Nanoscale Polishing of TC4 Titanium Alloy Surface Based on Dual-Pole Magnetic Abrasive Finishing Method

Abstract

1. Introduction

2. Methods and Experimental Procedures

2.1. Analysis of Magnetic Field Strength

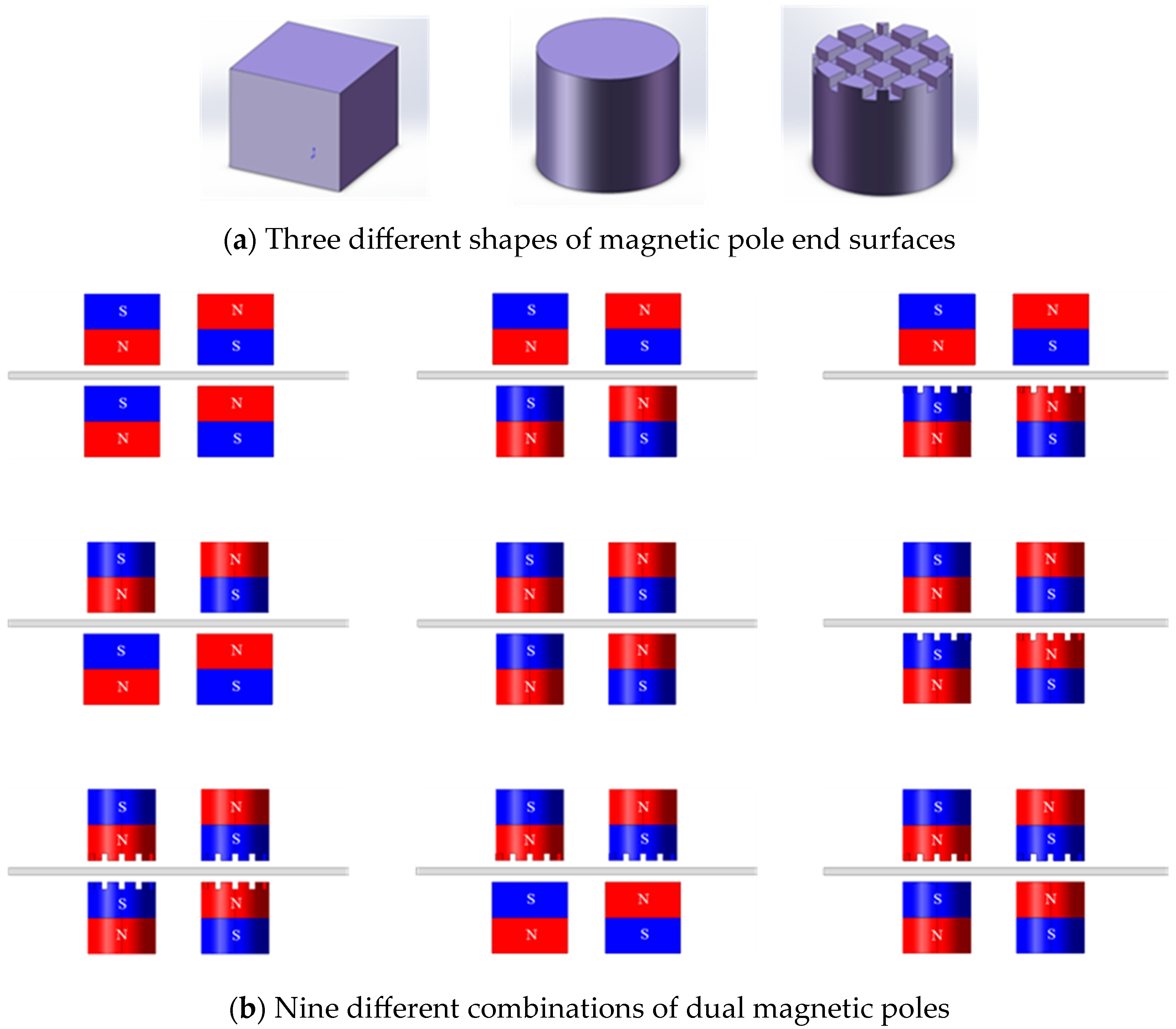

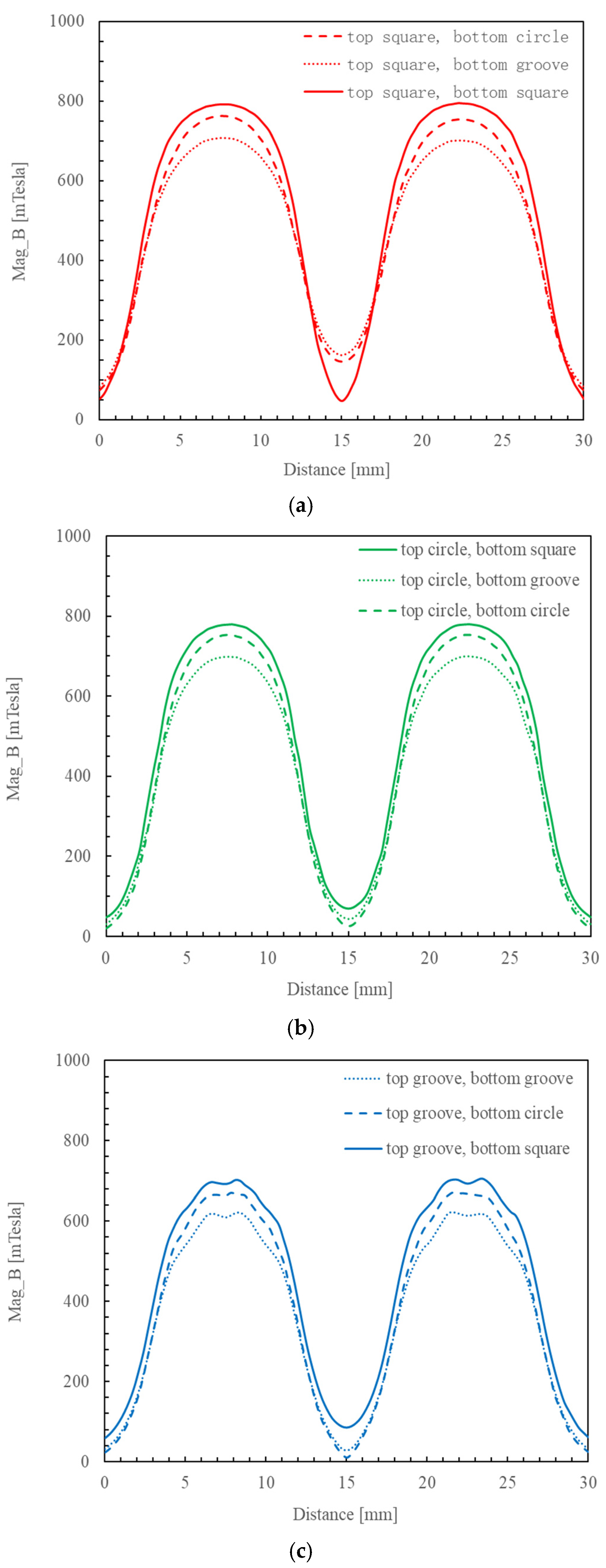

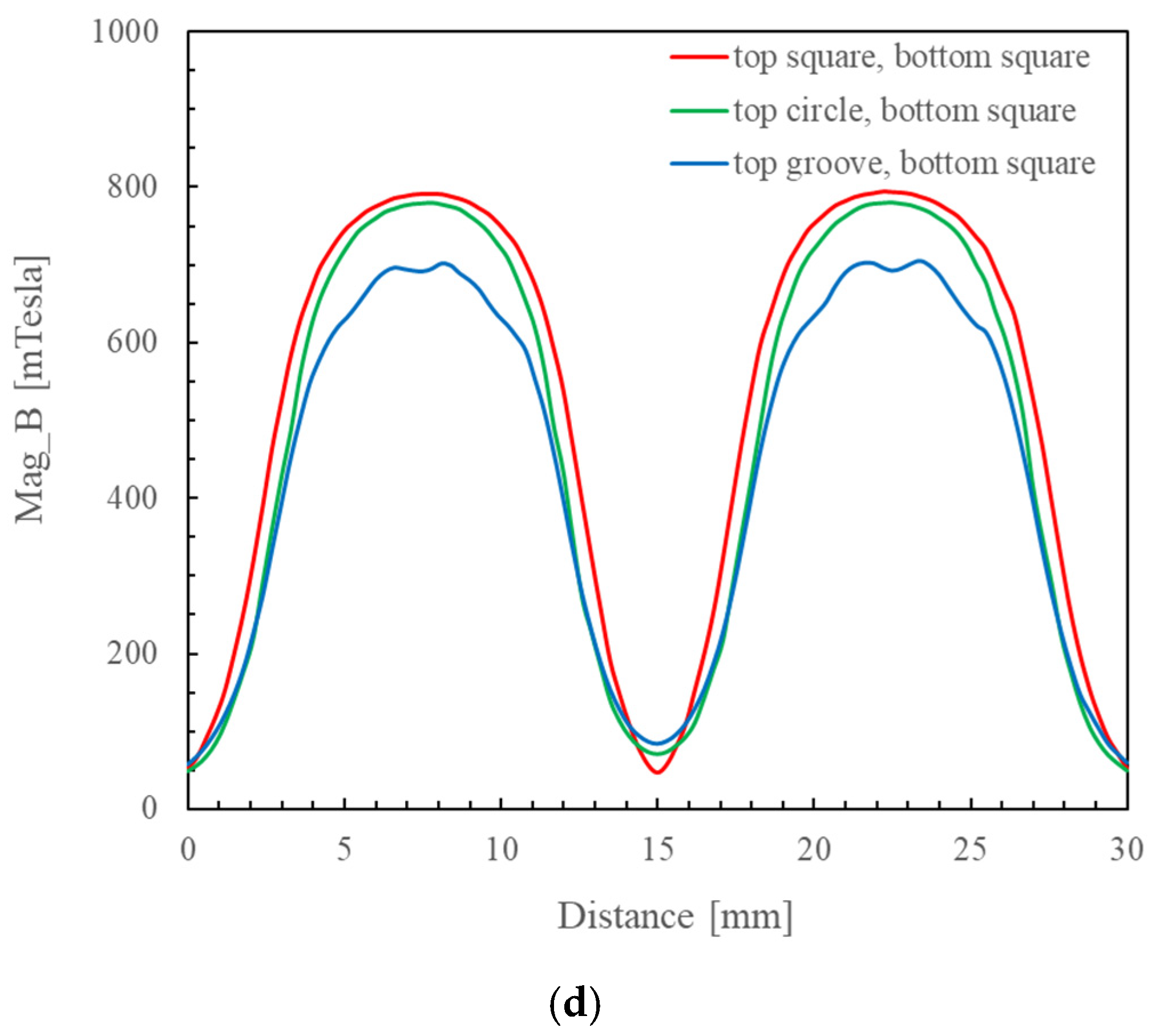

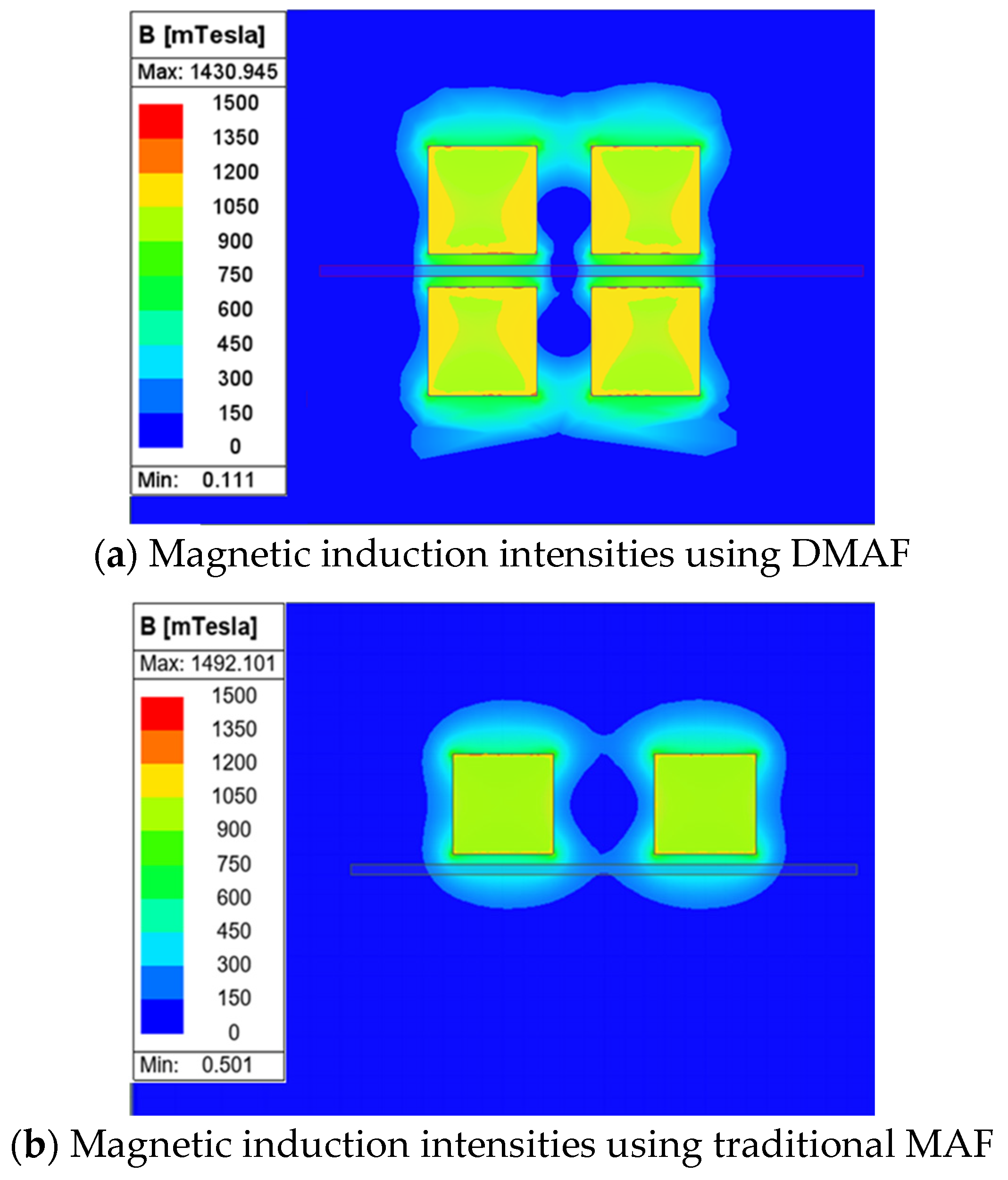

2.1.1. The Shape and Combination of the Magnetic Poles

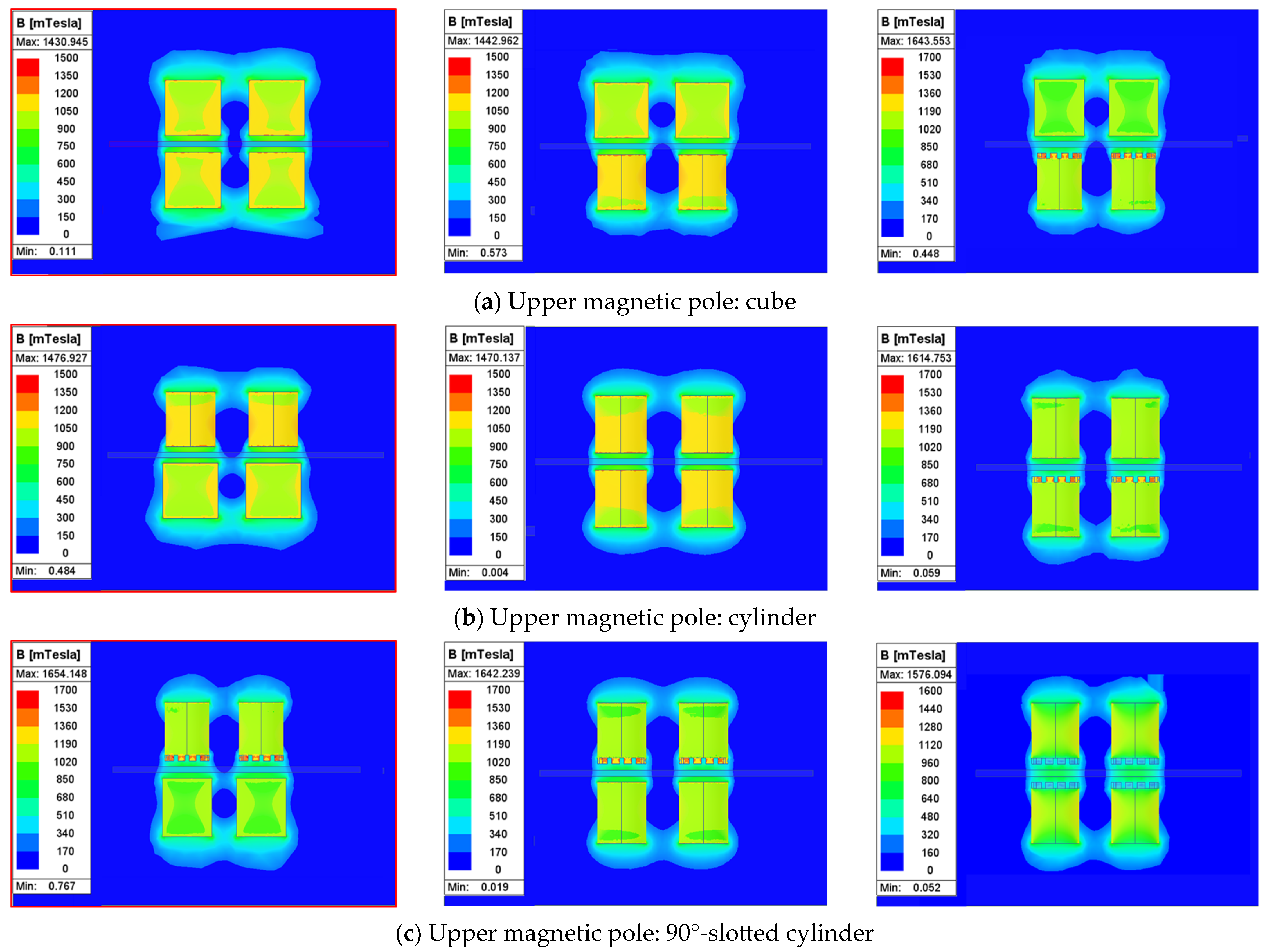

2.1.2. Simulation Analysis of the Magnetic Pole Combinations

2.2. The Machining Principle

2.3. The Experimental Setup

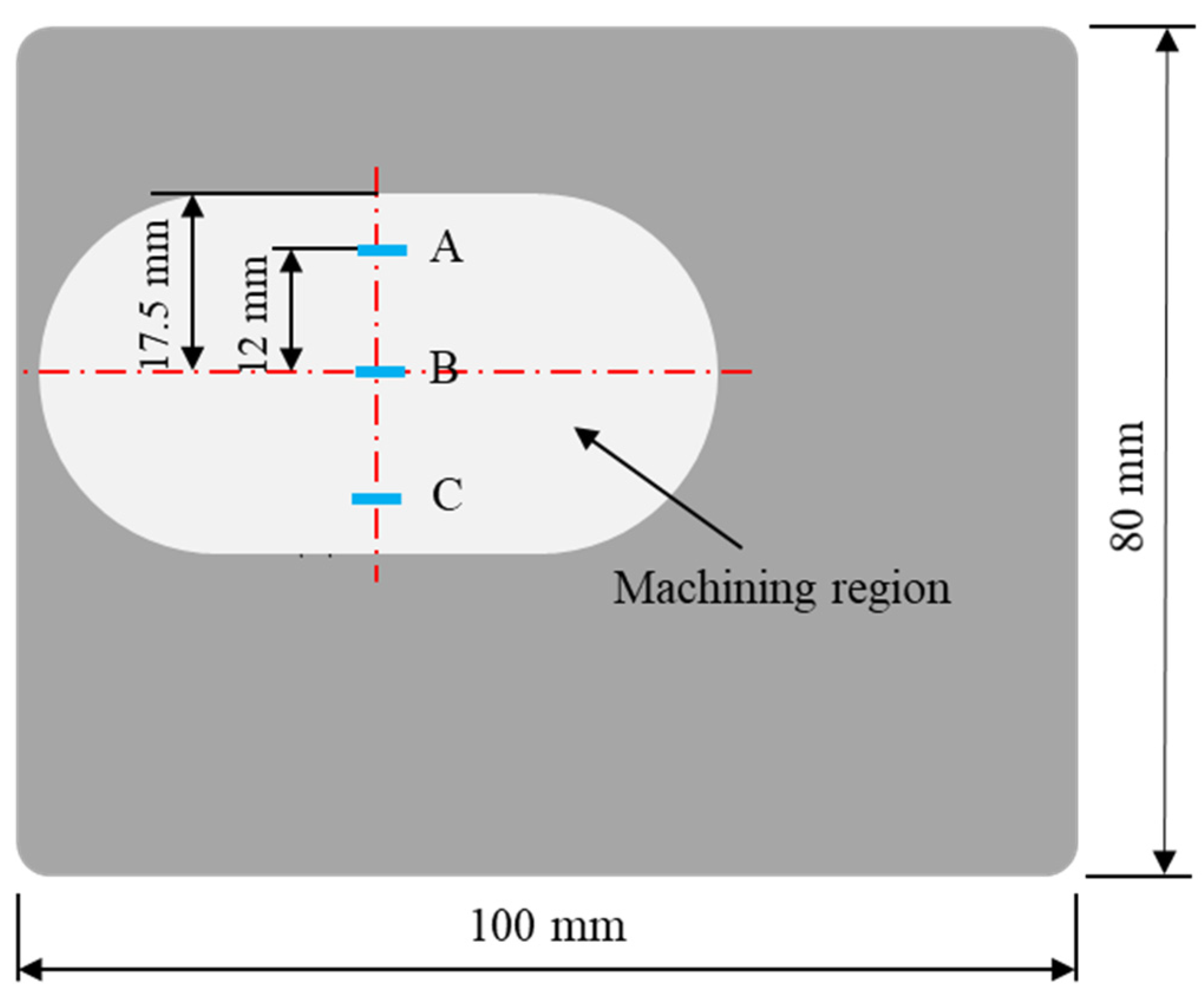

2.4. The Experimental Conditions and the Measuring Method

3. Results

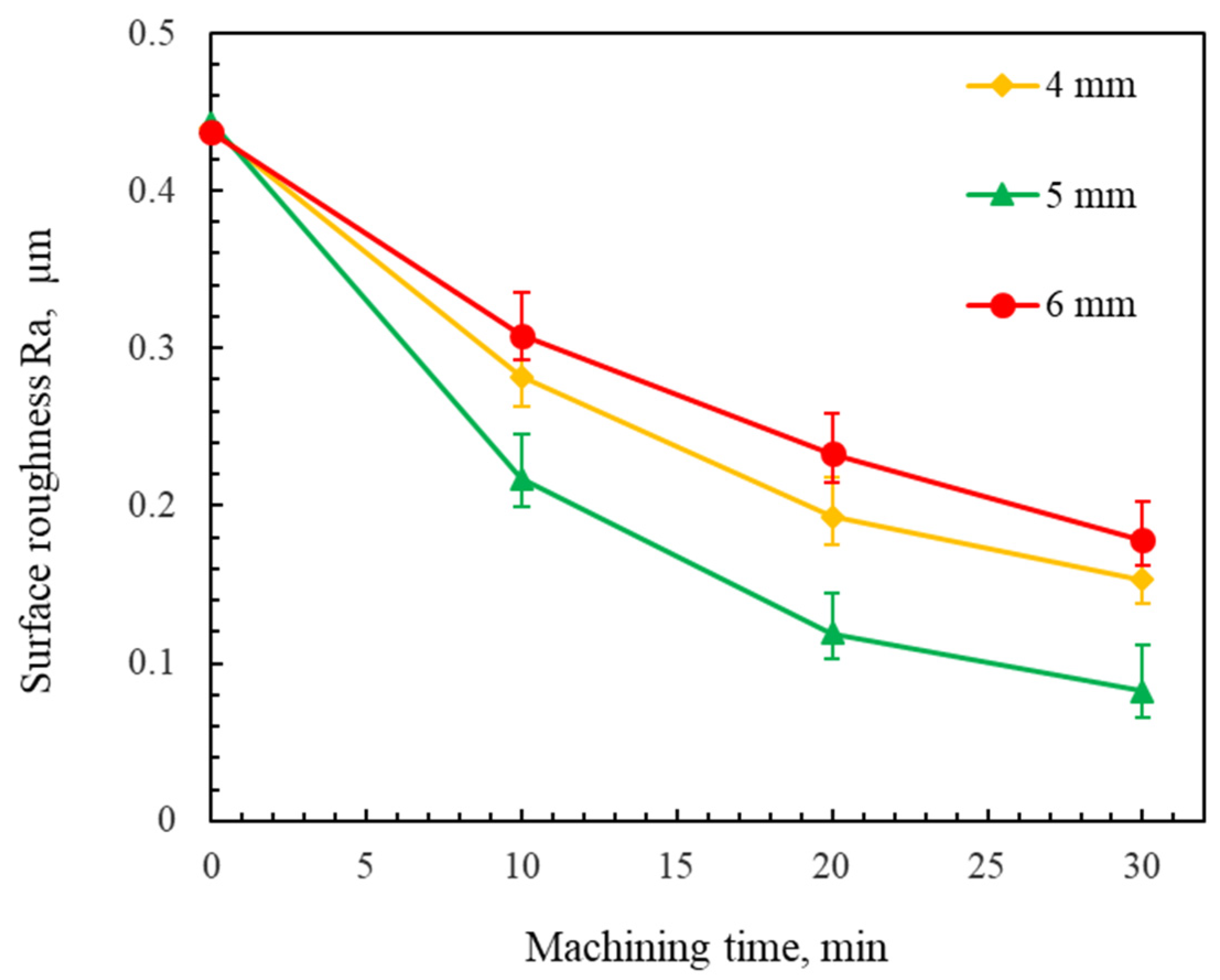

3.1. The Influence of the Gap Between the Upper and Lower Magnetic Poles on the Polishing Effect

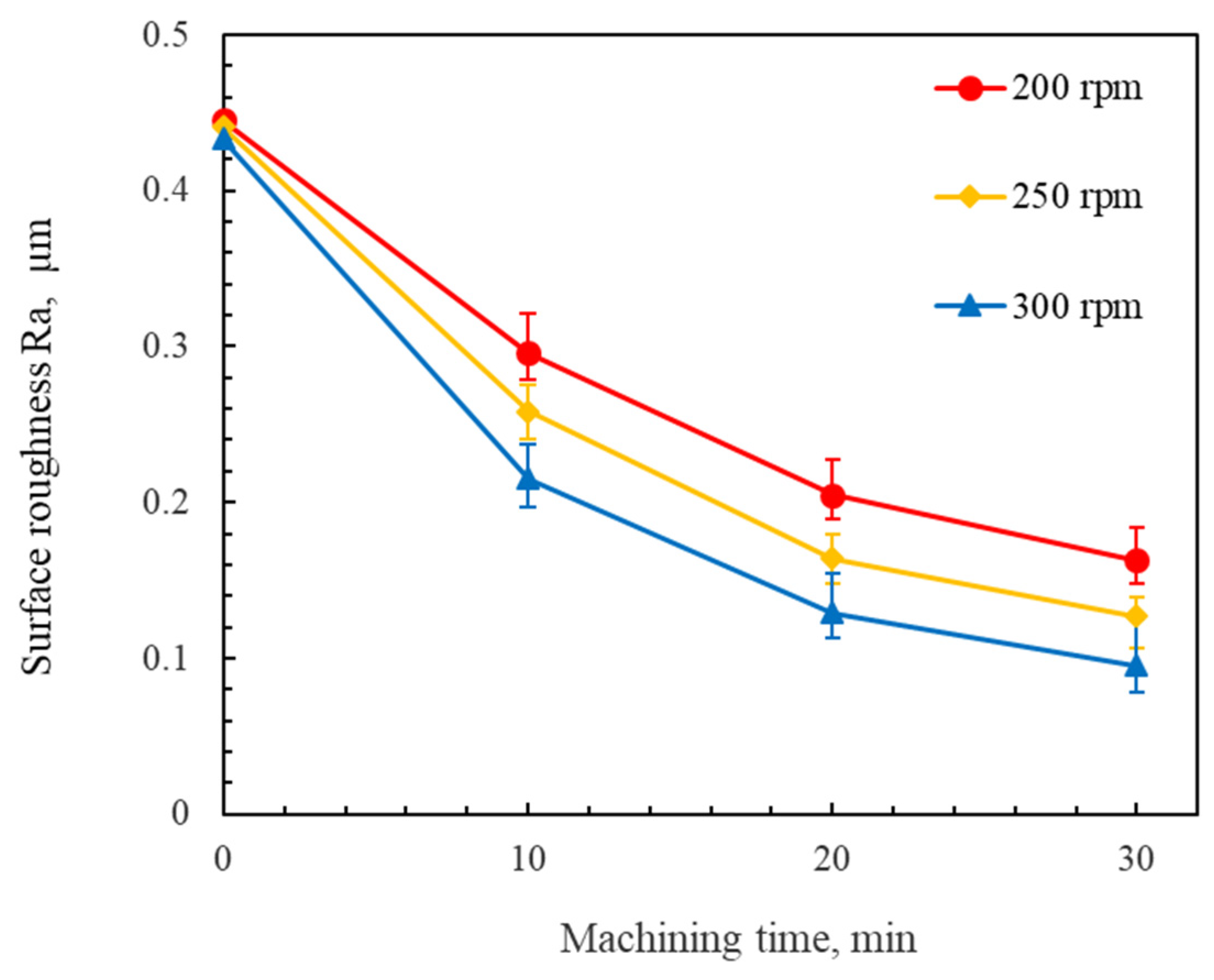

3.2. The Influence of the Rotational Speed of the Magnetic Poles on the Polishing Effect

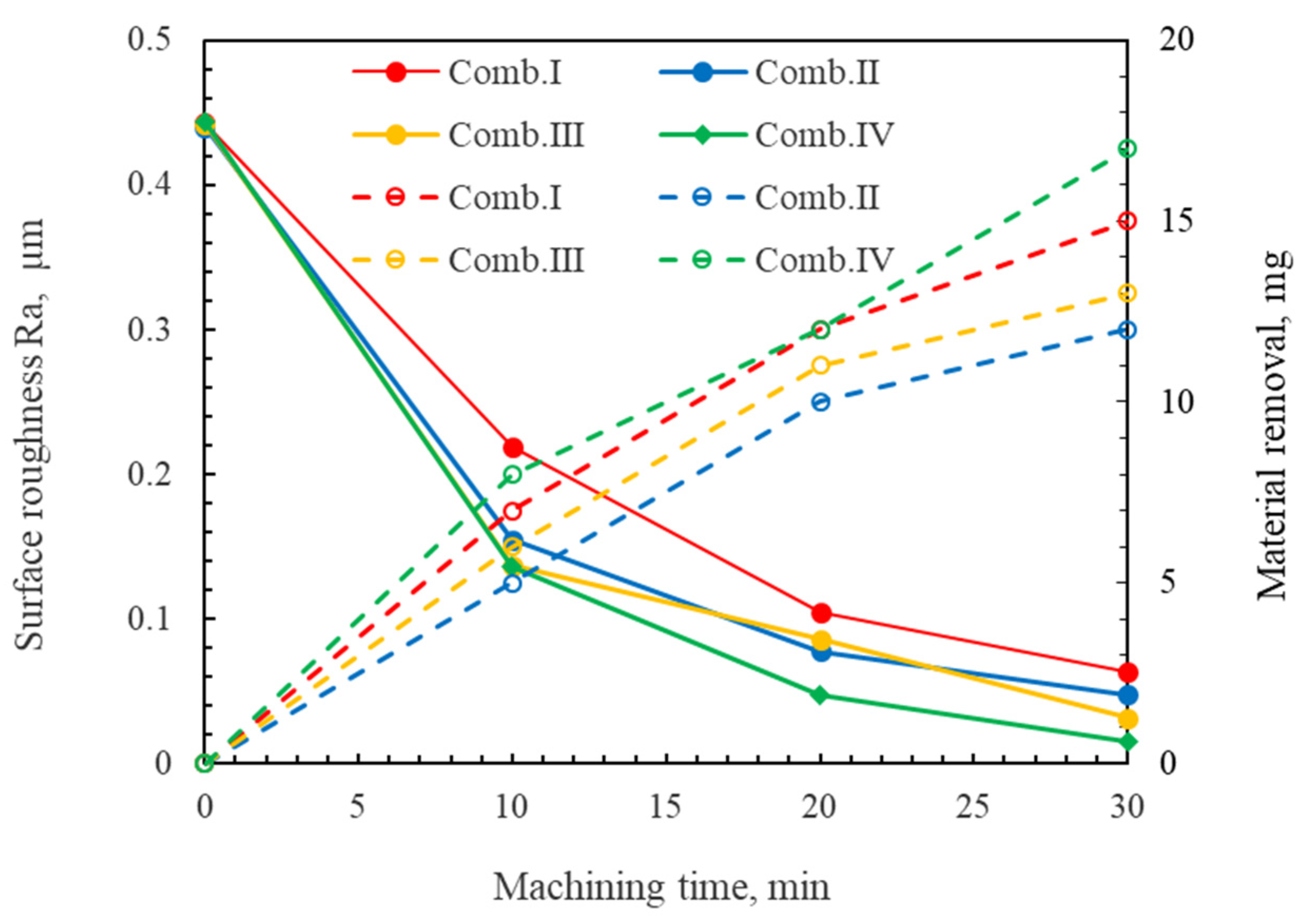

3.3. The Influence of the Abrasive Combination on the Polishing Effect

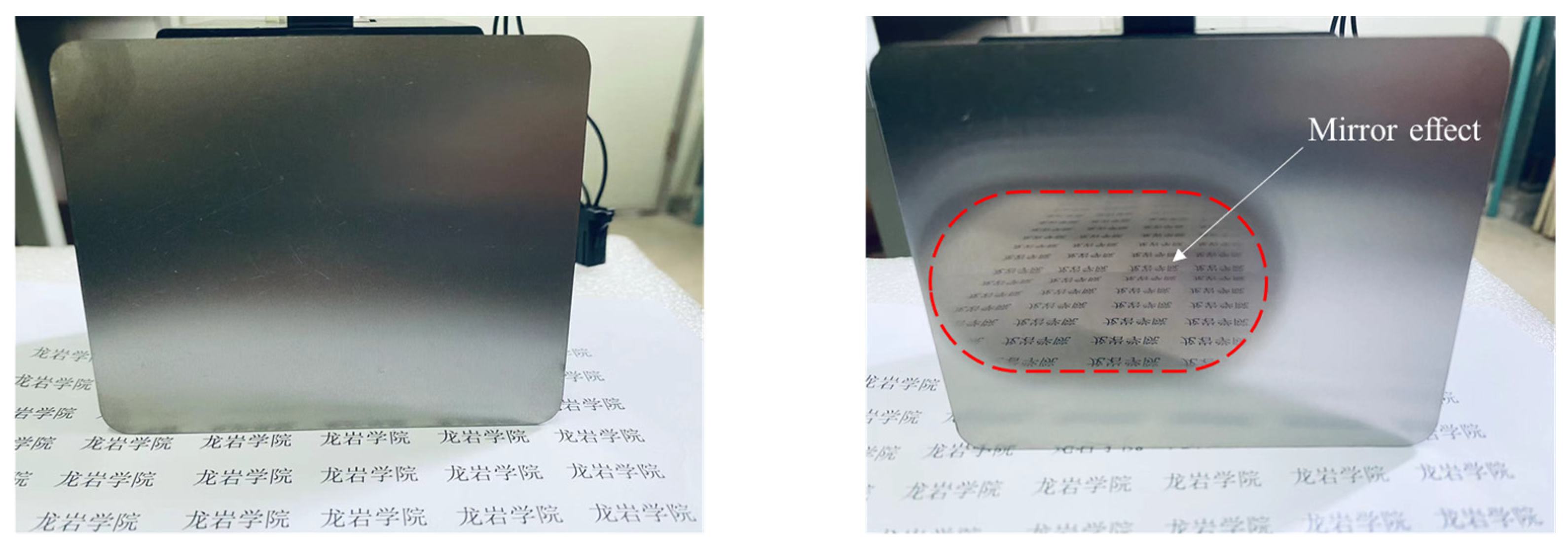

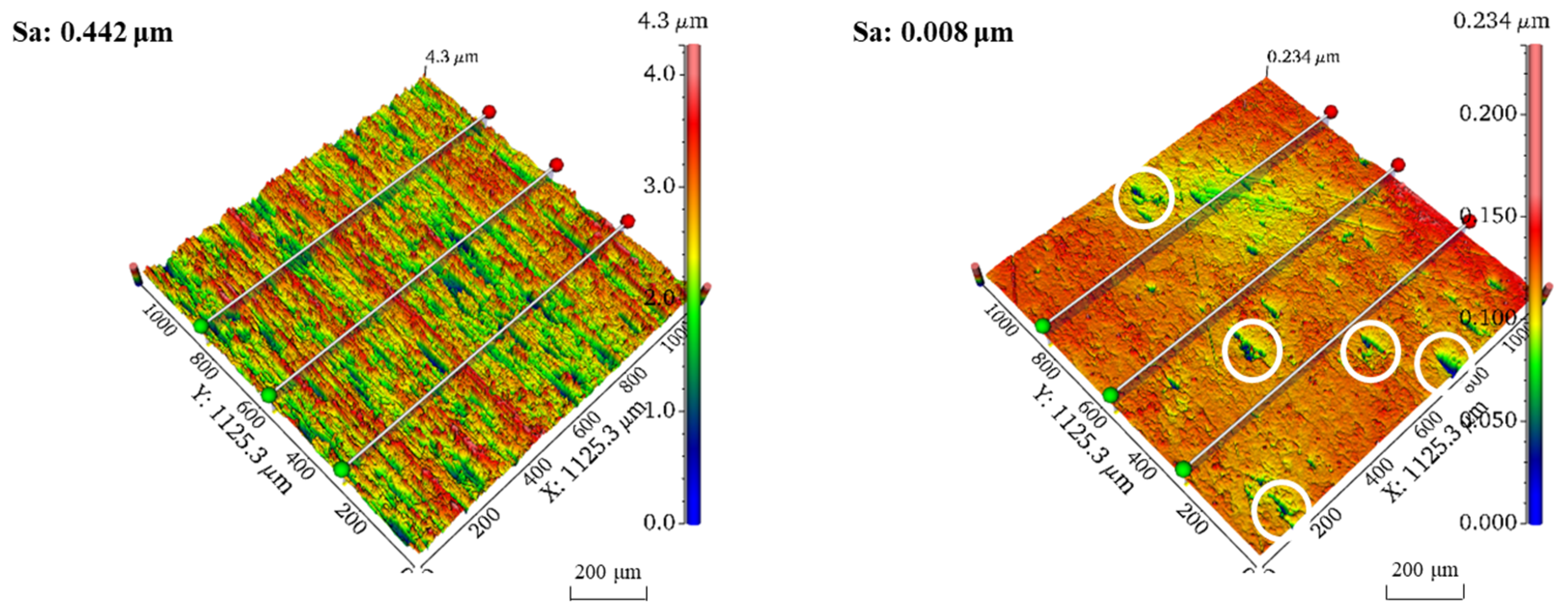

3.4. Characterization of the Workpiece Surface After Multi-Stage Polishing

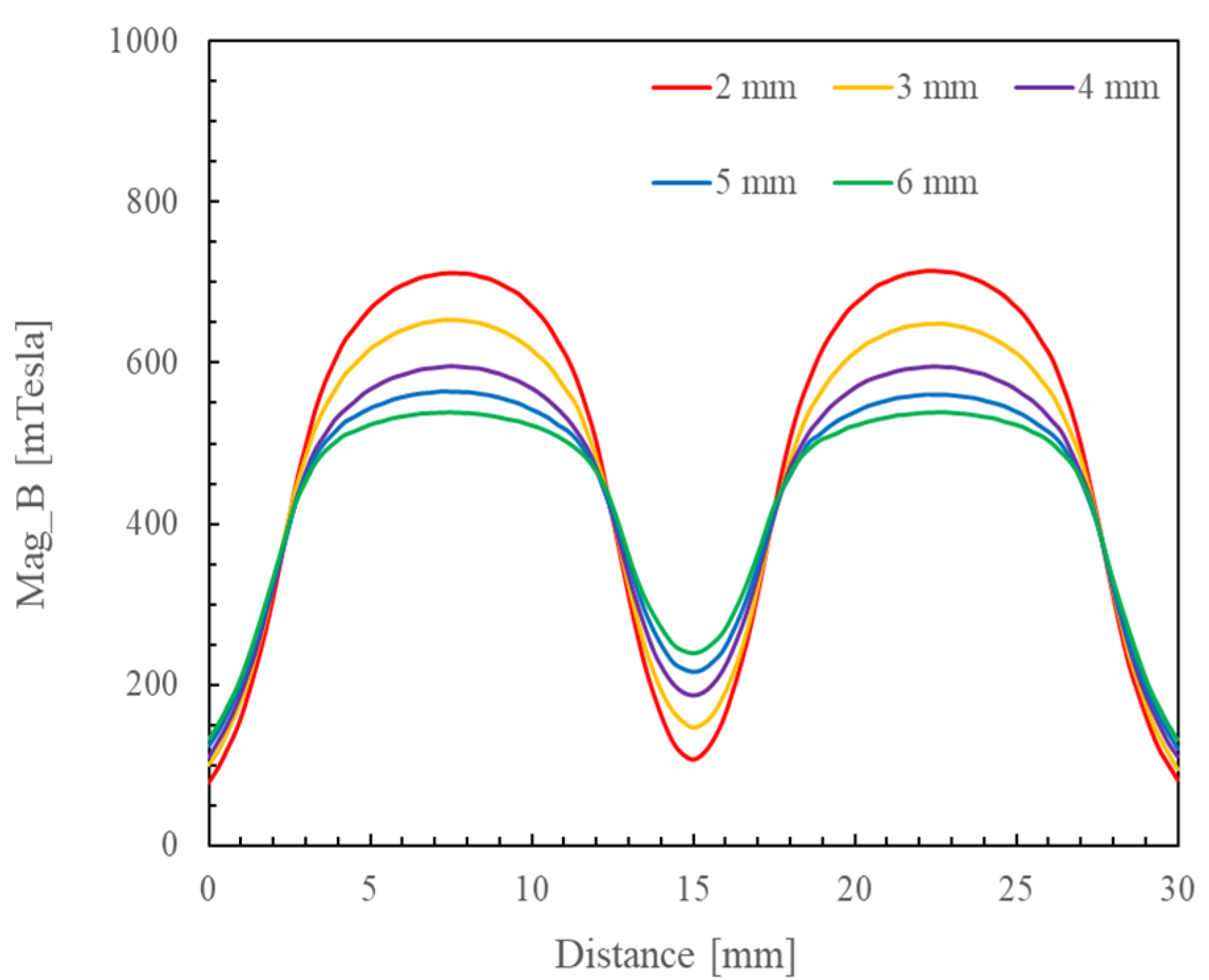

3.5. Simulation of the Intensity of Magnetic Induction

4. Discussion

5. Conclusions

- (1)

- The distribution of the magnetic field and the magnetic induction intensity generated using different combinations of magnetic poles were analyzed using Ansys Maxwell simulation software. The strongest magnetic induction intensity generated by the upper and lower magnetic poles in the polishing zone, which were both cubic magnetic poles, reached a maximum value of 0.792 T.

- (2)

- By studying the effect of the gap between the upper and lower magnetic poles and the rotational speed of the magnetic poles on the polishing effect, we found that a better surface polishing effect could be obtained using a 5 mm gap between dual-magnetic poles and a 300 rpm rotational speed for the magnetic poles.

- (3)

- Using the same gap between the upper and lower magnetic poles and the same rotational speed of the magnetic poles, when using combination IV of the mixed magnetic abrasive, the surface roughness Ra of the workpiece could be reduced from an initial 0.433 μm to 0.015 μm. Additionally, a mirror-like polishing effect was achieved in the polishing zone on the workpiece surface.

- (4)

- The surface morphology of the workpiece was evaluated using a white light interferometer. The results show that the surface roughness Sa of the measurement point was reduced to below 10 nm, and the 3D morphology of the workpiece’s surface basically tended to become flat. However, a small number of defects still existed on the workpiece surface.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, N.; Raj, T.; Jangra, K. Applications of nickel-titanium alloy. J. Eng. Technol. 2015, 5, 1–7. [Google Scholar] [CrossRef]

- Xu, Z.W.; Jiang, X.H. Osteogenic TiO2 composite nano-porous arrays: A favorable platform based on titanium alloys applied in artificial implants. Colloids Surf. A Physicochem. Eng. Asp. 2022, 640, 128301. [Google Scholar] [CrossRef]

- Pesode, P.; Barve, S. A review—Metastable β titanium alloy for biomedical applications. J. Eng. Appl. Sci. 2023, 70, 25–60. [Google Scholar] [CrossRef]

- Chen, X.Y.; Li, F.M.; Ding, L.P.; Wang, C.L.; Yang, Q.B.; Shuai, L.F.; Weng, Y.Y.; Jiang, H.T.; Jia, Z.H. Influence of solution treatment on surface recrystallization and age-hardening response of extruded 2196 Al-Li alloy. Mater. Today Commun. 2025, 44, 111927. [Google Scholar] [CrossRef]

- Wang, H.H.; Wang, C.G.; Dang, J.Q.; Gao, P.J.; An, Q.L.; Zheng, T.C.; Deng, Y.D.; Ming, W.W.; Chen, M.; Wang, T.; et al. Frication behaviors, wear and failure mechanisms of CBN tool and machined surface morphology in high-speed turning of high strength refractory alloy cast steel. J. Manuf. Process. 2025, 138, 186–202. [Google Scholar] [CrossRef]

- Demirci, S.; Tünçay, M.M. Surface engineering of additively manufactured Ti-6Al-4V alloys: A comparative study on micro/nanoscale topographies for biomedical applications. Mater. Today Commun. 2025, 42, 111010. [Google Scholar] [CrossRef]

- Shinmura, T.; Takazawa, K.; Hatano, E. Study on magnetic abrasive process (Application to plane finishing). J. Jpn. Soc. Precis. Eng. 1985, 19, 289–294. [Google Scholar]

- Shinmura, T. Study on plane magnetic abrasive finishing (3rd Report on the finishing characteristics of non-ferromagnetic substance). J. Jpn. Soc. Precis. Eng. 1989, 55, 1271–1276. [Google Scholar] [CrossRef]

- Shinmura, T.; Aizawa, T. Development of plane magnetic abrasive finishing apparatus and its finishing performance (2nd Report, Finishing apparatus using a stationary type electromagnet). J. Jpn. Soc. Precis. Eng. 1988, 54, 928–933. (In Japanese) [Google Scholar] [CrossRef]

- Shinmura, T.; Takazawa, K.; Hatano, E.; Matsunaga, M. Study on magnetic abrasive finishing. Ann. CIRP 1990, 39, 325–328. [Google Scholar] [CrossRef]

- Natsume, M.; Shinmura, T.; Yamguchi, H. Observation of the abrasive force and abrasive scratches in magnetic abrasive finishing process. J. Jpn. Soc. Abras. Technol. 2005, 49, 213–218. [Google Scholar]

- Yamaguchi, H.; Shinmura, T. Study of an internal magnetic abrasive finishing using a pole rotation system. Precis. Eng. 2000, 24, 237–244. [Google Scholar] [CrossRef]

- Natsume, M.; Shinmura, T.; Yamaguchi, H. The effects of lubricant on the characteristics of the magnetic abrasive brush in magnetic abrasive finishing. In Proceedings of the International Conference on Leading Edge Manufacturing in 21st Century (LEM21), Niigata, Japan, 3–6 November 2003; pp. 397–402. [Google Scholar]

- Fang, Z.C.; Zhang, Y.L.; Wang, H.; Ning, D.T.; Li, Y. Research on the mechanism of high precision planar magnetic grinding. Acad. J. Eng. Technol. Sci. 2024, 7, 164–169. [Google Scholar]

- Kang, J.; Yamaguchi, H. Internal finishing of capillary tubes by magnetic abrasive finishing using a multiple pole-tip system. Precis. Eng. 2012, 36, 510–516. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Nteziyaremye, V.; Stein, M.; Li, W. Hybrid tool with both fixed-abrasive and loose-abrasive phases. CIRP Ann. 2015, 64, 337–340. [Google Scholar] [CrossRef]

- Zou, Y.H.; Liu, J.N.; Shinmura, T. Study on internal magnetic field assisted finishing process using a magnetic machining jig for thick non-ferromagnetic tube. Adv. Mater. Res. 2011, 325, 530–535. [Google Scholar] [CrossRef]

- Liu, J.N.; Zou, Y.H. Study on mechanism of roundness improvement by the internal magnetic abrasive finishing process using magnetic machining tool. Machines 2022, 9, 112. [Google Scholar] [CrossRef]

- Xie, H.J.; Zou, Y.H. Study on the magnetic abrasive finishing process using an alternating magnetic field—Discussion on the application of full-wave rectifier current. Mater. Sci. Forum. 2021, 6099, 117–122. [Google Scholar] [CrossRef]

- Sun, X.; Zou, Y.H. Development of magnetic abrasive finishing combined with electrolytic process for finishing SUS304 stainless steel plane. Int. J. Adv. Manuf. Tech. 2017, 92, 3373–3384. [Google Scholar] [CrossRef]

- Sun, X.; Zou, Y.H. Study on electrolytic magnetic abrasive finishing stainless steel SUS304 plane with a special compound machining tool. J. Manuf. Mater. Proc. 2018, 2, 41. [Google Scholar] [CrossRef]

- Sun, X.; Fu, Y.J.; Lu, W.; Hang, W. Investigation on the electrochemical assisted magnetic abrasive finishing for a stainless steel of SUS304. Int. J. Adv. Manuf. Tech. 2021, 116, 1509–1522. [Google Scholar] [CrossRef]

- Xiang, Y.; Cao, F.H. Ultrasonic magnetic abrasive finishing of Al7075-T6 and A356.0-T6 using SiC-brush with CNT nano-lubricant. Mater. Manuf. Process. 2025, 40, 882–891. [Google Scholar] [CrossRef]

- Abbas, P.; Mohammad, S.; Amir, A.; Yahya, C. Ultrasonic assisted magnetic abrasive finishing of DIN 1.2738 tool steel using vitrified bonded magnetic abrasive particles. Part E J. Process Mech. Eng. 2024, 238, 2293–2304. [Google Scholar]

- Heng, L.D.; Kim, J.S.; Tu, J.F.; Mun, S.D. Fabrication of precision meso-scale diameter ZrO2 ceramic bars using new magnetic pole designs in ultra-precision magnetic abrasive finishing. Ceram. Int. 2020, 46, 17335–17346. [Google Scholar] [CrossRef]

- Zou, Y.H.; Xie, H.J.; Zhang, Y.L. Study on surface quality improvement of the plane magnetic abrasive finishing process. Int. J. Adv. Manuf. Tech. 2020, 109, 1825–1839. [Google Scholar] [CrossRef]

- Dong, C.W.; Zou, Y.H.; Xie, H.J. Study on a new kind of magnetic abrasive finishing by using alternating magnetic field for ultra-precision plane finishing. Mater. Sci. Forum. 2020, 5996, 42–49. [Google Scholar] [CrossRef]

- Zou, Y.H.; Shinmura, T. Development of Magnetic Field Assisted Machining Process Using Magnetic Machining Jig. Trans. Japan Soc. Mech. Eng. Ser. C 2002, 68, 1575–1581. [Google Scholar] [CrossRef]

- Zhou, Z.F.; Sun, X.; Yang, Y.Z.; Fu, Y.J. A study on using magnetic abrasive finishing with a 6-axis robot to polish the internal surface finishing of curved tubes. Coatings 2023, 13, 1179. [Google Scholar] [CrossRef]

| Machining Parameters | Numerical Value |

|---|---|

| Workpiece | TC4 titanium alloy plate (100 × 80 × 1 mm) |

| Initial surface roughness Ra | 0.4~0.5 μm |

| Magnetic pole material | NdFe35 permanent magnet |

| Mixed magnetic abrasive | Electrolytic iron powder (Fe3O4): #45 (325 μm), #100 (150 μm), #200 (75 μm), #450 (30 μm); |

| WA(Al2O3): #800 (18 μm), #2000 (6.5 μm), #4000 (3 μm), #8000 (1.6 μm); DMD: #W5 (3 μm), #W2 (1.2 μm), #W1 (0.6 μm); | |

| Diamond oil-based grinding fluid | |

| Mass ratio of iron-based phase to polishing phase | 2:1 |

| Rotational speed of magnetic pole | 200 rpm, 250 rpm, 300 rpm |

| Gap between upper and lower magnetic poles | 4 mm, 5 mm, 6 mm |

| Total polishing time | 30 min (each polishing stage is 10 min) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Sun, X.; Liang, S.; Fang, Y.; Yang, Y.; Fu, Y.; Zou, S. Nanoscale Polishing of TC4 Titanium Alloy Surface Based on Dual-Pole Magnetic Abrasive Finishing Method. Micromachines 2025, 16, 620. https://doi.org/10.3390/mi16060620

Zhou Z, Sun X, Liang S, Fang Y, Yang Y, Fu Y, Zou S. Nanoscale Polishing of TC4 Titanium Alloy Surface Based on Dual-Pole Magnetic Abrasive Finishing Method. Micromachines. 2025; 16(6):620. https://doi.org/10.3390/mi16060620

Chicago/Turabian StyleZhou, Zhenfeng, Xu Sun, Shibing Liang, Ying Fang, Yanzhen Yang, Yongjian Fu, and Shiqing Zou. 2025. "Nanoscale Polishing of TC4 Titanium Alloy Surface Based on Dual-Pole Magnetic Abrasive Finishing Method" Micromachines 16, no. 6: 620. https://doi.org/10.3390/mi16060620

APA StyleZhou, Z., Sun, X., Liang, S., Fang, Y., Yang, Y., Fu, Y., & Zou, S. (2025). Nanoscale Polishing of TC4 Titanium Alloy Surface Based on Dual-Pole Magnetic Abrasive Finishing Method. Micromachines, 16(6), 620. https://doi.org/10.3390/mi16060620