Recent Design and Application Advances in Micro-Electro-Mechanical System (MEMS) Electromagnetic Actuators

Abstract

1. Introduction

2. MEMS Electromagnetic Actuator Designs

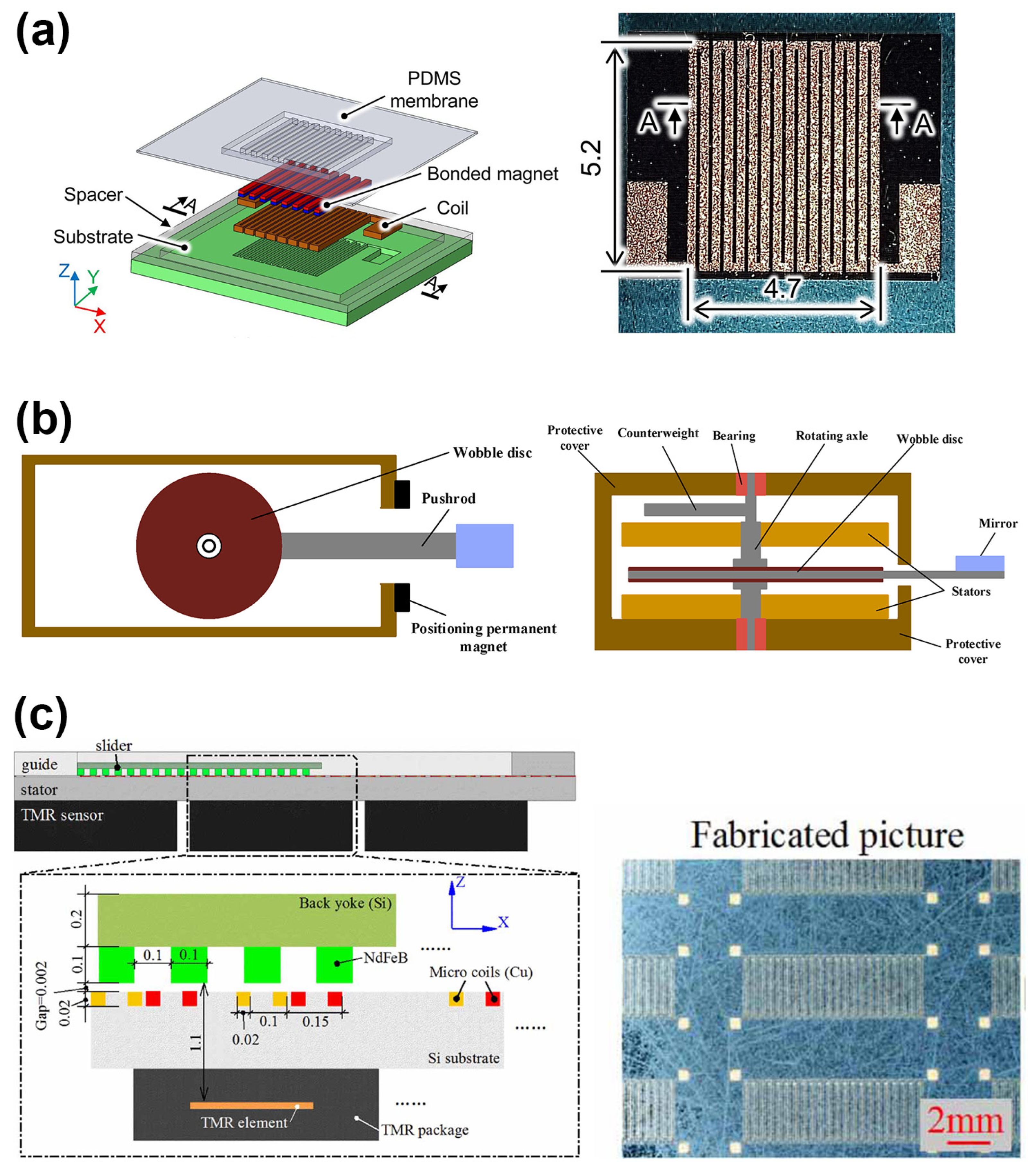

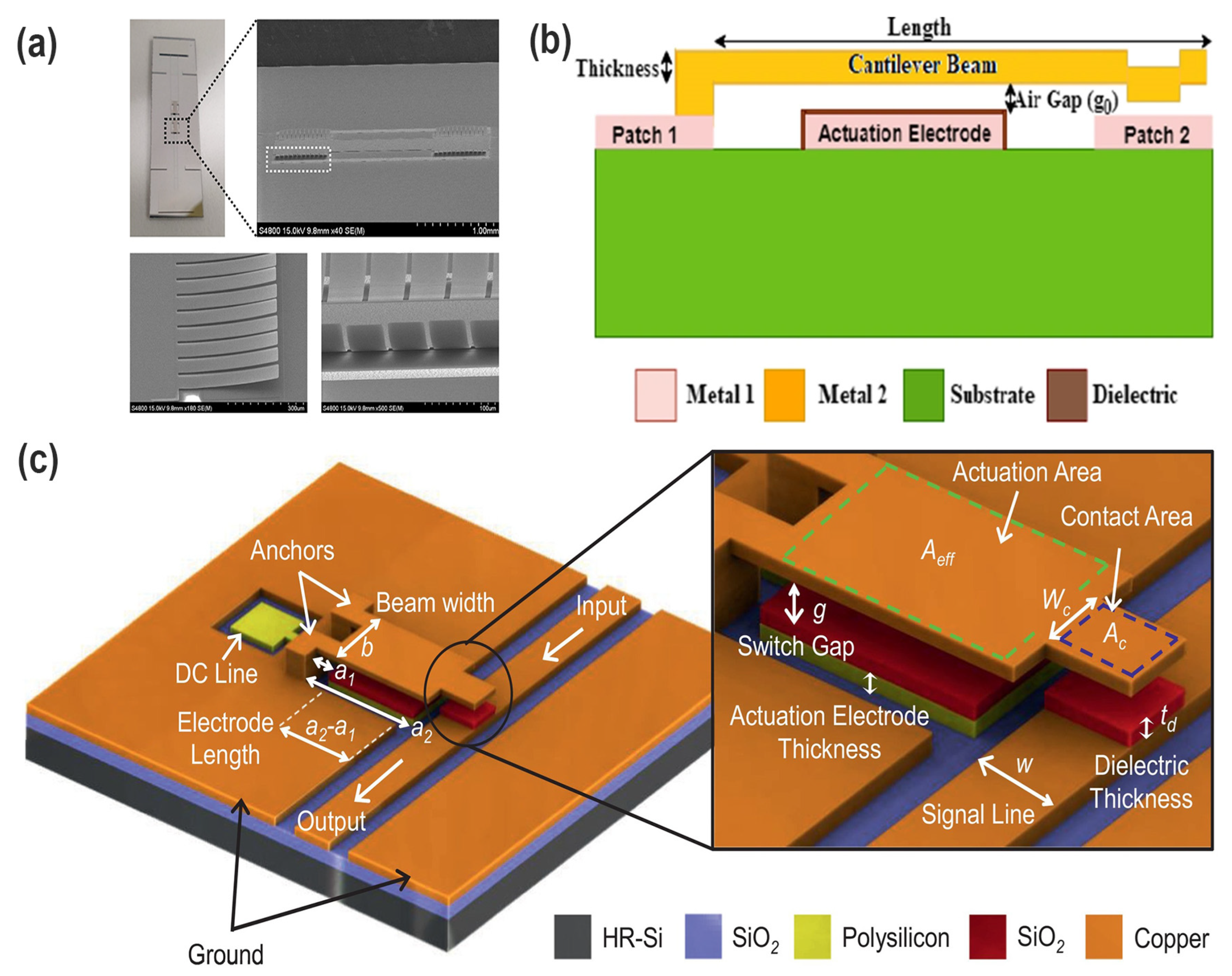

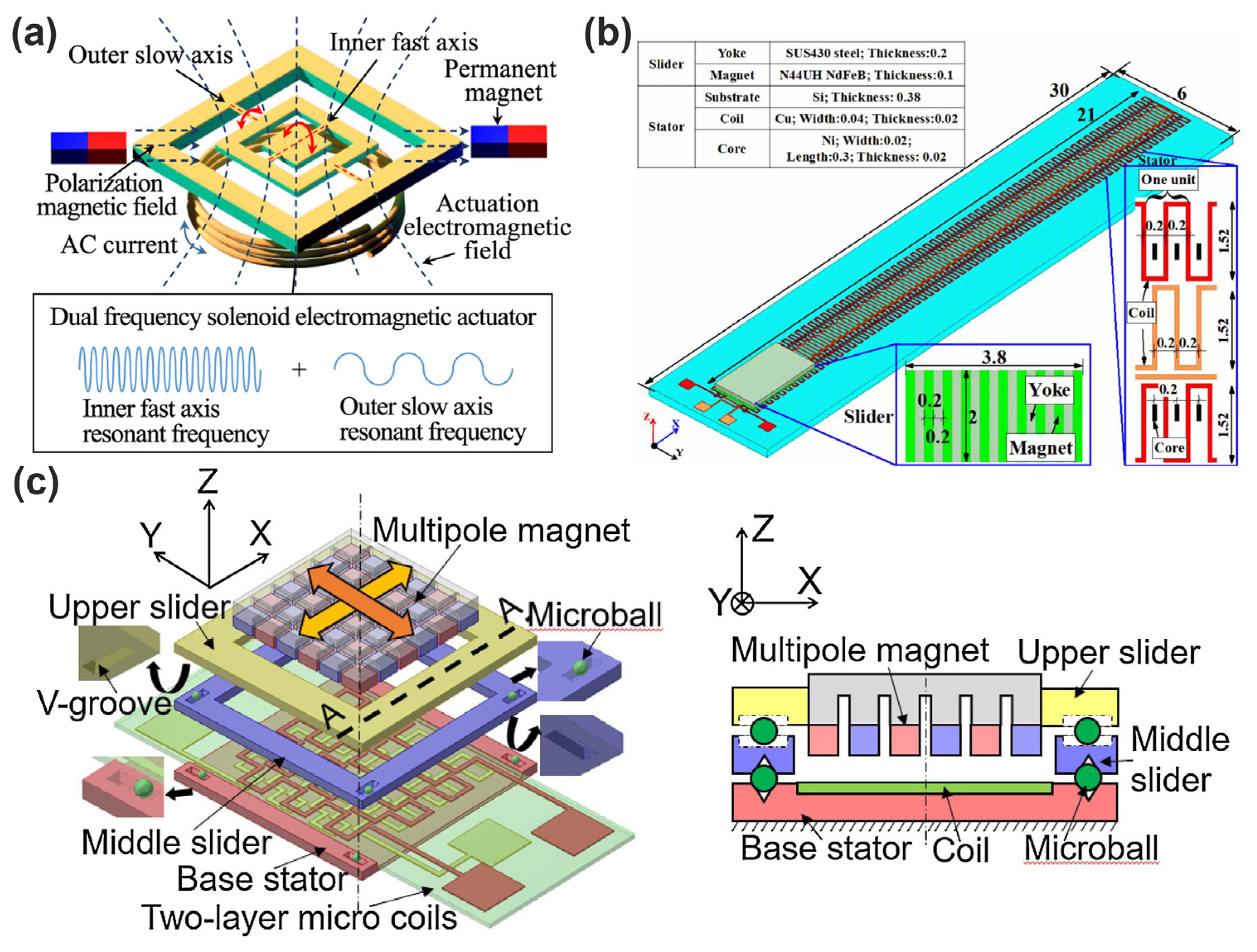

2.1. Lorentz Force Actuators

2.2. Magnetic Attraction/Repulsion Actuators

2.3. Typical Design Configurations and Geometries

3. Fabrication Techniques and Technological Advances

3.1. MEMS Fabrication Methods Relevant to Electromagnetic Actuators

3.2. Smart and Adaptive Actuator Systems

4. Key Applications

4.1. Micro-Optical Systems and Micromirrors

4.2. Microrobotics and Precision Micromanipulation

4.3. Microfluidic Components

5. Conclusions

Funding

Conflicts of Interest

References

- Mao, G.; Drack, M.; Karami-Mosammam, M.; Wirthl, D.; Stockinger, T.; Schwödiauer, R.; Kaltenbrunner, M. Soft Electromagnetic Actuators. Sci. Adv. 2020, 6. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Nabavi, S.; Rabih, A.A.S.; Menard, M.; Nabki, F. Hybrid MEMS Actuator With 3 Degrees-of- Freedom for Efficient Planar Optical Switching. J. Microelectromech. Syst. 2023, 32, 593–603. [Google Scholar] [CrossRef]

- Lv, S.; Feng, H.; Lou, W.; Xiao, C.; Kan, W.; Su, W.; Wang, J.; Ji, T. Design and Process of Force-Electric Fusion for Electromagnetic Driven Si Based MEMS S&A. J. Phys. Conf. Ser. 2024, 2740. [Google Scholar] [CrossRef]

- Ahmad, M.; Bahri, M.; Sawan, M. MEMS Micromirror Actuation Techniques: A Comprehensive Review of Trends, Innovations, and Future Prospects. Micromachines 2024, 15. [Google Scholar] [CrossRef]

- Pruchnik, B.; Piasecki, T.; Orlowska, K.; Majstrzyk, W.; Sierakowski, A.; Gotszalk, T.; Rangelow, I. Study of the Efficiency of Microcantilevers: Cases of Electrothermal and Electromagnetic Actuation. J. Microelectromech. Syst. 2022, 31, 784–790. [Google Scholar] [CrossRef]

- Han, P.; Lu, F.; Gong, G.; Yang, H.; Han, D. A Bistable Four-Working-States Electromagnetic Mini Valve Based on Flexible Magnets for Pneumatic Soft Actuators. IEEE Trans. Ind. Electron. 2024, 71, 11061–11071. [Google Scholar] [CrossRef]

- Shi, X.; Yang, C.; Cai, K.; Wang, X.; Liu, Y.; Zhang, Z.; Yu, F.; Ji, B.; Meng, G. A Variable Stiffness Methodology to Extend Travel Range of Micro Electromagnetic Actuators. IEEE Magn. Lett. 2024, 15. [Google Scholar] [CrossRef]

- Lecerf, I.; Angulo-Cervera, J.E.; Orlandini-Keller, F.; Moritz, P.; Mathieu, F.; Bourrier, D.; Charlot, S.; Nicu, L.; Leïchlé, T.; Devillers, T.; et al. A MEMS Electromagnetic Vibration Energy Harvester with Monolithically Integrated NdFeB Micromagnets. Adv. Mater. Technol. 2025, 2401817. [Google Scholar] [CrossRef]

- Zhu, K.; Li, H.; Zhao, W.; Zhang, X.; Li, S.; Zhang, K.; Xu, T. A Millimeter-Scale Micro Crawling Robot with Fast-Moving Driven by a Miniature Electromagnetic Linear Actuator. Adv. Intell. Syst. 2024, 6. [Google Scholar] [CrossRef]

- Li, C.; Zheng, X.; Sun, Z.; Zhou, L.; Guo, X.; Huang, X.; Yang, B. Design and Demonstration of an Electromagnetic Force-Rebalanced Sub-10-Hz Interferometric MEMS Accelerometer. IEEE Trans. Instrum. Meas. 2023, 72. [Google Scholar] [CrossRef]

- Shi, X.; Ren, C.; Li, Y.; Ding, G. Design, Modeling, and Optimization of a Bistable Electromagnetic Actuator with Large Deflection. IEEE Magn. Lett. 2021, 12. [Google Scholar] [CrossRef]

- Takeshita, T.; Nguyen, T.V.; Daniel, Z.; Takei, Y.; Kobayashi, T. Mechanical Characteristics of Laminated Film Vibrator Using an Ultra-Thin MEMS Actuator. J. Micromech. Microeng. 2022, 32. [Google Scholar] [CrossRef]

- Qi, C.; Miyahara, Y.; Wang, Z.; Sugita, N.; Nakano, M.; Shinshi, T. An Electromagnetic Microactuator with Tunable Dynamic Characteristics Using a Thick-Film FePt Permanent Magnet. AIP Adv. 2024, 14. [Google Scholar] [CrossRef]

- Tahmasebipour, M.; Dehghan, M. A Novel Electromagnetic Microactuator with a Stainless Steel Mas-Spring Structure. J. Micromech. Microeng. 2022, 32. [Google Scholar] [CrossRef]

- Angulo-Cervera, E.; Orlandini-Keller, F.; Lecerf, I.; Moritz, P.; Mathieu, F.; Bourrier, D.; Charlot, S.; Haettel, R.; Devillers, T.; Nicu, L.; et al. Monolithic Integration of Thick NDFeB Micro-Magnets into Mems: Application to Electromagnetic Energy Harvesting. In Proceedings of the 2023 22nd International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Kyoto, Japan, 25–29 June 2023; pp. 45–48. [Google Scholar]

- Shi, X.; Ding, G. An Optimized Magnet Circuit Design to Reduce Power Consumption for Torsional Electromagnetic Actuators. IEEE Magn. Lett. 2022, 13. [Google Scholar] [CrossRef]

- Alcheikh, N.; Shalabi, A.T.; Ouakad, H.M. A Novel Approach for Improving the Performance of Gas Sensors Using a Thermal-Conductivity-Based Micro-Resonator and Lorentz-Forces. Sens. Actuators A Phys. 2024, 376, 115619. [Google Scholar] [CrossRef]

- Wang, Y.; Song, X.; Xi, J.; Li, F.; Xu, L.; Liu, H.; Wang, C.; Kuang, S.; Tu, L.C.; Kraft, M.; et al. A Resonant Lorentz-Force Magnetometer Exploiting Blue Sideband Actuation to Enhance Sensitivity and Resolution. J. Microelectromech. Syst. 2022, 31, 402–407. [Google Scholar] [CrossRef]

- Zhang, L.; Tsukamoto, T.; Tanaka, S. Frequency Modulated MEMS Lorentz Force Magnetometer Using CW/CCW Modes. In Proceedings of the 2022 IEEE International Symposium on Inertial Sensors and Systems (INERTIAL), Avignon, France, 8–11 May 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Yunas, J.; Mulyanti, B.; Hamidah, I.; Said, M.M.; Pawinanto, R.E.; Wan Ali, W.A.F.; Subandi, A.; Hamzah, A.A.; Latif, R.; Majlis, B.Y. Polymer-Based MEMS Electromagnetic Actuator for Biomedical Application: A Review. Polymers 2020, 12. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.S.; Mitra, B. Design and Fabrication of Out of Plane MEMS Actuator Driven by Lorentz Force. In Proceedings of the 2024 IEEE Microwaves, Antennas, and Propagation Conference (MAPCON), Hyderabad, India, 9–13 December 2024; pp. 1–4. [Google Scholar] [CrossRef]

- Yu, J.; Cai, P.; Liang, H. A Lorentz-Force MEMS Magnetometer with an Annular Resonance Beam for Z-Axis Sensing. IEEE Sens. J. 2024, 25, 2502–2509. [Google Scholar] [CrossRef]

- Nazari, A.; Aghajani, A.; Buhr, P.; Park, B.; Belov, M.; Wang, Y.; Shafai, C. Surrogate-Assisted Multi-Objective Design Optimization of a Lorentz Force Actuator. In Proceedings of the 2024 IEEE Canadian Conference on Electrical and Computer Engineering (CCECE), Kingston, ON, Canada, 6–9 August 2024; pp. 648–653. [Google Scholar] [CrossRef]

- Tu, C.; Ou-Yang, X.H.; Wu, Y.J.; Zhang, X.S. Single-Structure 3-Axis Lorentz Force Magnetometer Based on an AlN-on-Si MEMS Resonator. Microsyst. Nanoeng. 2024, 10. [Google Scholar] [CrossRef]

- Mohammed, Z.; Choi, D.S.; Elfadel, I.M. An Alternative Capacitive Transducer Design for Sensitivity Enhancement in MEMS Lorentz Force Magnetometers. Microsyst. Technol. 2024, 30, 221–230. [Google Scholar] [CrossRef]

- Valle, J.J.; Sánchez-Chiva, J.M.; Fernández, D.; Madrenas, J. Design, Fabrication, Characterization and Reliability Study of CMOS-MEMS Lorentz-Force Magnetometers. Microsyst. Nanoeng. 2022, 8. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Kaur, D. Magnetoelectric Heterostructures for Next-Generation MEMS Magnetic Field Sensing Applications. J. Alloys Compd. 2022, 897, 163091. [Google Scholar] [CrossRef]

- Deshmukh, A.; Petit, L.; Khan, M.U.; Lamarque, F.; Prelle, C. Planar Micro-Positioning Device Based on a 3D Digital Electromagnetic Actuator. Actuators 2021, 10. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, W.; Chen, G.; Toda, M.; Koizumi, S.; Koide, Y.; Liao, M. On-Chip Diamond MEMS Magnetic Sensing through Multifunctionalized Magnetostrictive Thin Film. Adv. Funct. Mater. 2023, 33. [Google Scholar] [CrossRef]

- Algamili, A.S.; Khir, M.H.M.; Dennis, J.O.; Ahmed, A.Y.; Alabsi, S.S.; Ba Hashwan, S.S.; Junaid, M.M. A Review of Actuation and Sensing Mechanisms in MEMS-Based Sensor Devices. Nanoscale Res. Lett. 2021, 16. [Google Scholar] [CrossRef]

- Hoffmann, J.; Roldan-Vasco, S.; Krüger, K.; Niekiel, F.; Hansen, C.; Maetzler, W.; Orozco-Arroyave, J.R.; Schmidt, G. Pilot Study: Magnetic Motion Analysis for Swallowing Detection Using MEMS Cantilever Actuators. Sensors 2023, 23. [Google Scholar] [CrossRef]

- Wang, H.; Matsuura, M.; Yamada, S.; Sugimoto, S.; Tanaka, S. Temperature Stable Rare Earth Magnetic Powder Sm-Fe-N Based Micro Magnets with Remanence Enhanced by Easy Axis Alignment and Its Application in MEMS Actuator. J. Micromech. Microeng. 2021, 31. [Google Scholar] [CrossRef]

- Qi, C.; Han, D.; Shinshi, T. A MEMS-Based Electromagnetic Membrane Actuator Utilizing Bonded Magnets with Large Displacement. Sens. Actuators A Phys. 2021, 330, 112834. [Google Scholar] [CrossRef]

- Jia, S.; Peng, J.; Bian, J.; Zhang, S.; Xu, S.; Zhang, B. Design and Fabrication of a MEMS Electromagnetic Swing-Type Actuator for Optical Switch. Micromachines 2021, 12. [Google Scholar] [CrossRef]

- Zhi, C.; Qu, M.; Wang, Y.; Li, Y.; Xie, J.; Feng, W.; Tang, B. Fabrication and Characterization of Micro Electromagnetic Linear Actuators. J. Micromech. Microeng. 2020, 30. [Google Scholar] [CrossRef]

- Wang, Y.; Zhi, C.; Tang, B.; Yang, K.; Xie, J.; Xu, W.; Li, H.; Wang, X. A Micro Electromagnetic Actuator with High Force Density. Sens. Actuators A Phys. 2021, 331, 112771. [Google Scholar] [CrossRef]

- Wu, H.; Tao, Z.; Li, H.; Xu, T.; Wang, W.; Sun, J.; Xiao, W.; Li, H. A Micro-Electromagnetic Vibration Energy Harvester with Higher Power Density and Wider Bandwidth Utilizing 3D MEMS Coils. Appl. Phys. Lett. 2021, 119. [Google Scholar] [CrossRef]

- Yixuan, Z.; Qiwei, X.; Sheng, L.; Zhihao, C.; Chao, Z. Design of a New Micro Linear Actuator Owning Two-Phase No-Cross Planar Coils. In Proceedings of the 2021 IEEE 4th International Electrical and Energy Conference (CIEEC), Wuhan, China, 28–30 May 2021; pp. 1–11. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Qu, M.; Wang, J.; Zhi, C.; Xiong, Z. A Long-Stroke Planar Linear Actuator Equipped with Magnetic Guide. J. Micromech. Microeng. 2022, 32. [Google Scholar] [CrossRef]

- Sun, Y.; Lou, W.; Feng, H.; Zhao, Y. Study on Characteristics of Electromagnetic Coil Used in MEMS Safety and Arming Device. Micromachines 2020, 11. [Google Scholar] [CrossRef]

- Zhou, S.; Liang, C.; Mei, Z.; Xie, R.; Sun, Z.; Li, J.; Zhang, W.; Ruan, Y.; Zhao, X. Design and Implementation of a Flexible Electromagnetic Actuator for Tunable Terahertz Metamaterials. Micromachines 2024, 15. [Google Scholar] [CrossRef]

- Tao, Z.; Wu, H.; Li, H.; Li, H.; Xu, T.; Sun, J.; Wang, W. Theoretical Model and Analysis of an Electromagnetic Vibration Energy Harvester with Nonlinear Damping and Stiffness Based on 3D MEMS Coils. J. Phys. D Appl. Phys. 2020, 53. [Google Scholar] [CrossRef]

- Qi, C.; Sugita, N.; Shinshi, T. Development of a Flexible Coil Based on Conductive Polymer Composite for PDMS-Based Soft Electromagnetic Microactuators. Sens. Actuators A Phys. 2023, 363, 114766. [Google Scholar] [CrossRef]

- Dong, Z.; Wang, Y.; Wen, J.; Li, F.; Du, Q.; Zhang, Y.; Zhao, X. NdFeB/PDMS Flexible Electromagnetic Actuator with Vibration and Nonvibration Dual Modes Based on Three-Dimensional Coils. ACS Appl. Electron. Mater. 2024, 6, 310–318. [Google Scholar] [CrossRef]

- Tao, Z.; Sun, J.; Li, H.; Huang, Y.; Li, H.; Xu, T.; Wu, H. A Radial-Flux Permanent Magnet Micromotor with 3D Solenoid Iron-Core MEMS In-Chip Coils of High Aspect Ratio. IEEE Electron. Device Lett. 2020, 41, 1090–1093. [Google Scholar] [CrossRef]

- Lei, K.; Li, H.; Xu, T.; Wu, Y.; Zhu, K.; Zhai, Y. Optimization and Investigation of Radial-Flux Permanent Magnet Micromotor Utilizing MEMS 3D Solenoid Coils with Iron Core. In Proceedings of the ACTUATOR 2024; International Conference and Exhibition on New Actuator Systems and Applications, Wiesbaden, Germany, 13–14 June 2024; pp. 3–6. [Google Scholar]

- Zhu, K.; Li, H.; Zhang, X.; Xu, T.; Li, S. A Miniature Electromagnetic Linear Actuator With 3D MEMS Coil. IEEE Electron. Device Lett. 2023, 44, 1732–1735. [Google Scholar] [CrossRef]

- Sun, J.; Tao, Z.; Li, H.; Zhu, K.; Wang, D.; Wu, H.; Xu, T. A MEMS Voice Coil Motor with a 3D Solenoid Coil. In Proceedings of the 2021 IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 25–29 April 2021; pp. 1745–1748. [Google Scholar] [CrossRef]

- Kasambe, P.V.; Bhole, K.S.; Raykar, N.R.; Oza, A.D.; Ramesh, R.; Bhoir, D.V. Mechanical Modeling, Numerical Investigation and Design of Cantilever Beam for Low Pull-in MEMS Switch. Int. J. Interact. Des. Manuf. 2022. [Google Scholar] [CrossRef]

- Saleh, H.; Shojaeian, M.; Bajwa, R.; Tekin, I.; Yapici, M.K. Low Actuation Voltage Cantilever-Type RF-MEMS Shunt Switches for 5G Applications. Microelectron. Reliab. 2022, 136, 114645. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Mao, M.; Shao, J. An Improved Method for Electromagnetic Calculations of Dynamically Varying Cantilever Beam RF-MEMS Switches. In Proceedings of the 2024 IEEE 21st Biennial Conference on Electromagnetic Field Computation (CEFC), Jeju, Republic of Korea, 2–5 June 2024; pp. 1–2. [Google Scholar] [CrossRef]

- Kasambe, P.V.; Bhole, K.S.; Bhoir, D.V. Analytical Modelling, Design Optimisation and Numerical Simulation of a Variable Width Cantilever Beam MEMS Switch. Adv. Mater. Process. Technol. 2022, 8, 2850–2870. [Google Scholar] [CrossRef]

- Anitha, G.; Suresh Kumar, M.; Ayyadurai, M.; Senthil Kumar, C.; Ramkumar, G. Design of Miniaturized Single Bit MEMS Phase Shifter Using MEMS Switches. In Proceedings of the 2021 5th International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 3–5 June 2021; pp. 235–239. [Google Scholar] [CrossRef]

- Chung, M.; Jeong, H.; Kim, Y.K.; Lim, S.; Baek, C.W. Design and Fabrication of Millimeter-Wave Frequency-Tunable Metamaterial Absorber Using MEMS Cantilever Actuators. Micromachines 2022, 13. [Google Scholar] [CrossRef]

- Jiang, B.; Zhu, F.; Yang, Y.; Zhu, J.; Yang, Y.; Yuan, M. A Hybrid Piezoelectric and Electromagnetic Broadband Harvester with Double Cantilever Beams. Micromachines 2023, 14. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.; Liu, G.; Jin, W.; Howard, I. Nonlinear Multimodal Energy Harvesting System: A Dual-Cantilever Beam Structure for Combining Piezoelectric and Electromagnetic Mechanisms. J. Intell. Mater. Syst. Struct. 2023, 34, 65–78. [Google Scholar] [CrossRef]

- Girija Sravani, K.; Srinivasa Rao, K.; Prathyusha, D.; Sai Kiran, B.V.; Siva Kumar, B.; Prem Kumar, R.; Santhi Tarun, K. Design and Performance Analysis of Double Cantilever Type Capacitive Shunt RF MEMS Switch. Microsyst. Technol. 2020, 26, 345–352. [Google Scholar] [CrossRef]

- Mettes, S.; Bates, J.; Allen, K.W.; Mazumdar, Y.C. A Fully 3D Printed, Multi-Material, and High Operating Temperature Electromagnetic Actuator. In Proceedings of the 2023 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Seattle, WA, USA, 28–30 June 2023; pp. 517–524. [Google Scholar] [CrossRef]

- Vergara, A.; Tsukamoto, T.; Fang, W.; Tanaka, S. Feedback Control of Thin Film PZT MEMS Actuator with Integrated Buried Piezoresistors. Sens. Actuators A Phys. 2021, 332, 113131. [Google Scholar] [CrossRef]

- Ulkir, O. Design and Fabrication of an Electrothermal MEMS Micro-Actuator with 3D Printing Technology. Mater. Res. Express 2020, 7. [Google Scholar] [CrossRef]

- Pavone, A.; Stano, G.; Percoco, G. On the Fabrication of Modular Linear Electromagnetic Actuators with 3D Printing Technologies. Procedia CIRP 2022, 110, 139–144. [Google Scholar] [CrossRef]

- Kawa, B.; Lee, C.; Walczak, R. Inkjet 3D Printed MEMS Electromagnetic Multi-Frequency Energy Harvester. Energies 2022, 15. [Google Scholar] [CrossRef]

- Chen, H.; Miao, X.; Lu, H.; Liu, S.; Yang, Z. High-Efficiency 3D-Printed Three-Chamber Electromagnetic Peristaltic Micropump. Micromachines 2023, 14. [Google Scholar] [CrossRef] [PubMed]

- Ruotsalainen, K.; Morits, D.; Ylivaara, O.M.E.; Kyynäräinen, J. Resonating AlN-Thin Film MEMS Mirror with Digital Control. J. Opt. Microsyst. 2022, 2. [Google Scholar] [CrossRef]

- Ou, C.H.; Van Toan, N.; Tsai, Y.C.; Voiculescu, I.; Toda, M.; Ono, T. A Large-Stroke 3-DOF Micromirror With Novel Lorentz Force-Based Actuators Utilizing Metallic Glass Thin Film. J. Microelectromech. Syst. 2024, 33, 46–53. [Google Scholar] [CrossRef]

- Nabavi, S.; Menard, M.; Nabki, F. A SOI Out-of-Plane Electrostatic MEMS Actuator Based on In-Plane Motion. J. Microelectromech. Syst. 2022, 31, 820–829. [Google Scholar] [CrossRef]

- Xue, J.; Li, H.; Zeng, T.; Liu, X.; Zhang, Y. Study on Driving Characteristics of MEMS Electromagnetic Coil Using in the UAV. J. Phys. Conf. Ser. 2023, 2501. [Google Scholar] [CrossRef]

- Yang, Y.; Radhakrishna, U.; Hunter, J.F.; Eagar, T.W.; Lang, J.H. An Electromagnetic Translational Vibration Energy Harvester Fabricated in MP35N Alloy. J. Microelectromech. Syst. 2020, 29, 1518–1522. [Google Scholar] [CrossRef]

- Rothermel, F.; Thiele, S.; Jung, C.; Krapf, A.; Ilse, S.E.; Merle, B.; Giessen, H.; Herkommer, A.M. Fabrication and Characterization of a Magnetic 3D-Printed Microactuator. Adv. Mater. Technol. 2024, 9, 1–11. [Google Scholar] [CrossRef]

- Li, C.; Chen, S.; Xu, S. Electromagnetic Biaxial Scanning Mirror Based on 3D Printing and Laser Patterning. Sens. Actuators A Phys. 2022, 348, 113999. [Google Scholar] [CrossRef]

- Ilie, C.; Popa, M.; Tanase, N.; Chirita, I.; Ovezea, D. Electromagnetic Actuator for Laser Beam Positioning–Manufacturing Process. Int. J. Mechatron. Appl. Mech. 2021, 1, 7–17. [Google Scholar] [CrossRef]

- Zhou, T.; Wu, Q.; Pang, B.; Su, Y. Design and Fabrication Method of a Large-Size Electromagnetic MEMS Two-Dimensional Scanning Micromirror. J. Microelectromech. Syst. 2023, 32, 552–561. [Google Scholar] [CrossRef]

- Zeng, Y.; Groenesteijn, J.; Alveringh, D.; Wiegerink, R.J.; Lotters, J.C. Design, Fabrication, and Characterization of a Micro Coriolis Mass Flow Sensor Driven by PZT Thin Film Actuators. J. Microelectromech. Syst. 2021, 30, 885–896. [Google Scholar] [CrossRef]

- Kawa, B.; Sliwa, K.; Lee, V.C.; Walczak, Q.; Shi, R. Inkjet 3D Printed MEMS Vibrational Electromagnetic Energy Harvester. Energies 2020, 13. [Google Scholar] [CrossRef]

- Seo, J.; Hwang, J.Y.; Ji, C.H. Electromagnetic 2D Scanning Micromirror Fabricated with 3D Printed Polymer Parts for LiDAR Applications. Sens. Actuators A Phys. 2022, 348, 113997. [Google Scholar] [CrossRef]

- Dehghan, M.; Tahmasebipour, M.; Ebrahimi, S. Design, Fabrication, and Characterization of an SLA 3D Printed Nanocomposite Electromagnetic Microactuator. Microelectron. Eng. 2022, 254, 111695. [Google Scholar] [CrossRef]

- Paknahad, A.A.; Tahmasebipour, M. An Electromagnetic Micro-Actuator with PDMS-Fe3O4 Nanocomposite Magnetic Membrane. Microelectron. Eng. 2019, 216, 111031. [Google Scholar] [CrossRef]

- Zhi, C.; Tang, B.; Wang, Y.; Qu, M.; Li, Y.; Xie, J.; Xiong, Z. A Self-Attachable and Self-Alignable Micro Electromagnetic Linear Actuator. J. Micromech. Microeng. 2020, 31. [Google Scholar] [CrossRef]

- Xu, B.; Ji, Y.; Liu, K.; Li, J. Piezoelectric MEMS Mirror with Lissajous Scanning for Automobile Adaptive Laser Headlights. Micromachines 2022, 13. [Google Scholar] [CrossRef]

- Gu, C.; Tan, C.; Li, B.; Lu, J.; Wang, G.; Chi, X. Data-Driven Model-Free Adaptive Sliding Mode Control for Electromagnetic Linear Actuator. J. Micromech. Microeng. 2022, 32. [Google Scholar] [CrossRef]

- Alzaydi, A. Cost-Efficient Electromagnetically-Actuated Rotational Adaptive Mirror Design. Eng. Rev. 2024, 44, 14–33. [Google Scholar] [CrossRef]

- Gan, H.; Qin, Y.; Zhang, J.; Lv, C.; Chen, Z.; Hu, Y. Adaptive Internal Model Backstepping Control for a Class of Second-Order Electromagnetic Micromirror with Output Performance Constraints and Anomaly Control. Micromachines 2024, 15. [Google Scholar] [CrossRef]

- Pîslaru-Dănescu, L.; Zărnescu, G.C.; Popescu, I.; Popa, M.; Miu, J.; Iliescu, C. Enhancing the Precision of Proportional Electromagnetic Actuators Used in Automatic Processes Control. EEA–Electroteh. Electron. Autom. 2024, 72, 3–14. [Google Scholar] [CrossRef]

- Wei, W.; Li, Q.; Xu, F.; Zhang, X.; Jin, J.; Jin, J.; Sun, F. Research on an Electromagnetic Actuator for Vibration Suppression and Energy Regeneration. Actuators 2020, 9. [Google Scholar] [CrossRef]

- Hartansky, R.; Mierka, M.; Jancarik, V.; Bittera, M.; Halgos, J.; Dzuris, M.; Krchnak, J.; Hricko, J.; Andok, R. Towards a MEMS Force Sensor via the Electromagnetic Principle. Sensors 2023, 23. [Google Scholar] [CrossRef]

- Hua, Y.; Wang, S.; Li, B.; Bai, G.; Zhang, P. Dynamic Modeling and Anti-Disturbing Control of an Electromagnetic Mems Torsional Micromirror Considering External Vibrations in Vehicular Lidar. Micromachines 2021, 12. [Google Scholar] [CrossRef]

- Xu, Y.; Xie, J.; Wu, D. Feedback Signal Detection and Drive Signal Compensation for Electromagnetic MEMS Scanning Mirror Based on FPGA. IEICE Electron. Express 2024, 21. [Google Scholar] [CrossRef]

- Vikrant, K.S.; Dadkhah, D.; Moheimani, S.O.R. Measurement of Electromagnetic Force Using a Feedback-Controlled MEMS Force Sensor. In Proceedings of the 2024 Australian & New Zealand Control Conference (ANZCC), Gold Coast, Australia, 1–2 February 2024; pp. 90–91. [Google Scholar] [CrossRef]

- Muscat, A.; Bhattacharya, S.; Zhu, Y. Electromagnetic Vibrational Energy Harvesters: A Review. Sensors 2022, 22. [Google Scholar] [CrossRef]

- Ou, C.H.; Lin, Y.C.; Keikoin, Y.; Ono, T.; Esashi, M.; Tsai, Y.C. Two-Dimensional MEMS Fe-Based Metallic Glass Micromirror Driven by an Electromagnetic Actuator. Jpn. J. Appl. Phys. 2019, 58. [Google Scholar] [CrossRef]

- Han, D.; Shinshi, T.; Azuma, N.; Kadota, S. An In-Plane, Large-Stroke, Multipole Electromagnetic Microactuator Realized by Guideways Stacking Mechanism. Sens. Actuators A Phys. 2019, 298, 111563. [Google Scholar] [CrossRef]

- Jiang, B.; Peng, M.; Liu, Y.; Zhou, T.; Su, Y. The Fabrication of 2D Micromirror with Large Electromagnetic Driving Forces. Sens. Actuators A Phys. 2019, 286, 163–168. [Google Scholar] [CrossRef]

- Fang, X.Y.; Tu, E.Q.; Zhou, J.F.; Li, A.; Zhang, W.M. A 2D MEMS Crosstalk-Free Electromagnetic Micromirror for LiDAR Application. J. Microelectromech. Syst. 2024, 33, 559–567. [Google Scholar] [CrossRef]

- Fang, X.Y.; Li, X.Y.; Hu, K.M.; Yan, G.; Zhang, W.M.; Wu, J.H. Destructive Reliability Analysis of Electromagnetic MEMS Micromirror under Vibration Environment. IEEE J. Sel. Top. Quantum Electron. 2022, 28. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, L. Modeling and Implementation of Synchronization for Large-Aperture Electromagnetic MEMS Mirrors. Micromachines 2025, 16. [Google Scholar] [CrossRef]

- Xiao, Q.; Wang, Y.; Dricot, S.; Kraft, M. Design and Experiment of an Electromagnetic Levitation System for a Micro Mirror. Microsyst. Technol. 2019, 25, 3119–3128. [Google Scholar] [CrossRef]

- Mohamed, S.; Ahmad, E.; Im, Y.W.; Kim, W.C.; Kim, Y.; Shin, B. Design of a 2-DOF Scanning Mirror Using Flexible Membrane and Electromagnetic Actuators. Microsyst. Technol. 2025, 31, 1191–1202. [Google Scholar] [CrossRef]

- Qian, L.; Shan, Y.; Wang, J.; Li, H.; Wang, K.; Yu, H.; Zhou, P.; Shen, W. Experimental Investigation of Vibration Isolator for Large Aperture Electromagnetic MEMS Micromirror. Micromachines 2023, 14. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, G.; Meng, L.; Geng, S.; You, Z. Magnetic Field Density Concentrated Permanent Magnet Structure for Electromagnetic MEMS Scanning Mirror. Sens. Actuators A Phys. 2024, 373, 115390. [Google Scholar] [CrossRef]

- Pawinanto, R.E.; Yunas, J.; Alwani, A.; Indah, N.; Alva, S. Electromagnetic Micro-Actuator with Silicon Membrane for Fluids Pump in Drug Delivery System. Int. J. Mech. Eng. Robot. Res. 2019, 8, 576–579. [Google Scholar] [CrossRef]

- Reddy, J.; Chaman, J.J.; Pradeep, K.; Nayak, M.M.; Pratap, R. A Method for Realizing Robust Micro-Scale Electromagnetic Actuators for High Current Density Applications. ISSS J. Micro Smart Syst. 2021, 10, 1–6. [Google Scholar] [CrossRef]

- Bhushan, P.; Tomlin, C. Design of an Electromagnetic Actuator for an Insect-Scale Spinning-Wing Robot. IEEE Robot. Autom. Lett. 2020, 5, 4188–4193. [Google Scholar] [CrossRef]

- Çetin, L.; Alasli, A.; Akçura, N.; Kahveci, A.; Can, F.C.; Tamer, Ö. Dynamical Electromagnetic Actuation System for Microscale Manipulation. Robotica 2022, 40, 3586–3603. [Google Scholar] [CrossRef]

- Li, D.; Niu, F.; Li, J.; Li, X.; Sun, D. Gradient-Enhanced Electromagnetic Actuation System with a New Core Shape Design for Microrobot Manipulation. IEEE Trans. Ind. Electron. 2020, 67, 4700–4710. [Google Scholar] [CrossRef]

- Tisnes, S.D.; Petit, L.; Prelle, C.; Lamarque, F. Modeling and Experimental Validation of a Planar Microconveyor Based on a 2 × 2 Array of Digital Electromagnetic Actuators. IEEE/ASME Trans. Mechatron. 2021, 26, 1422–1432. [Google Scholar] [CrossRef]

- Mohd Ghazali, F.A.; Hasan, M.N.; Rehman, T.; Nafea, M.; Mohamed Ali, M.S.; Takahata, K. MEMS Actuators for Biomedical Applications: A Review. J. Micromechanics Microengineering 2020, 30. [Google Scholar] [CrossRef]

- Zhao, R.; Lu, Q. Design and Experiments of a Galfenol Composite Cantilever Beam-Driven Magnetostrictive Micro-Gripper. Iran. J. Sci. Technol.-Trans. Mech. Eng. 2020, 44, 1–10. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.; Xu, T.; Huang, Y.; Fang, W. High Performance Electromagnetic Micropump with Bio-Inspired Synchronous Valves for Integrated Microfluidics. Sens. Actuators A Phys. 2023, 360, 114568. [Google Scholar] [CrossRef]

- Mi, S.; Pu, H.; Xia, S.; Sun, W. A Minimized Valveless Electromagnetic Micropump for Microfluidic Actuation on Organ Chips. Sens. Actuators A Phys. 2020, 301, 111704. [Google Scholar] [CrossRef]

- Liu, X.; Song, H.; Zuo, W.; Ye, G.; Jin, S.; Wang, L.; Li, S. Theoretical and Experimental Studies of a PDMS Pneumatic Microactuator for Microfluidic Systems. Energies 2022, 15. [Google Scholar] [CrossRef]

- Bhushan, B.M.; Yoon, J.Y.; Griffith, L.G.; Trumper, D.L. Flux-Biased, Energy-Efficient Electromagnetic Micropumps Utilizing Bistable Magnetic Latching and Energy-Storage Springs. IEEE/ASME Trans. Mechatron. 2021, 26, 2362–2372. [Google Scholar] [CrossRef]

- Lu, F.; Han, P.; Gong, G.; Yang, H.; Han, D. Energy-Saving, High-Pressure Resistant Mini Valve Based on a Bistable Electromagnetic Actuator. Sens. Actuators A Phys. 2024, 379, 116002. [Google Scholar] [CrossRef]

- Cioboată, D.D.; Kacprzyk, J.; Gomide, F.; Kaynak, O.; Liu, D.; Pedrycz, W.; Polycarpou, M.M.; Rudas, I.J.; Wang, J. International Conference on Reliable Systems Engineering (ICoRSE)–2023; Springer Nature: Berlin/Heidelberg, Germany, 2023; Volume 762, ISBN 9783031406270. [Google Scholar]

- Annabestani, M.; Fardmanesh, M. Ionic Electro Active Polymer-Based Soft Actuators and Their Applications in Microfluidic Micropumps, Microvalves, and Micromixers: A Review. arXiv 2019, arXiv:1904.07149. [Google Scholar] [CrossRef]

- Dehghan, M.; Tahmasebipour, M. A Novel Electromagnetic Micropump with PDMS Membrane Supported by a Stainless-Steel Microstructure. J. Micromech. Microeng. 2023, 33. [Google Scholar] [CrossRef]

- Subandi, A.; Yunas, J.; Hamzah, A.A.; Buyong, M.R.; Sugandi, G.; Sudrajat, N. Fabrication and Characterization of Dome-Shaped Actuator Membrane for Peristaltic Valveless Electromagnetic Micropump. Int. J. Nanoelectron. Mater. 2024, 17, 487–491. [Google Scholar] [CrossRef]

- Joswig, L.; Vellekoop, M.J.; Lucklum, F. Miniature 3D-Printed Centrifugal Pump with Non-Contact Electromagnetic Actuation. Micromachines 2019, 10. [Google Scholar] [CrossRef]

- Kim, N.; Chan, W.X.; Ng, S.H.; Yoon, Y.J.; Allen, J.B. Understanding Interdependencies between Mechanical Velocity and Electrical Voltage in Electromagnetic Micromixers. Micromachines 2020, 11. [Google Scholar] [CrossRef]

- Annabestani, M.; Azizmohseni, S.; Esmaeili-Dokht, P.; Bagheri, N.; Aghassizadeh, A.; Fardmanesh, M. Multiphysics Analysis and Practical Implementation of a Soft μ-Actuator- Based Microfluidic Micromixer. J. Microelectromech. Syst. 2020, 29, 268–276. [Google Scholar] [CrossRef]

- Zhao, Y.; Lv, X.; Li, X.; Rcheulishvili, N.; Chen, Y.; Li, Z.; Deng, Y. Microfluidic Actuated and Controlled Systems and Application for Lab-on-Chip in Space Life Science. Sp. Sci. Technol. 2023, 3. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, Q.; Ai, J.; Su, B. Ferromagnetic Liquid Droplet on a Superhydrophobic Surface for the Transduction of Mechanical Energy to Electricity Based on Electromagnetic Induction. ACS Nano 2021, 15, 12151–12160. [Google Scholar] [CrossRef]

- Subandi, A.; Buyong, M.R.; Hamzah, A.A.; Majlis, B.Y.; Raub, A.A.M.; Pawinanto, R.E.; Mulyanti, B.; Yunas, J. A Peristaltic Electromagnetic (EM) Micropump with Dome-Shaped PDMS Membranes for Biomedical Application. Sens. Actuators A Phys. 2024, 379, 115942. [Google Scholar] [CrossRef]

| Actuation Principle | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Electromagnetic Actuation |

|

| Micro motors, Micropumps, Optical scanners, speakers, Micromirror arrays, Microvalves |

| Piezoelectric Actuation |

|

| Precision positioning, Microactuators, Inkjet printers, Acoustic sensors |

| Electrostatic Actuation |

|

| Micro relays, Micromirror arrays, RF MEMS switches |

| Thermal Actuation |

|

| Microvalves, Thermal actuators, Microfluidic devices |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, J.; Xue, N.; Qiu, B.; Qin, B.; Zhao, Q.; Fang, G.; Yao, Z.; Zhou, W.; Sun, X. Recent Design and Application Advances in Micro-Electro-Mechanical System (MEMS) Electromagnetic Actuators. Micromachines 2025, 16, 670. https://doi.org/10.3390/mi16060670

Cheng J, Xue N, Qiu B, Qin B, Zhao Q, Fang G, Yao Z, Zhou W, Sun X. Recent Design and Application Advances in Micro-Electro-Mechanical System (MEMS) Electromagnetic Actuators. Micromachines. 2025; 16(6):670. https://doi.org/10.3390/mi16060670

Chicago/Turabian StyleCheng, Jianqun, Ning Xue, Bocang Qiu, Boqi Qin, Qingchun Zhao, Gang Fang, Zhihui Yao, Wenyi Zhou, and Xuguang Sun. 2025. "Recent Design and Application Advances in Micro-Electro-Mechanical System (MEMS) Electromagnetic Actuators" Micromachines 16, no. 6: 670. https://doi.org/10.3390/mi16060670

APA StyleCheng, J., Xue, N., Qiu, B., Qin, B., Zhao, Q., Fang, G., Yao, Z., Zhou, W., & Sun, X. (2025). Recent Design and Application Advances in Micro-Electro-Mechanical System (MEMS) Electromagnetic Actuators. Micromachines, 16(6), 670. https://doi.org/10.3390/mi16060670