The Influence of Multiple Pass Submerged Friction Stir Processing on the Microstructure and Mechanical Properties of the FSWed AA6082-AA8011 Joints

Abstract

1. Introduction

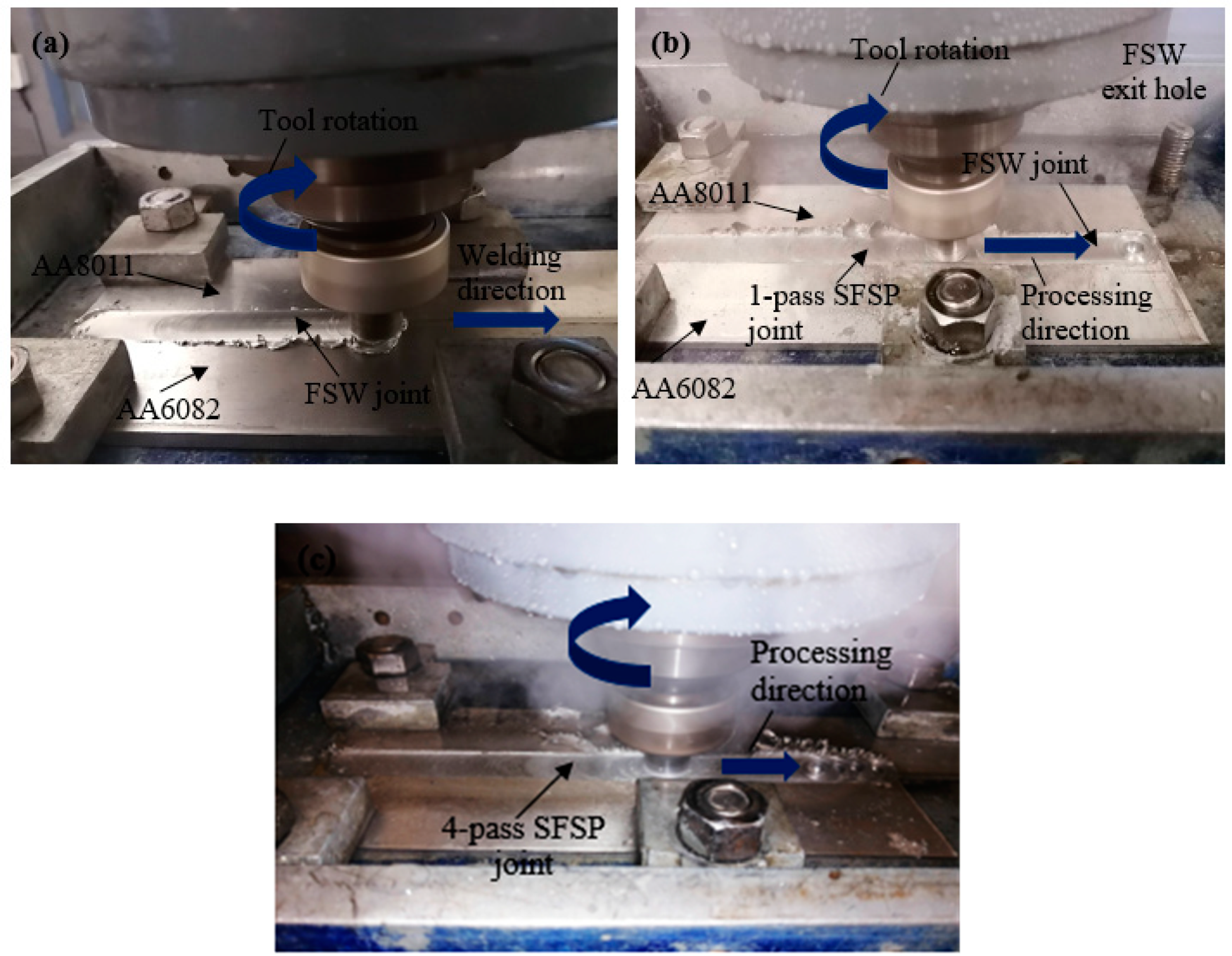

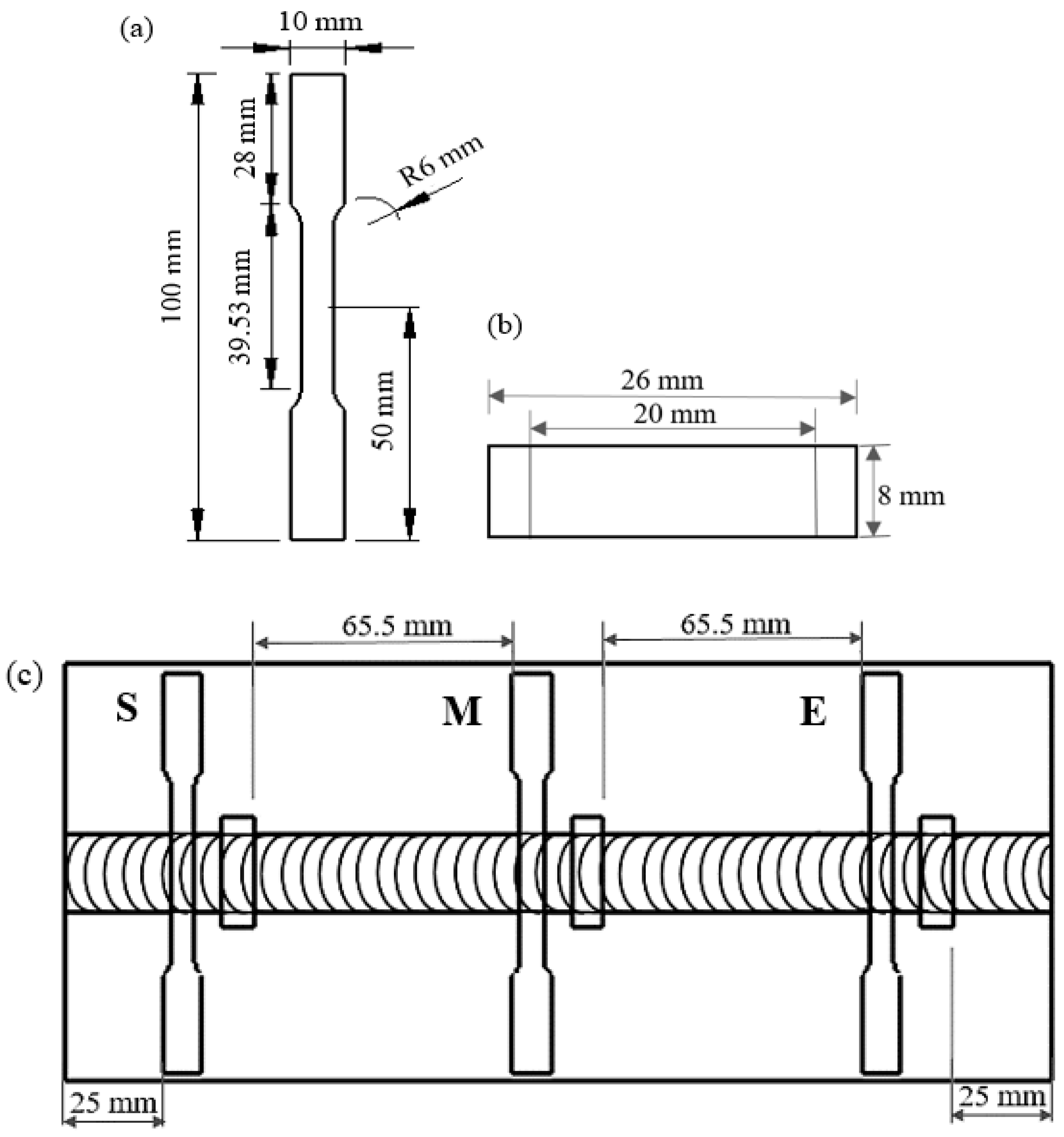

2. Materials and Methods

3. Results and Discussions

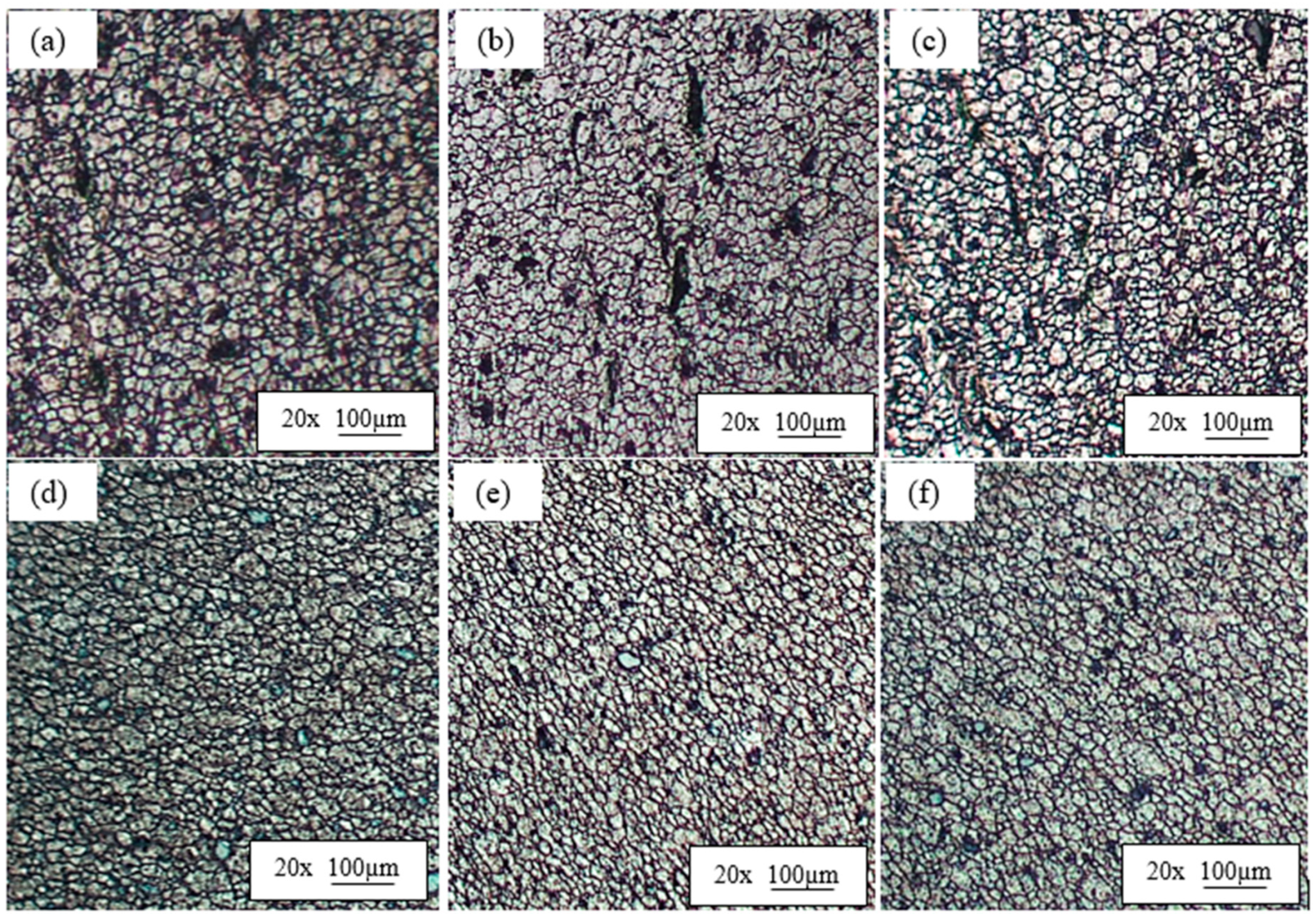

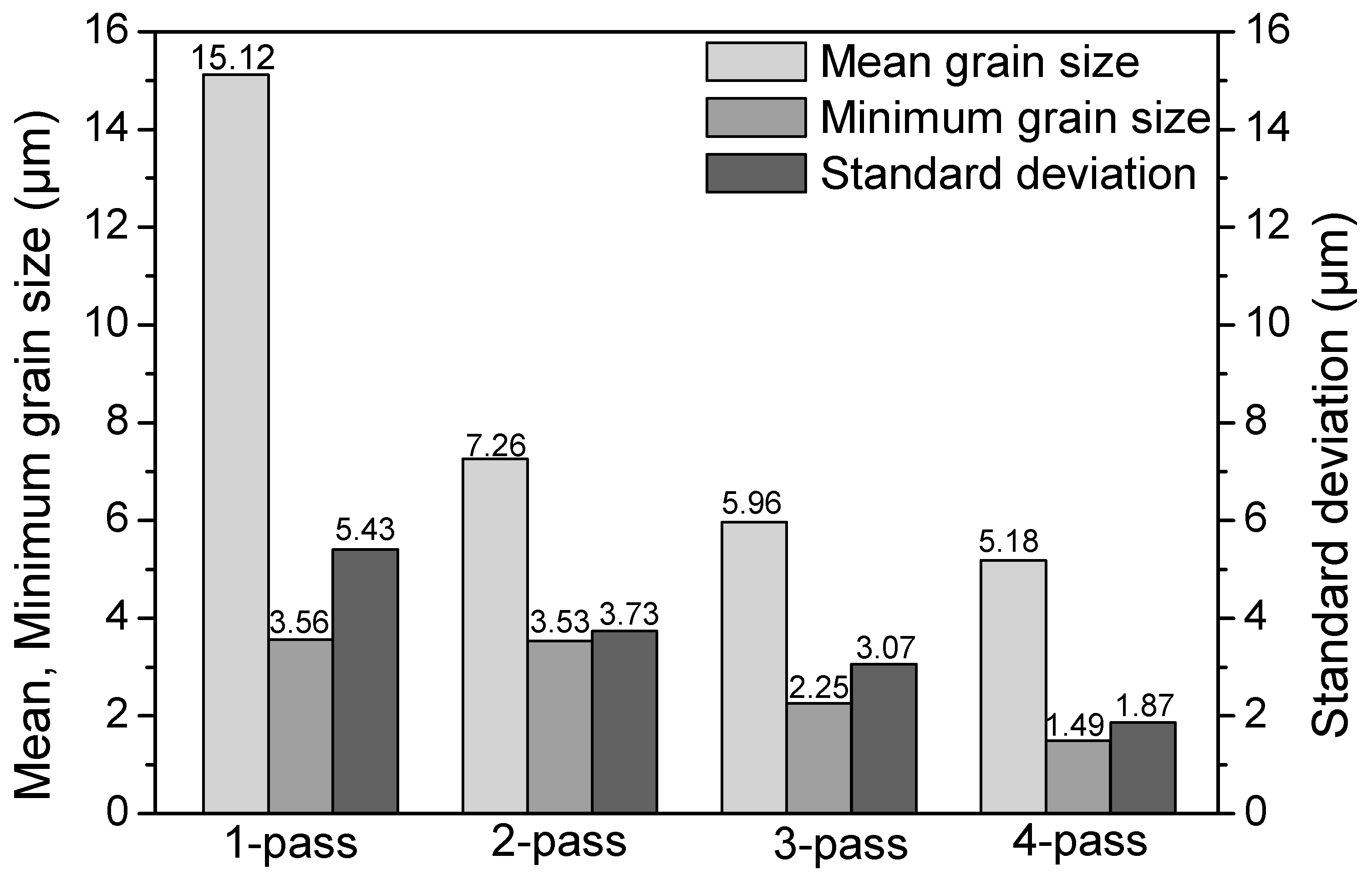

3.1. Microstructural Analysis

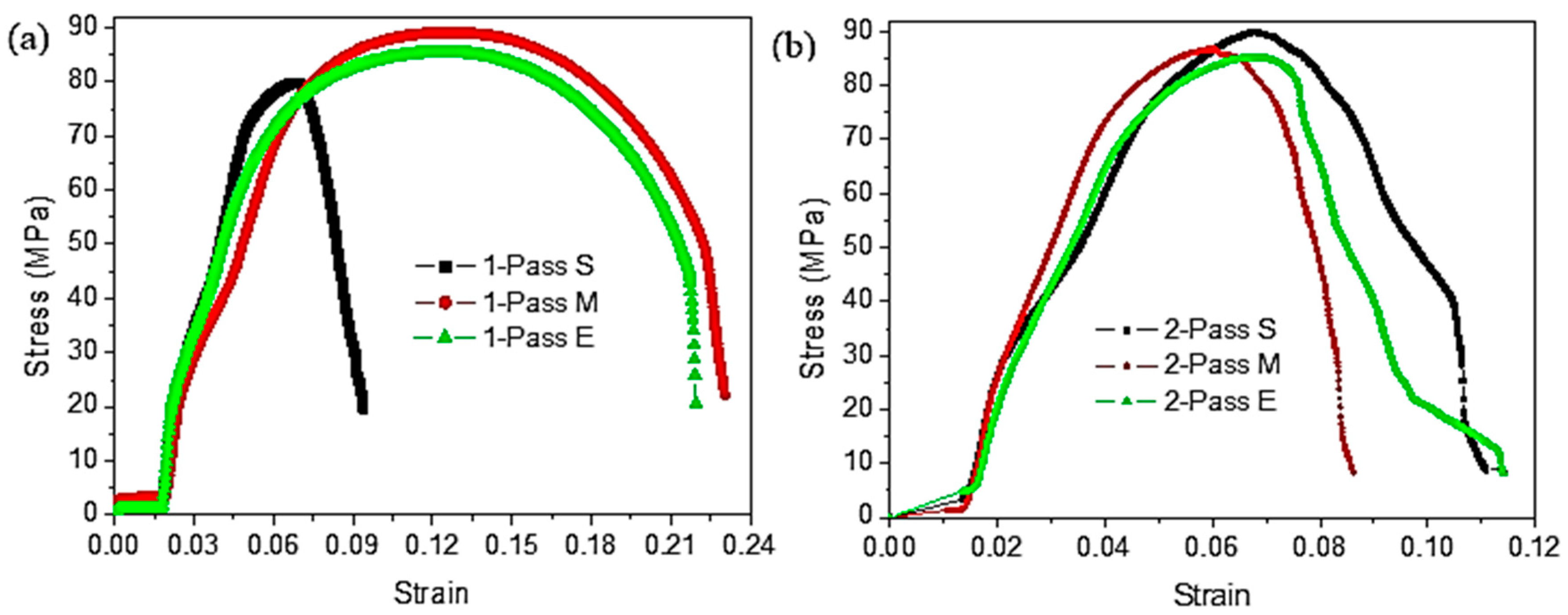

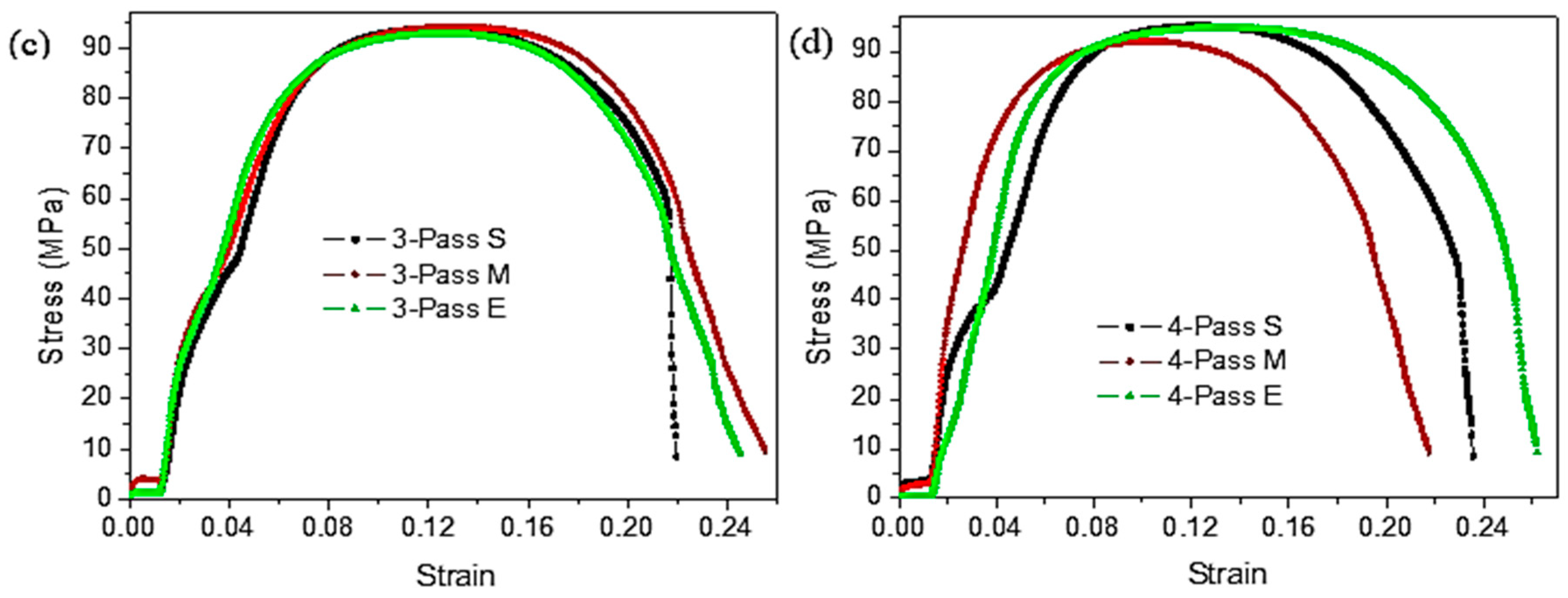

3.2. Tensile Properties

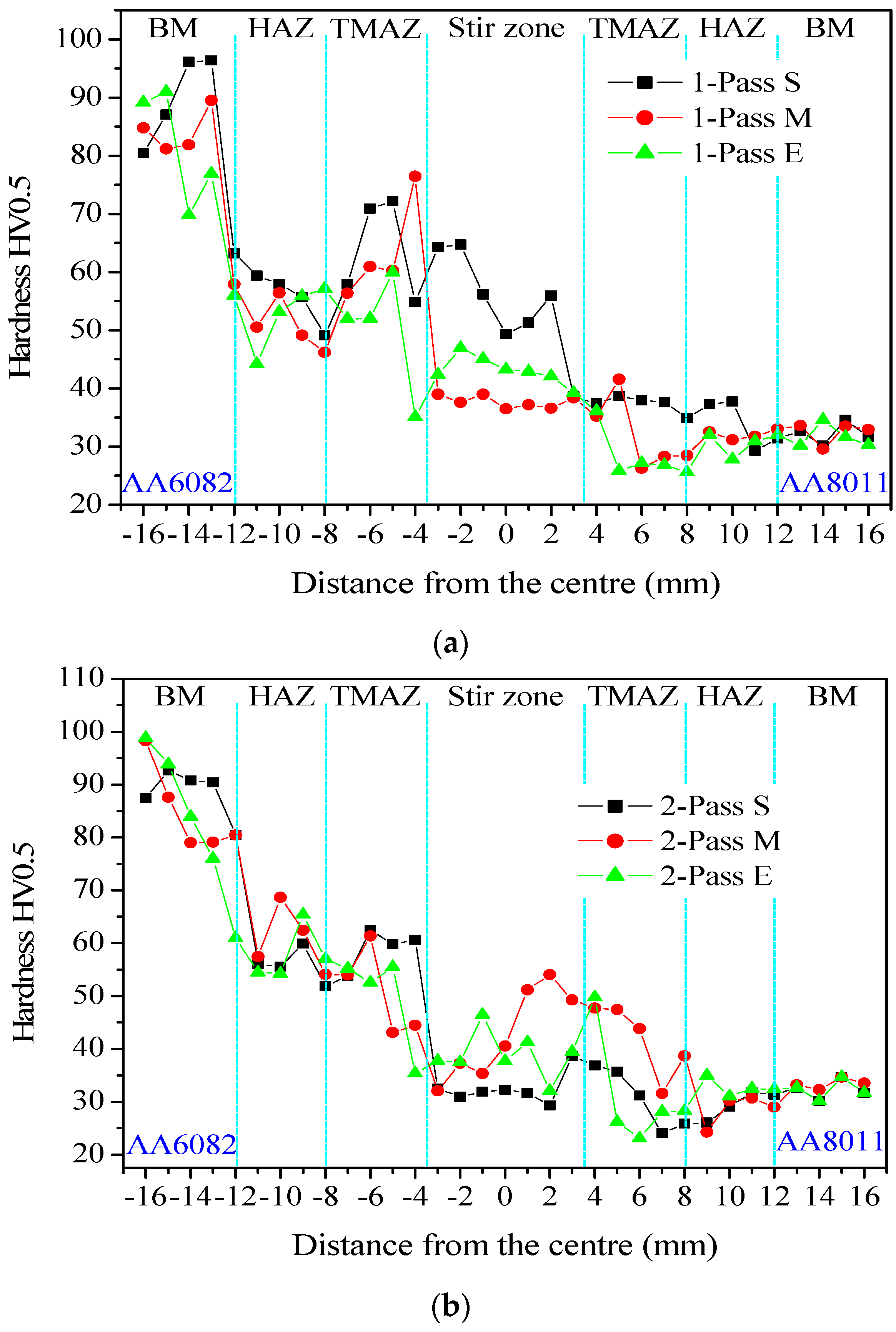

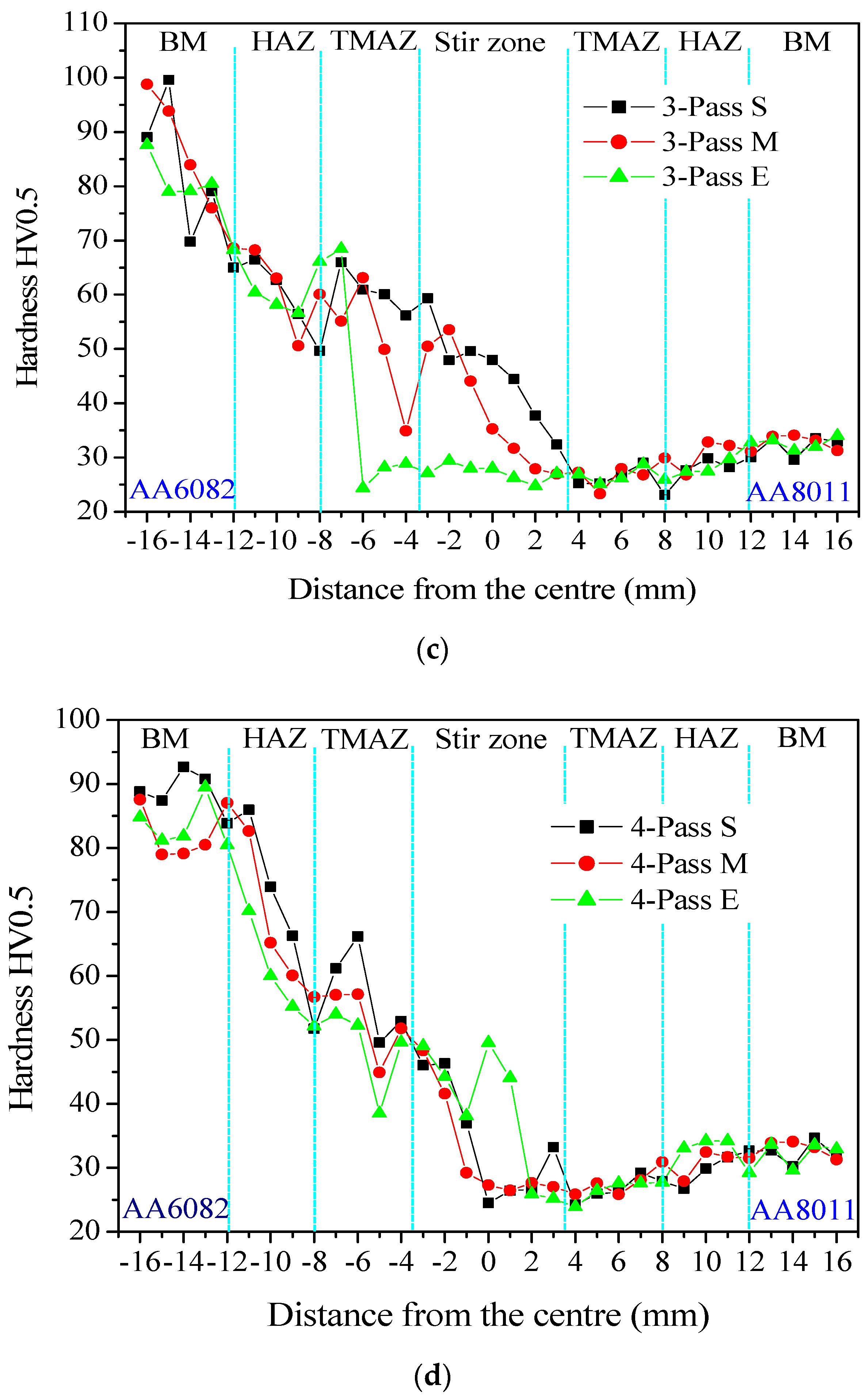

3.3. Hardness

4. Conclusions

- There was no particular trend in the microstructure and mechanical positioning when looking at the specimen positioning in all the passes. The mean grain sizes were refined from 15.12 to 5.42 µm. The minimum mean grain sizes were refined from 3.54 to 1.49 µm and the standard deviation from 5.43 to 1.87 µm.

- The ultimate tensile strength was improved from 84.96 to 94.77 MPa. The four-pass SFSPed specimens were found to have more ductile properties compared to the one-pass SFSPed specimen. The percentage elongation of the joints was improved from 18.13% to 24.13%. The fracture surface morphologies revealed a ductile failure mode.

- The hardness of the stir zones in all the passes was found to be higher compared to the AA8011 base material but lower than the AA6082 one. The maximum stir zone hardness of 75 HV was observed on the one-pass SFSP joints.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barmouz, M.; Zall, V.; Pashazadeh, H. Mechanical and Microstructural Characterization of Hybrid Cu-SiC-Zn Composites Fabricated Via Friction Stir Processing. Mater. Res. 2016, 19, 1292–1298. [Google Scholar] [CrossRef]

- Mishra, R.; Ma, Z. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Peng, J.; Zhang, Z.; Liu, Z.; Li, Y.; Guo, P.; Zhou, W.; Wu, Y. The effect of texture and grain size on improving the mechanical properties of Mg-Al-Zn alloys by friction stir processing. Sci. Rep. 2018, 8, 1–9. [Google Scholar] [CrossRef]

- Mabuwa, S.; Msomi, V. Effect of Friction Stir Processing on Gas Tungsten Arc-Welded and Friction Stir-Welded 5083-H111 Aluminium Alloy Joints. Adv. Mater. Sci. Eng. 2019, 2019, 3510236. [Google Scholar] [CrossRef]

- Narayana, Y.; Sivanandam, A.; Sharma, V. Fabrication of Al5083/B4C surface composite by friction stir processing and its tribological characterization. J. Mater. Res. Technol. 2015, 4, 398–410. [Google Scholar]

- Orozco-Caballero, A.; Ruano, O.A.; Rauch, E.F.; Carreño, F. Severe friction stir processing of an Al-Zn-Mg-Cu alloy: Misorientation and its influence on superplasticity. Mater. Des. 2018, 137, 128–139. [Google Scholar] [CrossRef]

- Ma, Z.; Mishra, R.S.; Mahoney, M.; Grimes, R. High strain rate superplasticity in friction stir processed Al–Mg–Zr alloy. Mater. Sci. Eng. A 2003, 351, 148–153. [Google Scholar] [CrossRef]

- Mohan, A.; Yuan, W.; Mishra, R.S. High strain rate superplasticity in friction stir processed ultrafine grained Mg-Al-Zn alloys. Mater. Sci. Eng. USA 2013, 562, 69–76. [Google Scholar] [CrossRef]

- Sharma, V.; Singla, Y.K.; Gupta, Y.; Raghuwanshi, J. Post-processing of metal matrix composites by friction stir processing. AIP Conf. Proc. 1953, 2018, 090062. [Google Scholar]

- Das, H.; Mondal, M.; Hong, S.-T.; Chun, D.-M.; Han, H. Joining and fabrication of metal matrix composites by friction stir welding/processing. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 151–172. [Google Scholar] [CrossRef]

- Kurtyka, P.; Rylko, N.; Tokarski, T.; Wójcicka, A.; Pietras, A. Cast aluminium matrix composites modified with using FSP process—Changing of the structure and mechanical properties. Compos. Struct. 2015, 133, 959–967. [Google Scholar] [CrossRef]

- Reddy, G.M.; Rao, K.S. Enhancement of wear and corrosion resistance of cast A356 aluminium alloy using friction stir processing. Trans. Indian Inst. Met. 2010, 63, 793–798. [Google Scholar] [CrossRef]

- Darras, B.M.; Kishta, E.E. Submerged friction stir processing of AZ31 Magnesium alloy. Mater. Des. 2013, 47, 133–137. [Google Scholar] [CrossRef]

- Chai, F.; Zhang, D.; Li, Y.; Zhang, W. High strain rate superplasticity of a fine-grained AZ91 magnesium alloy prepared by submerged friction stir processing. Mater. Sci. Eng. A 2013, 568, 40–48. [Google Scholar] [CrossRef]

- Liu, H.J.; Feng, X.L. Effect of post-processing heat treatment on microstructure and microhardness of water-submerged friction stir processed 2219-T6 aluminum alloy. Mater. Des. 2013, 47, 101–105. [Google Scholar] [CrossRef]

- Feng, X.; Liu, H.; Lippold, J.C. Microstructure characterization of the stir zone of submerged friction stir processed aluminum alloy 2219. Mater. Charact. 2013, 82, 97–102. [Google Scholar] [CrossRef]

- Mabuwa, S.; Msomi, V. The impact of submerged friction stir processing on the friction stir welded dissimilar joints. Mater. Res. Express 2020, 7, 096513. [Google Scholar] [CrossRef]

- Patel, V.; Badheka, V.; Li, W.; Akkireddy, S. Hybrid friction stir processing with active cooling approach to enhance superplastic behavior of AA7075 aluminum alloy. Arch. Civ. Mech. Eng. 2019, 19, 1368–1380. [Google Scholar] [CrossRef]

- Rathinasuriyan, C.; Senthil, V.S. Modelling and optimization of submerged friction stir welding parameters for AA6061-T6 alloy using RSM. Met. Mater. 2016, 54, 297–304. [Google Scholar] [CrossRef][Green Version]

- Wang, J.; Lu, Y.; Zhou, D.; Zhang, Y.; Bai, Z.; Li, X. Effects of cooling condition on microstructural evolution and mechanical properties of friction stir processed 2A14 aluminum alloy. Mater. Res. Express 2019, 6, 126577. [Google Scholar] [CrossRef]

- Chai, F.; Zhang, D.; Li, Y. Microstructures and tensile properties of submerged friction stir processed AZ91 magnesium alloy. J. Magnes. Alloy. 2015, 3, 203–209. [Google Scholar] [CrossRef]

- Huang, G.; Yan, Y.; Wu, J.; Shen, Y.; Gerlich, A. Microstructure and mechanical properties of fine-grained aluminum matrix composite reinforced with nitinol shape memory alloy particulates produced by underwater friction stir processing. J. Alloys Compd. 2019, 786, 257–271. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Maheshwari, S.; Siddiquee, A.N. Influence of multiple-passes on microstructure and mechanical properties of Al-Mg/SiC surface composites fabricated via underwater friction stir processing. Mater. Res. Express 2018, 5, 066511. [Google Scholar] [CrossRef]

- Huang, G.; Wu, J.; Hou, W.; Shen, Y. Microstructure, mechanical properties and strengthening mechanism of titanium particle reinforced aluminum matrix composites produced by submerged friction stir processing. Mater. Sci. Eng. USA 2018, 734, 353–363. [Google Scholar] [CrossRef]

- Satyanarayana, M.; Kumar, A. Effect of heat treatment on AA2014 alloy processed through multi-pass friction stir processing. J. Phys. Conf. Ser. 2019, 1240, 012077. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, B.; Wang, Q.; Ma, Z. In situ Al3Ti and Al2O3 nanoparticles reinforced Al composites produced by friction stir processing in an Al-TiO2 system. Mater. Lett. 2011, 65, 2070–2072. [Google Scholar] [CrossRef]

- Sharifitabar, M.; Sarani, A.; Khorshahian, S.; Afarani, M.S. Fabrication of 5052Al/Al2O3 nanoceramic particle reinforced composite via friction stir processing route. Mater. Des. 2011, 32, 4164–4172. [Google Scholar] [CrossRef]

- Selvaraj, G.; Karthikeyan, T.; Mohanadass, R.; Indhumath, S. Investigation on mechanical properties of welded aluminium joints of aa 8011 using friction stir welding. Int. J. Appl. Eng. Res. 2015, 10, 11095–11100. [Google Scholar]

- Kumar, H.M.A.; Ramana, V.V.; Pawar, M. Experimental Study on Dissimilar Friction Stir welding of Aluminium Alloys (5083-H111 and 6082-T6) to investigate the mechanical properties. IOP Conf. Ser. Mater. Sci. Eng. USA 2018, 330, 012076. [Google Scholar] [CrossRef]

- Mabuwa, S.; Msomi, V. Comparative analysis between normal and submerged friction stir processed friction stir welded dissimilar aluminium alloy joints. J. Mater. Res. Technol. 2020, 9, 9632–9644. [Google Scholar] [CrossRef]

- Eyvazian, A.; Hamouda, A.; Tarlochan, F.; Derazkola, H.A.; Khodabakhshi, F. Simulation and experimental study of underwater dissimilar friction-stir welding between aluminium and steel. J. Mater. Res. Technol. 2020, 9, 3767–3781. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.; Simchi, A.; Kokabi, A. Cryogenic friction-stir processing of ultrafine-grained Al–Mg–TiO2 nanocomposites. Mater. Sci. Eng. USA 2015, 620, 471–482. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Nosko, M.; Gerlich, A. Dynamic restoration and crystallographic texture of a friction-stir processed Al–Mg–SiC surface nanocomposite. Mater. Sci. Technol. 2018, 34, 1773–1791. [Google Scholar] [CrossRef]

- Luo, X.C.; Zhang, D.T.; Cao, G.H.; Qiu, C.; Chen, D.L. Multi-pass submerged friction stir processing of AZ61 magnesium alloy: Strengthening mechanisms and fracture behavior. J. Mater. Sci. 2019, 54, 8640–8654. [Google Scholar] [CrossRef]

- Chandrana, R.; Santhanam, S.K.V. Submerged friction stir welding of 6061-T6 aluminium alloy under different water heads. Mater. Res. 2018, 21, 1–12. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, D.; Zhang, W.; Qiu, C.; Chen, D. Tensile properties of AZ61 magnesium alloy produced by multi-pass friction stir processing: Effect of sample orientation. Mater. Sci. Eng. USA 2018, 725, 398–405. [Google Scholar] [CrossRef]

- Ramesh, K.N.; Pradeep, S.; Pancholi, V. Multipass friction-stir processing and its effect on mechanical properties of aluminum alloy 5086. Metall. Mater. Trans. A 2012, 43, 4311–4319. [Google Scholar] [CrossRef]

- Cavaliere, P.; Squillace, A.; Panella, F.W. Effect of welding parameters on mechanical and microstructural properties of AA6082 joints produced by friction stir welding. J. Mater. Process. Technol. 2008, 200, 364–372. [Google Scholar] [CrossRef]

- Kumar, S.R.; Rao, V.S.; Pranesh, R. Effect of Welding Parameters on Macro and Microstructure of Friction Stir Welded Dissimilar Butt Joints between AA7075-T651 and AA6061-T651 Alloys. Procedia Mater. Sci. 2014, 5, 1726–1735. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng. USA 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Barcellona, A.; Buffa, G.; Fratini, L.; Palmeri, D. On microstructural phenomena occurring in friction stir welding of aluminium alloys. J. Mater. Process. Technol. 2006, 177, 340–343. [Google Scholar] [CrossRef]

- Sameer; Birru, A.K. Mechanical and metallurgical properties of friction stir welded dissimilar joints of AZ91 magnesium alloy and AA 6082-T6 aluminium alloy. J. Magnes. Alloy. 2019, 7, 264–271. [Google Scholar] [CrossRef]

- Niu, P.; Li, W.Y.; Chen, D. Strain hardening behavior and mechanisms of friction stir welded dissimilar joints of aluminum alloys. Mater. Lett. 2018, 231, 68–71. [Google Scholar] [CrossRef]

| Mg | Ti | Zn | Cr | Si | Mn | Fe | Cu | Al | |

|---|---|---|---|---|---|---|---|---|---|

| AA8011–H14 | 0.28 | 0.016 | 0.084 | 0.028 | 0.52 | 0.46 | 0.74 | 0.13 | Bal |

| AA6082–T651 | 0.6–1.2 | - | 0.0–0.1 | 0.0–0.25 | 0.7–1.3 | 0.4–1.0 | 0.0–0.5 | 0.0–0.1 | Bal |

| Tool Traverse Speed (mm/min) | Tool Rotation Speed (rpm) | Tool Tilt Angle (°) | Tool Pin Diameter (mm) | Tool Shoulder (mm) | Tool Pin Length (mm) |

|---|---|---|---|---|---|

| 55 | 1200 | 2 | 7 | 20 | 5.8 |

| Average Grain Size (µm) | Ultimate Tensile Strength (MPa) | Average Elongation (%) | Microhardness (HV) | |

|---|---|---|---|---|

| AA8011–H14 | 51.57 | 94.1 | 40.17 | 33.8 |

| AA6082–T651 | 65.04 | 308 | 25.42 | 92 |

| FSW AA6082–AA8011 | 16.77 (stir zone) | 82.9 | 17.98 | 58 (stir zone) |

| No. of SFSP Passes | Specimen Position | Mean Grain Size (µm) | Standard Deviation (µm) | Minimum Mean Grain Size (µm) |

|---|---|---|---|---|

| 1-pass | S | 15.69 | 6.42 | 3.63 |

| M | 16.51 | 5.52 | 3.74 | |

| E | 13.17 | 4.32 | 3.29 | |

| 2-pass | S | 7.51 | 3.76 | 4.04 |

| M | 7.03 | 3.13 | 3.04 | |

| E | 7.36 | 3.56 | 4.12 | |

| 3-pass | S | 5.61 | 2.12 | 3.26 |

| M | 6.03 | 2.03 | 2.54 | |

| E | 6.36 | 2.61 | 3.36 | |

| 4-pass | S | 5.15 | 1.65 | 1.20 |

| M | 5.03 | 1.78 | 1.86 | |

| E | 5.38 | 2.18 | 1.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mabuwa, S.; Msomi, V. The Influence of Multiple Pass Submerged Friction Stir Processing on the Microstructure and Mechanical Properties of the FSWed AA6082-AA8011 Joints. Metals 2020, 10, 1429. https://doi.org/10.3390/met10111429

Mabuwa S, Msomi V. The Influence of Multiple Pass Submerged Friction Stir Processing on the Microstructure and Mechanical Properties of the FSWed AA6082-AA8011 Joints. Metals. 2020; 10(11):1429. https://doi.org/10.3390/met10111429

Chicago/Turabian StyleMabuwa, Sipokazi, and Velaphi Msomi. 2020. "The Influence of Multiple Pass Submerged Friction Stir Processing on the Microstructure and Mechanical Properties of the FSWed AA6082-AA8011 Joints" Metals 10, no. 11: 1429. https://doi.org/10.3390/met10111429

APA StyleMabuwa, S., & Msomi, V. (2020). The Influence of Multiple Pass Submerged Friction Stir Processing on the Microstructure and Mechanical Properties of the FSWed AA6082-AA8011 Joints. Metals, 10(11), 1429. https://doi.org/10.3390/met10111429