Abstract

Peter Jost is known to the international tribology community as the father of the subject—‘the man who made the world spin a little easier’. He was the author of the eponymous ‘Jost Report’, the report of the Working Group set up in 1964 to investigate the state of lubrication education and research in the UK. Over the following five decades, up to his death in 2016, he was tireless in extolling the importance of tribology to manufacturing efficiency, energy conversion and environmental sustainability. He was instrumental in establishing the International Tribology Council and its prestigious gold, silver and bronze medals. Jost was himself the recipient of numerous national and international awards. In 1976, he was the President of the Institution of Production Engineers, and in 2013, he received the Sustained Achievement Award from the Royal Academy of Engineering. What is less well known is the story behind the Jost report—what was it that led the recently elected Labour government and its newly established Ministry of Technology to investigate lubrication and to choose Jost to lead the investigating panel? The story illustrates the combination of serendipity and determination on which success can so often depend.

1. Introduction

Peter Jost was born in Berlin in 1921 and arrived in Britain in April 1939 [1] as a refugee from Nazi Germany to take up an apprenticeship at Glasgow’s Associated Metal Works. However, once war was declared, as technically he was an enemy alien, this was terminated in July 1940 and was followed by seven months internment on the Isle of Man. After his release in February 1941 Jost resumed his apprenticeship but now at D. Napier and Son in Liverpool while studying mechanical engineering at the City of Liverpool Technical College and, subsequently, at Manchester Metropolitan College of Technology. In 1944, he won the Sir John Larking Medal from the Liverpool Engineering Society for a student paper somewhat prophetically entitled ‘The measurement of surface finish’.

In 1943 Jost moved to Letchworth in Hertfordshire as a methods engineer with K. and L. Steelfounders, and then in 1946 to London as chief planning engineer for the Datim Machine Tool Company. Four years later, aged only 28, he became the general manager and subsequently a director of Trier Bros. Ref. [2], a long-established international lubricants company, where we can suppose that his interest in the challenges of controlling friction and wear developed.

Although now based in London, Jost was proud of his association with the North West, taking on the post of organising secretary of the London branch of the Manchester Technical College Old Students’ Association. In this role, he regularly organised dinners, inviting as guest of honour Dr. Vivian Bowden, who had been in post as the College Principal since 1953. For those with an interest in the history of tribology, there is some scope for confusion here, as two figures in the story have the surname—Bowden. It is easy to confuse Vivian Bowden, subsequently Lord Bowden, with Philip Bowden, whose name is associated with that of David Tabor and the Cambridge school. In fact both Bowdens had a strong Cambridge connection—Vivian had been an undergraduate and graduate student at Emmanuel College completing his PhD thesis in the physics department in 1934. Philip Bowden, who had been a student in Australia and who was the elder by seven years, had arrived in Cambridge in 1929 to undertake his PhD. In 1931, he had been appointed as a junior lecturer in physical chemistry—so it is possible that they met.

Vivian Bowden in Manchester was an active member of the Labour Party, in particular of its Science Committee, and it seems that through him Peter Jost met and corresponded with several members of the party who subsequently achieved high office. The Science Group, which met regularly for dinners at the Reform Club in London, was led by Richard Crossman. Probably its most distinguished member was the physicist Patrick Blackett, who had had a colourful career—he had been a midshipman in the Navy in the First World War before graduating from Magdalene College, Cambridge, and then being a research student of Earnest Rutherford in the Cavendish. In 1948, Blackett had been awarded the Nobel Prize for Physics and, in 1963, had just retired after ten years as head of the Physics Department at Imperial College. He was President of the Royal Society from 1965 to 1970.

In the election of 1964, the Conservative administration that had been in power since 1951 was replaced—by a Labour government with a majority of four, with Harold Wilson as Prime Minister. One of the principal themes of the party’s manifesto had been the modernisation of British industry—harnessing the ‘white heat of the technological revolution’. Wilson had hoped to appoint Blackett as a minister but this would have meant Blackett’s accepting a peerage and moving to the House of Lords; this he was reluctant to do—or, at least, refused until 1969, when he became Baron Blackett. At one of the Reform Club dinners Wilson happened to be sitting next to Vivian Bowden and, impressed by his ability and enthusiasm, decided to invite him to join the government. So it was that Manchester Bowden became Lord Bowden of Chesterfield and was appointed a Minister of State in the Department of Education and Science. It is actually pretty clear that this was not seen by Bowden as a permanent change of career as, back in Manchester, his successor was only the ‘Acting Principal’. Subsequently, Blackett became the Chief Scientific Adviser to the newly established Ministry of Technology, in which C. P. Snow, now Lord Snow of Leicester, was the Parliamentary Secretary.

Meanwhile, Jost had left Trier Bros. in 1955 and was in the process of forging a career as an entrepreneur, co-founding and chairing several successful companies involved with the practical application of lubrication. These included both K. S. Paul and Centralube, who designed and supplied lubrication systems for industrial plants, including refineries, ships and steel mills. As well as maintaining his active membership of the Institution of Production Engineers, Jost had also joined the Institution of Mechanical Engineers and, in particular, in 1960, became a founder member of its Lubrication and Wear Committee.

In 1958, the steelmakers Richard, Thomas and Baldwins set in motion the design and construction of a new steelworks, to be known as the Spencer Works, on a green-field site of some 170 acres at Llanwern in South Wales, just outside Newport. It was to be the first oxygen-blown integrated steelworks in Britain and was designed to have an initial output of 1.4 million ingot tonnes per annum and to open in 1962. The Spencer Works hot strip mill was a pioneering installation, as it was the first successful use in the UK of computer control of all of the mill operations involving active, real-time adjustments of all the rolling variables [3].

There would be a lot of bearings—on the hot rolling lines, 144 Morgoil specialised bearings (these are essentially plain bearings with a degree of radial compliance, introducing an element of effective elasto-hydrodynamics), in excess of 20,000 plain bearings, 45,000 gear trains and more than 350,000 rolling element bearings. Of course, this was of interest to Jost and Centralube, who hoped to tender successfully for contracts. However, Jost became even more involved when, in 1960, he persuaded RTB to take him on as their lubrication-engineering consultant. In this novel role, he was able to draw up plans to rationalise the supply and organization of lubricants throughout the site—from those required for the most energy-hungry pieces of equipment—furnaces, slabbing and rolling mills and so on, down to the engine oil in the managing director’s limousine. Although he had been appointed to this position before the erection of a single building, as he subsequently commented [4]:

‘…greater progress could have been made had this appointment taken place … before enquiries were sent out or orders placed on the various manufactures of major equipment, …it was at times difficult, and at other times impossible, to effect lubrication-wise highly desirable modifications of plant design or of lubrication requirement and layouts.’

In October 1964, the Institution of Mechanical Engineers Lubrication and Wear Committee, no doubt encouraged by Jost, and in conjunction with the Iron and Steel Institute, held a major conference on the topic ‘Iron and Steel works Lubrication’. This was held in Cardiff, so only a few miles from the Spencer Works, which the delegates visited on 29 October. At this meeting, Jost presented three papers with two differing affiliations: the first as a consultant to RTB and then as a director of Centralube. As he later said in an interview with Jim Fitch at the 2005 World Tribology Congress [5]:

“One of the sessions [at the 1964 conference] was called ‘Damage and Failures’. During this session speaker after speaker from the United States, Germany, Italy, the United Kingdom and other countries, presented slides showing cemeteries of broken steel-mill machinery and equipment… During the discussion, the lack of knowledge of the designers of steel-mill plant became obvious”.

2. The Jost Committee

Vivian Bowden’s appointment to the government was clearly a stroke of luck for Jost because it gave him an inside track, not only to his old friend, who now had ministerial responsibility together with his senior administrator, Sir Frank Turnbull. Over lunch with Bowden, Peter conveyed his dismay about the considerable financial losses exposed during the 1964 conference and expressed the view that since the new government was committed to ‘white-hot technology’, Bowden should try to do something about it. Bowden was not finding it easy acclimatising to Whitehall [6], and so it was an apposite time for Jost’s initiative—his suggestion fell on fertile ground as Bowden was keen to have a project, and, before the end of the year on 22 December, Jost was invited by Bowden to form a Working Group to investigate the question of lubrication education and research and the needs of industry (although there was no clear evidence that poor lubrication was the key to all the steel-work problems).

The lubrication working group was chaired by Jost, and he was joined by twelve others, all men: five from industry, three academics, three from the scientific branch of government service and two assessors from the Department of Education and Science—all essentially mechanical engineers. As Jost rather ruefully noted in a later publication [7]:

‘Amongst the distinguished members of the D.E.S. Working Group dealing with the subject, not one had any formal education in the constituent subject parts, including lubrication’.

This comment is perhaps a little unfair as the Working Group included Dr. Duncan Dowson from Leeds University, who, together with his colleague Dr. Gordon Higginson, had recently published their seminal paper on elasto-hydrodynamic lubrication [8].

Over the following twelve months, the Group held ten full meetings and eight evidence sessions, which involved in-depth interviews with leading individuals. Written expert opinions were obtained from forty-nine corporate bodies or practitioners. The group’s enquiries into lubrication education included an approach to 385 technical colleges and 40 universities and colleges of advanced technology. Their enquiries into current lubrication research led them to contact 33 university departments, 20 colleges of technology, 53 research associations, 21 government laboratories and more than 120 companies in the private sector.

The Working Group soon came to feel that the term ‘lubrication’ was too narrow and prevented many people from fully appreciating the economic and technological significance of their subject matter. The prefix ‘tribo-‘ was well established, as in ‘tribochemistry’, and indeed, Tabor had coined the word ‘Tribophysics’ for the laboratory that Philip Bowden had started during World War II in Melbourne. Jost visited Oxford to consult the editor of the Oxford English Dictionary, the renowned lexicographer R W Burchfield, and so Tribology it was.

The report was submitted in November 1965, so less than twelve months after Jost’s initial overtures. However, this was not to Lord Bowden, who only a few weeks before had resigned from the DES and returned to Manchester to resume his duties as Principal of the College of Technology and to complete its conversion to UMIST. Jost submitted his report to Reg Prentice, who was now one of the two Ministers of State for Education and Science; it was published in March of the following year [9].

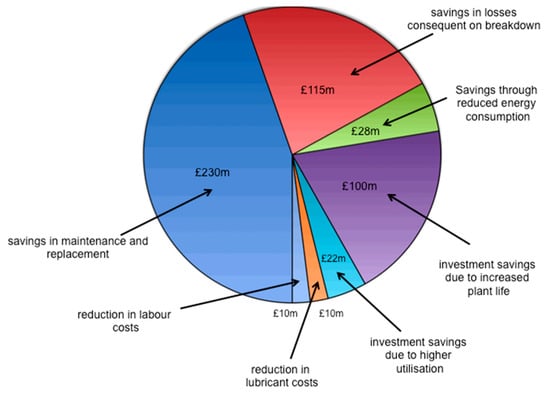

The principal finding of the Group was that “British industry suffers considerable losses resulting from inadequate appreciation of the application of Tribology…”. To give additional weight to this, an effort was made to quantify what they meant by ‘considerable’: the figure the group first came up with was in excess of GBP 800 million per annum—but this they felt was probably too large to be feasible and, on reflection, reduced the estimate to GBP 515 million. To put this into context, this represented about 1% of the UK GDP in 1965, so today the corresponding figure would be of the order of GBP 21 billion.

The potential savings were grouped under various headings, see Figure 1, and an attempt was made to produce estimates for each. Major savings were associated with reduced breakdowns and stoppages for unscheduled maintenance—these constituted about two-thirds of the total. The Working Group seems to have relied rather heavily in coming to this figure on Jost’s experience in the steel industry—perhaps at RTB—and figures he had obtained from a report on lubrication in the East German steel industry. On the basis of ‘rating the output of all UK industries to that of the iron and steel industry’ together with their interviews with expert witnesses, their estimate was that improved tribological design and practice could reduce maintenance costs by some 20%.

Figure 1.

Projected savings suggested by the Jost report amounted to some GBP 515 million per annum.

They recommended that there should be improved education and training in tribology at all levels—shop-floor, technician, undergraduate and post-graduate. The Industrial Training Boards were encouraged to include an appreciation of the importance of tribology in their training schemes, and tribology should form an integral part of engineering courses at the Higher National Certificate. A core undergraduate course in tribology should be established and post-graduate MSc courses should be made available in three or four university centres. Several National Institutes or Centres of Tribology should be set up to form and maintain a two-way bridge with industry. These centres should undertake industrial consultancy work as well as organising specialist short courses. Finally, there should be a Co-ordinating and Advisory Committee established to oversee the introduction of these recommendations.

Initially, the response of the Department of Education and Science was to delay publication to allow for ‘consideration in detail of its recommendations particularly on education and research’. As one interdepartmental memo put it [10]:

‘… what we are doing about the Report would hardly pass for vigorous activity and we are exposed to being chivvied in parliament… So far there is no pressure on us to be active—except from Mr Jost. How much pressure he could create if he tried I do not know.’

Once the report was published, as journalist Peter Stone remarked, ‘no doubt a pigeon-hole was set aside for it’. However, Jost was not going to let the matter rest there. He realised that the real centre of influence within the government now lay in the new Ministry of Technology, generally known as MinTech, with its active minister, Anthony Wedgwood-Benn, and particularly in its Permanent Secretary, Sir Richard ‘Otto’ Clarke. MinTech grew from small beginnings to become a very significant part of the government machine; in time, it absorbed the Ministry for Aviation, the Ministry of Power, the Atomic Energy Authority and all the government-supported research laboratories such as the National Physical Laboratory and the National Engineering Laboratory.

Jost realised that it was essential to get ‘Otto’ Clarke on side. He could, quite easily, have felt that he had done his duty, fulfilled his commission and turned in the report on time. But he was determined that the Jost report would not simply find its way onto some departmental shelf and have no real effect. As was later commented [11]:

“Miraculously, a transition was made and the DES Working Group was transmuted in to a Committee on Tribology at the Ministry of technology. This kind of performance will be recognized by connoisseurs of the Government committee game as qualifying for the master-class category”

The report was presented to the technical press soon after, on 20 September, and this was followed by the first meeting of the newly constituted Committee on Tribology. The press conference didn’t perhaps go as well as it might [10]:

“…[the meeting began with a] press conference which the Minister of Technology [Benn] opened with a short and clear exposition. This was followed by a long and over-technical harangue by Mr P Jost. The press received this with manifest incredulity, the general line of questioning being ‘Are our engineers so bad in both design and operation that they have been throwing away 515 million pounds a year without anyone—except Mr Jost—realising it?’”

3. The Committee on Tribology

Undeterred, Jost threw himself into the work of the new committee, which he chaired and which met on some twenty-eight occasions. Based on the Working Group, it now included Professor Freddie Barwell from Swansea (who was the chairman of the IMechE Lubrication and Wear Committee), Sir Hugh Ford from Imperial College and David Tabor from Cambridge. Within twelve months they set up three sub-committees on research, education and publicity, and had invited expressions of interest from those wishing to establish ‘Centres of Tribology’: they also established a group to explore the production of a comprehensive ‘Tribology Handbook’. To celebrate their first annual report in December 1967 Jost organised a London dinner at which the guests included both Tony Benn and Vivian Bowden. This seemed to re-energise Bowden’s interest in the subject and, no doubt encouraged by Jost, in the possibility that UMIST might bid for one of the proposed centres. On his return, Bowden wrote to the two big guns in mechanical engineering at UMIST—Professors Koenigsberger and W. (Bill) Johnson. Neither was encouraging—Johnson being particularly sceptical, responding [12]:

“I do not think we should get involved in tribology simply because it is fashionable… I recommend against pursuing tribology as you suggest. We (I) and no good university should need the Ministry of Technology to set out its sights.”

In the event, MinTech approved the proposal that there should be three centres—one each at the Universities of Leeds and Swansea and one at the Reactor Engineering Laboratory of the UK Atomic Energy Authority at Risley. The Ministry would provide pump-priming finance of between 50 and 75 thousand GBP, and each would offer a degree of specialisation—Leeds in ‘bearing design’, Swansea in ‘metallurgical industries’ and Risley in ‘hostile environments’.

The promotion of the subject undertaken by the Committee on Tribology was mainly at two levels. At that of awareness for relatively senior management, collaboration between the DES, CBI and the professional institutions led to the inclusion of a section on tribology in the ‘Technology Today’ touring exhibition, and a film ‘No More Problems’ was produced as part of a series of ‘Profit from Tribology’ road-shows held in regional centres. Aimed more at designers and technicians, a series of short courses, again supported by MinTech, reached their peak in 1968–1969, when they had been attended by nearly 950 students.

In September 1969, the IMechE and the Iron and Steel Institute held a follow-up conference to the influential 1964 meeting with the same scope, i.e., ‘Tribology in Iron and Steel Works’ [13]. The conference was introduced by Sir Monty Finniston, then Technical Director of the British Steel Corporation, and the conference dinner was addressed by both Tony Benn and Sir Richard Clarke. At the dinner, the president of the IMechE was able to announce the formation of the Tribology Trust, which would henceforth fund the annual award of the Tribology Gold and Silver medals.

The first European Tribology Congress was held in September 1973 in Salford, and it was at this meeting that the International Tribology Council was born with Dr. Jost (he had received an honorary degree from Salford in 1970) as its president—a post he was to hold for the next forty-three years. In the general election of 1970, the Conservative Party returned to office and merged the Ministry of Technology with the Board of Trade to form the Department of Trade and Industry. Notwithstanding this, the CoT carried on, becoming a technical panel of the Committee for Industrial Technologies. The other panels covered corrosion, materials handling and maintenance engineering. This last was also an area of particular interest to Jost, who again felt that its authority and influence would be enhanced by a new name. This entailed another visit to Oxford to consult Mr. Burchfield. The suggestions were even more outlandish than last time and included ‘temology’, syntrology’ and ‘phrurology’ before they settled on ‘tero-technolgy’.

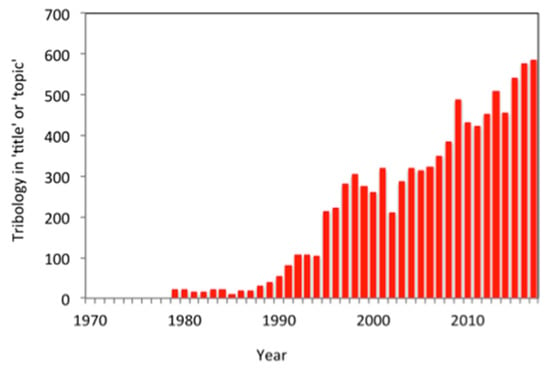

Without doubt, one of the most lasting and influential outcomes of the CoT was the publication in 1973 of the ‘Tribology Handbook’ [14], edited by Mike Neale, who, in 1958, had set up his own design and consultancy service and in 1991 served as President of the IMechE. This was the result of collaboration between more than a hundred contributors and met with almost universal praise. Although in some quarters there had been resistance to the introduction of the word ‘tribology’, thanks to Jost’s enthusiasm and commitment it soon began to be accepted. The IMechE Lubrication and Wear Committee became the Tribology Group, and groups with similar interests were formed within the Institute of Physics and the Institute of Mining and Materials. The journal ‘Wear’ had been founded in 1957 and ‘Tribology’ in 1968, this becoming ‘Tribology International’ in 1974. In 1982, the American Society of Lubrication Engineers, which had been in existence since 1944, became the Society of Tribologists and Lubrication Engineers, and in 1984, the Transactions of the American Society of Mechanical Engineers Series F, Lubrication Technology’ became the ‘Journal of Tribology’. Over the years, the number of journals published in English with ‘tribology’ in the title has grown to more than twenty, with a corresponding exponential growth at an average rate of about 8% p.a. in the number of published papers dealing with the subject—Figure 2.

Figure 2.

The growth of publications in tribology.

The Committee on Tribology continued to generate annual reports until it was formally wound up in 1974, although Jost continued to maintain his interest in government policy through his membership of the UK Parliamentary and Scientific Committee, of which he was a life member and, at some time, vice-chairman. The CoT itself became the subject of academic research when, in 1974, Ms. Cherie Knowles, a graduate in sociology at Leicester University, began work on her doctoral thesis [15], which was submitted in 1979 with the title ‘The emergence of an industrial technology—a sociological study of tribology’. Dr. Knowles, who carried out extensive questionnaire surveys of both industry and academia, was also able to interview many of the principal actors of the time and obtain some revealing insights. While all her interviewees agreed that Jost’s enthusiasm had been a key feature of the successful launch of the subject, it is hardly surprising that such an indomitable personality aroused some mixed feelings.

In 1976, Jost was able to review ten years of progress in the implementation of the recommendations of the Working Group when he addressed the Institution of Production Engineers as its president [16]. He estimated that the application of improved tribological practice was saving British industry some GBP 300 million annually for a total government expenditure of less than half a million. Five years later, he was invited to give the IMechE James Clayton lecture and chose as his topic ‘Energy saving though tribology’: this change of emphasis—energy rather than cost—was no doubt influenced by the energy crisis of the early 1970s, when the price of crude oil had risen by a factor of four. The preparation for this publication [17] was a major exercise carried out in conjunction with Dr. Jack Schofield of Liverpool Polytechnic. They considered the impact of tribology on the three major sectors that dominate energy use, viz., transport, industrial manufacture and domestic consumption, and illustrated their data with both conventional pie charts and the then less conventional Sankey diagrams. They concluded that, at 1981 levels, annual savings of up to 11 million tonnes of coal (equivalent to about 8 million tonnes of crude oil) were possible, of which a significant proportion was attributable to improvements in the efficiency of road vehicles. In terms of our concern with CO2 emissions, this converts to about 500 kg per head of the UK population.

The influence of the Jost report and the follow-up documents from the CoT, not least through Jost’s missionary work, was also felt overseas, and a number of official investigations confirmed the Working Group’s estimates. The Chinese report of 1986 [18] was particularly comprehensive and searching. The rate of return, i.e., the ratio of the savings in energy and replacement costs to that of the research and development needed to bring them about, was estimated at around 40:1. This ratio was similar to the figure of 64:1 contained within the US Government-funded reports ‘Strategy of Energy Saving for Tribology’ of 1977 and 1981 and revalidated in a 2017 document from the US Department of Energy [19].

The first World Tribology Congress was held in London in 1997, and subsequent venues have been Vienna, Washington, Kyoto, Turin, Beijing and Lyon, with the next scheduled for 2024 in Rio. Jost was able to participate, as president, in the first five of these and, in the course of numerous international visits, collected a plethora of awards and medals. He was honoured in one way or another in eighteen countries with honorary memberships of sixteen technical associations and honorary degrees from eight universities. His contribution was recognised with the award of a batch of national honours—the Gold Insignia, Order of Merit from Poland, the Officer Cross Order of Merit from Germany, the Decoration of Honour for Science and Art from Austria, the Palmes Academiques from France and the Order of the Rising Sun, Gold Rays from Japan. He was the first British honorary member of the Russian Academy of Engineering and the Chinese Mechanical Engineering Society.

In the UK, Jost was made a CBE in 1969 and became an Honorary Fellow of both the Institution of Mechanical Engineers and the Institution of Production Engineers—which merged with the Institute for Electrical Engineering in 1991, becoming the IET in 2006. In 2013, he received the Sustained Achievement Award from the Royal Academy of Engineering. He remained a member of the Tribology Group Committee of the IMechE, attending his last meeting in 2011.

4. Beyond Tribology

The Peter Jost that the tribology community is most familiar with was the vigorous promoter of the subject, but, of course, there was more to his personality than this. Jost was a successful businessman, sitting on the management boards of a number of companies. He was a name at Lloyds, a Liveryman of the Company of Engineers, and, in 1984, became a Freeman of the City of London. Peter was also generous with more than his time: in 1984, together with Margaret, his wife, he established a charity—the Michael John Trust—named in honour of his father-in-law through which to make generous financial donations. The Josts took a special interest in medical education and research, particularly deafness, and the relief of suffering from both physical and mental illness. The first and unofficial report [20], chaired by Lord Archer, into the so-called NHS ‘Factor 8’ blood scandal was largely financed by Peter and Margaret Jost. Their charity also made substantial benefactions to a number of UK institutions to establish or maintain tribology activities—these included the Universities of Bournemouth, Leeds, Sheffield and Central Lancashire.

Peter Jost passed away in June 2016, and in February of the following year, his wife, Margaret, also died. In their wills, they made generous bequests that allow the charity to continue. Today, it has been renamed the Peter Jost Charitable Foundation and Professors Pwt Evans, Hugh Spikes and I are pleased, indeed honoured, to act as trustees. The Foundation continues to provide funds for the sort of work that we feel Peter and Margaret would have wished to support: the encouragement of tribology being through both the Peter Jost Travel Fund, which is aimed at assisting young tribologists to participate in tribology meetings and conferences, and the recently introduced annual Research Studentship. Over the past five years, we have been able to make donations to support both scientific and medical work, amounting to several hundred thousand pounds.

Obituaries for Jost appeared in the major newspapers and many technical journals; he has an entry in the Oxford Dictionary of National Biography [21]. Peter made no claims to be a tribologist himself—his skill was not in solving Reynolds’ equation or investigating surface films. Rather, he was a promoter of the subject because he saw its neglect as an impediment to efficient manufacture and so a hindrance to the success of the business—particularly UK business. Nevertheless, through his tireless promotion of tribology for more than fifty years, those who do have a technical or scientific interest in the ‘interaction of loaded surfaces in relative motion’ have an enormous amount for which to give him thanks.

Funding

This research received no external funding.

Conflicts of Interest

The author declares no conflict of interest.

References

- Jost arrived in the UK on 8th April 1939 and Gave His Profession as ‘Lathe Drilling Machinist’. His Uncle Ludwig, a Doctor, Was Already Resident in the London. Available online: https://discovery.nationalarchives.gov.uk/details/r/C11122867 (accessed on 10 January 2024).

- Hill, T.J. History of the British Lubricants Industry; Merton Priory Press: Chesterfield, UK, 2018. [Google Scholar]

- Aylen, J.; Ranieri, R. Ribbon of Fire; Pendragon Press: Maesteg, UK, 2012. [Google Scholar]

- Jost, H.P. The planning and organisation of lubrication for a new integrated iron and steel works. Proc. Inst. Mech. Eng. 1964, 179, 287–310. [Google Scholar]

- Interview with Luminary Professor H. Peter Jost—The Man who Gave Birth to the Word “Tribology”. Available online: https://www.machinerylubrication.com/Read/834/tribology-jost (accessed on 10 January 2024).

- Crossman, R. Diaries of a Cabinet Minister: Ministry of Housing 1964–66; Hamish Hamilton: London, UK, 1976; p. 42. [Google Scholar]

- Jost, H.P. Some Problems in the introduction of tribology. In Proceedings of the Great Britain Gesellschaft fur Tribologie und Schmierungstechnik, Essen, Germany, 4–7 September 1990. [Google Scholar]

- Dowson, D.; Higginson, G. A Numerical Solution to the Elasto-Hydrodynamic Problem. J. Mech. Eng. Sci. 1959, 1, 6–15. [Google Scholar] [CrossRef]

- Great Britain; Department of Education and Science. Lubrication (Tribology) Education and Research: A Report on the Present Position and Industr’s Needs; HMSO: London, UK, 1966. [Google Scholar]

- Lubrication (Tribology): Reactions to Report of Working Group Chaired by Peter Jost. Available online: https://discovery.nationalarchives.gov.uk/details/r/C1330985 (accessed on 10 January 2024).

- Stone, P. Tribology: New Word for an Old Problem. British Industry Week, 16 February 1968. [Google Scholar]

- Manchester University Archives. Correspondence file: BVB 1/58 ‘Tribology’. Available online: http://archiveshub.jisc.ac.uk/manchesteruniversity/data/gb133-bvb/bvb/1/58 (accessed on 10 January 2024).

- Institution of Mechanical Engineers. Tribology in Iron and Steel Works: Proceedings of the Conference on ‘Tribology in Iron and Steel Works’, (ISI Publication 125); Iron and Steel Institute: Washington, DC, USA, 1970. [Google Scholar]

- Neale, M. Tribology Handbook; Butterworth-Heinemann: London, UK, 1973. [Google Scholar]

- Knowles, C.M. The Emergence of an Industrial Technology: A Sociological Study of Tribology. Ph.D. Thesis, University of Leicester, Leicester, UK, 1979. [Google Scholar]

- Jost, H.P. Ten Years of Tribology: The Story of the Birth and Growth of a Vital Science in Just One Decade. Ind. Lubr. Tribol. 1976, 28, 98–100. [Google Scholar] [CrossRef]

- Jost, H.P.; Schofield, J. Energy saving through tribology: A techno-economic study. Proc. Inst. Mech. Eng. 1981, 195, 151–172. [Google Scholar] [CrossRef]

- An Investigation of the Application of Tribology in China’ Report; Tribology Institution of the Chinese Mechanical Engineering Society: Beijing, China, 1986.

- Tribology Opportunities for Enhancing America’s Energy Efficiency. Advanced Research Projects Agency-US Department of Energy. Available online: https://www.stle.org/images/PDF/STLE_ORG/whitepaper/Opportunities_for_Enhancing_Energy.pdf (accessed on 10 January 2024).

- Independent Public Inquiry Report on NHS Supplied Contaminated Blood and Blood Products. Available online: https://www.infectedbloodinquiry.org.uk/evidence/arch0000001-independent-public-inquiry-report-nhs-supplied-contaminated-blood-and-blood (accessed on 10 January 2024).

- Oxford Dictionary of National Biography. Available online: https://www.oxforddnb.com/display/10.1093/odnb/9780198614128.001.0001/odnb-9780198614128-e-111499 (accessed on 10 January 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).