Application of Sawdust-Derived Activated Carbon as a Bio-Based Filler in Vulcanized Rubber Bushings

Abstract

1. Introduction

2. Methods

2.1. Instrumentation

2.2. Materials and Specifications

2.3. Experimental Design

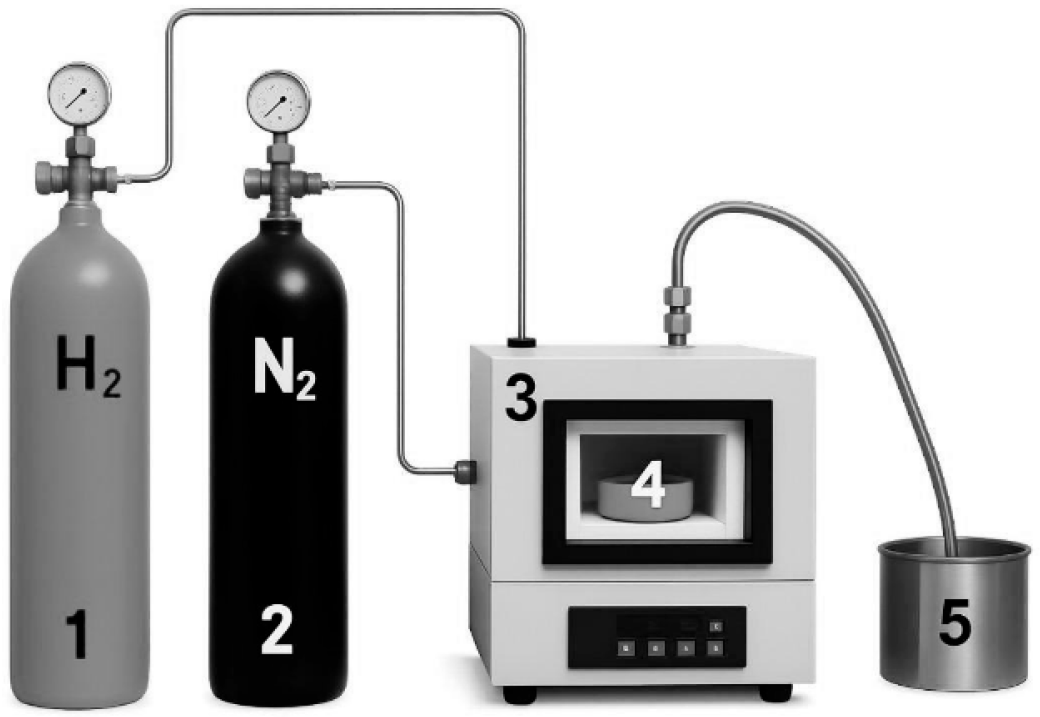

2.3.1. Preparation of Activated Charcoal

2.3.2. Rubber Compounding Procedure

2.3.3. Vulcanization

2.4. Test Method

2.4.1. FTIR Spectroscopy

2.4.2. Curing Characteristics

2.4.3. Mechanical Testing Procedures

3. Results and Discussion

3.1. FTIR Analysis of Sawdust-Based Activated Carbon

3.2. Curing Characteristics of Natural Rubber Compounds

3.3. Mechanical Properties and Performance Analysis

3.3.1. Hardness

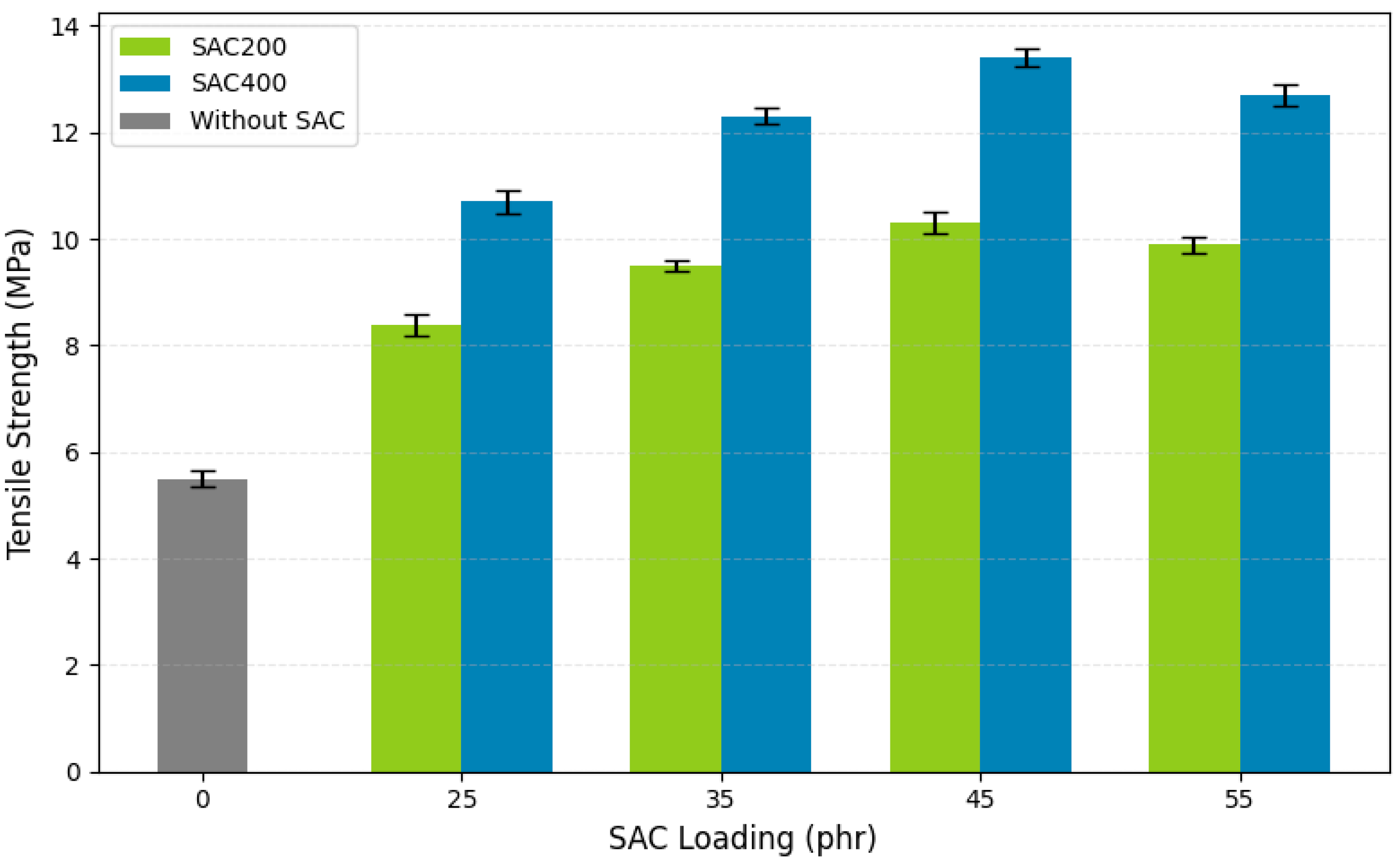

3.3.2. Tensile Strength

3.3.3. Elongation at Break

3.3.4. Compression Set

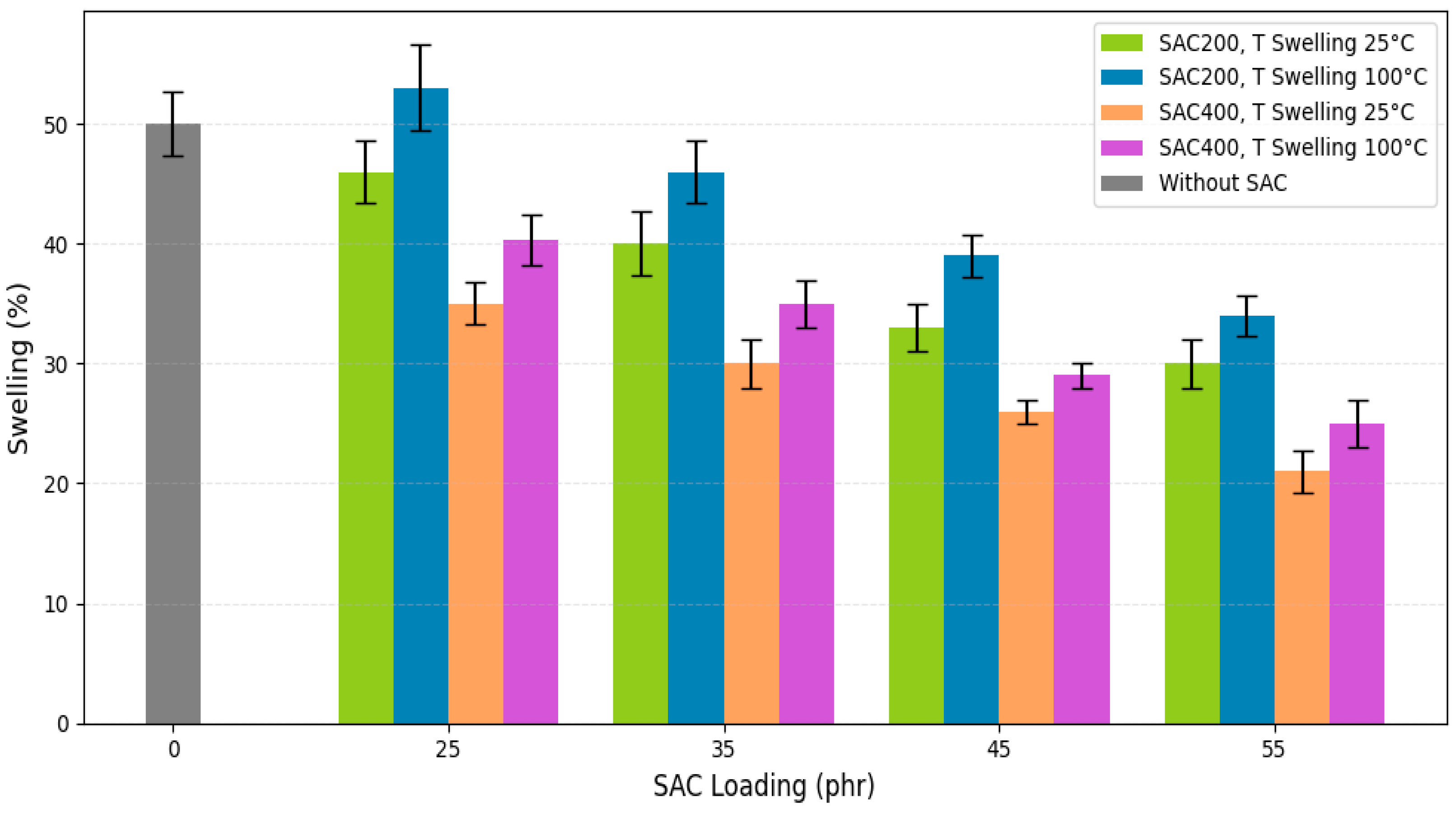

3.3.5. Swelling Behavior

4. Conclusions

- (1)

- Sawdust-derived activated carbon (SAC) successfully incorporates oxygenated and aromatic functional groups, as confirmed by FTIR and XPS.

- (2)

- The addition of SAC improves the hardening properties, tensile strength, modulus, hardness, and tear resistance of NR vulcanizates.

- (3)

- SAC200 retains more oxygenated groups, enhancing interfacial interactions, while SAC400 increases stiffness due to the increase in aromatic domains.

- (4)

- Compared with conventional carbon black and other biomass-derived fillers, SAC exhibits superior sustainability and reinforcement potential.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NR | Natural rubber |

| SAC | Sawdust-derived activated carbon |

| VRB | vulcanized rubber bushings |

| SAC200 | Activated carbon derived from sawdust with a particle size of 75 µm, carbonized at a temperature of 200 °C |

| SAC400 | Activated carbon derived from sawdust with a particle size of 38 µm, carbonized at a temperature of 400 °C |

| ZnO | Zinc Oxide |

| CBS | N-Cyclohexyl2-benzothiazole sulfenamide |

| TMTD | Tetramethyl thiuram disulfide |

| MNR | Maleated natural rubber |

| SIR-20 | Standar Indonesia Rubber |

| TMQ | Polymerized 2,2,4-trimethyl-1,2-dihydroquinoline |

| 6PPD | N-(1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine |

| PVI | Pre-Vulcanization Inhibitor |

| H3PO4 | Phosphoric Acid |

| CB | Carbon black |

| H2 | Hydrogen |

| N2 | Nitrogen |

| FTIR | Fourier transform infrared |

| ATR | Attenuated Total Reflectance |

| MDR | Moving Die Rheometer |

| CRI | Cure rate index |

| ASTM | American Society for Testing and Material |

| W | Weight |

| Mpa | Megapascal |

| °C | Degrees Celsius |

| % | Percent |

| Mikrometer | µm |

| kgf | Kilogram-force |

| cm | Centimeters |

| µm | micrometer |

| phr | parts per hundred of rubber |

| ts2 | Scorch time |

| t90 | Cure time |

| Smax | Maximum torque |

| Smin | Minimum torque |

| ΔS | Torque difference |

References

- Andler, R. Bacterial and enzymatic degradation of poly(cis-1,4-isoprene) rubber: Novel biotechnological applications. Biotechnol. Adv. 2020, 44, 107606. [Google Scholar] [CrossRef]

- Whba, R.; Su’ait, M.S.; Whba, F.; Sahinbay, S.; Altin, S.; Ahmad, A. Intrinsic challenges and strategic approaches for enhancing the potential of natural rubber and its derivatives: A review. Int. J. Biol. Macromol. 2024, 276, 133796. [Google Scholar] [CrossRef]

- Marrero Nunes, F.; Emmel Silva, A.L.; May, J.; da Silva Szarblewski, M.; Flemming, L.; Assmann, E.E.; Ribas Moraes, J.A.; Machado, Ê.L. Environmental impacts associated with the life cycle of natural rubbers: A review and scientometric analysis. Ind. Crops Prod. 2025, 224, 120350. [Google Scholar] [CrossRef]

- Dunuwila, P.; Rodrigo, V.H.L.; Goto, N. Sustainability of natural rubber processing can be improved: A case study with crepe rubber manufacturing in Sri Lanka. Resour. Conserv. Recycl. 2018, 133, 417–427. [Google Scholar] [CrossRef]

- Rahman, M.M.; Oßwald, K.; Reincke, K.; Langer, B. Influence of bio-based plasticizers on the properties of NBR materials. Materials 2020, 13, 2095. [Google Scholar] [CrossRef]

- Zhao, W.; He, J.; Yu, P.; Jiang, X.; Zhang, L. Recent progress in the rubber antioxidants: A review. Polym. Degrad. Stab. 2023, 207, 110223. [Google Scholar] [CrossRef]

- Yang, J.; Wang, F.; Liang, C.; Zhou, S.; Huang, J.; Zhao, G.; Liu, Y. Trans-1,4-poly(isoprene-co-butadiene) rubber enhances abrasion resistance in natural rubber and polybutadiene composites. Polymer 2025, 316, 127855. [Google Scholar] [CrossRef]

- Sethulekshmi, A.S.; Saritha, A.; Joseph, K. A comprehensive review on the recent advancements in natural rubber nanocomposites. Int. J. Biol. Macromol. 2022, 194, 819–842. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, G.W.; Kim, H.J.; Chung, K.; Jang, K.S. Effects of Filler Functionalization on Filler-Embedded Natural Rubber/Ethylene-Propylene-Diene Monomer Composites. Polymers 2022, 14, 3502. [Google Scholar] [CrossRef]

- Farida, E.; Bukit, N.; Ginting, E.M.; Bukit, B.F. The effect of carbon black composition in natural rubber compound. Case Stud. Therm. Eng. 2019, 16, 100566. [Google Scholar] [CrossRef]

- Mekbuntoon, P.; Kongpet, S.; Kaeochana, W.; Luechar, P.; Thongbai, P.; Chingsungnoen, A.; Chinnarat, K.; Kaewnisai, S.; Harnchana, V. The Modification of Activated Carbon for the Performance Enhancement of a Natural-Rubber-Based Triboelectric Nanogenerator. Polymers 2023, 15, 4562. [Google Scholar] [CrossRef]

- Cifriadi, A.; Sugita, P.; Wismogroho, A.S.; Kemala, T.; Nikmatin, S.; Widayatno, W.B.; Amal, M.I.; Jayadi; Firdharini, C.; Kinasih, N.A. Development and Characterization of Biomass-Based Biocarbon Fillers for Natural Rubber Composites. Int. J. Technol. 2025, 16, 982–992. [Google Scholar] [CrossRef]

- Adduci, R.; Vermaut, M.; Perrelli, M.; Cosco, F.; Vanpaemel, S.; Naets, F.; Mundo, D. A review of bushing modelling approaches for MultiBody simulations. Mech. Mach. Theory 2024, 191, 105496. [Google Scholar] [CrossRef]

- Guo, P.; Li, J.; Lin, Z.; Lin, J. Analysis and Optimization of Driveline Bushing for Lateral Ride Vibration under Shock Excitation. Appl. Sci. 2021, 11, 2647. [Google Scholar] [CrossRef]

- Ambarev, K.; Taneva, S. A Comparative Study of Vibrations in Front Suspension Components Using Bushings Made from Different Materials. Eng. Proc. 2025, 100, 42. [Google Scholar] [CrossRef]

- Dadkhah, M.; Messori, M. A comprehensive overview of conventional and bio-based fillers for rubber formulations sustainability. Mater. Today Sustain. 2024, 27, 100886. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; John, M.J. Bio-based fillers for environmentally friendly composites. Handb. Compos. Renew. Mater. 2017, 1–8, 243–270. [Google Scholar] [CrossRef]

- Wang, L.; Li, Q.; Jin, H.; Wang, J.; Wang, N.; Zhou, X. Research progress of bio-filler and its application in asphalt materials: Review and discussion. Clean Technol. Environ. Policy 2025. [Google Scholar] [CrossRef]

- Kiran, M.D.; Govindaraju, H.K.; Jayaraju, T.; Kumar, N. Review-Effect of Fillers on Mechanical Properties of Polymer Matrix Composites. Mater. Today Proc. 2018, 5, 22421–22424. [Google Scholar] [CrossRef]

- Haslilywaty, G.; Siti Fatma, A.K.; Roslim, R.; Mohibbah, M.; Jefri, J. Effect of bio fillers on mechanical properties of natural rubber latex films. Key Eng. Mater. 2019, 797, 249–254. [Google Scholar] [CrossRef]

- Joshi, M.; Dwivedi, C.; Manjare, S. A renewable cellulose-rich biofiller material extracted from waste banana stem fibers for reinforcing natural rubber composites. J. Mater. Sci. 2024, 59, 519–534. [Google Scholar] [CrossRef]

- Tong, H.S.; Kabeb, S.M.; Abd Hamid, H.; Zulkifli, F.H. A review of biodegradability of natural rubber products: Physicochemical, thermal and mechanical properties. Int. J. Biol. Macromol. 2025, 318, 144973. [Google Scholar] [CrossRef] [PubMed]

- Thomas, S.K.; Parameswaranpillai, J.; Krishnasamy, S.; Begum, P.M.S.; Nandi, D.; Siengchin, S.; George, J.J.; Hameed, N.; Salim, N.V.; Sienkiewicz, N. A comprehensive review on cellulose, chitin, and starch as fillers in natural rubber biocomposites. Carbohydr. Polym. Technol. Appl. 2021, 2, 100095. [Google Scholar] [CrossRef]

- Sahu, N. Walnut Shells ’ Potential Use as Biofillers in Natural Rubber Composites. Int. J. Polym. Sci. Eng. 2024, 10, 1–5. [Google Scholar]

- Kumar Mishra, R.; Singh, B.; Acharya, B. A comprehensive review on activated carbon from pyrolysis of lignocellulosic biomass: An application for energy and the environment. Carbon Resour. Convers. 2024, 7, 100228. [Google Scholar] [CrossRef]

- Eguare, K.O.; Ekabafe, L.O.; Ayo, M.D. Comparative Study of Acetylated Sawdust Powder as Filler in Natural Rubber Compounding. NIPES—J. Sci. Technol. Res. 2020, 2, 78–84. [Google Scholar]

- Negara, D.N.K.P.; Nindhia, T.G.T.; Kencanawati, C.I.P.K.; Suriadi, I.G.A.K.; Widiyarta, I.M.; Lokantara, I.P.; Budiarsa, I.N. The Effect of Carbonisation Heating Rates on the Properties of N-Doped Teak Sawdust Waste Activated Carbon. J. Phys. Sci. 2023, 34, 1–20. [Google Scholar] [CrossRef]

- Wang, A.; Wang, H.; Ling, C.; Wang, T.; Li, F.; Yang, S.; Zhao, M. Fatigue life prediction of rubber suspension bushings based on virtual road load spectrum pulses. Results Eng. 2024, 23, 102693. [Google Scholar] [CrossRef]

- Fan, Y.; Fowler, G.D.; Zhao, M. The past, present and future of carbon black as a rubber reinforcing filler—A review. J. Clean. Prod. 2020, 247, 119115. [Google Scholar] [CrossRef]

- Calaf-Chica, J.; Cea-González, V.; García-Tárrago, M.J.; Gómez-Gil, F.J. Fractional viscoelastic models for the estimation of the frequency response of rubber bushings based on relaxation tests. Results Eng. 2023, 20, 101465. [Google Scholar] [CrossRef]

- Ying, D.; Addimulam, S. Innovative Additives for Rubber: Improving Performance and Reducing Carbon Footprint. Asia Pac. J. Energy Environ. 2022, 9, 81–88. [Google Scholar] [CrossRef]

- Mohamad Aini, N.A.; Othman, N.; Hussin, M.H.; Sahakaro, K.; Hayeemasae, N. Lignin as Alternative Reinforcing Filler in the Rubber Industry: A Review. Front. Mater. 2020, 6, 329. [Google Scholar] [CrossRef]

- Oladimeji, T.E.; Odunoye, B.O.; Elehinafe, F.B.; Obanla, O.R.; Odunlami, O.A. Production of activated carbon from sawdust and its efficiency in the treatment of sewage water. Heliyon 2021, 7, e05960. [Google Scholar] [CrossRef]

- Gong, Y.; Chen, X.; Wu, W. Application of fourier transform infrared (FTIR) spectroscopy in sample preparation: Material characterization and mechanism investigation. Adv. Sample Prep. 2024, 11, 100122. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Nguyen, D.T.; Nguyen, T.T.; Nguyen, H.P.T.; Khuat, H.B.; Nguyen, T.H.; Tran, V.K.; Woong Chang, S.; Nguyen-Tri, P.; Nguyen, D.D.; et al. Activated carbon with ultrahigh surface area derived from sawdust biowaste for the removal of rhodamine B in water. Environ. Technol. Innov. 2021, 24, 101811. [Google Scholar] [CrossRef]

- Candau, N.; Fernández Navarrete, A.; Lara Casanova, G.; Utrera-Barrios, S.; Hernandez Santana, M.; Stoclet, G.; Maspoch, M.L. Control by the curing time of the strain induced crystallization and elastocaloric properties in natural rubber and natural/waste rubber blends. Polymers 2024, 312, 127628. [Google Scholar] [CrossRef]

- Poyraz, B. Poly(ethylene-co-(acrylic acid)) and maleic anhydride effect on micro crystalline cellulose and lignin-filled EPDM automotive sealing profiles. Int. J. Biol. Macromol. 2025, 297, 139602. [Google Scholar] [CrossRef]

- Liu, X.; Qi, R.; Liao, W.; Dai, B.; Liu, D.; Wang, Q. Shear-sensing characteristics and theoretical model analysis of multiwalled carbon nanotube/natural rubber composite. Compos. Commun. 2025, 53, 102215. [Google Scholar] [CrossRef]

- Methods, S.T. D395-14: Standard Test Methods for Rubber Property—Compression Set 1. Current 2003, 9, 1–6. [Google Scholar] [CrossRef]

- ASTM D471-16a; Standard Test Method for Rubber Property—Effect of Liquids. ASTM—Amereican Society for Testing and Materials: West Conshohocken, PA, USA, 2021; pp. 1–16.

- Darko, C. The link between swelling ratios and physical properties of EPDM rubber compound having different oil amounts. J. Polym. Res. 2022, 29, 325. [Google Scholar] [CrossRef]

- Joselin, J.; Benila, B.S.; Brintha, T.S.S.; Jeeva, S. Phytochemical profiling, FT-IR spectroscopy, and antioxidant evaluation of select Lamiaceae species. Intell. Pharm. 2025, 3, 111–117. [Google Scholar] [CrossRef]

- Rosson, E.; Sgarbossa, P.; Mozzon, M.; Venturino, F.; Bogialli, S.; Glisenti, A.; Talon, A.; Moretti, E.; Carturan, S.M.; Tamburini, S.; et al. Novel correlations between spectroscopic and morphological properties of activated carbons from waste coffee grounds. Processes 2021, 9, 1637. [Google Scholar] [CrossRef]

- Yang, S.Y.; Bai, B.C.; Kim, Y.R. Effective Surface Structure Changes and Characteristics of Activated Carbon with the Simple Introduction of Oxygen Functional Groups by Using Radiation Energy. Surfaces 2024, 7, 12–25. [Google Scholar] [CrossRef]

- Ilić, M.; Haegel, F.H.; Lolić, A.; Nedić, Z.; Tosti, T.; Ignjatović, I.S.; Linden, A.; Jablonowski, N.D.; Hartmann, H. Surface Functional Groups and Degree of Carbonization of Selected Chars from Different Processes and Feedstock. PLoS ONE 2022, 17, e0277365. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, S.; Tsuji, Y.; Yoshizawa, K. Role of Hydrogen-Bonding and OH-πInteractions in the Adhesion of Epoxy Resin on Hydrophilic Surfaces. ACS Omega 2020, 5, 26211–26219. [Google Scholar] [CrossRef] [PubMed]

- Saito, K.; Xu, T.; Ishikita, H. Correlation between C•O Stretching Vibrational Frequency and p KaShift of Carboxylic Acids. J. Phys. Chem. B 2022, 126, 4999–5006. [Google Scholar] [CrossRef]

- Kingkohyao, N.; Boonsiri, T.; Johns, J.; Nip, R.L.; Nakaramontri, Y. Synergistic effect of zinc ions from tire waste and modified zinc oxide on mechanical, thermo-mechanical and antibacterial properties in epoxidized natural rubber composites. Ind. Crops Prod. 2025, 225, 120577. [Google Scholar] [CrossRef]

- Qiu, C.; Jiang, L.; Gao, Y.; Sheng, L. Effects of oxygen-containing functional groups on carbon materials in supercapacitors: A review. Mater. Des. 2023, 230, 111952. [Google Scholar] [CrossRef]

- Hiranobe, C.T.; Ribeiro, G.D.; Torres, G.B.; Dos Reis, E.A.P.; Cabrera, F.C.; Job, A.E.; Paim, L.L.; Dos Santos, R.J. Cross-linked density determination of natural rubber compounds by different analytical techniques. Mater. Res. 2021, 24 (Suppl. S1), e20210041. [Google Scholar] [CrossRef]

- Wang, Y.; Su, S.; Liu, H.; Wang, R.; Liao, L.; Peng, Z.; Li, J.; Wu, H.; He, D. Effect of Proteins on the Vulcanized Natural Rubber Crosslinking Network Structure and Mechanical Properties. Polymer 2024, 16, 2957. [Google Scholar] [CrossRef]

- Yan, Z.; Zaoui, A.; Zaïri, F. Physical and mechanical properties of vulcanized and filled rubber at high strain rate. Chin. J. Phys. 2023, 86, 12–23. [Google Scholar] [CrossRef]

- Naik, P.; Pradhan, S.; Sahoo, P.; Acharya, S.K. Effect of filler loading on mechanical properties of natural carbon black reinforced polymer composites. Mater. Today Proc. 2019, 26, 1892–1896. [Google Scholar] [CrossRef]

- Aboughaly, M.; Babaei-Ghazvini, A.; Dhar, P.; Patel, R.; Acharya, B. Enhancing the Potential of Polymer Composites Using Biochar as a Filler: A Review. Polymer 2023, 15, 3981. [Google Scholar] [CrossRef] [PubMed]

- Sivaselvi, K.; Varma, V.S.; Harikumar, A.; Jayaprakash, A.; Sankar, S.; Krishna, C.Y.; Gopal, K. Improving the mechanical properties of natural rubber composite with carbon black (N220) as filler. Mater. Today Proc. 2020, 42, 921–925. [Google Scholar] [CrossRef]

- Li, G.; Iakunkov, A.; Boulanger, N.; Lazar, O.A.; Enachescu, M.; Grimm, A.; Talyzin, A.V. Activated carbons with extremely high surface area produced from cones, bark and wood using the same procedure. RSC Adv. 2023, 13, 14543–14553. [Google Scholar] [CrossRef]

- Ma, F.; Ding, S.; Ren, H.; Liu, Y. Sakura-based activated carbon preparation and its performance in supercapacitor applications. RSC Adv. 2019, 9, 2474–2483. [Google Scholar] [CrossRef]

- Alfatah, T.; Mistar, E.M.; Supardan, M.D. Porous structure and adsorptive properties of activated carbon derived from Bambusa vulgaris striata by two-stage KOH/NaOH mixture activation for Hg2+ removal. J. Water Process Eng. 2021, 43, 102294. [Google Scholar] [CrossRef]

- Mumtaz, N.; Li, Y.; Artiaga, R.; Farooq, Z.; Mumtaz, A.; Guo, Q.; Nisa, F.U. Fillers and methods to improve the effective (out-plane) thermal conductivity of polymeric thermal interface materials—A review. Heliyon 2024, 10, e25381. [Google Scholar] [CrossRef]

- Ren, X.; Barrera, C.S.; Tardiff, J.L.; Gil, A.; Cornish, K. Liquid guayule natural rubber, a renewable and crosslinkable processing aid in natural and synthetic rubber compounds. J. Clean. Prod. 2020, 276, 122933. [Google Scholar] [CrossRef]

- Gobetti, A.; Cornacchia, G.; La Monica, M.; Zacco, A.; Depero, L.E.; Ramorino, G. Assessment of the influence of electric arc furnace slag as a non-conventional filler for Nitrile Butadiene Rubber. Results Eng. 2023, 17, 100987. [Google Scholar] [CrossRef]

- Hu, Y.; Cai, Y.; Wei, J.; Yin, Z.; Fan, H. Design and preparation of novel silicon rubber with homogeneous crosslinking network and its application in high-performance SR/EPDM blend. Eur. Polym. J. 2023, 198, 112381. [Google Scholar] [CrossRef]

- Kratina, O.; Pöschl, M.; Stoček, R. The effect of apparent density of sulfidic crosslink and their chemical nature on self-heat build-up in carbon black filled Natural Rubber under cyclic mechanical loading. Polym. Degrad. Stab. 2024, 227, 110871. [Google Scholar] [CrossRef]

- Wu, J.; Chen, L.; Su, B.L.; Wang, Y.S. Evolution of Payne effect of silica-filled natural rubber in curing process. J. Rubber Res. 2019, 22, 127–132. [Google Scholar] [CrossRef]

- Lubura, J.; Kočková, O.; Strachota, B.; Bera, O.; Pavlova, E.; Pavličević, J.; Ikonić, B.; Kojić, P.; Strachota, A. Natural Rubber Composites Using Hydrothermally Carbonized Hardwood Waste Biomass as a Partial Reinforcing Filler—Part II: Mechanical, Thermal and Ageing (Chemical) Properties. Polymer 2023, 15, 2397. [Google Scholar] [CrossRef]

- Ajay, C.; Das Gupta, S.; Mukhopadhyay, R.; Chattopadhyay, D.; Das, M. Exploring crosslink density in rubber vulcanisates—A comprehensive analysis using a dynamic mechanical analyser and an insight into mechanical properties. J. Rubber Res. 2025, 28, 305–323. [Google Scholar] [CrossRef]

- Wang, W.; Yu, X.; Lai, C.; Li, G.; Zhu, P.; Sun, R. Systematic study of the effect of silane coupling agent on the hydrothermal aging resistance of the underfill epoxy resin and silica interface via molecular dynamics simulation. Appl. Surf. Sci. 2025, 688, 162313. [Google Scholar] [CrossRef]

- Wei, Y.; Jia, X.; Chen, Y.; Ji, J. Single step carbonating and activating fir sawdust to activated carbon by recyclable molten carbonates and steam. Sci. Total Environ. 2022, 818, 151778. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, Z.; Luan, Y.; Wu, S.; Wu, Y. Influence of carbon black surface characteristics on CB-NR interfacial interaction: Molecular simulation and experimental study. Compos. Part A Appl. Sci. Manuf. 2024, 182, 108198. [Google Scholar] [CrossRef]

- Azura, A.R.; Leow, S.L. Effect of carbon black loading on mechanical, conductivity and ageing properties of Natural Rubber composites. Mater. Today Proc. 2019, 17, 1056–1063. [Google Scholar] [CrossRef]

- Głowacka, K.; Klemenc, J.; Nagode, M.; Łagoda, T. Fatigue lifetime of rubber composites—State-of-the-art. Polym. Test. 2025, 143, 108713. [Google Scholar] [CrossRef]

- Sultana, S.; Munna, N.; Sakib, T.U.; Ahmed, N.; Akanda, M.R.; Saha, M.S.; Zaman, M.N. High performance activated carbon derived from sawdust: Preparation, characterizations, methyl orange removal and kinetics investigation. Biomass Convers. Biorefinery 2025, 15, 17295–17307. [Google Scholar] [CrossRef]

- Samal, S. Effect of shape and size of filler particle on the aggregation and sedimentation behavior of the polymer composite. Powder Technol. 2020, 366, 43–51. [Google Scholar] [CrossRef]

- Sittitanadol, I.O.; Srakeaw, N.L.O.; Somdee, P.; Chumsamrong, P.; Noyming, S.; Singsang, W.; Prasoetsopha, N. Utilizing Coconut Biochar as a Bio-reinforcing Agent in Natural Rubber Composites. Starch/Staerke 2024, 77, 2400168. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, K.; Feng, Y.; Liang, L.; Chi, M.; Zhang, Z.; Chen, X. Recent advances in thermal-conductive insulating polymer composites with various fillers. Compos. Part A Appl. Sci. Manuf. 2024, 178, 107998. [Google Scholar] [CrossRef]

- Kartal, İ.; Karagöz, İ. Enhancing natural rubber properties: A comprehensive study on the synergistic effects of wood sawdust and carbon black as fillers in rubber composites. Polym. Bull. 2025, 82, 2091–2109. [Google Scholar] [CrossRef]

- Amoke, A.; Tenebe, O.G.; Ayo, M.D. Comparison of Mechanical Properties of Natural Rubber Vulcanizates Filled with Hybrid Fillers (Carbon Black/Palm Kernel Shell and Palm Kernel Shell/Sandbox Seed Shell). Int. J. Res. Innov. Appl. Sci. 2021, 6, 2454–6194. [Google Scholar]

- He, S.; Zhang, F.; Liu, S.; Cui, H.; Chen, S.; Peng, W.; Chen, G.; Liao, X.; Liao, L. Influence of sizes of rubber particles in latex on mechanical properties of natural rubber filled with carbon black. Polymer 2022, 261, 125393. [Google Scholar] [CrossRef]

- Li, X.; Ding, Y.; Zhang, H.; He, T.; Hao, J.; Wu, J.; Wu, Y.; Bai, H. Pine sawdust derived ultra-high specific surface area activated carbon: Towards high-performance hydrogen storage and supercapacitors. Int. J. Hydrogen Energy 2024, 84, 623–633. [Google Scholar] [CrossRef]

- Bernal-Ortega, P.; Bernal, M.M.; González-Jiménez, A.; Posadas, P.; Navarro, R.; Valentín, J.L. New insight into structure-property relationships of natural rubber and styrene-butadiene rubber nanocomposites filled with MWCNT. Polymer 2020, 201, 122604. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Yu, X.; Zhang, H.; Yan, S. Study on the Use of CTAB-Treated Illite as an Alternative Filler for Natural Rubber. ACS Omega 2021, 6, 19017–19025. [Google Scholar] [CrossRef]

- Buaksuntear, K.; Panmanee, K.; Wongphul, K.; Lim-arun, P.; Jansinak, S.; Shah, D.U.; Smitthipong, W. Enhancing mechanical properties and stabilising the structure of epoxide natural rubber using non-covalent interactions: Metal–ligand coordination and hydrogen bonding. Polymer 2024, 291, 126626. [Google Scholar] [CrossRef]

- Mensah, B.; Onwona-Agyeman, B.; Nsaful, F.; Aboagye, I.A.; Sowah, N.L.; Angnunavuri, P.N.; Apalangya, V.A. Vulcanization kinetics and reinforcement behaviour of natural rubber-carbon black composites: Addition of Shea-butter versus aromatic oil as plasticizers. Heliyon 2024, 10, e25592. [Google Scholar] [CrossRef]

- Zedler, L.; Colom, X.; Cañavate, J.; Saeb, M.R.; Haponiuk, J.T.; Formela, K. Investigating the impact of curing system on structure-property relationship of natural rubber modified with brewery by-product and ground tire rubber. Polymer 2020, 12, 545. [Google Scholar] [CrossRef]

| No | Equipment | Specifications |

|---|---|---|

| 1 | Muffle Furnace (Nabertherm GmbH, Lilienthal, Germany) | Max Temp: 1700 °C; Volume: 0.15 ft3; Heating Elements: MoSi2; Controller: Shimaden FP93 |

| 2 | XK-160 Open Mill (Qingdao Ouli Machine Co., Ltd., Qingdao, China) | Roll Ø: 160 mm; Working length: 320 mm; Motor: 7.5 kW |

| 3 | Hydraulic Press (HTM10042T, Toyo Seiki Seisaku-sho, Ltd., Tokyo, Japan) | Pressure: 100 Ton; Platens: 2 levels; Temp: up to 300 °C |

| 4 | Digital Scale (Ohaus Corporation, Parsippany, NJ, USA) | Capacity: 5 kg; Resolution: 0.1 g; LCD display |

| No | Chemical Name | Source and Specifications |

|---|---|---|

| 1 | Natural Rubber (SIR-20) | PT. Prasidha Aneka Niaga Tbk, Indonesia; Compliant with SNI 1903:2017 (Ash: 0.25%, Dirt: 0.042%, Nitrogen: 0.24%, Volatile matter: 0.2%, PRI: 65%, Mooney viscosity: 70) |

| 2 | SAC200 (75 µm), SAC400 (38 µm) | Local supplier, Palembang, Indonesia |

| 3 | Zinc oxide (ZnO) | Shanghai, China; CAS No.: 1314-13-2; Purity: 99.7% |

| 4 | Stearic acid | Guangdong, China; CAS No.: 57-11-4; Purity: 99% |

| 5 | TMTD | Jiangsu, China; CAS No.: 137-26-8; Purity: 98% |

| 6 | CBS | Fujian, China; CAS No.: 95-33-2; Purity: 96% |

| 7 | TMQ | Hunan, China; CAS No.: 793-47-8; Purity: 99.9% |

| 8 | Paraffin oil (PO-60) | PT. Pertamina, Indonesia |

| 9 | 6PPD | China; CAS No.: 793-24-8; Purity: 96% |

| 10 | PVI | Henan, China; CAS No.: 17796-82-6; Purity: 99% |

| 11 | Maleated Natural Rubber (MNR) | Local supplier |

| 12 | Phosphoric Acid (H3PO4) | Zhejiang, China; Purity: 85% |

| 13 | Sulfur | Tamil Nadu, India; CAS No.: 7704-34-9; Purity: 99.5% |

| 14 | Engine Oil 10W/40 4T | Local supplier, Indonesia |

| Parameter | Content |

|---|---|

| Water content | 6.24% |

| Ash content | 7.36% |

| Volatile matter | 11.34% |

| Carbon | 87.85% |

| Absorption of iodine | 1161.34 mg/g |

| Material | Formula (Per Hundred Rubber, phr) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| SIR 20 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| ZnO | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Stearic acid | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 6PPD | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| TMQ | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| SAC200 | - | 25 | 35 | 45 | 55 | - | - | - | - |

| SAC400 | - | - | - | - | - | 25 | 35 | 45 | 55 |

| Minarex oil | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| CBS | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| TMTD | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| MNR | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Sulfur | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| PVI | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Sample | Loading (phr) | Curing Characteristic | |||||

|---|---|---|---|---|---|---|---|

| Smax (N·m) | Smin (N·m) | Smax − Smin (N·m) | Opt Cure Time (tc90) (min; s) | Scorch Time (ts2) (min; s) | CRI (s−1) | ||

| NR/CB Without filler | 0 | 3.683 | 0.874 | 2.810 | 12:35 | 6:79 | 0.316 |

| Without filler | 0 | 3.451 | 0.796 | 2.655 | 15:59 | 8:45 | 0.230 |

| SAC200 (75 µm) | 25 | 3.037 | 0.610 | 2.427 | 15:29 | 8:02 | 0.223 |

| 35 | 3.065 | 0.584 | 2.480 | 14:45 | 7:56 | 0.244 | |

| 45 | 3.143 | 0.512 | 2.631 | 13:57 | 7:25 | 0.255 | |

| 55 | 3.247 | 0.708 | 2.539 | 13:07 | 7:10 | 0.273 | |

| Without filler | 0 | 3.451 | 0.796 | 2.655 | 15:59 | 8:45 | 0.230 |

| SAC400 (38 µm) | 25 | 3.241 | 0.775 | 2.466 | 14:57 | 7:47 | 0.233 |

| 35 | 3.526 | 0.834 | 2.693 | 13:15 | 7:00 | 0.267 | |

| 45 | 3.722 | 0.847 | 2.874 | 12:28 | 6:46 | 0.292 | |

| 55 | 3.733 | 0.884 | 2.850 | 11:05 | 5:58 | 0.326 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wulandari, E.P.; Marlina, P.; Nasruddin; Lanjar; Yohanes, H.; Widodo, W.E.; Munarso, S.J.; Astuti; Susetyo, E.B.; Bakhtiar, Y.; et al. Application of Sawdust-Derived Activated Carbon as a Bio-Based Filler in Vulcanized Rubber Bushings. Polymers 2025, 17, 2996. https://doi.org/10.3390/polym17222996

Wulandari EP, Marlina P, Nasruddin, Lanjar, Yohanes H, Widodo WE, Munarso SJ, Astuti, Susetyo EB, Bakhtiar Y, et al. Application of Sawdust-Derived Activated Carbon as a Bio-Based Filler in Vulcanized Rubber Bushings. Polymers. 2025; 17(22):2996. https://doi.org/10.3390/polym17222996

Chicago/Turabian StyleWulandari, Enasty Pratiwi, Popy Marlina, Nasruddin, Lanjar, Heryoki Yohanes, Wahju Eko Widodo, S. Joni Munarso, Astuti, Eko Bhakti Susetyo, Yenni Bakhtiar, and et al. 2025. "Application of Sawdust-Derived Activated Carbon as a Bio-Based Filler in Vulcanized Rubber Bushings" Polymers 17, no. 22: 2996. https://doi.org/10.3390/polym17222996

APA StyleWulandari, E. P., Marlina, P., Nasruddin, Lanjar, Yohanes, H., Widodo, W. E., Munarso, S. J., Astuti, Susetyo, E. B., Bakhtiar, Y., Guo, H., & Setianto, W. B. (2025). Application of Sawdust-Derived Activated Carbon as a Bio-Based Filler in Vulcanized Rubber Bushings. Polymers, 17(22), 2996. https://doi.org/10.3390/polym17222996