Quantitative Relationships between Mechanical Properties and Microstructure of Ti17 Alloy after Thermomechanical Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

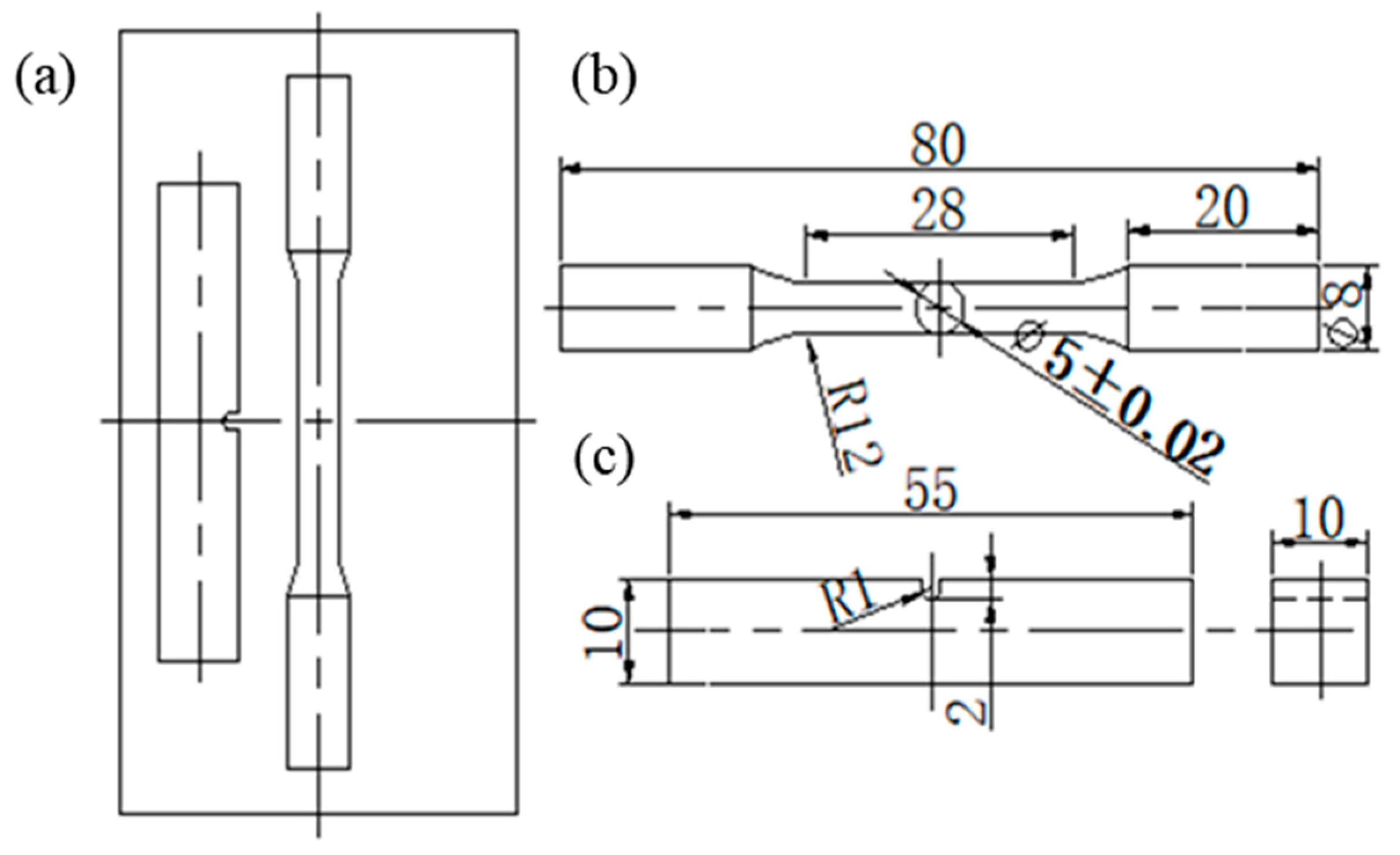

2.2. Experimental Procedures

3. Results and Discussion

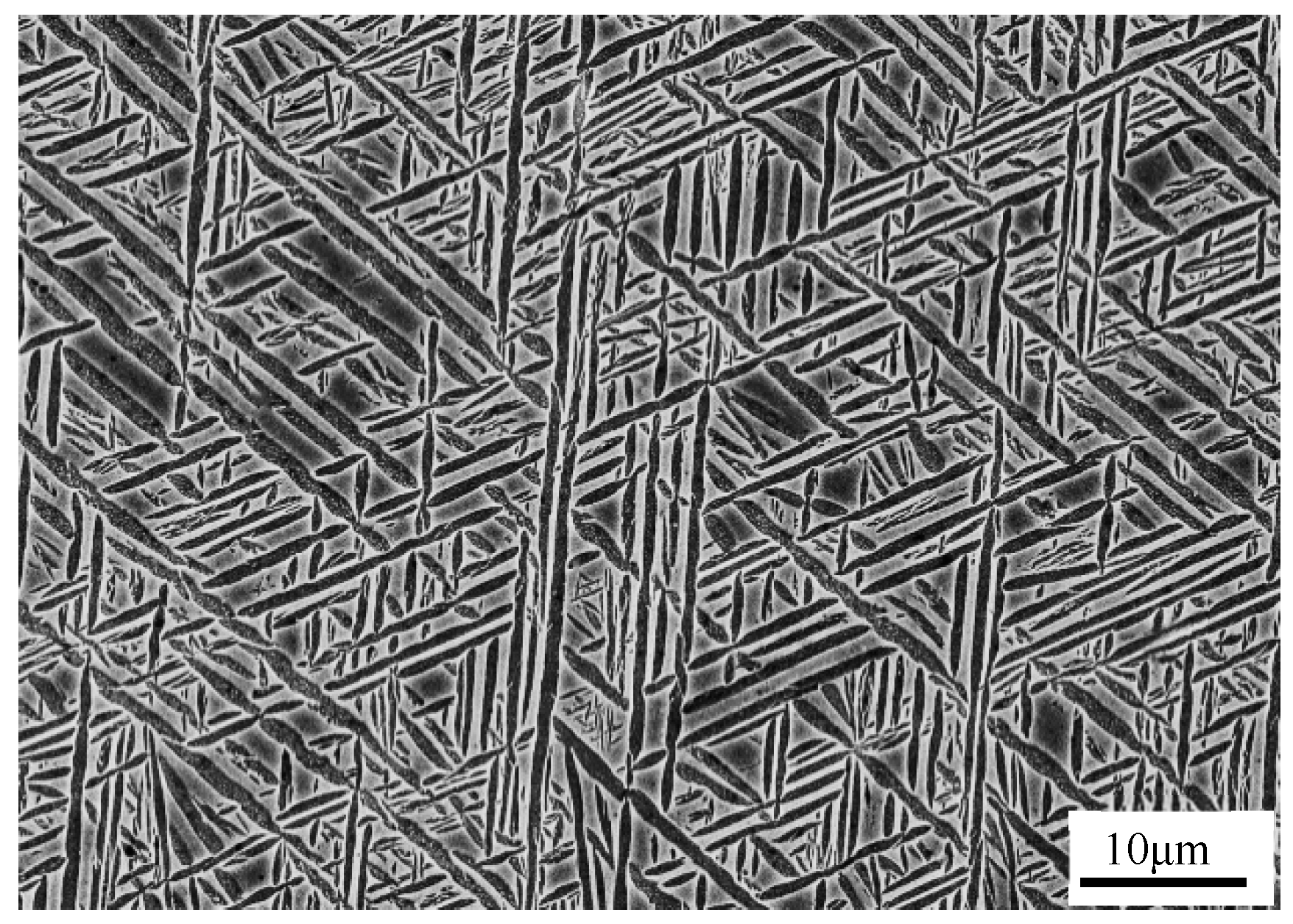

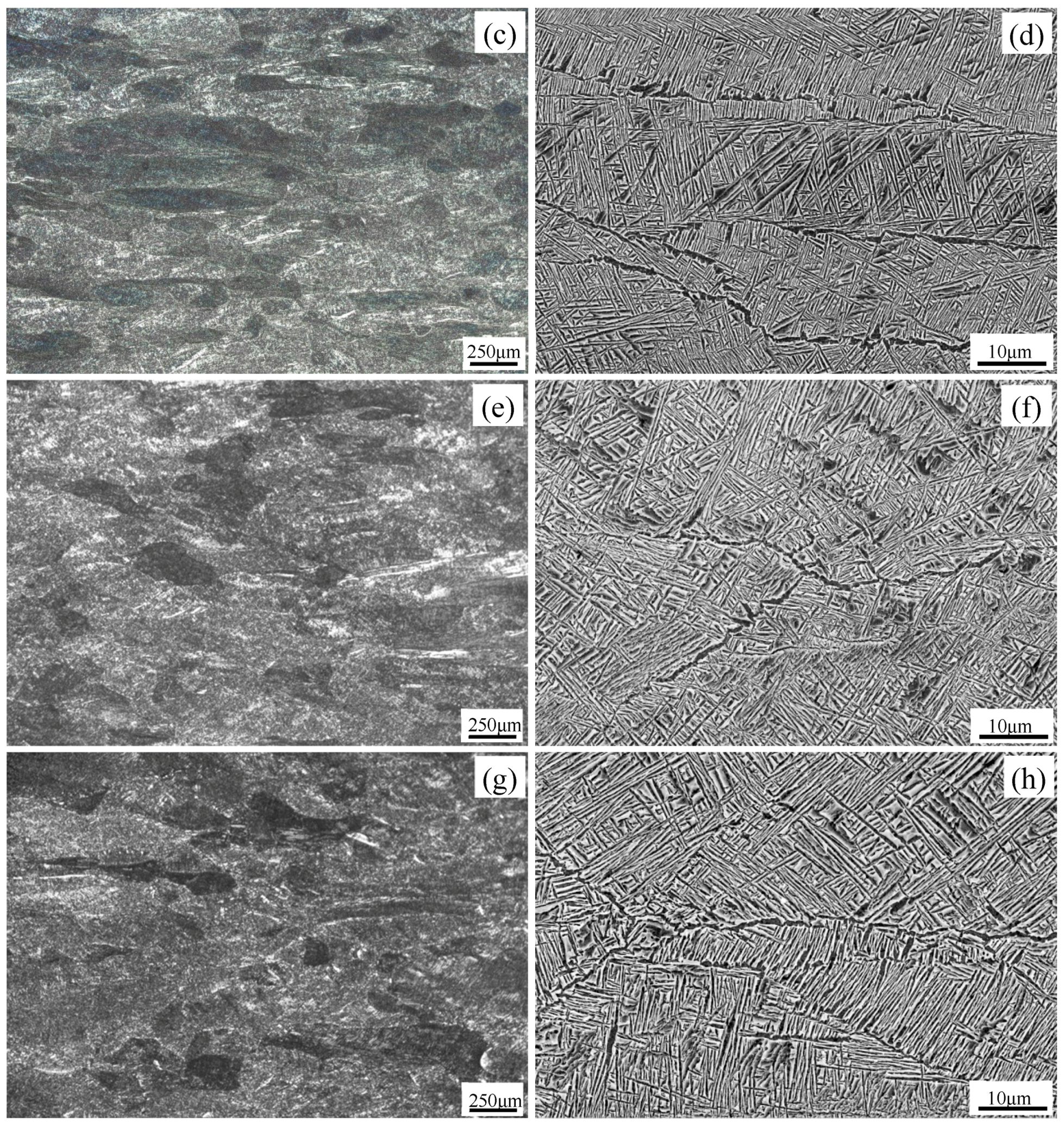

3.1. Microstructure Evolution

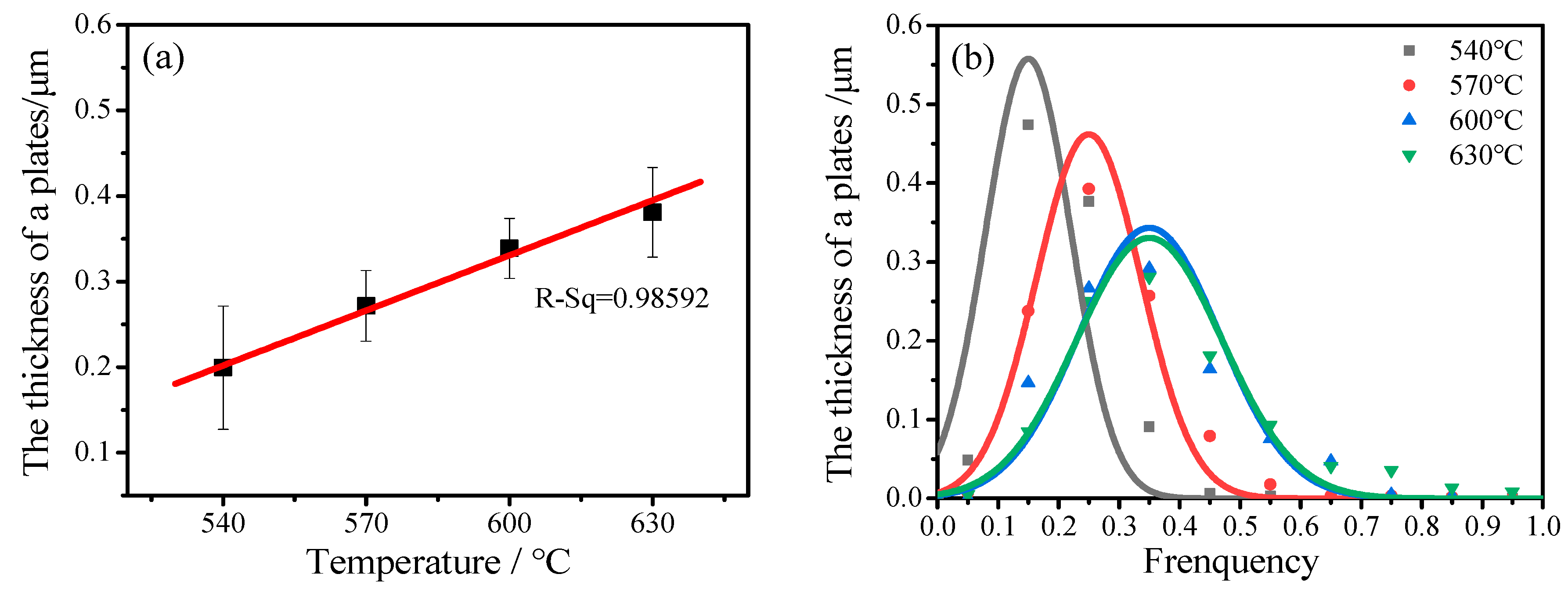

3.2. Quantitative Analysis of Microstructure Evolution

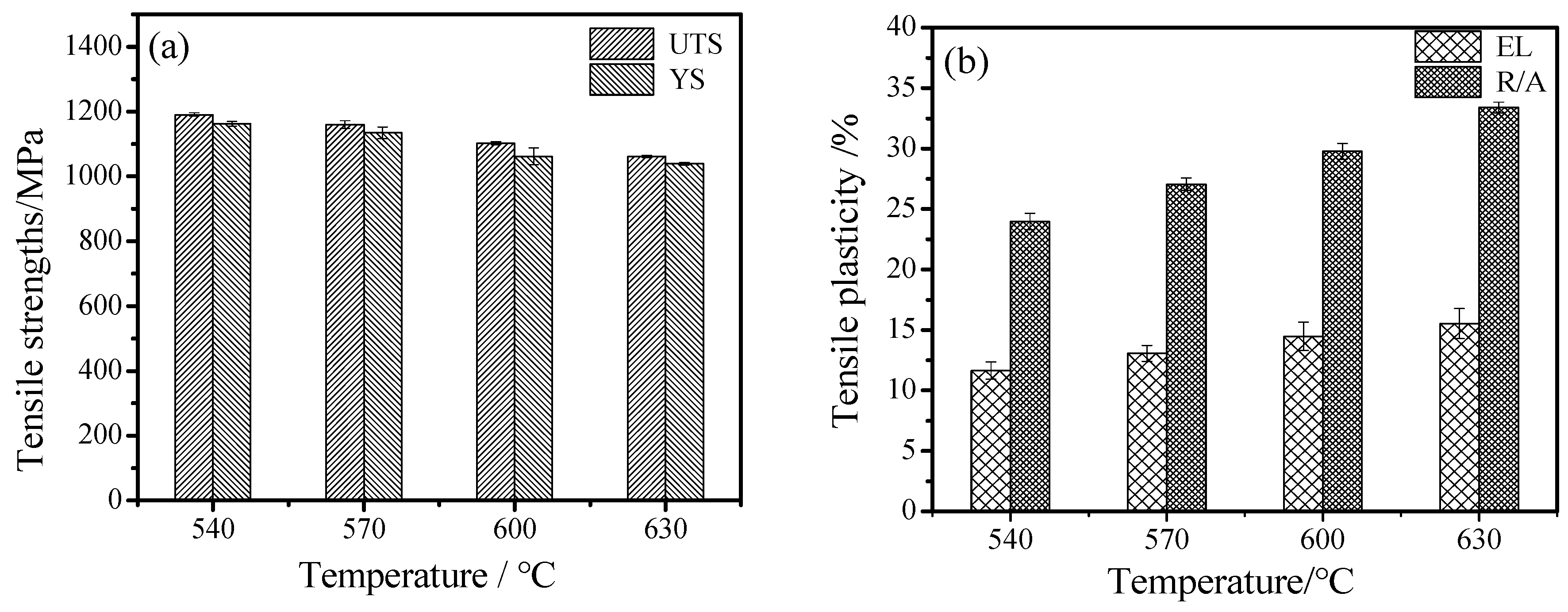

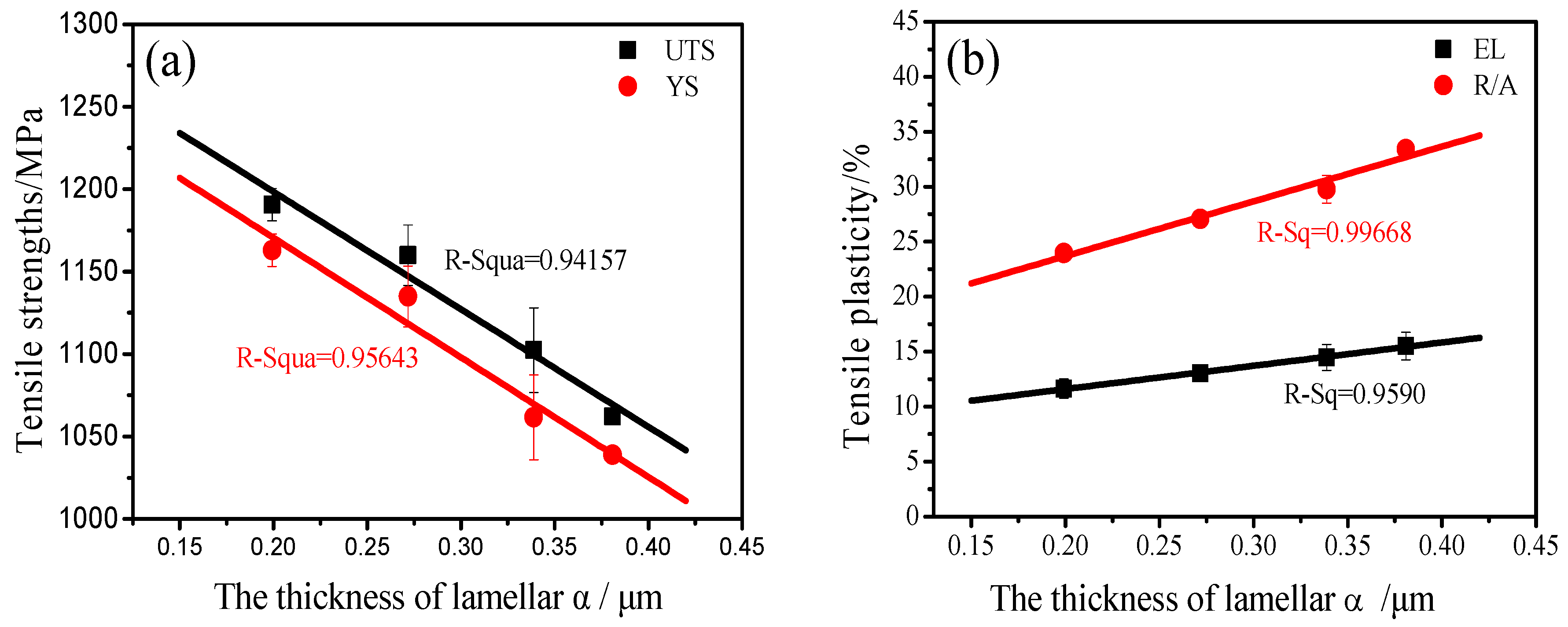

3.3. Effect of the Lamellar Thickness on Tensile Property of Ti17 Alloy

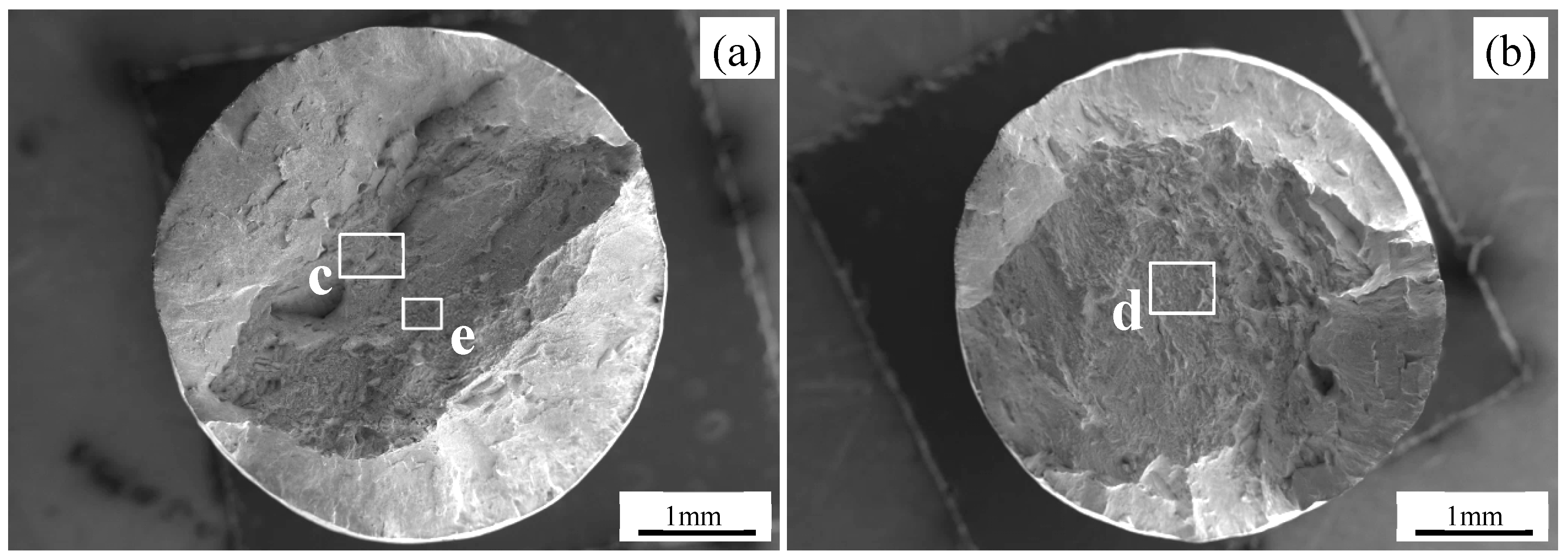

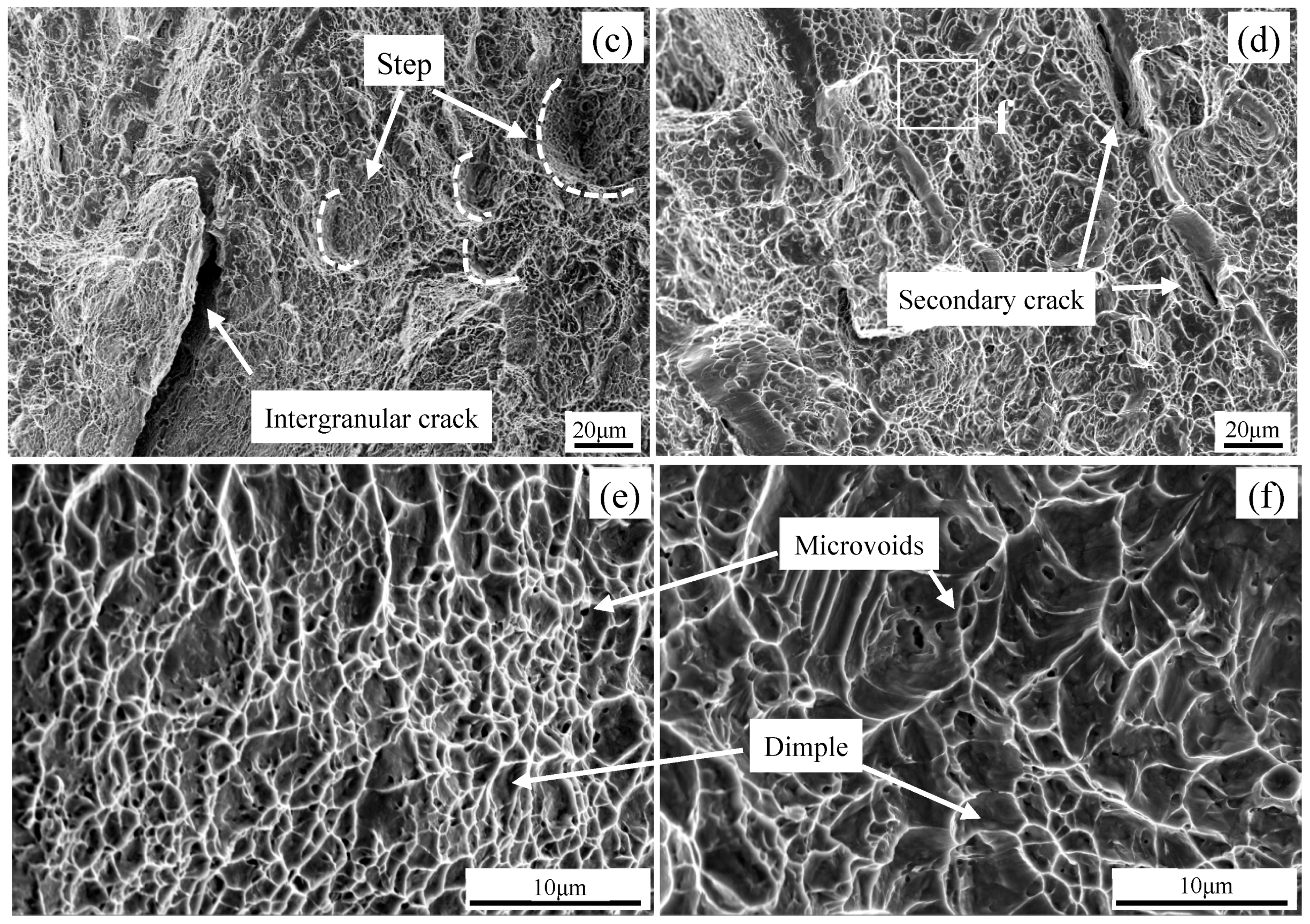

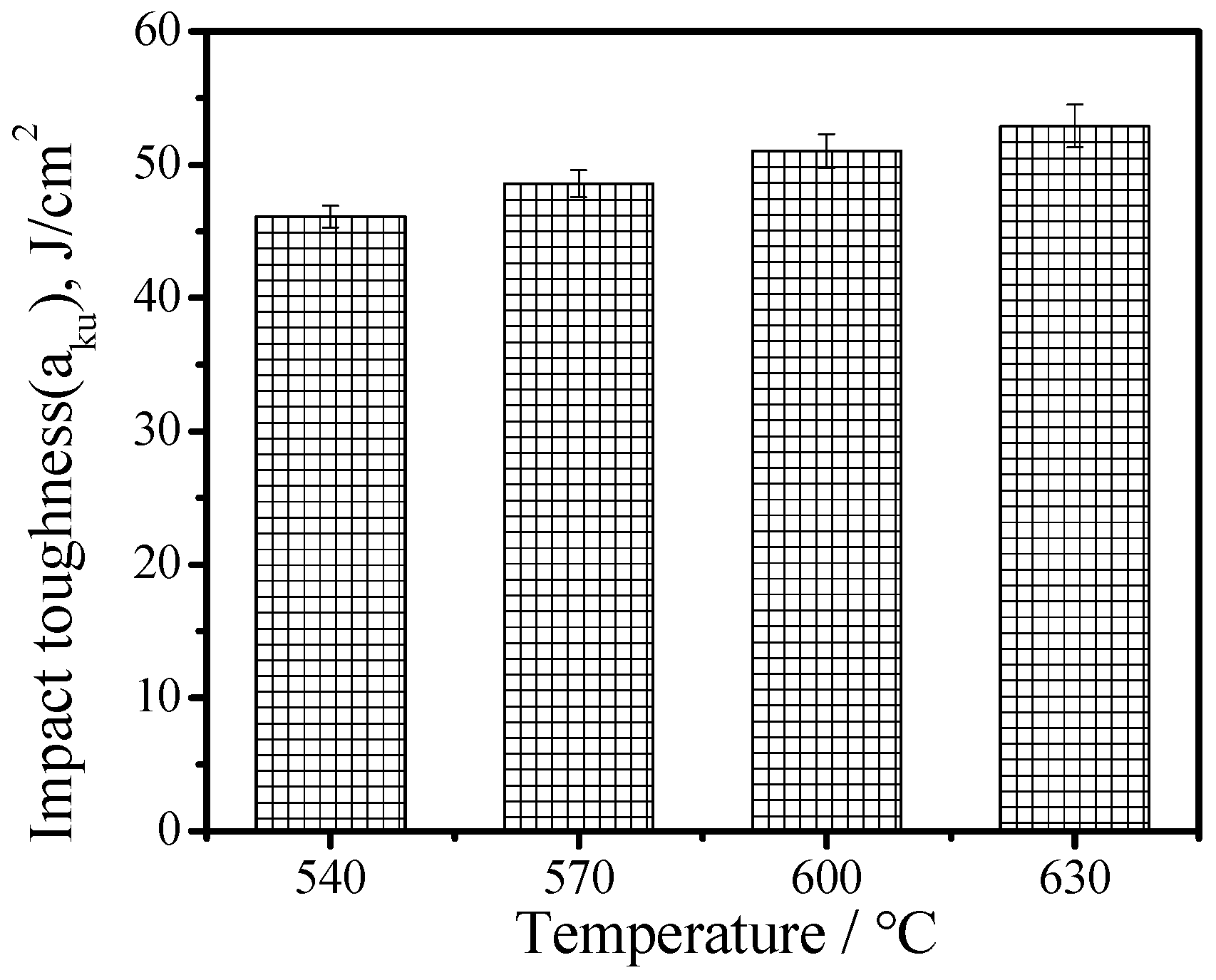

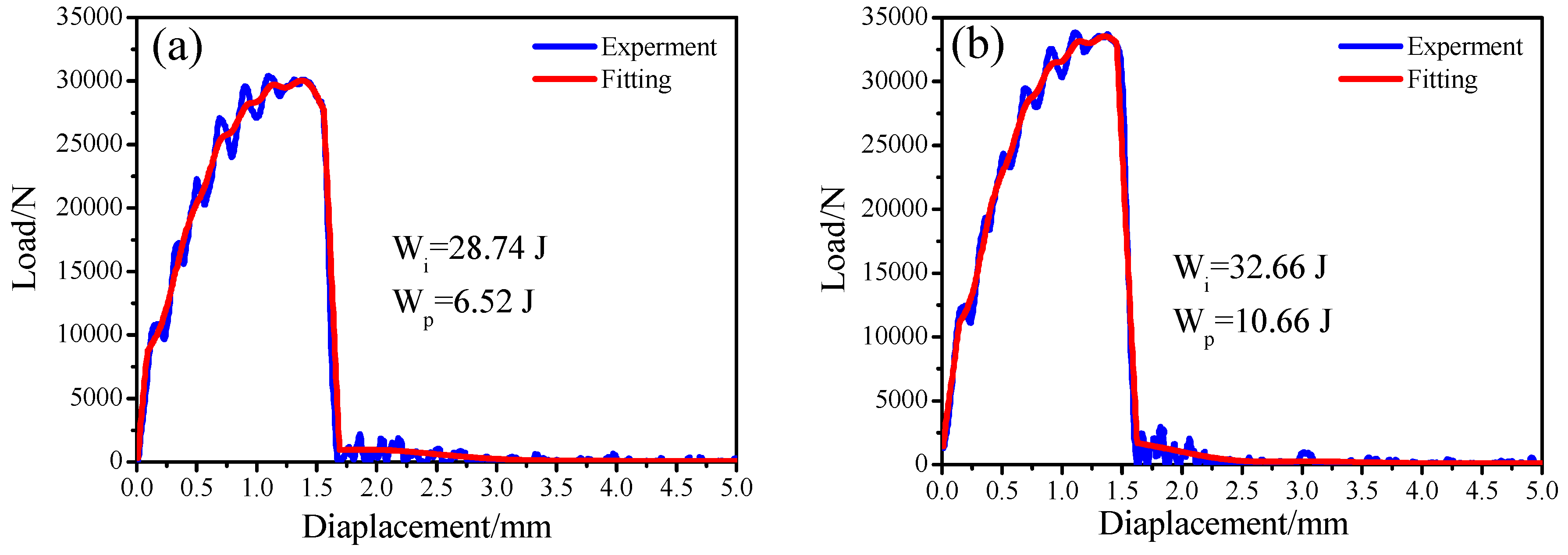

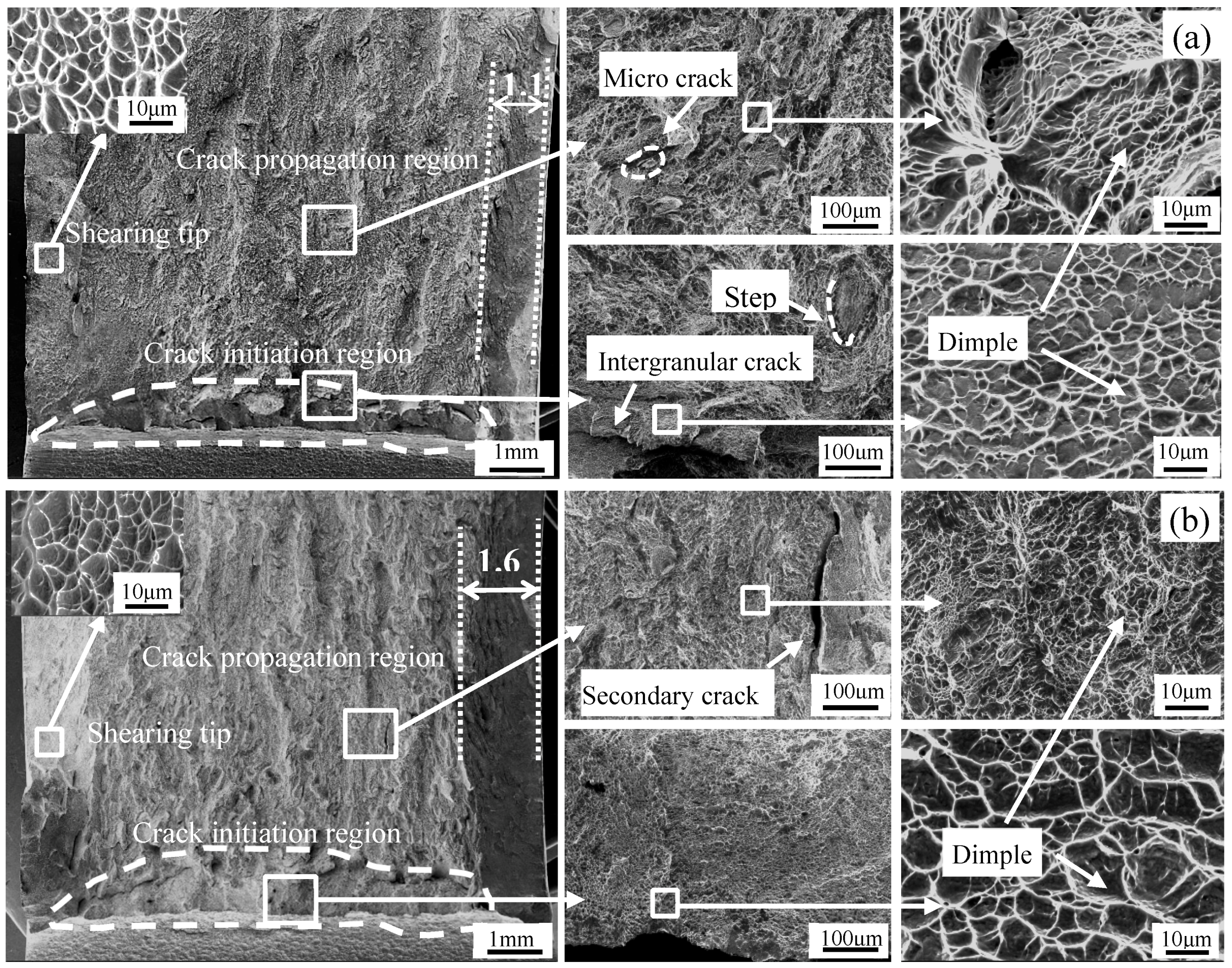

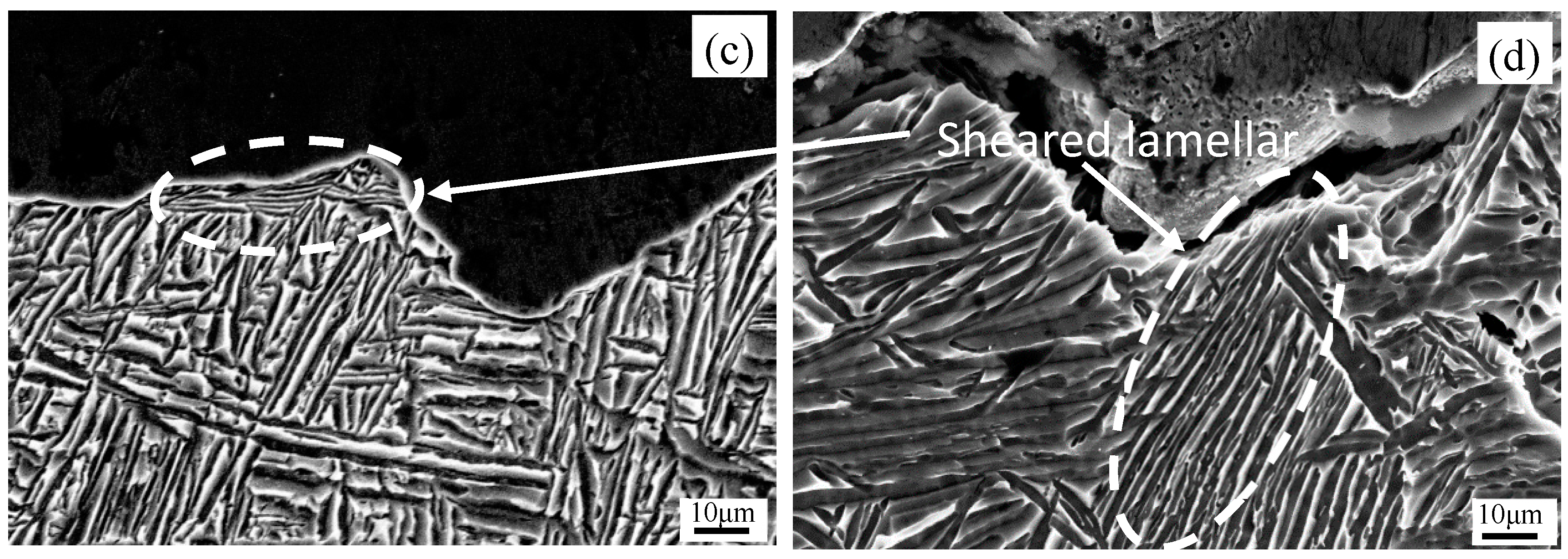

3.4. Analysis of Impact Toughness on Ti17 Alloy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lu, K. The future of metals. Science 2010, 328, 319–320. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.H.; Li, T.R.; Wang, X.Q.; Guo, R.Q.; Misra, R.D.K.; Wang, Z.D.; Wang, G.D. Effect of alloying additions on work hardening, dynamic recrystallization and mechanical properties of Ti–44Al–5Nb–1Mo alloys during direct hot-pack rolling. Mater. Sci. Eng. A 2019, 138838. [Google Scholar] [CrossRef]

- Chen, S.H.; Zhang, M.C.; Jia, M.L.; Li, W. Investigations on microstructure and grain orientation uniformity of Ti-17 titanium alloy under different hot deformation modes. J. Mater. Process Tech. 2018, 252, 148–158. [Google Scholar] [CrossRef]

- Li, L.; Li, M.Q.; Luo, J. Mechanism in the β phase evolution during hot deformation of Ti–5Al–2Sn–2Zr–4Mo–4Cr with a transformed microstructure. Acta Mater. 2015, 94, 36–45. [Google Scholar] [CrossRef]

- Wen, X.; Wan, M.; Huang, C.; Tan, Y.; Lei, M.; Liang, Y.; Cai, X. Effect of microstructure on tensile properties, impact toughness and fracture toughness of TC21 alloy. Mater. Des. 2019, 180, 107898. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, Y.; Xin, S.; Zhou, W.; Li, Q.; Zeng, W. Effect of microstructure on tensile properties of Ti–5Al–5Mo–5V–3Cr–1Zr alloy. J. Alloys Compd. 2017, 693, 582–591. [Google Scholar] [CrossRef]

- Kuroda, P.A.B.; Lourenço, M.L.; Correa, D.R.N.; Grandini, C.R. Thermomechanical treatments influence on the phase composition, microstructure and selected mechanical properties of Ti–20Zr–Mo alloys system for biomedical applications. J. Alloys Compd. 2020, 812, 152108. [Google Scholar] [CrossRef]

- Sheremetyev, V.; Kudryashova, A.; Dubinskiy, S.; Galkin, S.; Prokoshkin, S.; Brailovski, V. Structure and functional properties of metastable beta Ti-18Zr-14Nb (at.%) alloy for biomedical applications subjected to radial shear rolling and thermomechanical treatment. J. Alloys Compd. 2018, 737, 678–683. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Zheng, X.H.; Cai, W. Effects of thermomechanical treatment on microstructure and shape memory effect of Ti–13V–3Al lightweight shape memory alloy. Mater. Sci. Eng. A 2016, 655, 122–131. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Saeid, T.; Klemm, V.; Chabok, A.; Pei, Y. Effect of stacking fault energy on the restoration mechanisms and mechanical properties of friction stir welded copper alloys. Mater. Des. 2019, 162, 185–197. [Google Scholar] [CrossRef]

- Xue, C.; Zeng, W.; Wangi, W.; Liang, X.; Zhang, J. Coarsening behavior of lamellar orthorhombic phase and its effect on tensile properties for the Ti–22Al–25Nb alloy. Mater. Sci. Eng. A 2014, 611, 320–325. [Google Scholar] [CrossRef]

- Chen, Y.; Du, Z.; Xiao, S.; Xu, L.; Tian, J. Effect of aging heat treatment on microstructure and tensile properties of a new β high strength titanium alloy. J. Alloys Compd. 2014, 586, 588–592. [Google Scholar] [CrossRef]

- Yoshimura, H.; Nakahigashi, J. Tensile and impact properties of mesoscopic-grained α+β-type titanium alloys obtained through hydrogen treatments. J. Alloys Compd. 1999, 293–295, 858–861. [Google Scholar] [CrossRef]

- Balasubramanian, T.S.; Balakrishnan, M.; Balasubramanian, V.; Manickam, M.A.M. Influence of welding processes on microstructure, tensile and impact properties of Ti-6Al-4V alloy joints. Nonferr. Metal. Soc. 2011, 21, 1253–1262. [Google Scholar] [CrossRef]

- Safeen, W.; Hussain, S.; Wasim, A.; Jahanzaib, M.; Aziz, H.; Abdalla, H. Predicting the tensile strength, impact toughness and hardness of friction stir-welded AA6061-T6 using response surface methodology. Int. J. Adv. Manuf. Tech. 2016, 87, 1765–1781. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Zhao, Y.; Jia, Z. Effect of microstructure evolution of the lamellar alpha on impact toughness in a two-phase titanium alloy. Mater. Sci. Eng. A 2016, 676, 434–440. [Google Scholar] [CrossRef]

- Buirette, C.; Huez, J.; Gey, N.; Vassel, A.; Andrieu, E. Study of crack propagation mechanisms during Charpy impact toughness tests on both equiaxed and lamellar microstructures of Ti–6Al–4V titanium alloy. Mater. Sci. Eng. A 2014, 618, 546–557. [Google Scholar] [CrossRef]

- Fréour, S.; Gloaguen, D.; François, M.; Guillén, R. Application of inverse models and XRD analysis to the determination of Ti-17 β-phase coefficients of thermal expansion. Scripta Mater. 2006, 54, 1475–1478. [Google Scholar] [CrossRef]

- Shamblen, C.E. Minimizing beta flecks in the Ti-17 alloy. Metall. Mater. Trans. B. 1997, 28, 899–903. [Google Scholar] [CrossRef]

- Salib, M.; Teixeira, J.; Germain, L.; Lamielle, E.; Gey, N.; Aeby-Gautier, E. Influence of transformation temperature on microtexture formation associated with α precipitation at β grain boundaries in a β metastable titanium alloy. Acta Mater. 2013, 61, 3758–3768. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Sun, X.; Jia, Z.; Zhou, J. Static coarsening behavior of the lamellar alpha in Ti-17 alloy. J. Alloys Compd. 2015, 631, 248–254. [Google Scholar] [CrossRef]

- Wang, K.; Zeng, W.; Zhao, Y.; Lai, Y.; Zhou, Y. Dynamic globularization kinetics during hot working of Ti-17 alloy with initial lamellar microstructure. Mater. Sci. Eng. A 2010, 527, 2559–2566. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Ma, H.; Zhou, D. Static globularization mechanism of Ti-17 alloy during heat treatment. J. Alloys Compd. 2018, 736, 99–107. [Google Scholar] [CrossRef]

- Jeffries, Z.; Kline, A.H.; Zimmer, E.B. The Determination of the Average Grain Size in Metals. Trans. Am. Ins. Min. Metall. Pet. Eng. 1917, 54, 594–607. [Google Scholar]

- Obasi, G.C.; Birosca, S.; Quinta da Fonseca, J.; Preuss, M. Effect of β grain growth on variant selection and texture memory effect during α→β→α phase transformation in Ti–6 Al–4 V. Acta Mater. 2012, 60, 1048–1058. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Murzinova, M.; Salishchev, G.; Semiatin, S.L. Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 2011, 59, 4138–4150. [Google Scholar] [CrossRef]

- Chan, H.P.; Won, J.W.; Park, J.W.; Semiatin, S.L.; Chong, S.L. Mechanisms and Kinetics of Static Spheroidization of Hot-Worked Ti-6Al-2Sn-4Zr-2Mo-0.1Si with a Lamellar Microstructure. Metall. Mater. Trans. A 2012, 43, 977–985. [Google Scholar]

- Sharma, G.; Ramanujan, R.V.; Tiwari, G.P. Instability mechanisms in lamellar microstructures. Acta Mater. 2000, 48, 875–889. [Google Scholar] [CrossRef]

- Li, C.; Mi, X.; Ye, W.; Hui, S.; Yu, Y.; Wang, W. A study on the microstructures and tensile properties of new beta high strength titanium alloy. J. Alloys Compd. 2013, 550, 23–30. [Google Scholar] [CrossRef]

- Sauer, C.; Luetjering, G. Thermo-mechanical processing of high strength β-titanium alloys and effects on microstructure and properties. Mater. Process. Technol. 2001, 117, 311–317. [Google Scholar] [CrossRef]

- Filip, R.; Kubiak, K.; Ziaja, W.; Sieniawski, J. The effect of microstructure on the mechanical properties of two-phase titanium alloys. Mater. Process. Technol. 2003, 133, 84–89. [Google Scholar] [CrossRef]

- Chen, M.; Chen, D.; Lin, D. Influence of lamellar lath orientation on crack propagation in a gamma TiAl alloy. Scripta Mater. 1997, 36, 497–501. [Google Scholar] [CrossRef]

- Duan, Q.Q.; Qu, R.T.; Zhang, Z.J.; Zhang, Z.F.; Zhang, P. Intrinsic impact toughness of relatively high strength alloys. Acta Mater. 2018, 142, 226–235. [Google Scholar] [CrossRef]

- Boyer, R.R.; Kuhlman, G.W. Processing properties relationships of Ti-10V-2Fe-3Al. Mater. Trans. A 1987, 18, 2095–2103. [Google Scholar] [CrossRef]

- Sánchez, L.; Gutiérrez-Solana, F. Correlation between impact resistance and fracture toughness in aged duplex stainless steels. Eur. Struct. Integrity Soc. 2002, 30, 87–94. [Google Scholar]

- Chaouadi, R.; Fabry, A. On the utilization of the instrumented Charpy impact test for characterizing the flow and fracture behavior of reactor pressure vessel steels. Eur. Struct. Integrity Soc. 2002, 30, 103–117. [Google Scholar]

- Niinomi, M.; Kobayashi, T. Fracture characteristics analysis related to the microstructures in titanium alloys. Mater. Sci. Eng. A 1996, 213, 16–24. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Chan, K.S. Tensile ductility of extrinsically toughened intermetallics. Metall. Mater. Trans. A 1994, 25, 299–308. [Google Scholar] [CrossRef]

- Wood, J.R.; Russo, P.A.; Welter, M.F.; Crist, E.M. Thermomechanical processing and heat treatment of Ti–6Al–2Sn–2Zr–2Cr–2Mo–Si for structural applications. Mater. Sci. Eng. A 1998, 243, 109–118. [Google Scholar] [CrossRef]

- Richards, N.L. Quantitative Evaluation of Fracture Toughness-Microstructural Relationships in Alpha-Beta Titanium Alloys. Mater. Eng. Perform. 2004, 13, 218–225. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Zhao, F.; Liu, Y.; Huang, C. Quantitative Relationships between Mechanical Properties and Microstructure of Ti17 Alloy after Thermomechanical Treatment. Metals 2020, 10, 67. https://doi.org/10.3390/met10010067

Han Y, Zhao F, Liu Y, Huang C. Quantitative Relationships between Mechanical Properties and Microstructure of Ti17 Alloy after Thermomechanical Treatment. Metals. 2020; 10(1):67. https://doi.org/10.3390/met10010067

Chicago/Turabian StyleHan, Yan, Fei Zhao, Yuan Liu, and Chaowen Huang. 2020. "Quantitative Relationships between Mechanical Properties and Microstructure of Ti17 Alloy after Thermomechanical Treatment" Metals 10, no. 1: 67. https://doi.org/10.3390/met10010067

APA StyleHan, Y., Zhao, F., Liu, Y., & Huang, C. (2020). Quantitative Relationships between Mechanical Properties and Microstructure of Ti17 Alloy after Thermomechanical Treatment. Metals, 10(1), 67. https://doi.org/10.3390/met10010067