Abstract

Agricultural machinery components suffer from severe soft abrasive wear when interacting with flexible materials like rice stalks. To address this, we investigate the friction-reduction mechanism, parameter optimization, and experimental validation of a biomimetic non-smooth surface inspired by the dung beetle’s microstructure. The bionic design was first established by characterizing the beetle’s unique micro-bump array. To ensure simulation accuracy, the critical bonding parameters of a flexible rice stalk DEM model were precisely calibrated via three-point bending tests combined with Response Surface Methodology (RSM). Subsequent DEM simulations revealed that the bionic surface disrupts continuous sliding by reducing the contact area and inducing high-frequency micro-vibrations in the stalk. Using RSM, the bump geometry was systematically optimized, yielding an optimal combination of a 2.975 mm diameter and a 1.0 mm spacing, which theoretically reduces the average normal contact force by 69.3%. Finally, reciprocating wear tests confirmed that the optimized bio-inspired surface exhibited significantly lower mass loss and effectively suppressed the formation of plowing grooves compared to a smooth surface, showing high agreement with simulation predictions. This study provides both a fundamental understanding of the friction-reduction mechanism and precise quantitative guidance for engineering wear-resistant agricultural components.

1. Introduction

In modern agricultural production, the wear of mechanical components is a prevalent and critical issue requiring urgent attention [1,2,3,4]. Particularly in equipment such as rice combine harvesters, components like header platforms and conveying channels are subjected to intense and prolonged contact and relative sliding with large volumes of rice stalks [5,6,7,8]. Although classified as a “soft abrasive”, the epidermis of rice stalks is rich in amorphous silicate bodies of relatively high hardness [9,10,11,12,13]. Under high contact stress, these exhibit a significant abrasive capacity, leading to severe abrasive wear on component surfaces. This drastically shortens the equipment’s service life and increases maintenance costs [14,15,16,17,18,19]. Conventional approaches to wear resistance have primarily focused on developing materials with higher hardness or applying surface coatings; however, these methods are often costly and have limited effectiveness under complex operating conditions. Therefore, exploring novel, highly efficient, and low-cost friction-reduction technologies is of significant engineering value.

Nature, honed over millions of years of evolution, provides a boundless source of inspiration for solving engineering challenges [20,21,22]. Bionics, particularly in the field of bionic surface engineering, has shown immense potential in areas such as adhesion reduction, drag reduction, and wear resistance by mimicking the unique structures and functions of biological surfaces [23,24,25]. Designs for bio-inspired textured surfaces are currently categorized into several types: dimpled, bumped, grooved, gridded, and scaled. Research has shown that different structures are suited for different applications. For example, dimpled textures are widely used to enhance performance under lubricated conditions by acting as micro-reservoirs for lubricants [26], while grooved patterns have demonstrated significant drag reduction in fluid flows and wear reduction against sand erosion [27,28]. In contrast, scale-like surfaces, inspired by creatures like desert lizards, have demonstrated superior performance against particle erosion and impact wear, as investigated by Huang et al. [29].

Among the vast array of biological models, the dung beetle (Coleoptera) has attracted considerable attention due to its remarkable adaptations for interacting with challenging environments like soil and dung. Researchers have drawn inspiration from various parts of its body. For instance, the microstructure of the dung beetle’s head and forelegs has been mimicked to design tillage components with superior anti-adhesion and friction-reduction properties [30,31]. Furthermore, the unique nanostructures on its elytra have inspired the development of self-cleaning and wear-resistant surfaces for applications ranging from solar panels to aviation materials [32,33,34]. These studies collectively demonstrate the dung beetle’s significant potential as a versatile model for engineering functional surfaces.

Meanwhile, bumped surfaces have proven particularly effective in tribological systems involving solid or cohesive materials. Studies have shown that these protrusions can effectively reduce soil adhesion by minimizing the real contact area and trapping air pockets, a principle inspired by the skin of earthworms and other fossorial animals [35,36,37,38,39]. This concept has been successfully extended to agricultural applications, where bumped surfaces on tillage tools significantly lower frictional forces. Notably, the body surfaces of creatures like dung beetles, which thrive in sticky and complex environments, are often densely covered with micron-scale protrusions (bumps) that provide outstanding anti-adhesion and friction-reduction functions [40,41,42,43].

Inspired by such fossorial animals, bumped surfaces have proven particularly effective in tribological systems involving solid or cohesive materials. Studies have shown that these protrusions can effectively reduce soil adhesion by minimizing the real contact area, a principle also found on the skin of earthworms and moles. However, the existing body of research on bio-inspired textured surfaces has predominantly focused on applications involving rigid or semi-rigid interfaces, such as reducing soil adhesion or handling granular and fluidic materials. For example, Zhang et al. [44] innovatively applied convergent evolution theory to design serrated structures for improving soil imprinting efficiency, a scenario dominated by soil-tool interaction. Similarly, Nie et al. [45] investigated the effect of groove textures on frictional energy dissipation in magnetic fluid lubrication. The mechanical properties (e.g., rigidity, flowability) and contact modes of soil and magnetic fluids differ significantly from those of flexible, long-stalk biomass such as rice stalks. The latter involves complex line and area contact, accompanied by large elastic deformations, making it difficult to directly extrapolate existing findings. This highlights a critical research gap: the specific mechanisms governing friction and wear at the interface of bionic surfaces and flexible, long-stalk biomass remain largely unexplored, limiting the development of effective wear-resistant solutions for this specific context.

Furthermore, the performance of a textured surface is highly dependent on its key geometric parameters. While some studies have successfully employed systematic optimization tools like Response Surface Methodology (RSM), they have often targeted different objectives or systems. For instance, Mao and Zeng [46] used RSM to optimize texture parameters for reducing friction under cavitation conditions, while Qin et al. [47] and Gao et al. [48] applied it to optimize bionic coatings on titanium alloys. Consequently, a targeted and systematic optimization of bump parameters specifically for reducing wear from rice stalks represents a significant and unaddressed challenge. This lack of specialized design optimization is a critical bottleneck hindering the practical engineering application of these promising bionic designs in agriculture.

In light of this, this study aims to systematically investigate the friction-reduction mechanism of a novel bio-inspired textured surface on rice stalks, with the dung beetle’s foreleg microstructure as the bionic prototype, and to optimize its key geometric parameters. The specific objectives are:

- (1)

- To quantitatively characterize the microstructure of the dung beetle’s foreleg surface to provide prototype data for the bionic design.

- (2)

- To precisely calibrate the key material parameters for the DEM model through experimental methods, ensuring the accuracy of the numerical simulations.

- (3)

- To reveal the intrinsic physical mechanism by which the bio-inspired bumped surface reduces wear from rice stalks, using a combination of theoretical analysis and Discrete Element numerical simulation.

- (4)

- To perform a multi-objective optimization of the bump diameter and spacing using Response Surface Methodology (RSM) to identify the optimal parameter combination for friction reduction.

2. Models, Methods, and Parameter Calibration

2.1. Bionic Surface Design and Characterization

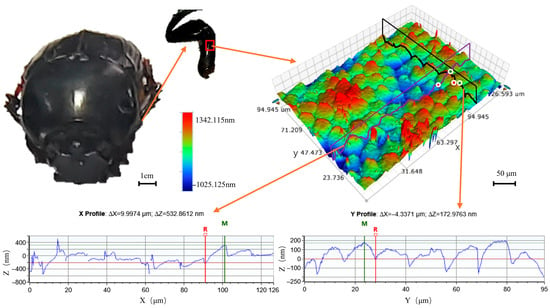

The dung beetle (Catharsius molossus), sourced from the Nanyang region of Henan Province, was selected as the bionic prototype. The micro-morphology of its foreleg femur’s carapace surface was observed and measured using an Optec optical electron microscope. As shown in Figure 1, the surface is densely covered with numerous, near-circular micro-protrusions (bumps). Through statistical analysis of multiple micrographs using image analysis software, the average geometric parameters of these bumps were determined: the average diameter is approximately 11.88 μm, the height ranges from 573 to 585 nm, and the average spacing between them is approximately 12.76 μm. These micro-bump structures form a natural, non-smooth, friction-reducing surface.

Figure 1.

Micro-morphology and profile curve of the dung beetle’s foreleg surface. Scale bars are included for the macroscopic image and the surface micrograph.

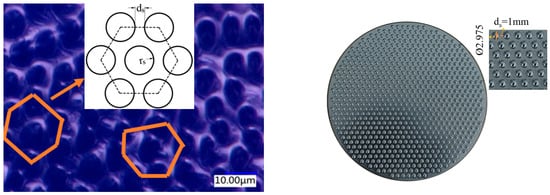

Based on these observations, and to facilitate theoretical analysis and engineering application, the complex, micron-scale bump structure was scaled up and morphologically simplified. A geometric model of a bio-inspired textured surface, composed of an array of hemispherical bumps, was thus established. The bumps were arranged in a hexagonal close-packed array on the surface (Figure 2).

Figure 2.

Hexagonal arrangement of bumps on the bio-inspired surface.

It is noteworthy that this design employs a strategy of dimensional scaling, transitioning from the micrometer (μm) scale of the biological prototype to the millimeter (mm) scale for engineering application. This decision is not aimed at achieving an exact geometric replication but is instead grounded in the bionic principle of functional similarity.

The rationale for this approach is that, although the geometric dimensions are magnified, the core friction-reduction mechanism of the design is preserved at the macroscopic scale. This mechanism is the transformation of the continuous line-contact between the stalk and the surface into a series of discrete point contacts. It is this fundamental change in contact mode that forms the physical basis for inducing micro-vibrations in the stalk and disrupting continuous plowing wear—a mechanism that exhibits inherent similarity across different scales. Furthermore, for rice stalks with millimeter-scale diameters, a surface texture at the millimeter scale is more mechanically compatible.

Therefore, the focus of this study is not on replicating the biological micro-morphology itself but rather on validating the effectiveness of this nature-inspired “discrete contact” bionic principle at the macroscopic engineering scale of agricultural machinery.

2.2. DEM Model Development and Parameter Calibration

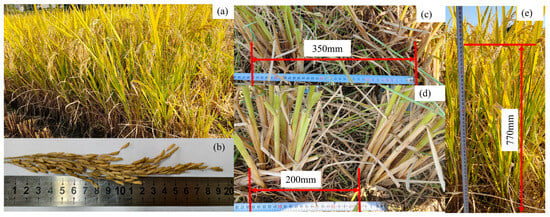

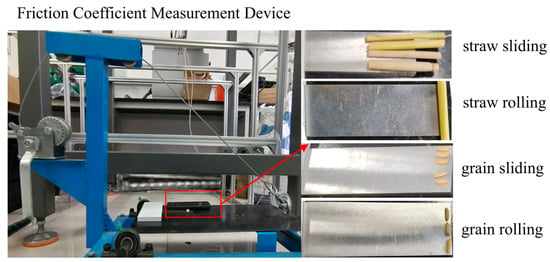

To ensure the accuracy of the DEM simulation, it is essential to experimentally calibrate the key parameters within the model. To obtain the fundamental parameters required for the DEM model, field measurements were conducted on rice samples (cultivated in the Zhenjiang urban district), as shown in Figure 3. Data such as the major/minor axis dimensions and moisture content were recorded (Table 1). An inclined plane test apparatus (Figure 4) was used to determine the coefficients of static and rolling friction between the rice stalks/grains and a Q235 steel plate. The experiment was repeated 10 times for each condition, and the average values were taken. The measured coefficient of static friction between the stalk and the steel plate ranged from 0.25 to 0.40 (with an average of 0.3153), while the coefficient of rolling friction ranged from 0.19 to 0.22 (with an average of 0.21).

Figure 3.

Field measurement process of rice, (a) Field environment; (b) Panicle length; (c) Row spacing; (d) Plant spacing; (e) Stem length before harvesting.

Table 1.

Rice parameters.

Figure 4.

Determination of coefficient of friction in rice straw.

The critical parameters for the flexible stalk model are the bonding parameters within the Bonding V2 contact model, which include the normal and tangential stiffness. To accurately determine these parameters, a hybrid approach that combines physical experimentation with simulation-based optimization was employed.

To obtain the key mechanical properties of a single rice stalk, which are essential for calibrating the bonding parameters in the DEM model, a three-point bending test was conducted on actual rice stalks using a universal testing machine, as shown in Figure 5. Samples with a uniform length of 100 mm were prepared. Each sample was placed on a support fixture with a specified span. A cylindrical upper indenter was then used to apply a load at the midpoint of the stalk at a constant velocity of 0.5 mm/s, and the corresponding force-displacement curves were recorded. The primary objective of this test was to determine the stalk’s resistance to bending. Using Equation (2), the average bending elastic modulus of the stalks was calculated to be 2.164 GPa. This experimentally determined value served as the benchmark target for the subsequent DEM model parameter calibration. To account for the structural difference between the hollow nature of a real stalk and the solid-particle chain used in the simulation model, a correction for the moment of inertia was applied. Following this adjustment, the target equivalent elastic modulus for the simulation was determined to be 1.814 GPa.

where F is the applied load (N); L is the support span (mm); S is the bending deflection of the stalk (mm); I is the moment of inertia of the stalk’s cross-section (mm4); I = π/64 × [d4 − (d − 2w)4]; d is the outer diameter; and w is the wall thickness of the rice stalk, both in mm.

Figure 5.

Three-point bending test for mechanical property characterization and DEM model calibration. (a) Experimental setup for the physical test, showing the upper indenter, rice stalk sample, and support fixture. (b) Corresponding simulation model used for parameter calibration in EDEM.

A three-point bending simulation model, which corresponded exactly to the physical experiment, was created in EDEM (Figure 5). With the normal and tangential stiffness coefficients as the input variables and the simulated equivalent elastic modulus as the response value, an optimization was performed using Response Surface Methodology (RSM) within the Design-Expert 13 software. By performing a regression analysis on the results from 13 simulation runs, a predictive model for the elastic modulus was established.

2.3. Numerical Simulation of the Friction-Reduction Process

It is important to clarify the rationale behind the simplified simulation model used in this study. The primary objective of this simulation is not to replicate the full complexity of a combine harvester’s operation, but rather to isolate and fundamentally understand the core physical mechanism of friction reduction at the interface between a flexible stalk and a non-smooth surface. To achieve this, a simplified approach was deliberately adopted for the following reasons. First, a single flexible stalk model is used to precisely analyze the micro-vibrations and “contact-disengagement” dynamics induced by the bumped surface, avoiding the confounding effects of inter-stalk friction and packing that would dominate a bulk simulation. Second, reciprocating sliding under a constant load simulates the essential condition of continuous abrasive wear, allowing for a clear focus on the tribological interaction. This controlled approach allows for a clear, quantitative comparison between different surface geometries, which is essential for the effective application of Response Surface Methodology (RSM) and for providing a foundational understanding of the wear-reduction principles.

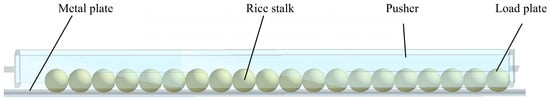

To thoroughly investigate the friction-reduction mechanism of the bio-inspired surface and to optimize its key geometric parameters, this study developed a simplified reciprocating sliding wear simulation platform (Figure 6). The platform primarily consists of a bottom metal plate (modeled as either a smooth plane or a bio-inspired bumped surface), the flexible rice stalk model, a load plate for applying a normal load, and a pusher to drive the motion of the stalk.

Figure 6.

Schematic diagram of the reciprocating sliding wear simulation setup.

The specific parameters for the simulation are detailed in Table 2. These settings were designed to simulate the fundamental physical process of a stalk undergoing continuous relative sliding against different surfaces under a constant load. The control group utilized a smooth plane, while the experimental groups featured bio-inspired bumped surfaces with varying geometric parameters, as designed by the Response Surface Methodology (RSM).

Table 2.

Key parameter settings for the friction-reduction simulation test.

During the simulation, the built-in Archard wear model in EDEM was enabled to track and record the wear depth on the metal plate’s surface in real-time. This allowed for the evaluation of the friction-reduction performance of the different surface designs.

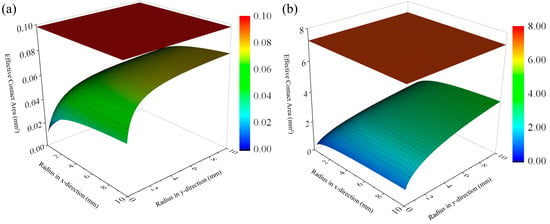

To conduct a preliminary theoretical investigation into the friction-reduction potential of the bumped surface, this study analyzed the contact behavior based on Hertzian contact theory. The analysis considered the contact of both a rice stalk (simplified as an elastic cylinder) and a rice grain (simplified as an elastic ellipsoid) with two distinct counter-surfaces: a smooth plane and a single bio-inspired bump (simplified as an elastic sphere).

Under an identical normal load, Q, the contact area, A, and the maximum contact stress, P0, were identified as the key evaluation metrics. Theoretical derivations indicate that, in contrast to the contact with a smooth plane, the contact with a bump constitutes a point or highly localized contact, resulting in a substantial reduction in the effective contact area. According to the classic Archard wear model, the wear volume (V) is proportional to the normal load (Fn) and the sliding distance (s) and inversely proportional to the material’s hardness (H). The relationship is expressed as:

where K is the dimensionless wear coefficient. This equation implies that under a constant total load, reducing the effective contact area—which often leads to a reduction in the friction force and consequently the energy dissipated by sliding—is an effective approach to mitigating wear.

Numerical calculations were performed using MATLAB 2024a, and the results (Figure 7) show that as the bump radius increases from 0 mm to 10 mm, the effective contact area for the stalk decreases from 7.26 mm2 to 3.63 mm2 (a 50.0% reduction). Similarly, the effective contact area for the grain decreases from 0.0983 mm2 to 0.0783 mm2 (a 20.3% reduction). These results theoretically confirm the significant effectiveness of the bump structure in reducing the contact area, particularly for the stalk, which exhibits a line-contact geometry.

Figure 7.

Theoretical calculation results of the influence of bio-inspired bump radius on contact area: (a) for the grain; (b) for the stalk.

To determine the optimal geometric parameters for the bio-inspired bumps, Response Surface Methodology (RSM) was employed for systematic design and optimization.

- (1)

- Factor and Level Selection: Based on preliminary simulations and theoretical analysis, the two geometric parameters with the most significant influence on friction reduction were selected as the factors: bump diameter and bump spacing. Each factor was set at three levels, as detailed in Table 3.

Table 3. Factors and levels for the response surface methodology experiment.

Table 3. Factors and levels for the response surface methodology experiment. - (2)

- Experimental Design: A Central Composite Design (CCD) was used to arrange the simulation experiments, resulting in a total of 14 simulation runs.

- (3)

- Response Value: The average normal contact force exerted on the metal plate during the simulation was selected as the response value. A lower value for this metric indicates reduced contact impact and pressure, which in turn corresponds to a lower degree of wear.

2.4. Experimental Validation of the Friction-Reduction Performance

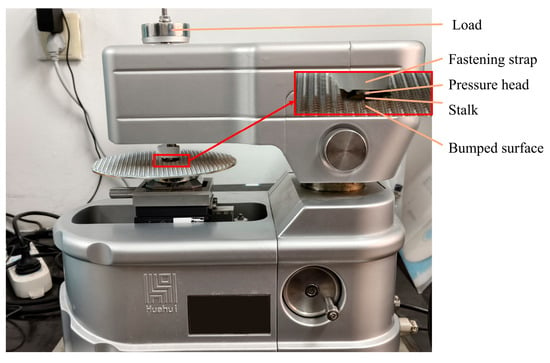

To experimentally validate the actual friction-reduction performance of the optimized bio-inspired surface and to confirm the predictions from the numerical simulations, this study conducted a series of reciprocating wear comparison tests. The experiments were performed on a reciprocating wear test rig (Figure 8), an apparatus capable of accurately simulating the continuous relative sliding process between a rice stalk and a metal surface.

Figure 8.

The reciprocating tribological test rig used for wear experiments.

The experimental design included two sample groups. The control group consisted of a standard Q235 steel plate (dimensions: 100 mm × 33.3 mm; hardness: 165 HB), the surface of which was polished to represent a conventional smooth surface. The experimental group utilized a Q235 steel plate of identical dimensions and material, but with a bio-inspired textured structure fabricated on its surface using laser cladding technology. The geometry of this structure strictly adhered to the optimal parameters determined by the Response Surface Methodology (RSM) optimization: a hexagonal array of hemispherical bumps with a diameter of 2.975 mm and a center-to-center spacing of 1.0 mm. The abrasive material used was fresh rice stalk, which was cut into 50 mm segments and securely fastened to the slider of the wear test rig.

To ensure comparability between the experiment and the simulation, the experimental conditions were carefully designed to match the key settings of the numerical simulation. The specific operating parameters are detailed in Table 4.

Table 4.

Operating parameters for the friction-reduction performance validation test.

Upon completion of the wear tests, a quantitative evaluation was conducted using the mass loss method. Before the start of the experiment and after the full 240 h duration, the mass of each steel plate was precisely measured using a high-precision analytical balance (Sartorius BS-224S, precision 0.1 mg, Sartorius AG, Göttingen, Germany). Prior to each measurement, the specimens were ultrasonically cleaned in an acetone solution to remove any impurities.

In addition, a qualitative and semi-quantitative analysis was performed through surface morphology observation. After the tests, a 3D digital microscope (Keyence VHX-900f, Keyence Corporation, Osaka, Japan) was used to meticulously examine the specimen surfaces to analyze the differences in wear features, such as grooves and scratches. This comprehensive experimental design ensures that a direct and reliable comparison can be made between the simulation predictions and the actual performance of the bio-inspired surface.

3. Results and Discussion

3.1. DEM Model Calibration and Validation

Through the response surface analysis of the three-point bending simulation tests, the optimal solution for the normal and tangential stiffness coefficients was determined. When the target elastic modulus was set to 1.814 GPa, the optimization yielded a normal stiffness coefficient of 2.592 × 1012 N/m3 and a tangential stiffness coefficient of 2.5 × 1012 N/m3.

A verification simulation was conducted using this parameter set, resulting in an equivalent elastic modulus of 1.8317 GPa. This value has a relative error of only 0.97% compared to the target value, demonstrating that the calibration results are both accurate and reliable.

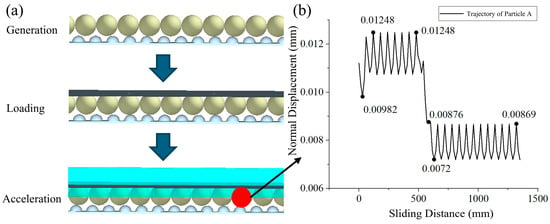

3.2. Simulation Results for the Friction-Reduction Mechanism Analysis and Parameter Optimization

The simulation results for the smooth surface (control group) were compared with those for a bio-inspired surface with a representative set of parameters (diameter: 3 mm; spacing: 1 mm) (experimental group). On the smooth surface, the normal force experienced by the stalk remained stable at approximately 0.5047 N. In contrast, on the bio-inspired bumped surface, the normal force exhibited intense, periodic fluctuations, with an average value of only 0.1737 N—a reduction of 65.6% compared to the smooth surface.

By analyzing these results in conjunction with the stalk’s normal displacement curve (Figure 9), the friction-reduction mechanism can be elucidated. As the stalk slides over the crest of a bump, it is lifted and subjected to a large, instantaneous force. As it moves into the valley between the bumps, the stalk disengages from the surface, and the force rapidly drops to zero. This periodic “contact-disengagement” process induces high-frequency, low-amplitude vibrations in the stalk, perpendicular to the direction of sliding.

Figure 9.

Simulation of the stalk’s motion on the bio-inspired bumped surface. (a) Snapshots illustrating the periodic “contact-disengagement” process. (b) The corresponding normal displacement curve of a particle on the stalk, showing micro-vibrations perpendicular to the sliding direction.

A regression analysis was performed on the results of the 14 CCD simulation runs (as shown in Table 5), establishing a quadratic polynomial regression model for the average normal force (Ftt1) as a function of the bump diameter (At1) and spacing (Bt1).

where Ftt1 is the predicted average normal force (N), and At1 and Bt1 are the bump diameter and bump spacing (mm), respectively.

Table 5.

Design matrix and results for the response surface analysis.

The analysis of variance (ANOVA) results, presented in Table 6, show a p-value for the model that is substantially less than 0.0001, indicating that the regression model is highly significant. Furthermore, the coefficient of determination (R2) is 0.9992, and the adjusted R2 is 0.9974, which demonstrates a high goodness of fit and strong predictive capability for the model. It is important to clarify that the small numerical values appearing in the ANOVA table, such as the Mean Square for Pure Error (on the order of 10−5), are calculated statistical quantities derived from the regression analysis. These values reflect the model’s fitting accuracy and should not be misinterpreted as physically measured forces with ultra-high precision.

Table 6.

Analysis of variance (ANOVA) for the average normal force regression model.

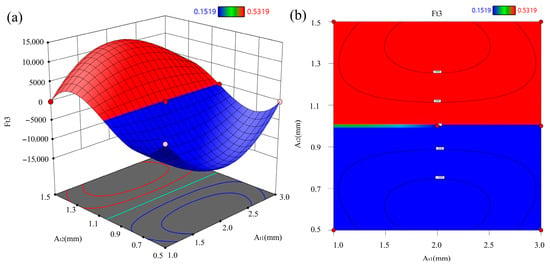

Figure 10 presents the response surface and contour plots, which visually illustrate the effects of the two factors and their interaction on the normal force. It is evident from the plots that an optimal region exists within the experimental range where the normal force reaches a minimum value.

Figure 10.

(a) Response surface and (b) contour plots.

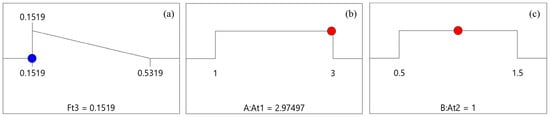

The optimization module in the Design-Expert software was used to solve the regression model, with the objective set to “minimize the normal force”. The optimization results (Figure 11) indicate that a theoretically minimum average normal force is achieved when the bump diameter is 2.975 mm and the bump spacing is 1.0 mm. The predicted minimum value for the force under these conditions is 0.1519 N.

Figure 11.

Prediction results from the response surface optimization: (a) target value for the normal force; (b) bump diameter; (c) bump spacing.

3.3. Experimental Validation of the Optimized Bio-Inspired Surface

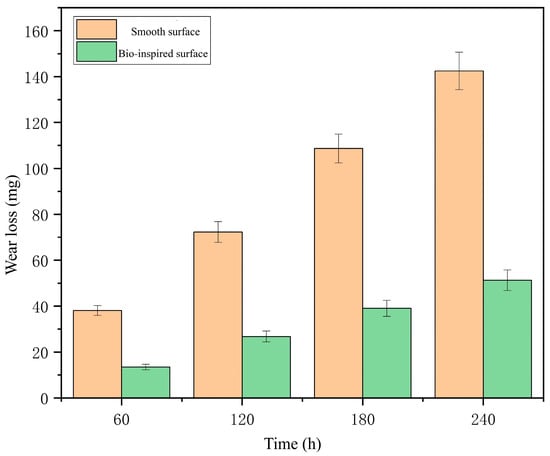

To definitively validate the predictive accuracy of the simulation model and the actual friction-reduction performance of the optimized bio-inspired design, this study conducted a comparative reciprocating wear bench test. The test compared a bio-inspired surface, fabricated according to the optimal parameters (bump diameter: 2.975 mm; spacing: 1.0 mm), against a conventional smooth surface.

After 240 h of continuous wear testing, the two surfaces exhibited a significant difference in their degree of wear. Figure 12 presents a comparison of the cumulative mass loss for the smooth surface (control group) and the bio-inspired surface (experimental group) over the test period. The control group (smooth surface) experienced an average cumulative mass loss of approximately 142.5 ± 8.2 mg, with its wear rate remaining relatively constant throughout the experiment. In stark contrast, the experimental group (bio-inspired surface) showed an average cumulative mass loss of approximately 51.3 mg.

Figure 12.

Bar chart comparing the cumulative mass loss of the smooth surface and the bio-inspired surface.

This result indicates that the optimized bio-inspired surface reduced the total wear by approximately 64%, a substantial inhibition that provides strong experimental evidence for the effectiveness of the bionic design. This macroscopic outcome can be explained by a combination of theoretical principles and micro-scale mechanisms.

First, the experimentally measured reduction in wear is in high agreement with the 69.3% reduction in the average normal contact force predicted by the DEM simulation. According to the classic Archard wear model (V = K·Fn·s/H), where V is the wear volume, and Fn is the normal load, wear volume is directly proportional to the normal contact force [49]. Therefore, the significant decrease in contact force, induced by the “contact-disengagement” mechanism of the bumped surface, is the primary theoretical reason for the observed reduction in mass loss. This validates not only the bionic design principle but also the predictive capability of the simulation model at the macroscopic level.

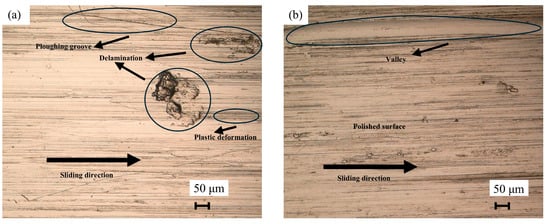

Furthermore, this reduction in wear is directly linked to a fundamental shift in the wear mechanism, as will be detailed in the following micro-morphological analysis (Figure 13). The bio-inspired surface mitigates wear by transitioning the dominant wear mode from severe abrasive plowing, which involves significant material removal, to mild polishing. This change in the physical process of material removal at the micro-scale is the root cause of the dramatic decrease in mass loss.

Figure 13.

Micrographs of (a) the smooth and (b) bio-inspired surfaces after the wear test.

To further elucidate the distinct wear mechanisms of the two surfaces, a micro-morphological analysis was conducted on the specimens after the friction tests, as shown in Figure 13. The smooth surface (Figure 13a) exhibited features characteristic of severe abrasive wear. Its surface was covered with numerous deep and continuous plowing grooves parallel to the sliding direction. Along the sides of these grooves, plastic deformation ridges, formed by the extrusion of material, could be observed. In certain localized areas, there were even signs of material delamination.

In contrast, the overall structure of the bio-inspired surface (Figure 13b) remained intact. Wear was primarily concentrated on the apex of the bumps, manifesting as slight abrasion or polishing. The valley regions between the bumps, however, showed almost no signs of damage, and there were no continuous plowing grooves present. This visual evidence clearly demonstrates that the bio-inspired bump array successfully disrupted the continuity of the plowing mechanism. It effectively dispersed the wear forces and confined them to the discrete tops of the bumps, thereby providing effective protection for the substrate material.

In summary, the results of the physical wear tests, from both a quantitative (mass loss) and a qualitative (surface morphology) perspective, irrefutably confirm the superior friction-reduction performance of the optimized bio-inspired textured surface compared to the conventional smooth surface. The substantial reduction in wear observed in the experiments is in high agreement with the significant decrease in contact force predicted by the simulation. Concurrently, the experimentally observed suppression of the plowing behavior perfectly corroborates the “contact-disengagement” micro-vibration friction-reduction mechanism revealed by the simulation.

This high degree of consistency between the physical experiments and the numerical simulation results not only completes the full research loop of this study, from “theoretical design” to “physical validation”, but also thoroughly validates both the predictive accuracy of the developed DEM model and the practical effectiveness of the proposed bio-inspired design.

4. Conclusions

Inspired by the microstructure of the dung beetle’s foreleg, this study systematically investigated the friction-reduction mechanism of a bio-inspired, textured, bumped surface and optimized its key geometric parameters. The main conclusions of this work are summarized as follows.

First, through a hybrid approach combining experimentation and simulation, the critical bonding parameters for the DEM model describing flexible rice stalks were successfully calibrated, laying a robust foundation for subsequent high-fidelity simulations.

Second, a bio-inspired, textured, bumped surface was successfully designed. DEM simulations confirmed that this surface has a significant friction-reduction effect on rice stalks. The core mechanism is the transformation of continuous surface contact into discrete point contact, which reduces the effective contact area and induces high-frequency micro-vibrations in the stalk perpendicular to the direction of sliding, thereby substantially lowering the average contact force.

Third, using Response Surface Methodology (RSM), the key geometric parameters of the bumped surface were successfully optimized. The optimal combination was determined to be a bump diameter of 2.975 mm and a bump spacing of 1.0 mm, which theoretically leads to a 69.3% reduction in the average normal contact force.

Finally, the effectiveness of the optimized design was successfully validated through wear bench tests. The experimental results demonstrated that the optimized bio-inspired surface can reduce wear-induced mass loss by approximately 64% and effectively suppress plowing behavior, in high agreement with the simulation predictions.

5. Significance and Future Work

This study provides significant contributions to both the fundamental understanding and practical application of bionic wear-reduction technologies in agricultural machinery. From a theoretical perspective, this research deepens the comprehension of the wear reduction mechanisms at the interface between flexible biomass and non-smooth surfaces, experimentally validating the effectiveness of the “discrete contact” and “micro-vibration” principles at a macroscopic scale. Furthermore, the complete research paradigm established herein—encompassing physical parameter calibration, numerical optimization, and experimental validation—offers a rigorous verification framework for simulation-based studies in the field of agri-tribology. From a practical standpoint, the findings offer a precise and quantitative design guide (i.e., a bump diameter of 2.975 mm and a spacing of 1.0 mm) for developing novel, cost-effective, and highly efficient wear-resistant surfaces for agricultural components. This validated simulation-driven approach enables manufacturers to rapidly evaluate different bionic designs in the early stages, thereby shortening development cycles and reducing reliance on expensive wear-resistant materials.

Although this research has made significant progress, several avenues for future work exist. To address more complex real-world conditions, future investigations could focus on several main areas that bridge the gap between simplified models and practical application.

First, the effect of bump arrangement needs to be explored. The current study focused on a uniform hexagonal array as a baseline, but non-uniform arrangements (e.g., graded spacing, random distribution, or anisotropic patterns) could offer tailored performance benefits, such as directional friction control or enhanced debris-clearing capabilities. Future work should investigate the influence of these more complex patterns on wear resistance.

Second, a more comprehensive material model for flexible stalks should be developed. The current study utilized a three-point bending test to calibrate the model’s bending stiffness, which is the dominant parameter in the simulated scenario. However, to create a higher-fidelity model capable of simulating more complex behaviors like twisting and compression, future work should establish a multi-parameter calibration framework incorporating a suite of experimental tests, including torsion, compression, and tensile tests.

Third, multi-objective optimization and analysis under diverse conditions are needed. The current study employed a single-objective (minimizing normal force) optimization under dry friction. Future work should develop a multi-objective optimization framework that considers a broader set of performance criteria, such as wear resistance, anti-clogging efficiency (especially with wet biomass), and surface durability (by analyzing stress concentration on the bumps). Furthermore, the tribological behavior under lubricated or contaminated conditions should also be investigated.

Fourth, the development of a mixed-abrasive wear model is crucial. The current study focuses on soft abrasive wear from stalks, but future work must incorporate hard abrasives like soil and sand into both DEM simulations and experiments to investigate the bionic surface’s performance and failure mechanisms in “soft-hard” mixed wear environments.

Finally, constructing a corrosion-wear synergistic effect model would significantly enhance predictive accuracy. Given the high humidity and corrosive nature of stalk juices in field environments, coupling corrosion kinetics models with the DEM wear model could lead to an integrated framework capable of simulating the synergistic effects of corrosion and wear, thus enabling a more accurate service life prediction for bionic components under actual operating conditions.

Author Contributions

Conceptualization, H.Z., Z.T. and B.Z.; Methodology, H.Z., Z.T., M.F. and B.Z.; Software, H.Z., Z.T. and B.Z.; Validation, H.Z., Z.T. and B.Z.; Formal analysis, H.Z., Z.T. and B.Z.; Investigation, H.Z., Z.T., M.F. and B.Z.; Resources, H.Z., Z.T., M.F. and B.Z.; Data curation, H.Z., L.T., Z.T. and B.Z.; Writing—original draft, H.Z. and B.Z.; Writing—review & editing, H.Z., L.T. and Z.T.; Visualization, H.Z., Z.T. and B.Z.; Supervision, H.Z., Z.T., M.F. and B.Z.; Project administration, H.Z., L.T. and Z.T.; Funding acquisition, H.Z., L.T. and Z.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research work was supported by the National Natural Science Foundation of China (32272002), the Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX25_4246), the Key Laboratory Equipment of Modern Agricultural Equipment and Technology (Jiangsu University), Ministry of Education (MAET202326), and the National Natural Science Foundation of China (52175235).

Data Availability Statement

The data in this article is available on request.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

References

- Guan, C.S.; Fu, J.J.; Cui, Z.C.; Wang, S.L.; Gao, Q.S.; Yang, Y.T. Evaluation of the tribological and anti-adhesive properties of different materials coated rotary tillage blades. Soil Tillage Res. 2021, 209, 104933. [Google Scholar] [CrossRef]

- Yu, Z.W.; Li, Y.M.; Du, X.X.; Liu, Y.B. Threshing cylinder unbalance detection using a signal extraction method based on parameter-adaptive variational mode decomposition. Biosyst. Eng. 2024, 244, 26–41. [Google Scholar] [CrossRef]

- Guo, Y.F.; Sun, Z.Y.; Guo, S.; Fu, J.L. Research on a Novel Heat Treatment Process for Boron Steel Used for Soil-Engaging Components of Tillage Machinery. Agriculture 2024, 14, 1555. [Google Scholar] [CrossRef]

- Rakibuzzaman, M.; Islam, M.D.; Kim, H.H.; Suh, S.H.; Zhou, L.; Iqbal, A. Numerical Simulation of Solid-Liquid Two-Phase Flow Analysis of Submersible Drainage Pumps. Irrig. Drain. 2025. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.Z.; Gao, Z.P.; Lu, E.; Li, Y.M. Effect of vibration on rapeseed header loss and optimization of header frame. Trans. ASABE 2021, 64, 1247–1258. [Google Scholar] [CrossRef]

- Liu, W.J.; Zeng, S.; Chen, X.G. Design and Experiment of Adaptive Profiling Header Based on Multi-Body Dynamics-Discrete Element Method Coupling. Agriculture 2024, 14, 105. [Google Scholar] [CrossRef]

- Song, Z.Q.; Du, C.X.; Chen, Y.C.; Han, D.L.; Wang, X.Z. Development and test of a spring-finger roller-type hot pepper picking header. J. Agric. Eng. 2024, 55, 246–253. [Google Scholar] [CrossRef]

- Liang, Z.W.; Liu, J.; Yang, D.Y.; Ouyang, K.C. Modeling and Simulation of Reel Motion in a Foxtail Millet Combine Harvester. Agriculture 2025, 15, 19. [Google Scholar] [CrossRef]

- Wu, S.; Wei, X.H. Mechanical interaction between a canopy opener and rice stalks based on the transient dynamic analysis. Biosyst. Eng. 2019, 178, 256–263. [Google Scholar] [CrossRef]

- Liang, Z.W.; Li, Y.M.; Xu, L.Z.; Zhao, Z. Sensor for monitoring rice grain sieve losses in combine harvesters. Biosyst. Eng. 2016, 147, 51–66. [Google Scholar] [CrossRef]

- Wang, B.; Khir, R.; Pan, Z.L.; Wood, D.; Mahoney, N.E.; El-Mashad, H.; Wu, B.G.; Ma, H.L.; Liu, X.R. Simultaneous decontamination and drying of rough rice using combined pulsed light and holding treatment. J. Sci. Food Agric. 2016, 96, 2874–2881. [Google Scholar] [CrossRef]

- Xu, L.Z.; Hansen, A.C.; Li, Y.M.; Liang, Z.W.; Yu, L.J. Numerical and experimental analysis of airflow in a multi-duct cleaning system for a rice combine harvester. Trans. ASABE 2016, 59, 1101–1110. [Google Scholar] [CrossRef]

- Hou, F.R.; Ding, W.H.; Qu, W.J.; Oladejo, A.O.; Xiong, F.; Zhang, W.W.; He, R.H.; Ma, H.L. Alkali solution extraction of rice residue protein isolates: Influence of alkali concentration on protein functional, structural properties and lysinoalanine formation. Food Chem. 2017, 218, 207–215. [Google Scholar] [CrossRef]

- Xu, L.Z.; Ma, Z.; Li, Y.M. Test and Analyses of the Reciprocal Friction Properties between the Rapeseeds Threshing Mixture and Non-smooth Bionic Surface. Ama Agric. Mech. Asia Afr. Lat. Am. 2016, 47, 17–23. [Google Scholar]

- Wei, C.C.; Xu, L.Z.; Wang, J.T.; Li, Y.M. Inertial force balance and ADAMS simulation of the oscillating sieve and return pan of a rice combine harvester. Int. J. Agric. Biol. Eng. 2018, 11, 129–137. [Google Scholar] [CrossRef]

- Liang, Z.W.; Li, Y.M.; De Baerdemaeker, J.; Xu, L.Z.; Saeys, W. Development and testing of a multi-duct cleaning device for tangential-longitudinal flow rice combine harvesters. Biosyst. Eng. 2019, 182, 95–106. [Google Scholar] [CrossRef]

- Liang, Z.W.; Xu, L.Z.; De Baerdemaeker, J.; Li, Y.M.; Saeys, W. Optimisation of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments. Biosyst. Eng. 2020, 190, 25–40. [Google Scholar] [CrossRef]

- Li, Y.M.; Liu, Y.B.; Ji, K.Z.; Zhu, R.H. A Fault Diagnosis Method for a Differential Inverse Gearbox of a Crawler Combine Harvester Based on Order Analysis. Agriculture 2022, 12, 1300. [Google Scholar] [CrossRef]

- Liang, Z.W.; Wada, M.E. Development of cleaning systems for combine harvesters: A review. Biosyst. Eng. 2023, 236, 79–102. [Google Scholar] [CrossRef]

- Tian, K.P.; Zhang, B.; Ji, A.M.; Huang, J.C.; Liu, H.L.; Shen, C. Design and experiment of the bionic disc cutter for kenaf harvesters. Int. J. Agric. Biol. Eng. 2023, 16, 116–123. [Google Scholar] [CrossRef]

- Jin, Y.C.; Liu, J.Z.; Xu, Z.J.; Yuan, S.Q.; Li, P.P.; Wang, J.Z. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Safdar, B.; Pang, Z.H.; Liu, X.Q.; Jatoi, M.A.; Rashid, M.T. Rheological and tribological nature of flaxseed gum influenced by concentration and temperature and its application as a coating agent for potato chips. J. Food Sci. 2022, 87, 2058–2071. [Google Scholar] [CrossRef]

- Ren, L. Progress in the bionic study on anti-adhesion and resistance reduction of terrain machines. Sci. China Ser. E Technol. Sci. 2009, 52, 273–284. [Google Scholar] [CrossRef]

- Ren, L.; Liang, Y. Preliminary studies on the basic factors of bionics. Sci. China Technol. Sci. 2014, 57, 520–530. [Google Scholar] [CrossRef]

- Yu, H.; Shao, L.; Zhang, S.; Zhang, J.; Han, Z. An innovative strategy of anti-erosion: Combining bionic morphology and bionic arrangement. Powder Technol. 2022, 407, 1–13. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Li, H.; Xia, H.; Li, L.; Li, L.; Su, X.; Peng, J.; Ma, Y.; Tan, C.; Song, X.; Wu, T. Enhancing the reliability of laser welded-brazed aluminum/stainless steel joints via laser-chemical hybrid surface texturing. Thin Walled Struct. 2024, 199, 1–13. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, Y.; Ren, L. Particle Erosion Resistance of Bionic Samples Inspired from Skin Structure of Desert Lizard, Laudakin stoliczkana. J. Bionic Eng. 2012, 9, 465–469. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.-W.; Hsu, H.-H.; Chiang, Y.-S.; Lin, P.-C. Design and Implementation of a Dung Beetle Robot. In Proceedings of the International Conference on Advanced Robotics and Intelligent Systems (ARIS), Taipei, Taiwan, 6–8 September 2017; p. 24. [Google Scholar]

- Tong, J.; Sun, J.Y.; Chen, D.H.; Zhang, S.J. Geometrical features and wettability of dung beetles and potential biomimetic engineering applications in tillage implements. Soil Tillage Res. 2005, 80, 1–12. [Google Scholar] [CrossRef]

- Clemente, C.J.; Beale, A.; Bullock, J.M.; Federle, W. Evidence for self-cleaning in fluid-based smooth and hairy adhesive systems of insects. Comp. Biochem. Physiol. A Mol. Integr. Physiol. 2009, 153A, S123. [Google Scholar] [CrossRef]

- Clemente, C.J.; Bullock, J.M.R.; Beale, A.; Federle, W. Evidence for self-cleaning in fluid-based smooth and hairy adhesive systems of insects. J. Exp. Biol. 2010, 213, 635–642. [Google Scholar] [CrossRef] [PubMed]

- Orchard, M.J.; Kohonen, M.; Humphries, S. The influence of surface energy on the self-cleaning of insect adhesive devices. J. Exp. Biol. 2012, 215, 279–286. [Google Scholar] [CrossRef]

- Li, J.; Kou, B.; Liu, G.; Fan, W.; Liu, L. Resistance reduction by bionic coupling of the earthworm lubrication function. Sci. China Technol. Sci. 2010, 53, 2989–2995. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, C.-h.; Ren, L.-q. Biology Coupling Characteristics of Mole Crickets’ Soil-Engaging Components. J. Bionic Eng. 2008, 5, 164–171. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, C. Bionics design of stubble blade based on the digging claw of mole cricket. In Proceedings of the 3rd International Conference on Advanced Design and Manufacturing Engineering (ADME 2013), Anshan, China, 13–14 July 2013; pp. 775–778. [Google Scholar]

- Cui, Y.; Zheng, M.; Zhang, W.; Wang, B.; Zhang, L. Study of dry sliding friction and wear behavior of bionic surface of hardened steel. Mater. Express 2019, 9, 535–544. [Google Scholar] [CrossRef]

- Pan, C.; Qi, X.; Hao, Q. Bionic model design of aviation materials based on Coleoptera structure of dung beetle. In Proceedings of the Annual IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), Xi’an, China, 2–6 August 2021; pp. 188–191. [Google Scholar]

- Shen, X.; Fu, Z.; Su, C.; Sun, Z. Research on the mechanism between no-smooth surface, desorption and friction increasing based on bionic. In Proceedings of the 2nd International Conference on Materials and Products Manufacturing Technology (ICMPMT 2012), Guangzhou, China, 22–23 September 2013; pp. 2205–2209. [Google Scholar]

- Sun, D.; Lin, S.; Wang, Y.; Cui, J.; Tuo, Z.; Lin, Z.; Liang, Y.; Ren, L. Study of Self-Locking Structure Based on Surface Microstructure of Dung Beetle Leg Joint. Biomimetics 2024, 9, 622. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Chen, D.; Tong, J.; Pan, C. Differential Constitutive Equation of Elytra Cuticle by Nanoindentation. In Proceedings of the International Conference on Materials for Environmental Protection and Energy Application (MEPEA), Kuala Lumpur, Malaysia, 9–10 December 2012; p. 1133. [Google Scholar]

- Tuo, Z.; Yang, K.; Ma, S.; Cui, J.; Shi, Y.; Zhao, H.; Liang, Y.; Liu, C.; Lin, Z.; Han, Z.; et al. Multi-Level Structural Enhancement Mechanism of the Excellent Mechanical Properties of Dung Beetle Leg Joint. Small 2024, 20, 1–13. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Tong, J.; Carr, S. Convergent evolution inspired serrated structure for improving efficiency of soil imprinting and its mechanism investigation. Int. J. Agric. Biol. Eng. 2019, 12, 16–26. [Google Scholar] [CrossRef]

- Nie, S.; Gong, F.; Ji, H.; Wang, Y.; Che, C.; Zhang, G. Effect of surface texture on frictional energy dissipation under magnetic fluid lubrication used for semi-active nonlinear energy sink. Tribol. Int. 2024, 192, 1–14. [Google Scholar] [CrossRef]

- Mao, Y.; Zeng, L. Comparative study of response surface methodology and hybrid back-propagation network for optimizing friction coefficient for textured surface under cavitation conditions. Ind. Lubr. Tribol. 2018, 70, 856–864. [Google Scholar] [CrossRef]

- Qin, S.; Peng, Z.; Shi, X.; Xue, Y.; Zhang, K.; Huang, Q. Optimization of Textured Parameters to Improve the Tribological Behavior of TC4-Based Bionic Coating Using RSM. Tribol. Trans. 2022, 65, 441–456. [Google Scholar] [CrossRef]

- Gao, H.; Shi, X.; Xue, Y.; Zhang, K.; Huang, Q.; Wu, C. Optimization of Bionic Textured Parameters to Improve the Tribological Performance of TC4-Based Self-Lubricating Composite Using Response Surface Methodology. J. Mater. Eng. Perform. 2023, 32, 11296–11309. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, Z.; Gu, X.; Zhang, B. Understanding the Lubrication and Wear Behavior of Agricultural Components Under Rice Interaction: A Multi-Scale Modeling Study. Lubricants 2025, 13, 388. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).