Compressive Rheological Behavior and Microstructure Evolution of a Semi-Solid CuSn10P1 Alloy at Medium Temperature and Low Strain

Abstract

:1. Introduction

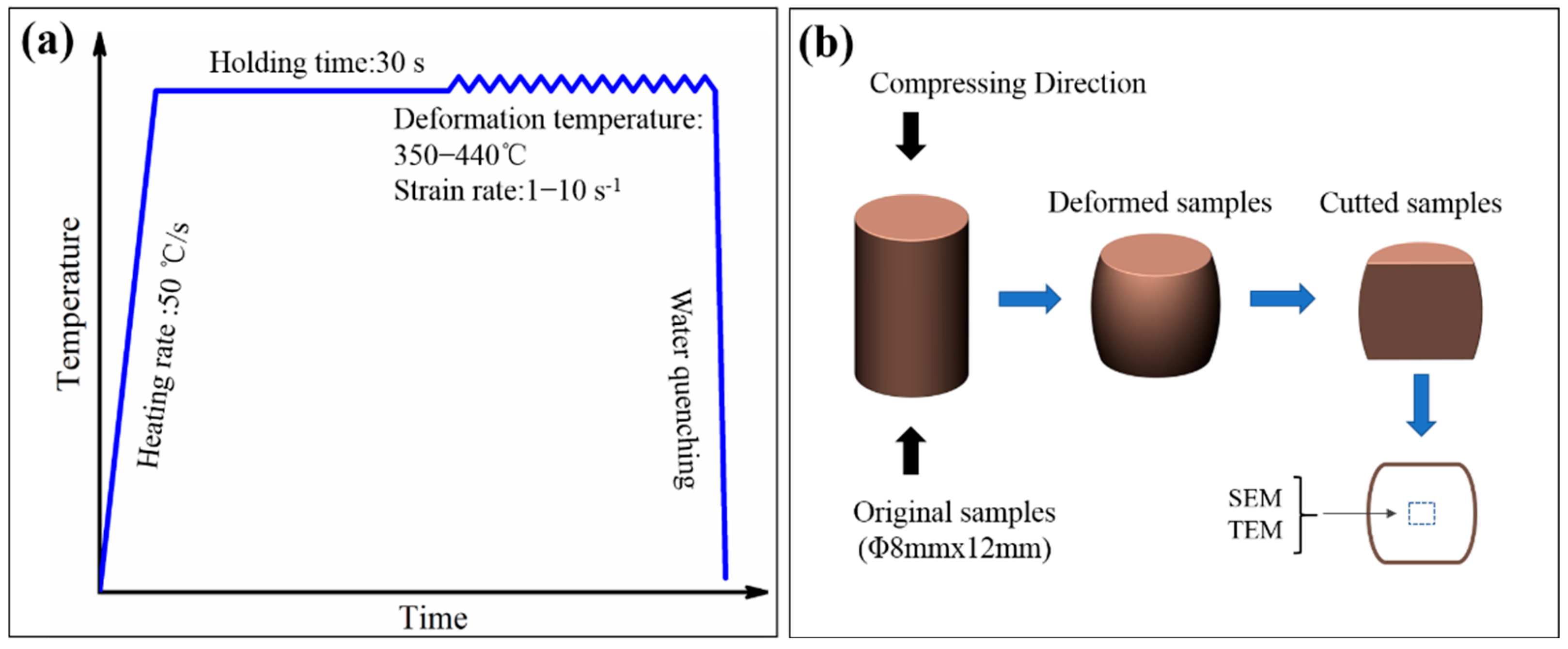

2. Materials and Methods

3. Results

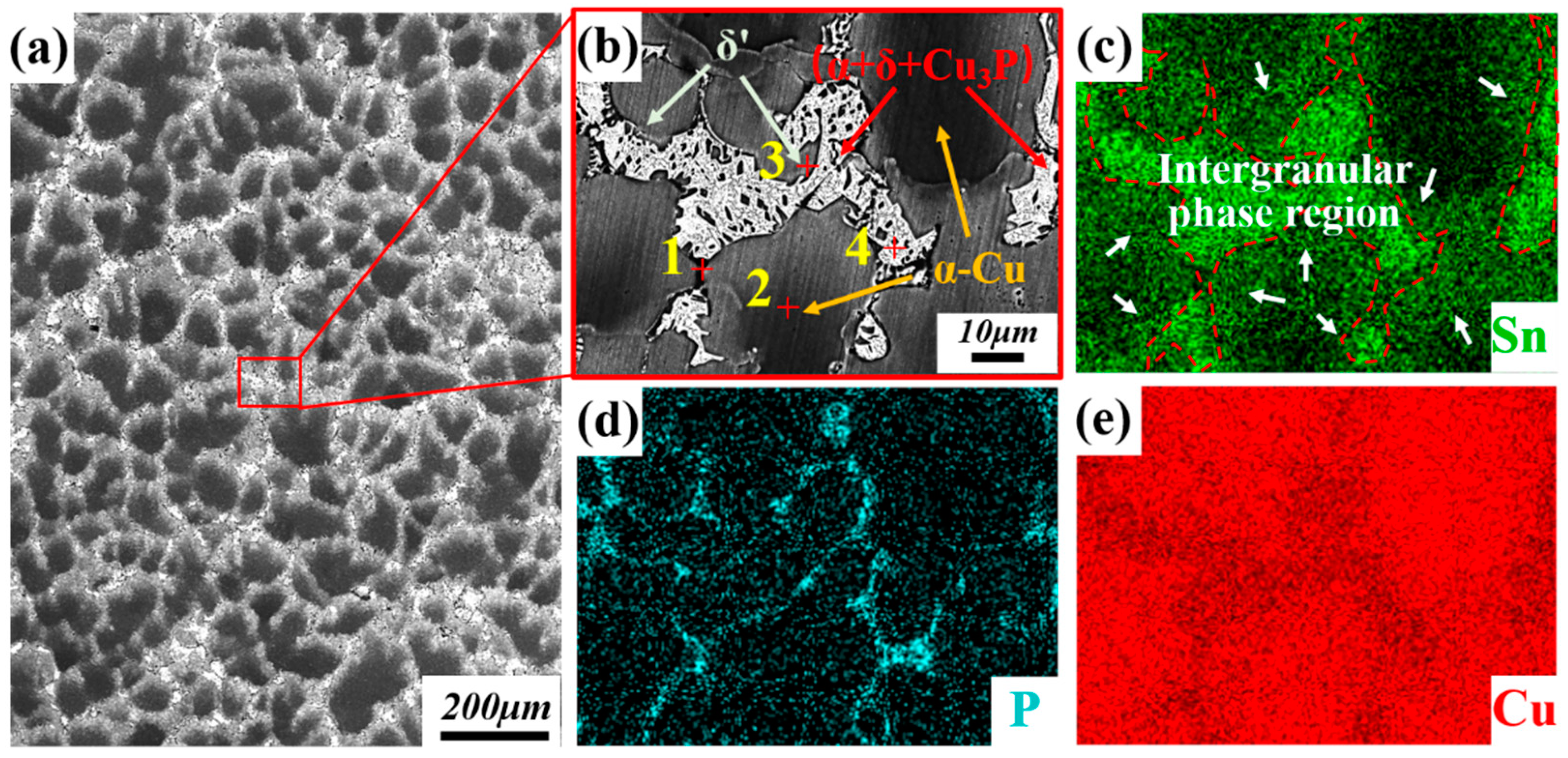

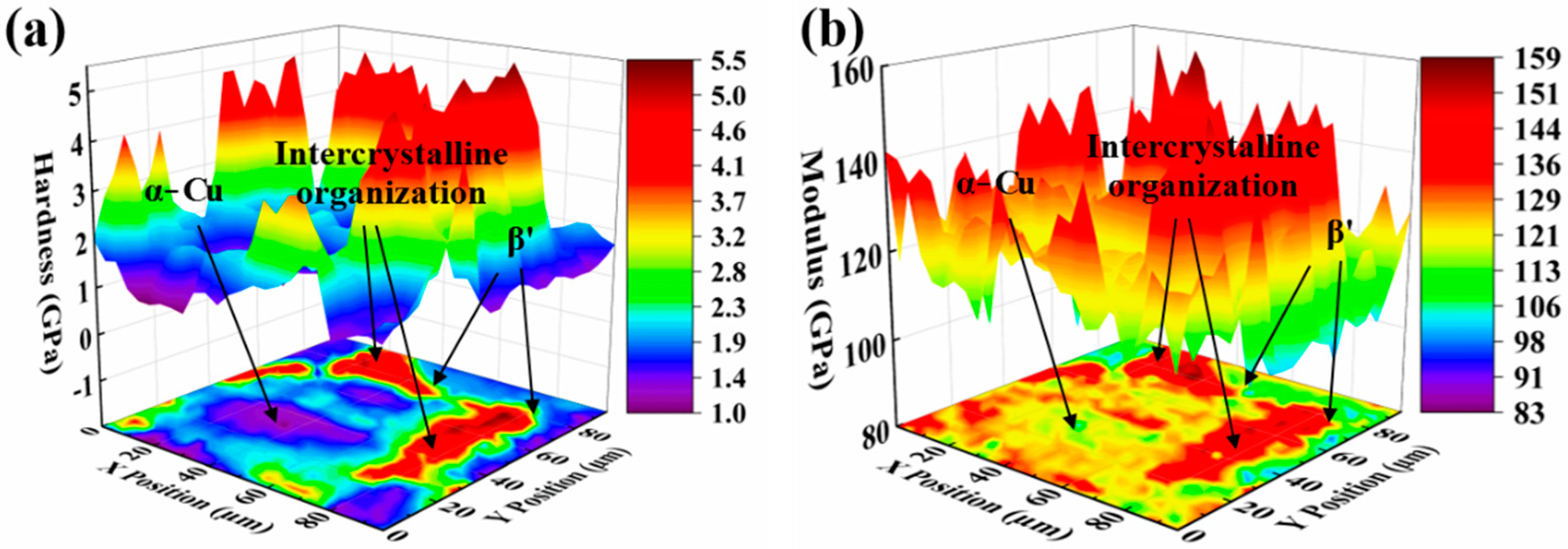

3.1. Initial State of Alloy

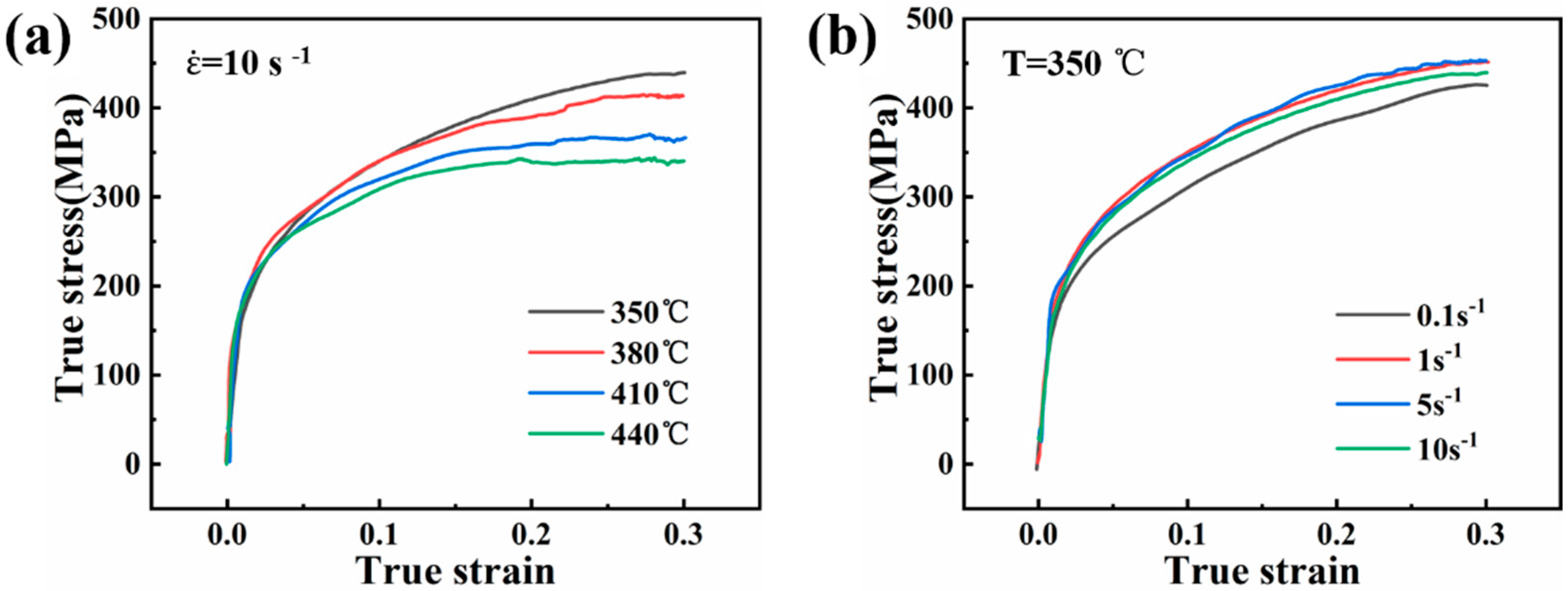

3.2. Effect of Deformation Parameters on True Stress-True Strain Curve

3.3. Microstructure Evolution of Alloy at Medium Temperature Deformation

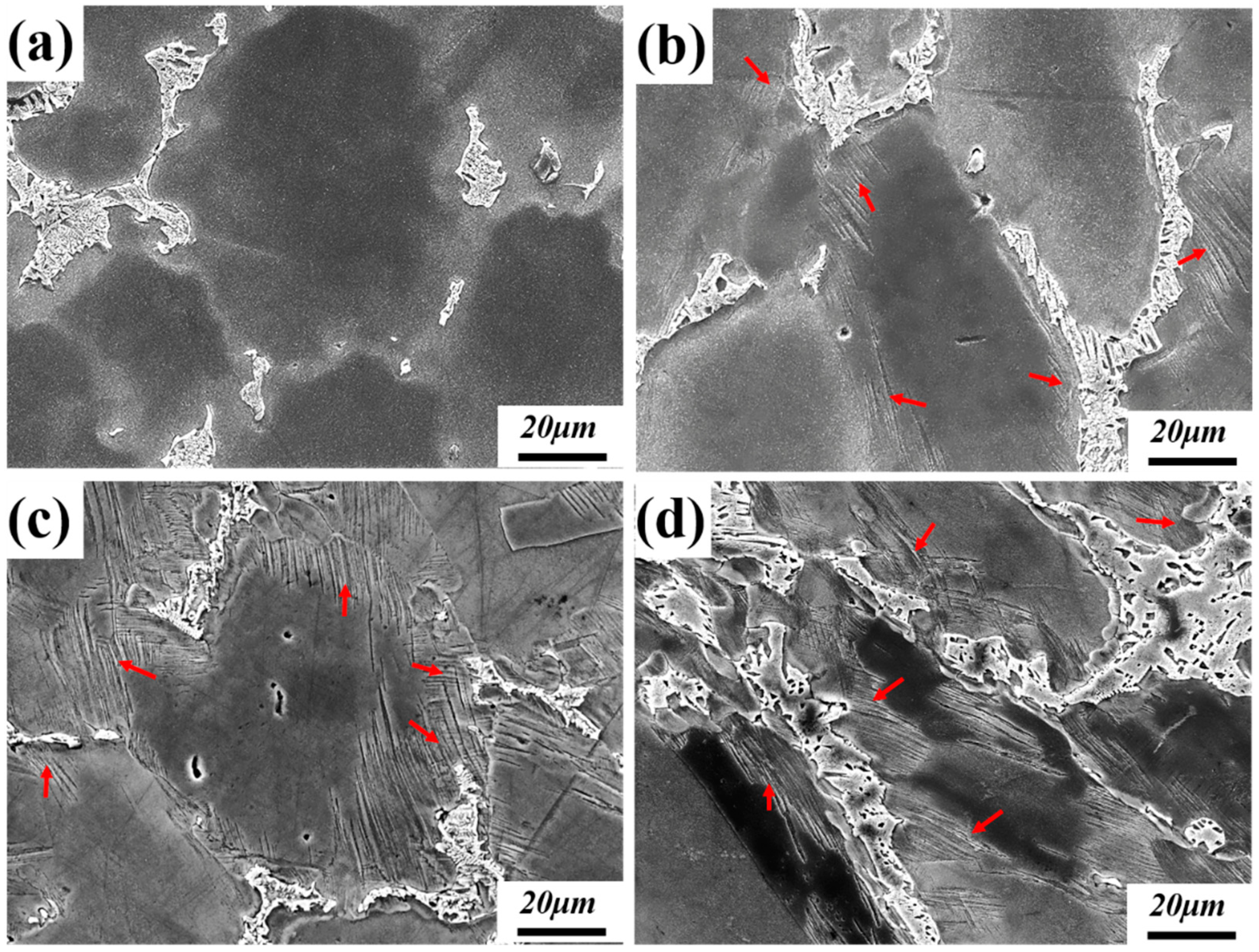

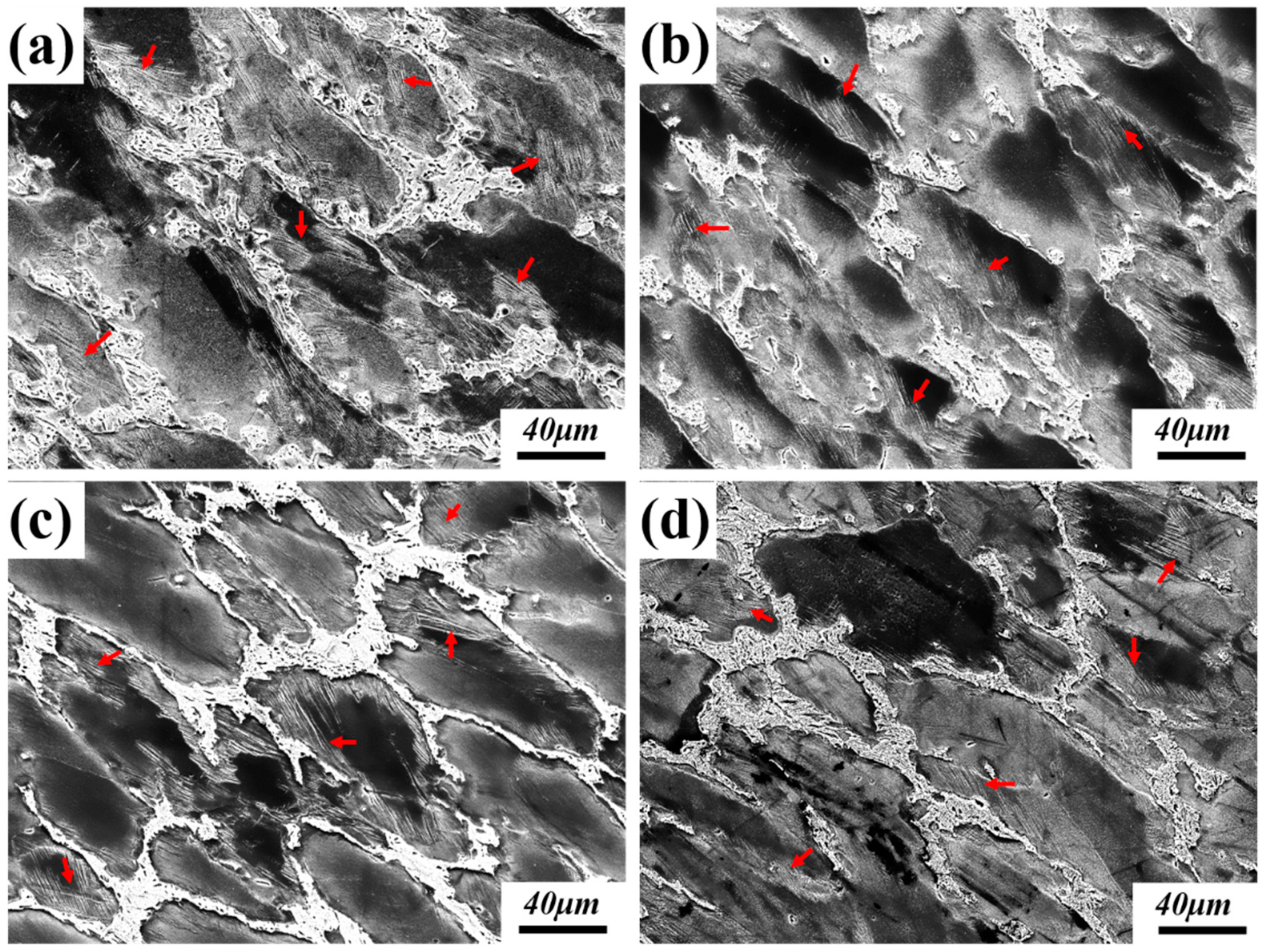

3.3.1. Impact of Variables

3.3.2. Effect of Deformation Temperature

3.3.3. Effect of Strain Rate

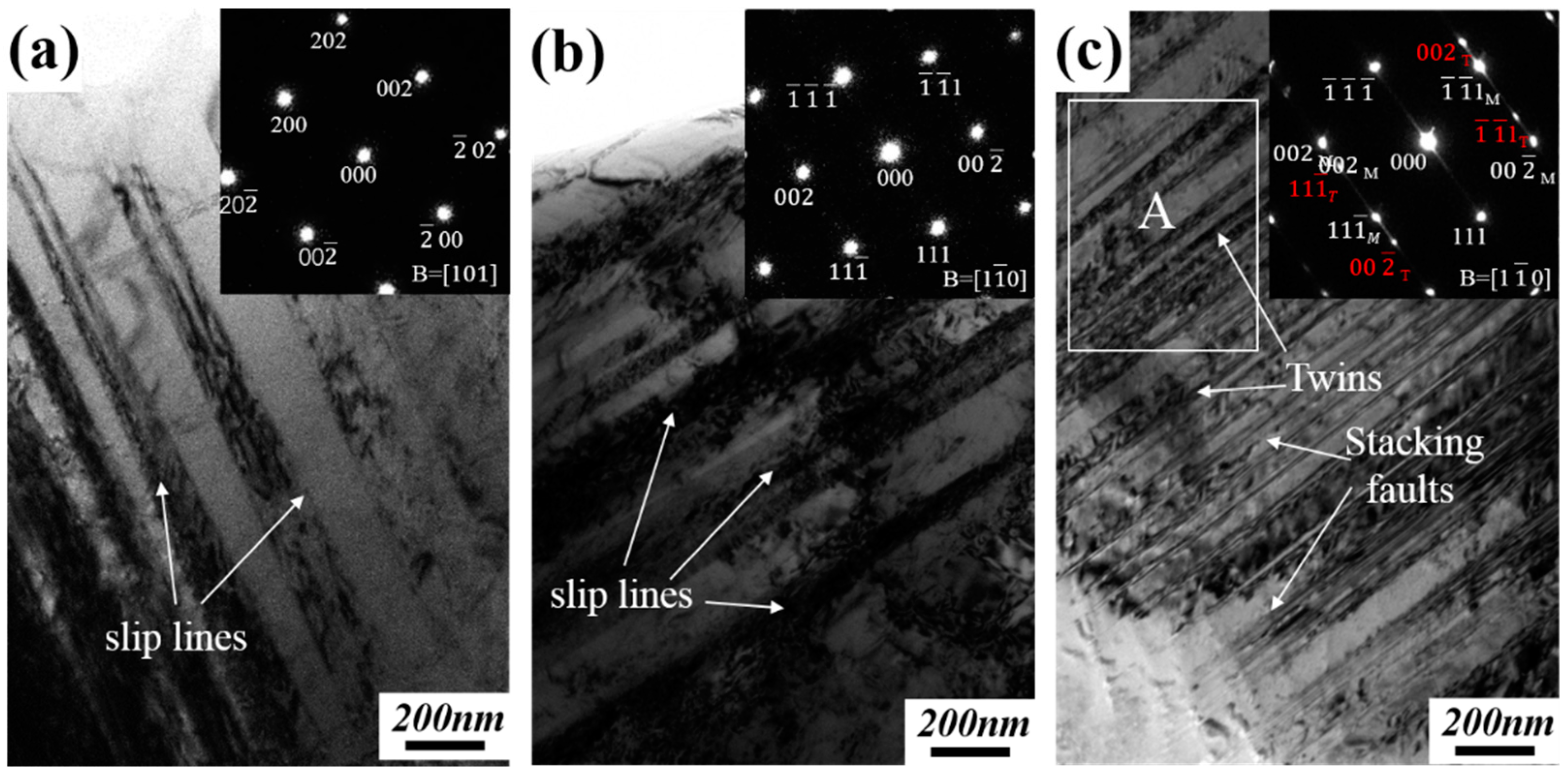

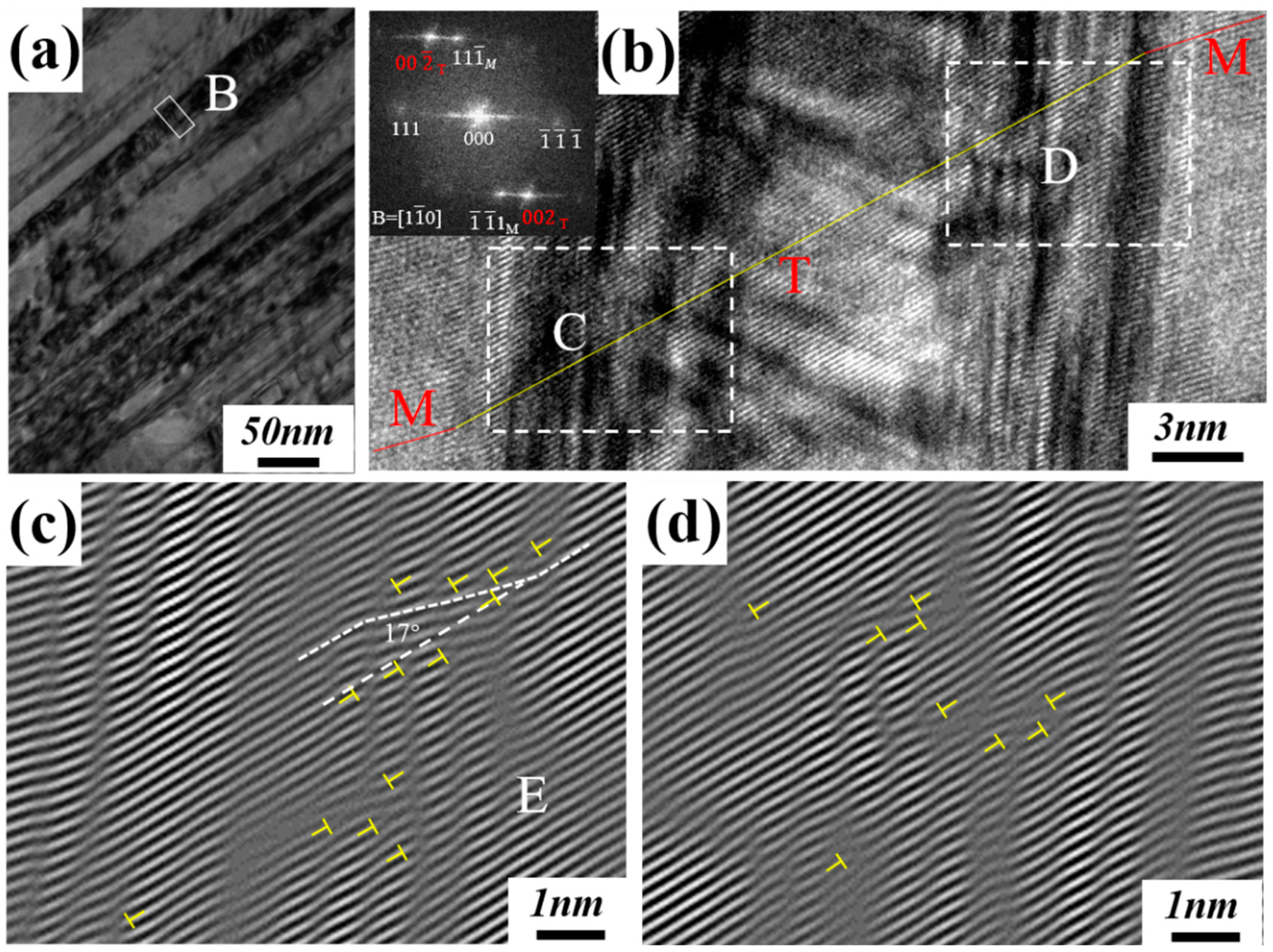

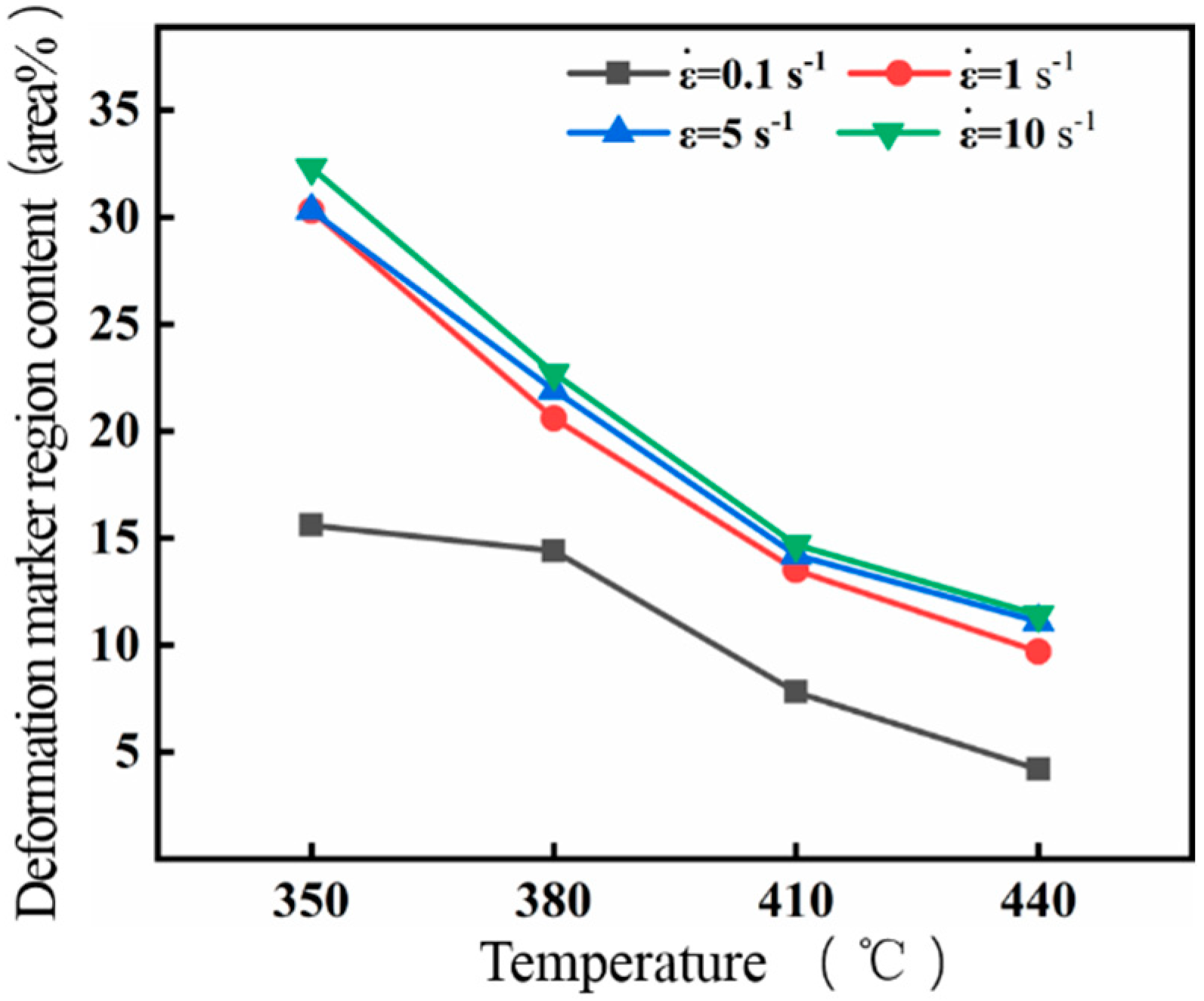

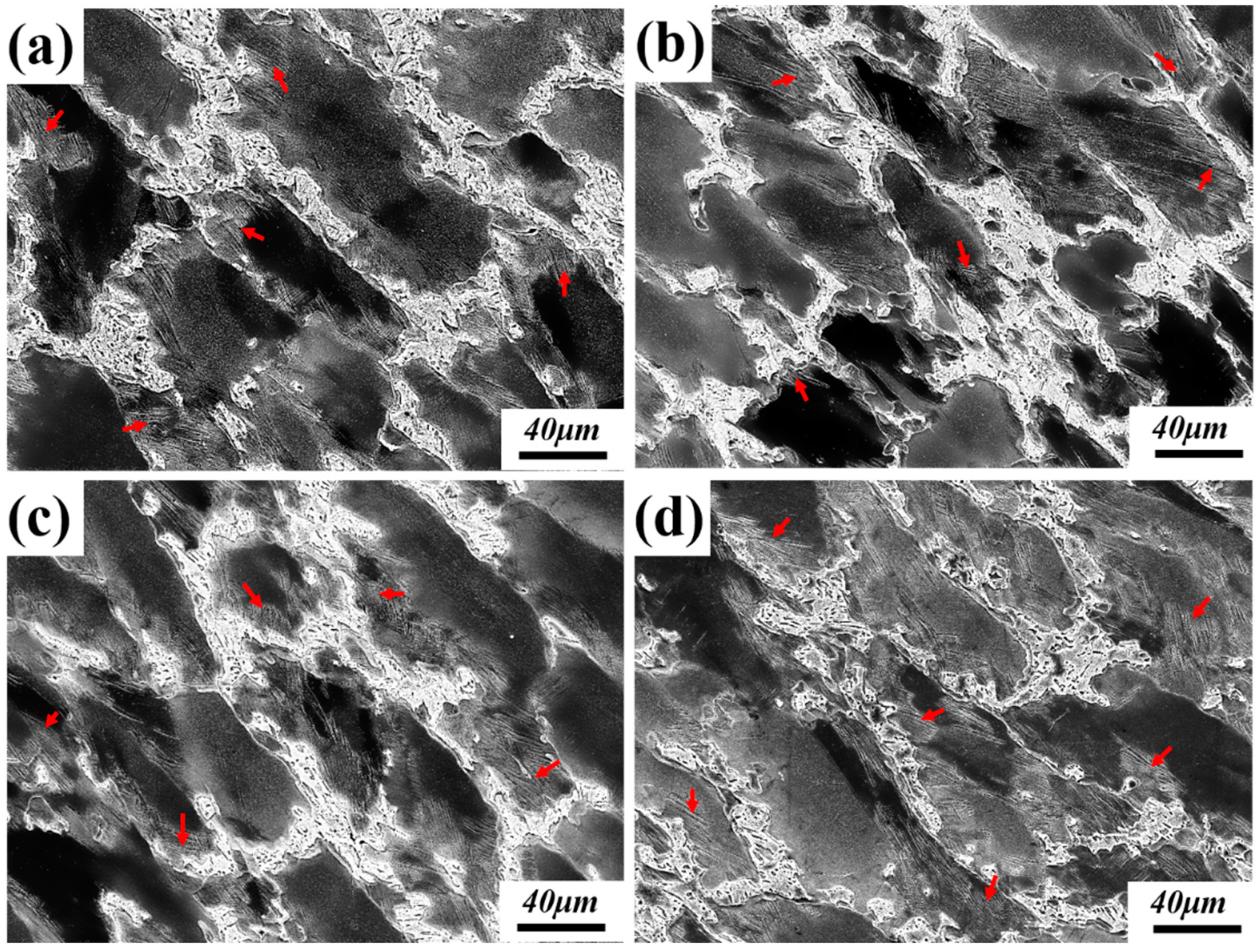

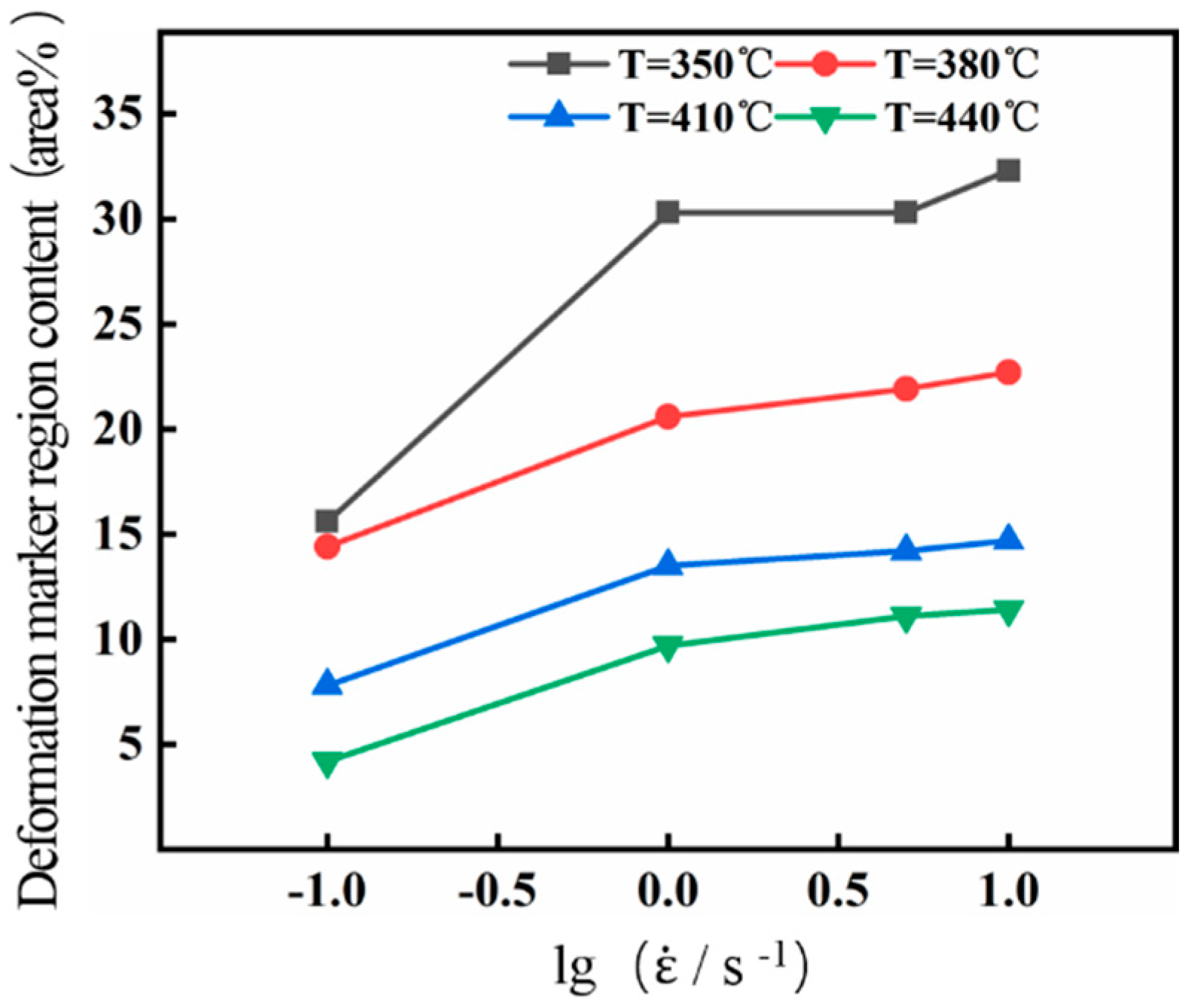

3.4. Evolution of Deformation Markers

4. Conclusions

- The microstructure of the initial semi-solid CuSn10P1 alloy is nearly spherical, with a high-tin solid-solution circle around its primary α-Cu phase. The intergranular phase of the alloy is a brittle phase with high tin content composed of (α-Cu+δ-Cu41Sn11+Cu3P) phases. The microhardness and elastic modulus of the different phases in the alloy are intergranular phase > β’ > incipient α-Cu phase.

- At a certain strain rate, the rheological stress of the alloy decreases with the increase in deformation temperature; at higher strain rates, the rheological stress of the alloy is not sensitive to the strain rate due to the softening effect of the rise in temperature.

- The simulation results show that the alloy is deformed in unidirectional compression, where the stress in the core is the largest, called the stress concentration zone. As the degree of deformation increases, the maximum value of the equivalent stress also increases gradually.

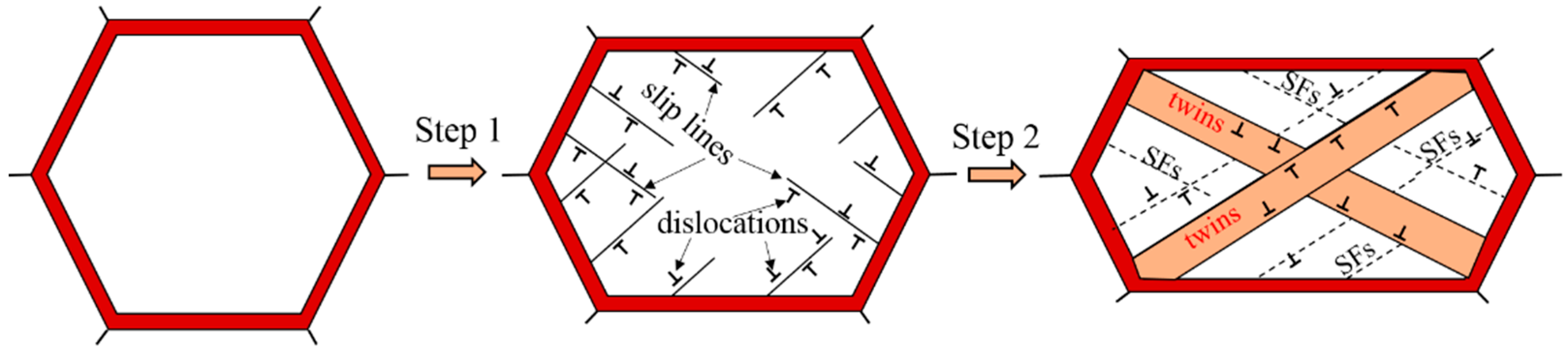

- With the increase in strain, filamentary deformation marks appear. The deformation marks are composed of dislocations, stacking faults and twins. The number of deformation marks increases with the increase in strain and strain rate and decreases with the increase in temperature.

- Twin crystals may be preferentially nucleated at the crystal plane where the slip lines exist in advance, and a large amount of dislocation plugging is found near the twin boundary.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jie, S.; Ting-yun, M.; Hui-xuan, Q.; Qi-song, L. Electrochemical behaviors and electrodeposition of single-phase Cu-Sn alloy coating in [BMIM]Cl. Electrochim. Acta 2019, 297, 87–93. [Google Scholar] [CrossRef]

- Gohar, G.A.; Manzoor, T.; Ahmad, A.; Raza, H.; Farooq, A.; Karim, I.; Iftikhar, W.; Umar, M.; Asad, F. Synthesis and investigate the properties of Cu–Al–Ni alloys with Ag addition using powder metallurgy technique. J. Alloys Compd. 2020, 817, 153281. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Jiang, K.; Yang, S. Electro-deposition preparation of self-standing Cu-Sn alloy anode electrode for lithium ion battery. J. Alloys Compd. 2019, 775, 818–825. [Google Scholar] [CrossRef]

- Mu, D.; Nan, P.H.; Wang, J.Y.; Song, G.D.; Luo, W.G. Metallurgical and Chemical Characterization of Bronze Remains Found at the Houhe Site in Shanxi Province, China. JOM 2015, 67, 1659–1666. [Google Scholar] [CrossRef]

- Kohler, F.; Germond, L.; Wagnière, J.D.; Rappaz, M. Peritectic solidification of Cu–Sn alloys: Microstructural competition at low speed. Acta Mater. 2009, 57, 56–68. [Google Scholar] [CrossRef] [Green Version]

- Hui, J.; Feng, Z.; Fan, W.; Yuan, X. The influence of power spinning and annealing temperature on microstructures and properties of Cu-Sn alloy. Mater. Charact. 2018, 144, 611–620. [Google Scholar] [CrossRef]

- So, S.; Kim, K.; Lee, S.; Yu, Y.; Lim, H.; Oh, M. Effects of Sn content and hot deformation on microstructure and mechanical properties of binary high Sn content Cu–Sn alloys. Mater. Sci. Eng. A 2020, 796, 140054. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, R.; Li, L.; Xiao, H.; Jiang, Y. Microstructure and Properties of Semi-solid ZCuSn10P1 Alloy Processed with an Enclosed Cooling Slope Channel. Metals 2018, 8, 275. [Google Scholar] [CrossRef] [Green Version]

- Fan, W.; Hui, J.; XinFeng, Z.; Gao, W.; Xue, C. Effect of different annealing temperatures on microstructures and properties of Cu–Sn Alloy. Mater. Res. Express 2018, 5, 106520. [Google Scholar] [CrossRef]

- Scudino, S.; Unterdörfer, C.; Prashanth, K.G.; Attar, H.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J. Additive manufacturing of Cu–10Sn bronze. Mater. Lett. 2015, 156, 202–204. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, R.; Li, L.; Xiao, H.; Jiang, Y. Microstructures formation, distribution of tin element and properties of CuSn10P1 alloy during controlled by melt cooling. Mater. Res. Express 2018, 5, 66517. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Geng, B.; Wang, Q.; Zhou, R.; Wu, X.; Xiao, H. Microstructure characteristics and strengthening mechanism of semisolid CuSn10P1 alloys. Mater. Charact. 2021, 172, 110898. [Google Scholar] [CrossRef]

- Yang, J.Y.; Kim, G.H.; Kim, W.J. High-strain-rate solute drag creep in a Cu-22%Sn alloy (Cu17Sn3) with near peritectic composition. Mater. Charact. 2020, 164, 110325. [Google Scholar] [CrossRef]

- Hui, J.; Feng, Z.; Fan, W.; Wang, P. Microstructures and mechanical properties of Cu-Sn alloy subjected to elevated-temperature heat deformation. Mater. Res. Express 2018, 5, 46511. [Google Scholar] [CrossRef]

- Yang, J.Y.; Kim, W.J. The effect of addition of Sn to copper on hot compressive deformation mechanisms, microstructural evolution and processing maps. J. Mater. Res. Technol. 2020, 9, 749–761. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, R.; Li, Y.; Geng, B. Characteristics of dynamic recrystallization in semi-solid CuSn10P1 alloy during hot deformation. Mater. Charact. 2020, 159, 109996. [Google Scholar] [CrossRef]

- Hui, J.; Feng, Z.; Xue, C.; Gao, W. Effects of hot compression on distribution of Σ3n boundary and mechanical properties in Cu–Sn alloy. J. Mater. Sci. 2018, 53, 15308–15318. [Google Scholar] [CrossRef]

- McDonald, D.T.; Humphreys, J.F.; Bate, P.S.; Brough, I. Dynamic Recrystallization in Copper and Copper-Tin Alloys. Mater. Sci. Forum 2007, 558–559, 449–456. [Google Scholar] [CrossRef]

- Cram, D.G.; Fang, X.Y.; Zurob, H.S.; Bréchet, Y.J.M.; Hutchinson, C.R. The effect of solute on discontinuous dynamic recrystallization. Acta Mater. 2012, 60, 6390–6404. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, R.; Guan, J.; Wang, C. The deformation compatibility and recrystallisation behaviour of the alloy CuSn10P1. Mater. Charact. 2021, 174, 110940. [Google Scholar] [CrossRef]

- Li, X.; Ivas, T.; Spierings, A.B.; Wegener, K.; Leinenbach, C. Phase and microstructure formation in rapidly solidified Cu-Sn and Cu-Sn-Ti alloys. J. Alloys Compd. 2018, 735, 1374–1382. [Google Scholar] [CrossRef]

- Valloton, J.; Wagnière, J.D.; Rappaz, M. Competition of the primary and peritectic phases in hypoperitectic Cu–Sn alloys solidified at low speed in a diffusive regime. Acta Mater. 2012, 60, 3840–3848. [Google Scholar] [CrossRef] [Green Version]

- Bao, Y.W.; Wang, W.; Zhou, Y.C. Investigation of the relationship between elastic modulus and hardness based on depth-sensing indentation measurements. Acta Mater. 2004, 52, 5397–5404. [Google Scholar] [CrossRef]

- Feaugas, X. On the origin of the tensile flow stress in the stainless steel AISI 316L at 300 K: Back stress and effective stress. Acta Mater. 1999, 47, 3617–3632. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Goetz, R.L.; Semiatin, S.L. The Adiabatic Correction Factor for Deformation Heating During the Uniaxial Compression Test. J. Mater. Eng. Perform. 2001, 10, 710–717. [Google Scholar] [CrossRef]

- Xiao, G.H.; Tao, N.R.; Lu, K. Effects of strain, strain rate and temperature on deformation twinning in a Cu–Zn alloy. Scr. Mater. 2008, 59, 975–978. [Google Scholar] [CrossRef]

- Brasche, F.; Wang, J.; Timokhina, I.; Haase, C.; Lapovok, R.; Molodov, D.A. Mechanical twinning and texture evolution during asymmetric warm rolling of a high manganese steel. Mater. Sci. Eng. A 2019, 764, 138183. [Google Scholar] [CrossRef]

- Xuefeng, X.; Tayyeb, A.; Lin, W.; Huanwu, C.; Zhe, Z.; Zixuan, N.; Xiaopin, L.; Anjin, L.; Binbin, Z.; Xingwang, C. Research on dynamic compression properties and deformation mechanism of Ti6321 titanium alloy. J. Mater. Res. Technol. 2020, 9, 11509–11516. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Ma, H. Evolution of Microstructure, Texture, and Mechanical Properties of As-Extruded ND/ZK60 Composite during Hot Compression Deformation. Metals 2020, 10, 1191. [Google Scholar] [CrossRef]

- Xu, D.S.; Wang, H.; Yang, R.; Veyssière, P. Point defect formation by dislocation reactions in TiAl. IOP Conf. Ser. Mater. Sci. Eng. 2009, 3, 12024. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; McCabe, R.J.; Tomé, C.N. Effect of microstructure on the nucleation of deformation twins in polycrystalline high-purity magnesium: A multi-scale modeling study. J. Mech. Phys. Solids 2011, 59, 988–1003. [Google Scholar] [CrossRef]

- Meyers, M.A.; Vöhringer, O.; Lubarda, V.A. The onset of twinning in metals: A constitutive description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

| Elementel | Points | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Cu | 98.8 | 94.4 | 75.3 | 82.8 |

| Sn | 1.2 | 6.5 | 1.2 | 17.2 |

| P | 0 | 0 | 23.5 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Zhou, R.; Xiong, W.; He, Z.; Liu, T.; Li, Y. Compressive Rheological Behavior and Microstructure Evolution of a Semi-Solid CuSn10P1 Alloy at Medium Temperature and Low Strain. Metals 2022, 12, 143. https://doi.org/10.3390/met12010143

Liu Z, Zhou R, Xiong W, He Z, Liu T, Li Y. Compressive Rheological Behavior and Microstructure Evolution of a Semi-Solid CuSn10P1 Alloy at Medium Temperature and Low Strain. Metals. 2022; 12(1):143. https://doi.org/10.3390/met12010143

Chicago/Turabian StyleLiu, Zhangxing, Rongfeng Zhou, Wentao Xiong, Zilong He, Tao Liu, and Yongkun Li. 2022. "Compressive Rheological Behavior and Microstructure Evolution of a Semi-Solid CuSn10P1 Alloy at Medium Temperature and Low Strain" Metals 12, no. 1: 143. https://doi.org/10.3390/met12010143

APA StyleLiu, Z., Zhou, R., Xiong, W., He, Z., Liu, T., & Li, Y. (2022). Compressive Rheological Behavior and Microstructure Evolution of a Semi-Solid CuSn10P1 Alloy at Medium Temperature and Low Strain. Metals, 12(1), 143. https://doi.org/10.3390/met12010143