-2008 standard, the length, width, and thickness of the dog-bone tensile specimen are 32 mm, 6 mm, and 2 mm, respectively [33]. Three tensile tests are performed for each case to reduce experimental error. The fracture occurred along the fusion line close to the HAZ. It is due to the burning of alloying elements, pores, and cracks produced in the welding process.

Figure 8.

Macroscopic morphology of the welded joints.

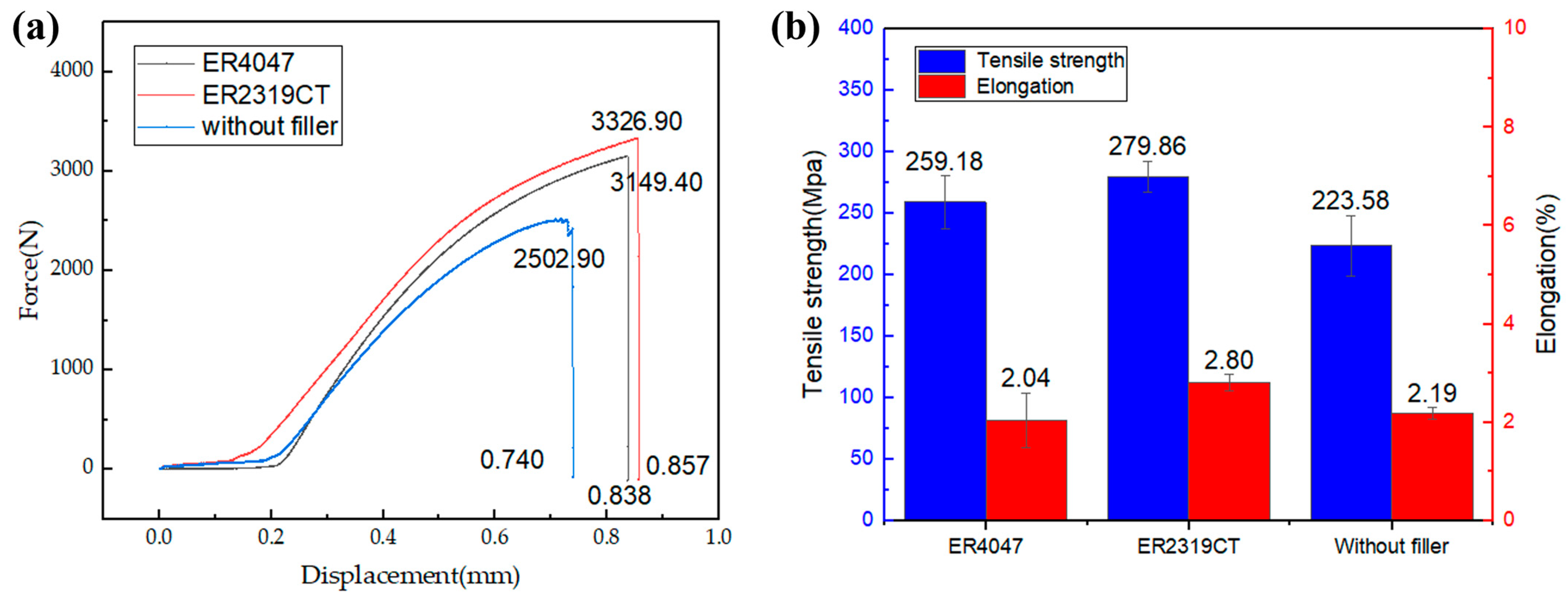

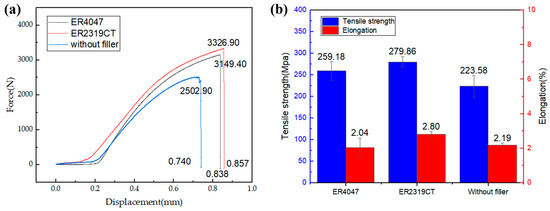

The tensile curve of displacement and force of different cases are shown in Figure 9a. The displacements of the three tensile specimens are 0.740 mm, 0.838 mm, and 0.857 mm, respectively. The corresponding forces are 2502.9 N, 3149.4 N, and 3326.9 N, respectively. The results of tensile strength and elongation are shown in Figure 9b. The average tensile strengths of the weld joints obtained by ER4047 and ER2319CT are 259.18 MPa and 279.86 MPa, respectively; the latter is slightly larger than the former. The elongation of the weld joints by ER2319CT is 2.8%, which is higher than that by ER4047. ER4047 filler wire with high Si content can reduce the seam’s hot-cracking sensitivity, generating a strengthening phase to improve the strength of the joint. However, the Cu element supplied by ER2319CT filler wire produces phase θ and phase T1, which prevent the dislocation from moving and enhance the strength of the WS. Moreover, with fine grains and uniform microstructure, the WS has better tensile strength and elongation. Compared to laser welding without filler wire, the tensile properties of laser welding with filler wire are improved, but it is still lower than that of the BM. Further study is needed to improve the mechanical properties of lithium aluminum alloy.

Figure 9.

Tensile strength and elongation of the weld joints: (a) the tensile curve of displacement and force; (b) tensile strength and Elongation rate of the weld joints.

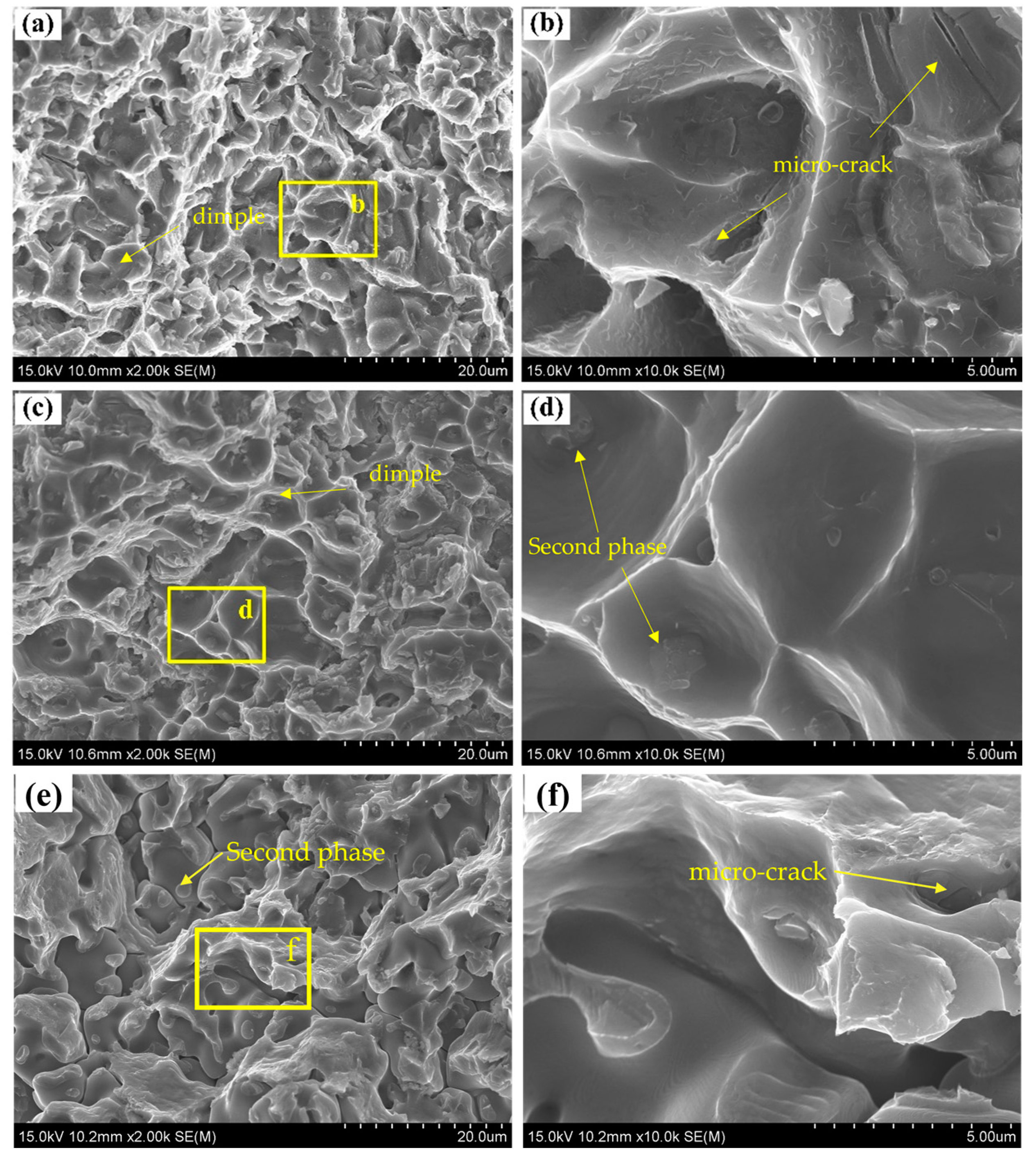

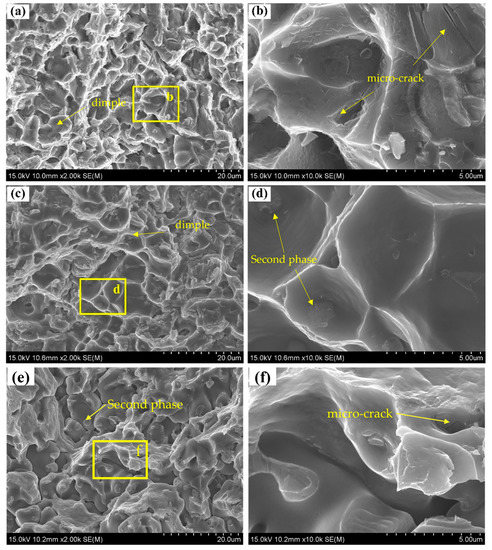

The fractures of the WS are observed under 10,000 × SEM to investigate the fracture mechanism by different filler wires. Figure 10a shows a typical fracture morphology in the ductile fracture of the WS by ER4047. With the increase in external force, micropores are generated after plastic deformation. The micropores progressively increase, then form a plurality of uneven pits on the fracture, which are called dimples [30]. In Figure 10b, there are many micro-cracks (which expand quickly during the tensile process) in the fracture that reduce the tensile performance of the WS.

Figure 10.

Tensile fracture morphology: (a,b) ER4047; (c,d) ER2319CT; (e,f) without filler.

As shown in Figure 10c,d, larger dimples are observed in the fracture of the WS by ER2319CT. Furthermore, some second-phase particles are observed at the bottom of the dimples, revealing the fracture to be intergranular-dominated and to undergo extensive plastic deformation before the final fracture. In Figure 10e,f, the fracture surface appeared to be both a ductile intergranular and brittle transgranular fracture, indicating that the fracture belonged to mixed-mode fracture features. Limited plastic deformation is created in the WS by laser welding without filler. In general, after adding filler wires, the fracture morphology of the WS changes from a quasi-cleavage fracture to a ductile fracture.

4. Conclusions

In summary, the effects of different filler wires on the weld microstructure, the burning behavior of Li and Cu elements, and the tensile properties of 2195 Al-Li alloy WSs are investigated. The primary conclusions are summarized as follows:

(1) From the fusion boundary to the center of the WS, the crystal morphologies vary in the sequence of fine equiaxed grains, columnar dendrite, and equiaxed dendrite. The equiaxed grains and columnar dendrite disappear in certain areas of the WS by ER2319CT.

(2) The precipitated phases are distributed along the grain boundaries in the EQZ and CZ, suggesting the segregation of alloying elements to the grain boundary. Precipitated phases are phase T or binary silicon eutectic in the WS by ER4047, and phase θ, T1 or T2 in the WS by ER2319CT.

(3) The burning loss rate of Li in the WS by ER4047 is higher than that by ER2319CT. The burning loss rates of Li and Cu in the WS by filler wires are higher than those by laser welding without filler.

(4) Compared to laser welding without filler wire, the tensile properties of laser welding with filler wire are improved. The tensile strength and the elongation rate of the WS by ER2319CT are higher than that by ER4047. After adding filler wires, the fracture morphology of the WS changes from a quasi-cleavage fracture to a ductile fracture.

Author Contributions

Conceptualization, B.X. and X.Z.; methodology, X.Z.; study design, B.X., Z.Z. and G.J.; investigation, B.X.; resources, X.Z. and G.J.; data curation, B.X. and Z.Z.; writing—original draft preparation, B.X. and Z.Z.; writing—review and editing, B.X., J.W. and G.J.; All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Natural Science Foundation of Guangdong Province (2023A1515010960), the Key Laboratory Project of the Chaohu University (kj20zsys03), Key Scientific Research Project of Chaohu University (XLZ 202203).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available.

Conflicts of Interest

The author declares no conflict of interest.

References

- Lavernia, E.J.; Tirumalai, S.; Mohamed, F.A. Strength, deformation, fracture behavior and ductility of aluminium-lithium alloys. J. Mater. Sci. 1990, 25, 1137–1158. [Google Scholar] [CrossRef]

- Steuwer, A.; Dumont, M.; Altenkirch, J.; Birosca, S.; Deschamps, A.; Prangnell, P.B.; Withers, P.J. A combined approach to microstructure mapping of an Al–Li AA2199 friction stir weld. Acta Mater. 2011, 59, 3002–3011. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, S.; Jin, Y.; Chen, Y. Microstructural characterization and mechanical performance of Al–Cu–Li alloy electron beam welded joint. Aerosp. Sci. Technol. 2018, 82–83, 61–69. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Xiao, R. Microstructure and mechanical properties of laser beam welded Al–Li alloy 2060 with Al–Mg filler wire. Mater. Des. 2015, 88, 446–450. [Google Scholar] [CrossRef]

- Xia, H.; Li, L.; Tan, C.; Yang, J.; Li, H.; Song, W.; Zhang, K.; Wang, Q.; Ma, N. In situ SEM study on tensile fractured behavior of Al/steel laser welding-brazing interface. Mater. Des. 2022, 224, 111320. [Google Scholar] [CrossRef]

- Yang, Z.; Zhao, X.; Tao, W.; Jin, C. Effects of keyhole status on melt flow and flow-induced porosity formation during double-sided laser welding of AA6056/AA6156 aluminium alloy T-joint. Opt. Laser Technol. 2019, 109, 39–48. [Google Scholar] [CrossRef]

- Yang, J.; Oliveira, J.; Li, Y.; Tan, C.; Gao, C.; Zhao, Y.; Yu, Z. Laser techniques for dissimilar joining of aluminum alloys to steels: A critical review. J. Mater. Process. Technol. 2022, 301, 117443. [Google Scholar] [CrossRef]

- Shao, Y.; Li, X.; Chen, L.; He, E. Study on Microstructure Formation in Non-autogenous Laser Welded 2A97 Al-Li Alloy. Met. Mater. Trans. B 2021, 52, 1413–1423. [Google Scholar] [CrossRef]

- Xiao, R.; Zhang, X. Problems and issues in laser beam welding of aluminum-lithium alloys. J. Manuf. Process. 2014, 16, 166–175. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Tao, W.; Lei, Z.; Yang, Z.; Nan, T. Influence of Post-Weld Heat Treatments on Microstructure and Mechanical Properties of Laser Beam Welded 2060-T3/2099-T3Al-Li T-Joints. Metals 2019, 9, 1318. [Google Scholar] [CrossRef]

- Enz, J.; Riekehr, S.; Ventzke, V.; Kashaev, N. Influence of the local chemical composition on the mechanical properties of laser beam welded Al-Li alloys. In Proceedings of the 7th Conference on Laser Assisted Net shape Engineering/ International Conference on Photonic Technologies, Furth, Germany, 3 November 2012. [Google Scholar]

- Han, B.; Tao, W.; Chen, Y.; Chen, Y.; Li, H. Double-sided laser beam welded T-joints for aluminum-lithium alloy aircraft fuselage panels: Effects of filler elements on microstructure and mechanical properties. Opt. Laser Technol. 2017, 93, 99–108. [Google Scholar] [CrossRef]

- Lei, Z.; Bi, S.; Zhang, X.; Li, B. Microstructure and Mechanical Properties of Double-Sided Laser Swing Welding of 2195Al-Li Alloy T-joints. Chin. J. Lasers 2022, 49, 30–39. [Google Scholar]

- Chen, Y.; Sun, S.; Zhang, T.; Zhou, X.; Li, S. Effects of post-weld heat treatment on the microstructure and mechanical properties of laser-welded NiTi/304SS joint with Ni filler. Mater. Sci. Eng. A 2020, 771, 138545. [Google Scholar] [CrossRef]

- Cui, L.; Li, X.; He, D.; Chen, L.; Gong, S. Effect of Nd: YAG laser welding on microstructure and hardness of an Al–Li based alloy. Mater. Charact. 2012, 71, 95–102. [Google Scholar] [CrossRef]

- Yan, J.; Gao, M.; Li, G.; Zhang, C.; Zeng, X.; Jiang, M. Microstructure and mechanical properties of laser-MIG hybrid welding of 1420 Al-Li alloy. Int. J. Adv. Manuf. Technol. 2013, 66, 1467–1473. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, S.; Zhang, T.; Zhou, X.; Li, S. Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting. Mater. Sci. Eng. A 2021, 819, 141507. [Google Scholar]

- Liu, Z.; Liu, P.; Xiang, H.; Huang, Y.; Ma, P.; Chen, Y.; Li, J.; Zhang, R. Effect of Filler Wire on Mechanical Properties, Microstructure and Natural Aging Behavior of 2A55 Al-Li Alloy TIG Welded Joint. Metals 2023, 13, 347. [Google Scholar] [CrossRef]

- Tao, W.; Han, B.; Chen, Y. Microstructural and mechanical characterization of aluminum-lithium alloy 2060 welded by fiber laser. J. Laser Appl. 2016, 28, 1–8. [Google Scholar] [CrossRef]

- Lin, K.; Yang, W.; Lu, J.; Xiao, R. Laser Beam Welding Study of 2198-T851 Aluminum-Lithium Alloy. Chin. J. Lasers 2014, 41, 90–95. [Google Scholar]

- An, N.; Zhang, X.; Wang, Q.; Yang, W.; Xiao, R. Fiber Laser Welding of 2060 Aluminum Lithium Alloy with Filler Wire. Chin. J. Lasers 2014, 41, 100–105. [Google Scholar]

- Yang, W.; Zhang, X.; Xiao, R. Dual-Beam Laser Welding of T-Joint of Aluminum-Lithium Alloy. Chin. J. Lasers 2013, 40, 89–93. [Google Scholar]

- Zhang, X.; Huang, T.; Yang, W.; Xiao, R.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser beam welded AA2060 Al-Li alloy. J. Mater. Process. Technol. 2016, 237, 301–308. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, M.; Jin, X.; Zhang, H.; Mao, C. Study on the Burning Loss of Magnesium in Fiber Laser Welding of an Al-Mg Alloy by Optical Emission Spectroscopy. Int. J. Adv. Manuf. Technol. 2017, 88, 1373–1381. [Google Scholar] [CrossRef]

- Sanchez-Amaya, J.; Delgado, T.; De Damborenea, J.; Lopez, V.; Botana, F. Laser welding of AA 5083 samples by high power diode laser. Sci. Technol. Weld. Join. 2009, 14, 78–86. [Google Scholar] [CrossRef]

- Zhan, X.; Chen, J.; Liu, J.; Wei, Y.H.; Zhou, J.; Meng, Y. Microstructure and Magnesium Burning Loss Behavior of AA6061 Electron Beam Welding joints. Mater. Des. 2016, 99, 449–458. [Google Scholar] [CrossRef]

- Molian, P.; Srivatsan, T. Laser-beam Weld Microstructures and Properties of Aluminum-lithium Alloy 2090. Mater. Lett. 1990, 9, 245–251. [Google Scholar] [CrossRef]

- Xu, F.; Chen, L.; Gong, S.; Li, X.; Yang, J. Microstructure and Mechanical Properties of Al-Li Alloy by Laser Welding with Filler Wire. Rare Met. Mat. Eng. 2011, 40, 1775–1779. [Google Scholar]

- Zhao, T. Hardness distribution and aging response associated with precipitation behavior in a laser pressure welded Al–Li alloy 2198. Mater. Sci. Eng. A 2021, 808, 140946. [Google Scholar] [CrossRef]

- Yang, M.; Lu, J.; Wang, H.; Liu, Y.; Yang, H.; Zhang, W. Effect of the laser power on the microstructure and mechanical properties of the laser-MIG hybrid welding joints of the 2195 Al–Li alloy. Sci. Technol. Weld. Join. 2021, 26, 75–83. [Google Scholar] [CrossRef]

- Han, B.; Chen, Y.; Tao, W.; Lei, Z.; Li, H.; Guo, S.; Li, P. Nano-indentation investigation on the local softening of equiaxed zone in 2060-T8/2099-T83 aluminum-lithium alloys T-joints welded by double-sided laser beam welding. J. Alloy Compd. 2018, 756, 145–162. [Google Scholar] [CrossRef]

- Liu, T.; Zhao, Y.; Kang, Y.; Zhan, X. Effect of micro morphology in different zones on mechanical properties of 2060 Al-Li alloy laser welded joints. J. Manuf. Process. 2020, 50, 336–344. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).