Abstract

In this paper, the degradation behaviors of the ferroelectric gate Gallium nitride (GaN) high electron mobility transistor (HEMT) under positive gate bias stress are discussed. Devices with a gate dielectric that consists of pure Pb(Zr,Ti)O3 (PZT) and a composite PZT/Al2O3 bilayer are studied. Two different mechanisms, charge trapping and generation of traps, both contribute to the degradation. We have observed positive threshold voltage shift in both kinds of devices under positive gate bias stress. In the devices with a PZT gate oxide, we have found the degradation is owing to electron trapping in pre-existing oxide traps. However, the degradation is caused by electron trapping in pre-existing oxide traps and the generation of traps for the devices with a composite PZT/Al2O3 gate oxide. Owing to the large difference in dielectric constants between PZT and Al2O3, the strong electric field in the Al2O3 interlayer makes PZT/Al2O3 GaN HEMT easier to degrade. In addition, the ferroelectricity in PZT enhances the electric field in Al2O3 interlayer and leads to more severe degradation. According to this study, it is worth noting that the reliability problem of the ferroelectric gate GaN HEMT may be more severe than the conventional metal–insulator–semiconductor HEMT (MIS-HEMT).

1. Introduction

Gallium nitride(GaN) high electron mobility transistor (HEMT) has been studied over the last decade in consideration of high power and high frequency electronic applications [1,2,3,4,5,6,7,8,9]. Recently, GaN HEMT with ferroelectric insulated gate have attracted a large number of attentions. Of particular interest is the combination of ferroelectric oxides with GaN HEMT due to the strong polarization of GaN-based materials and the switchable polar nature of ferroelectrics, leading to the possibility of tunning the polarization in GaN HEMT with ferroelectric oxides. Many studies focus on achieving E-mode GaN metal–insulator–semiconductor HEMT(MIS-HEMT) by modulating the polarization of AlGaN/GaN with ferroelectric material [10,11,12]. Extensive studies have reported that the growth of ferroelectric oxides on AlGaN/GaN heterostructure could improve the lattice-mismatch problem, the basic electric characteristics of device after modulation of threshold voltage by ferroelectric oxides, or the polarization-modulation behavior between the ferroelectric gate and AlGaN/GaN [13,14]. Similar as the conventional GaN MIS-HEMT, the presence of the dielectric layer would cause threshold voltage drifts due to trapping at the dielectric/III-V interface under positive gate bias stress [15,16,17,18]. Especially for ferroelectric gate GaN MIS-HEMT, the ferroelectric oxide layer may lead to different degeneration effects due to the polarization coupling between the ferroelectric oxide and AlGaN/GaN. However, so far, little attention has been paid on the reliability of the ferroelectric gate GaN MIS-HEMT under electric stress. The degeneration of electric characteristics under electric stress limits the applied voltage at which the ferroelectric gate GaN HEMT can be safely operated.

As Pb(Zr,Ti)O3 (PZT) is a typical ferroelectric for the dielectric layer in ferroelectric/AlGaN/GaN HEMT, in this paper, we investigate the roles of charge trapping and trap generation during the positive gate bias stress in PZT/AlGaN/GaN HEMT devices. The threshold voltage, subthreshold, and transconductance are examined before and after the stress test to reveal the different trap effects during the test. As compared, the device with an Al2O3 interlayer between PZT and AlGaN(PZT/Al2O3/AlGaN/GaN HEMT) is also investigated, which shows a different degeneration behavior from that without Al2O3.

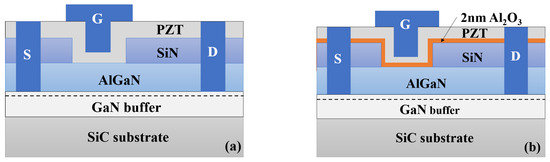

2. Device Design and Fabrication

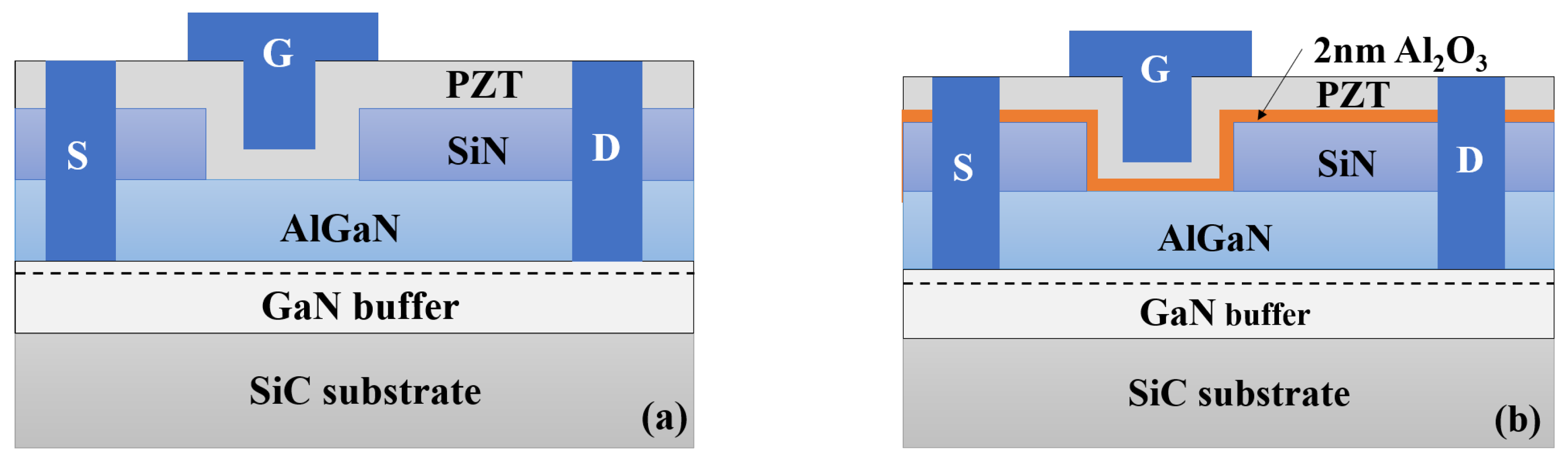

The structure diagram of the fabricated ferroelectric gate AlGaN/GaN HEMT is presented in Figure 1. The device was fabricated on SiC substrate by metal organic chemical vapor deposition (MOCVD), containing 180 nm AlN nucleation layer, 3-μm GaN buffer, 1 nm AlN interlayer, and 20 nm Al0.3Ga0.7N barrier. Device fabrication started with ohmic contact formation by depositing a Ti/Al/Ni/Au (20/160/55/45 nm) metal stack annealed at 840 °C for 30 s in N2 ambient, followed by the device isolation using inductively coupled plasma (ICP). The pressure and N2 flow during the annealing is one atmosphere (101 kPa) and 2L/min, respectively. The contact resistance of the Ti/Al/Ni/Au metal stack is 0.45 Ω·mm measured by 2-probe linear transmission line method (TLM). Then, the surface passivation was conducted by depositing Si3N4 using plasma-enhanced chemical vapor deposition (PECVD). The SiN presented under the gate was removed by dry-etching with ICP. PZT was deposited using a pulsed laser deposition (PLD) system at 500 °C. For the device with Al2O3 interlayer as shown in Figure 1b, prior to a 30 nm PZT ferroelectric layer deposition, a 2 nm Al2O3 interfacial layer was grown by atomic layer deposition (ALD) and oxidized with O2 plasma at 300 °C for 30 min. Finally, Pt was sputtered using a magnetron sputter and lifted off to define the gate electrodes.

Figure 1.

Schematic cross-section of (a) the PZT/AlGaN/GaN HEMT and (b) the PZT/Al2O3/AlGaN/GaN HEMT.

3. Device Performance and Discussion

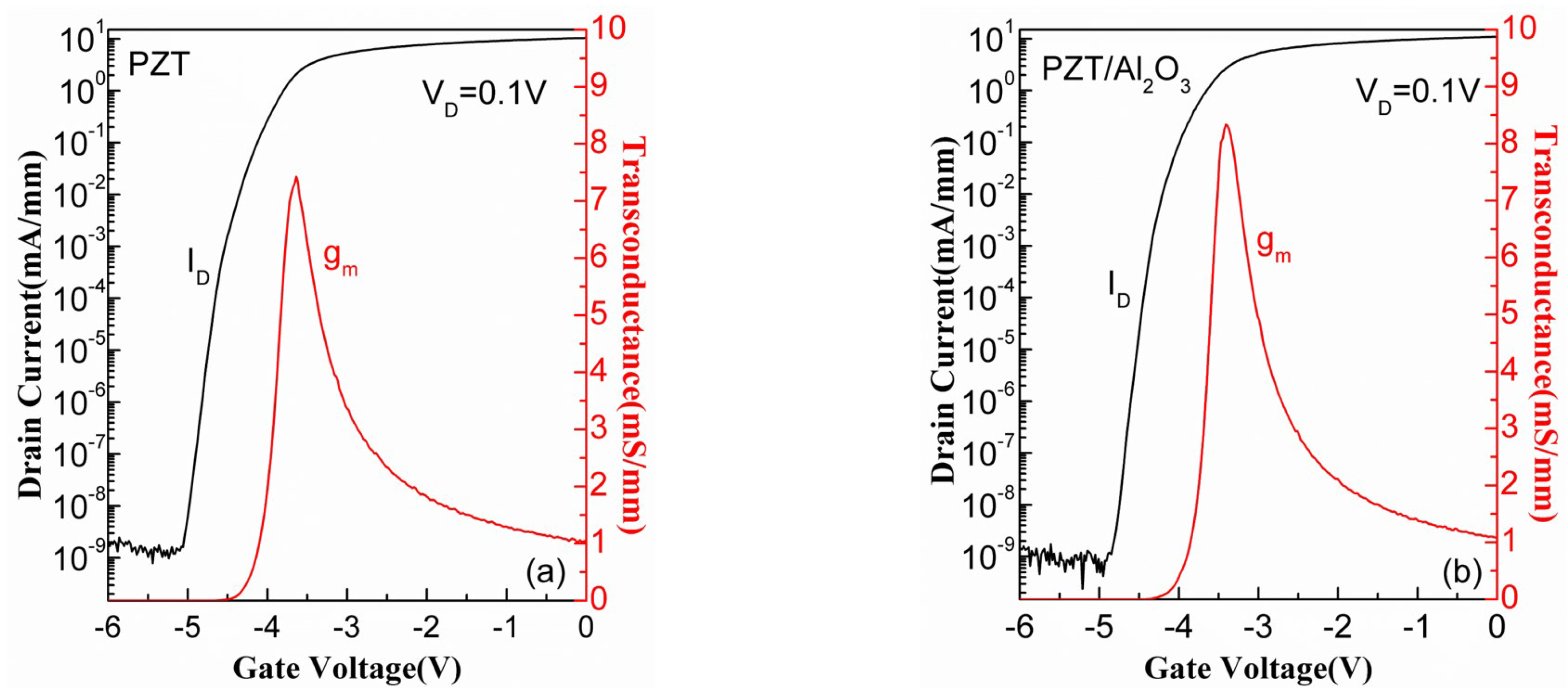

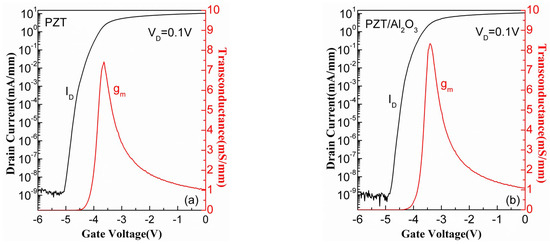

The DC measurements were performed using a Keithley 4200 semiconductor analyzer. In this paper, we focus on the stability of the threshold voltage (Vth), the maximum transconductance(gm), and the subthreshold swing (S.S) of the devices with and without a Al2O3 interlayer. To compare the characteristics of the devices before and after the stress test, the transfer characteristics of both kinds of fresh devices (PZT GaN HEMT and PZT/Al2O3 GaN HEMT) were measured, as presented in Figure 2. Drain voltage was applied with 0.1 V to measure the transconductance and subthreshold in the linear region, which decreases the influence of the drain electric field on the gate. The peak gm of the two types of devices was 7.5 mS/mm and 8.3 mS/mm, respectively.

Figure 2.

Transfer characteristic of (a) the PZT/AlGaN/GaN HEMT and (b) the PZT/Al2O3/AlGaN/GaN HEMT at VD = 0.1 V.

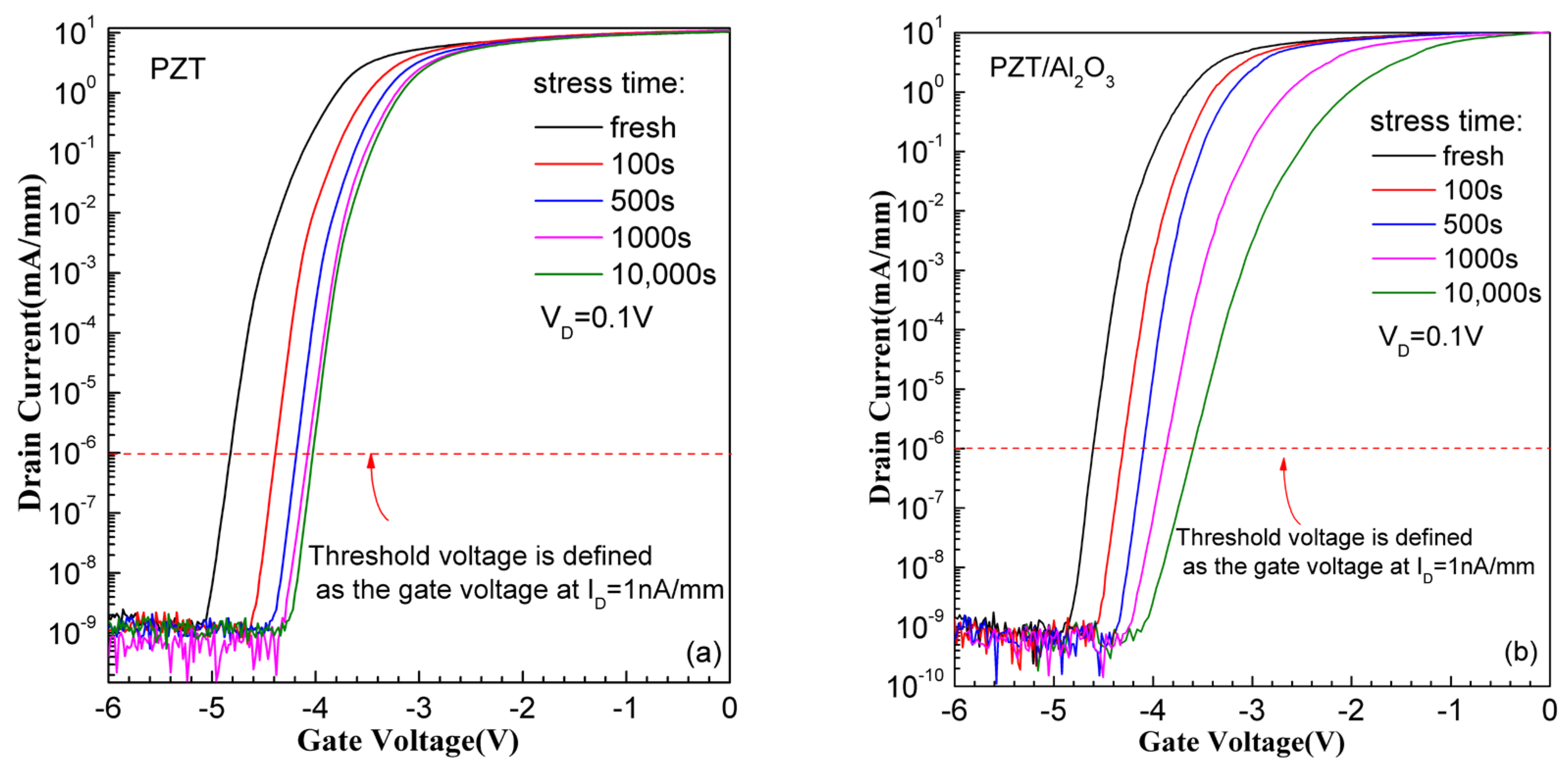

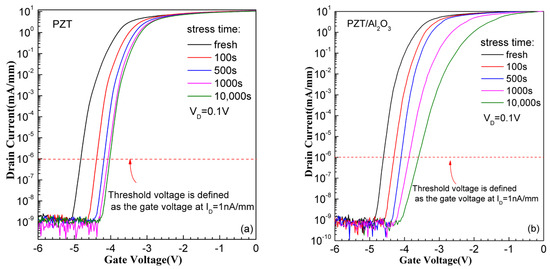

During the test, positive gate bias stress was applied with 15 V with drain and source grounded, and the stress time (tstress) was set from 10 s to 10,000 s. The transfer characteristics of both kinds of devices were measured during the positive stress to monitor the evolution of Vth, gm and S.S with stress time. Figure 3 shows the ID-VGS curves of PZT GaN HEMT and PZT/Al2O3 GaN HEMT in several typical stress times. The threshold voltage is defined as the gate voltage at ID = 1 nA/mm. As can be seen, the threshold voltages of both kinds of devices positively shift with the increase in stress time. For PZT GaN HEMT, the Vth shifting tend to saturation with stress time increased to 1000 s, while Vth shifting of PZT/Al2O3 GaN HEMT is still obvious when the stress time reaches 10,000 s. The Vth shift during positive gate bias stress indicates electron trapping in the gate stack.

Figure 3.

The ID-VGS curves of (a) the PZT/AlGaN/GaN HEMT and (b) the PZT/Al2O3/AlGaN/GaN HEMT after positive gate bias stress with different stress time.

However, it is worth pointing out that the S.S is almost no changing for the PZT GaN HEMT as shown in Figure 3a, which means no traps generation during the stress in PZT GaN HEMT. As for the PZT/Al2O3 GaN HEMT, the S.S degrades when stress time increase to 1000 s, indicating the generation of traps (interface or border) according to the formula for the S.S [19]. These generated traps cause the positive shift of Vth when the stress time increase to 1000 s for the PZT/Al2O3 GaN HEMT.

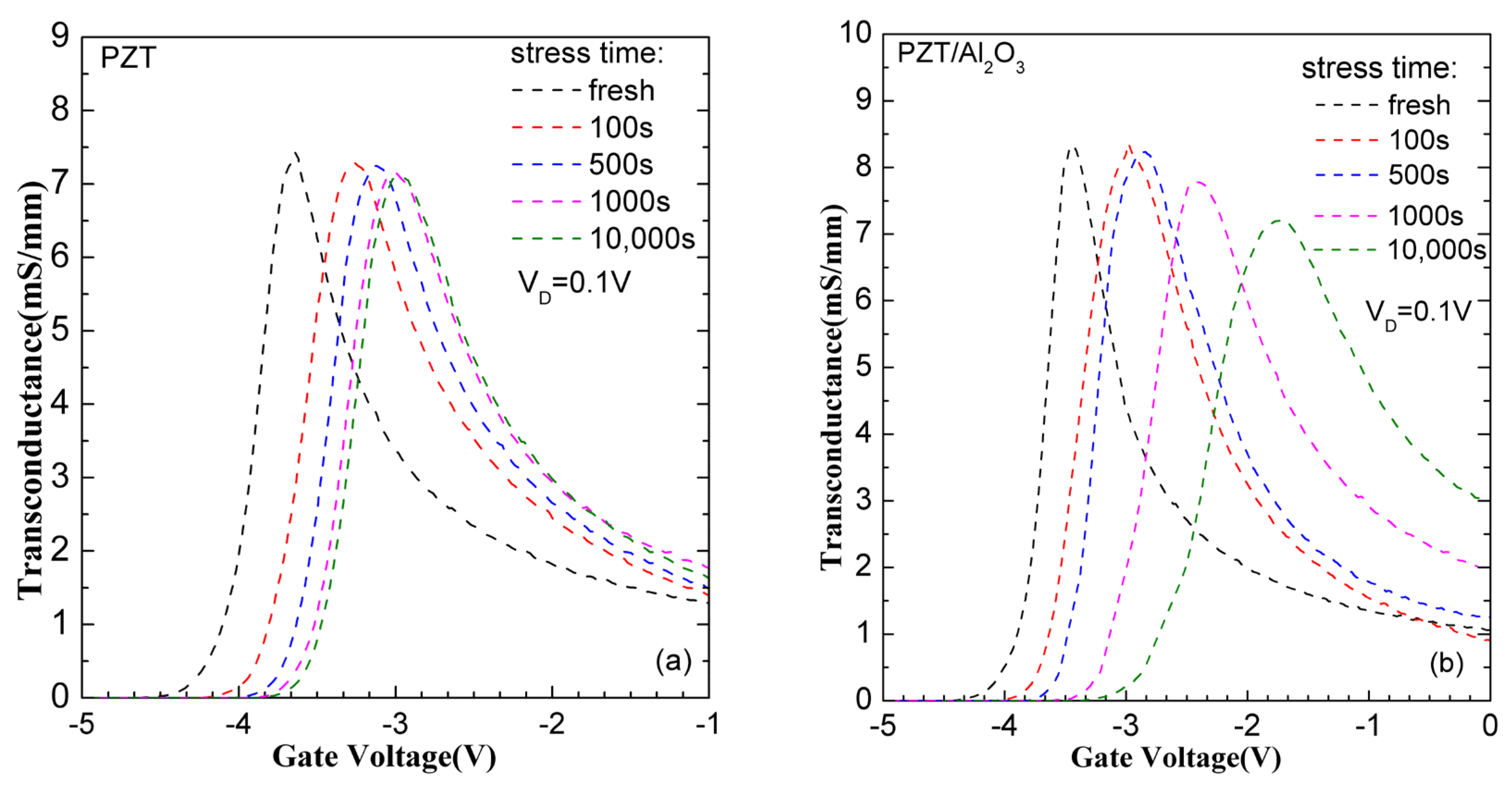

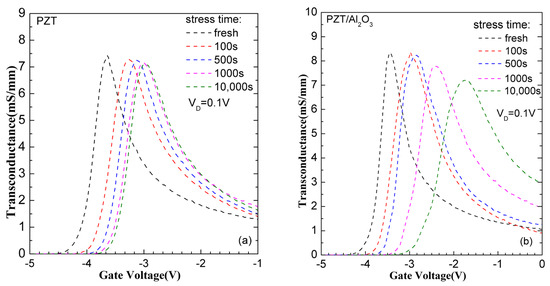

Figure 4 presents the transconductance curves extracted from Figure 2. It is easy to see that the gm drops slightly for the PZT GaN HEMT while the gm decreases obviously when the stress time reaches 1000 s for the PZT/Al2O3 GaN HEMT. The obvious drop of gm during the stress suggests that the generated traps have a significant influence on the mobility of the PZT/Al2O3 GaN HEMT. The charge-trapping process mainly occurs near the oxide/AlGaN interface which is close to the channel because of its influence on channel mobility.

Figure 4.

Transconductance curves of (a) the PZT/AlGaN/GaN HEMT and (b) the PZT/Al2O3/AlGaN/GaN HEMT after positive gate bias stress with different stress time.

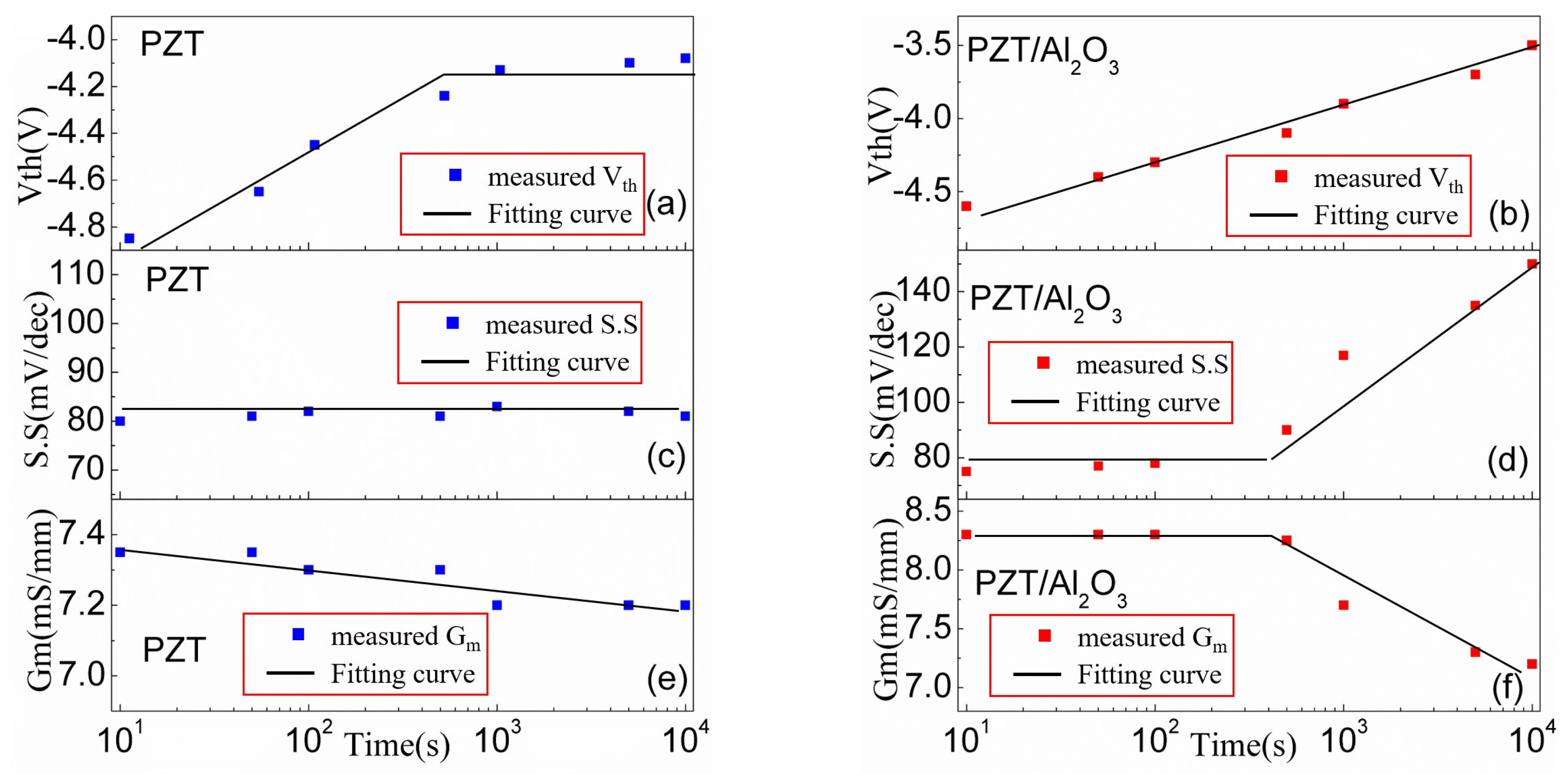

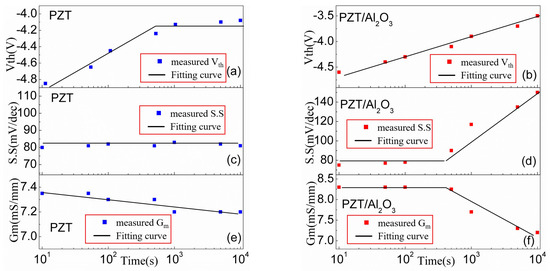

In order to identify the different trends of Vth, S.S, and gm for both kinds of devices during the stress applied, Figure 5 summarizes the evolution of Vth, S.S, and gm over the stress time. For the PZT GaN HEMT, the Vth increases linearly with stress time before 600s, and then increases very slightly with stress time, as can be seen in Figure 5a. The S.S is almost stable at around 80~85 mV/dec during the stress test as shown in Figure 5c. In Figure 5e, the gm drops slightly with stress time increases, indicating that the electron trapping just has a slight impact on the mobility of the device. Since gm drops slightly and no S.S degeneration during the stress test, it can be concluded that the Vth positive shift is mainly due to the electron trapping in the oxide for the PZT GaN HEMT. Besides, due to there is no generated traps during the stress test, the Vth shift tends to saturation when the stress time increases after 600 s. For the PZT/Al2O3 GaN HEMT, the Vth increases with stress time even in long-term stress region as shown in Figure 5b, which is different from the PZT GaN HEMT. When the stress time is less than 500 s, the S.S and gm are stabilized at about 80 mV/dec and 8.3 mS/mm, respectively. The S.S starts to increase, and gm starts to drop when stress time is above 500 s. This suggests that new trap generation takes place for the PZT/Al2O3 GaN HEMT when stress time is greater than a certain level. According to the discussion above, we find that the PZT/Al2O3 GaN HEMT is easier to degradation under positive gate bias stress than the PZT GaN HEMT.

Figure 5.

Stress time evolution of Vth, S.S, and gm of (a,c,e) the PZT/AlGaN/GaN HEMT and (b,d,f) the PZT/Al2O3/AlGaN/GaN HEMT.

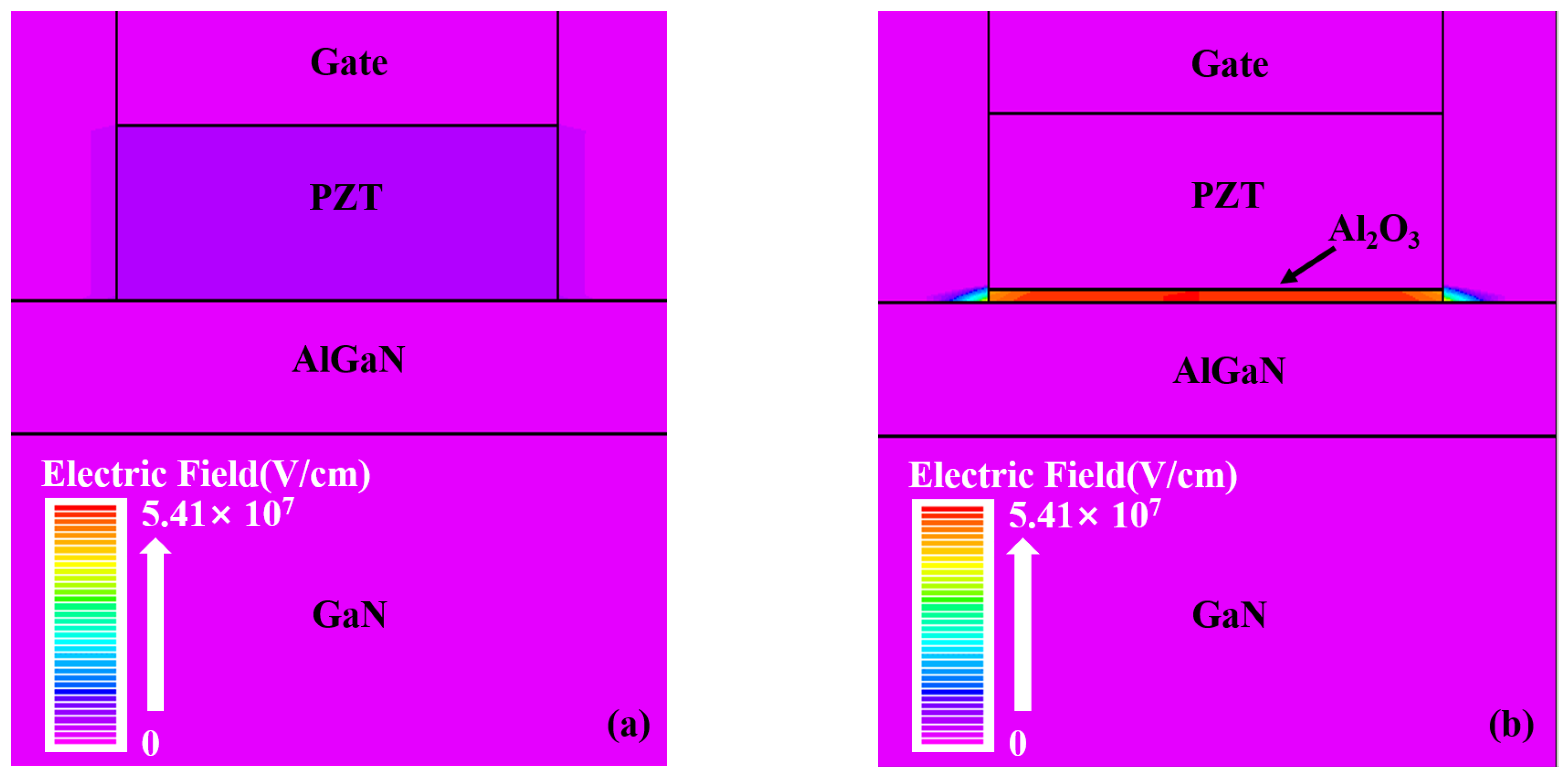

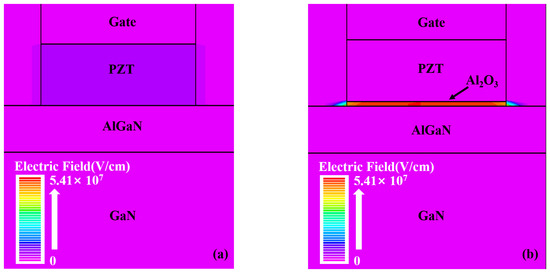

To clarify the reason for the new trap generation of the PZT/Al2O3 GaN HEMT in our stress test, we simulated the electrical field distribution under the gate of both kinds of devices with VG = 15 V by Silvaco Technology Computer Aided Design (TCAD). In our simulation, the dielectric constant of PZT and Al2O3 was set to 500 and 9, respectively. As shown in Figure 6, the electrical field under the gate stacks mainly concentrate on Al2O3 interlayer for the PZT/Al2O3 GaN HEMT, which is owing to the large difference in dielectric constants between PZT and Al2O3. The strong electric field in the Al2O3 interlayer leads to the generation of new traps during the stress test, which degrades the S.S and gm of devices. For the PZT GaN HEMT, the electric field in the gate oxide layer is relatively weak and therefore not so easy to degrade.

Figure 6.

Electric field simulation of (a) the PZT/AlGaN/GaN HEMT and (b) the PZT/Al2O3/AlGaN/GaN HEMT at VG = 15 V.

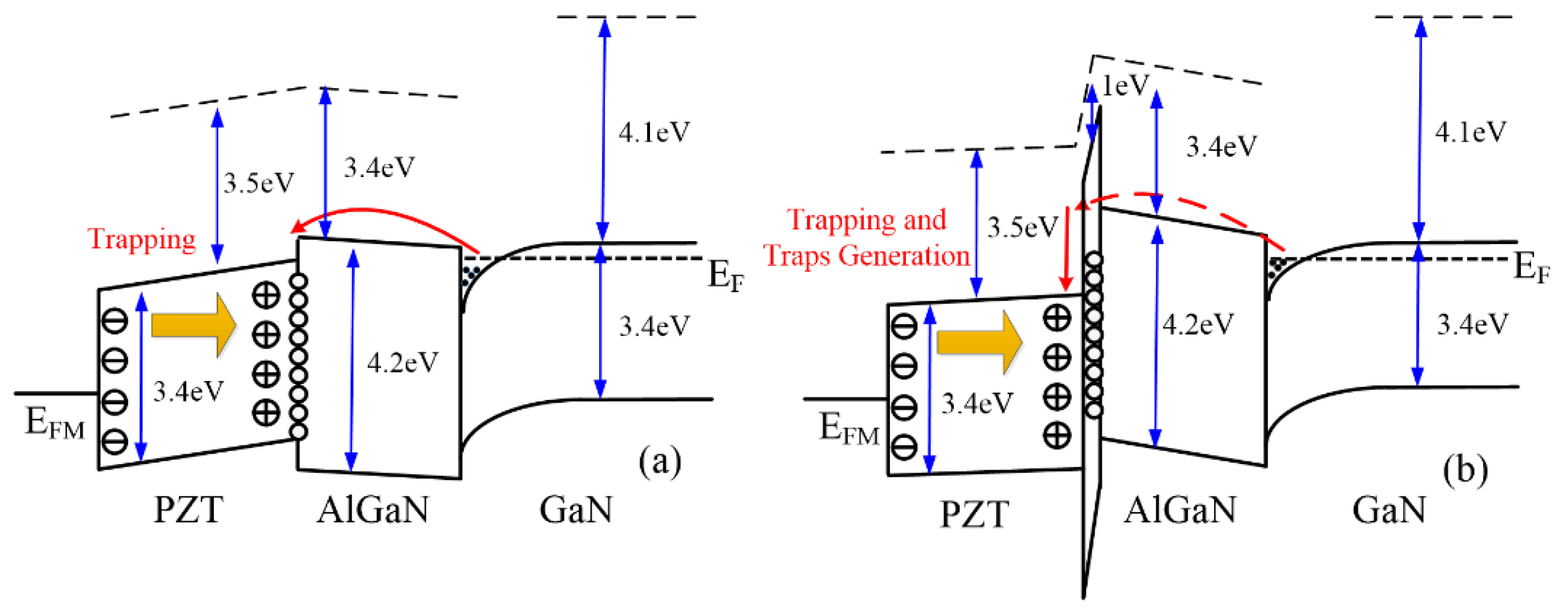

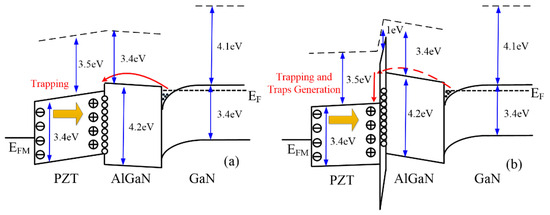

Figure 7 presents the band diagram to illustrate the underlying reason for the trapping behavior of both kinds of devices during the positive gate stress test. The direction of polarization in PZT is toward to substrate due to the applied gate voltage is positive. For the PZT GaN HEMT, there are some trap states at the PZT/AlGaN interface (interface states) or in the PZT close to the interface (border traps) due to the lattice mismatch between PZT and AlGaN [13]. Therefore, as shown in Figure 7a, the electrons from AlGaN/GaN channel are trapped at the PZT/AlGaN interface with the positive gate voltage, which leads to the Vth positive shift as mentioned above. When the trap states below the fermi level are all filled, the Vth shifting approaches saturation.

Figure 7.

Band diagrams under the gate of (a) the PZT/AlGaN/GaN HEMT and (b) the PZT/Al2O3/AlGaN/GaN HEMT at VG = 15V.

There are two stages of electrons trapping for the PZT/Al2O3 GaN HEMT. At the first stage, similar as the PZT GaN HEMT, electrons trapped at Al2O3/AlGaN interface or in Al2O3 interlayer with the positive gate voltage, causing the positive Vth shift. At the second stage, as shown in Figure 7b, electrons tunnel through the Al2O3 interlayer and enter the PZT. Owing to the conduction band difference between Al2O3 and PZT, the tunneling electrons start to lose energy in PZT and the lost energy from these electrons could be used to generate traps at Al2O3 or near the PZT/Al2O3 interface. Moreover, a strong electric field in Al2O3 makes a large conduction band bending, which leads to the tunnel electrons losing more energy and cause more severe generation of traps. These new trap states may be filled by electrons from the channel, which not only leads to the Vth positive shift continually but also causes the S.S and gm degradation with the increase in stress time. In addition, the ferroelectricity in PZT could also enhance the electric field in the Al2O3 interlayer (indicated by the arrow in Figure 7b) compared with the case that gate stacks are non-ferroelectric [19]. Such a high electric field would cause more severe degradation of the devices compared with the conventional MIS-HEMT. It is also worth pointing that some research shows utilizing oxides as interlayer can mitigate the lattice mismatch between PZT and AlGaN, but it also makes the device more susceptible to degradation. Furthermore, the ferroelectricity in PZT makes the degradation more severe.

4. Conclusions

In conclusion, this paper studied the positive gate bias stress of the ferroelectric gate GaN HEMT with PZT and PZT/Al2O3 as gate dielectric. The degradation mechanisms of the PZT GaN HEMT and the PZT/Al2O3 GaN HEMT are compared. For the PZT GaN HEMT, a positive Vth shift is caused by the electron trapping in pre-exiting oxide trap in the early stage, then the Vth tends to saturation with stress time increase. The S.S and gm degrade slightly with stress time. For the PZT/Al2O3 GaN HEMT, the Vth positive shift is due to the electron trapping in pre-exiting oxide trap and the generation of the new traps. The generated traps cause the obvious degradation of the S.S and gm. Owing to the large difference in the dielectric constants between PZT and Al2O3, the strong electric field in the Al2O3 interlayer makes the PZT/Al2O3 GaN HEMT easier to degrade. In addition, the ferroelectricity in PZT enhances the electric field in Al2O3 interlayer and leads to more severe degradation. Therefore, it is worth noting that the reliability problem of the ferroelectric gate GaN HEMT may be more severe than the conventional GaN MIS-HEMT. Using the ferroelectric oxide with a relatively small dielectric constant in gate stacks may mitigate the degradation in the real applications.

Author Contributions

Conceptualization, L.C. and Z.B.; methodology, Z.L.; software, C.F.; validation, L.C., M.Q. and J.S.; formal analysis, Y.S.; investigation, Z.L.; resources, C.F.; data curation, L.C.; writing—original draft preparation, L.C.; writing—review and editing, Y.S.; visualization, M.Q.; supervision, Y.S.; project administration, Z.B.; funding acquisition, L.C., J.S. and Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (Grant No.62104167, 62101374) and Jiangsu Natural Science Foundation (Grant No. BK20210863, BK20210861, BK20221385).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mishra, U.K.; Shen, L.; Kazior, T.E.; Wu, Y.F. GaN-based RF power devices and amplifiers. Proc. IEEE 2008, 96, 287–305. [Google Scholar] [CrossRef]

- Mishra, U.K.; Parikh, P.; Wu, Y.F. AlGaN/GaN HEMTs—An overview of device operation and applications. IEEE Electron Device Lett. 2012, 90, 1022–1031. [Google Scholar] [CrossRef]

- Saito, W.; Takada, Y.; Kuraguchi, M.; Tsuda, K.; Omura, I. Recessed-gate structure approach toward normally off high-voltage AlGaN/GaN HEMT for power electronics applications. IEEE Trans. Electron Devices 2006, 53, 356–362. [Google Scholar] [CrossRef]

- Pengelly, R.S.; Wood, S.M.; Milligan, J.W.; Sheppard, S.T.; Pribble, W.L. A review of GaN on SiC high electron-mobility power transistors and MMICs. IEEE Trans. Microw. Theory Tech. 2012, 60, 1764–1783. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, L.; Ma, X.; Ma, J.; Cao, M.; Pan, C.; Wang, C.; Zhang, J. High-Performance Microwave Gate-Recessed AlGaN/AlN/GaN MOS-HEMT with 73% Power-Added Efficiency. IEEE Electron Device Lett. 2011, 32, 626–628. [Google Scholar] [CrossRef]

- Yu, Q.; Shi, C.; Yang, L.; Lu, H.; Zhang, M.; Wu, M.; Hou, B.; Jia, F.; Guo, F.; Ma, X.; et al. High Current and Linearity AlGaN/GaN/-Graded-AlGaN:Si-doped/GaN Heterostructure for Low Voltage Power Amplifier Application. IEEE Electron Device Lett. 2023, 44, 582–585. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, X.-H.; Yang, L.; Mi, M.; Hou, B.; He, Y.; Wu, S.; Lu, Y.; Zhang, H.-S.; Zhu, Q.; et al. Influence of Fin Configuration on the Characteristics of AlGaN/GaN Fin-HEMTs. IEEE Trans. Electron Devices 2018, 65, 1745–1752. [Google Scholar] [CrossRef]

- Chen, K.J.; Häberlen, O.; Lidow, A.; Tsai, C.L.; Ueda, T.; Uemoto, Y.; Wu, Y.-F. GaN-on-Si Power Technology: Devices and Applications. IEEE Trans. Electron Devices 2017, 64, 779–795. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, Y.; Guo, S.; Lu, H.; Zhu, Q.; Mi, M.; Wu, M.; Hou, B.; Yang, L.; Ma, X.; et al. Influence of Gate Geometry on the Characteristics of AlGaN/GaN Nanochannel HEMTs for HighLinearity Applications. Micromachines 2023, 14, 1513. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.Z.; Zhu, J.; Liu, Y.J.; Liao, X.W.; Wang, S.L.; Zhou, J.J.; Kong, C.; Zeng, H.Z.; Zhang, Y.; Zhang, W.L.; et al. Normally-off characteristics of LiNbO3/AlGaN/GaN ferroelectric field-effect transistor. Thin Solid Film. 2012, 520, 6313–6317. [Google Scholar] [CrossRef]

- Lee, C.-T.; Yang, C.-L.; Tseng, C.-Y.; Chang, J.-H.; Horng, R.-H. GaN-Based Enhancement-Mode Metal-Oxide-Semiconductor High Electron Mobility Transistors Using LiNbO3 Ferroelectric Insulator on Gate-Recessed Structure. IEEE Trans. Electron. Devices 2015, 62, 2481–2487. [Google Scholar] [CrossRef]

- Chen, L.; Ma, X.; Zhu, J.; Hou, B.; Song, F.; Zhu, Q.; Zhang, M.; Yang, L.; Hao, Y. Polarization Engineering in PZT/AlGaN/GaN High-Electron-Mobility Transistors. IEEE Trans. Electron Devices 2018, 65, 3149–3155. [Google Scholar] [CrossRef]

- Li, L.; Liao, Z.; Gauquelin, N.; Nguyen, M.; Hueting, R.; Gravesteijn, D.; Lobato, I.; Houwman, E.; Lazar, S.; Verbeeck, J.; et al. Epitaxial Stress-Free Growth of High Crystallinity Ferroelectric PbZr0.52Ti0.48O3 on GaN/AlGaN/Si(111) Substrate. Adv. Mater. Interfaces 2018, 5, 1700921. [Google Scholar] [CrossRef]

- Stolichnov, I.; Malin, L.; Muralt, P.; Setter, N. Ferroelectric Gate for control of transport properties of two-dimensional electron gas at AlGaN/GaN heterostructures. Appl. Phys. Lett. 2006, 88, 043512. [Google Scholar] [CrossRef]

- Zhang, K.; Wu, M.; Lei, X.; Chen, W.; Zheng, X.; Ma, X.; Hao, Y. Observation of threshold voltage instabilities in AlGaN/GaN MIS HEMTs. Semicond. Sci. Technol. 2014, 29, 075019. [Google Scholar] [CrossRef]

- Lagger, P.; Ostermaier, C.; Pobegen, G.; Pogany, D. Towards understanding the origin of threshold voltage instability of AlGaN/GaN MIS-HEMTs. In Proceedings of the 2012 International Electron Devices Meeting, San Francisco, CA, USA, 10–13 December 2012; pp. 13.1.1–13.1.4. [Google Scholar] [CrossRef]

- Liu, S.-C.; Chen, B.-Y.; Lin, Y.-C.; Hsieh, T.-E.; Wang, H.-C.; Chang, E.Y. GaN MIS-HEMTs With Nitrogen Passivation for Power Device Applications. IEEE Electron Device Lett. 2014, 35, 1001–1003. [Google Scholar] [CrossRef]

- Lu, B.; Matioli, E.; Palacios, T. Tri-Gate Normally-Off GaN Power MISFET. IEEE Electron Device Lett. 2012, 33, 360–362. [Google Scholar] [CrossRef]

- Müller, J.; Polakowski, P.; Müller, S.; Mulaosmanovic, H.; Ocker, J.; Mikolajick, T.; Slesazeck, S.; Müller, S.; Ocker, J.; Mikolajick, T.; et al. High endurance strategies for hafnium oxide based ferroelectric field effect transistor. In Proceedings of the 2016 16th Non-Volatile Memory Technology Symposium (NVMTS), Pittsburgh, PA, USA, 17–19 October 2016; pp. 1–7. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).