Abstract

Heat-treatment furnaces for workpiece pre-rolling heating are heating plants of the transition type where sheet slabs with various characteristics are simultaneously heated. The heat treatment furnace performance is directly connected with the efficient operation of the rolling mill process plants. The irregular operation pace of the rolling mill complicates the implementation of energy-saving workpiece pre-rolling heating modes and increases the risk of delivering an insufficiently heated workpiece. This paper proposes the system of controlling the heat mode of the heat-treatment furnace by the criterion of fuel consumption rate minimization and controlling over a real heated state of a sheet slab located at the workpiece pushing from the heat-treatment furnace to the rolling mill. The author uses a simplified mathematical model of workpiece heating intended for defining the energy-saving heating path accounting for the impact of technological and structural constraints in the workpiece heating process. The calculation is conducted in real time and allows obtaining an optimal heating path of each workpiece at the moment of its loading into the heat-treatment furnace. The paper considers the necessity of interaction and the interaction itself of the subsystems performing the key function in the energy-saving operation mode of the heat-treatment furnace at workpiece heating. The author studied the subsystems of forecasting the workpiece heating time on the state of the rolling mill equipment and the geometrical dimensions of the rolled band, control over gaseous fuel burning in the heat-treatment furnace operation space, system of control over the workpiece heating state before pushing from the heat-treatment furnace and forecasting the roll temperature after the treatment of the rolling mill roughing train.

1. Introduction

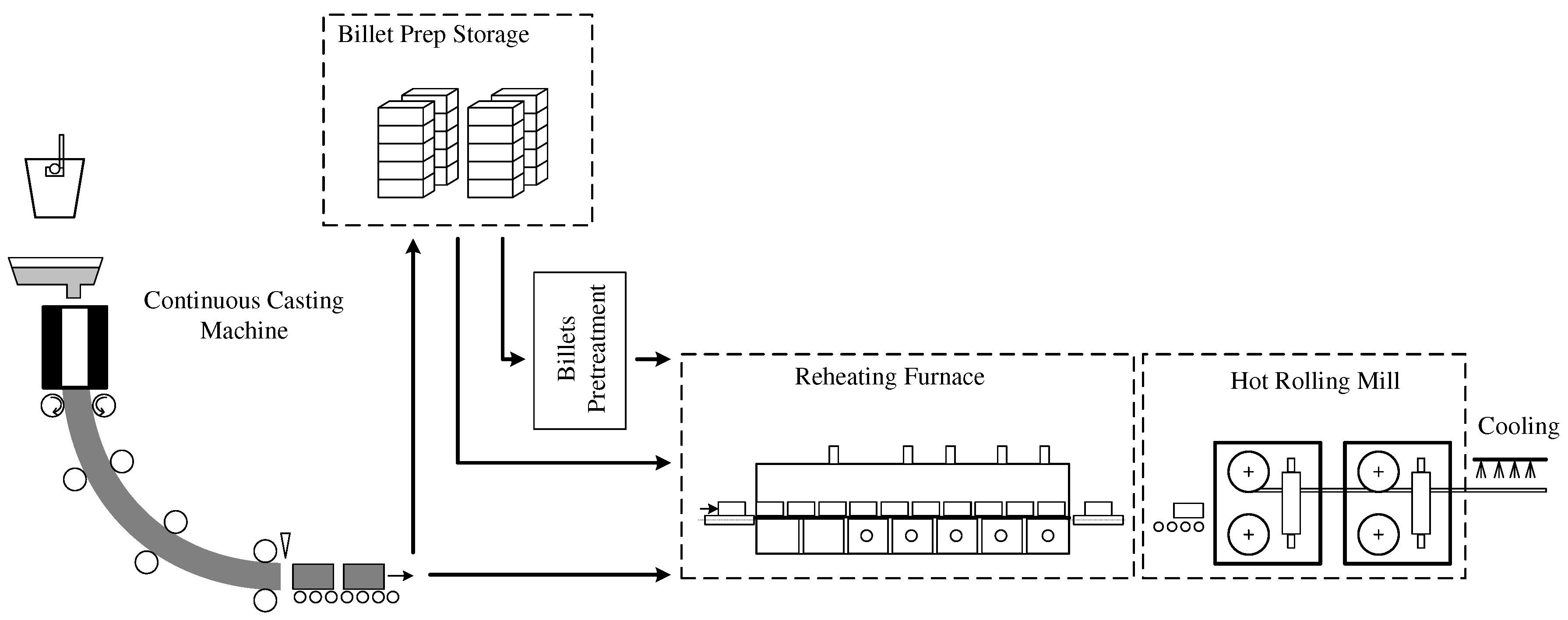

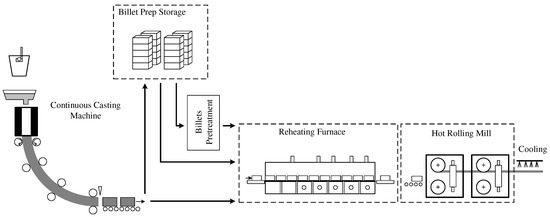

Pre-rolling heating of metal in heat-treatment furnaces is one of the most energy-intensive processes of making flat-rolled steel. The bulk of such products is made of slab blanks produced by continuous casting machines (CCM). Figure 1 presents the production diagram.

Figure 1.

Flat rolling line.

CCM-cast blanks go to the warehouse. Some of them, if possible, go to the heat-treatment furnace to equalize the temperatures within the cross-section and to heat them to the level required for rolling. Storage is necessary to bring the CCM production rates in line with those of the rolling mill.

What complicates heating the blanks is the fact that a single furnace may simultaneously treat blanks of different initial thermal condition, different geometry, and different steel grades. Besides, the furnace performance is tied to that of the rolling mill. Heat-treatment furnaces are naturally continuously-running units that feature significant thermal inertia. A rolling mill is a discrete unit that rolls blanks one by one. Past a certain number of blanks, the mill needs to be stopped for maintenance. While under maintenance, it cannot roll, but the furnace is running. All of this complicates controlling the thermal condition of the furnace and optimizing the energy use of the pre-rolling heat treatment process.

The industry-average fuel consumption of the conventional metal heating process is 1.6 GJ/t [1], or 18% of the total specific energy costs of rolling steel. The figure could be lowered by altering the rolling technology, improving the furnace design, and optimizing the production planning [2,3,4] or the heat-treatment furnace parameters [5].

A heat-treatment furnace is a thermal unit that transports blanks from the loading tray through its chamber to the unloading tray, from where the blanks go to the receiving roller table of the mill. The chamber burns fuel fed through rows of burners installed in the furnace vault and lateral walls under the passageway for blanks. Such placement of burners helps independently regulate the heating levels at different points in the furnace to adjust the furnace performance to that of the rolling mill. In turn, controlling the temperature distribution in the furnace helps attain the required heating curves to bring them in line with the chosen heating technology and the rolling stand production rates. The curves must minimize the energy costs of heating.

There are numerous papers on the problem. Thus, Tang [6] presented a slab heating trajectory algorithm based on penalty functions, concluding that the furnace loads must be calculated in advance to reduce the energy costs of heating. Banadaki [7] presented a neuro-fuzzy predictive heating model that calculates the required furnace zone-specific thermal loads.

The authors of [8,9,10,11] proposed mathematical loads to predict the thermal condition and optimize the operation of the heating furnace. The models vary in complexity as well as in the representation of the heat transfer processes. Wang [12] proposed a dynamic adaptive fuzzy reasoning Petri net for machine state inferences to save energy considering the real-time production information.

The authors of [4,13,14,15,16,17] considered various approaches to dynamic optimization that can generate the blank heating trajectories to the specified criteria. Possible optimization criteria include fuel efficiency and heating quality. Some approaches use simplified mathematical models to generate blank-specific heating trajectories in real time.

When controlling a heating furnace, the main problem is choosing a blank heating trajectory that will minimize the total energy costs of heating the slab to a level required for further rolling.

What complicates the problem is that a furnace may simultaneously process blanks of varying initial thermal condition as well as of different steel grades. Rolling mills tend to have uneven, difficult-to-predict production rates, a fact that cannot be ignored. An additional thermal test of a blank before it exits the furnace helps prevent rolling mill accidents and stops by preventing insufficiently hot blanks from leaving the furnace.

In the mentioned papers, the operation of one particular control system is usually discussed with the stable operation of a rolling mill and without taking into account the operation of other subsystems for controlling parameters of a heating furnace or a current state of the rolling process. In this paper, the general structure of the optimal control system for heating billets before rolling is given. The presented control system shows the relationship of individual subsystems, each of which performs a strictly defined function. The joint work of these subsystems and their information interaction allows them to have common access to information about the technological process state. This allows creating optimal heating modes, taking into account all aspects that arise during the heating process.

2. Statement of Problem

The problem of optimizing the metal heating parameters is down to finding and implementing a heating trajectory at which the functional of heating costs or quality are minimum. Below are the principles of optimal heating control:

- Minimize fuel costs by intensifying the blank heating at the end of the allocated time slot: Intensifying the heating closer to the end of the furnace before the blank exits is fundamental to energy-saving heating strategy; as such, this tactic is used regardless of the furnace performance or the product range. Shifting the thermal loads to the soaking zone and intensifying the heating process closer to the end of it helps minimize the specific fuel costs but increases the risk of underheating [16].

- Optimizing the fuel combustion process in the furnace chamber helps consume the fuel more efficiently, improves the heat transfer between the flare, the metal, and the masonry while also maintaining a specific gas composition inside the furnace. The results of heating depend not only on the general fuel costs of heating and heat distribution along the furnace, but also on the air flow, which is an important secondary parameter of the energy-intensive fuel combustion process [18].

- Providing more complete and relevant heating data enables the energy-saving control system to optimize its control actions targeted at the effectors.

Analysis of the pass-through furnaces on an existing enterprise has identified the technological specifics of the pre-rolling heating process [19]:

- Compliance with the heating restrictions includes furnace lining and blank surface temperature constraints as well as constraints on the temperature variance within the cross-section of the heated blank to prevent the thermal stress from exceeding the ultimate stress of the blank material.

- The furnace performance should be aligned with that of the rolling mill considering stops and emergency downtimes.

Research has identified the need for a complex optimized control system for heating continuous castings in pass-through furnaces.

3. Materials and Methods

Optimizing the metal heating in pass-through furnaces while minimizing the fuel consumption requires solving a variational problem. It is necessary to generate such control action that will change the thermal condition of the blank from its initial state to the required end state within given time while minimizing the functional of energy costs.

3.1. Theoretical Method for Optimal Control

The most appropriate functional is as follows:

where T is the configured heating time, s. is a value proportional to the fuel costs of heating-control temperature, C.

The value of is proportional to fuel consumption and, in a first approximation, can be represented as

where is the fuel consumption in the heating furnace, m/h. is the proportionality factor, hC/m.

The value of is the value of the control action proportional to fuel consumption. Since the fuel consumption in a heating furnace has limits of change, the value of also varies from to . The value of kp is determined experimentally for a heating furnace. The method for determining is beyond the scope of this paper. Thus, Equation (1) is an integral criterion expressing the amount of fuel spent on heating.

The system input is the control proportional to the gas consumption; the output is the heating medium temperature approximated by the first-order inertial link with the time constant . The differential equation that links the heating-medium temperature to the control action is as follows:

where is the temperature of the heating medium, C.

The mathematical description of the heating process of the billet in a heating furnace is represented as a one-dimensional heat equation:

where is the temperature field; is the time, s; x is the spatial coordinate, m; T is the specified time of the heating process, s; is the heat capacity per unit volume, J/(mK); is the factor of thermal conductivity, W/(m·K); and S is the assumed thickness of the workpiece, m.

Use the first variation of the functional for systems with distributed parameters and apply L.S. Pontryagin’s maximum method [20,21,22] to write the necessary optimal condition for the stated problem as the functional:

where , , , and are conjugate variables found by partial differentiation of the functional in Equation (4) with respect to the variables, to which the conjugates are calculated.

From the optimality condition in Equation (4), derive the optimal control expression:

Integrating numerically the equation system derived from Equation (4) by differentiating by conjugate variables means that finding a partial solution requires computing the functions of conjugate variables at zero time, i.e., and .

The method for finding conjugate variables proceeds as follows.

1. Introduce an objective function to calculate the deviation of the computed end state of the system from the specified end state:

where is the required distribution of temperatures within the blank cross-section, C. is the actual distribution of temperatures at the end of the heating time T, C.

2. Reduce the problem by finding the initial values of the functions of conjugates and to a search problem, with reference to Equation (8). Find such and that the criterion J is minimum.

3. Find the minimum of the function in Equation (8) by directly searching for the minimum of the function for multiple variables.

To calculate the actual blank temperature as it gets heated in the furnace given a pre-configured zonal temperature distribution, use the mathematical model based on a unidimensional thermal conductivity equation taking into account how the thermophysical properties of the material could be affected by the temperature [23,24,25]. A fairly simple mathematical description enables the user to calculate the heating trajectory for each blank in real time.

3.2. Constraint Satisfaction

The heating process is subject to the process and design constraints of the heating unit. In that case, practical implementation of these calculations becomes difficult, as it is necessary to consider the actual design and process constraints that may exist on the site.

In that case, practical implementation of these calculations becomes difficult, as it is necessary to consider the actual design and process constraints that may exist on the site.

To solve the variational problem with constraints, such control action must be generated in the domain where the controlled process parameter faces its constraint such that it stays within it constraint. The constrained heating process parameters are the maximum temperature difference within the cross-section , the maximum heating-medium temperature , and the maximum blank surface temperature . Besides, it is also necessary to constrain the maximum magnitude of the control action .

To solve the variational problem with the constraints, use the developed algorithm and apply algorithms based on automatic control laws, including the PI control law, to keep the process parameters at their specified values [26]. As input variable parameters, values are used on which constraints are imposed; as a value for setting the regulator, numerical values of constraints are used.

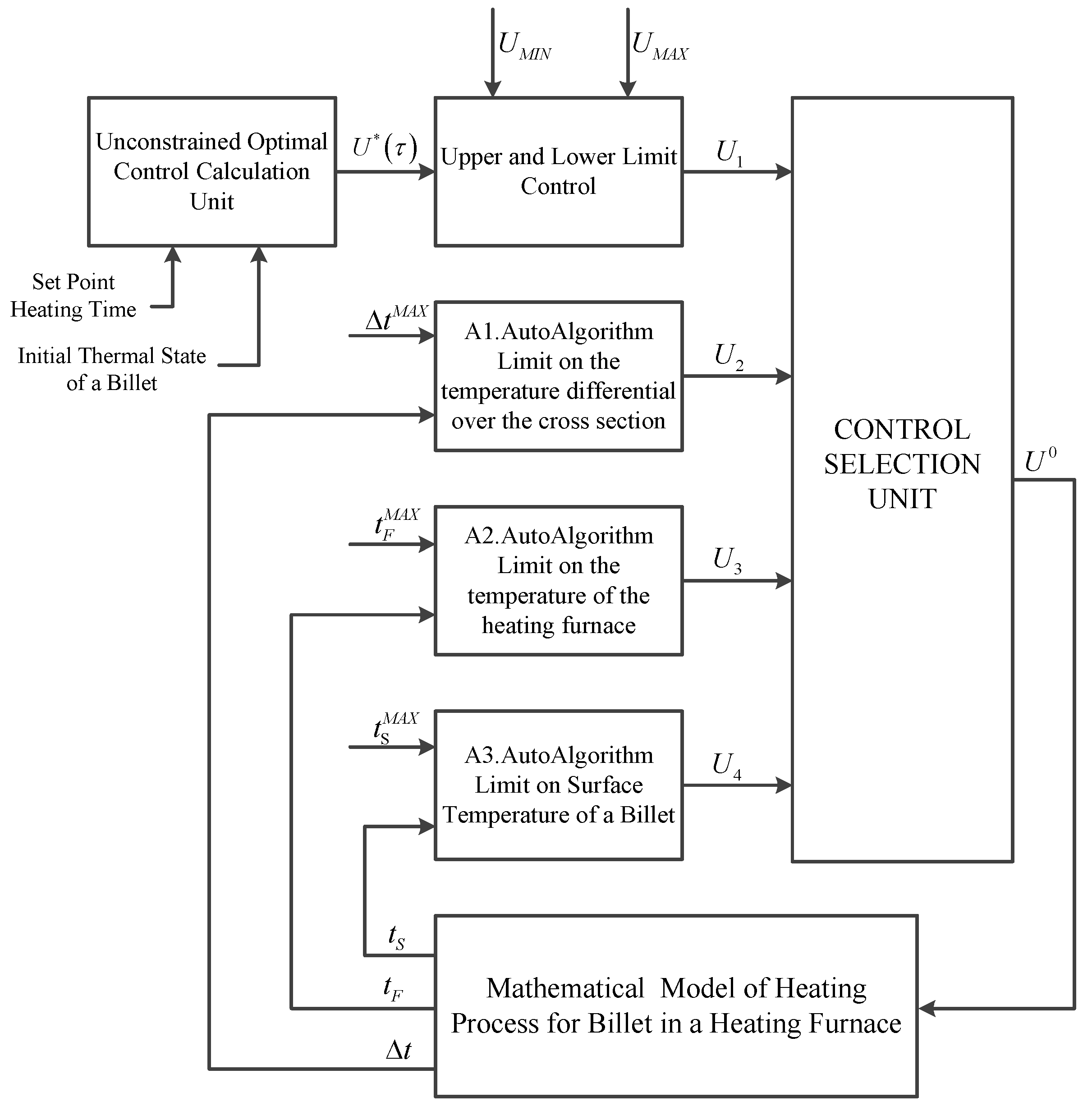

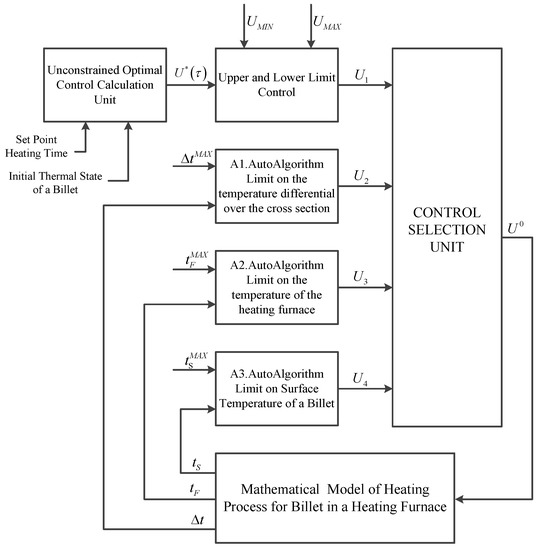

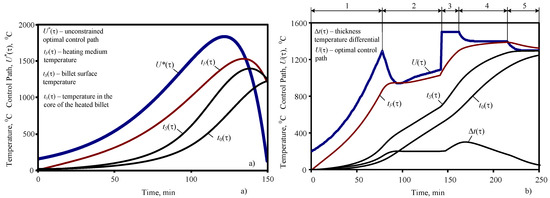

Automatic algorithms are configured to the requirement that the process parameter reach its maximum permissible value as fast as possible, with minimum subsequent deviations. Figure 2 presents the diagram of generating an optimal-heating, minimum-fuel control trajectory accounting for the control action and heating constraints; the process uses automatic algorithms (AutoAlgorithms).

Figure 2.

Selecting the optimal metal heating control path to minimize fuel costs in compliance with the process constraints.

Figure 2 uses the following notations: is the control action, non-constrained; – are algorithm-generated control actions fit to the constraints; U is the control action chosen to the priority of the constraints in place; and , , and are the heating-medium temperature, the blank surface temperature, and the cross-section temperature difference, respectively, C.

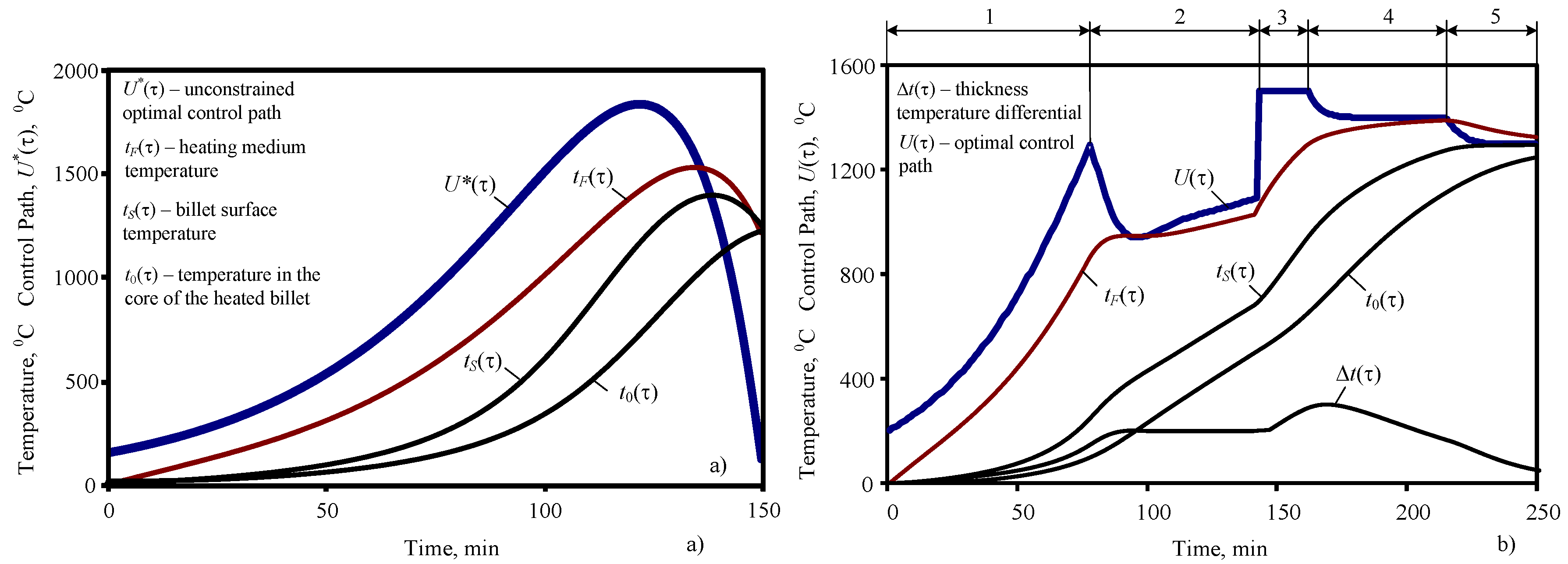

The control selection block is to select one specific control action value to be in line with the priority of the constraints in place as well as with the optimal control strategy. The chosen control action is fed to the mathematical model of blank heating, which finds the temperature parameters of the heating process. The parameter values are fed to the respective algorithms. Repeat the cycle for each point of the control trajectory to find the full optimal control trajectory and to adjust the heating process parameters. Figure 3 shows the optimal control trajectories with and without constraints.

Figure 3.

Calculated heating trajectories of the solved optimal control program: (a) without constraints; and (b) with constraints.

Figure 3b uses the following notation: (1) no constraints; (2) maximum temperature difference within the cross-section constrained; (3) control action constrained; (4) heating-medium temperature constraints; and (5) surface temperature constrained.

The calculation produces the trajectories of heating-medium temperature and heated-blank surface temperature , the values of which can be fed to the local thermal condition control circuits placed in the zones of a pass-through heat-treatment furnace as the blank goes through it.

4. Implementation

What determines the effectiveness of heating optimization is whether it guarantees heating the blank as required before it exits the furnace. Given how uneven the rolling performance could be, optimized heating must not increase the risk of releasing an underheated blank that has been heated for a shorter time than assumed when calculating the optimal heating trajectory. Exceeding the assumed heating time is not acceptable either. In that case, although the heating quality might meet the requirements, heating could well be inefficient as more gas would have to be consumed to maintain the attained thermal condition.

It is also necessary to account for the redundant power of the heat-treatment furnace. At higher rolling performance, specific heating costs become lower. At peak rolling performance, the furnace also attains its peak performance, in which case further optimization by zonal heating control becomes impossible. This means pre-rolling heating efficiency can only be improved if the furnace performance is below its maximum.

The core subsystems directly involved with the control optimization are:

- the instrumentation subsystem that monitors the blank movement in the furnace(s), and predicts and adjusts the blank heating time;

- the subsystem that monitors the thermal condition of blanks when they enter and exit the furnace;

- the subsystem that configures the zonal controllers to optimize heating and adjust the heating values depending on actual thermal condition of blanks leaving the furnace; and

- the fuel combustion control subsystem.

Coordination of these core subsystems enables efficient energy-saving control over blank heating and prevents underheated blanks from leaving the furnace while also stabilizing the transients in transient states.

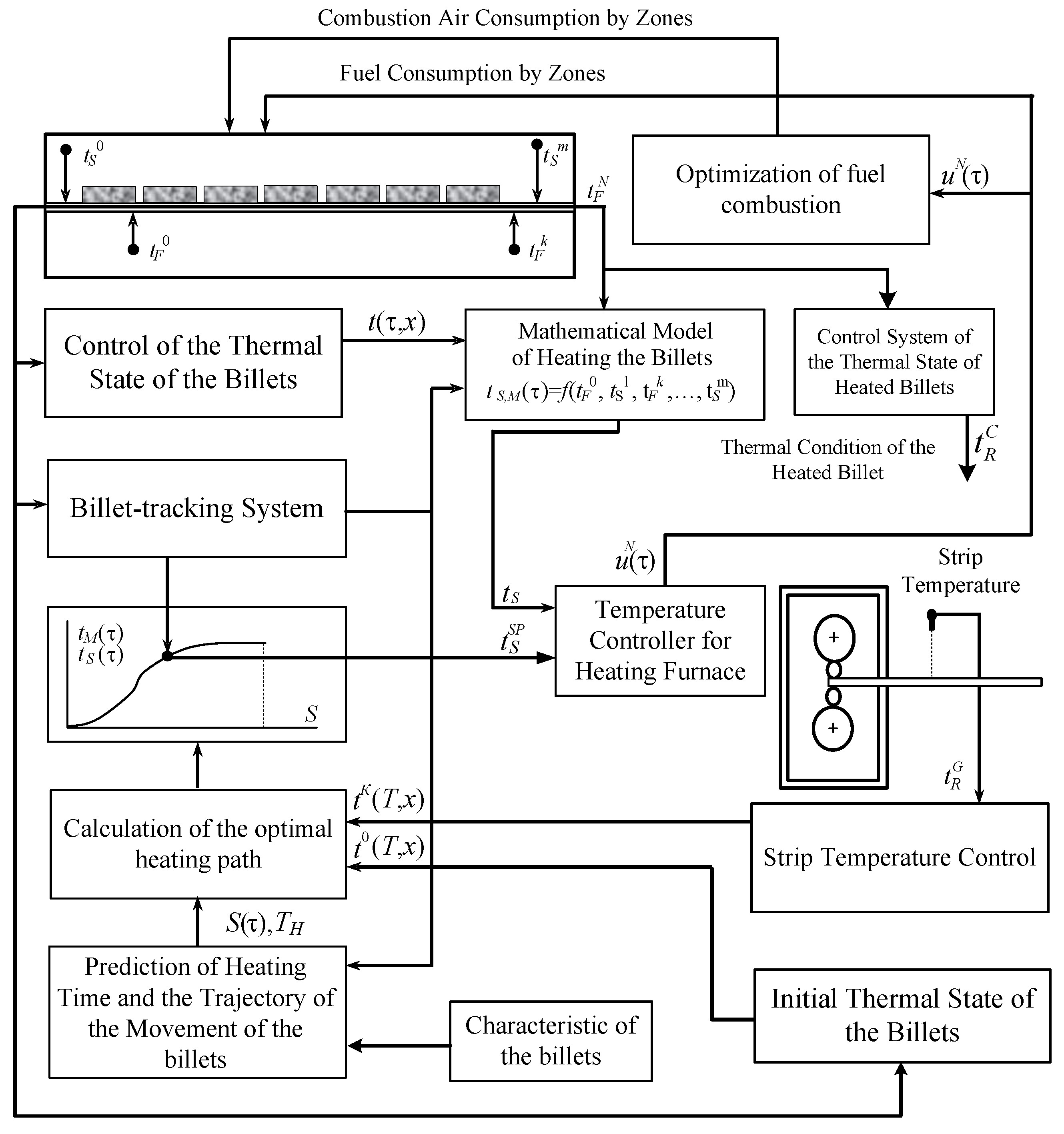

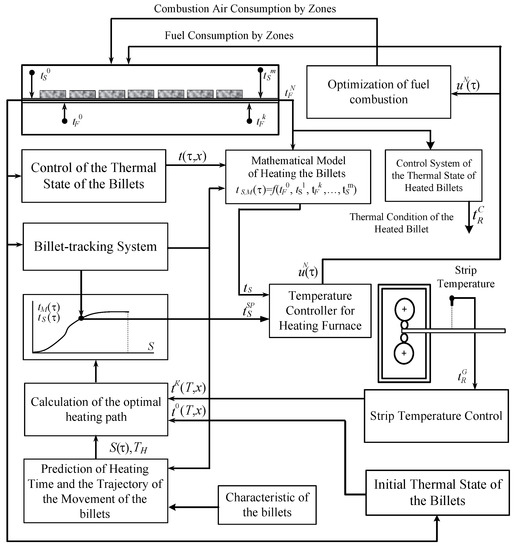

Figure 4 shows the structural diagram of the optimal energy-saving heating control system for a pass-through heat-treatment furnace. For each slab loaded in the furnace, calculate the optimal heating trajectory on the basis of the predicted heating time and initial thermal condition to minimize the energy costs of heating while also complying with all heating constraints; the trajectory is to be used by the furnace as the blank passes through. An additional stand-alone pre-exit heating quality control system will help prevent underheated blanks from leaving the furnace for a better rolling quality.

Figure 4.

Structural diagram of the optimal energy-saving heating control system for a pass-through heat-treatment furnace.

The blank monitoring system counts the steps taken by the walking beams once the blank is in the furnace; thus, it tracks the position of each blank in the furnace [27]. The heating modeling algorithm uses the current blank coordinates and the zonal temperature sensor readings to calculate the thermal condition of each blank in the furnace. The energy-saving heating trajectory optimization algorithm is coordinated with the heating time prediction algorithm as well as with the initial state algorithm to calculate the metal surface temperature trajectory that will match the energy-saving heating curve; thus, it calculates the required blank surface temperature specific to its current position in the furnace.

This value is fed to the surface temperature controller operating at a specific point in the furnace. The actual surface temperature is a calculated value, either found by the blank heating model or measured by the surface temperature sensor. The surface temperature controller sends a control signal that adjusts the zone-specific gas flow. The fuel combustion optimization system optimizes the zonal air flow as a function of the actual gas flow. The upon-exit thermal condition monitoring system provides secondary objective heating quality control to prevent underheated blanks from entering the rolling mill. The rolling temperature stabilization system corrects the configured final thermal condition of the metal as it exits the running furnace so as to ensure the required value of the temperature of blanks leaving different furnaces.

One particular feature of this algorithm is that the thermal condition of a blank can be controlled with reference to the surface temperature, whether calculated mathematically or read by the surface temperature sensors. This does not affect the algorithm structures; sensorless furnaces can be gradually upgraded with sensors without altering the algorithm, which simplifies configuring the system.

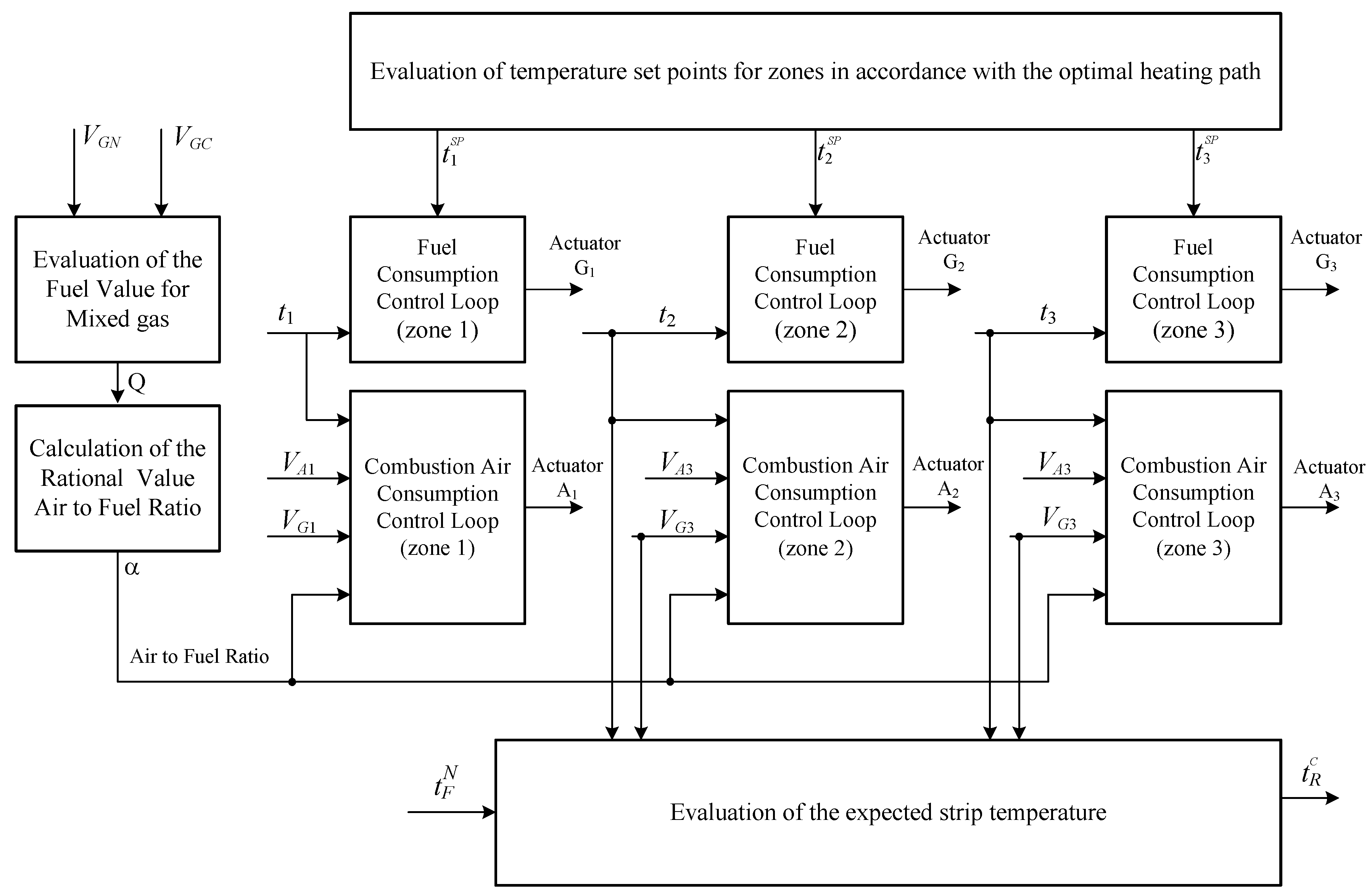

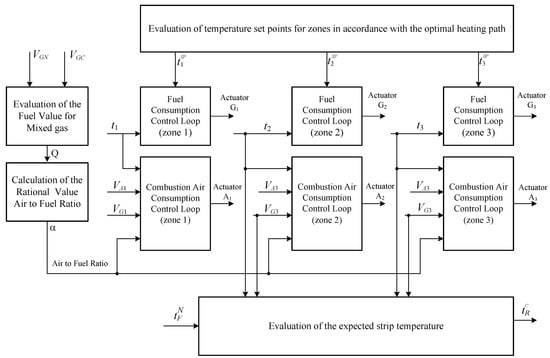

The system has been implemented at Mill 2500, a hot-rolling mill of ”Magnitogorsk Iron and Steel Works Inc”, (Magnitogorsk, Chelyabinsk, Russia). The mill has six push-type heat-treatment furnaces, each featuring five controllable heating zones and firing a mixture of coke and natural gas. The core heating zones are Zones 1–3. The optimal control system has only been implemented for the core heating zones. Zones 4 and 5 are intended to level the temperature cross-section-wise; they have low heat output and are always fueled at max, which is why they are not involved in heating controls. Figure 5 shows the zone control system structure.

Figure 5.

Structural diagram of the heating control system at Mill 2500, “Magnitogorsk Iron and Steel Works Inc”, Magnitogorsk, Chelyabinsk, Russia.

5. Result

The optimal control system configures zone-specific temperatures to optimize the blank heating path. Measured coke and natural gas flow rates are used to optimize the gas-mixture combustion factor and adjust the zone-specific air flow accordingly. The upon-exit thermal condition monitoring system prevents underheated blanks from going to the rolling mill.

When assessing the performance of the system, a period of time was selected at which the productivity of the rolling mill did not change. The productivity of heating furnaces at this time remained constant and equals 140–145 t/h. During this time, the operation of the furnace was transferred to control from the existing system to the optimal control system and returned back. This was done so that all external factors affecting fuel consumption remain unchanged and do not affect the estimate of the amount of change in fuel consumption for heating under different control modes.

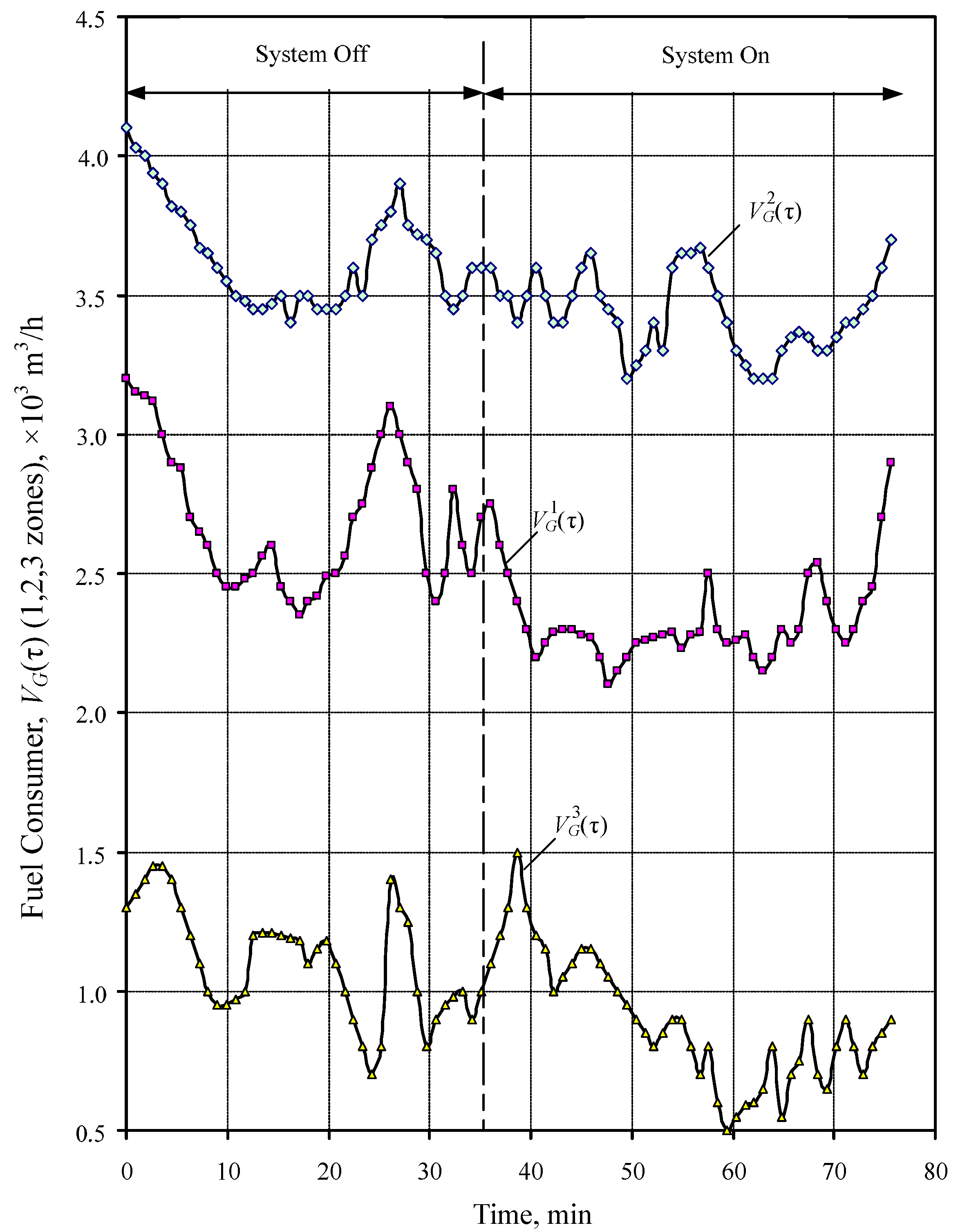

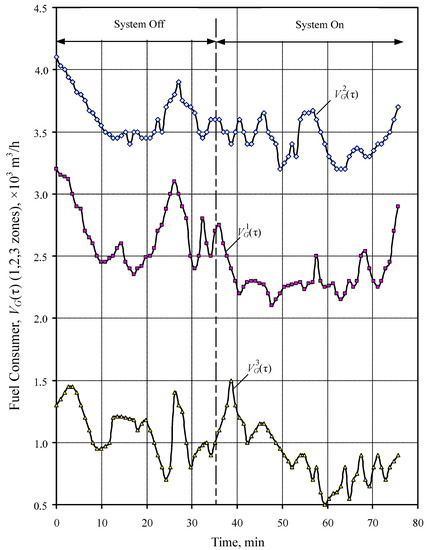

Figure 6 presents the gas flow curves for Zones 1–3 with the optimal thermal load control system on and off.

Figure 6.

Mixed-gas flow rate curves, Zones 1–3, Furnace No. 4, Mill 2500: optimal heating control system on and off.

Where the optimal control system is off, the zonal temperatures are set per the process map.

Table 1 shows the changes of gas-flow rates in Zones 1–3 and compares the optimized thermal loads vs. process-map thermal loads. Table 1 shows the final indicators obtained as a result of averaging the results of several experiments when switching to control the thermal regime from the proposed system with the same productivity of a heating furnace (140–145 t/h).

Table 1.

Thermal load control results. Average flow of the mixed gas in the heat-treatment furnace by zone, m/h.

Experiments have shown that using the optimal control system reduces the fuel consumption by 8.46% given there is enough time to heat the blanks. Whether the system is going to be efficient depends on the furnace runtime, during which redundant power is available. This accounts for 30–45% of the total furnace runtime. The rest of the time, heat-treatment furnaces are running at peak performance and maximum zonal thermal loads. YoY reduction in fuel consumption is 2.54–3.81% per furnace, or 1311 to 1505 thousand m of natural gas per annum.

6. Conclusions

The optimal heating control system is efficient provided that the furnaces have redundant power and are capable of zonal distribution of thermal loads. For a typical hot-rolling mill, redundant power is available for 30–45% of the total runtime; the rest of the time, furnaces run at peak performance and minimum specific fuel costs. Furnace control optimization requires solving a number of interrelated problems using separate subsystems. The implemented optimal control system saves 2.54–3.81% of fuel for heating, which equates to 1311–1505 thousand m of natural gas per annum for Mill 2500 at Magnitogorsk Iron and Steel Works Inc, (Magnitogorsk, Chelyabinsk, Russia).

Moving forward a comprehensive investigation of the process of optimal heating path generation is planned to be conducted. To this end, a mathematical model of the operation of a heating furnace will be created, in which the emphasis will be placed on modeling relationships between individual processes and control systems for these processes. Using a mathematical model, simulations will be made of the supply, movement and heating of a billet in the working space of a heating furnace under different operating conditions. This will clarify the proposed method for an optimal heating path generation, taking into account the influence of the initial thermal state of a billet, mill capacity, thermophysical characteristics of a heated billet, and the interaction of individual subsystems.

Conflicts of Interest

Declare conflicts of interest or state. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Mikhailovskii, V.N.; Nosov, S.K.; Pirozhkov, A.N.; Tikhomirov, A.I.; Partin, V.N. Mastering the heating furnaces of the 2000 hot-rolling mill. Steel Transl. 1998, 28, 27–31. [Google Scholar]

- Assaf, I.; Chen, M.; Katzberg, J. Steel scheduling optimization for IPSCO’s rolling mill and reheat furnace. In Proceedings of the IEEE WESCANEX 95, Communications, Power, and Computing, Winnipeg, MB, Canada, 15–16 May 1995; pp. 294–299. [Google Scholar]

- Lopez, L.; Carter, M.W.; Gendreau, M. The hot strip mill production scheduling problem: A tabu search approach. Eur. J. Oper. Res. 1998, 106, 317–335. [Google Scholar] [CrossRef]

- Li, K.; Tian, H. Integrated Scheduling of Reheating Furnace and Hot Rolling Based on Improved Multiobjective Differential Evolution. Complexity 2018, 2018. [Google Scholar] [CrossRef]

- Jang, J.-Y.; Huang, J.-B. Optimization of a slab heating pattern for minimum energy consumption in a walking-beam type reheating furnace. Appl. Therm. Eng. Pergamon 2015, 85, 313–321. [Google Scholar] [CrossRef]

- Tang, L.; Ren, H.; Yang, Y. Reheat furnace scheduling with energy consideration. Int. J. Prod. Res. 2015, 53, 313–321. [Google Scholar] [CrossRef]

- Banadaki, H.D.; Nozari, H.A.; Shoorehdeli, M.A. Short-term and long-term thermal prediction of a walking beam furnace using neuro-fuzzy techniques. Therm. Sci. 2015, 19, 703–721. [Google Scholar] [CrossRef]

- Pollhammer, W.; Spijker, C.; Six, J.; Zoglauer, D.; Raupenstrauch, H. Modeling of a walking beam furnace using CFD-methods. Energy Procediae 2017, 120, 477–483. [Google Scholar] [CrossRef]

- Tang, G.; Wu, B.; Bai, D.; Wang, Y.; Bodnar, R.; Zhou, C.Q. Modeling of the slab heating process in a walking beam reheating furnace for process optimization. Int. J. Heat Mass Transf. 2017, 113, 1142–1151. [Google Scholar] [CrossRef]

- Singh, V.K.; Talukdar, P.; Coelho, P.J. Performance evaluation of two heat transfer models of a walking beam type reheat furnace. Heat Transf. Eng. 2015, 36, 91–101. [Google Scholar] [CrossRef]

- Zhou, W.; Qiu, T. Zone modeling of radiative heat transfer in industrial furnaces using adjusted Monte-Carlo integral method for direct exchange area calculation. Appl. Therm. Eng. 2015, 81, 161–167. [Google Scholar] [CrossRef]

- Wang, J.; Fei, Z.; Chang, Q.; Li, S. Energy Saving Operation of Manufacturing System Based on Dynamic Adaptive Fuzzy Reasoning Petri Net. Energies 2019, 12, 2216. [Google Scholar] [CrossRef]

- Hu, Y.; Tan, C.K.; Broughton, J.; Roach, P.A.; Varga, L. Model-based multi-objective optimisation of reheating furnace operations using genetic algorithm. Energy Procedia 2017, 142, 2143–2151. [Google Scholar] [CrossRef]

- Strommer, S.; Niederer, M.; Steinboeck, A.; Kugi, A. Hierarchical nonlinear optimization-based controller of a continuous strip annealing furnace. Control Eng. Pract. Pergamon 2018, 73, 40–55. [Google Scholar] [CrossRef]

- Steinboeck, A.; Graichen, K.; Kugi, A. Dynamic optimization of a slab reheating furnace with consistent approximation of control variables. IEEE Trans. Control Syst. Technol. 2011, 19, 1444–1456. [Google Scholar] [CrossRef]

- Parsunkin, B.N.; Andreev, S.M.; Zhadinskii, D.Y. Energy-saving heating of continuous-cast billet. Steel Transl. 2007, 37, 384–387. [Google Scholar] [CrossRef]

- Parsunkin, B.N.; Andreev, S.M.; Logunova, O.S.; Akhmetov, T.U. Energy-saving optimal control over heating of continuous cast billets. Int. J. Adv. Manuf. Technol. 2015, 79, 1797–1803. [Google Scholar] [CrossRef]

- Parsunkin, B.N.; Andreev, S.M.; Prozorov, V.V. Optimizing control of the fuel combustion process in the working volume of heating furnaces. Steel Transl. 2000, 30, 36–41. [Google Scholar]

- Parsunkin, B.N.; Andreev, S.M. Requirements in energy-saving metal heating. Steel Transl. 2002, 32, 37–41. [Google Scholar]

- Andreev, Y.N.; Butkovskii, A.G. Optimum control of the heating of massive bodies. J. Eng. Phys. 1968, 8, 64–67. [Google Scholar] [CrossRef]

- Pontryagin, L.S.; Boltyansky, V.G.; Gamkrelidze, R.V.; Mishchenko, E.F. Mathematical Theory of Optimal Processes; Nauka: Moscow, Russia, 1983. [Google Scholar]

- Butkovskii, A.G. The Maximum Principle for Optimum Systems with Distributed Parameters. Autom. Remote. Control. 1961, 22, 1156–1169. [Google Scholar]

- Parsunkin, B.N.; Andreev, S.M.; Zhadinsky, D.Y.; Akhmetova, A.U. Optimal Fuel-Efficient Modes of Heating Continuously Cast Billets in Continuous Reheating Furnaces; Vestnik of Nosov Magnitogorsk State Technical University: NMSTU, Magnitogorsk, Russia, 2015; Volume 3, pp. 89–96. [Google Scholar]

- Andreev, S.M.; Akhmetov, T.U.; Nuzhin, D.V.; Parsunkin, B.N. Automated Control System of Fuel Saving in Asymmetric Heating of Continuous Cast Billets Before Rolling. Electrotech. Syst. Complexes 2016, 3, 60–65. [Google Scholar] [CrossRef]

- Wanli, C.; Ning, K.; Daohong, W. Dynamic Furnace Temperature Setting Research on Combustion System of Rolling Mill Reheating Furnace. Phys. Procedia 2015, 66, 217–220. [Google Scholar] [CrossRef][Green Version]

- Wang, N.; Wang, J.; Li, Z.; Tang, X.; Hou, D. Fractional-Order PID Control Strategy on Hydraulic-Loading System of Typical Electromechanical Platform. Sensors 2018, 18, 3024. [Google Scholar] [CrossRef] [PubMed]

- Andreev, S.M. Continuous-Cast Billet Heating Time Forecast In The Context Of Non-Stationary Run Of A Continuous Furnace. Electrotech. Syst. Complexes 2017, 3, 35–40. [Google Scholar] [CrossRef]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).