1. Introduction

Metal cutting processes are industrial processes in which the metal parts are shaped by the removal of unwanted material. They are required for almost all products, so the conventional machining operations, such as turning, boring, drilling, and milling, are the most crucial part of the production. For the conventional approach, the solution to finishing hardened steel parts has been grinding, but this process still has some main drawbacks like low material removal rate, heat deterioration, and the negative effects of coolant usage for the environment. Recently, hard machining has been considered an alternative solution for many traditional finish grinding operations. It has gained much attention and can be defined as the machining operation of a workpiece with the hardness value typically in the 45–70 HRC range by directly using the tools with geometrically defined cutting edges [

1]. A number of clear benefits have been observed for machining of hard parts with a cutting tool such as high productivity, ease to adapt to complex part contours, the elimination of cutting fluids, good surface quality, and the reduction of machine tool investment. However, the selection of the cutting-tool inserts that can ensure the proper tool life and high precision of the machining components always faces the challenge. In addition, the biggest question is whether the cooling and lubricating fluids are used or not because the thermal shock must be taken into account to avoid the breakage of the inserts. In the earliest type of hard machining, the cutting processes without coolant gave out obvious cost benefits, but the high hardness materials and the enormous amount of generated heat demand the high-grade inserts such as coated carbide, ceramics, (P)CBN, PCD tools.

The WC/Co cemented carbide tools were developed for dry turning by coating with a thin wear resistant Ti55Al45N coating deposited by physical vapor deposition (PVD) method reported by K. Zhang et al. [

2]. The obtained results showed that the cutting performance of nano-scale textured tools was improved when compared to that of un-textured tools. The reduction of contact length at tool–chip interface at rake face contributes to the decrease of friction coefficient, cutting forces, cutting temperature, and tool wear. Moreover, Liu, Y. et al. [

3] investigated the femtosecond laser on the WC/Co carbide tools’ flank face in dry cutting of green Al

2O

3 ceramics, the difficult-to-cut material. The better wear resistance of the tools and an improvement of surface quality were achieved. C.S. Kumar and his co-authors investigated the dry cutting of hardened AISI 52100 steel (62 HRC) using Al

2O

3/TiCN composite ceramic inserts which were fabricated on the rake surface with microscale textures by WEDM process [

4]. The reduced chip-tool contact length was also observed, and it contributed to superior anti-adhesion behavior when compared to the conventional cutting tool. In addition, the cutting temperatures during hard turning process are very high, ranging from 720 to 1050 °C with cutting speed 100–180 m/min when using different ceramic tools [

5]. Su, Y. et al. [

6] used the micro-textured polycrystalline diamond tool in dry turning of Ti6Al4V titanium alloy. The tribological properties of the tool–chip interface were better than that of the untextured PCD tools. The reduction of cutting force and tool-chip contact length were obtained by using micro-grooved PCD tools. Bouacha, K. et al. [

7] studied surface roughness and cutting forces in hard turning of AISI 52100 bearing steel with CBN tool. The experiment results had shown that the thrust force has the highest value, and the surface roughness is highly affected by feed rate. The cutting forces increase along with the rise of feed rate, depth of cut and hardness, which also contribute to the higher wear rate of CBN tool. During dry cutting processes of hardened steels, the large amount of heat is generated, which would lead to thermal failure of cutting tools and the reduction of tool life. The cutting speed is limited due to the rise of cutting temperature. The part-thermal distortion, handling, and in-process gauging caused by high heat are necessarily considered. Thus, it is necessary to find the solution for decreasing the temperature in the cutting zone while ensuring the environmentally friendly characteristics of hard cutting processes.

Minimum quantity lubrication (MQL) has been developing to be an attractive alternative solution for flood and dry machining. The use of a small amount of cutting fluid in the form of an oil mist directly sprayed to the contact zone helps to reduce the friction coefficient significantly [

1]. It contributes to the decrease of cutting forces, cutting temperature and tool wear as well as the improvement of surface quality and tool life [

8,

9,

10,

11,

12,

13]. However, the low cooling effect is the main drawback of MQL technology, so it does not work so well when applied to difficult-to-cut materials, especially for high hardness steels. The cutting tools usually suffer rapid wear rate caused by the enormous generated heat from cutting zone. To improve MQL technique assisted for hard machining, many studies have been made by following two approaches: (1) MQCL and (2) MQL using nanofluids. Among these, the nanofluids used in MQL have been a new research trend and gained much attention of the researchers around the world in recent years. The use of different types of nanoparticles, such as Al

2O

3, MoS

2, SiO

2, ZrO

2, CNTs and diamond, reinforced in MQL fluids not only improve the tribological property but also enhance the viscosity of the based fluids, from which the cutting performance significantly improves. Li, B. et al. [

14] studied the heat transfer performance of MQL grinding with different nanofluids for Ni-based alloy. Six types of nanoparticles including MoS

2, ZrO

2, CNT, PCD, Al

2O

3, SiO

2 were suspended in palm oil to prepare the nanofluids. From the obtained results, the increase of viscosity and thermal conductivity of the base fluid was confirmed when adding nanoparticles. CNT nanofluid has the highest heat transfer coefficient. Hence, the use of nanofluids contributed to reduce the cutting forces and cutting temperature during grinding process. Pil-Ho Lee et al. [

15] investigated diamond and Al

2O

3 nanofluids for MQL micro grinding. The experimental results demonstrated that the grinding forces were much reduced and the surface quality was significantly improved. The higher volumetric concentration and smaller size of nanoparticle were more effective to decrease the cutting forces. Ali, M.K.A. et al. [

16] evaluated the tribological characteristics of Al

2O

3 and TiO

2 nano-lubricant in automotive engines with different concentrations (0.05, 0.1, 0.25 and 0.5 wt %). The decrease in friction coefficient, power losses and wear had been reported. The kinematic viscosity of nano-lubricants decreased slightly, but the viscosity index increased. Especially, the worn surfaces were smoother due to the formation of self-laminating protective films of Al

2O

3 nanoparticles. The presence of nanoparticles played an important role in creating the rolling effect to reduce the friction coefficient. Garg, A. et al. [

17] studied the effect of nanofluid concentration of MQL micro-drilling process. From the experimental results, the authors pointed out that the nanofluid concentration had the strongest influence on the torque and power consumption. Yıldırım, C. V. and his co-authors [

18] recently investigated the effect of hBN nanofluid for MQL turning of Ni-based Inconel 625. The significant enhancement of tool life and surface quality was observed by using hBN nanofluid (0.5 wt %). The results also showed the reduction of cutting temperature and tool wear by using MQL nanofluids when compared to dry machining. Duc, T.M. et al. [

19] studied the performance of Al

2O

3 nanofluids in MQL hard milling using carbide tools. The experimental results revealed the decrease of friction coefficient, cutting forces and tool wear due to the effectiveness of Al

2O

3 nanofluids, which led to the improvement of cutting performance, surface quality, and tool life. Interestingly, the authors also proved that the addition of Al

2O

3 nanoparticles in MQL fluids enlarged the applicability of the carbide tools in hard milling while ensuring the proper tool life and achieving the good surface quality, from which the reduction of manufacturing cost can be made. Uysal, A. et al. [

20] evaluated the performance of MoS

2 nanofluid in MQL milling of AISI 420 stainless steel. The results obtained also revealed the reduction in both tool wear and surface roughness due to the lubricating effect of MoS

2 nanoparticles. Hegab, H. et al. [

21,

22] studied the turning performance of Ti-6Al-4V alloy under the MQL technique using nano-cutting fluids. By using multi-walled carbon nanotubes (MWCNTs) suspended in vegetable oil, the MQL heat capacity was improved and the power consumption, as well as flank wear, reduced significantly with the nano concentration of 2 wt %. The authors concluded that the cutting performance and surface quality improved due to the interface bonding between the tool and workpiece surface. They also extended the study to investigate the tool performance and chip morphology during machining Inconel 718 by using MWCNTs and Al

2O

3 nanofluid [

23,

24]. The results indicated the enhancement of MQL cooling and lubricating capabilities, which contribute to improve the machining performance compared to the case with no nano-additives. The lower deformed chip thickness was observed, which led to lower cutting forces. Furthermore, a 2-D axisymmetric computational fluid dynamics (CFD) model is developed to simulate the thermal characteristics of nanofluid when machining Ti-6Al-4V and Inconel 718, which was used in the finite element model [

25]. This is the first attempt to simulate the MQL machining process using nanofluid. From the obtained results, the improvement of thermal properties and the reduction of friction coefficient were confirmed. The authors also suggested that the negative effect on the tool wear could occur when increasing the nano concentration, but the induced friction could be decreased. Accordingly, the nanofluid concentration should be studied and optimized in order to be applied efficiently to fulfill the technical and economic requirements [

26]. Eltaggaz, A. et al. [

27,

28] investigated the effect on tool life and surface roughness during cutting austempered ductile iron alloys (ADI). Compared to dry, flood, MQL conditions, a significant reduction in the cutting forces and the better surface roughness were reported due to the cooling and lubricating enhancement of gamma-Al

2O

3 nanofluids. Hence, the lower wear rates and wear levels were observed.

Sharma, A.K. et al. [

29] made a review of the effect of MQL in machining processes using conventional and nano cutting fluids. This study covered the important researches regarding the MQL techniques using mineral oils, vegetable oils and nanofluids for different machining processes. From the results, most of the experimental studies had shown better surface quality by using MQL technique with nanofluids when compared to dry and wet cutting. The cutting forces were much reduced due to the rolling effect of nanoparticles suspended in the base fluids. The authors also suggested focusing on the further studies of the application of MQL with hybrid nanofluids. Singh, R.K. et al. [

30] evaluated the performance of alumina-graphene hybrid nanofluid in hard turning. The experimental results revealed that the addition of graphene in alumina nanofluid enhanced the performance of hybrid nanofluids. The reduction of the values of surface roughness and cutting forces was also reported. In addition, the coefficient of friction of hybrid nanofluid was lower when compared to Al

2O

3 nanofluid and the base fluid, from which the significant decrease of tool wear was observed. Jamil, M. et al. [

31] studied the effects of hybrid Al

2O

3–CNT nano additive-based MQL and cryogenic cooling when machining Ti–6Al–4V alloy. Based on the experimental results, the MQL technique using hybrid nanofluid reduced the values of surface roughness, cutting forces and extended the tool life more effectively than the cryogenic technique. Nevertheless, the cryogenic CO

2 exhibited heat dissipation efficiently at low cutting speed. Moreover, Sharma, A.K. et al. [

32] used alumina-MoS

2 hybrid nanofluid in hard turning of AISI 304 steel. The improvement of tribological properties of hybrid nanofluids was confirmed by experimental results. The thermal conductivity of alumina nanofluid increased by about 9.98%, but the hybridization of MoS

2 in alumina nanofluid brought out the negative effect with the rise of thermal conductivity by about 8.4%. On the other hand, the increase of temperature and nanoparticle concentration contributed to the improvement of thermal conductivity. The significant reduction of cutting forces and surface roughness had been shown by using the Al

2O

3–MoS

2 hybrid nanofluid when compared to the Al

2O

3 nanofluid. The authors also suggested the further studies for investigating the effect of the volumetric ratio of two different nanofluids as well as the optimization of nanoparticle concentration.

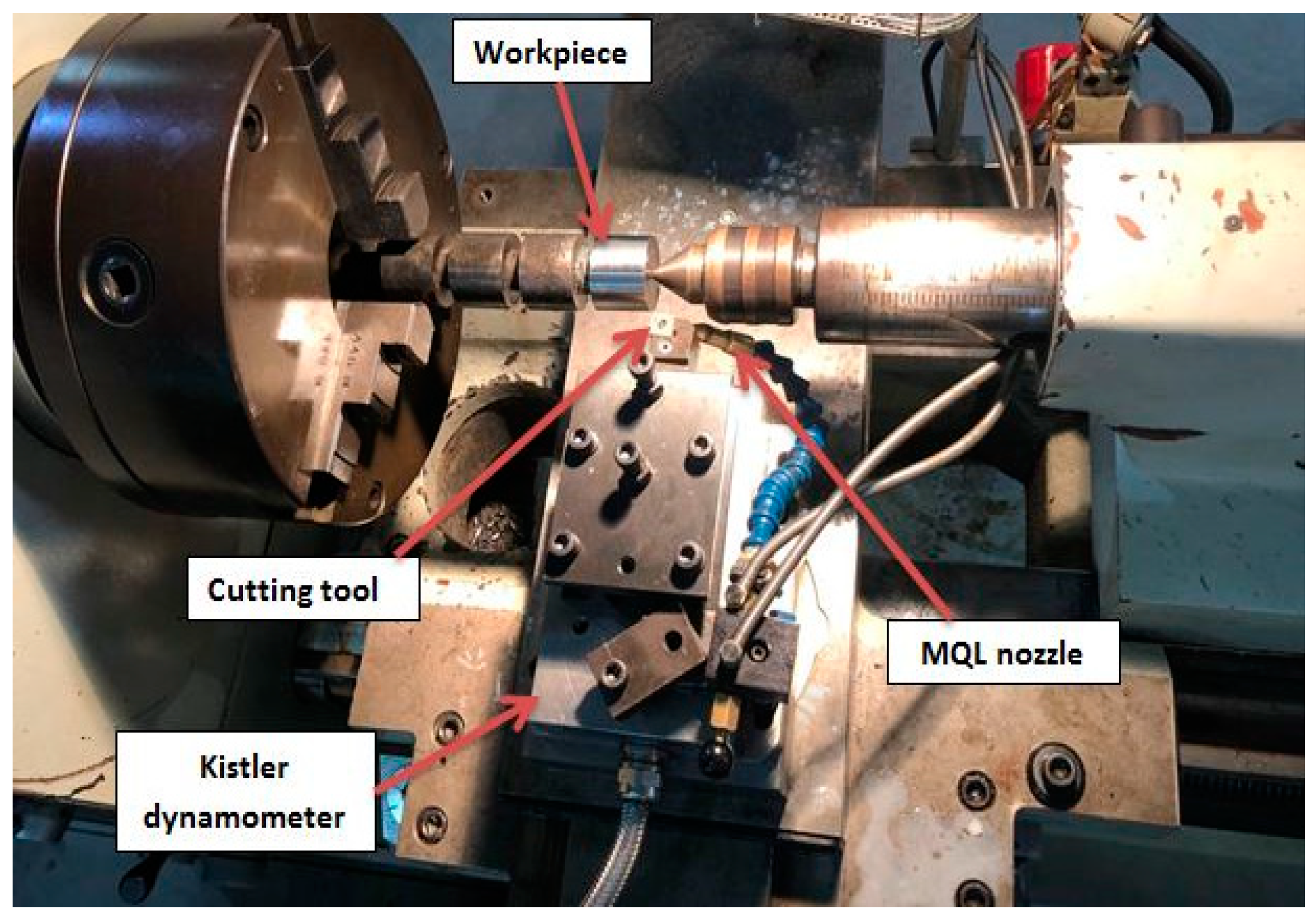

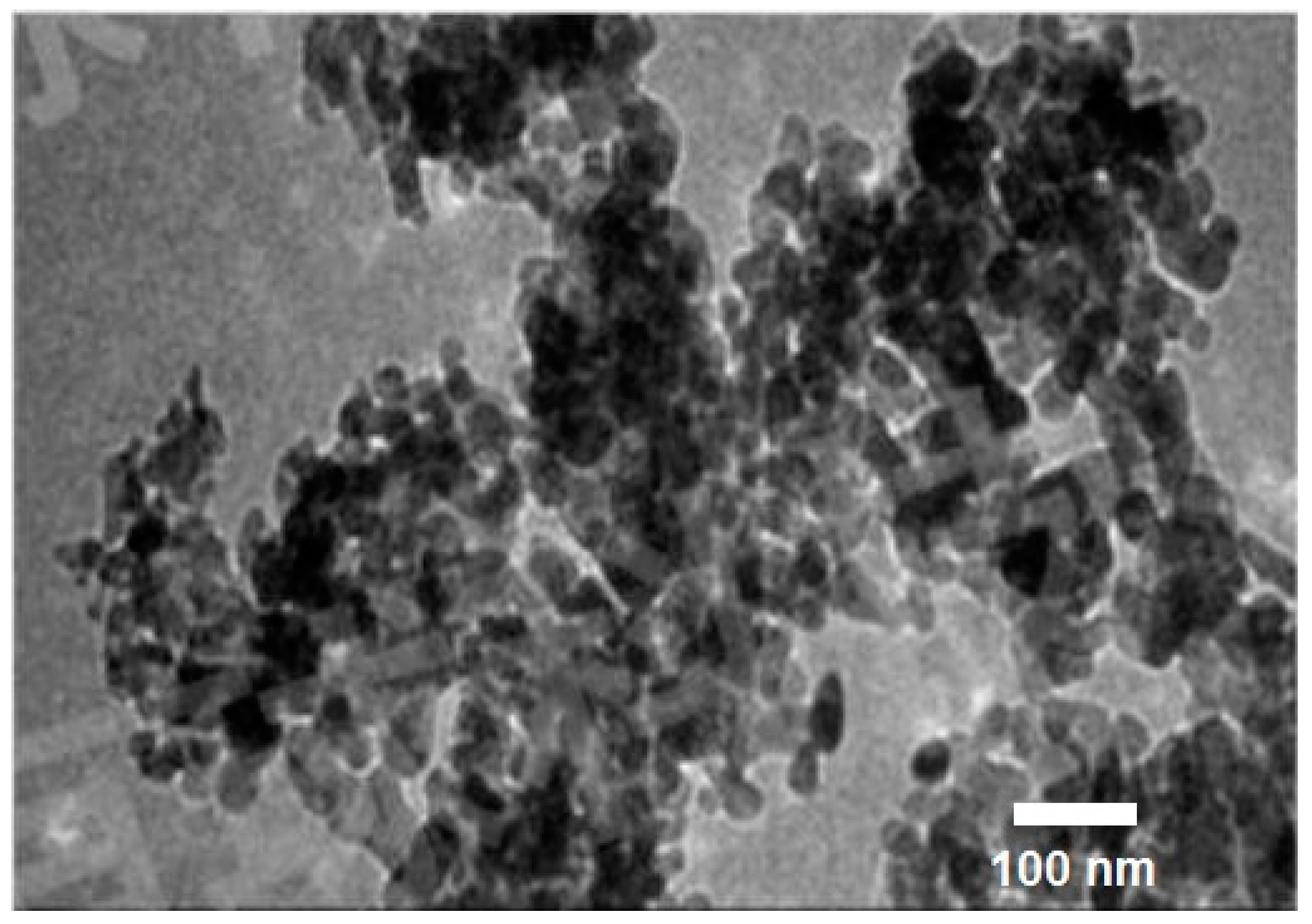

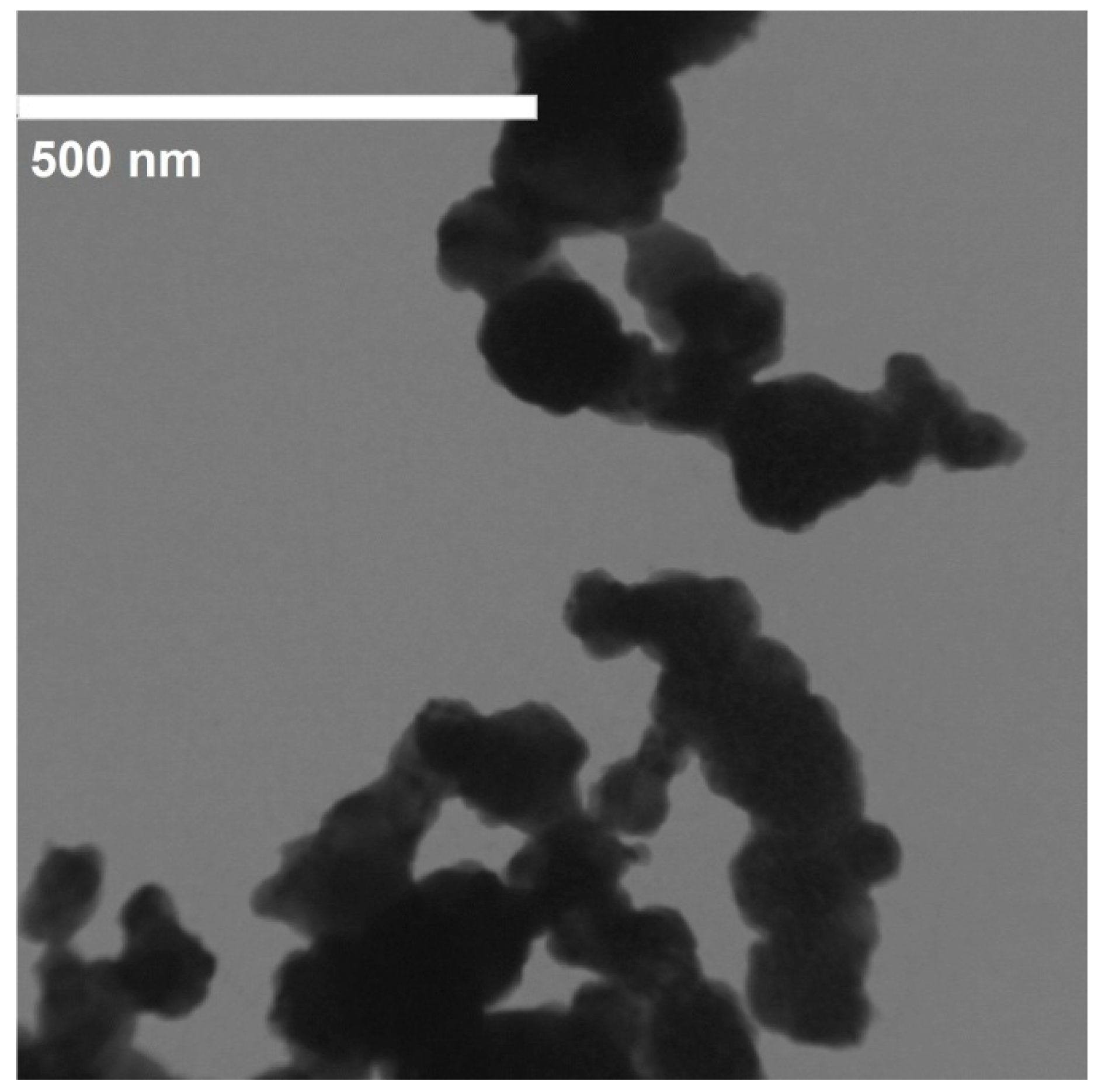

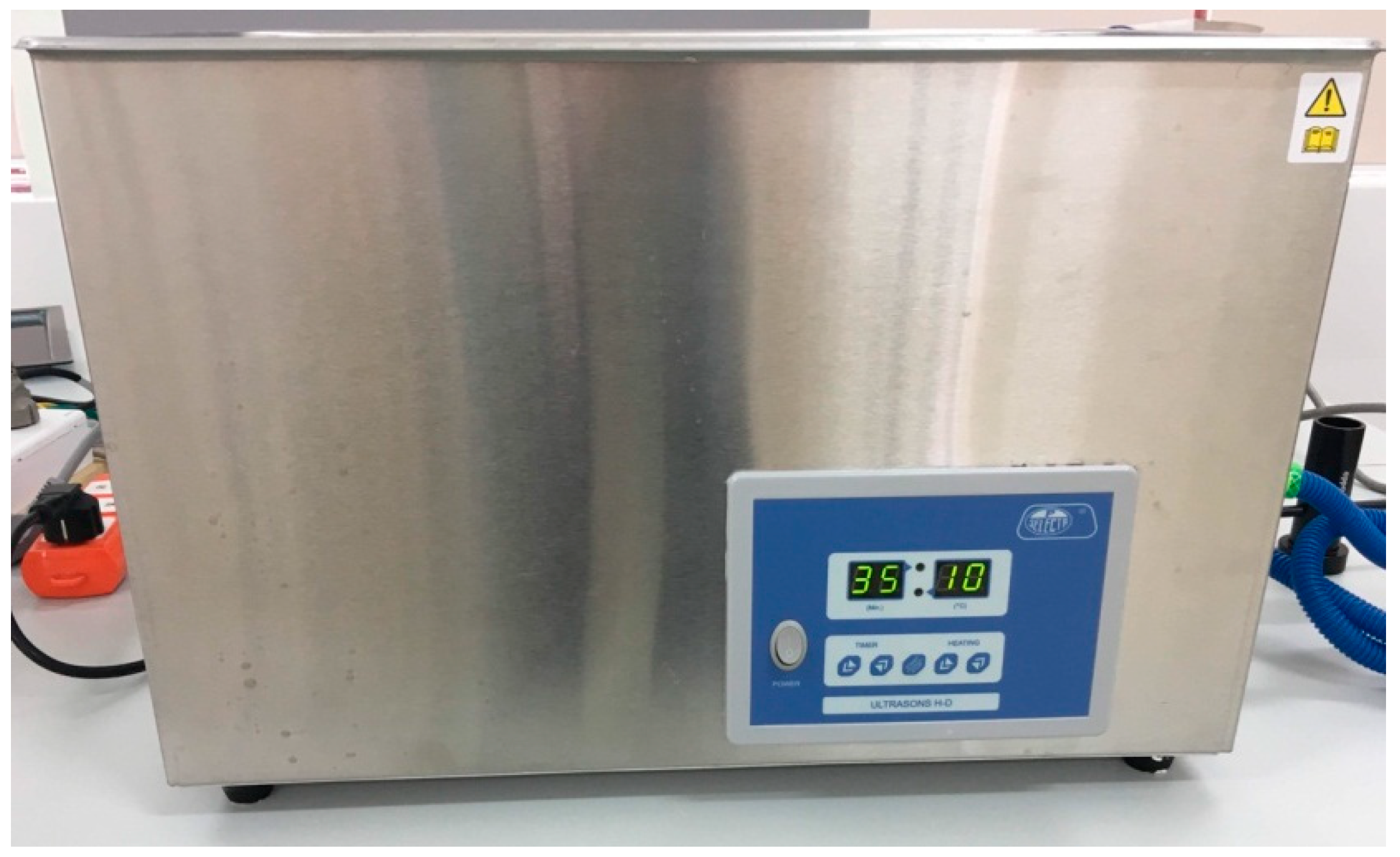

From the literature review, it is well documented that the use of nanofluids in MQL hard machining brings out better cutting performance in terms of cutting forces, surface roughness, tool wear, tool life. The main reasons are the improvement of tribological and thermophysical properties of the base fluids when adding nanoparticles. Further studies are necessary for investigating the special properties of nanofluid in order to apply in MQL hard machining more effectively. In addition to that, there are few studies about the effect of alumina and MoS2 nanofluids in MQL hard turning in terms of nanoparticle types, nano concentration, and different base fluids. For those reasons, the authors are motivated to conduct MQL hard turning experiments of 90CrSi steel (60–62 HRC) using Al2O3 and MoS2 nanofluids with coated carbide tools. The results of this study will not only provide the important technical guide for using Al2O3 and MoS2 nanoparticles in MQL hard turning, but also be the basis of hybrid nanofluids’ applications and development for sustainable production.

4. Conclusions

The cutting performance of carbide inserts is improved by the use of the MQL technique with Al2O3 and MoS2 nanofluids. The enhancement of thermal conductivity and lubricating characteristic of the base fluid is observed due to the presence of Al2O3 and MoS2 nanoparticles.

The factorial experimental design is used to evaluate the effects of variables on the objective functions, from which the directions of further studies can be made. In this study, the influence of MQL parameters, including the fluid types, nanoparticle types, nanoparticle concentration, and cutting speed, is investigated in terms of cutting forces and surface roughness. The obtained results will provide the important direction for selecting the control factors of the further studies.

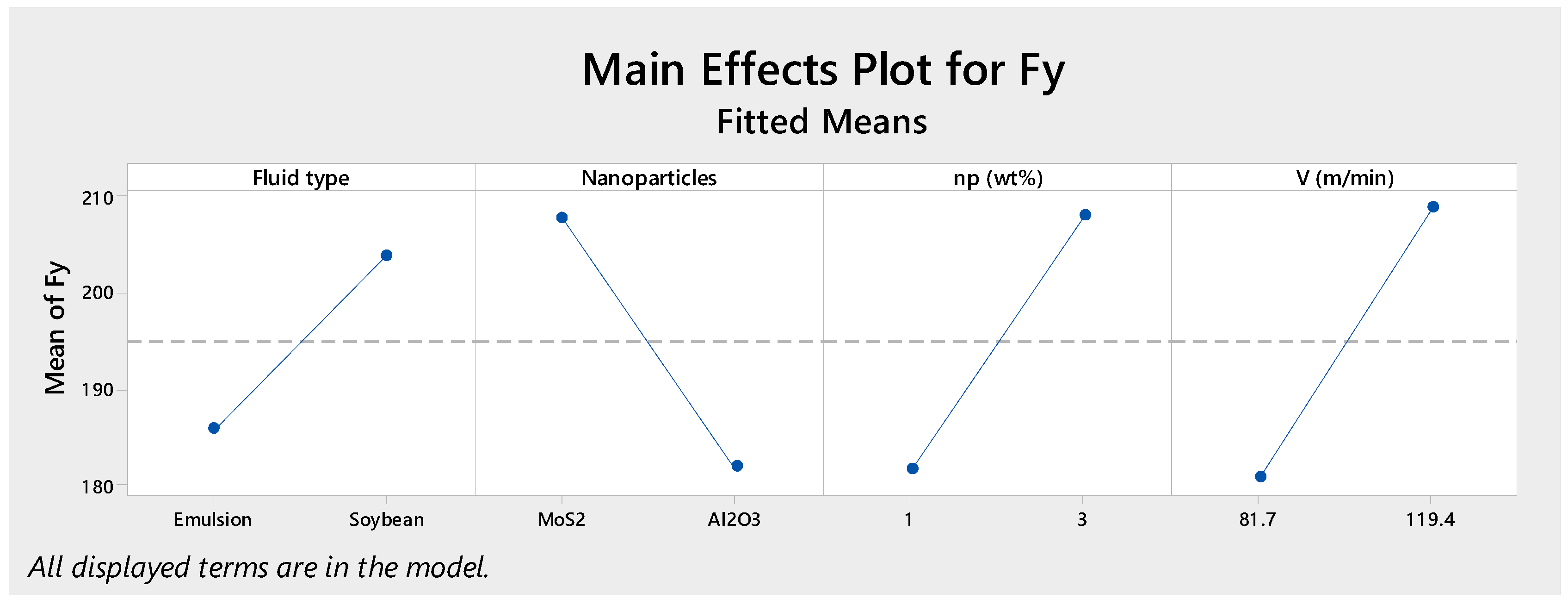

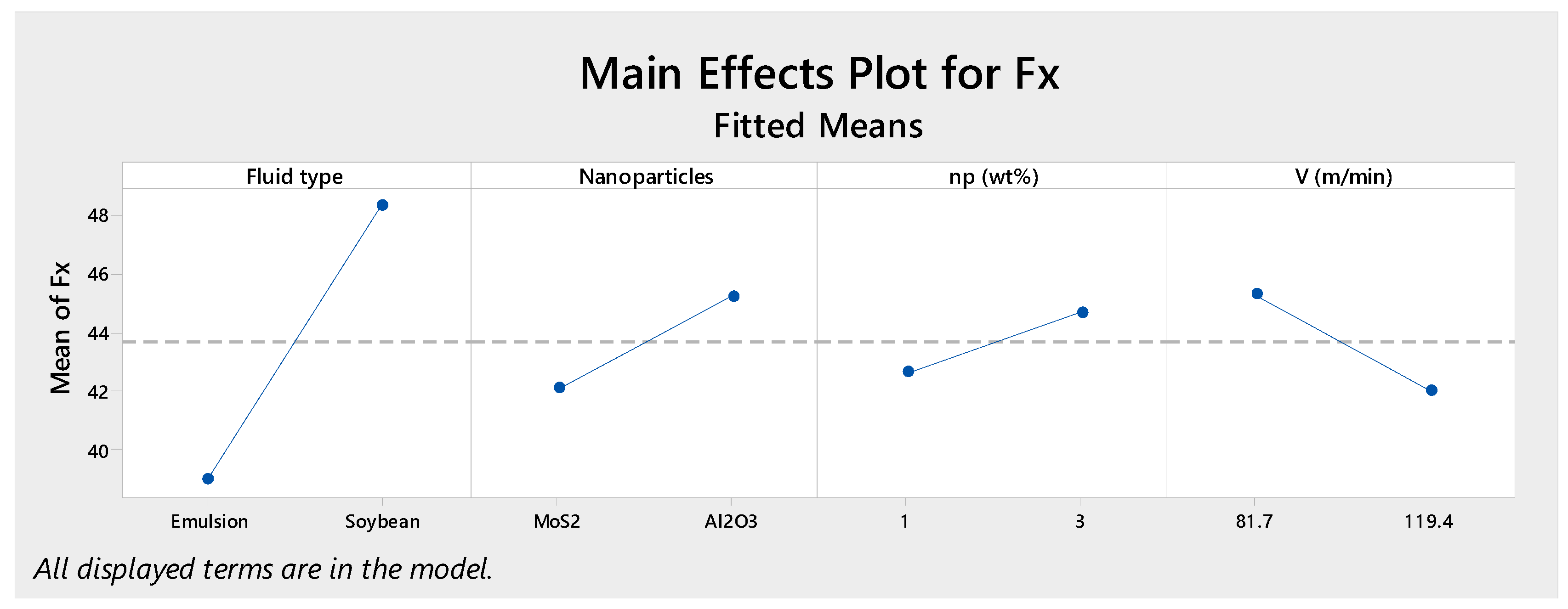

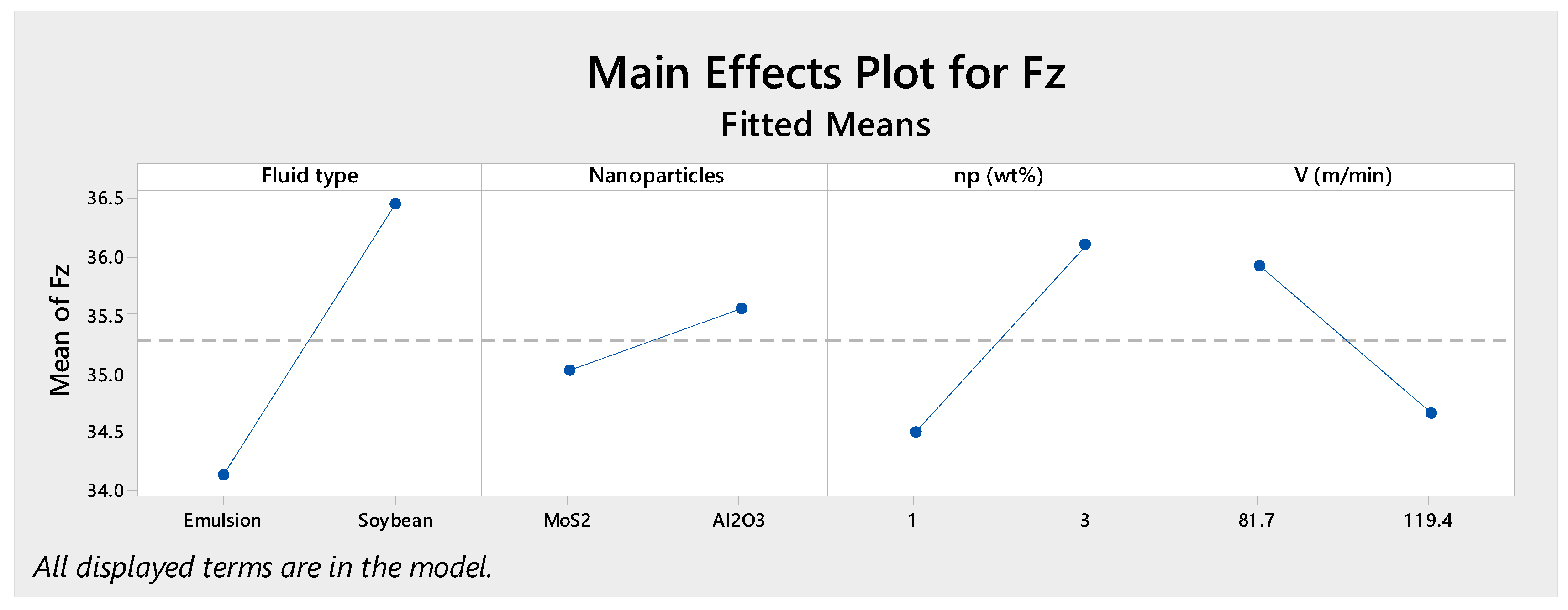

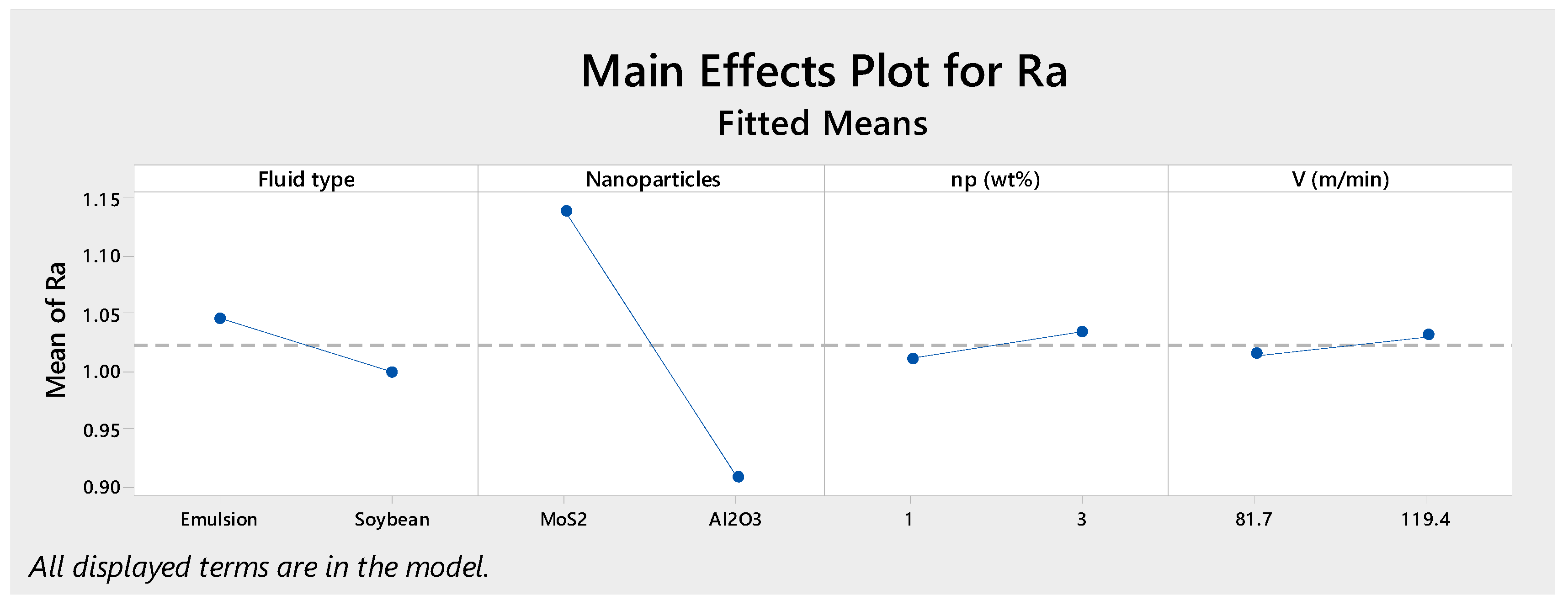

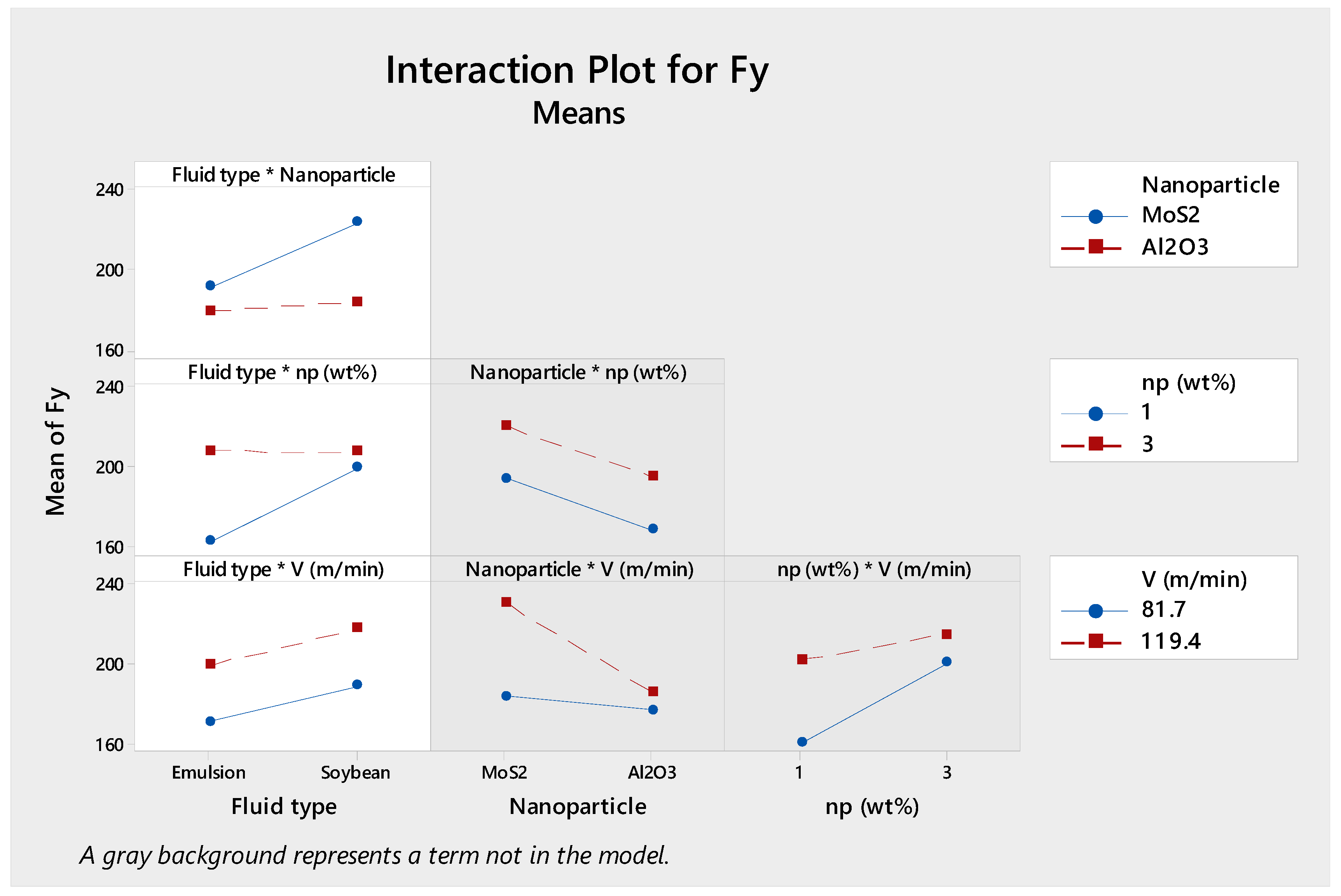

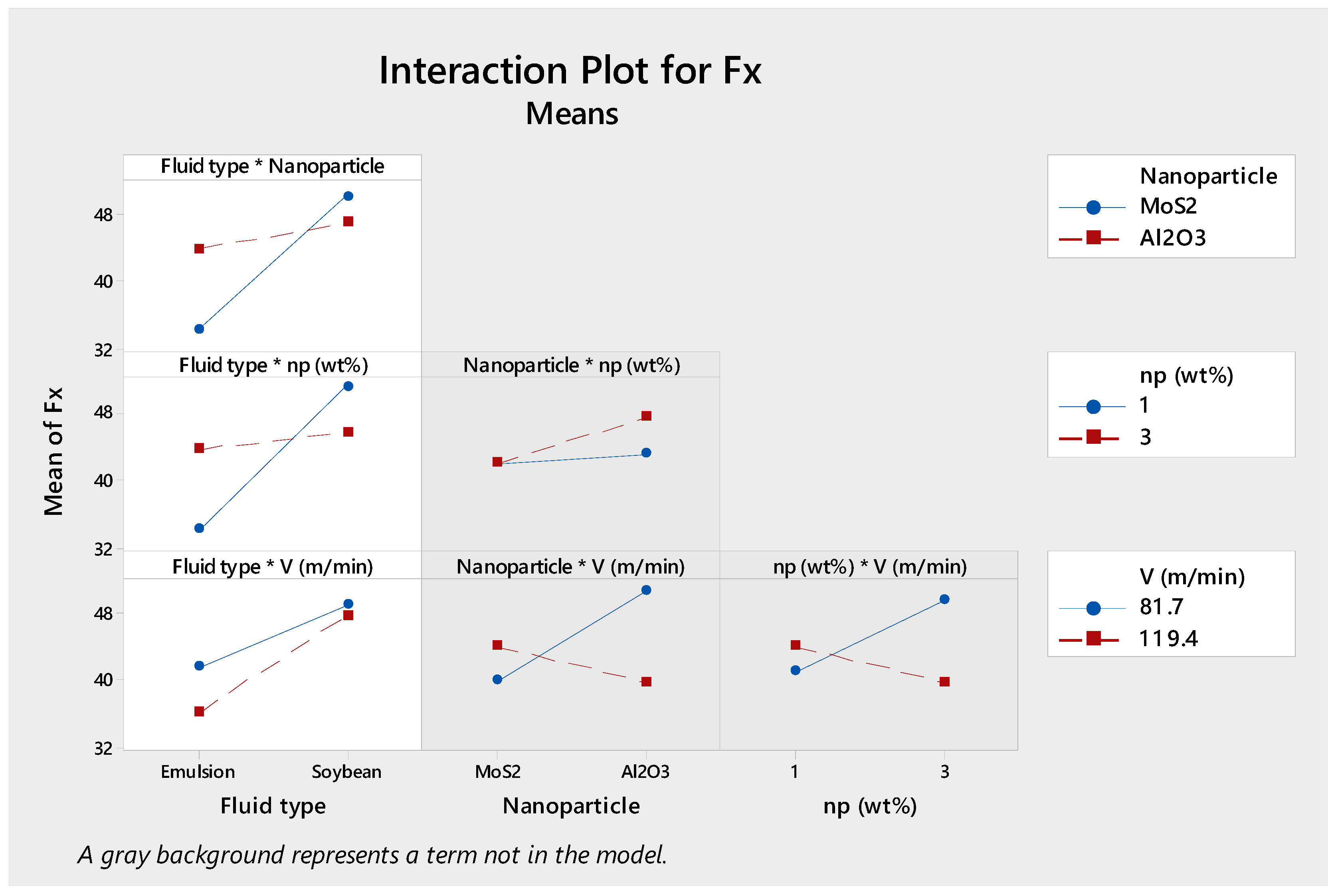

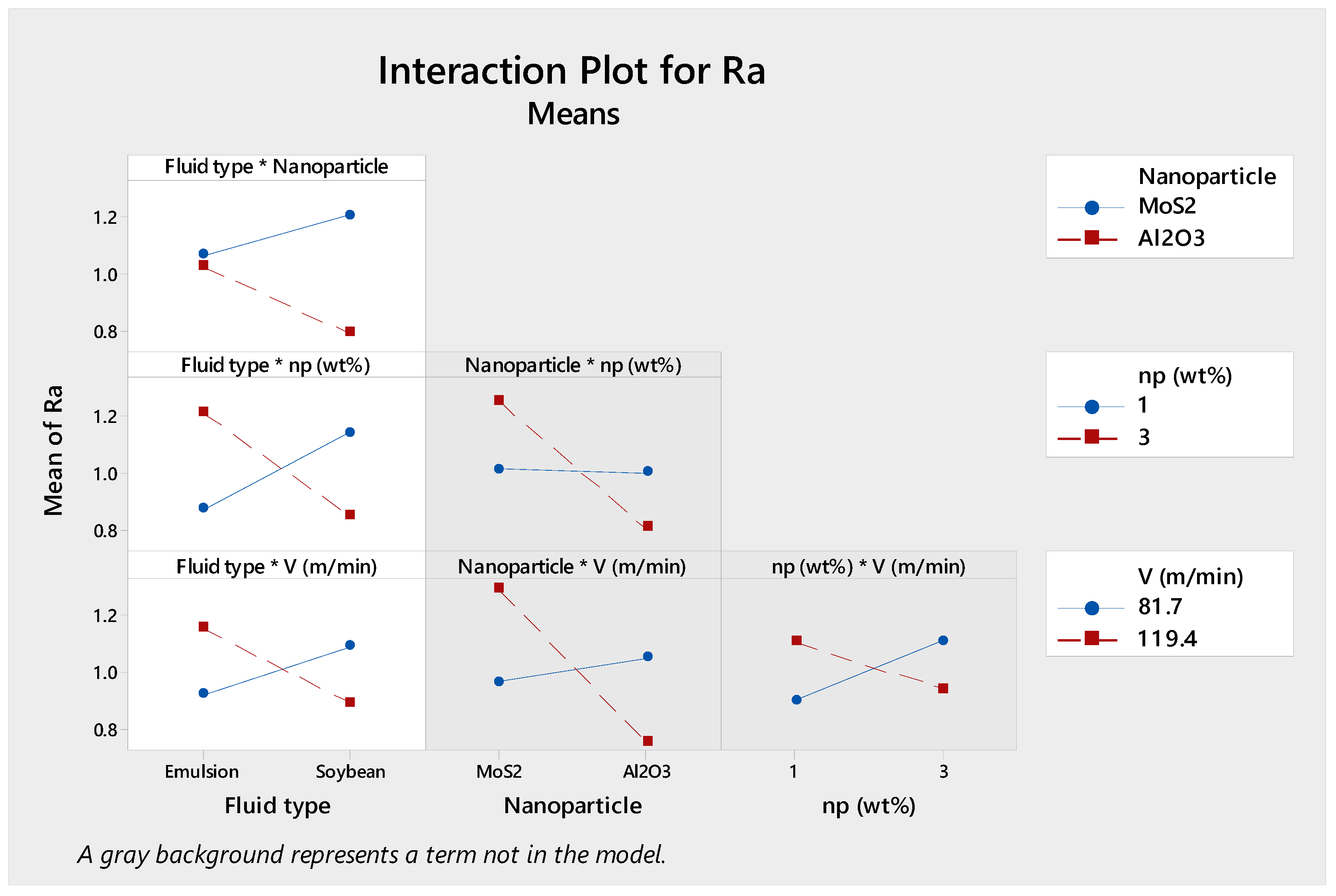

The empirical regression equations (Equations (2)–(5)) are formulated, and ANOVA analysis is carried out at a confidence level of 95% (i.e., 5% significance level). Most of possibility values (p-value) are smaller than the significance level α = 0.05, from which the investigated variables have a significant effect on the objective functions of Fx, Fy, Fz and Ra. In addition, the possibility values of linear models are much smaller than the significance level α = 0.05 and the regression models judged by the coefficients of determination (R2) are suitable.

Based on the experimental results, the direction for MQL parameters using nanofluids is studied in order to reach the desired outputs. MoS2 nanofluid has a strong effect on reducing cutting forces Fx, Fz but increasing thrust force (Fy), which is contrary to that of Al2O3 nanofluid. In finish hard turning machining, the thrust force (Fy) has a strongest influence on the dimensional accuracy, so Al2O3 nanofluid should be used in this case. Furthermore, to achieve the lowest value of surface roughness Ra, Al2O3 soybean-based nanofluid shows the better performance than that of the other investigated ones.

The investigation of Al2O3 and MoS2 nanofluids for MQL hard turning will provide the necessary technical guideline on using nanofluids and hybrid nanofluid more efficiently.

In further research, more investigations need to be focused on the effects of the concentration and size of nanoparticles and their interaction with the fluid types on tribological and heat transfer mechanisms in hard machining. The influence of nanoparticle morphology is necessary to be performed to understand the interaction with the friction coefficient. In addition, more focus will be given to optimize the parameter of Al2O3 and MoS2 nanofluid.