Tribological Properties of h-BN, Ag and MgO Nanostructures as Lubricant Additives in Vegetable Oils

Abstract

1. Introduction

2. Experimental

2.1. Materials

| Raw Lubricant | Viscosity @ 50 °C [mPa·s] | Density @ 20 °C [kg/m3] | Thermal Conductivity @ 50 °C [W/m K] |

|---|---|---|---|

| Sunflower | 28.50 | 917.8 | 0.163 |

| Soybean | 23.59 | 910.6 | 0.155 |

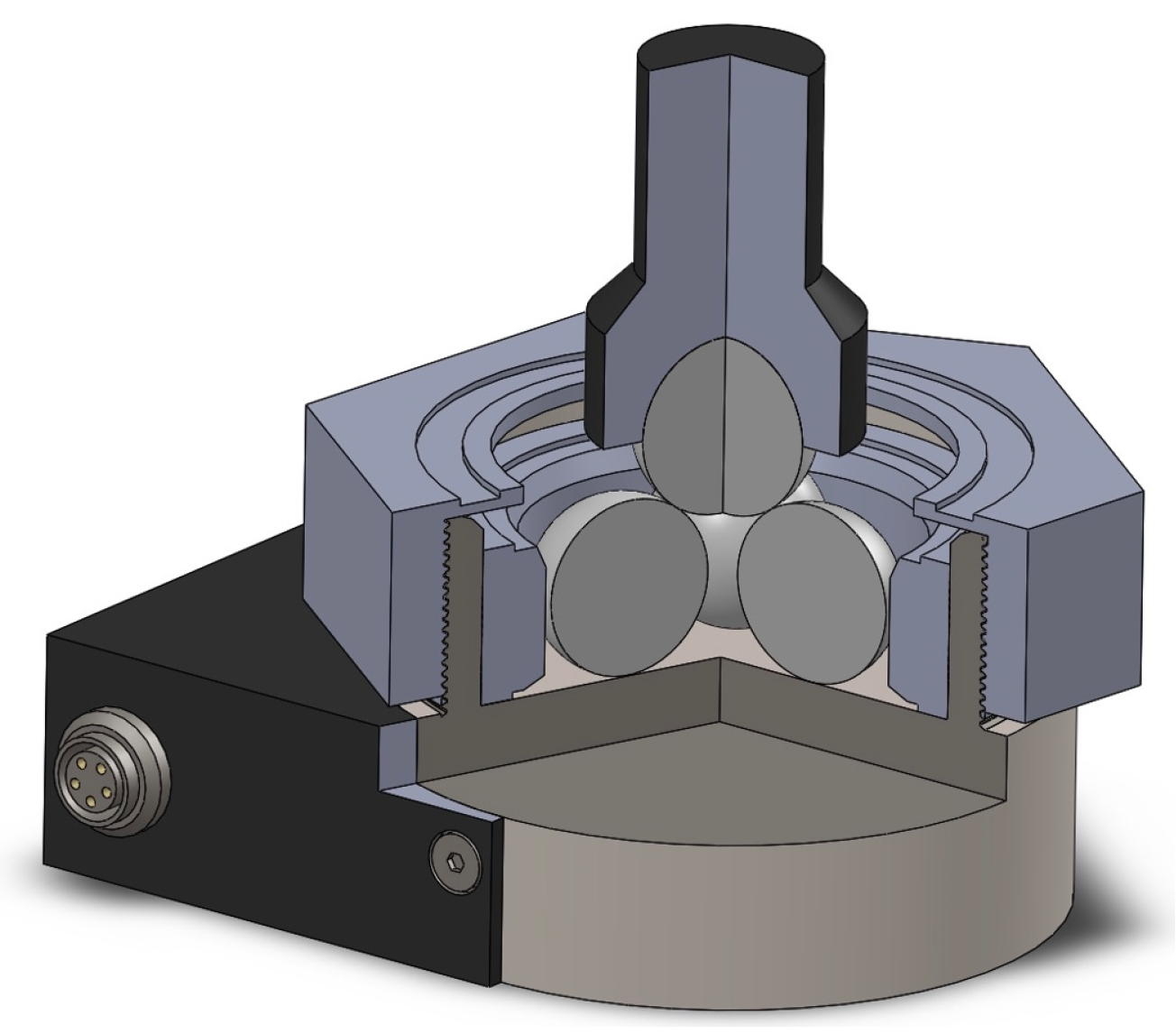

2.2. Tribological Testing—Four-Ball Configuration

2.3. Thermophysical and Fluid Property Evaluation

2.3.1. Thermal Conductivity

2.3.2. Viscosity

2.4. Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Spectroscopy (EDS)

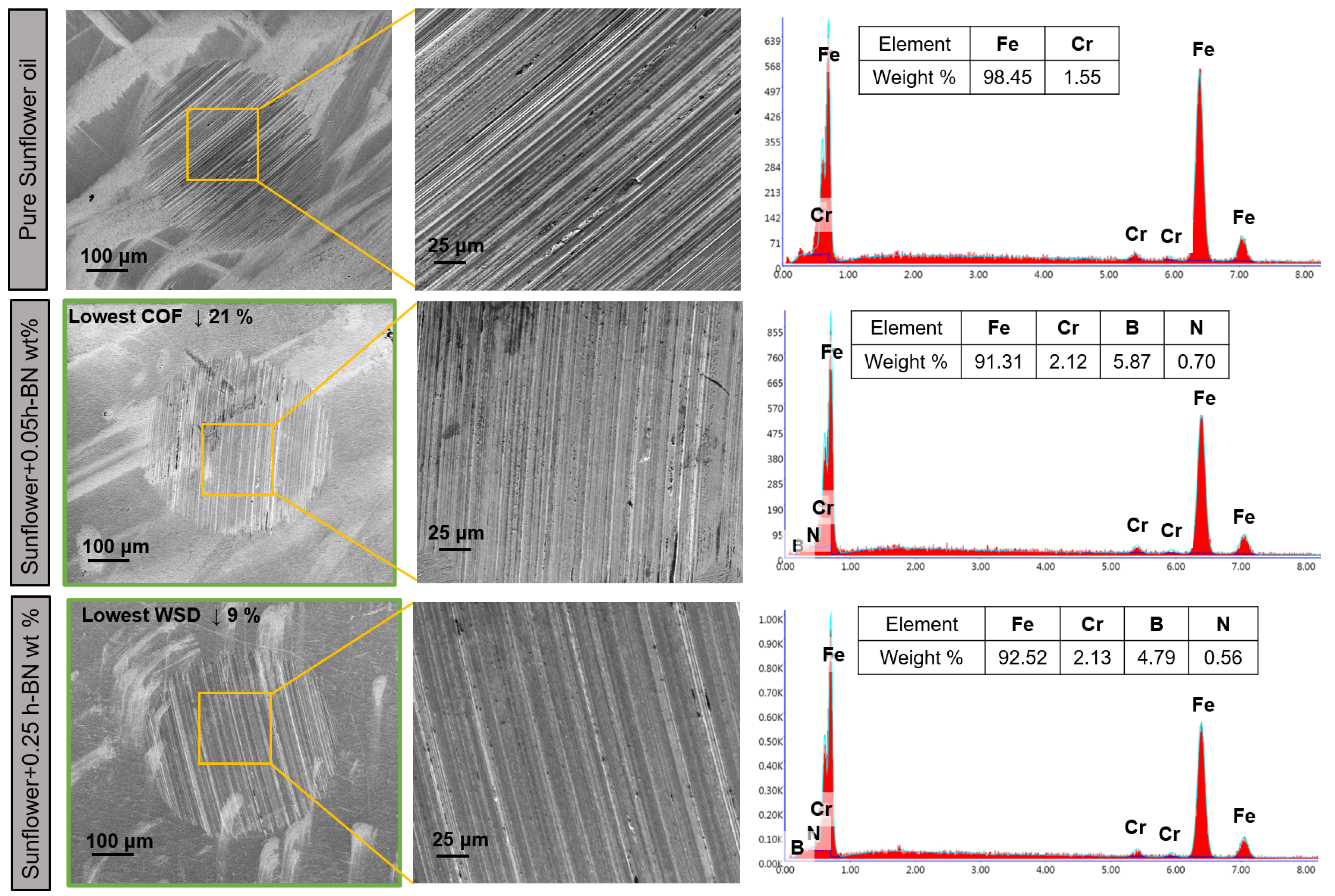

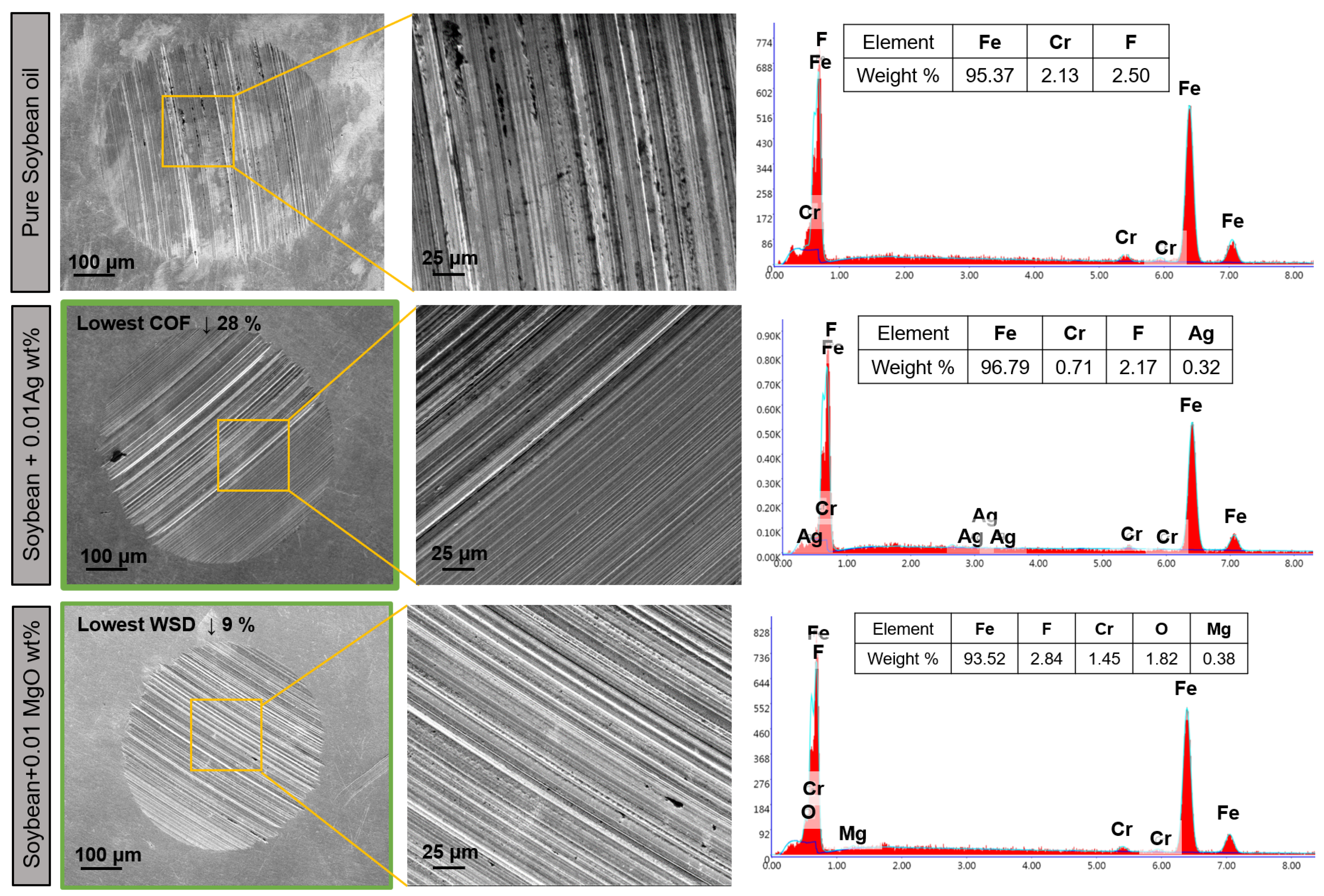

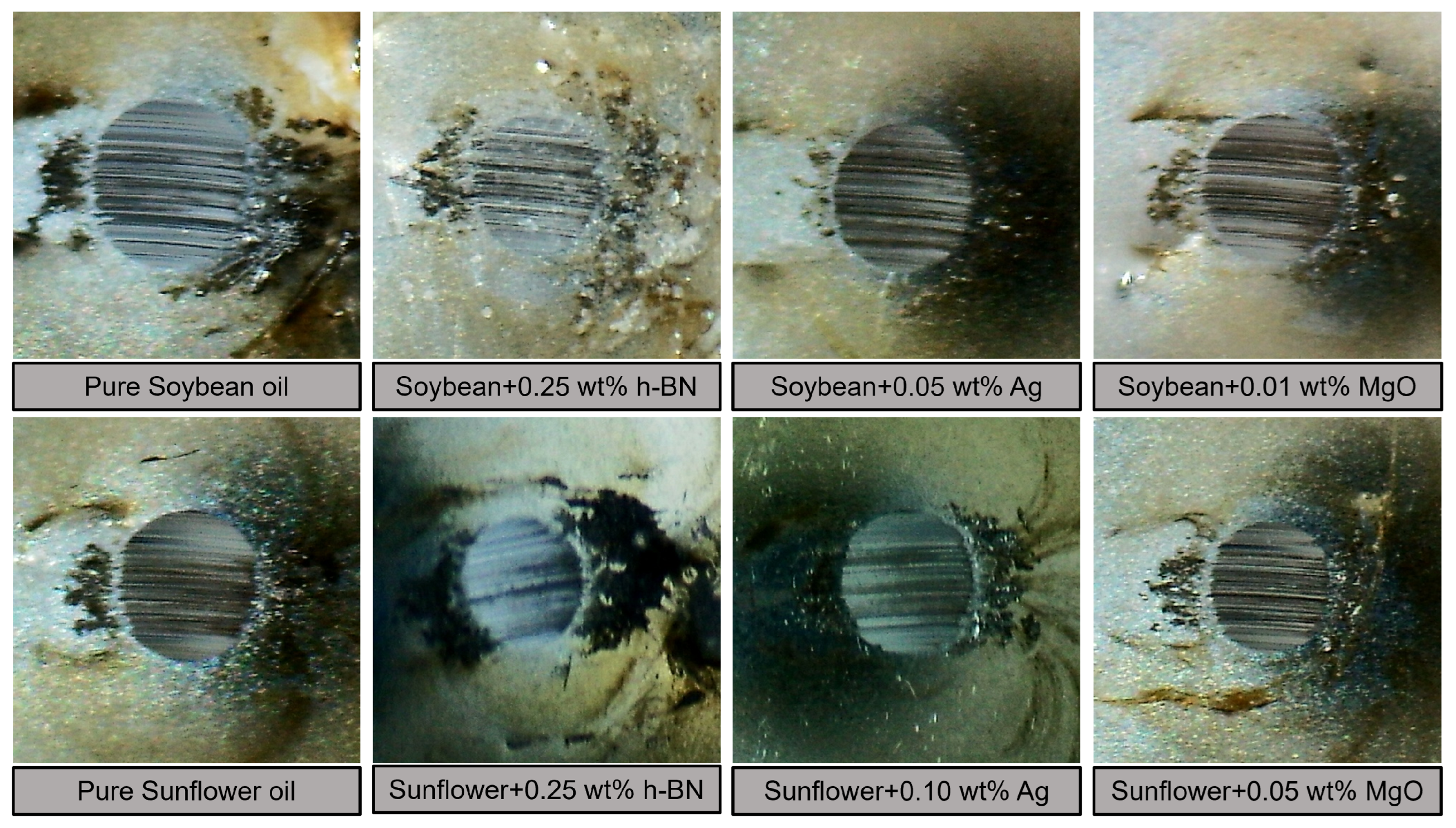

3. Results and Discussion

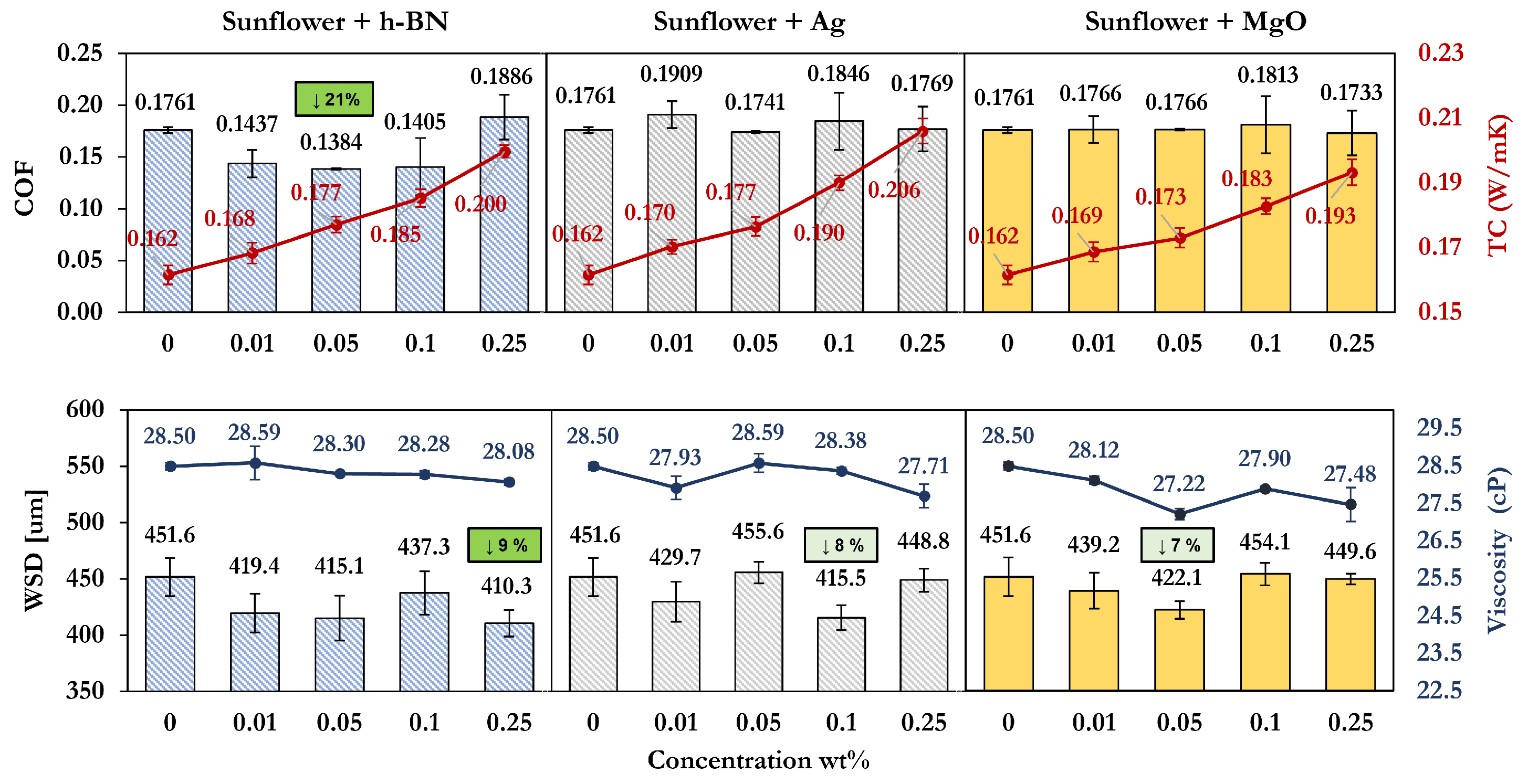

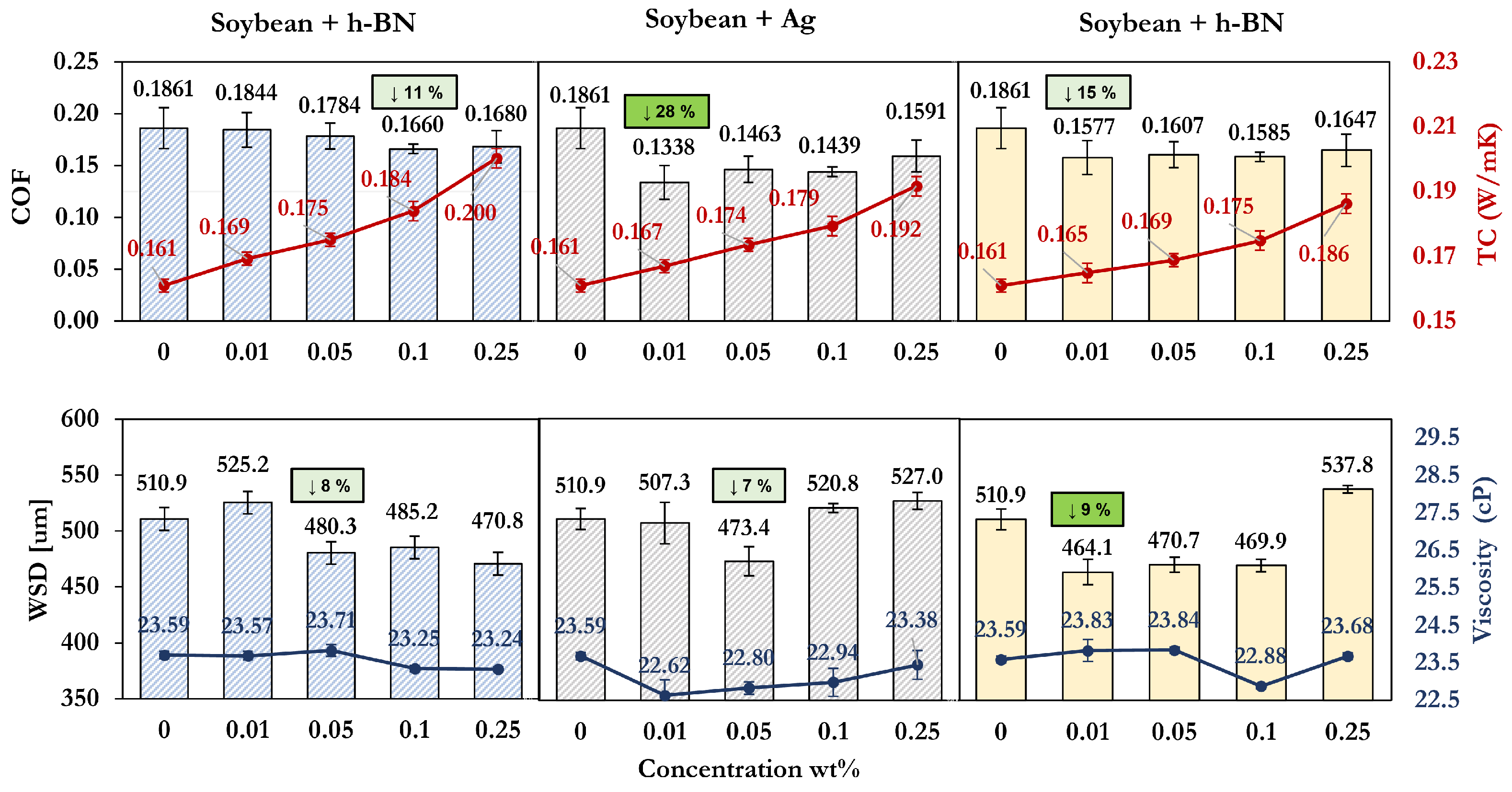

3.1. Tribological Tests

3.2. Nanostructures Size

3.3. Thermophysical Properties

3.4. Lubrication Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Willing, A. Lubricants based on renewable resources—An environmentally compatible alternative to mineral oil products. Chemosphere 2001, 43, 89–98. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Encinar, J.M.; González, J.F. A Review on Biolubricants Based on Vegetable Oils through Transesterification and the Role of Catalysts: Current Status and Future Trends. Catalysts 2023, 13, 1299. [Google Scholar] [CrossRef]

- Hamnas, A.; Unnikrishnan, G. Bio-lubricants from vegetable oils: Characterization, modifications, applications and challenges—Review. Renew. Sustain. Energy Rev. 2023, 182, 113413. [Google Scholar] [CrossRef]

- Shafi, W.K.; Raina, A.; Ul Haq, M.I. Friction and wear characteristics of vegetable oils using nanoparticles for sustainable lubrication. Tribol.-Mater. Surf. Interfaces 2018, 12, 27–43. [Google Scholar] [CrossRef]

- Murru, C.; Badía-Laíño, R.; Díaz-García, M.E. Oxidative stability of vegetal oil-based lubricants. ACS Sustain. Chem. Eng. 2021, 9, 1459–1476. [Google Scholar] [CrossRef]

- Boyde, S. Green lubricants. Environmental benefits and impacts of lubrication. Green Chem. 2002, 4, 293–307. [Google Scholar] [CrossRef]

- Panchal, T.M.; Patel, A.; Chauhan, D.; Thomas, M.; Patel, J.V. A methodological review on bio-lubricants from vegetable oil based resources. Renew. Sustain. Energy Rev. 2017, 70, 65–70. [Google Scholar] [CrossRef]

- Choi, U.; Ahn, B.; Kwon, O.; Chun, Y. Tribological behavior of some antiwear additives in vegetable oils. Tribol. Int. 1997, 30, 677–683. [Google Scholar] [CrossRef]

- Karmakar, G.; Ghosh, P.; Sharma, B.K. Chemically modifying vegetable oils to prepare green lubricants. Lubricants 2017, 5, 44. [Google Scholar] [CrossRef]

- Erhan, S.Z.; Asadauskas, S. Lubricant basestocks from vegetable oils. Ind. Crop. Prod. 2000, 11, 277–282. [Google Scholar] [CrossRef]

- Menezes, P.L.; Lovell, M.R.; Kabir, M.; Higgs, C.F.; Rohatgi, P.K. Green lubricants: Role of additive size. In Green Tribology: Biomimetics, Energy Conservation and Sustainability; Springer: Berlin/Heidelberg, Germany, 2012; pp. 265–286. [Google Scholar]

- Fox, N.; Stachowiak, G. Vegetable oil-based lubricants—A review of oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Progress of nanofluid application in machining: A review. Mater. Manuf. Process. 2015, 30, 813–828. [Google Scholar] [CrossRef]

- Ben Said, L.; Kolsi, L.; Ghachem, K.; Almeshaal, M.; Maatki, C. Application of nanofluids as cutting fluids in machining operations: A brief review. Appl. Nanosci. 2023, 13, 4247–4278. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Deiab, I.; Eltaggaz, A. Sustainability assessment during machining Ti-6Al-4V with nano-additives-based minimum quantity lubrication. J. Manuf. Mater. Process. 2019, 3, 61. [Google Scholar] [CrossRef]

- Kadirgama, K. A comprehensive review on the application of nanofluids in the machining process. Int. J. Adv. Manuf. Technol. 2021, 115, 2669–2681. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.; Kalam, M.; Varman, M.; Zulkifli, N.; Mufti, R.; Zahid, R. Tribological performance of nanoparticles as lubricating oil additives. J. Nanopart. Res. 2016, 18, 1–25. [Google Scholar] [CrossRef]

- Hu, Z.; Dong, J.; Chen, G.; He, J. Preparation and tribological properties of nanoparticle lanthanum borate. Wear 2000, 243, 43–47. [Google Scholar] [CrossRef]

- Demas, N.G.; Timofeeva, E.V.; Routbort, J.L.; Fenske, G.R. Tribological effects of BN and MoS 2 nanoparticles added to polyalphaolefin oil in piston skirt/cylinder liner tests. Tribol. Lett. 2012, 47, 91–102. [Google Scholar] [CrossRef]

- Ghaednia, H. An Analytical and Experimental Investigation of Nanoparticle Lubricants. Ph.D. Thesis, Auburn University, Auburn, AL, USA, 2014. [Google Scholar]

- Kumar, R.; Gautam, R. Tribological investigation of sunflower and soybean oil with metal oxide nanoadditives. Biomass Convers. Biorefinery 2024, 14, 2389–2401. [Google Scholar] [CrossRef]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 2013, 65, 28–36. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Narayanan, T.N.; Gao, G.; Rohde, M.; Tsentalovich, D.A.; Pasquali, M.; Ajayan, P.M. Electrically insulating thermal nano-oils using 2D fillers. ACS Nano 2012, 6, 1214–1220. [Google Scholar] [CrossRef]

- Rojas, E.E.G.; Coimbra, J.S.; Telis-Romero, J. Thermophysical properties of cotton, canola, sunflower and soybean oils as a function of temperature. Int. J. Food Prop. 2013, 16, 1620–1629. [Google Scholar] [CrossRef]

- Advincula, P.A.; Granja, V.; Wyss, K.M.; Algozeeb, W.A.; Chen, W.; Beckham, J.L.; Luong, D.X.; Higgs, C.F., III; Tour, J.M. Waste plastic-and coke-derived flash graphene as lubricant additives. Carbon 2023, 203, 876–885. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, M.; Zhu, H.; Tian, Y.; Wang, K.; Wei, J.; Ji, F.; Li, X.; Li, Z.; Zhang, P.; et al. Tribological properties of oleic acid-modified graphene as lubricant oil additives. J. Phys. D Appl. Phys. 2011, 44, 205303. [Google Scholar] [CrossRef]

- Lovell, M.R.; Kabir, M.; Menezes, P.L.; Higgs, C.F., III. Influence of boric acid additive size on green lubricant performance. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4851–4868. [Google Scholar] [CrossRef]

- Ilie, F.; Tita, C. Tribological properties of solid lubricant nanocomposite coatings on base of tungsten disulphide nanoparticles. Tribol.-Finn. J. Tribol. 2008, 27, 5–11. [Google Scholar]

- Hu, X.; Hu, S.; Zhao, Y. Synthesis of nanometric molybdenum disulphide particles and evaluation of friction and wear properties. Lubr. Sci. 2005, 17, 295–308. [Google Scholar] [CrossRef]

- Hu, X. On the size effect of molybdenum disulfide particles on tribological performance. Ind. Lubr. Tribol. 2005, 57, 255–259. [Google Scholar] [CrossRef]

- Cizaire, L.; Vacher, B.; Le Mogne, T.; Martin, J.; Rapoport, L.; Margolin, A.; Tenne, R. Mechanisms of ultra-low friction by hollow inorganic fullerene-like MoS2 nanoparticles. Surf. Coat. Technol. 2002, 160, 282–287. [Google Scholar] [CrossRef]

- Leshchinsky, V.; Popovitz-Biro, R.; Gartsman, K.; Rosentsveig, R.; Rosenberg, Y.; Tenne, R.; Rapoport, L. Behavior of solid lubricant nanoparticles under compression. J. Mater. Sci. 2004, 39, 4119–4129. [Google Scholar] [CrossRef]

- Rapoport, L.; Leshchinsky, V.; Lvovsky, M.; Lapsker, I.; Volovik, Y.; Feldman, Y.; Popovitz-Biro, R.; Tenne, R. Superior tribological properties of powder materials with solid lubricant nanoparticles. Wear 2003, 255, 794–800. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Hu, K.H.; Han, C.L.; Hu, X.G.; Xu, Y.F. Morphological influence of molybdenum disulfide on the tribological properties of rapeseed oil. Tribol. Lett. 2013, 49, 513–524. [Google Scholar] [CrossRef]

- Saidur, R.; Leong, K.; Mohammed, H.A. A review on applications and challenges of nanofluids. Renew. Sustain. Energy Rev. 2011, 15, 1646–1668. [Google Scholar] [CrossRef]

- Liu, M.S.; Lin, M.C.C.; Huang, I.T.; Wang, C.C. Enhancement of thermal conductivity with carbon nanotube for nanofluids. Int. Commun. Heat Mass Transf. 2005, 32, 1202–1210. [Google Scholar] [CrossRef]

- Ismail, M.F.; Azmi, W.H.; Mamat, R.; Ali, H.M. Thermal and tribological properties enhancement of PVE lubricant modified with SiO2 and TiO2 nanoparticles additive. Nanomaterials 2022, 13, 42. [Google Scholar] [CrossRef]

- Ahmed Abdalglil Mustafa, W.; Dassenoy, F.; Sarno, M.; Senatore, A. A review on potentials and challenges of nanolubricants as promising lubricants for electric vehicles. Lubr. Sci. 2022, 34, 1–29. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, G.; Zhang, C.; Zhang, Y.; Zhang, S.; Zhang, P. Synthesis of water-soluble Cu nanoparticles and evaluation of their tribological properties and thermal conductivity as a water-based additive. Friction 2019, 7, 246–259. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Aviña, K.; Martínez, J.M.; Arquieta-Guillén, P.Y.; González-Escobedo, M. Carbon Nanotori Structures for Thermal Transport Applications on Lubricants. Nanomaterials 2021, 11, 1158. [Google Scholar] [CrossRef]

- Hwang, Y.; Park, H.; Lee, J.; Jung, W. Thermal conductivity and lubrication characteristics of nanofluids. Curr. Appl. Phys. 2006, 6, e67–e71. [Google Scholar] [CrossRef]

- Ji, J.; Lu, W.; Si, C.; Zhang, S.; Yao, X.; Wang, W.; Chu, D. Overview on the preparation and heat transfer enhancement of nanofluids. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Porgar, S.; Vafajoo, L.; Nikkam, N.; Vakili-Nezhaad, G. A comprehensive investigation in determination of nanofluids thermophysical properties. J. Indian Chem. Soc. 2021, 98, 100037. [Google Scholar] [CrossRef]

- Porgar, S.; Vafajoo, L. Experimental investigation on viscosity and density of MWCNT-Transformer oil nanofluid: Developed a new correlation. J. Chem. Lett. 2021, 2, 133–143. [Google Scholar]

- McGrory, S. Lubrication. In Plant Engineer’s Handbook; Elsevier: Amsterdam, The Netherlands, 2001; pp. 915–960. [Google Scholar]

- Abdollah, M.F.B.; Amiruddin, H.; Azmi, M.A.; Tahir, N.A.M. Lubrication mechanisms of hexagonal boron nitride nano-additives water-based lubricant for steel–steel contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1038–1046. [Google Scholar] [CrossRef]

- Basiron, J.; Abdollah, M.F.B.; Abdullah, M.I.C.; Amiruddin, H. Lubricant mechanisms of eco-friendly lubricant blended with mineral oil for steel-steel contact. Tribol. Int. 2023, 186, 108653. [Google Scholar] [CrossRef]

- Williams, J.A. Engineering Tribology; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Zhao, J.; Yang, G.; Zhang, Y.; Zhang, S.; Zhang, C.; Gao, C.; Zhang, P. Controllable synthesis of different morphologies of CuO nanostructures for tribological evaluation as water-based lubricant additives. Friction 2021, 9, 963–977. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, C.; Hwang, Y.; Park, M.; Lee, J.; Choi, C.; Jung, M. Tribological behavior of copper nanoparticles as additives in oil. Curr. Appl. Phys. 2009, 9, e124–e127. [Google Scholar] [CrossRef]

- Xie, H.; Jiang, B.; He, J.; Xia, X.; Pan, F. Lubrication performance of MoS2 and SiO2 nanoparticles as lubricant additives in magnesium alloy-steel contacts. Tribol. Int. 2016, 93, 63–70. [Google Scholar] [CrossRef]

- Nehme, G.; Mourhatch, R.; Aswath, P.B. Effect of contact load and lubricant volume on the properties of tribofilms formed under boundary lubrication in a fully formulated oil under extreme load conditions. Wear 2010, 268, 1129–1147. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, K.; Lin, H.; Zhang, F.; Xiong, B.; Zhang, H.; Zhang, C. Important contributions of multidimensional nanoadditives on the tribofilms: From formation mechanism to tribological behaviors. Compos. Part B Eng. 2022, 234, 109732. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Liu, W.; Wang, R.; Wen, J.; Sheng, H.; Peng, J.; Erdemir, A.; Luo, J. Tribological Behavior of NiAl-Layered Double Hydroxide Nanoplatelets as Oil-Based Lubricant Additives. ACS Appl. Mater. Interfaces 2017, 9, 30891–30899. [Google Scholar] [CrossRef] [PubMed]

| Nanostructures | CAS | Size [nm] | Hardness [MPa] | Density [kg/m3] | Thermal Conductivity [W/m K] |

|---|---|---|---|---|---|

| h-BN | 10043-11-5 | 300 by 400 | 660–3000 | 2100 | 220–420 |

| Ag | 7440-22-4 | <100 | 250–1100 | 10,490 | 430 |

| MgO | 1309-48-4 | <50 | 5000–7000 | 3600 | 30–60 |

| Parameter | Equation | Sunflower Oil | Soybean Oil |

|---|---|---|---|

| Reduced radius, R′ [m] | 0.00159 | 0.00159 | |

| Reduced Youngs’ modulus, E′ [Pa] | ) | 2.31 × 1011 | 2.31 × 1011 |

| Contact load (per ball), F [N] | 60.012505 | 60.012505 | |

| Viscosity, [mPa·s] | measured exp | 27.22–28.59 | 22.62–23.84 |

| Elliptical parameter, k | 1.03 | 1.03 | |

| Asymptotic isoviscous pressure, [Pa] | 1.09 × 108 | 1.14 × 108 | |

| Pressure viscosity coefficient, [GPa−1] | 9.2 | 8.8 | |

| Dimensionless speed parameter, U | 3.06 × 10 | 2.54 × 10 | |

| Dimensionless material parameter, G | 2123.08 | 2123.08 | |

| Dimensionless load parameter, W | 1.03 × 10 | 1.03 × 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Granja, V.; Jogesh, K.; Taha-Tijerina, J.; Higgs, C.F., III. Tribological Properties of h-BN, Ag and MgO Nanostructures as Lubricant Additives in Vegetable Oils. Lubricants 2024, 12, 66. https://doi.org/10.3390/lubricants12030066

Granja V, Jogesh K, Taha-Tijerina J, Higgs CF III. Tribological Properties of h-BN, Ag and MgO Nanostructures as Lubricant Additives in Vegetable Oils. Lubricants. 2024; 12(3):66. https://doi.org/10.3390/lubricants12030066

Chicago/Turabian StyleGranja, Victoria, Kollol Jogesh, Jaime Taha-Tijerina, and C. Fred Higgs, III. 2024. "Tribological Properties of h-BN, Ag and MgO Nanostructures as Lubricant Additives in Vegetable Oils" Lubricants 12, no. 3: 66. https://doi.org/10.3390/lubricants12030066

APA StyleGranja, V., Jogesh, K., Taha-Tijerina, J., & Higgs, C. F., III. (2024). Tribological Properties of h-BN, Ag and MgO Nanostructures as Lubricant Additives in Vegetable Oils. Lubricants, 12(3), 66. https://doi.org/10.3390/lubricants12030066