A Woven Soft Wrist-Gripper Composite End-Effector with Variable Stiffness: Design, Modeling, and Characterization

Abstract

1. Introduction

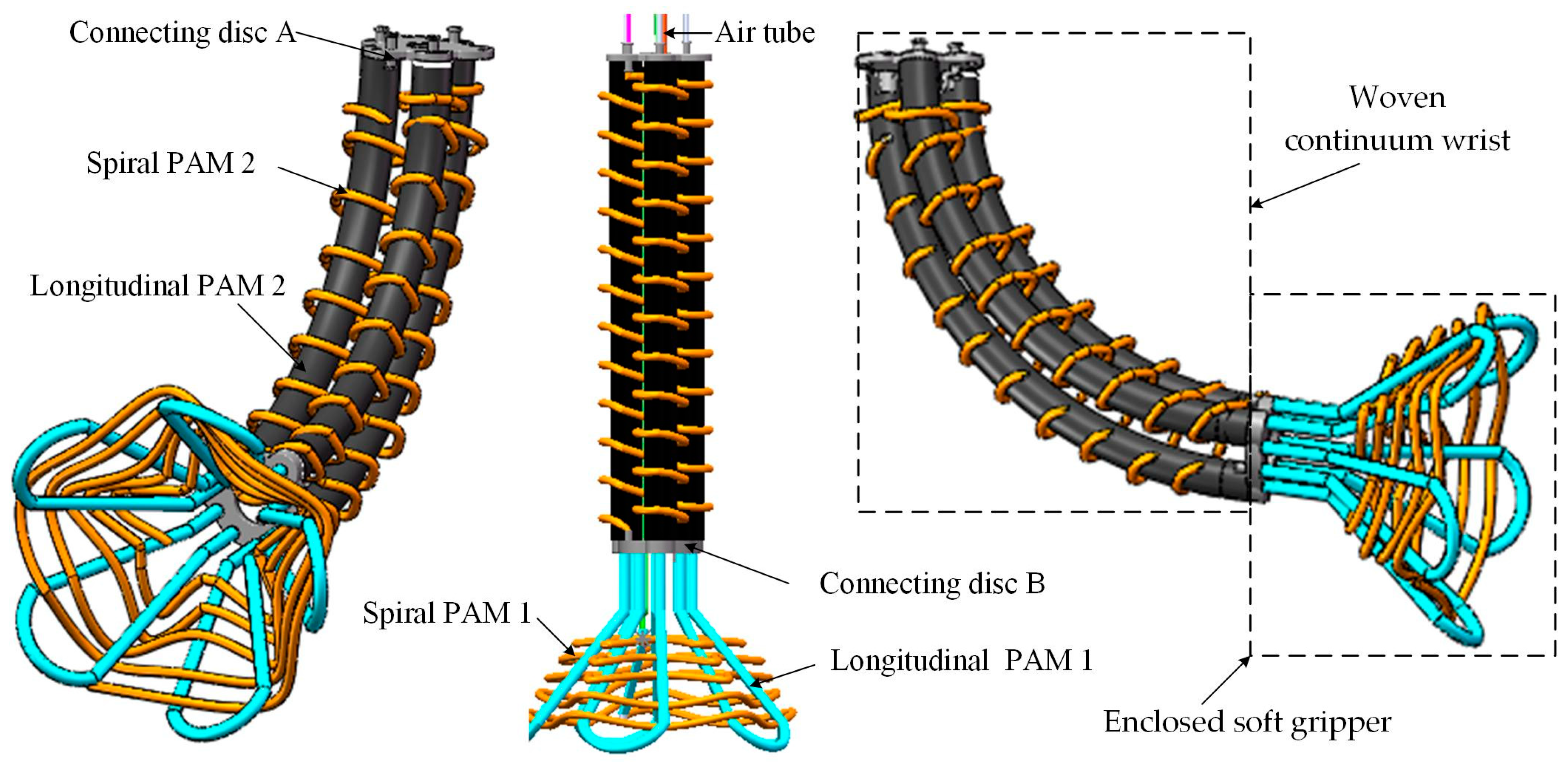

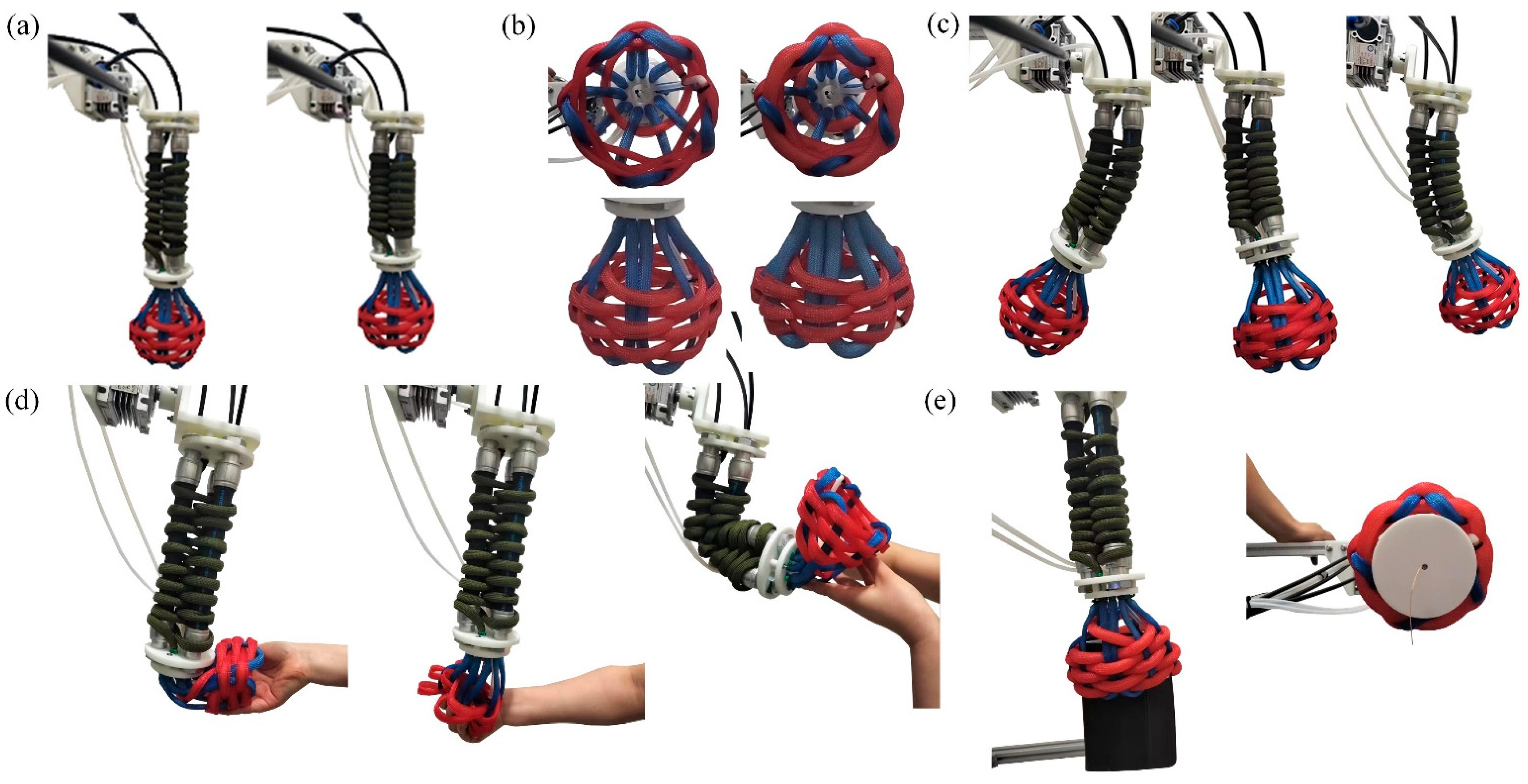

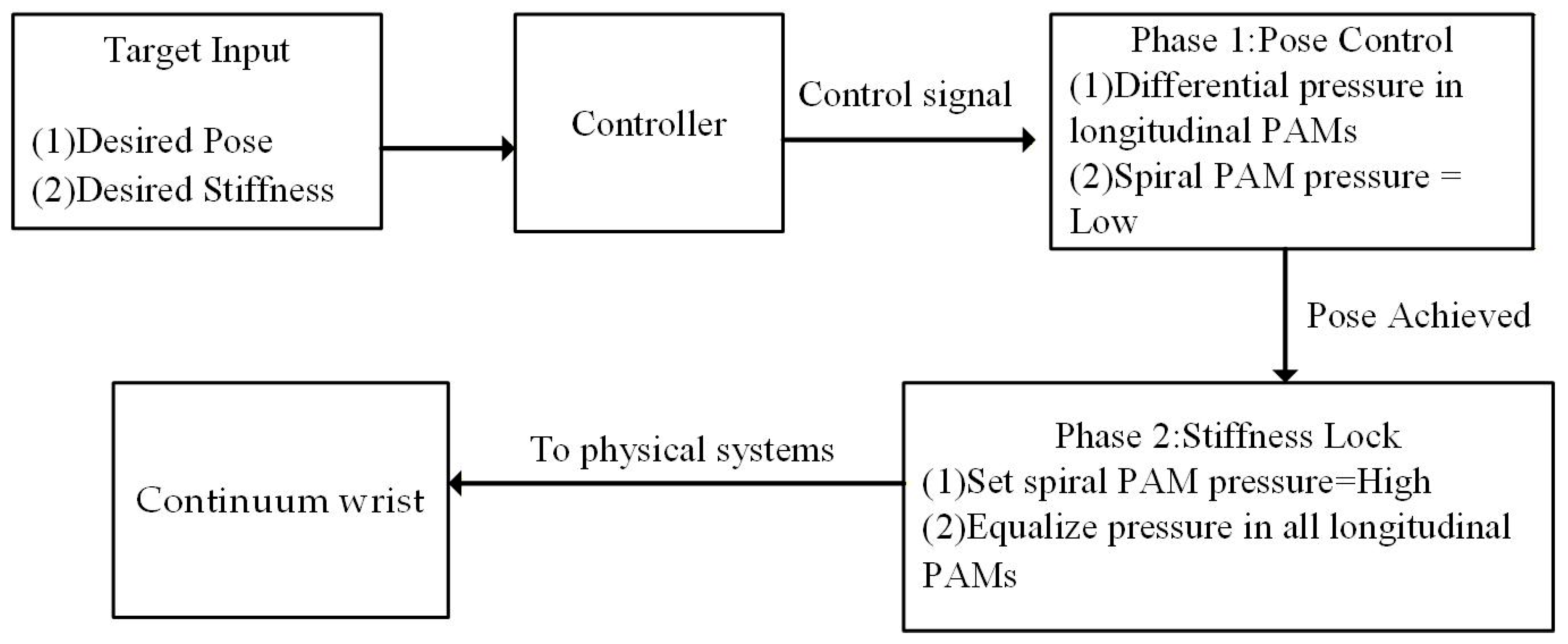

2. Design and Fabrication

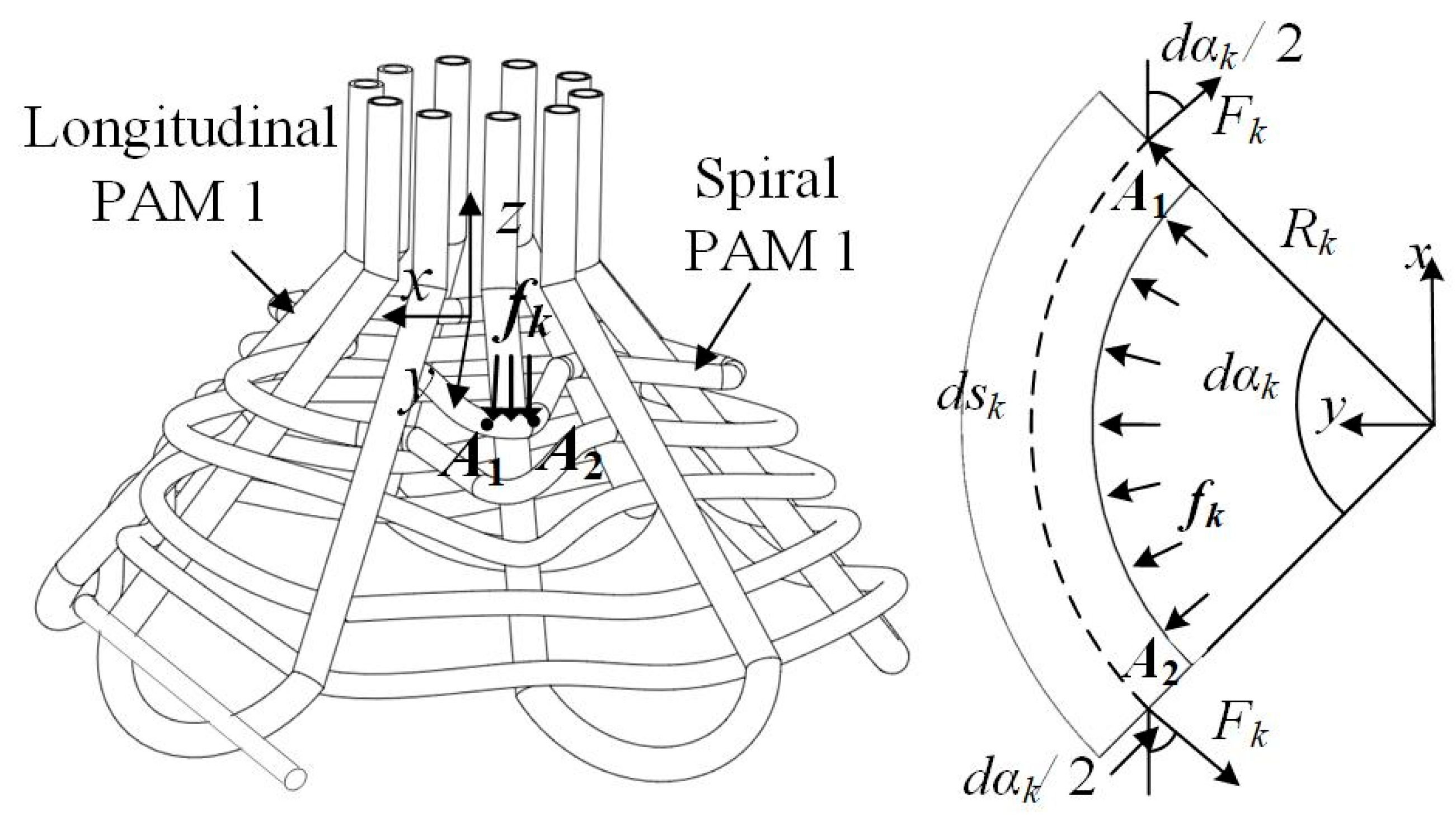

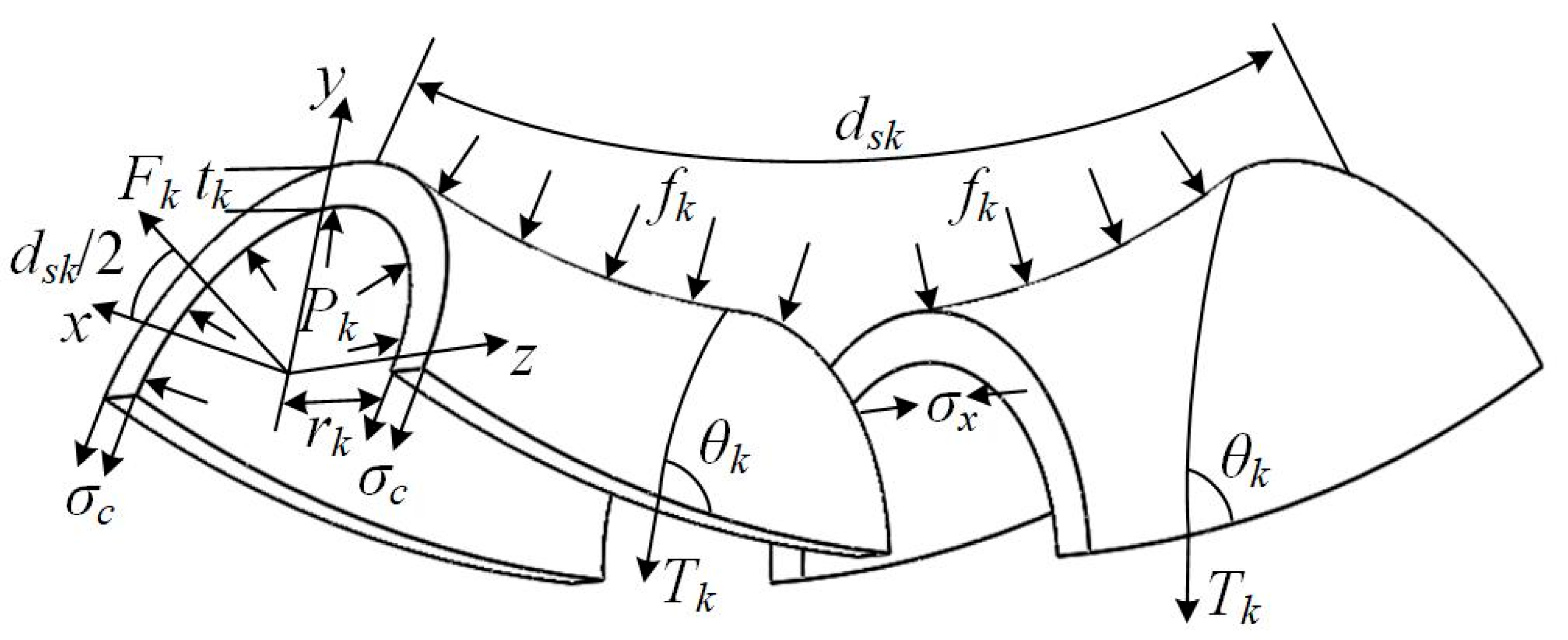

3. Force Modeling of Enclosed Soft Gripper

3.1. Gripping Force Analysis of Enclosed Soft Gripper

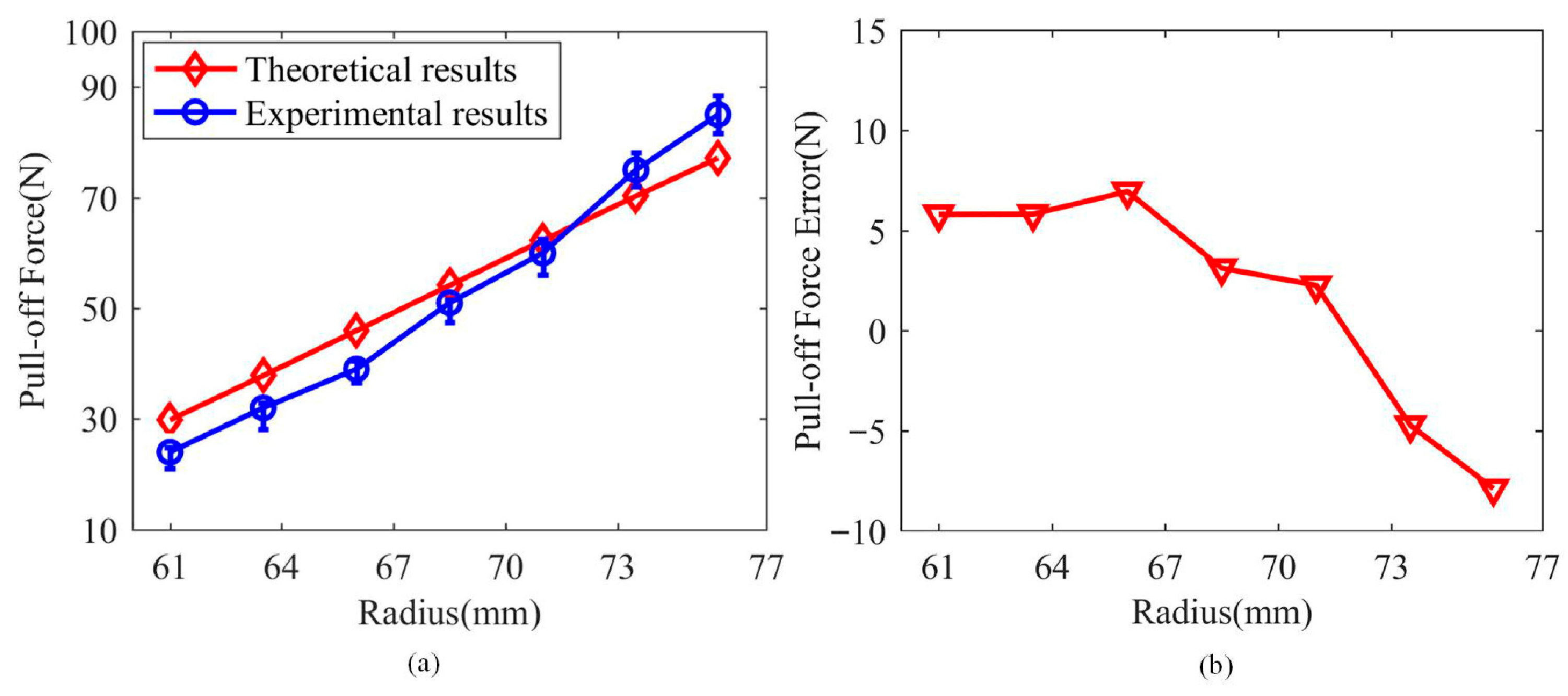

3.2. Theoretical Model Verification of Gripping Force

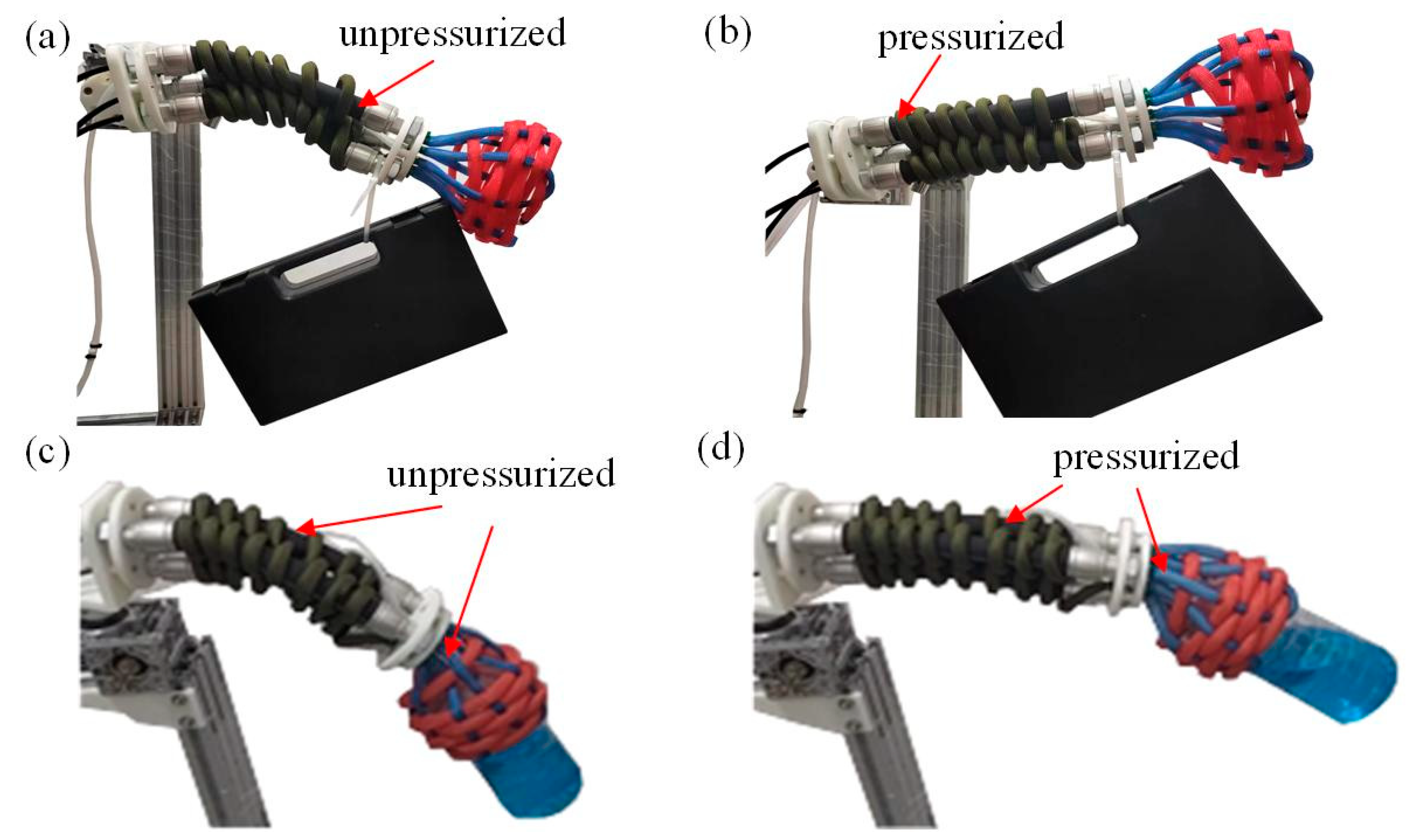

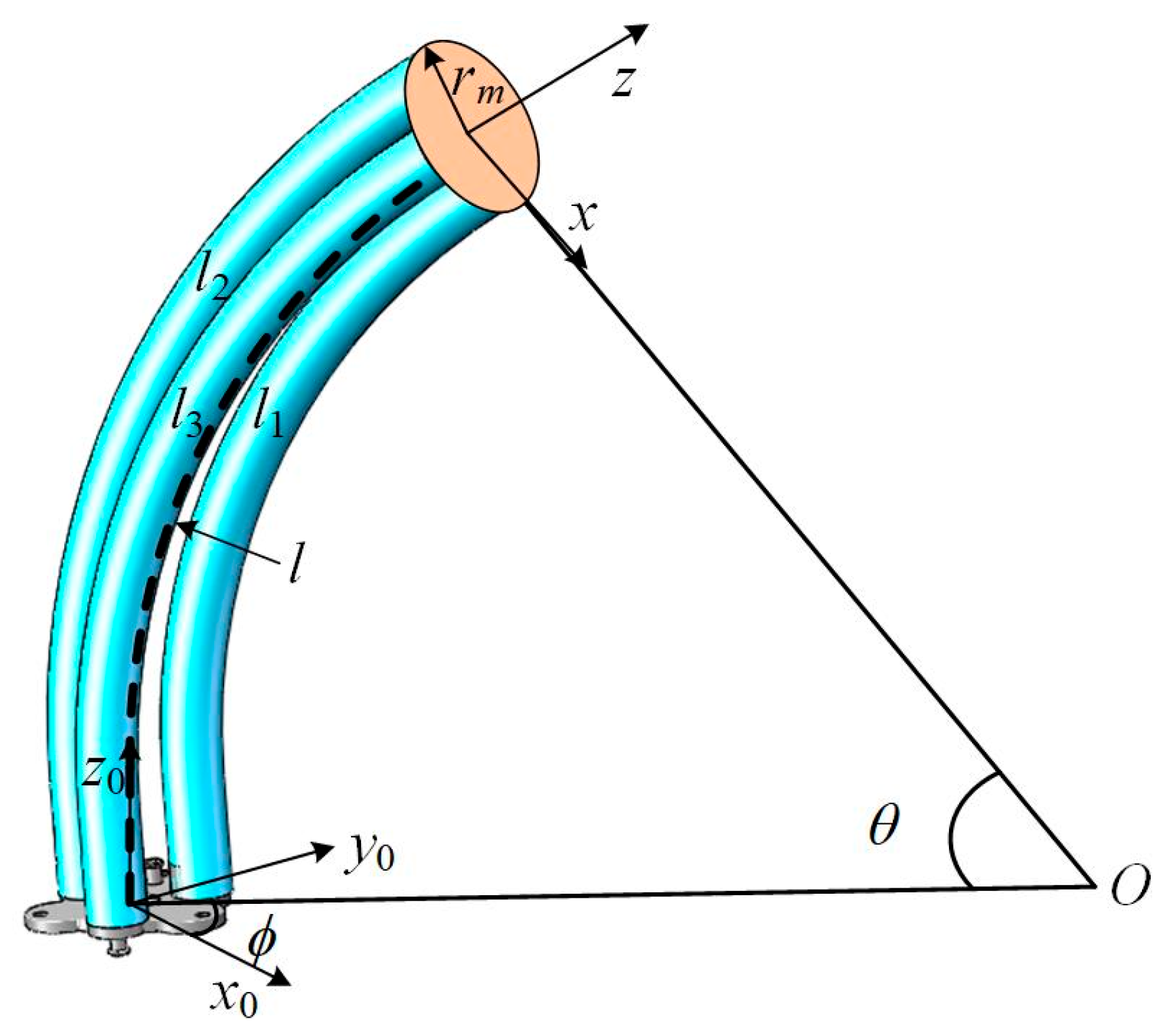

4. Kinematics Analysis of Woven Continuum Wrist

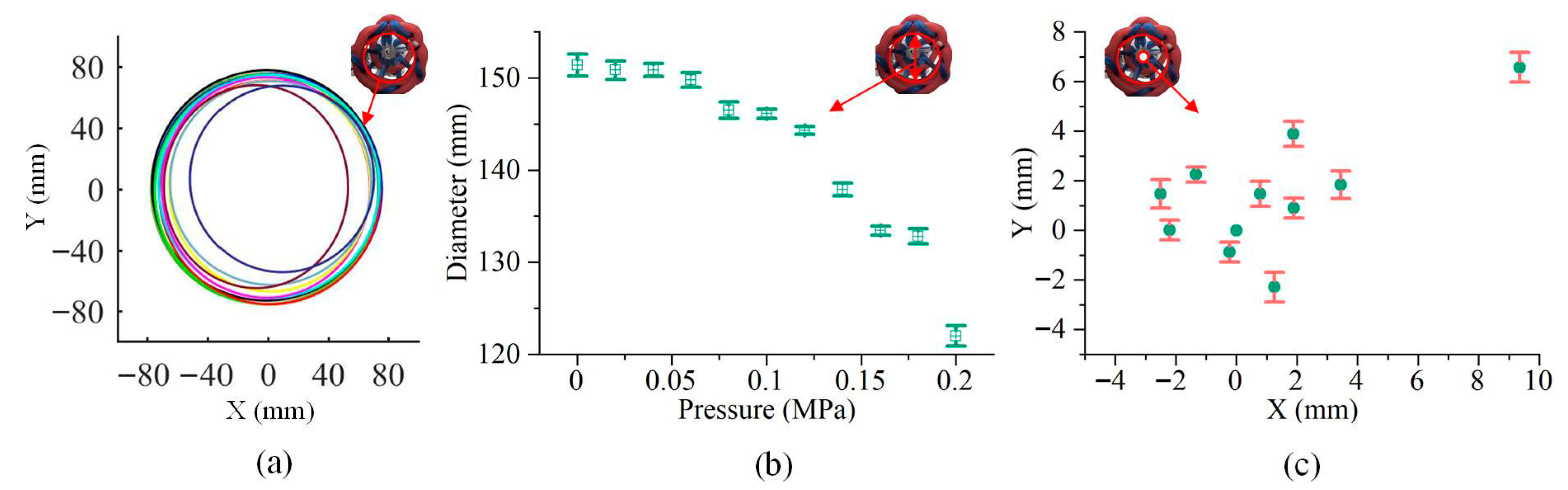

5. Experimental Testing

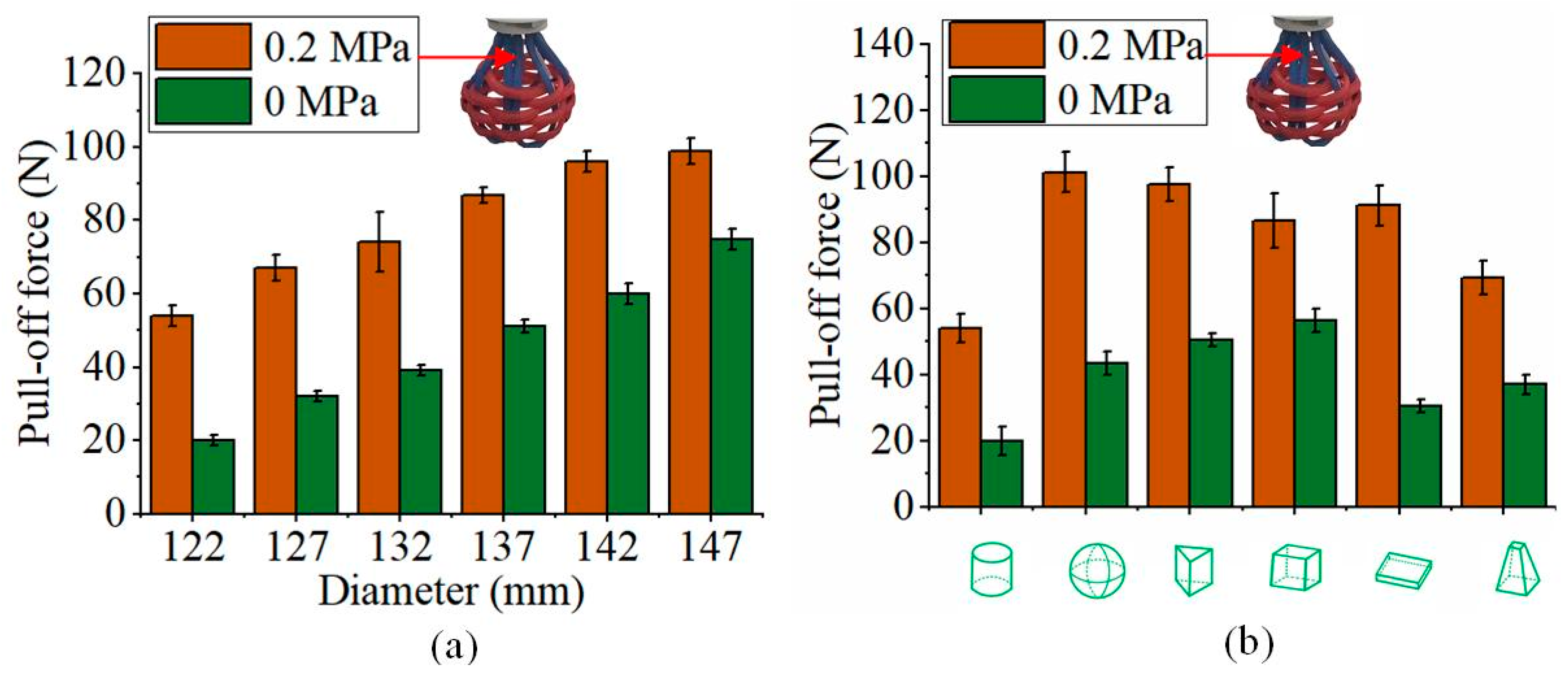

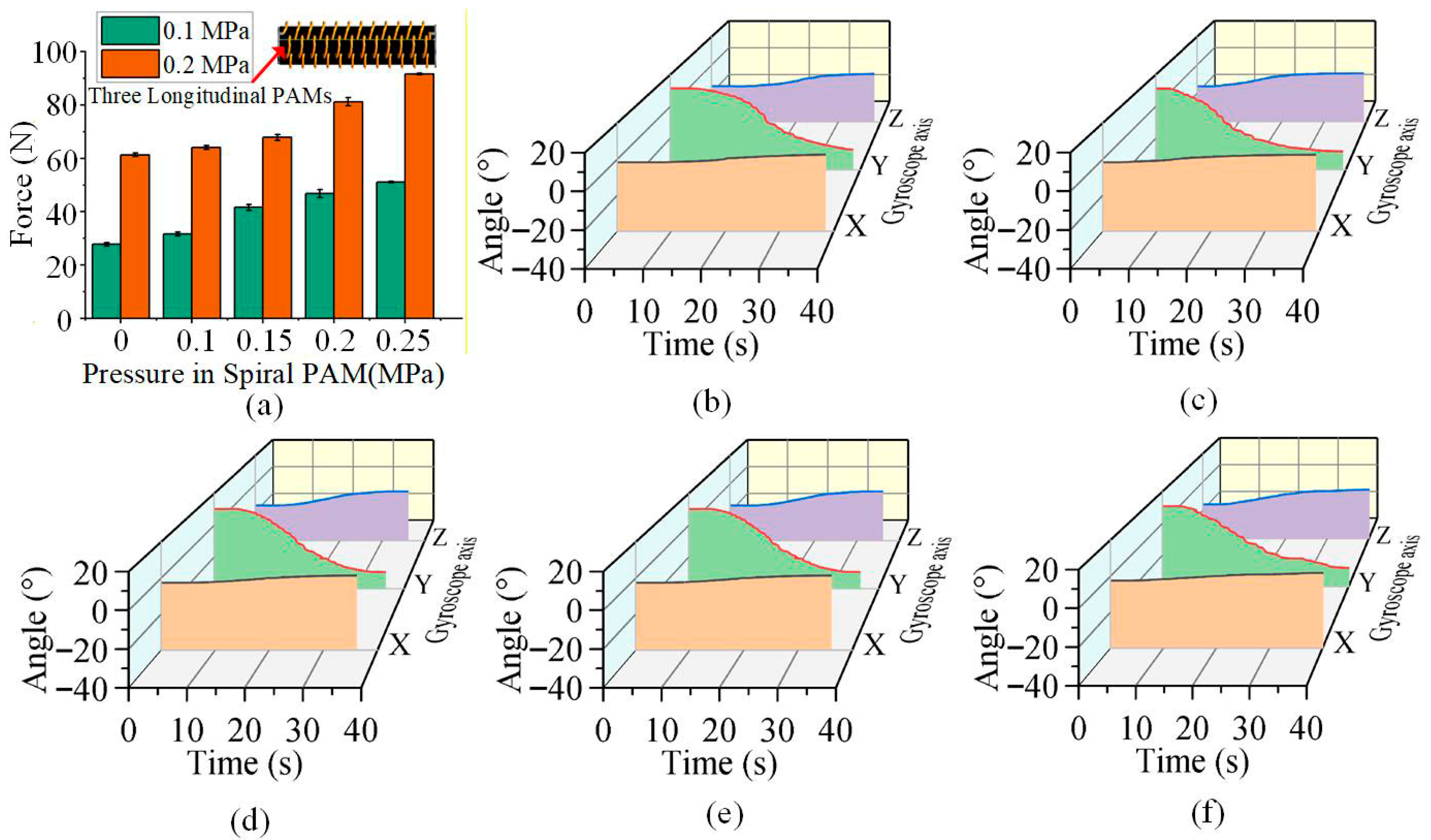

5.1. Stiffness Testing of Enclosed Soft Gripper

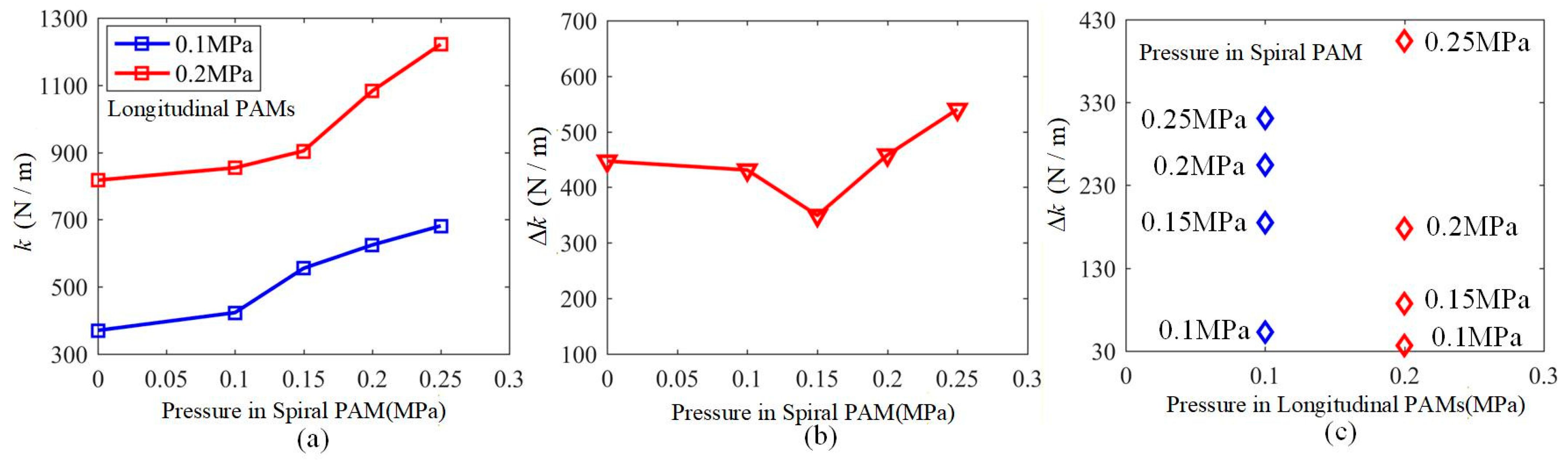

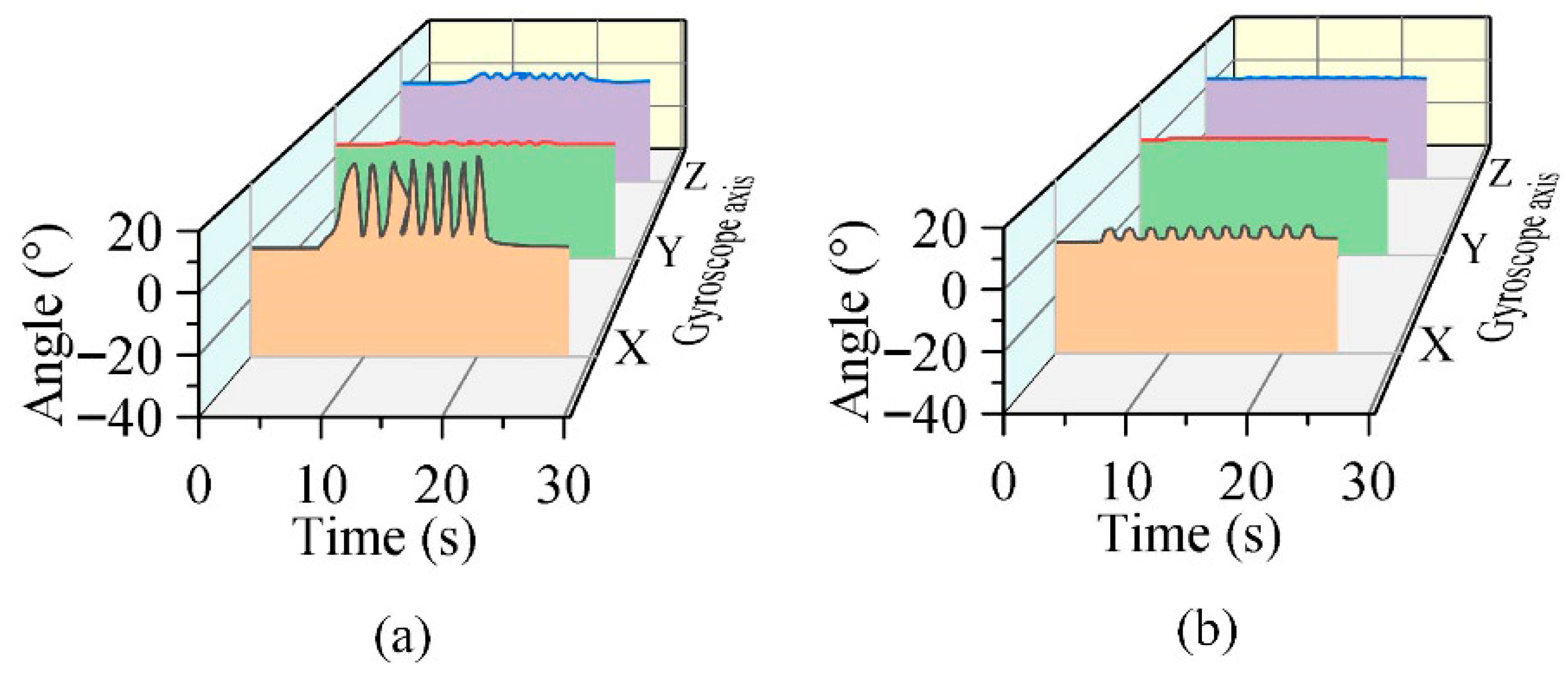

5.2. Stiffness Testing of Woven Continuum Wrist

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tsukagoshi, H.; Kitagawa, A.; Segawa, M. Active Hose: An artificial elephant’s nose with maneuverability for rescue operation. In Proceedings of the IEEE International Conference on Robotics and Automation, Seoul, Republic of Korea, 21–26 May 2001; IEEE: Seoul, Republic of Korea, 2001; pp. 2454–2459. [Google Scholar]

- Kim, Y.; Cheng, S.S.; Diakite, M.; Gullapalli, R.P.; Simard, J.M.; Desai, J.P. Toward the Development of a Flexible Mesoscale MRI-Compatible Neurosurgical Continuum Robot. IEEE Trans. Robot. 2017, 33, 1386–1397. [Google Scholar] [CrossRef]

- Xu, K.; Zhao, J.; Fu, M. Development of the SJTU Unfoldable Robotic System (SURS) for Single Port Laparoscopy. IEEE/ASME Trans. Mechatron. 2015, 20, 2133–2145. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Cheng, S.; Kim, S.; Iagnemma, K. A Novel Layer Jamming Mechanism with Tunable Stiffness Capability for Minimally Invasive Surgery. IEEE Trans. Robot. 2013, 29, 1031–1042. [Google Scholar] [CrossRef]

- Runciman, M.; Darzi, A.; Mylonas, G.P. Soft Robotics in Minimally Invasive Surgery. Soft Robot. 2019, 6, 423–443. [Google Scholar] [CrossRef]

- Tonapi, M.M.; Godage, I.S.; Walker, I.D. Next generation rope-like robot for in-space inspection. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2014; IEEE: Big Sky, MT, USA, 2014; pp. 1–13. [Google Scholar]

- Walker, I.D. Robot strings: Long, thin continuum robots. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 2–9 March 2013; IEEE: Big Sky, MT, USA, 2013; pp. 1–12. [Google Scholar]

- Buckingham, R.; Graham, A. Nuclear snake-arm robots. Ind. Robot Int. J. 2012, 39, 6–11. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Park, S.; Hwang, D.; Yang, S. Soft Robotic Palm with Tunable Stiffness Using Dual-Layered Particle Jamming Mechanism. IEEE/ASME Trans. Mechatron. 2021, 26, 1820–1827. [Google Scholar] [CrossRef]

- Jiang, P.; Yang, Y.; Chen, M.Z.; Chen, Y. A variable stiffness gripper based on differential drive particle jamming. Bioinspir. Biomim. 2019, 14, 036009. [Google Scholar] [CrossRef] [PubMed]

- Jiang, A.; Ranzani, T.; Gerboni, G.; Lekstutyte, L.; Althoefer, K.; Dasgupta, P.; Nanayakkara, T. Robotic Granular Jamming: Does the Membrane Matter? Soft Robot. 2014, 1, 192–201. [Google Scholar] [CrossRef]

- Do, B.H.; Choi, I.; Follmer, S. An all-soft variable impedance actuator enabled by embedded layer jamming. IEEE/ASME Trans. Mechatron. 2022, 27, 5529–5540. [Google Scholar] [CrossRef]

- Bamotra, A.; Walia, P.; Prituja, A.V.; Ren, H. Layer-Jamming Suction Grippers with Variable Stiffness. J. Mech. Robot. 2019, 11, 035003. [Google Scholar] [CrossRef]

- Liu, C.; Li, Z.Y.; Chen, H.L. A novel flexible electrostatic adsorption variable stiffness structure. J. Xi’an Jiaotong Univ. 2018, 52, 23–29. [Google Scholar]

- Wang, T.; Zhang, J.; Li, Y.; Hong, J.; Wang, M.Y. Electrostatic Layer Jamming Variable Stiffness for Soft Robotics. IEEE/ASME Trans. Mechatron. 2019, 24, 424–433. [Google Scholar] [CrossRef]

- Miller-Jackson, T.; Sun, Y.; Natividad, R.; Yeow, C.H. Tubular Jamming: A Variable Stiffening Method Toward High-Force Applications with Soft Robotic Components. Soft Robot. 2020, 6, 468–482. [Google Scholar] [CrossRef]

- Al Abeach, L.A.; Nefti-Meziani, S.; Davis, S. Design of a Variable Stiffness Soft Dexterous Gripper. Soft Robot. 2017, 4, 274–284. [Google Scholar] [CrossRef]

- Al-Fahaam, H.; Nefti-Meziani, S.; Theodoridis, T.; Davis, S. The design and mathematical model of a novel variable stiffness extensor-contractor pneumatic artificial muscle. Soft Robot. 2018, 5, 576–591. [Google Scholar] [CrossRef] [PubMed]

- Xiang, C.; Li, W.; Guan, Y. A Variable Stiffness Electroadhesive Gripper Based on Low Melting Point Alloys. Polymers 2022, 14, 4469. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.F.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-response, stiffness-tunable soft actuator by hybrid multimaterial 3D printing. Adv. Funct. Mater. 2019, 29, 1806698. [Google Scholar] [CrossRef]

- Xing, T.; He, A.; Huang, Z.; Luo, Y.; Zhang, Y.; Wang, M.; Shi, Z.; Ke, G.; Bai, J.; Zhao, S.; et al. Silk-based ffexible electronics and smart wearable textiles: Press and beyond. Chem. Eng. J. 2023, 474, 145534. [Google Scholar] [CrossRef]

- Lugger, S.J.; Engels, T.A.; Cardinaels, R.; Bus, T.; Mulder, D.J.; Schenning, A.P. Melt-Extruded Thermoplastic Liquid Crystal Elastomer Rotating Fiber Actuators. Adv. Funct. Mater. 2023, 33, 2306853. [Google Scholar] [CrossRef]

- Weichart, J.; Sivananthaguru, P.; Coulter, F.B.; Burger, T.; Hierold, C. Artificial Fingertip with Embedded Fiber-Shaped Sensing Arrays for High Resolution Tactile Sensing. Soft Robot. 2024, 11, 573–584. [Google Scholar] [CrossRef]

- Jones, B.; Walker, I. Kinematics for multisection continuum robots. IEEE Trans. Robot. 2006, 22, 43–55. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, P.; Liu, Y.; Chen, J.; Chen, H.; Li, H.; Yao, J. A Woven Soft Wrist-Gripper Composite End-Effector with Variable Stiffness: Design, Modeling, and Characterization. Machines 2025, 13, 1042. https://doi.org/10.3390/machines13111042

Zhou P, Liu Y, Chen J, Chen H, Li H, Yao J. A Woven Soft Wrist-Gripper Composite End-Effector with Variable Stiffness: Design, Modeling, and Characterization. Machines. 2025; 13(11):1042. https://doi.org/10.3390/machines13111042

Chicago/Turabian StyleZhou, Pan, Yangzuo Liu, Junxi Chen, Haoyuan Chen, Haili Li, and Jiantao Yao. 2025. "A Woven Soft Wrist-Gripper Composite End-Effector with Variable Stiffness: Design, Modeling, and Characterization" Machines 13, no. 11: 1042. https://doi.org/10.3390/machines13111042

APA StyleZhou, P., Liu, Y., Chen, J., Chen, H., Li, H., & Yao, J. (2025). A Woven Soft Wrist-Gripper Composite End-Effector with Variable Stiffness: Design, Modeling, and Characterization. Machines, 13(11), 1042. https://doi.org/10.3390/machines13111042