Effect of Dynamic Tilting Speed on the Flow Field of Distributed Multi-Propeller Tilt-Wing Aircraft During Transition Flight

Abstract

1. Introduction

2. Model and Numerical Method

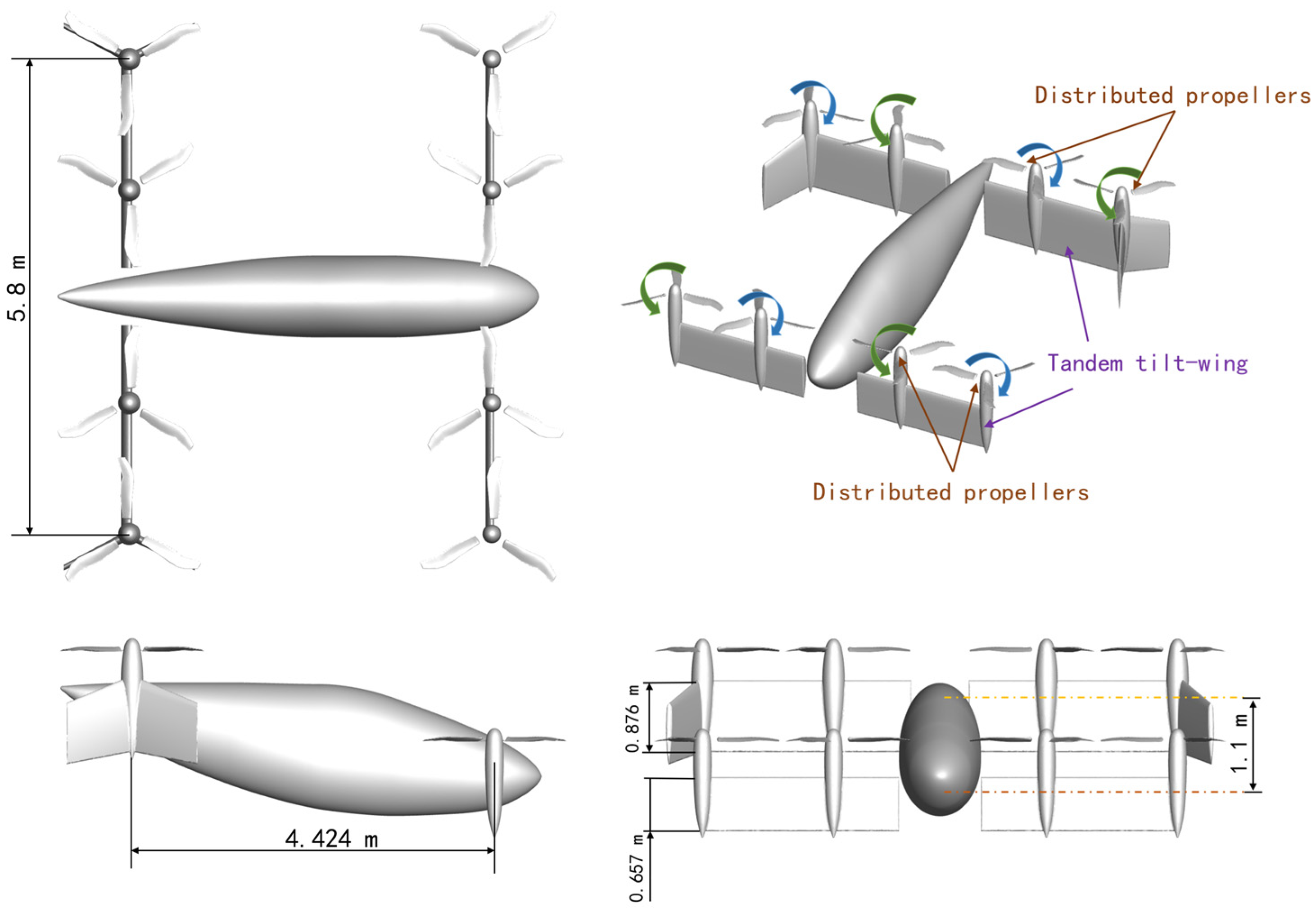

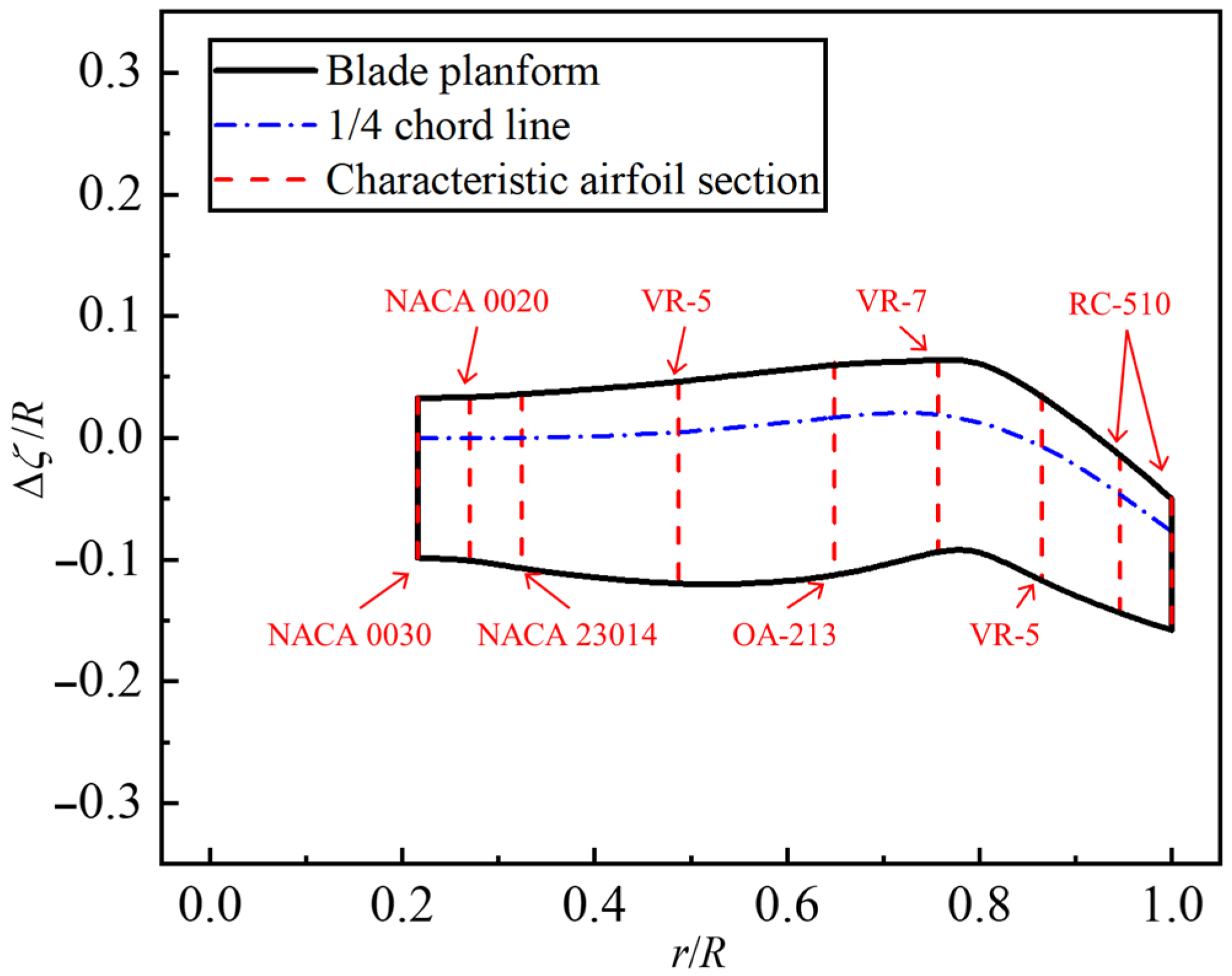

2.1. Geometric Modeling of the DMT Aircraft

2.2. Construction of the Overset Mesh System

2.3. Flow Field Solver

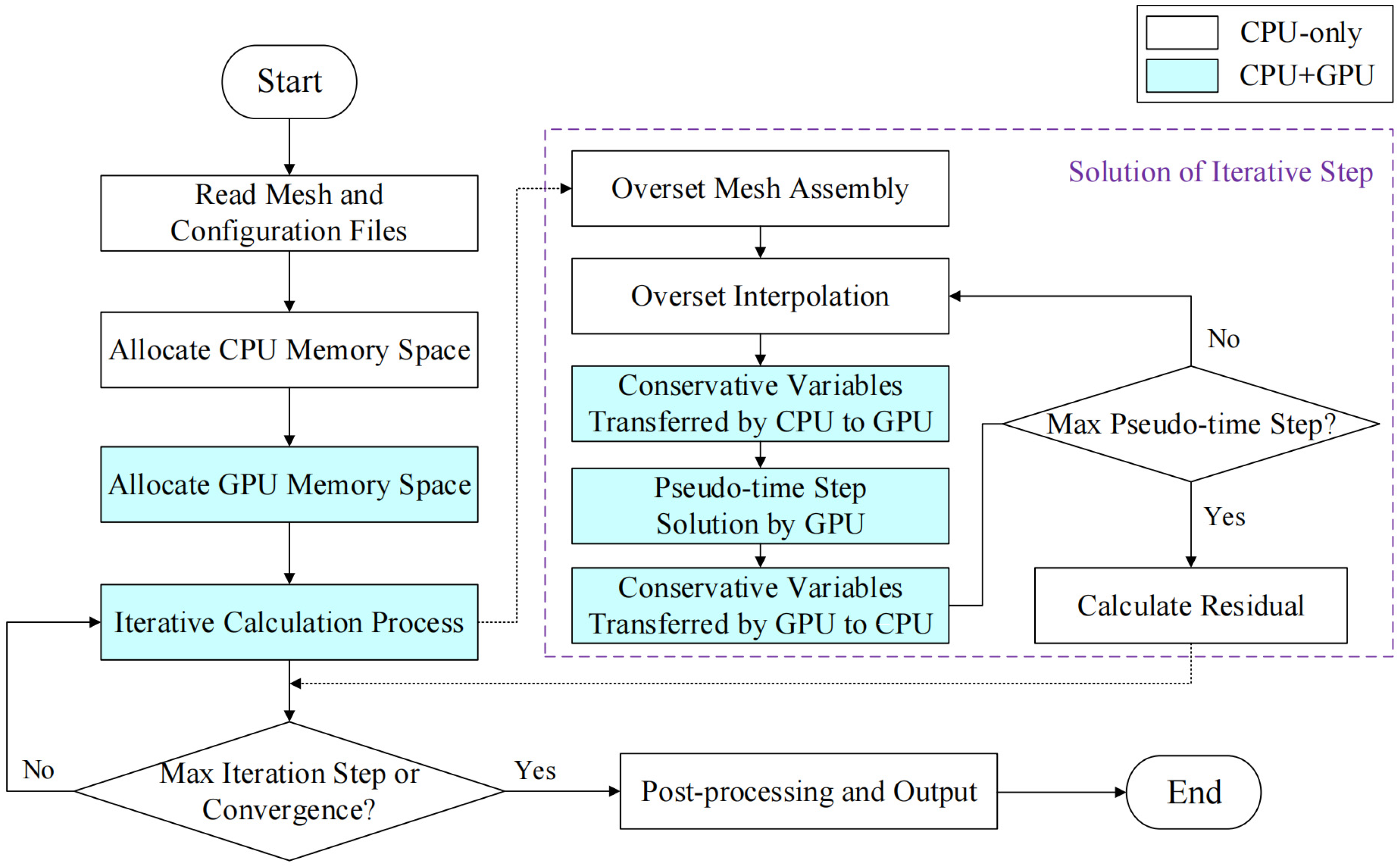

2.4. CPU-GPU Coordinated Acceleration Technology

- The work task allocation parallel method involves creating distinct task loads for various work tasks and distributing them to different threads for parallel processing. In this study, independent tasks within the three CFD solving processes—mesh motion assembly, numerical flow field solving, and result post-processing—are parallelized using work task allocation.

- OpenMP is a multi-threaded programming model based on shared memory architectures. The core principle underlying parallelization via OpenMP lies in the parallelization of individual loop computations within the process. In the CFD solver program of this study, the multi-loop structure in the flux calculation part of the flow field solving process is processed in parallel using OpenMP.

- MPI is a communication protocol standard for parallel computing. Using MPI-based communication methods, meshes can be partitioned for parallel acceleration. By distributing the number of mesh volume cells, the task load across each computing node is balanced as much as possible. Independent point-to-point communication is adopted for information transmission, which does not rely on forwarding via a central node, thus improving communication efficiency.

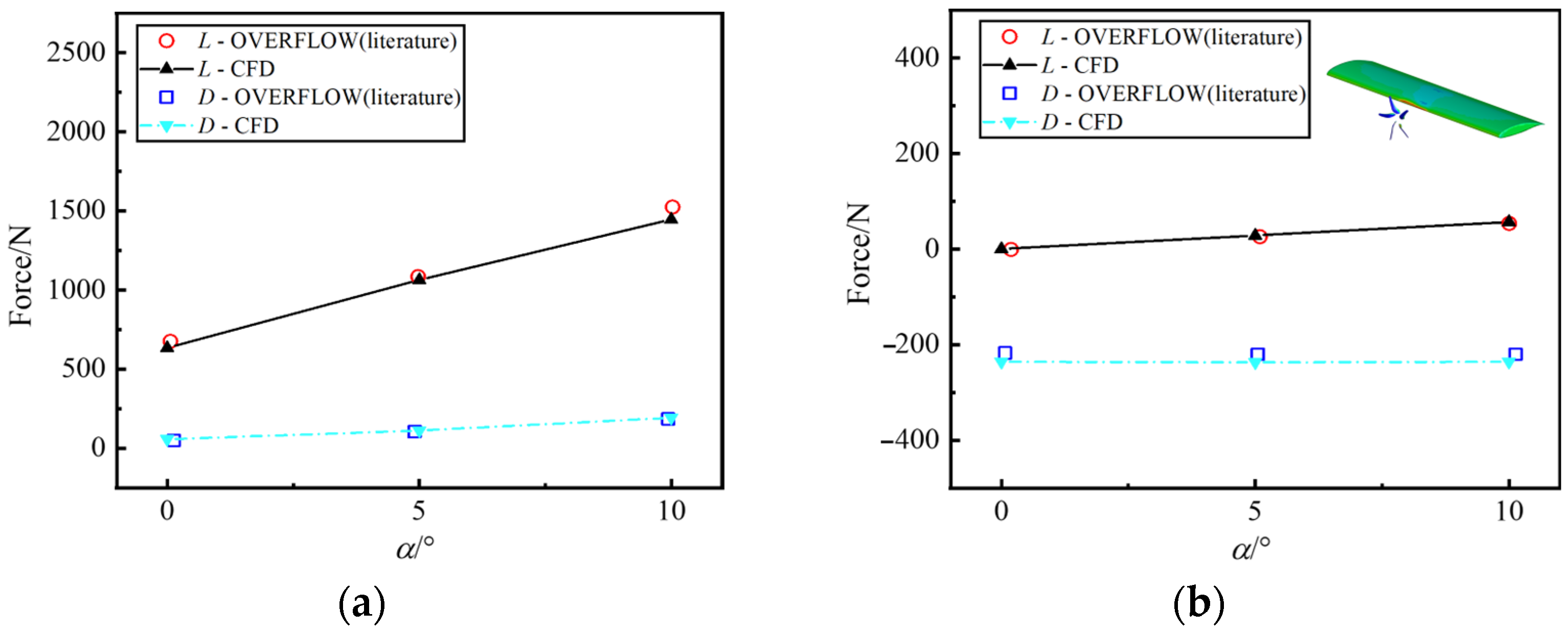

2.5. Simulation Validation

3. Results and Discussion

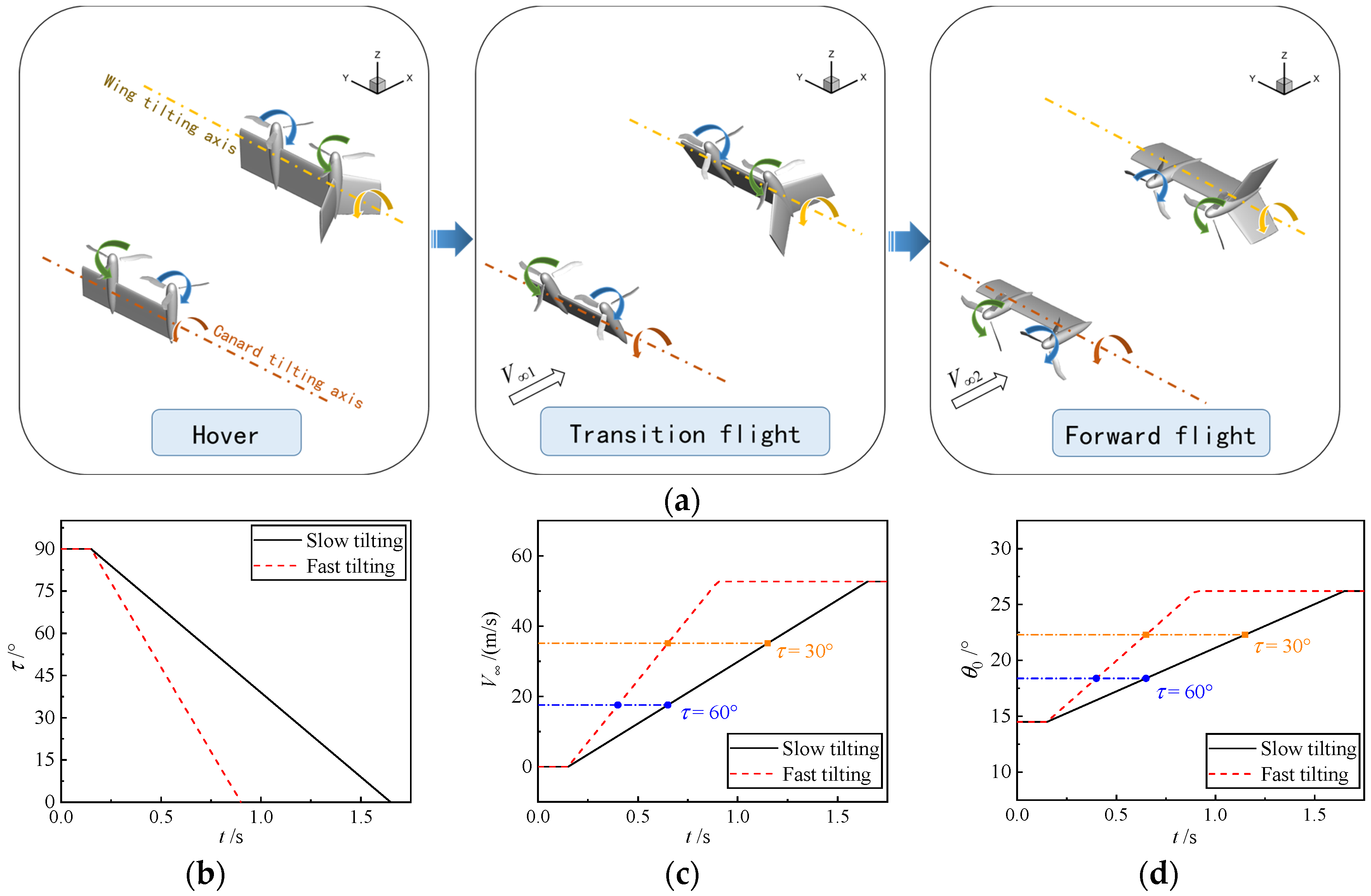

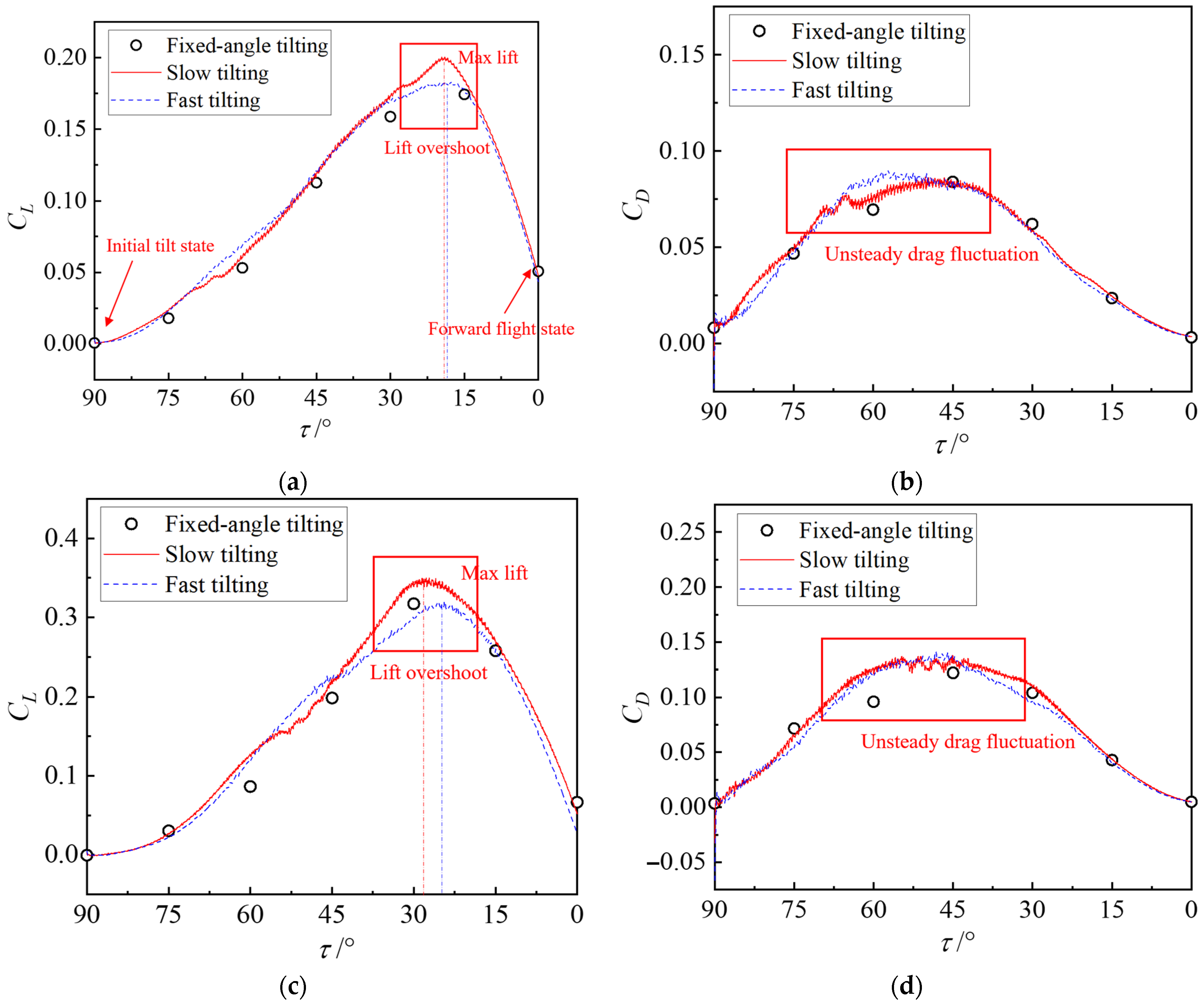

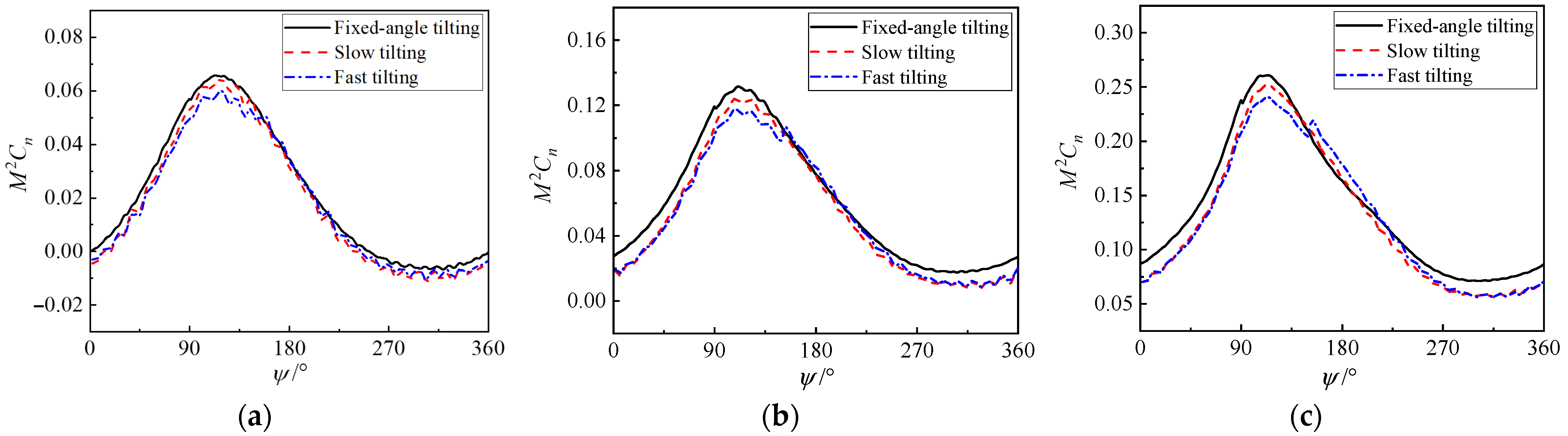

3.1. Aerodynamic Characteristics of Multi-Propeller/Tilt-Wing During Dynamic Transition

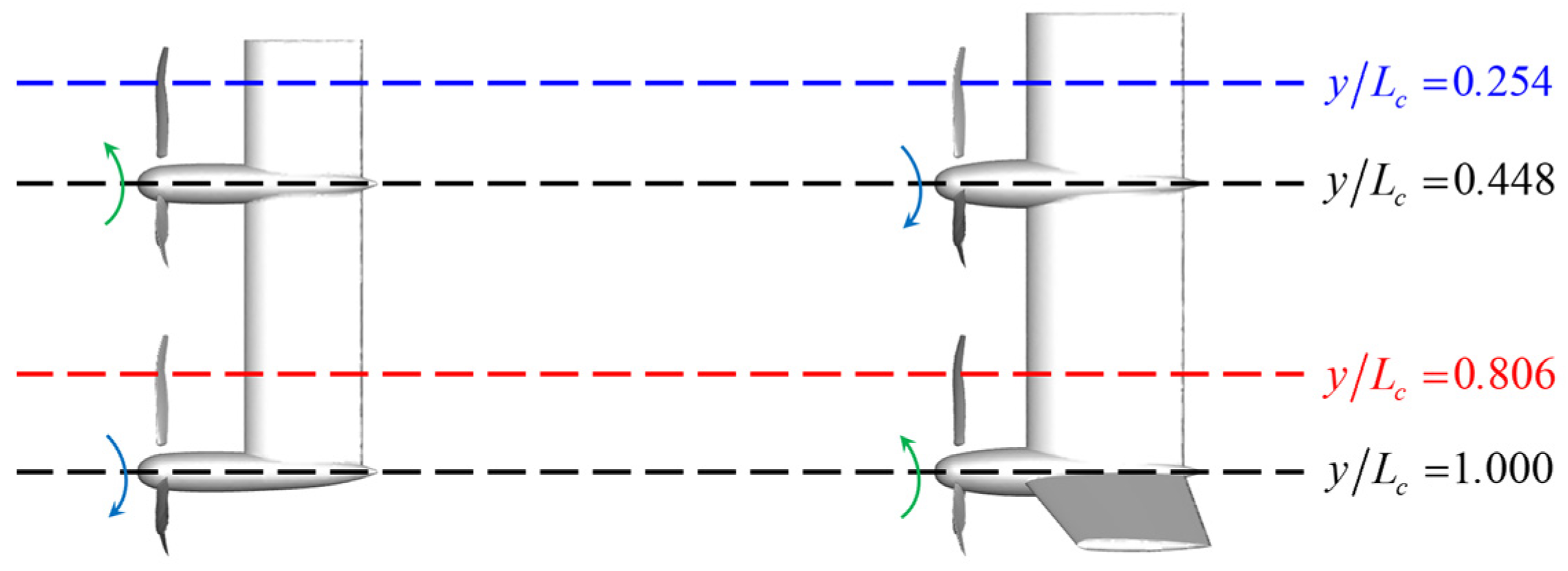

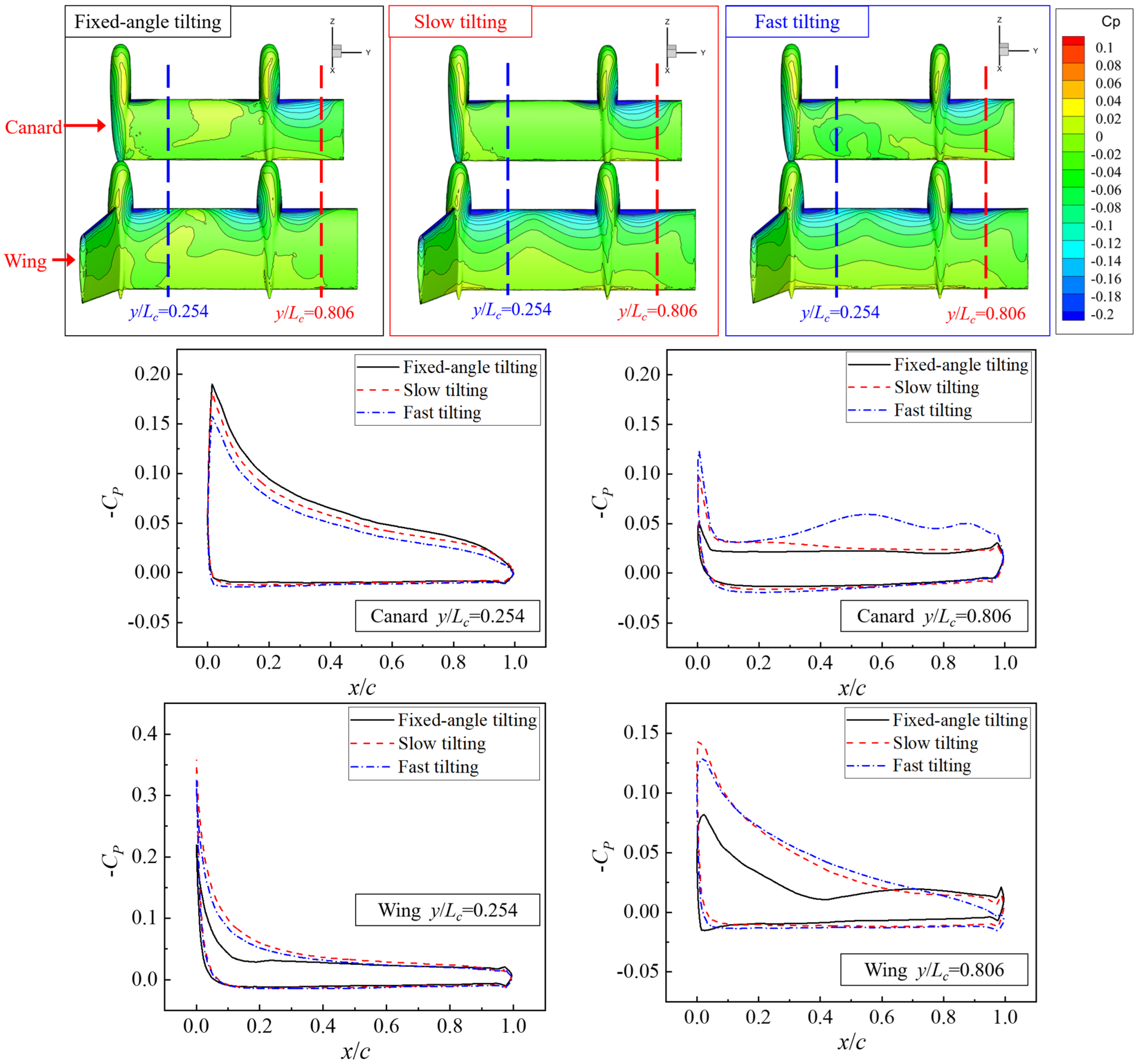

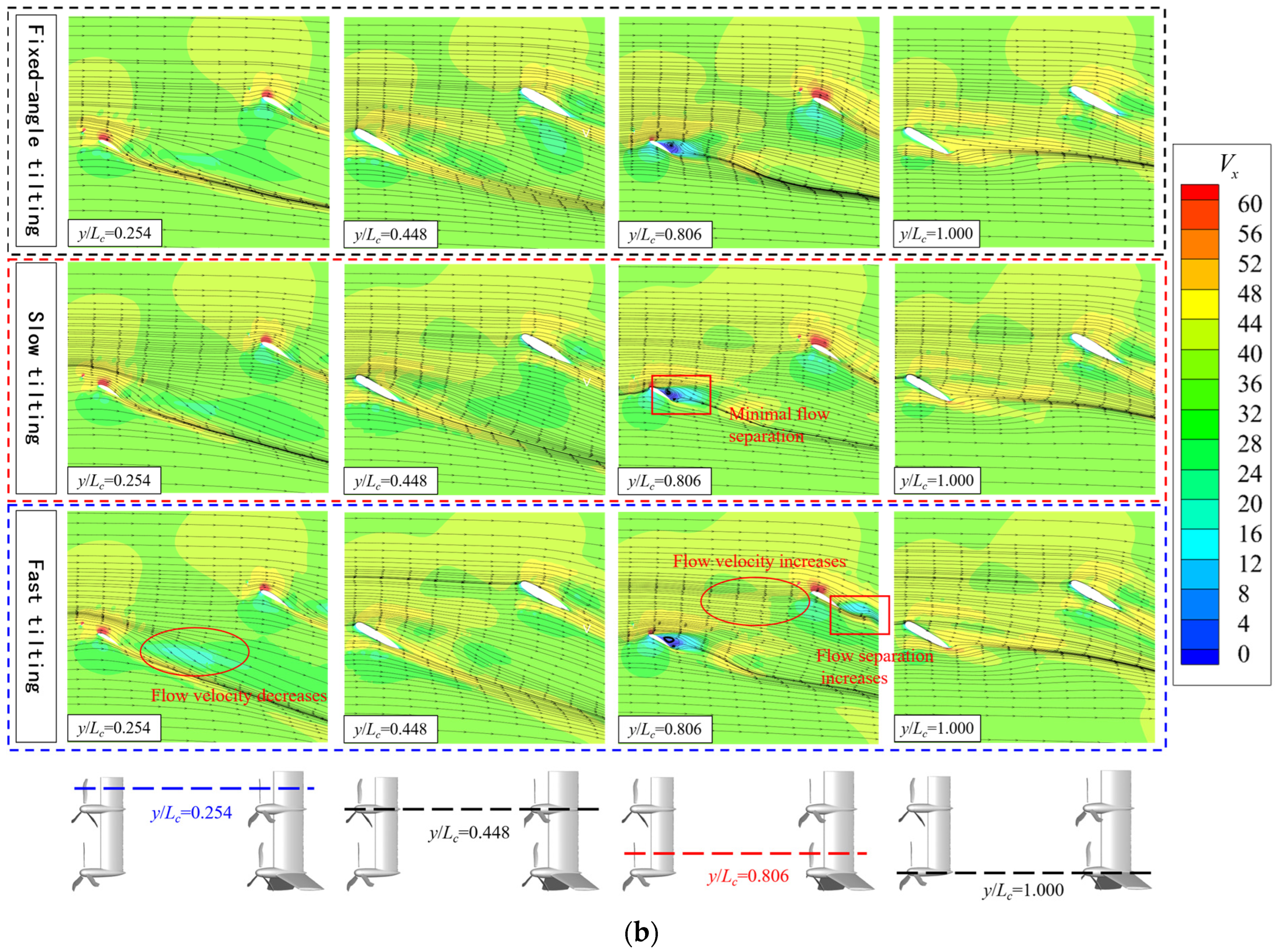

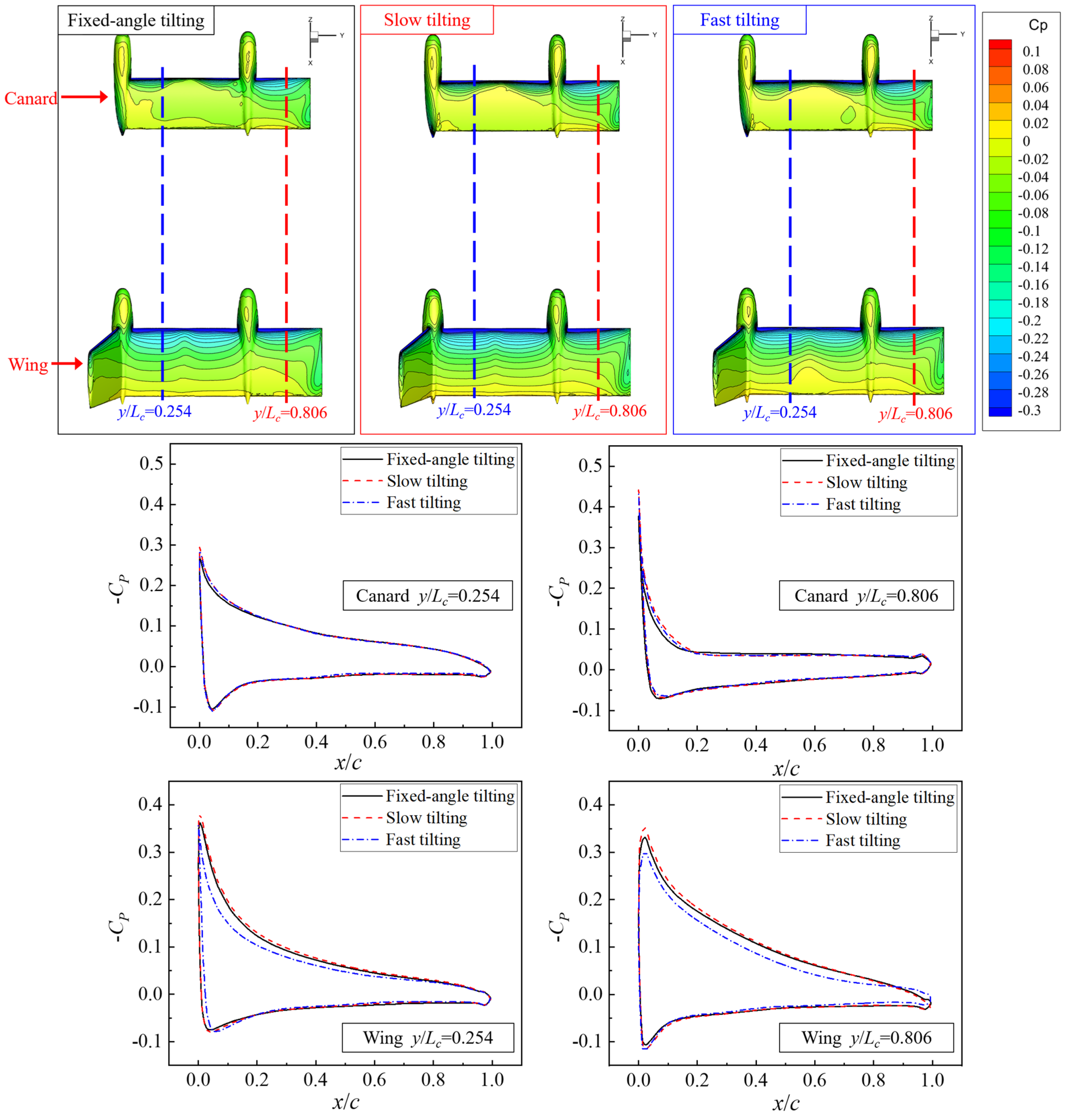

3.2. Influence of Dynamic Tilting Speed on Flow Field Evolution

4. Conclusions

- This paper establishes an overset mesh system and flow field numerical method applicable to DMT aircraft. Case study validation demonstrates that the body-fitted CFD method achieves high computational accuracy for aerodynamic characteristics under various disturbances. The proposed method enables the simulation of unsteady aerodynamic characteristics during the dynamic flight of DMT aircraft.

- The developed CPU-GPU parallel acceleration method effectively improves the flow field numerical simulation speed of the CFD method. It achieves a speedup ratio of 14.37 in the full-aircraft body-fitted mesh CFD calculation of DMT aircraft.

- During the full dynamic tilting process, the aerodynamic force of the propellers exhibits a trend of first increasing and then decreasing, gradually transitioning from vertical force to forward force. The lift and drag of the tilt-wings also follow a similar trend, but the tilting angles corresponding to their extreme points differ. In dynamic tilt conditions, the CT of both the forward and aft propellers is lower than that in fixed-angle conditions, and the value is similar. However, the tilting speed exerts distinct positive or negative effects on the lift and drag of the canard and wing at different tilting angles. Compared with fast tilting, the wing under slow tilting can achieve a higher peak lift coefficient when the drag is similar.

- Dynamic tilting speed affects the aerodynamic performance of multi-propeller and tilt-wings by altering the local airflow velocity and vortex-lift surface interference. The effect of tilt speed differs between the forward and rear sections of the tilting axis of the canard and wing. It facilitates lift generation under significant flow separation, while high tilting speed conversely reduces aerodynamic force when flow separation is slight. Fast tilting greatly modifies the wake of the front propellers and canard, leading to varying effects on the aerodynamic force of the wing at different tilting angles.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| eVTOL | electric Vertical Take-Off and Landing |

| DMT | Distributed multi-propeller tilting-wing |

| CFD | Computational fluid dynamics |

| CPU | Central processing unit |

| GPU | Graphics processing unit |

| DEP | Distributed Electric Propulsion |

| RANS | Reynolds-averaged Navier–Stokes |

| S-A | Spalart–Allmaras |

| MPI | Message passing interface |

| RADAS | Rotorcraft Aerodynamics and Aeroacoustics Solver |

| LU-SGS | Lower-Upper Symmetric Gauss-Seidel |

| OpenMP | Open Multi-Processing |

| A | = Propeller disk area, πR2 (m2) |

| α | = Angle of Attack (°) |

| c | = Chord length (m) |

| CD | = Drag coefficient, D/(1/2ρVtip2S) (non-dimensional) |

| CL | = Lift coefficient, L/(1/2ρVtip2 S) (non-dimensional) |

| CT | = Trust coefficient, Trust/(1/2ρVtip2A) (non-dimensional) |

| CP | = Pressure coefficient, (p-p0)/(1/2ρVtip2) (non-dimensional) |

| Cpower | = Power coefficient, P/(1/2ρVtip2AΩ) (non-dimensional) |

| D | = Drag (N) |

| FM | (non-dimensional) |

| K | = Thermal conductivity (W/(m·K)) |

| L | = Lift (N) |

| Lc | = Canard semi-span (m) |

| Lw | = Wing semi-span (m) |

| M2Cn | = Normal force coefficient, N/(1/2ρMa2c) (non-dimensional) |

| Ma | = Mach number (non-dimensional) |

| N | = Normal force (N) |

| Ω | = Propeller rotational speed (rad/s) |

| P | = Power (W) |

| p | = Absolute pressure (Pa) |

| p0 | = Atmospheric pressure (Pa) |

| R | = Propeller Radius (m) |

| ρ | = Air density (kg/m3) |

| S | = Tilt-wings Reference Area (m2) |

| σ | = Rotor solidity (non-dimensional) |

| T | = Temperature (K) |

| τ | = Tilting angle (°) |

| θ | = Twist angle (°) |

| θ0 | = Pitch angle (°) |

| μ | = Fluid viscosity (Pa·s) |

| V∞ | = Flight speed (m/s) |

| Vtip | = Propeller tip speed, ΩR (m/s) |

| Δζ | = Local displaced section (m) |

References

- Wang, M.; Cao, Y. A Review of Coaxial Compound Helicopters: Aerodynamics and Flight Dynamics. Arch. Comput. Methods Eng. 2025, 32, 4001–4031. [Google Scholar] [CrossRef]

- Tai, T.C. Simulation and Analysis of V-22 Tiltrotor Aircraft Forward-Flight Flowfield. J. Aircr. 1996, 33, 369–376. [Google Scholar] [CrossRef]

- Qiao, G.; Zhang, T.; Barakos, G.N. Numerical Simulation of Distributed Propulsion Systems Using CFD. Aerosp. Sci. Technol. 2024, 147, 109011. [Google Scholar] [CrossRef]

- Marzouk, O.A. Aerial E-Mobility Perspective: Anticipated Designs and Operational Capabilities of eVTOL Urban Air Mobility (UAM) Aircraft. Edelweiss Appl. Sci. Technol. 2025, 9, 413–442. [Google Scholar] [CrossRef]

- Pradeep, P.; Wei, P. Energy Optimal Speed Profile for Arrival of Tandem Tilt-Wing eVTOL Aircraft with RTA Constraint. In Proceedings of the 2018 IEEE CSAA Guidance Navigation and Control Conference, Xiamen, China, 10–12 August 2018. [Google Scholar] [CrossRef]

- Bacchini, A.; Cestino, E. Electric VTOL Configurations Comparison. Aerospace 2019, 6, 26. [Google Scholar] [CrossRef]

- Yang, M.; Wan, Z.; Chen, J. Aerodynamic Interference of a Variable-Radius Rotor/Wing During Transition Flight. J. Phys. Conf. Ser. 2025, 3126, 012052. [Google Scholar] [CrossRef]

- Mahmuddin, F. Rotor Blade Performance Analysis with Blade Element Momentum Theory. Energy Procedia 2017, 105, 1123–1129. [Google Scholar] [CrossRef]

- May, M.; Milz, D.; Armanini, S.; Looye, G. Transition Strategies for Tilt-Wing Aircraft. J. Guid. Control Dyn. 2025, 48, 2326–2337. [Google Scholar] [CrossRef]

- Meng, F.; Li, Y.; Li, M.; Ning, C. Investigation of Blade Root Clearance Flow Effects on Pressure Fluctuations in an Axial Flow Pump. Machines 2025, 13, 733. [Google Scholar] [CrossRef]

- Ekici, K.; Hall, K.C.; Dowell, E.H. Computationally Fast Harmonic Balance Methods for Unsteady Aerodynamic Predictions of Helicopter Rotors. J. Comput. Phys. 2008, 227, 6206–6225. [Google Scholar] [CrossRef]

- Pomin, H.; Wagner, S. Navier-Stokes Analysis of Helicopter Rotor Aerodynamics in Hover and Forward Flight. J. Aircr. 2002, 39, 813–821. [Google Scholar] [CrossRef]

- Srinivasan, G.R.; Raghavan, V.; Duque, E.P.N.; McCroskey, W.J. Flowfield Analysis of Modern Helicopter Rotors in Hover by Navier-Stokes Method. J. Am. Helicopter Soc. 1993, 38, 3–13. [Google Scholar] [CrossRef]

- Poling, D.R.; Rosenstein, H.; Rajagopalan, G. Use of a Navier-Stokes Code in Understanding Tiltrotor Flowfields in Hover. J. Am. Helicopter Soc. 1998, 43, 103. [Google Scholar] [CrossRef]

- McVeigh, M.A.; Grauer, W.K.; Paisley, D.J. Rotor/Airframe Interactions on Tiltrotor Aircraft. J. Am. Helicopter Soc. 1990, 35, 43–51. [Google Scholar] [CrossRef]

- Garcia, A.J.; Barakos, G.N. Numerical Simulations on the ERICA Tiltrotor. Aerosp. Sci. Technol. 2017, 64, 171–191. [Google Scholar] [CrossRef]

- Sheng, C.; Narramore, J.C. Computational Simulation and Analysis of Bell Boeing Quad Tiltrotor Aero Interaction. J. Am. Helicopter Soc. 2009, 54, 42002. [Google Scholar] [CrossRef]

- Sahoo, S.; Zhao, X.; Kyprianidis, K. A Review of Concepts, Benefits, and Challenges for Future Electrical Propulsion-Based Aircraft. Aerospace 2020, 7, 44. [Google Scholar] [CrossRef]

- Russo, O.; Aprovitola, A.; de Rosa, D.; Pezzella, G.; Viviani, A. Computational Fluid Dynamics Analyses of a Wing with Distributed Electric Propulsion. Aerospace 2023, 10, 64. [Google Scholar] [CrossRef]

- Giovanni, D.; Monica, S.; Geoffrey, B. Tiltwing Multi-Rotor Aerodynamic Modeling in Hover, Transition and Cruise Flight Conditions. In Proceedings of the AHS International 74th Annual Forum & Technology Display, Phoenix, AZ, USA, 14–17 May 2018. [Google Scholar] [CrossRef]

- Stoll, A.; Mikic, G. Transition Performance of Tilt Propeller Aircraft. In Proceedings of the 78th Annual Forum & Technology Display of the Vertical Flight Society (VFS), Fort Worth, TX, USA, 10–12 May 2022. [Google Scholar] [CrossRef]

- Duvigneau, R.; Kloczko, T.; Praveen, C. A Three-Level Parallelization Strategy for Robust Design in Aerodynamics. In Proceedings of the 20th International Conference on Parallel Computational Fluid Dynamics, Lyon, France, 19–22 May 2008; Available online: https://math.tifrbng.res.in/~praveen/doc/parcfd_duvigneau.pdf (accessed on 10 March 2025).

- Wan, Y.; He, L.; Zhang, Y.; Zhao, Z.; Liu, J.; Zhang, H. An Efficient Communication Strategy for Massively Parallel Computation in CFD. J. Supercomput. 2023, 79, 7560–7583. [Google Scholar] [CrossRef]

- Corrigan, A.; Camelli, F.F.; Löhner, R.; Wallin, J. Running Unstructured Grid-Based CFD Solvers on Modern Graphics Hardware. Int. J. Numer. Methods Fluids 2011, 66, 221–229. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Martins, J.R.R.A. Tilt-Wing eVTOL Takeoff Trajectory Optimization. J. Aircr. 2020, 57, 93–112. [Google Scholar] [CrossRef]

- Ha, T.H.; Lee, K.; Hwang, J.T. Large-Scale Design and Economics Optimization of eVTOL Concepts for Urban Air Mobility. In Proceedings of the AIAA SciTech Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar] [CrossRef]

- Droandi, G.; Gibertini, G. Aerodynamic Blade Design with Multi-Objective Optimization for a Tiltrotor Aircraft. Aircr. Eng. Aerosp. Technol. 2015, 87, 19–29. [Google Scholar] [CrossRef]

- Spekreijse, S.P. Elliptic Grid Generation Based on Laplace Equations and Algebraic Transformations. J. Comput. Phys. 1995, 118, 38–61. [Google Scholar] [CrossRef]

- Hu, Z.; Xu, G.; Shi, Y. A Robust Overset Assembly Method for Multiple Overlapping Bodies. Numer. Methods Fluids 2021, 93, 653–682. [Google Scholar] [CrossRef]

- Hu, Z.; Xu, G.; Shi, Y.; Xia, R. Airfoil–Vortex Interaction Noise Control Mechanism Based on Active Flap Control. J. Aerosp. Eng. 2022, 35, 04021111. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, G.; Shi, Y.; Hu, Z. Analysis of the Aeroacoustic Characteristics of a Rigid Coaxial Rotor in Forward Flight Based on the CFD/VVPM Hybrid Method. Aerospace 2023, 11, 21. [Google Scholar] [CrossRef]

- Hu, Z.; Yu, P.; Xu, G.; Shi, Y.; Gu, F.; Zou, A. Comparative Study of Soft In-Plane and Stiff In-Plane Tiltrotor Blade Aerodynamics in Conversion Flight, Using CFD-CSD Coupling Approach. Aerospace 2024, 11, 77. [Google Scholar] [CrossRef]

- Kang, H.J.; Kwon, O.J. Unstructured Mesh Navier-Stokes Calculations of the Flowfield of a Helicopter in Hover. J. Am. Helicopter Soc. 2002, 47, 90–99. [Google Scholar] [CrossRef]

- Menter, F.R. Two-Equation Eddy-Viscosity Turbulence Models for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Li, P.; Zhao, Q.; Zhu, Q. CFD Calculations on the Unsteady Aerodynamic Characteristics of a Tilt-Rotor in a Conversion Mode. Chin. J. Aeronaut. 2015, 28, 1593–1605. [Google Scholar] [CrossRef]

- Yoon, S.; Jameson, A. Lower-Upper Symmetric-Gauss-Seidel Method for the Euler and Navier-Stokes Equations. AIAA J. 1988, 26, 1025–1026. [Google Scholar] [CrossRef]

- Hirt, C.W.; Amsden, A.A.; Cook, J.L. An arbitrary Lagrangian Eulerian Computing Method for All Flow Speeds. J. Comput. Phys. 1974, 14, 227–253. [Google Scholar] [CrossRef]

- Dagum, L.; Enon, R. OpenMP: An Industry Standard API for Shared-Memory Programming. IEEE Comput. Sci. Eng. 1998, 5, 46–55. [Google Scholar] [CrossRef]

- Boldini, P.C.; Hirai, R.; Costa, P.; Peeters, J.W.R.; Pecnik, R. CUBENS: A GPU-Accelerated High-Order Solver for Wall-Bounded Flows with Non-Ideal Fluids. Comput. Phys. Commun. 2025, 309, 109507. [Google Scholar] [CrossRef]

- Szalay, P.G.; Muller, T.; Gidofalvi, G.; Lischka, H.; Shepard, R. Multiconfiguration Self-Consistent Field and Multireference Configuration Interaction Methods and Applications. Chem. Rev. 2012, 112, 108–181. [Google Scholar] [CrossRef] [PubMed]

- Droandi, G.; Zanotti, A.; Gibertini, G. Aerodynamic Interaction Between Rotor and Tilting Wing in Hovering Flight Condition. J. Am. Helicopter Soc. 2015, 60, 1–20. [Google Scholar] [CrossRef]

- Sheridan, C.D.; Pham, D.V.; Whiteside, S.S. Evaluation of VSPAERO Analysis Capabilities for Conceptual Design of Aircraft with Propeller-Blown Wings. In Proceedings of the AIAA AVIATION Forum, Virtual, 2–6 August 2021. [Google Scholar] [CrossRef]

- Fei, X.; Litherland, B.L.; German, B.J. Development of an Unsteady Vortex Lattice Method to Model Propellers at Incidence. AIAA J. 2022, 60, 176–188. [Google Scholar] [CrossRef]

| r/R | c/R | θ (°) | Δζ/R | Airfoil |

|---|---|---|---|---|

| 0.216 | 0.131 | 9.061 | 0.000 | NACA 0030 |

| 0.270 | 0.133 | 8.351 | 0.000 | NACA 0020 |

| 0.324 | 0.144 | 8.324 | 0.000 | NACA 23014 |

| 0.487 | 0.168 | 5.217 | 0.003 | VR-5 |

| 0.649 | 0.179 | −0.005 | 0.017 | OA-213 |

| 0.757 | 0.155 | −2.265 | 0.025 | VR-7 |

| 0.865 | 0.154 | −2.849 | −0.003 | VR-5 |

| 0.946 | 0.131 | −3.540 | −0.046 | RC-510 |

| 1.000 | 0.108 | −4.759 | −0.077 | RC-510 |

| Component | Number of Blade Cells | CT | Computational Time |

| Propeller | 290,304 | 0.0267 | 15.08 h |

| 653,184 | 0.0298 | 46.65 h | |

| 1,655,808 | 0.0302 | 52.38 h | |

| Number of Canard Cells | CL | ||

| Canard | 4,422,370 | 0.0502 | 6.57 h |

| 9,446,643 | 0.0519 | 10.40 h | |

| 13,040,400 | 0.0519 | 12.48 h |

| Device Type | Computing Equipment | Runtime | Speedup Ratio |

|---|---|---|---|

| CPU | AMD EPYC 9554 64-Core Processor | 13.65 h | 1 |

| CPU-GPU | AMD EPYC 9554 64-Core Processor + NVIDIA GeForce RTX 4090 D × 4 | 0.95 h | 14.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Shi, Y.; Ma, T.; Xu, G.; Hu, Z. Effect of Dynamic Tilting Speed on the Flow Field of Distributed Multi-Propeller Tilt-Wing Aircraft During Transition Flight. Machines 2025, 13, 1130. https://doi.org/10.3390/machines13121130

Zhu J, Shi Y, Ma T, Xu G, Hu Z. Effect of Dynamic Tilting Speed on the Flow Field of Distributed Multi-Propeller Tilt-Wing Aircraft During Transition Flight. Machines. 2025; 13(12):1130. https://doi.org/10.3390/machines13121130

Chicago/Turabian StyleZhu, Jiahao, Yongjie Shi, Taihang Ma, Guohua Xu, and Zhiyuan Hu. 2025. "Effect of Dynamic Tilting Speed on the Flow Field of Distributed Multi-Propeller Tilt-Wing Aircraft During Transition Flight" Machines 13, no. 12: 1130. https://doi.org/10.3390/machines13121130

APA StyleZhu, J., Shi, Y., Ma, T., Xu, G., & Hu, Z. (2025). Effect of Dynamic Tilting Speed on the Flow Field of Distributed Multi-Propeller Tilt-Wing Aircraft During Transition Flight. Machines, 13(12), 1130. https://doi.org/10.3390/machines13121130