Abstract

The automotive industry is undergoing a transformative shift toward sustainability, driven by stringent environmental regulations, rising energy demands, and the pursuit of enhanced performance and efficiency. Lubricating materials play a pivotal role in reducing friction, wear, and energy losses in automotive systems, yet conventional lubricants, primarily petroleum-based, pose significant ecological and operational challenges. This review examines the development and performance of sustainable and advanced lubricant including bio-based oils, synthetic esters, nanolubricants, and ionic/solid lubricants for automotive applications. Drawing on tribological principles and recent advances in materials science, the article categorizes these lubricants based on source, chemical structure, and tribological behavior. A comparative framework is introduced to evaluate key performance indicators such as viscosity index, thermal stability, oxidation resistance, biodegradability, and compatibility with modern engine designs. The review also highlights emerging trends, including nanotechnology-based additives, green synthesis techniques, and novel antioxidant systems that enhance lubricant functionality and lifespan. Furthermore, a strategic research roadmap is proposed, outlining short-, medium-, and long-term priorities that integrate technical, environmental, and economic dimensions. By bridging foundational science with practical innovation, this article aims to guide researchers, manufacturers, and policymakers toward the adoption of high-performance, eco-compatible lubricants that support the transition to cleaner and more efficient mobility systems. Future directions and challenges in scaling, cost-effectiveness, and lifecycle assessment are discussed to guide innovation in this critical domain.

1. Introduction

Over the past few decades, the rapid expansion of the global vehicle fleet has led to a sharp rise in harmful emissions, posing one of the most pressing environmental challenges worldwide [1,2]. With road traffic expected to grow by nearly 45% in both developed and developing countries by 2025, the strain on transportation infrastructure and the environment is becoming increasingly evident [3,4]. This surge not only affects traffic flow and density but also places greater mechanical demands on vehicles [5]. In response, the role of lubrication has become more critical than ever. Modern lubricants must go beyond basic friction reduction they need to perform reliably under extreme conditions, enhance fuel efficiency, and contribute to lowering emissions, all while supporting the longevity of increasingly complex automotive system [6]. Lubrication plays a vital role in the smooth functioning in automotive systems. It reduces friction between moving parts, minimizes wear, and helps dissipate heat, thereby improving the efficiency and longevity of engines, transmissions, and other mechanical components. Without effective lubrication, vehicles would suffer from rapid degradation, increased fuel consumption, and frequent breakdowns [7,8]. As automotive technologies evolve, the demands placed on lubricants have grown more complex, requiring materials that can perform reliably under extreme conditions. Traditionally, the industry has relied heavily on petroleum-based lubricants due to their availability and proven performance. However, these conventional lubricants come with significant drawbacks. They are derived from non-renewable resources, contribute to environmental pollution, and often contain additives that are harmful to ecosystems. Moreover, their disposal poses challenges, and their degradation can release toxic by-products [3,8]. As global awareness of environmental issues increases, the automotive sector faces mounting pressure to adopt greener, more sustainable practices including the use of eco-friendly lubricants.

This shift has sparked interest in alternative lubricating materials that are both high-performing in the automotive and environmentally responsible. Bio-based oils, synthetic esters, nanomaterials, and ionic liquids are among the promising candidates being explored [8,9,10,11]. These advanced lubricants offer benefits such as biodegradability, reduced toxicity, and improved thermal and oxidative stability [12,13,14,15]. In addition, innovations in surface coatings and smart lubrication systems are opening new avenues for enhancing performance while reducing environmental impact [16]. Despite their potential, sustainable lubricants are not yet widely adopted. Challenges such as cost, scalability, compatibility with existing systems, and long-term durability must be addressed. Research is ongoing to refine these materials and develop standards that ensure their reliability across diverse automotive applications. The integration of these lubricants into mainstream use will require collaboration between researchers, manufacturers, and policymakers.

This review aims to provide a comprehensive and critical evaluation of sustainable and advanced lubricating materials for automotive applications, addressing both their technical performance and environmental implications. It seeks to trace the evolution of lubricants from conventional petroleum-based formulations to emerging alternatives such as bio-based oils, synthetic esters, nanolubricants, and ionic liquids. By integrating tribological principles, material science, and recent technological innovations, the review highlights the strengths, limitations, and suitability of each lubricant class across key performance metrics. Additionally, we have also introduced a conceptual framework and comparative analysis to guide material selection and formulation strategies. The article also outlines future research priorities and industrial pathways, emphasizing the need for scalable production, compatibility with evolving vehicle technologies, and alignment with global sustainability goals. Ultimately, the review aims to support informed decision-making among researchers, manufacturers, and policymakers working toward cleaner, more efficient, and environmentally responsible automotive lubrication systems.

2. Fundamental of Lubricants

Lubrication is a critical aspect of mechanical engineering, particularly in automotive systems where moving parts are constantly in contact under varying loads and speeds. The science that governs lubrication is known as tribology, which encompasses the study of friction, wear, and the mechanisms by which lubricants reduce these effects [7,17,18,19]. Understanding the fundamentals of tribology is essential for designing efficient, durable, and environmentally responsible automotive components.

2.1. Basic Principles of Tribology

At its core, tribology deals with three interrelated phenomena: friction, wear, and lubrication. Friction is the resistive force that occurs when two surfaces slide against each other. While some friction is necessary for functions like braking, excessive friction leads to energy loss and heat generation. Wear refers to the gradual removal or deformation of material from a surface due to mechanical action. It can manifest in various forms such as abrasion, adhesion, fatigue, or corrosion, each affecting the lifespan and reliability of automotive parts. Lubrication mechanisms are designed to mitigate both friction and wear. The primary goal is to create a film or barrier between surfaces to prevent direct contact. This film can be liquid, solid, or semi-solid, depending on the application. Lubrication operates in different regimes—boundary, mixed, and hydrodynamic—each defined by the thickness of the lubricant film relative to surface roughness. In hydrodynamic lubrication, a full fluid film separates the surfaces, offering minimal friction. Boundary lubrication, on the other hand, occurs when the film is thin and additives play a crucial role in protecting surfaces.

2.2. Types of Lubricants

Lubricants are broadly categorized based on their physical state and composition. Liquid lubricants are the most common and include mineral oils, synthetic oils, and bio-based oils. These are used extensively in engines, transmissions, and hydraulic systems due to their ability to flow and form continuous films. Solid lubricants, such as graphite, molybdenum disulfide (MoS2), and polytetrafluoroethylene (PTFE), are employed in extreme conditions where liquids may evaporate or degrade, such as high-temperature or vacuum environments. They function by forming a low-shear dependent strength layer and tribological behavior that reduces friction [20,21,22]. Semi-solid lubricants, commonly referred to as greases, consist of a base oil thickened with soaps or other agents. Greases are ideal for applications where re-lubrication is infrequent or where the lubricant must stay in place under gravity or centrifugal forces. Each type of lubricant has its own advantages and limitations, and the choice depends on factors like operating temperature, load, speed, and environmental exposure.

2.3. Key Performance Metrics

The effectiveness of a lubricant is determined by several performance metrics. Viscosity is one of the most critical parameters it defines the lubricant’s resistance to flow and its ability to maintain a film between surfaces. A lubricant must have the right viscosity to ensure adequate protection without causing excessive drag. Viscosity index (VI) measures how viscosity changes with temperature; a high VI indicates better stability across temperature ranges. Thermal stability refers to the lubricant’s ability to resist breakdown at elevated temperatures. In automotive applications, where components can reach high operating temperatures, thermal degradation can lead to sludge formation and loss of lubrication properties. Oxidation resistance is closely related and ensures that the lubricant maintains its chemical integrity over time.

Biodegradability has become an increasingly important metric in the context of environmental sustainability. Lubricants that break down naturally pose less risk to ecosystems in case of leaks or disposal. Other important properties include pour point (the lowest temperature at which a lubricant remains fluid), flash point (the temperature at which it can ignite), and load-carrying capacity, which determines how well the lubricant can protect surfaces under pressure. In summary, the fundamentals of lubrication involve a complex interplay of physical and chemical properties tailored to meet the demands of modern automotive systems. As the industry moves toward greener technologies, understanding these principles is essential for developing lubricants that not only perform well but also align with environmental goals.

The foundational tribological principles such as viscosity, film formation, and thermal stability with the performance of advanced lubricants in real-world automotive applications. Specifically, we now highlight how this core metrics influence the behavior and effectiveness of emerging lubricant technologies like nanolubricants and bio-based oils under dynamic operating conditions. Viscosity, for example, plays a pivotal role in determining whether a lubricant can maintain a stable film between moving surfaces, especially under varying loads and temperatures typical of automotive engines and transmissions. In the case of bio-based oils, their naturally high viscosity can offer excellent film-forming capabilities in boundary and mixed lubrication regimes. Similarly, nanolubricants leverage engineered nanoparticles to enhance film strength and reduce direct surface contact, even under extreme pressure and shear conditions. These nanoparticles can improve load-carrying capacity and reduce friction by forming protective tribofilms or acting as rolling elements between surfaces. Thermal stability is another critical factor, particularly in high-temperature zones such as combustion chambers and turbochargers. Bio-based oils, while environmentally friendly, often suffer from thermal degradation unless fortified with antioxidants [23,24,25]. In contrast, nanolubricants and ionic liquids exhibit superior thermal resilience, maintaining their structural integrity and lubricating properties even under prolonged exposure to heat. This makes them promising candidates for next-generation automotive systems that demand both high performance and environmental compliance.

3. Conventional Lubricants: Limitations and Environmental Impact

In the last several decades, petroleum-based lubricants have been the backbone of the automotive industry. Their widespread use stems from their proven performance, availability, and cost-effectiveness. These lubricants are typically derived from crude oil through refining processes that produce base oils, which are then blended with chemical additives to enhance properties such as viscosity, oxidation resistance, and anti-wear behavior. In automotive systems, they serve critical functions in engines, transmissions, axles, and hydraulic circuits reducing friction, cooling components, and preventing corrosion. Despite their functional advantages, petroleum-based lubricants present a range of environmental and sustainability challenges. One of the primary concerns is their toxicity. Many conventional lubricants contain additives like heavy metals, sulfur compounds, and chlorinated substances, which can be harmful to aquatic life and soil organisms if leaked or improperly disposed of. These substances can persist in the environment, accumulating in ecosystems and posing long-term risks to biodiversity and human health. We have also observed that sustainable lubricants can be categorized into four distinct classes, such as bio-based oils, synthetic esters, nanolubricants, and ionic/solid lubricants. This classification is grounded in three key criteria source, chemical structure, and tribological behavior which together provide a coherent basis for evaluating the suitability of each lubricant type for modern automotive applications. Bio-based oils are derived from renewable biological sources such as vegetable oils and animal fats. Their chemical structure typically consists of triglycerides and fatty acid esters, which offer high biodegradability and low toxicity [14,26]. However, they often require chemical modification or the addition of stabilizers to improve oxidative stability and thermal performance. Synthetic esters, on the other hand, are engineered through controlled chemical synthesis to achieve uniform molecular structures that enhance viscosity control, thermal resistance, and compatibility with engine components. These esters strike a balance between environmental friendliness and high-performance characteristics.

Nanolubricants represent a more recent innovation, incorporating nanoparticles such as metal oxides, carbon-based materials, or layered silicates into base fluids [27]. Their nanoscale dimensions enable unique surface interactions that reduce friction and wear, improve load-carrying capacity, and extend lubricant life [28,29]. Despite their promising tribological behavior, challenges remain in terms of dispersion stability, cost-effectiveness, and large-scale production. Ionic and solid lubricants such as ionic liquids, graphene, and molybdenum disulfide offer exceptional thermal and chemical stability, often functioning under extreme conditions where conventional lubricants fail [28,29,30]. These materials are increasingly explored for coatings and specialized applications, though their integration into mainstream automotive systems is still evolving.

Another major issue is non-biodegradability. Unlike natural oils, petroleum-based lubricants do not break down easily in the environment. When spilled or discarded, they can contaminate water bodies and soil, remaining active for years. This persistence complicates clean-up efforts and increases the likelihood of environmental damage. Moreover, the disposal of used lubricants often involves incineration or landfilling, both of which contribute to pollution and greenhouse gas emissions. The production of petroleum-based lubricants also contributes to resource depletion. Crude oil is a finite resource, and its extraction and processing are energy-intensive activities that release significant amounts of carbon dioxide and other pollutants. Further we have given brief comprehensive comparative table that systematically presents the differences between major lubricant types bio-based oils, synthetic esters, nanolubricants, ionic liquids, and conventional petroleum-based lubricants across key performance indicators such as tribological behavior, thermal stability, oxidation resistance, biodegradability, and compatibility with engine materials. This Table 1 clearly mentioned the understanding of the relative strengths, limitations, and suitability of each lubricant category for automotive applications, thereby improving the manuscript’s structural integrity and practical relevance. As global demand for transportation continues to rise, so does the pressure on oil reserves, raising concerns about long-term availability and the environmental cost of continued reliance on fossil fuels.

Table 1.

Comparative analysis of sustainable lubricant classes and their performance attributes [13,15,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45].

Furthermore, there are still several challenges including governments and regulatory bodies around the world have begun to impose stricter controls on lubricant composition, usage, and disposal. Agencies such as the U.S. Environmental Protection Agency (EPA), the European Chemicals Agency (ECHA), and India’s Central Pollution Control Board (CPCB) have introduced guidelines that limit the use of hazardous additives and promote the development of biodegradable alternatives. These regulations are pushing manufacturers to reformulate products and invest in greener technologies. Market trends are also shifting in favor of sustainability. Consumers and industries alike are becoming more conscious of environmental impact, leading to increased demand for lubricants that are both high-performing and eco-friendly. Automotive manufacturers are seeking lubricants that align with their broader goals of reducing emissions and improving fuel efficiency. As a result, the lubricant industry is witnessing a gradual but steady transition toward bio-based oils, synthetic esters, and other advanced formulations that promise lower toxicity and better environmental compatibility. In summary, while petroleum-based lubricants have served the automotive sector well for many years, their environmental drawbacks are becoming increasingly difficult to ignore. The combination of ecological concerns, regulatory pressure, and evolving market expectations is driving a shift toward more sustainable alternatives. Understanding these limitations is essential for guiding future innovation in lubricant technology and ensuring that automotive systems continue to evolve in harmony with environmental goals.

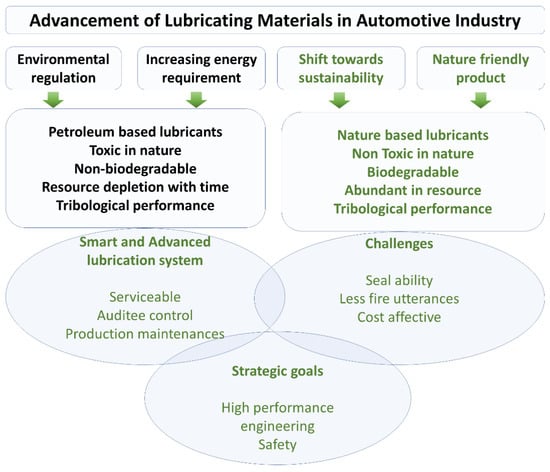

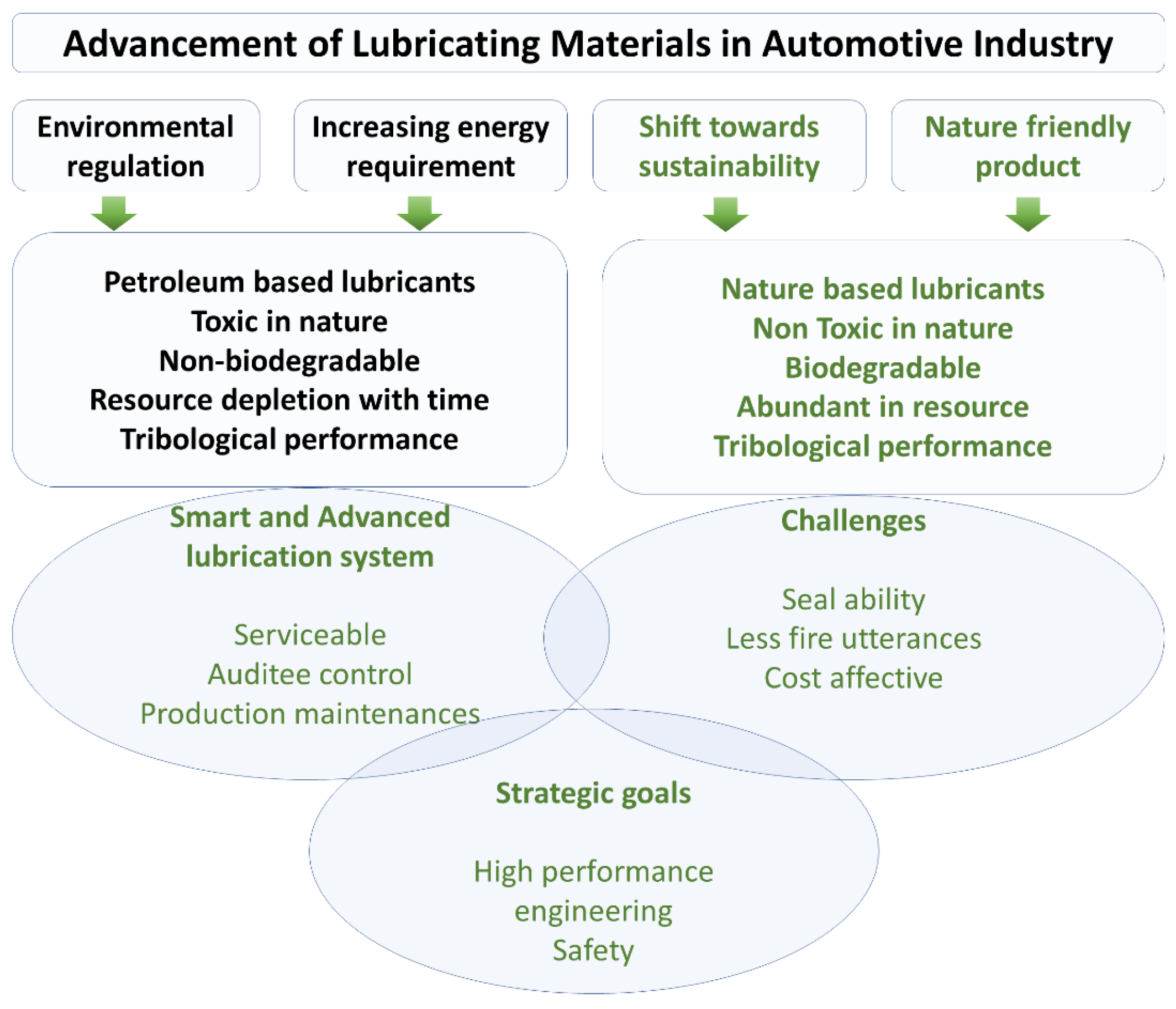

4. Sustainable and Nature Friendly Lubricating Materials

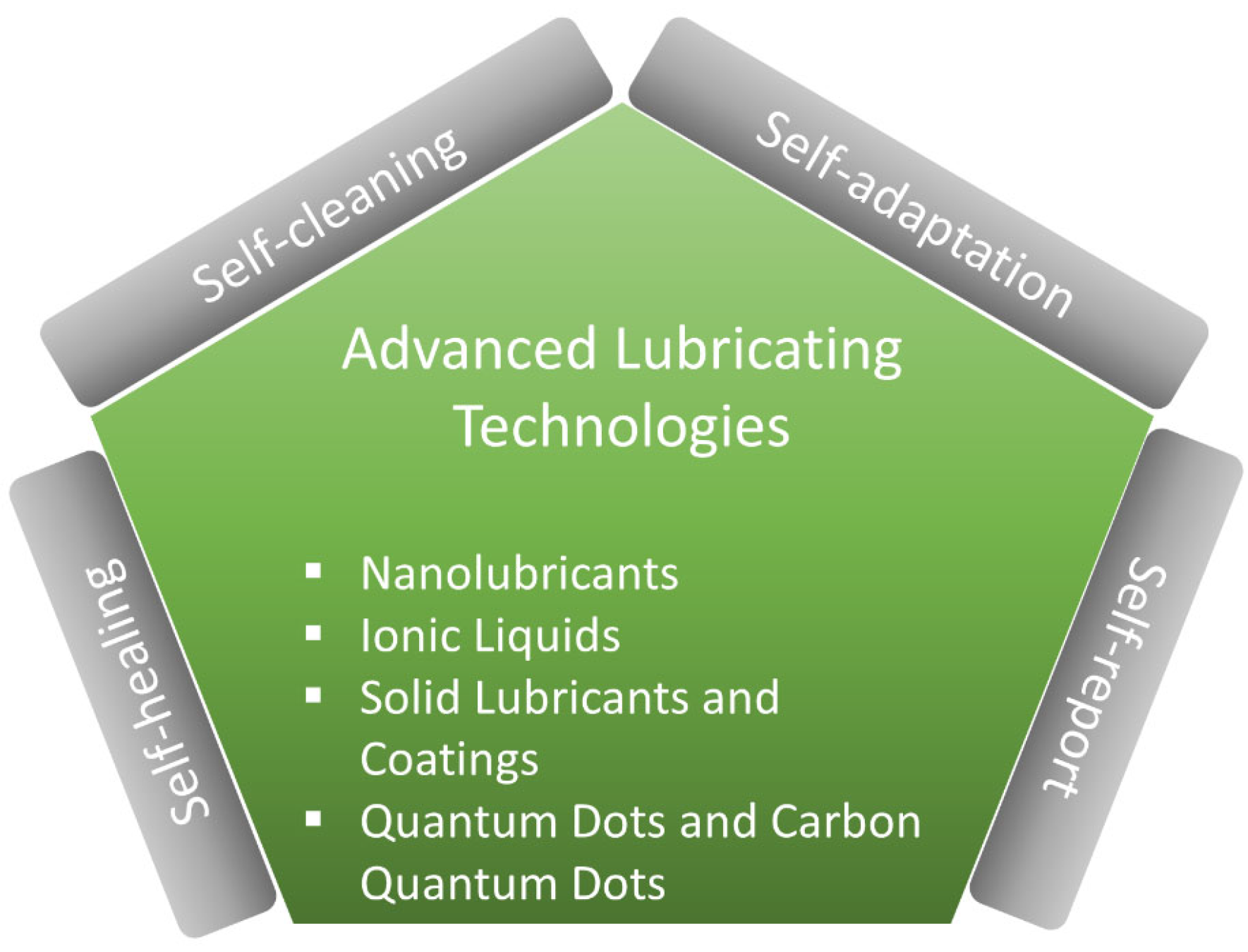

As the automotive industry moves toward cleaner technologies and reduced environmental impact, the development of sustainable lubricating materials has become a focal point of innovation (Figure 1). These alternatives aim to replace conventional petroleum-based lubricants with formulations that are not only high-performing but also environmentally responsible. Among the most promising categories are bio-based lubricants and synthetic esters enhanced with eco-friendly additives.

Figure 1.

The conceptual map of development of sustainable lubrication materials towards advancement of lubricating technology innovation for high performance.

Figure 1.

The conceptual map of development of sustainable lubrication materials towards advancement of lubricating technology innovation for high performance.

4.1. Biodegradable Lubricants

Bio-based lubricants are derived from renewable biological sources, making them an attractive alternative to fossil-derived oils. Common feedstocks include vegetable oils such as soybean, rapeseed, sunflower, and palm oil. These oils are rich in triglycerides, which provide excellent lubricity and film strength. In some formulations, animal fats are also used, although they are less common due to sourcing and processing limitations. Additionally, esters produced through chemical modification of these natural oils such as transesterification offer improved thermal and oxidative stability, making them suitable for more demanding automotive applications. One of the key advantages of bio-based lubricants is their renewability. Unlike petroleum, which is finite and geopolitically sensitive, vegetable oils can be cultivated annually, offering a more stable and sustainable supply chain. Moreover, these lubricants are generally biodegradable, meaning they break down naturally in the environment without leaving harmful residues. This property significantly reduces the ecological risk associated with leaks, spills, and disposal, especially in sensitive areas like agricultural zones or water bodies.

4.2. Nature Friendly Lubricants

The nature or bio-based lubricants face several technical challenges that limit their widespread adoption. One major issue is oxidation stability. Natural oils tend to degrade when exposed to high temperatures and oxygen, forming sludge and acids that can damage engine components. This necessitates the use of antioxidants and stabilizers, which can increase formulation costs. Another concern is cold flow behavior. Vegetable oils often have poor low-temperature properties, becoming viscous or even solidifying in cold climates. This can impair lubrication during engine start-up and reduce fuel efficiency. Researchers are actively working to overcome these limitations through chemical modification and additive technologies. Among the most promising developments are the use of nanotechnology-based additives, green synthesis techniques for chemical modification, and novel antioxidant formulations that collectively improve oxidative stability, thermal resilience, and cold flow behavior. Engineered nanoparticles such as graphene, boron nitride, and metal oxides (e.g., ZnO, TiO2, CuO) are being incorporated into vegetable oil matrices to enhance load-carrying capacity, reduce friction, and minimize wear. These nanoparticles can form protective tribofilms on metal surfaces, act as rolling elements between contact zones, and improve heat dissipation. Importantly, their high surface area and reactivity allow for performance enhancement at very low concentrations, making them economically viable for large-scale applications. In parallel, green synthesis techniques are being developed to chemically modify natural oils in an environmentally responsible manner. Processes such as enzymatic transesterification, epoxidation, and ring-opening polymerization are used to tailor the molecular structure of vegetable oils, improving their oxidative stability, viscosity index, and cold flow properties without introducing harmful byproducts. These methods often rely on bio-catalysts, low-energy inputs, and renewable reagents, aligning with the broader goals of sustainable manufacturing.

Another critical advancement is the development of novel antioxidant formulations specifically designed for bio-based lubricants. Traditional antioxidants such as zinc dialkyldithiophosphate (ZDDP) are effective but pose environmental concerns due to their metal content. Researchers have also explored natural and synthetic alternatives including tocopherols (vitamin E derivatives), phenolic compounds, and sulfur-free stabilizers that offer comparable protection against oxidation while reducing toxicity. These antioxidants help prevent the formation of sludge, acids, and varnish under high-temperature conditions, thereby extending the lubricant’s service life and protecting engine components. Together, these innovations represent a significant leap forward in overcoming the inherent limitations of bio-based lubricants. By integrating nanotechnology, green chemistry, and advanced additive science, the next generation of nature-friendly lubricants is poised to deliver high performance, environmental safety, and economic feasibility—making them increasingly viable for mainstream automotive applications. This evolving landscape underscores the importance of interdisciplinary research and industry collaboration in driving sustainable innovation in lubrication technology.

4.3. Synthetic Esters and Green Additives

The synthetic esters represent a more refined approach to sustainable lubrication. These compounds are engineered through controlled chemical reactions, allowing for tailored molecular structures that meet specific performance requirements. Unlike natural esters, synthetic variants can be designed to exhibit high viscosity indices, excellent thermal stability, and low volatility. This makes them ideal for high-performance automotive systems, including turbocharged engines and hybrid drivetrains. In addition to their base properties, synthetic esters are often combined with green additives to enhance functionality. These additives are selected not only for their performance benefits but also for their environmental compatibility. Anti-wear agents, such as boron-based compounds or phosphate esters, help protect metal surfaces under high load conditions. Anti-corrosion additives prevent rust and degradation in moist or chemically aggressive environments. Viscosity modifiers, often derived from biodegradable polymers, ensure consistent flow behavior across a wide temperature range. The use of synthetic esters and green additives allows formulators to strike a balance between sustainability and technical excellence. These lubricants can meet or exceed the performance of traditional oils while offering a cleaner environmental profile. However, their production is more complex and costlier, which can be a barrier to adoption in cost-sensitive markets. As demand grows and economies of scale improve, it is expected that these advanced lubricants will become more accessible to mainstream automotive applications.

Building on the promising attributes of synthetic esters and green additives, it is important to emphasize that several formulations of ideal lubricants have already been successfully developed and validated through laboratory testing and limited field trials. These advanced lubricants demonstrate exceptional tribological performance, high thermal and oxidative stability, and strong environmental compatibility meeting or even surpassing the benchmarks set by conventional petroleum-based oils. In many cases, they have proven effective in demanding automotive applications such as turbocharged engines, hybrid powertrains, and electric vehicle gearboxes. The only significant barrier to widespread adoption is the cost, primarily due to the complexity of production and the limited scale at which these lubricants are currently manufactured. According to the authors, this challenge is not insurmountable. With increased market demand, strategic investment in production infrastructure, and the development of streamlined synthesis pathways, economies of scale can be achieved. This would substantially reduce unit costs and make these high-performance, sustainable lubricants more accessible for mainstream automotive use—paving the way for a cleaner and more efficient future in transportation.

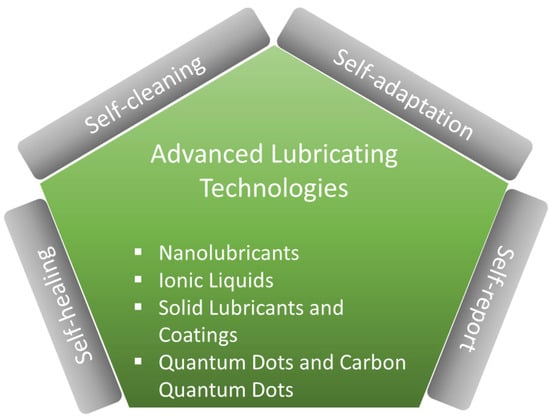

5. Advanced Lubricating Technologies

As automotive systems become more complex and performance demands intensify, conventional lubricants often fall short in meeting the rigorous requirements of modern engines and drivetrains. This has led to the development of advanced lubricating technologies that leverage cutting-edge materials and engineering principles to self-healing, self-cleaning, self-adaptation, and self-report (Figure 2), which directly enhance tribological performance, reduce energy losses, and extend component life. Among the most promising innovations in this domain are nanolubricants, ionic liquids, and solid lubricants with engineered coatings.

Figure 2.

The schematic representation of advanced lubricating technology in term and their properties.

5.1. Nanolubricants

Nanolubricants represent a significant leap forward in lubrication science. These formulations incorporate nanoparticles typically ranging from 1 to 100 nm in size—into base oils to improve their tribological properties. Commonly used nanoparticles include MoS2, graphene, and titanium dioxide (TiO2). Each of these materials brings unique benefits: MoS2 offers excellent anti-wear characteristics due to its layered structure, graphene provides high thermal conductivity and mechanical strength, and TiO2 contributes to surface protection and oxidation resistance.

The mechanisms by which nanolubricants enhance performance are multifaceted. One key process is the rolling effect, where spherical nanoparticles act like miniature ball bearings, reducing direct contact between surfaces and lowering friction. Another mechanism is mending, where nanoparticles fill in surface asperities and scratches, effectively repairing wear damage over time. Additionally, many nanoparticles contribute to the formation of a tribofilm a protective layer that adheres to the surface and minimizes wear under high loads and temperatures. Despite their advantages, nanolubricants face several technical challenges, particularly in terms of dispersion stability. Nanoparticles tend to agglomerate over time, which can lead to sedimentation and uneven distribution within the lubricant. This not only diminishes their effectiveness but can also cause clogging in narrow channels or filters. Achieving long-term stability requires careful selection of surfactants, surface treatments, and base oil compatibility. Moreover, the cost of high-purity nanoparticles and the complexity of formulation can limit their commercial viability in mass-market automotive applications.

5.2. Ionic Liquids

Ionic liquids are another class of advanced lubricants gaining attention for their unique physicochemical properties. These are salts that remain in a liquid state at or near room temperature, composed entirely of ions. Their molecular structure can be precisely tailored to achieve desired characteristics such as low volatility, high thermal stability, and excellent lubricity. Unlike traditional lubricants, ionic liquids do not evaporate easily and can maintain performance under extreme conditions.

Their application in high-temperature and extreme-pressure environments makes them particularly suitable for specialized automotive components such as turbochargers, high-performance gear systems, and electric vehicle drivetrains. Ionic liquids can form stable boundary films that protect surfaces even under severe mechanical stress. Some formulations also exhibit self-healing properties, where the ionic structure reconfigures to maintain lubrication after disruption. However, the adoption of ionic liquids is tempered by concerns over toxicity and cost. Certain ionic liquids contain fluorinated or halogenated compounds that may pose environmental and health risks. Additionally, their synthesis is often complex and expensive, making them less accessible for large-scale automotive use. Ongoing research is focused on developing greener ionic liquids with reduced toxicity and improved biodegradability, as well as exploring hybrid formulations that combine ionic liquids with conventional base oils to balance performance and cost.

5.3. Solid Lubricants and Coatings

In applications where liquid lubricants are impractical such as high-temperature zones, vacuum environments, or components with limited access, solid lubricants and surface coatings offer a reliable alternative. Materials like graphite, PTFE, and diamond-like carbon (DLC) are commonly used due to their low friction coefficients and thermal resilience. These substances can be applied directly to surfaces or embedded within composite materials to provide long-lasting lubrication.

Surface engineering plays a crucial role in enhancing the effectiveness of solid lubricants. Techniques such as physical vapor deposition, chemical vapor deposition, and plasma spraying are used to create thin films that adhere strongly to metal substrates. These coatings can be engineered to resist wear, corrosion, and thermal degradation, making them ideal for critical automotive components like piston rings, valve trains, and bearings. Solid lubricants are also increasingly used in hybrid lubrication systems, where they complement liquid or semi-solid lubricants to provide multi-layered protection. For example, a DLC-coated surface may be paired with a synthetic oil to reduce start-up friction and maintain lubrication under varying conditions. This approach allows for greater flexibility and durability, especially in engines designed for extended service intervals or harsh operating environments.

5.4. Quantum Dots and Carbon Quantum Dots

Quantum dots (QDs) are semiconductor nanocrystals with unique optical and electronic properties due to quantum confinement effects. In tribology, their potential lies in their ability to interact with surfaces at the molecular level, offering new mechanisms for friction reduction and wear control. Carbon quantum dots (CQDs), a subclass of QDs derived from carbon-based materials, have gained attention for their biocompatibility, chemical stability, and ease of synthesis from renewable sources. When dispersed in lubricants, CQDs can enhance thermal conductivity, improve oxidation resistance, and contribute to tribadism formation. Their small size allows them to penetrate surface asperities, reducing contact stress and smoothing rough surfaces. Additionally, CQDs can act as lubricant additives with multifunctional roles serving as antioxidants, anti-wear agents, and even sensors in smart lubrication systems. One of the most promising aspects of CQDs is their environmental friendliness. Unlike metal-based nanoparticles, carbon quantum dots are generally non-toxic and biodegradable, making them suitable for sustainable lubricant formulations. However, challenges remain in terms of scalability, cost, and long-term stability within lubricant matrices. Further research is needed to optimize their synthesis, surface functionalization, and compatibility with various base oils.

6. Smart and Adaptive Lubrication Systems

The evolution of automotive engineering has reached a point where traditional lubrication strategies are no longer sufficient to meet the demands of modern vehicles. With the rise in intelligent systems and digital technologies, lubrication is transitioning from a passive function to an active, adaptive process. Smart lubrication systems are designed to respond dynamically to changing operating conditions, ensuring optimal performance, reduced wear, and extended component life. This transformation is being driven by the integration of sensors, artificial intelligence (AI), and predictive maintenance frameworks such as digital twins.

6.1. Integration of Sensors and Real-Time Monitoring

At the heart of smart lubrication systems lies the ability to monitor conditions in real time. Advanced sensors embedded within engines, gearboxes, and hydraulic systems continuously measure parameters such as temperature, pressure, viscosity, and contamination levels. These sensors provide a constant stream of data that reflects the health and performance of the lubricant and the mechanical components it protects. Real-time monitoring enables immediate detection of anomalies, such as a sudden drop in oil pressure or an increase in particulate contamination. This allows for timely interventions, preventing damage before it escalates. For example, if a lubricant begins to degrade due to thermal stress, the system can alert the operator or automatically adjust the lubrication schedule. This level of responsiveness is particularly valuable in high-performance or mission-critical automotive applications, such as motorsports, commercial fleets, and electric vehicles.

6.2. AI-Driven Lubrication Control

Artificial intelligence is playing a transformative role in how lubrication is managed. By analyzing data collected from sensors, AI algorithms can identify patterns and predict future behavior. This enables the system to make informed decisions about when and how to lubricate specific components. Instead of relying on fixed intervals or manual checks, AI-driven systems adapt lubrication schedules based on actual usage, load conditions, and environmental factors.

Machine learning models can also optimize lubricant selection and dosage. For instance, in hybrid vehicles where operating conditions vary widely, AI can determine the most suitable lubricant formulation for each driving mode. Over time, these systems learn from historical data to improve accuracy and efficiency, reducing waste and enhancing overall vehicle reliability. Moreover, AI can facilitate automated control loops, where lubrication adjustments are made without human intervention. This is particularly useful in autonomous vehicles and industrial transport systems, where continuous operation and minimal downtime are essential. By integrating AI with onboard diagnostics and control units, smart lubrication becomes a seamless part of the vehicle’s broader performance management system.

6.3. Predictive Maintenance and Digital Twins

One of the most promising applications of smart lubrication is in predictive maintenance, which aims to anticipate failures before they occur. By combining sensor data with AI analytics, maintenance teams can identify early signs of wear, contamination, or lubricant degradation. This allows for proactive servicing, reducing the risk of unexpected breakdowns and extending the lifespan of critical components. The concept of digital twins further enhances this capability. A digital twin is a virtual replica of a physical system that mirrors its behavior in real time. In the context of lubrication, a digital twin can simulate how a lubricant performs under various conditions, predict its degradation curve, and recommend optimal maintenance actions. This model is continuously updated with live data from the vehicle, making it a powerful tool for diagnostics, optimization, and lifecycle management.

Digital twins also support scenario analysis, allowing engineers to test different lubricant formulations or operating strategies without physical trials. This accelerates innovation and helps manufacturers tailor lubrication systems to specific vehicle designs or usage profiles. In fleet operations, digital twins can be used to manage lubrication across multiple vehicles, ensuring consistency and reducing operational costs. Smart and adaptive lubrication systems represent a significant leap forward in automotive technology. By integrating sensors, AI, and predictive modeling, these systems offer a proactive approach to maintenance, improved energy efficiency, and enhanced component protection. As vehicles become more connected and autonomous, the role of intelligent lubrication will only grow, shaping the future of mobility with precision and sustainability.

7. Comparative Performance Analysis

Evaluating the effectiveness of lubricants whether conventional or sustainable—requires a rigorous and systematic approach. Comparative performance analysis plays a crucial role in determining how different lubricating materials behave under real-world conditions and whether they meet the demands of modern automotive systems. This section explores the methodologies used to assess lubricant performance, the criteria for benchmarking sustainable alternatives against traditional formulations, and case studies that illustrate their practical applications in engines, transmissions, and other critical components.

7.1. Tribological Testing Methods

Tribological testing is the foundation of lubricant evaluation [46]. It involves measuring key parameters such as friction coefficient, wear rate, load-carrying capacity, and surface roughness under controlled conditions. Several standardized tests are employed to simulate the mechanical interactions that occur in automotive systems [22,46,47,48]. One widely used method is the Four-Ball Wear Test, which assesses a lubricant’s ability to prevent wear between metal surfaces. In this test, three stationary steel balls are clamped together while a fourth ball rotates against them under a specified load and temperature. The wear scar diameter on the stationary balls provides a quantitative measure of the lubricant’s anti-wear properties. Another important technique is the Pin-on-Disk Test, where a stationary pin is pressed against a rotating disk. This setup allows researchers to study friction and wear behavior over time, especially under varying loads and speeds. The High-Frequency Reciprocating Rig (HFRR) is also commonly used to evaluate lubricants for fuel injection systems, particularly in diesel engines. Advanced tribometers equipped with sensors and data acquisition systems can simulate complex motion patterns and environmental conditions, such as temperature fluctuations, humidity, and contamination [13,34,44,45]. These instruments provide detailed insights into how lubricants perform in dynamic automotive environments.

7.2. Benchmarking Sustainable vs. Conventional Lubricants

Benchmarking involves comparing the performance of sustainable lubricants such as bio-based oils [49,50], bio-lubricants, synthetic esters, and nanolubricants with that of conventional petroleum-based formulations [33,49,50]. The goal is to determine whether these alternatives can match or exceed the tribological, thermal, and chemical properties required for automotive applications. Key performance indicators include: (a) viscosity stability across temperature ranges, (b) oxidation resistance and thermal degradation behavior, (c) anti-wear and friction reduction capabilities, (d) compatibility with seals, metals, and other materials, and (e) biodegradability and toxicity levels; in many cases, sustainable lubricants demonstrate comparable or superior performance. For example, synthetic esters often exhibit higher viscosity indices and better oxidative stability than mineral oils. Nanolubricants can significantly reduce friction and wear due to their unique surface interactions [30,49]. However, challenges such as cold flow behavior, cost, and long-term stability must be carefully considered. Benchmarking also involves lifecycle analysis and environmental impact assessments. Sustainable lubricants are evaluated not only for their operational performance but also for their carbon footprint, renewability, and end-of-life disposal options. These factors are increasingly important in regulatory compliance and corporate sustainability goals.

7.3. Case Studies in Automotive Applications

Real-world case studies provide valuable evidence of how sustainable lubricants perform in actual automotive systems. One notable example involves the use of bio-based engine oils in passenger vehicles. Field trials have shown that certain vegetable oil-derived formulations can maintain viscosity and protect engine components over extended service intervals, with reduced emissions and improved fuel economy. In transmission systems, synthetic esters blended with green additives have been tested in automatic and dual-clutch gearboxes. These lubricants demonstrated excellent thermal stability and wear protection, even under high torque and temperature conditions. Their low volatility also contributed to reduced oil consumption and longer fluid life. Greases formulated with biodegradable thickeners and nanoparticle additives have been deployed in wheel bearings and chassis components. These greases provided consistent lubrication over a wide temperature range and resisted water washout, making them suitable for both conventional and electric vehicles [30,51,52,53]. Fleet operators and OEMs are increasingly conducting long-term evaluations of sustainable lubricants in commercial vehicles, including trucks and buses. These studies often track parameters such as engine cleanliness, oil drain intervals, fuel efficiency, and maintenance costs. The results have been encouraging, with many sustainable formulations meeting or exceeding the performance of traditional lubricants. Comparative performance analysis is essential for validating the viability of sustainable lubricants in the automotive industry. Through standardized testing, benchmarking, and field trials, researchers and manufacturers can make informed decisions about formulation, application, and deployment. As the industry continues to prioritize efficiency and environmental responsibility, these evaluations will play a pivotal role in shaping the future of lubrication technology.

8. Challenges and Future Directions

The transition from conventional petroleum-based lubricants to sustainable and advanced alternatives marks a significant shift in automotive engineering. While the benefits of these new materials such as reduced environmental impact, improved tribological performance, and alignment with global sustainability goals are well documented, their widespread adoption is still hindered by several practical and technical challenges. Addressing these issues is essential to ensure that next-generation lubricants can meet the demands of modern vehicles and contribute meaningfully to a cleaner, more efficient transportation sector.

8.1. Scalability and Cost-Effectiveness

One of the most pressing challenges in the development of sustainable lubricants is scalability. Many promising formulations, such as bio-based oils, synthetic esters, and Nanolubricants, are currently produced in limited quantities, often in research or pilot-scale facilities [49,54]. Scaling these materials to meet the demands of global automotive markets requires significant investment in infrastructure, supply chain development, and manufacturing technologies. Moreover, the raw materials used in some advanced lubricants, such as high-purity nanoparticles or tailored esters, can be expensive to source and process.

8.2. Cost-Effectiveness Is Another Critical Barrier

While sustainable lubricants may offer superior performance and environmental benefits, their higher production costs can deter adoption, especially in cost-sensitive markets. Automotive manufacturers and fleet operators often prioritize affordability and reliability, making it difficult for newer formulations to compete with well-established petroleum-based products. To overcome this, researchers and industry stakeholders must focus on [55,56] optimizing production methods, identifying low-cost feedstocks, and developing efficient synthesis techniques that reduce overall expenses without compromising quality.

8.3. Compatibility with Evolving Automotive Technologies

The rapid evolution of automotive technologies particularly the rise in electric vehicles (EVs) and hybrid powertrains is reshaping the requirements for lubricants. Unlike internal combustion engines, EVs operate with fewer moving parts and generate less heat, but they still require specialized lubricants for components such as gearboxes, bearings, and thermal management systems [57,58,59,60]. These applications demand lubricants with unique properties, including high dielectric strength, low viscosity, and excellent thermal conductivity. Hybrid vehicles, which combine electric motors with traditional engines, present even more complex lubrication challenges. The frequent switching between power sources, variable operating temperatures, and regenerative braking systems create dynamic conditions that conventional lubricants may struggle to handle. Sustainable lubricants must be engineered to perform reliably across these diverse scenarios, ensuring seamless operation and long-term durability. Compatibility also extends to materials used in modern automotive systems. Advanced lubricants must interact safely with seals, polymers, metals, and coatings found in EVs and hybrids [16]. Any adverse chemical reactions or degradation can compromise component integrity and lead to costly failures. Therefore, thorough compatibility testing and formulation refinement are essential steps in the development process.

8.4. Lifecycle Assessment and Circular Economy Integration

To fully understand the environmental impact of lubricants, it is necessary to conduct comprehensive lifecycle assessments (LCAs). These evaluations consider the entire journey of a lubricant from raw material extraction and production to usage, disposal, and potential recycling [61,62,63]. Sustainable lubricants must demonstrate not only low emissions during use but also minimal ecological footprint throughout their lifecycle. Integrating lubricants into the circular economy is a forward-looking strategy that emphasizes resource efficiency and waste reduction. This involves designing lubricants that can be regenerated, reused, or safely biodegraded after their service life. For example, bio-based oils that decompose naturally reduce the burden on waste management systems, while synthetic formulations that can be re-refined offer opportunities for closed-loop recycling. Establishing infrastructure for collection, purification, and redistribution of used lubricants is a key step toward achieving circularity in the automotive sector.

8.5. Research Gaps and Innovation Opportunities

Despite significant progress, several research gaps remain in the field of sustainable lubrication. One major area is the long-term performance of advanced lubricants under real-world conditions. Laboratory tests often simulate ideal scenarios, but actual automotive environments involve fluctuating loads, contaminants, and unpredictable stresses [33,54]. More field trials and longitudinal studies are needed to validate the durability and reliability of these materials. Another gap lies in the standardization of testing protocols [8,17,54,64]. As new materials emerge, existing tribological tests may not adequately capture their unique behaviors. Developing new benchmarks and evaluation methods tailored to advanced lubricants will help ensure consistent quality and facilitate regulatory approval. There are also opportunities for innovation in smart lubrication systems, where sensors and AI can monitor lubricant condition and optimize usage in real time. Integrating sustainable lubricants with digital technologies opens the door to predictive maintenance, reduced waste, and enhanced vehicle performance. Furthermore, interdisciplinary collaboration between chemists, engineers, data scientists, and environmental experts can accelerate the development of multifunctional lubricants that meet both technical and ecological goals. In conclusion, while sustainable and advanced lubricating materials hold great promise for the future of automotive engineering, their path to widespread adoption is shaped by challenges in scalability, cost, compatibility, and lifecycle management. Addressing these issues through targeted research, innovation, and collaboration will be essential to unlocking their full potential and driving the industry toward a more sustainable future.

Finally, we would like to discussed about the research roadmap that outlines short-, medium-, and long-term priorities for advancing sustainable lubricants in automotive applications [49,54]. This roadmap is designed to integrate technical, environmental, and economic dimensions, offering a strategic guide for researchers, manufacturers, and policymakers aiming to accelerate innovation and adoption in this critical area. In the short term, the focus lies on optimizing existing formulations and improving compatibility with current automotive systems. This includes refining bio-based oils and synthetic esters to enhance their oxidative stability, thermal resistance, and material compatibility [12,14,26]. Immediate efforts should also target cost reduction through the identification of low-cost feedstocks and the development of scalable synthesis methods. Pilot-scale production facilities and collaborative industry-academia initiatives can play a vital role in validating performance under real-world conditions and generating data for regulatory approval. The medium-term priorities shift toward expanding the application in electric vehicles scope of advanced lubricants, particularly in emerging vehicle platforms such as electric and hybrid powertrains [13,35]. These systems demand lubricants with specialized properties such as high dielectric strength, low viscosity, and superior thermal conductivity that are not typically required in internal combustion engines. Research must focus on tailoring lubricant formulations to meet these evolving demands while ensuring compatibility with diverse materials like polymers, composites, and advanced coatings [12,14,26,28]. Additionally, lifecycle assessments and environmental impact studies should be conducted to support the development of eco-labeling standards and sustainability certifications. Looking to the long term, the roadmap envisions the integration of intelligent lubrication systems that align with Industry 4.0 principles. These systems would incorporate sensor-enabled monitoring, adaptive control mechanisms, and predictive maintenance capabilities to optimize lubricant performance dynamically. Such innovations could significantly reduce waste, extend component life, and improve energy efficiency across automotive fleets. Long-term goals also include the development of fully biodegradable, multifunctional lubricants that meet stringent performance criteria without compromising environmental safety. Achieving this will require breakthroughs in materials science, tribology, and green chemistry, supported by robust policy frameworks and global collaboration.

9. Conclusions

This review article comprehensively examined evolving lubricating materials, tracing their progression from conventional petroleum-based formulations to advanced, sustainable alternatives tailored for modern automotive demands. Through an integrated analysis of tribological fundamentals, material innovations, and emerging technologies, it is clear that traditional lubricants, despite their historical utility, present mounting environmental and operational concerns. Their toxicity, non-biodegradability, and dependence on finite fossil resources increasingly conflict with global sustainability goals and regulatory pressures. In contrast, bio-based oils, synthetic esters, nanolubricants, and ionic liquids offer promising pathways toward greener lubrication. These materials exhibit strong potential in reducing friction and wear, enhancing thermal and oxidative stability, and minimizing ecological impact. However, challenges related to cost, scalability, and long-term durability remain. Encouragingly, several ideal formulations have already been developed and validated, with performance metrics that meet or exceed those of conventional oils. The remaining barrier is an economic one that can be addressed through scaled-up production, streamlined synthesis methods, and strategic investment in manufacturing infrastructure. The integration of modern trends such as nanotechnology-based additives, green synthesis techniques, and novel antioxidant systems has significantly advanced the functionality and environmental compatibility of sustainable lubricants. These innovations not only improve tribological performance but also extend lubricant lifespan and reduce harmful byproducts. Furthermore, the emergence of smart lubrication systems—featuring sensor integration, adaptive control, and predictive maintenance—marks a paradigm shift in how lubrication is managed in real time. These intelligent systems align with Industry 4.0 principles and support the transition toward electrification, automation, and circular economy models. To fully realize the potential of sustainable lubricants, a coordinated effort is required across disciplines. Collaboration among researchers, manufacturers, policymakers, and industry stakeholders is essential to establish standardized testing protocols, robust lifecycle assessments, and scalable production frameworks. Policy support should incentivize innovation, promote infrastructure for recycling and re-refining, and ensure equitable market access to eco-friendly lubricants. Ultimately, the future of automotive lubrication lies at the intersection of sustainability, performance, and intelligence. By embracing advanced materials and fostering interdisciplinary collaboration, the industry can move toward a lubrication paradigm that not only enhances mechanical reliability but also contributes meaningfully to environmental stewardship and global climate objectives.

Funding

This research received no external funding.

Acknowledgments

The author gratefully acknowledges the continuous support provided by the Advanced Engineering Department and the Product Development team at Ashok Leyland Technical Centre. The insightful discussions and collaborative exchanges with them played a pivotal role in shaping the direction of this research.

Conflicts of Interest

Author Vijay Bhooshan Kumar was employed by the company Ashok Leyland Limited. The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yan, L.; Zhang, Q.; Zheng, B.; He, K. Modeling Fuel-, Vehicle-Type-, and Age-Specific CO2 Emissions from Global on-Road Vehicles in 1970–2020. Earth Syst. Sci. Data 2024, 16, 4497–4509. [Google Scholar] [CrossRef]

- Zhang, F.; Peng, J.; Zhang, J.; Liu, J.; Wu, Y.; Liu, P.; Liu, K.; Sun, B.; Zhang, Q.; Wu, L.; et al. Real World Particle Size Distribution from Vehicle Fleet and Implication on Emission Control. npj Clean Air 2025, 1, 8. [Google Scholar] [CrossRef]

- Kant, K.; Singh, R.C.; Maji, S. Opportunities to Improve the Lubrication, Fuel Efficiency, and Emission Reduction Using Nanotechnologies: A Review. J. Therm. Anal. Calorim. 2025, 150, 3173–3199. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, M. Advanced Lubrication Technologies for Enhanced Reliability, Efficiency, and Sustainability in Mechanical Systems. Int. J. Eng. Sci. Technol. Innov. 2025, 5. [Google Scholar] [CrossRef]

- Vehiche Tehnologies Office. 2013 Fuel & Lubricant Technologies; U.S. Department of Energy: Washington, DC, USA, 2014; Volume 20585. [Google Scholar]

- Mohd Tamam, M.Q.; Omi, M.R.T.; Yahya, W.J.; Ithnin, A.M.; Abdul Rahman, H.; Rahman, M.M.; Abd Kadir, H.; Noge, H.; Koga, T.; Hong, C.; et al. Engine Performance and Emissions Evaluation of Surfactant-Free B30 Biodiesel–Diesel/Water Emulsion as Alternative Fuel. Sci. Rep. 2023, 13, 10599. [Google Scholar] [CrossRef]

- Wang, J.; Hu, W.; Li, J. Lubrication and Anti-Rust Properties of Jeffamine-Triazole Derivative as Water-Based Lubricant Additive. Coatings 2021, 11, 679. [Google Scholar] [CrossRef]

- Rizvi, S.Q.A. History of Automotive Lubrication. J. Fuels Lubr. 1996, 105, 1420–1434. [Google Scholar] [CrossRef]

- Braumann, L.; de Viteri, V.S.; Morhard, B.; Lohner, T.; Ochoa, J.; Amri, H. Tribology Technologies for Gears in Loss of Lubrication Conditions: A Review. J. Mater. Sci. Mater. Eng. 2025, 20, 29. [Google Scholar] [CrossRef]

- Waqas, M.; Zahid, R.; Bhutta, M.U.; Khan, Z.A.; Saeed, A. A Review of Friction Performance of Lubricants with Nano Additives. Materials 2021, 14, 6310. [Google Scholar] [CrossRef]

- Masjuki, H.H.; Maleque, M.A.; Kubo, A.; Nonaka, T. Palm Oil and Mineral Oil Based Lubricants—Their Tribological and Emission Performance. Tribol. Int. 1999, 32, 305–314. [Google Scholar] [CrossRef]

- Filon, D.; Anastopoulos, G.; Karonis, D. Synthesis and Evaluation of Bio-Lubricants from Renewable Raw Materials. Lubricants 2024, 12, 446. [Google Scholar] [CrossRef]

- Singh, Y.; Farooq, A.; Raza, A.; Mahmood, M.A.; Jain, S. Sustainability of a Non-Edible Vegetable Oil Based Bio-Lubricant for Automotive Applications: A Review. Process Saf. Environ. Prot. Inst. Chem. Eng. 2017, 111, 701–713. [Google Scholar] [CrossRef]

- Ninduwezuor-Ehiobu, N.; Chukwuemeka Olisakwe, H.; Ejike Ewim, D.R. Future Directions in Bio-Lubricants: A Theoretical Synthesis of Current Trends and Innovations. J. Res. Innov. Sustain. Soc. 2025, 7, 163–171. [Google Scholar] [CrossRef]

- Berman, D. Plant-Based Oils for Sustainable Lubrication Solutions—Review. Lubricants 2024, 12, 300. [Google Scholar] [CrossRef]

- Zhou, Y.; Leonard, D.N.; Meyer, H.M.; Luo, H.; Qu, J. Does the Use of Diamond-Like Carbon Coating and Organophosphate Lubricant Additive Together Cause Excessive Tribochemical Material Removal? Adv. Mater. Interfaces 2015, 2, 1500213. [Google Scholar] [CrossRef]

- Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-Based Lubricants: Development, Properties, and Performances. Lubricants 2021, 9, 73. [Google Scholar] [CrossRef]

- Minami, I. Molecular Science of Lubricant Additives. Appl. Sci. 2017, 7, 445. [Google Scholar] [CrossRef]

- Abdulfatai, U.; Uzairu, A.; Shallangwa, G.A.; Uba, S. Computational Modelling of Some Anti-Friction Lubricant Additives. S. Afr. J. Chem. Eng. 2020, 32, 27–31. [Google Scholar] [CrossRef]

- Saini, V.; Pond, L.; Uhryn, J.; Kalayil, A.; Tomar, A.; Subramanian, K.; Trifkovic, M.; Egberts, P. Shear-Dependent Tribological Behavior of Oleic Acid as a Sustainable Lubricant Additive in Oils and Nano-Greases. Wear 2025, 570, 205932. [Google Scholar] [CrossRef]

- Manoj, A.; Chandra Verma, P.; Saravanan, P.; Kumar, S.; Narala, R. Effect of Solid Lubricant Particles on the Tribological Behavior of Grease. J. Tribol. 2024, 40, 247–267. [Google Scholar]

- Holmberg, K.; Laukkanen, A.; Hakala, T.; Ronkainen, H.; Suhonen, T.; Wolski, M.; Podsiadlo, P.; Woloszynski, T.; Stachowiak, G.; Gachot, C.; et al. Topography Orientation Effects on Friction and Wear in Sliding DLC and Steel Contacts, Part 3: Experiments under Dry and Lubricated Conditions. Wear 2021, 486–487, 204093. [Google Scholar] [CrossRef]

- Xia, D.; Wang, Y.; Liu, H.; Yan, J.; Lin, H.; Han, S. Research Progress of Antioxidant Additives for Lubricating Oils. Lubricants 2024, 12, 115. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Valencia, C.; Franco, J.M.; Gallegos, C. Natural and Synthetic Antioxidant Additives for Improving the Performance of New Biolubricant Formulations. J. Agric. Food Chem. 2011, 59, 12917–12924. [Google Scholar] [CrossRef]

- Abdulfatai, U.; Uzairu, A.; Uba, S.; Shallangwa, G.A. Molecular Design of Antioxidant Lubricating Oil Additives via QSPR and Analysis Dynamic Simulation Method. Heliyon 2019, 5, e02880. [Google Scholar] [CrossRef]

- Shazly, R.I.E.; El-Sheshtawy, H.S.; Ahmed, N.S.; Nassar, A.M. Synthesis and Biodegradation Testing of Some Synthetic Oils Based on Ester. Sci. Rep. 2024, 14, 3416. [Google Scholar] [CrossRef] [PubMed]

- Chimeno-Trinchet, C.; Pacheco, M.E.; Fernández-González, A.; Díaz-García, M.E.; Badía-Laíño, R. New Metal-Free Nanolubricants Based on Carbon-Dots with Outstanding Antiwear Performance. J. Ind. Eng. Chem. 2020, 87, 152–161. [Google Scholar] [CrossRef]

- Ahmed Abdalglil Mustafa, W.; Dassenoy, F.; Sarno, M.; Senatore, A. A Review on Potentials and Challenges of Nanolubricants as Promising Lubricants for Electric Vehicles. Lubr. Sci. 2022, 34, 1–29. [Google Scholar] [CrossRef]

- Deepika. Nanotechnology Implications for High Performance Lubricants. SN Appl. Sci. 2020, 2, 1128. [Google Scholar] [CrossRef]

- Garcia Tobar, M.; Contreras Urgiles, R.W.; Jimenez Cordero, B.; Guillen Matute, J. Nanotechnology in Lubricants: A Systematic Review of the Use of Nanoparticles to Reduce the Friction Coefficient. Lubricants 2024, 12, 166. [Google Scholar] [CrossRef]

- Atabani, A.E.; Silitonga, A.S.; Badruddin, I.A.; Mahlia, T.M.I.; Masjuki, H.H.; Mekhilef, S. A Comprehensive Review on Biodiesel as an Alternative Energy Resource and Its Characteristics. Renew. Sustain. Energy Rev. 2012, 16, 2070–2093. [Google Scholar] [CrossRef]

- Patil, V.; Tan, T.; Rispens, S.; Dabadghao, S.; Demerouti, E. Supplier Sustainability: A Comprehensive Review and Future Research Directions. Sustain. Manuf. Serv. Econ. 2022, 1, 100003. [Google Scholar] [CrossRef]

- Wilińska, I.; Wilkanowicz, S. Advancements in Environmentally Friendly Lubricant Technologies: Towards Sustainable Performance and Efficiency. Energies 2025, 18, 4006. [Google Scholar] [CrossRef]

- Shah, R.; Woydt, M.; Zhang, S. The Economic and Environmental Significance of Sustainable Lubricants. Lubricants 2021, 9, 21. [Google Scholar] [CrossRef]

- Opia, A.C.; Kadirgama, K.; Mamah, S.C.; Ghazali, M.F.; Harun, W.S.W.; Adeboye, O.J.; Agi, A.; Alibi, S. Electric Vehicles as a Promising Trend: A Review on Adaptation, Lubrication Challenges, and Future Work. Lubricants 2025, 13, 474. [Google Scholar] [CrossRef]

- Pourramezan, M.R.; Rohani, A.; Abbaspour-Fard, M.H. Comparative Analysis of Soft Computing Models for Predicting Viscosity in Diesel Engine Lubricants: An Alternative Approach to Condition Monitoring. ACS Omega 2024, 9, 1398–1415. [Google Scholar] [CrossRef]

- Hassan, K. Comparative Life Cycle Analysis of Environmental and Machining Performance under Sustainable Lubrication Techniques. Hybrid. Adv. 2022, 1, 100004. [Google Scholar] [CrossRef]

- Bashari, N.A.F.; Aziz, M.A.A.; Hairunnaja, M.A.; Mu’Tasim, T.M.A.B.N. Eco-Grease from Upcycling of Waste Oils: A Formulation Study for High-Performance Lubricants. Int. J. Environ. Sci. Technol. 2025, 22, 16095–16110. [Google Scholar] [CrossRef]

- Jafari, A.J.; Hassanpour, M. Analysis and Comparison of Used Lubricants, Regenerative Technologies in the World. Resour. Conserv. Recycl. 2014, 103, 179–191. [Google Scholar] [CrossRef]

- García-Miranda, J.S.; Aguilera-Camacho, L.D.; Hernández-Sierra, M.T.; Moreno, K.J. A Comparative Analysis of the Lubricating Performance of an Eco-Friendly Lubricant vs Mineral Oil in a Metallic System. Coatings 2023, 13, 1314. [Google Scholar] [CrossRef]

- Islam Sazzad, M.R.; Rahman, M.M.; Hassan, T.; Al Rifat, A.; Al Mamun, A.; Adib, A.R.; Meraz, R.M.; Ahmed, M. Advancing Sustainable Lubricating Oil Management: Re-Refining Techniques, Market Insights, Innovative Enhancements, and Conversion to Fuel. Heliyon 2024, 10, e39248. [Google Scholar] [CrossRef]

- Pichler, J.; Maria Eder, R.; Besser, C.; Pisarova, L.; Dörr, N.; Marchetti-Deschmann, M.; Frauscher, M. A Comprehensive Review of Sustainable Approaches for Synthetic Lubricant Components. Green. Chem. Lett. Rev. 2023, 16, 2185547. [Google Scholar] [CrossRef]

- Sua, L.S.; Balo, F. Optimizing Plant Oil-Derived Lubricants: A Sustainable Alternative to Petroleum-Based Lubricants Using Integer Programming. Tribol. Ind. 2025, 47, 260–278. [Google Scholar] [CrossRef]

- Liskiewicz, T.; Sherrington, I.; Khan, T.; Liu, Y. Advances in Sensing for Real-Time Monitoring of Tribological Parameters. Tribol. Int. 2023, 189, 108965. [Google Scholar] [CrossRef]

- Özakın, B.; Gültekin, K.; Yurdgülü, H.İ. Improvement of Oxidation Stability, Hydrolytic Stability and Tribological Properties of Kaolin Particles Doped Bio-Based Green Palm Oil. Colloids Surf. A Physicochem. Eng. Asp. 2025, 712, 136441. [Google Scholar] [CrossRef]

- Xiao, N.; Tang, J.; Zhou, S.; Shi, Y.; Qian, F.; Qiu, S.; Chen, Y.; Zhao, D.; Yang, K. Current Research on the Design, Properties and Applications of Tribological Materials: A Review. RSC Adv. 2025, 15, 34669–34717. [Google Scholar] [CrossRef]

- Piri, H.; Renzi, M.; Bietresato, M. Enhancing Performance and Sustainability of Engine Lubricants and Biolubricants by Dispersing SiO2 Nanoparticles Coated with KH570-Silane Coupling Agent. Appl. Sci. 2024, 14, 7943. [Google Scholar] [CrossRef]

- Biczó, R.; Kalácska, G.; Mankovits, T. Effects of Automotive Test Parameters on Dry Friction Fiber-Reinforced Clutch Facing Surface Microgeometry and Wear. Polymers 2021, 13, 3896. [Google Scholar] [CrossRef]

- Ijaz Malik, M.A.; Kalam, M.A.; Mujtaba, M.A.; Almomani, F. A Review of Recent Advances in the Synthesis of Environmentally Friendly, Sustainable, and Nontoxic Bio-Lubricants: Recommendations for the Future Implementations. Environ. Technol. Innov. 2023, 32, 103366. [Google Scholar] [CrossRef]

- Joshi, J.R.; Bhanderi, K.K.; Patel, J.V. A Review on Bio-Lubricants from Non-Edible Oils-Recent Advances, Chemical Modifications and Applications. J. Indian Chem. Soc. 2023, 100, 100849. [Google Scholar] [CrossRef]

- Kumar, V.B. Design and Development of Molten Metal Nanomaterials Using Sonochemistry for Multiple Applications. Adv. Colloid Interface Sci. 2023, 318, 102934. [Google Scholar] [CrossRef]

- Kumar, V.B.; Sahu, A.K.; Bhanu, K.; Rao, S. Development of Doped Carbon Quantum Dot-Based Nanomaterials for Lubricant Additive Applications. Lubricants 2022, 10, 144. [Google Scholar] [CrossRef]

- Tomala, A.M.; Kumar, V.B.; Porat, Z.; Michalczewski, R.; Gedanken, A.; Tomala, A.M.; Bhooshan Kumar, V.; Porat, Z.; Michalczewski, R.; Gedanken, A. Tribological Anti-Wear and Extreme-Pressure Performance of Multifunctional Metal and Nonmetal Doped C-Based Nanodots. Lubricants 2019, 7, 36. [Google Scholar] [CrossRef]

- Prasannakumar, P.; Sankarannair, S.; Prasad, G.; Krishna P.H., H.; Pranav, S.; Vivek, P.; Sidharth, S.; Shanmugam, R. Bio-Based Additives in Lubricants: Addressing Challenges and Leveraging for Improved Performance toward Sustainable Lubrication. Biomass Convers. Biorefin. 2025, 15, 17969–17997. [Google Scholar] [CrossRef]

- Hartmann, C.; Welm, M.; Schreyer, S.; Hartmann, C.; Volk, W. A Modular Car Body for Sustainable, Cost-Effective, and Versatile Vehicle Development. Technologies 2021, 9, 13. [Google Scholar] [CrossRef]

- Amaral, L.V.; Santos, N.D.S.A.; Roso, V.R.; Sebastião, R. de C. de O.; Pujatti, F.J.P. Effects of Gasoline Composition on Engine Performance, Exhaust Gases and Operational Costs. Renew. Sustain. Energy Rev. 2021, 135, 110196. [Google Scholar] [CrossRef]

- Zhang, W.; Fang, X.; Sun, C. The Alternative Path for Fossil Oil: Electric Vehicles or Hydrogen Fuel Cell Vehicles? J. Environ. Manag. 2023, 341, 118019. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Nazzal, M.A.; Darras, B.M.; Deiab, I.M. A Comprehensive Sustainability Assessment of Battery Electric Vehicles, Fuel Cell Electric Vehicles, and Internal Combustion Engine Vehicles through a Comparative Circular Economy Assessment Approach. Sustainability 2023, 15, 171. [Google Scholar] [CrossRef]

- Reddy, V.J.; Hariram, N.P.; Maity, R.; Ghazali, M.F.; Kumarasamy, S. Sustainable Vehicles for Decarbonizing the Transport Sector: A Comparison of Biofuel, Electric, Fuel Cell and Solar-Powered Vehicles. World Electr. Veh. J. 2024, 15, 93. [Google Scholar] [CrossRef]

- De Wolf, D.; Smeers, Y. Comparison of Battery Electric Vehicles and Fuel Cell Vehicles. World Electr. Veh. J. 2023, 14, 262. [Google Scholar] [CrossRef]

- Valladares Montemayor, H.M.; Chanda, R.H. Automotive Industry’s Circularity Applications and Industry 4.0. Environ. Chall. 2023, 12, 100725. [Google Scholar] [CrossRef]

- Leong, J.Y. Review on Circularity in the Electric Vehicle (EV) Industry. World Electr. Veh. J. 2024, 15, 426. [Google Scholar] [CrossRef]

- Du, B.; Bryson, J.R.; Qamar, A. Aspiring towards Automotive Circularity: A Critical Review and Research Agenda. J. Environ. Manag. 2025, 380, 125150. [Google Scholar] [CrossRef]

- Liu, X.; Huang, Z.; Tang, W.; Wang, B. Remarkable Lubricating Effect of Ionic Liquid Modified Carbon Dots as a Kind of Water-Based Lubricant Additives. Nano 2017, 12, 1750108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).