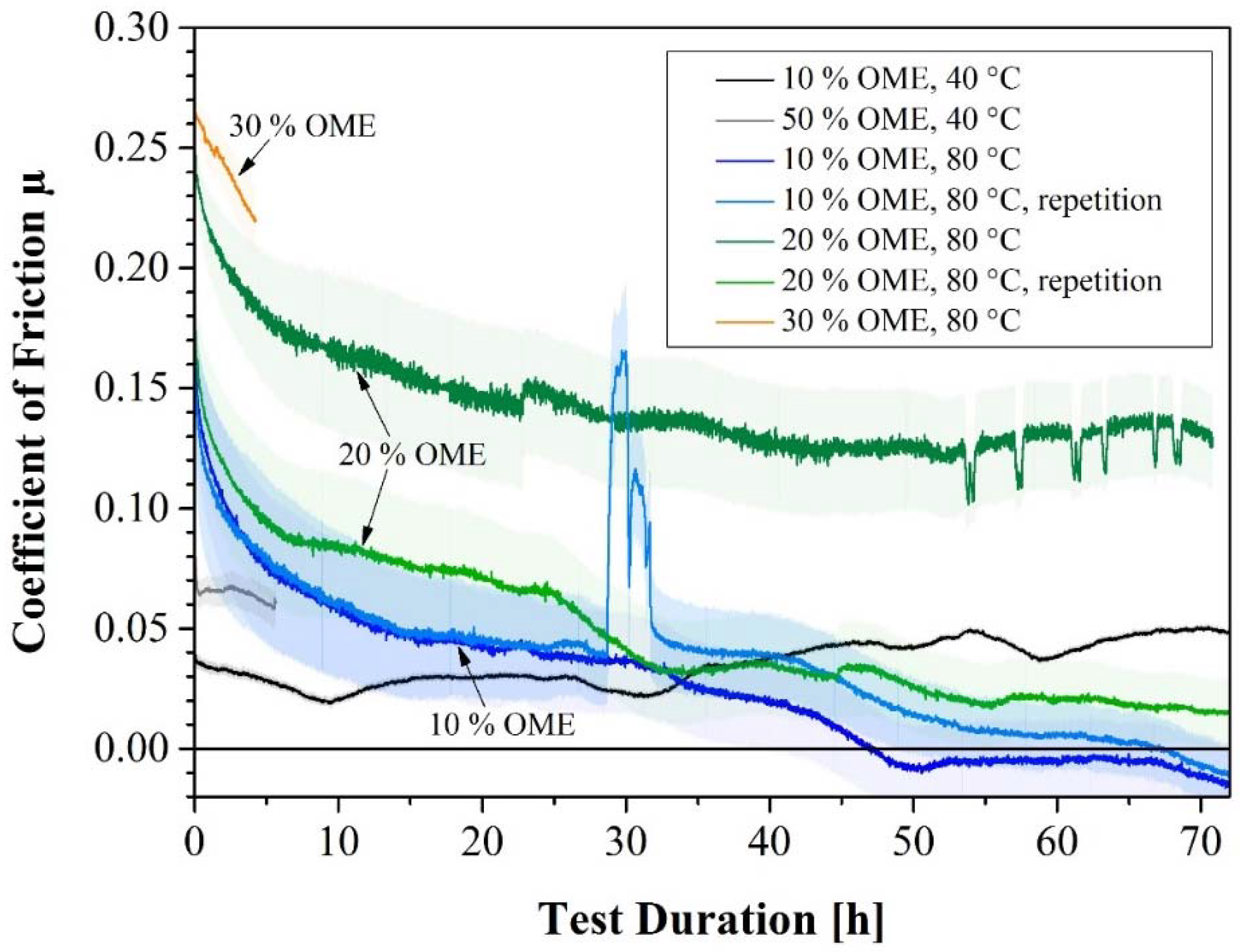

3.1. Tribological Results

To study the influence of OME on friction, tribometer tests were carried out at different OME concentrations (

Figure 2).

The friction coefficients that are plotted in

Figure 2 as a function of the test duration correlate with the OME dilution at constant temperature. Friction increases with increasing OME concentration at the same temperature. In addition, a time dependence can be seen in a decrease of the coefficient of friction at high temperature and an increase at low temperature.

The continuous increase in the coefficient of friction of 10% OME at 40 °C can be explained by the evaporation of the biofuel. Due to the high viscosity of the lubricant mixture (29.2 mPas), the operating point at the beginning of the test is in the range of hydrodynamics. After evaporation of the OME, viscosity increases even further and approaches the value of pure engine oil at 40 °C (58.5 mPas).

With increasing OME concentration in the lubricating oil, the viscosity of the oil-OME mixture decreases further, so that the solid contact in the mixed friction regime continues to increase. Consequently, the coefficient of friction continues to increase.

Within the first 10 h of the OME tests at 80 °C, a rapid decrease in the coefficient of friction can be observed, which can also be explained by the evaporation of the OME and the higher load-bearing capacity of the lubricant. The friction coefficients in the negative are artifacts and were caused by zero point shifts of the force sensor. The absolute value of the shift is low but can affect the coefficient of friction in the hydrodynamic regime.

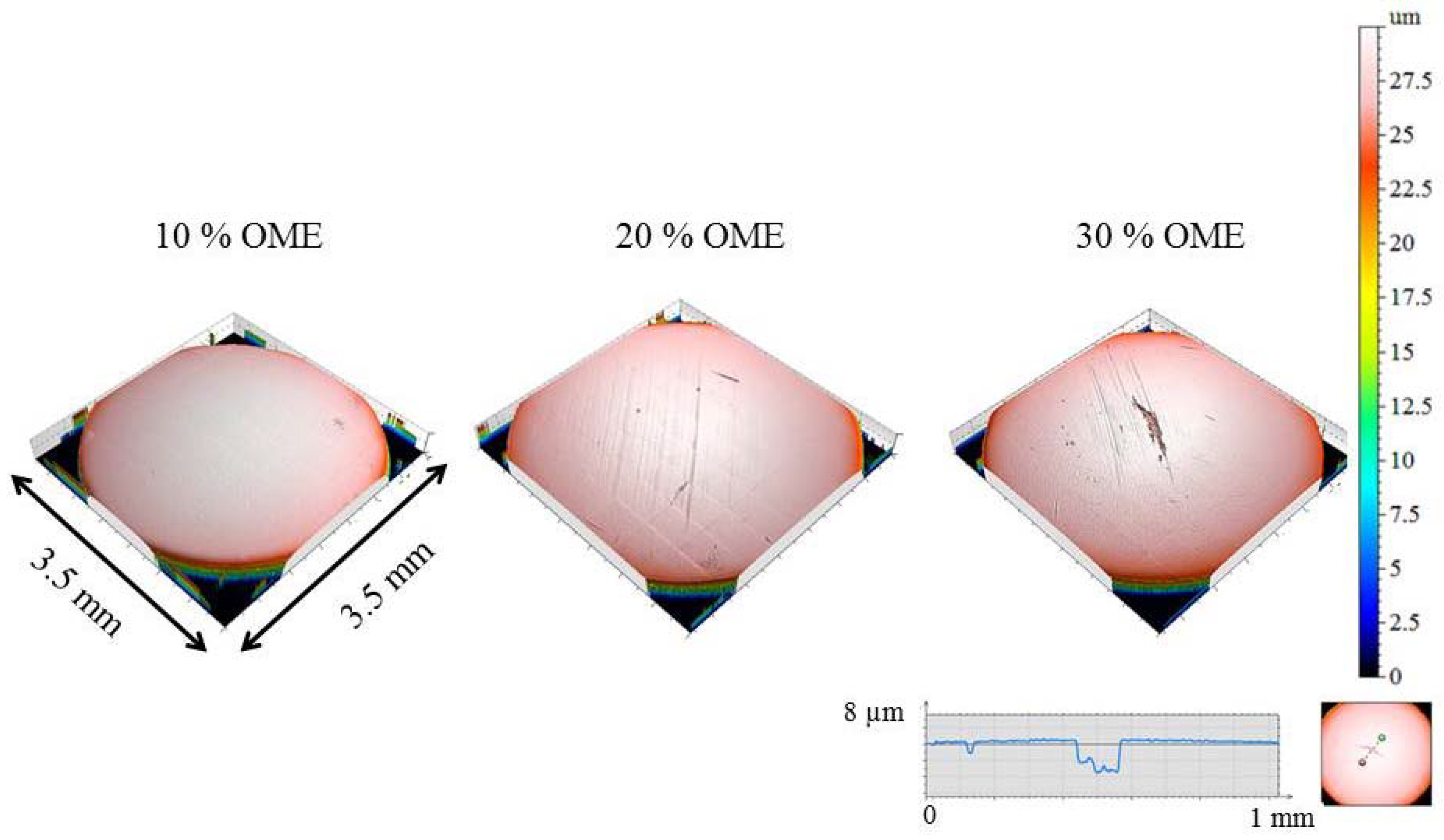

The described effect of viscosity reduction and the associated solid contact can also be determined on the surfaces of the DLC pins after tribological testing (

Figure 3).

After the experiment, the DLC layers of the pins show wear marks on their surfaces. The amount of marks increases with increasing OME dilution. The pin with 30% OME in the lubricant even has a deep crater reaching down to the substrate. Although distinct groove structures are present on the pin surfaces, the underlying wear mechanism is most likely carbon diffusion, which is typically found in DLC friction contacts [

8]. Abrasive wear is rather unusual with DLC systems [

9]. Furthermore, it is noticeable that at 30% OME dilution the DLC layer is ablated down to the substrate. The sharp edges of the wear mark indicate delamination as another wear mechanism.

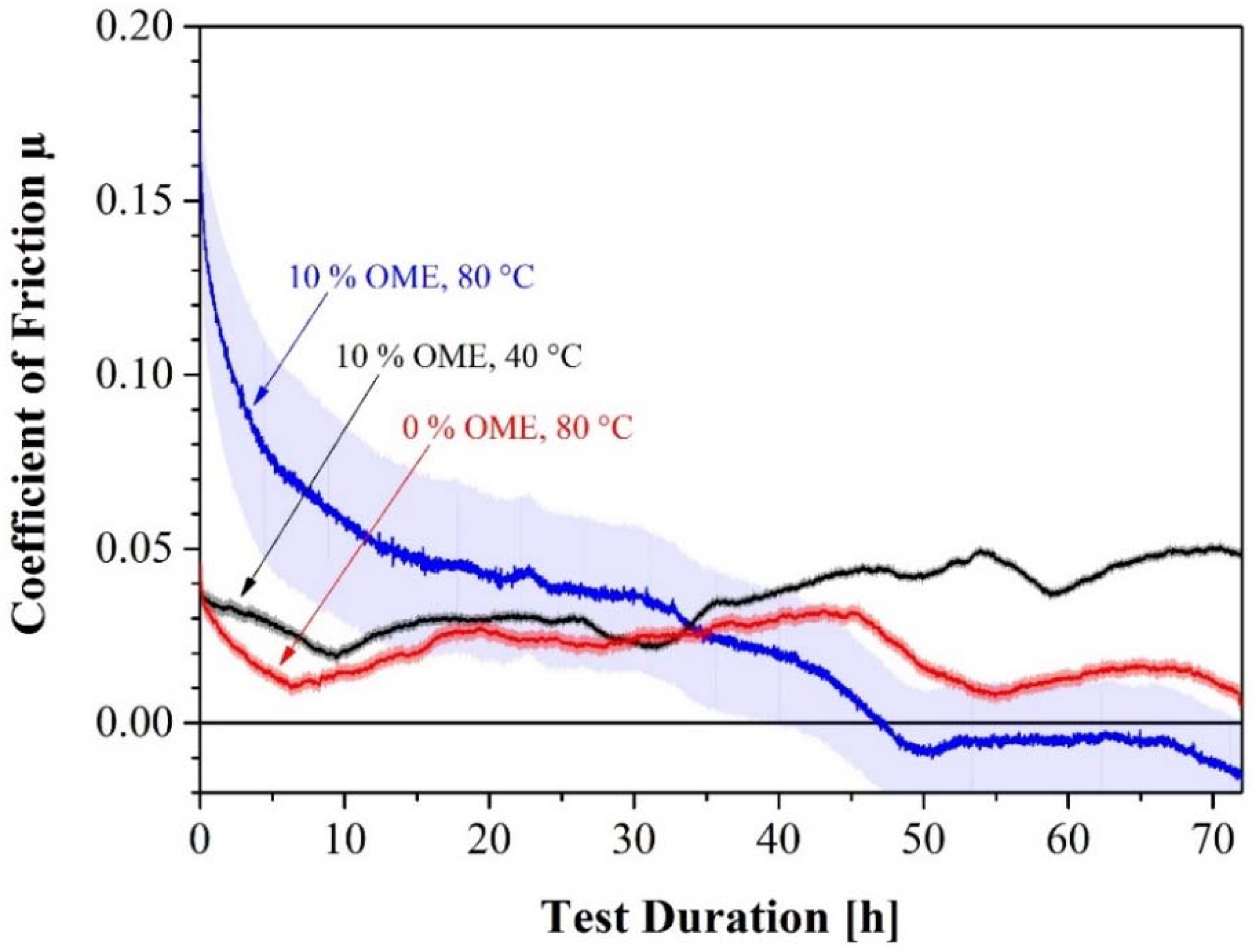

Figure 4 compares the friction coefficients of 10% OME at 40 and 80 °C with those of pure engine oil.

At 80 °C, the coefficient of friction is initially higher due to the reduced viscosity caused by the dilution with OME and the reduced viscosity of the base oil at that temperature. During the experiment the friction drops strongly, which we attribute to the evaporation of OME. Towards the end of the experiment the COF of undiluted and diluted oils are the same within the scatter of the data. For the diluted oil with 10% OME that is tested at 40 °C of the viscosity of the base oil is expected to be higher than at 80 °C, but due to the OME content, which does not evaporate, the friction is slightly higher than the pure base oil.

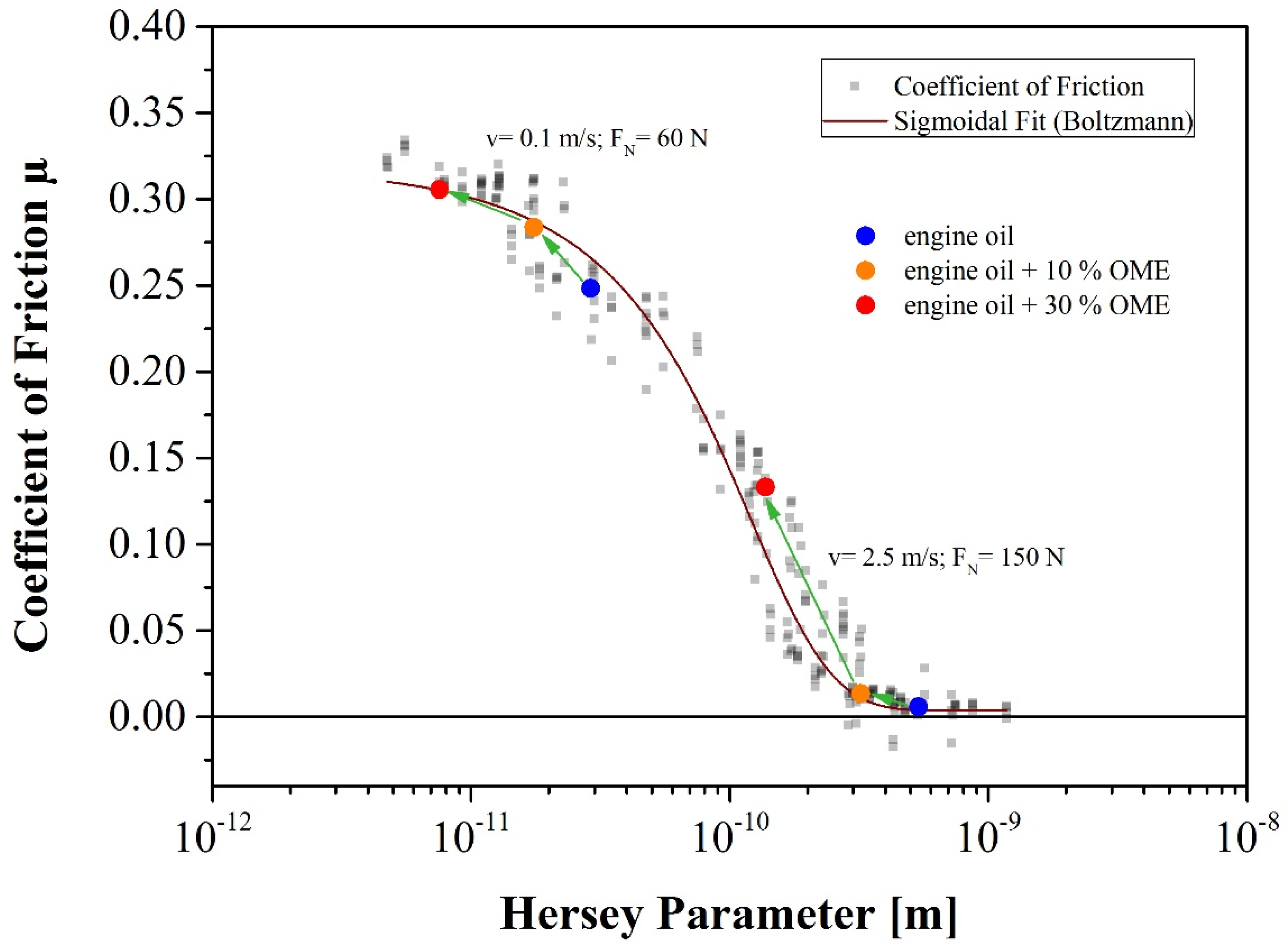

The addition of OME to the lubricating oil generally reduces viscosity. Friction partners can thus be separated less effectively from each other and the formation of a load-bearing lubricating film can be prevented. From a content of 30% OME (80 °C), no hydrodynamic conditions are achieved under the predefined test conditions. Operating points with very low coefficients of friction (e.g., at 2.5 m/s, 150 N) are already shifted at 10% OME into the mixed friction regime with a growing proportion of solid state friction. This trend is further intensified with increasing OME concentration, as can be seen in

Figure 5, where all friction data is plotted over the Hersey-number

H = η

v/

p, where η denotes the viscosity, v is the entrainment speed, and p the normal load. The Hersey number is related the oil film thickness and indicates the lubrication regime.

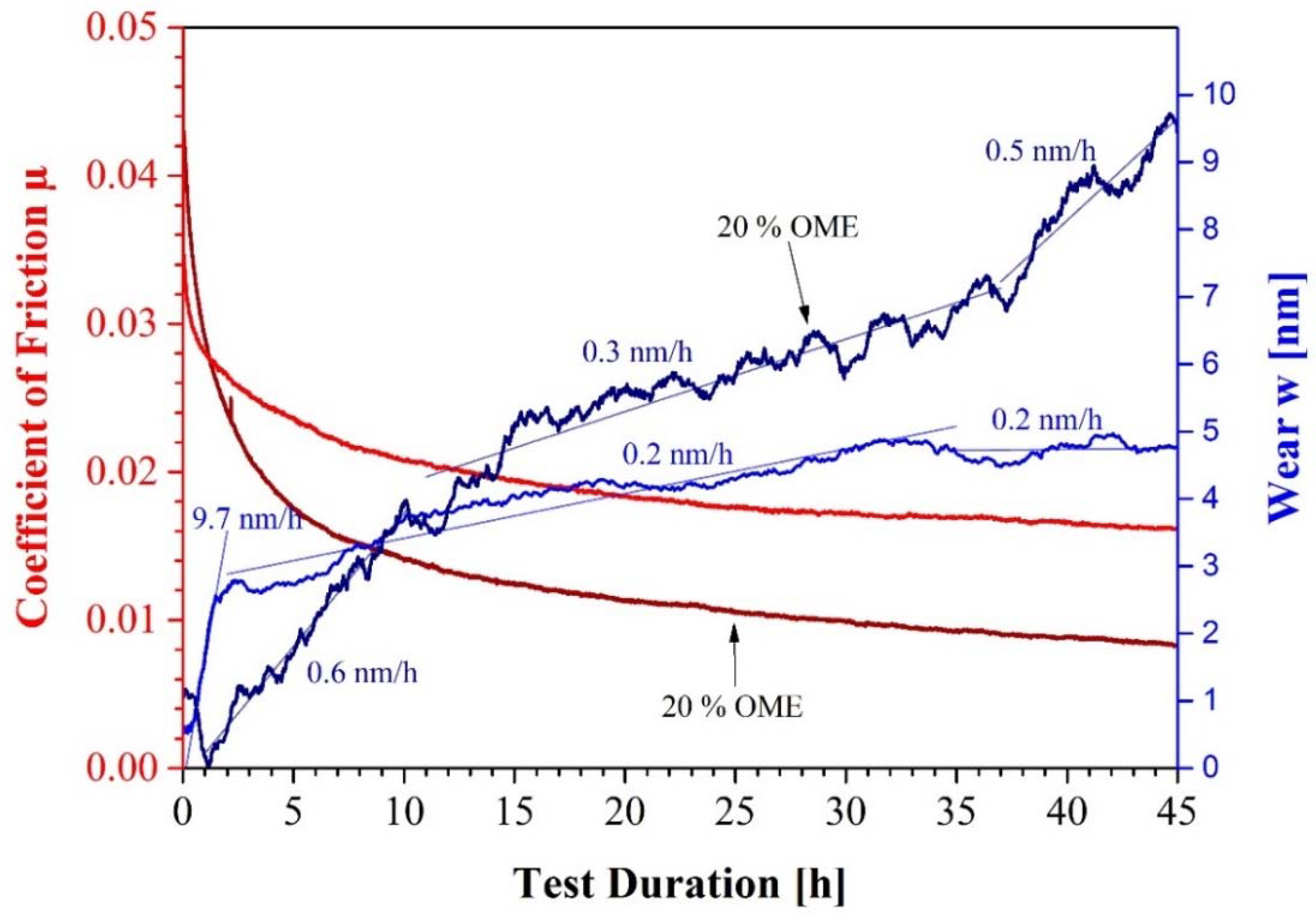

Figure 6 shows the RNT tests with the correlated friction curves.

The resolution limit of the radionuclide technique depends on the labelling and is approx. 0.1 μg/h (=0.05 nm/h for this sample).

In the tests with engine oil and engine oil plus 20% OME, the wear rates were below 1 nm/h. Due to the lower load-bearing capacity of the lubricating film of the oil thinned with 20% OME, higher contact pressures initially prevailed in the tribological system, which explain the higher beginning of the coefficient of friction.

3.2. Elemental Composition of the Worn Samples

The admixture of the biofuel could also have favored the formation of ZnDTP (zinc-dialkyl-dithiophosphate) layers, as higher friction densities were converted with increasing OME concentration. In Ref. [

10] it was found that an oil dilution with ethanol in the tribological system DLC-cast iron had positively influenced the layer formation of ZnDTP and thus a lower wear could be measured. Oxymethylene ether could have had a similar effect in this context, which could explain the lower wear rates within the first 5 h. The initially strong drop in the coefficient of friction at 20% OME can mainly be associated with the evaporation of the OME and the resulting increase in viscosity. The drop in the friction value below that of the test with pure engine oil could be due to the increased formation of a friction-reducing third body with the participation of ZnDTP. In order to clarify this situation, photoelectron spectroscopic measurements (XPS) was used to analyze the sliding tracks on the disks, which were tested with pure engine oil and with an OME content (

Figure 7).

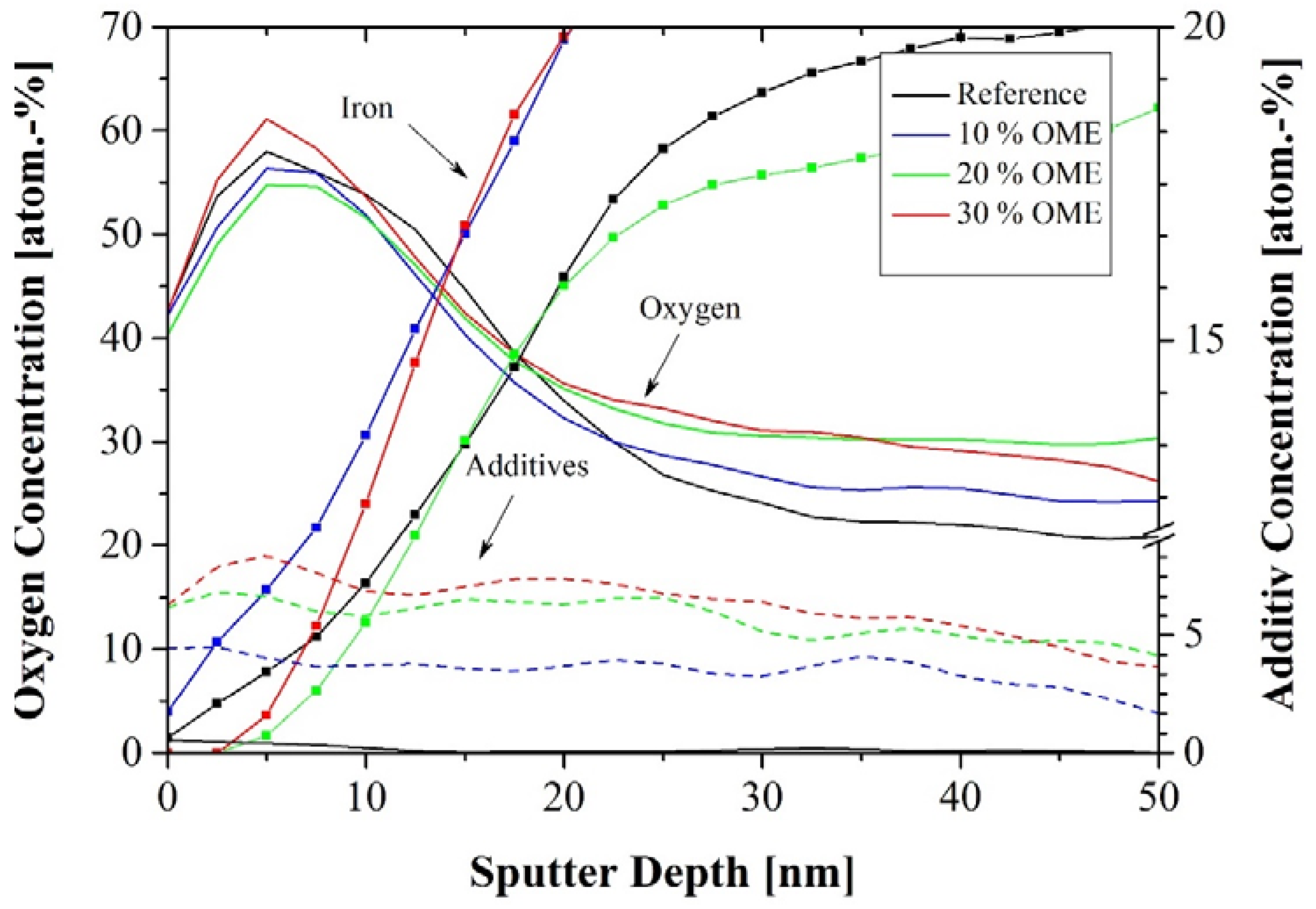

In all sliding tracks, a comparable depth profile (concentration and depth) of the oxygen concentration was detected independently of the OME content in the lubricant. Roughness on the length scale of the measurement area (several nm at 200 µm spot size) can in general influence the course of the depth signal but since all measured depth profiles show the same depth-concentration trend, does not affect the comparison of different OME concentrations. Therefore, a corrosive effect of oxymethylenether can be ruled out during the friction process. This is confirmed when the reference measurement (black) and the measurement at 30% OME (red) are compared in

Figure 6. Moreover, with an oxidative effect of OME, the values of 10% and 20% OME within the first 15 nm sputter depth should not be below the reference measurement. The oxygen content, which does not disappear at a depth of 50 nm, must be caused by oxidation of the spray particles during thermal spraying.

Furthermore, a correlation between the oxygen concentration and the concentration of the additives at a depth of more than 30 nm is found. As the OME concentration increases, oxides of the additives, namely Ca, Zn and P, are increasingly detected, which also led to an increase in the oxygen concentration at greater sputter depths.

By adding OME to the lubricating oil, the viscosity decreases so that the friction power density in the tribological contact increases. The friction track could have been exposed to locally higher temperatures, which could have caused ZnDTP to adsorb to the steel surface. With increasing OME content, the frictional stress increases due to a higher solid content and the formation of tribological layers becomes more probable. This assumption was confirmed by the increase in additive oxides, which had to be measured as the biofuel content increased.