Abstract

Anaerobic digestion (AD) produces renewable energy but releases biogenic CO2 and generates digestate requiring management. This paper evaluates four emerging pathways for CO2 capture and reuse in AD systems: (1) in situ CO2 conversion to CH4 via microbial electrolysis cells (MECs), (2) hydrogenotrophic CO2 methanation using green hydrogen, (3) enzymatic CO2 capture coupled with autotrophic algae cultivation, and (4) digestate pyrolysis with syngas biomethanation. Each pathway is assessed in terms of technical feasibility, biocatalyst performance, system configuration, and key implementation challenges. Integrated scenarios demonstrate up to 98% CO2 emission reduction, substantial bioenergy yield improvements, and enhanced nutrient and biomass recovery compared to conventional AD. MEC-based and hydrogenotrophic pathways show the highest energy efficiency, while algae-based systems provide added bioproduct valorization. The remaining limitations include cost, process integration, and scale-up. The study defines development priorities to advance zero-emission AD technologies for the agri-food and waste management sectors.

1. Introduction

With growing global pressure for action on climate change, carbon capture has emerged as a crucial strategy in efforts to reduce greenhouse gas emissions and transition to a sustainable future. Carbon capture, utilization, and storage (CCUS) technologies are viewed as essential tools in achieving net-zero emissions targets and mitigating the environmental impact of industries, especially those that are hard to decarbonize, such as cement, steel, air, and marine transport and energy production. Carbon capture technologies can also be applied to biogenic carbon dioxide, such as that produced from anaerobic digestion (AD). Although biogenic CO2 is generally not counted as a net greenhouse gas emission, capturing and storing it can still help reduce atmospheric CO2 concentrations and contribute to carbon-negative outcomes []. In fact, capturing CO2 from biogenic sources is often more energy-efficient and cost-effective than from fossil sources, as it typically involves cleaner gas streams and lower temperatures. This makes point-source capture from AD facilities a promising pathway for climate mitigation, especially when compared to more energy-intensive approaches like direct air capture (DAC).

AD is a mature technology for the sustainable treatment of liquid and solid organic waste, as well as biofuel production. It has a wide range of potential feedstocks, such as high organic content wastewater, the organic fraction of solid organic waste, waste activated sludge, manure, agricultural residues, microalgae, and food waste. Furthermore, the process yields a nutrient-rich digestate, which can be valorized for nutrient recovery and reuse [,]. AD systems are highly adaptable, as they can be used locally for heating or combined heat and power production, or they can be upgraded to biomethane, which has similar properties to natural gas, allowing for direct injection into natural gas grids or use for transportation [,]. The versatility of feedstocks together with product flexibility and nutrient recycling make AD a promising technology for sustainable biofuel production, waste treatment, and circular economy []. However, digestate, an inevitable by-product of AD, requires further treatment, as its direct application to farmland is often restricted or disfavored in many regions due to a range of factors. These include regulatory constraints (notably the EU Fertilizing Products Regulation [] and the Nitrates Directive []), concerns over contaminants and pathogens (e.g., heavy metals, microplastics, and microbial risks), and practical limitations such as dilution requirements, storage logistics, and timing of application. Such limitations motivate the development of transferable and scalable digestate treatment and valorization routes to produce market-compliant bio-based fertilizers [,,]. More fundamentally, the nutrient load, especially nitrogen, is frequently excessive due to the remote origin of inputs (e.g., imported feedstock), which exacerbates issues in nitrogen-limited zones. Additionally, concerns persist over soil degradation, leaching of dissolved nutrients, and the presence of contaminants such as heavy metals, pharmaceuticals, and endocrine disruptors [,,]. Thus, despite being applied worldwide and being well-established technology with a technological readiness level (TRL) of nine, AD still faces a lot of challenges. Although the core AD process is commercially mature (TRL nine), the technology now faces second-generation challenges driven by sustainability requirements. These do not reflect inherent flaws in anaerobic digestion, but rather application-related constraints that limit its deployment in environmentally sensitive regions or high-circularity systems. In particular, biogenic CO2 emissions and digestate handling are bottlenecks in achieving negative-emission bioenergy, advanced nutrient valorization, and compliance with tightening environmental regulations.

The combination of the current geopolitical landscape and the ongoing energy crisis highlights the urgent need for stronger energy security and the adoption of climate-friendly energy sources, such as biogas and biomethane. Currently, while circularity remains a long-term goal for the AD sector, existing policies such as REPowerEU focus on rapidly increasing biomethane production, using all available feedstocks, including energy crops, rather than prioritizing a transition toward organic waste-based substrates, potentially limiting progress toward more sustainable and food-secure feedstock strategies []. Additionally, biomethane production is stimulated by biogas upgrading for grid injection and transportation fuel to reduce the dependency on natural gas. Technological advancements, such as improved digestion processes, integration with renewable systems, and the development of CCUS technologies, boost efficiency and environmental benefits. These developments align with circular economic principles, promoting effective waste management, greenhouse gas reduction, and resource recovery.

AD and carbon capture can be complementary processes that together may enhance the sustainability of waste management and bioenergy production. Capturing the CO2 from biogas upgrades its methane content. Beyond climate-mitigation benefits, the valorization of biogenic CO2 also provides an economic incentive, as CO2 of biological origin is generally recognized as climate-neutral and can generate higher-value carbon credits compared with fossil-derived CO2 under EU certification schemes. The Renewable Energy Directive (RED II and RED III revisions) explicitly promotes the displacement of fossil carbon in fuels by renewable, biogenic carbon sources and prioritizes negative-emission value chains where biogenic CO2 is permanently stored or chemically converted into long-lived products. This regulatory direction strengthens interest in CO2 capture and utilization from AD as a transferable pathway to enhance both environmental performance and revenue generation in the biogas sector.

While captured CO2 holds potential for use in various industrial applications, legal and regulatory constraints, especially concerning CO2 sourced from waste containing animal by-products [], currently limit its classification and utilization across the EU, complicating integration into circular-economy pathways [] and requiring case-by-case assessments of end-of-waste status [], product safety, and market placement []. Integrating carbon capture into AD systems can generate negative emissions by removing biogenic CO2, thereby enhancing their role in climate change mitigation. Moreover, the integration of carbon capture technologies in AD can improve economic feasibility and thereby enhance renewable energy production and waste reduction. Enhanced research and development can drive advancements in this field by addressing impurities and optimizing capture technologies, fostering a sustainable future.

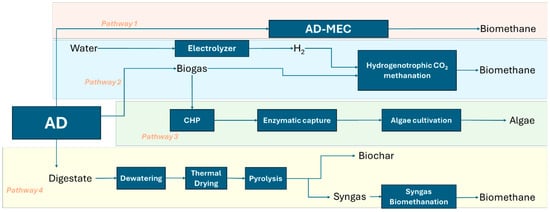

In this context, this paper addresses four different technological approaches that render AD with zero or negative carbon dioxide emissions, as illustrated in Figure 1. Pathway 1 involves the integration of microbial electrolysis cell into AD system, for in situ conversion of CO2 and H2 in methane.

Figure 1.

Technological approaches towards sustainable anaerobic digestion.

Pathway 2 involves the upgrading of biogas by CO2 capture through biological methanation using green hydrogen, providing a sustainable conversion of electricity in biomethane.

Pathway 3 utilizes enzymatic capture of post-combustion CO2 from biogas combustion in a combined heat and power engine, subsequently using this CO2 in autotrophic algae cultivation.

Pathway 4 involves CO2 capture through digestate management by biochar production and syngas biomethanation.

The four pathways evaluated in this paper target performance bottlenecks that remain even in fully commercial TRL-9 AD installations and should be viewed as complementary system upgrades to existing AD infrastructure, aiming to improve carbon circularity and environmental performance, not as replacements for the core AD process.

The description of these four pathways will be based on a comprehensive, systematic, and critical literature review, analyzing recent advancements, applications, and challenges. Each of the pathways will be critically assessed, providing a comprehensive overview of how they can contribute to the sustainability of AD. Although preliminary techno-economic analysis studies are available in the literature [,], suggesting that intensified concepts have promising economic potential under favorable renewable electricity pricing and carbon valorization incentives, consolidated evaluation requires a separate investigation to enlighten their large-scale implementation. Detailed CAPEX, OPEX, and market-dependent revenue assessments require case-specific assumptions that extend beyond the purpose of this comparative technological evaluation. Therefore, a full techno-economic analysis is considered out of the scope of the present study and will be addressed in future work, together with the integration of updated economic indicators and policy frameworks relevant to biomethane production.

2. Technological Approaches Towards Sustainable AD

2.1. Anaerobic Digestion Combined with Microbial Electrolysis Cell Technology (Pathway 1)

2.1.1. Description

The integration of microbial electrolysis cells (MECs) into anaerobic digesters offers a promising avenue to overcome several key limitations associated with conventional AD [], as it is a technology that potentially attacks all limitations at once, i.e., it reduces the start-up times [,], enhances methane content [], stabilizes the methanogenesis phase [], and enhances AD in psychrophilic conditions [].

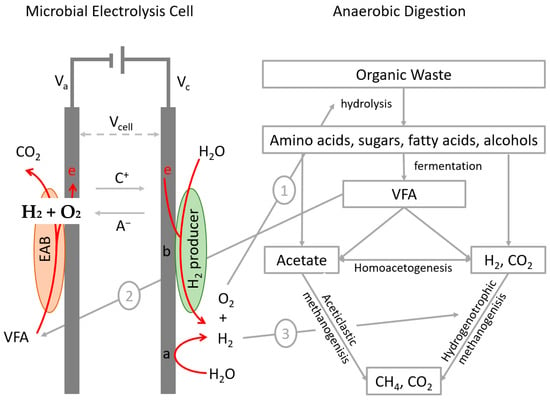

Microbial electrolysis cell (MEC) technology offers a potentially more energy-efficient alternative to conventional water electrolysis for hydrogen production. In MECs, electroactive microorganisms at the anode oxidize organic compounds, generating electrons that are subsequently transferred to the (bio)cathode. These electrons drive hydrogen generation through electrochemical or bio-electrochemical processes []. The integration of MECs in AD has been proposed for performance enhancement, process stabilization [], and CO2 capture [] (Figure 2).

Figure 2.

Microbial electrolysis cells (MECs) with abiotic or biocathode configurations integrated into anaerobic digestion (AD). Synergies include (1) formation of micro-oxic zones enhancing hydrolysis, (2) consumption of volatile fatty acids (VFAs) by electroactive bacteria to improve AD stability, and (3) H2 production supporting hydrogenotrophic methanogenesis and increasing CH4 content.

It has been reported that the integration of MECs into AD may enhance the following critical limitations of AD:

Extended start-up time: Water electrolysis in the MEC generates oxygen [,] and therefore facilitates the presence of micro-anaerobic zones which could enhance the hydrolysis rate of organic matter and reduce start up time. Additionally, the presence of oxygen promotes the presence of facultative hydrolytic and acidogenic microorganisms which excrete extracellular enzymes such as amylase, protease, and lipase and therefore enhance the hydrolysis rate and reduce start-up time [,].

Process stability: The enrichment of hydrogenotrophic methanogens not only enhances the CH4 content but also promotes AD stability due to their faster growth compared to the other methanogens and a greater resilience towards environmental changes such as changes in pH, NH4+, and temperature [,]. In addition, hydrogenotrophic methanogens help stabilize pH levels by consuming protons, thereby counteracting the acidification effects of VFA buildup []. They also facilitate the breakdown of propionate and butyrate by lowering the partial pressure of hydrogen through its uptake, which makes these degradation pathways more thermodynamically favorable []. Moreover, the formation of micro-aerobic zones promotes the growth, metabolic activity, and diversity of rapidly proliferating facultative microorganisms capable of efficiently converting volatile fatty acids, such as propionic, butyric, valeric, and lactic acids, into acetic acid []. The enhanced degradation of these VFAs into acetic acid prevents VFA accumulation and therefore overcomes the thermodynamic constraints of syntrophic anaerobic oxidation of VFAs to acetic acid [].

Methane content: The generation of hydrogen by the MEC promotes the enrichment of hydrogenotrophic methanogens and therefore promotes methanogenesis via the hydrogenotrophic pathway which enhances the conversion of CO2 and hydrogen into CH4 []. Moreover, CH4 can be produced via alternative routes such as methanogenesis via direct electron transport by electrotrophic methanogens or via the generation of acetate by homoacetogens using the hydrogen produced by the MECs. The produced acetate is subsequently converted into methane by acetoclastic methanogens [].

Efficiency under psychrophilic conditions: Temperature plays a key role in the efficiency of AD, influencing both the rate of biogas generation and its composition. Biogas production is typically most efficient in the mesophilic range of 35–40 °C, while lower psychrophilic temperatures (below 20 °C) are known to considerably reduce or even halt production []. Despite this limitation, there is growing interest in the application of AD coupled with AD-MECs under low-temperature conditions. This interest is driven by the fact that many industrial effluents, such as those from malt production, breweries, soft drink manufacturing, and municipal wastewater, are discharged at relatively low temperatures. Furthermore, maintaining mesophilic (30–40 °C) or thermophilic (50–60 °C) conditions year-round leads to higher energy requirements, particularly in colder climates [,]. In this context, AD-MEC systems have emerged as a promising alternative, potentially reducing the need for external heating while improving digestive performance. Research has shown that such systems can enhance the specific activity of methanogenic microorganisms by a factor of five or six under psychrophilic conditions, contributing to more robust process performance [,]. A recent study by Sun et al. [] further demonstrated that AD-MEC systems operating at 17 °C achieved a 1.3-fold increase in chemical oxygen demand removal efficiency and higher methane yields compared to conventional AD processes at the same temperature. This is highly likely due to DIET (Direct Interspecies Electron Transfer) in AD-MEC systems, due to the direct contact between methane-producing archaea and electroactive microorganisms eliminating the necessity of multiple enzymatic steps in electron transfer. In addition, electroactive microorganisms are deemed less sensitive to temperature changes [].

2.1.2. Biocatalysts

The microbial consortium within an anaerobic digestion (AD) system plays a vital role in substrate breakdown and biogas generation. In microbial electrolysis cells (MECs), communities are typically dominated by Geobacter species. Recent findings have identified Geobacter as the most prevalent bacterial genus across MECs operating at varying voltages []. In one study, Geobacter sulfurreducens accounted for up to 72% of the microbial population and demonstrated the capacity to produce hydrogen []. Additionally, electrogenic microbes are known to enhance and expedite the breakdown of substrates []. The integration of AD with MECs (AD-MEC) has been shown to stimulate the proliferation of exoelectrogenic microorganisms, particularly Geobacter, thereby accelerating substrate conversion. These organisms are capable of anaerobically metabolizing diverse organic compounds, including volatile fatty acids (VFAs) and aromatic hydrocarbons []. The electrons resulting from oxidation of these compounds can be transferred either to electrodes or other microbial partners [].

Furthermore, AD-MEC systems promote the enrichment of other substrate-specific microbial groups. For instance, the genus Smithella, known for syntrophic propionate degradation in partnership with G. sulfurreducens, is significantly more prevalent in AD-MEC reactors (9 ± 2%) compared to open-circuit controls (1.2 ± 0.3%) []. Microorganisms such as Bifidobacterium and Clostridium, which facilitate the breakdown of complex organic matter into hydrogen and acetate, are also found in greater abundance in AD-MECs (38.2% and 21.1%, respectively), versus control systems (13.7% and 13.2%) []. Moreover, Clostridium species have the capability to reduce Fe(III) by transferring electrons generated from the metabolism of organic substrates to insoluble iron forms, highlighting their potential role in anodic electron donation and in further lowering chemical oxygen demand (COD) [].

The application of external voltage in AD-MEC processes therefore drives a shift in microbial structure, favoring the development of electroactive communities enriched in substrate-degrading organisms. In terms of archaeal populations, methanogenic archaea are predominant. Hydrogenotrophic methanogens such as Methanobacterium, Methanobrevibacter, and Methanospirillum, along with acetoclastic types like Methanosarcina and Methanosaeta, are commonly identified in these systems [,].

2.1.3. Configuration

The AD-MEC system typically comprises a bioanode, (bio)cathode, and AD. The MEC configuration can be either a single chamber or a dual chamber. In the single-chamber configuration, both the anode and cathode are positioned within the chamber, without physical separation, and share the same electrolyte. Conversely, the dual-chamber configuration involves the use of a membrane to physically separate the anode and cathode. The advantage of the dual chamber configuration lies in its ability to regulate microbial communities within the system and achieve more efficient conversion of electrons into H2, resulting in the production of pure H2 []. However, the dual chamber setup has associated drawbacks, primarily concerning the cost of the membrane and issues such as membrane fouling and the development of a pH gradient, which elevate the internal resistance of the system. On the other hand, single-chamber MECs have lower capital and operational costs, minimal pH gradient, and a compact structure, rendering them more promising for scalability []. Furthermore, the purity of H2 is inconsequential in an AD-MEC setup, where H2 is utilized to convert CO2 into CH4, making the single-chamber configuration well-suited for integration into AD-MEC systems.

Numerous AD-MEC integration approaches have been explored in the literature, generally classified into two main configurations: in situ and ex situ systems [,]. The in situ configuration, where the microbial electrolysis cell is embedded directly within the anaerobic digester, is widely studied for its potential in enhancing anaerobic digestion performance. In two-phase anaerobic digestion setups, where hydrolysis/acidogenesis is separated from methanogenesis, the MEC can be incorporated into either phase depending on the process objective []. The in situ AD-MEC arrangement typically promotes the activity of electroactive bacteria (EAB), electro-affinitive methanogenic archaea (EMA), and hydrogenotrophic methanogens. However, a known limitation of this approach is the simultaneous occurrence of oxidation and reduction reactions in the same vessel, which may lead to reduced energy efficiency [].

On the other hand, the ex situ setup positions the MEC downstream of the AD unit, functioning as an independent reactor. This configuration allows for further degradation of organic intermediates and improved energy recovery. For example, using pre-fermented urine as a substrate in an ex situ MEC has been shown to achieve enhanced current density, higher COD removal, and improved coulombic efficiency [].

The integration of MECs into two-phase AD systems has demonstrated synergistic improvements [,]. Zheng et al. [] reported that applying a 1.2 V voltage led to performance increases of 12.5% and 13.2% in the methanogenic and hydrolytic/acidogenic reactors, respectively. A more complex three-stage system, comprising acidogenic fermentation, methanogenesis, and MEC treatment, outperformed simpler two- and single-stage designs in terms of overall process efficiency [].

While most AD-MEC studies have been conducted in batch mode under constant voltage conditions, a few continuous-mode experiments also exist []. Interestingly, intermittent voltage application has been reported to improve energy efficiency without compromising methane production, thereby optimizing the net energy gain from the system [,,].

The arrangement of electrodes plays a critical role in determining the overall efficiency and performance of AD-MEC systems. Proper electrode configuration can lead to a reduction in internal resistance, thereby improving both methane production and energy recovery [,]. For example, minimizing the distance between electrodes has been shown to enhance methane output. Additionally, positioning the electrodes strategically, such as placing the anode at the reactor base and the cathode above, can offer hydrodynamic benefits and promote better system flow dynamics [].

System performance in AD-MECs is governed by a combination of factors including the enrichment of electrogenic microorganisms, reactor architecture, electrode spacing, and the nature of the input substrate. Nevertheless, a comprehensive understanding of how different electrode configurations impact mass transfer processes within the reactor remains an area of ongoing research and technical uncertainty [].

2.1.4. Challenges

The AD-MEC system presents a promising technology applicable to a wide range of feedstock and waste for bioenergy production. While AD-MECs show promise in bioenergy production, there are several challenges to be addressed, as presented in Table 1.

Table 1.

Key challenges and knowledge gaps for AD–MEC integration.

The current research predominantly focuses on laboratory-scale testing due to the low TRL of MEC technologies [], with limited studies conducted at a larger scale. To enhance the TRL of AD-MEC systems there are still significant knowledge gaps requiring further investigation.

Several critical questions remain unresolved, including (i) identifying the most efficient methanogenic pathway, acetoclastic versus hydrogenotrophic; (ii) understanding the mechanisms that enable the dominant pathway to outcompete the other; (iii) clarifying the exact electron transfer process between the cathode and hydrogenotrophic methanogens; (iv) quantifying the proportion of methane produced via direct cathodic electron transfer versus hydrogenotrophic routes; (v) determining the optimal anode-to-cathode specific surface area ratio; (vi) defining the most effective AD-MEC configuration to minimize internal resistance []; and (vii) exploring the utility of machine learning and artificial intelligence tools in predicting and enhancing AD-MEC performance []. Additionally, research investigating the economic feasibility of AD-MEC primarily relies on lab-scale experiments. To facilitate the practical application of AD-MEC, there is a need for experiments, life cycle assessments, and techno-economic analyses based on larger-scale implementations [,].

An additional challenge is the ionic composition and chemical characteristics of the digester broth, which may lead to metal deposition on electrodes, undesired redox reactions, or the formation of inhibitory metabolites. These phenomena could reduce electron transfer efficiency, impact electrode lifespan, and inhibit microbial activity, particularly in mixed-culture systems. Further research is needed to understand and mitigate these effects on both laboratory and pilot scales.

2.2. Hydrogenotrophic CO2 Methanation (Pathway 2)

2.2.1. Description

CO2 can be considered an attractive agent for the synthesis of high-value end products such as fuels or platform chemicals []. However, the inherent stability of the CO2 molecule poses challenges when it is used as the sole reactant, primarily due to its high energy demands. To overcome this, introducing a co-reactant with higher Gibbs free energy, such as hydrogen (H2), can improve the thermodynamic feasibility of the reaction []. A feasible approach to recycle CO2 involves biological methanation, often referred to as biomethanation []. Biological methanation relies on the activity of hydrogenotrophic methanogens, which metabolize CO2 into CH4 using H2 as an electron donor []. This reaction has negative Gibbs free energy, providing the necessary energy for the growth of hydrogenotrophic methanogens. For example, the study by Kakuk et al. [] demonstrated that when external H2 was injected into a mixed mesophilic community, the gene expression of hydrogen-metabolizing methanogens increased and the archaea involved in hydrogenotrophic methanogenesis were rapidly activated. The authors showed that provision of H2 shifts the microbial community toward hydrogenotrophic pathways by increasing the availability of the electron donor (H2), thereby favoring methanogens that specialize in H2/CO2 → CH4 over other pathways.

Alternatively, CO2 methanation can be conducted chemically (out of the scope of this paper), employing catalysts to convert CO2 to CH4 []. While chemical methanation is technically mature and widely applied, biological methanation has several notable advantages. These include operation at moderate temperatures (30–60 °C), potential flexibility with ambient or elevated pressures depending on H2 availability, tolerance to impurities in the feed gas, intermittent operation compatible with variable renewable H2 supply, and in situ production of biocatalysts, which reduces downtime and avoids costs associated with chemical catalyst replacement or deactivation (e.g., due to trace H2S or NH3). These features make biological methanation particularly suitable for integration with renewable energy systems [,]. Raw biogas is an attractive source for biological methanation due to its biogenic origin and relatively high CO2 content compared to other CO2 sources (e.g., combustion gases and ambient air). Biogas CO2 separation, however, incurs significant investment and operational operation []. To reduce these expenses, focus has shifted toward direct methanation of raw biogas without preliminary CO2 separation. While trace compounds and impurities present in biogas can inhibit microbial activity or reduce process efficiency [], some impurities, such as NH3 and H2S, can serve as substrates for ex situ methanation, partially offsetting feed requirements. This dual role can support the downsizing of purification efforts both technically and economically, particularly when green H2 is available at a reasonable cost.

The required H2 is not readily available, necessitating its generation first. When H2 is derived from water electrolysis powered by renewable sources, this process falls within the domain of the Power-to-Methane (PtM) sector []. H2 together with CO2 can be converted into CH4 through biological methanation. In this way, excess electricity can be converted into a stable form of chemical energy, i.e., CH4, taking advantage of periods of overproduction or low electricity demand []. In addition to the increase in methane content, biomethanation offers the advantage of utilizing waste heat generated during thermophilic AD or exothermic CO2 hydrogenation reactions. This recovered heat can support the maintenance of optimal operating temperatures or pre-heat incoming feedstock streams, which is particularly valuable for improving process stability and reducing heating costs in biogas plants located in colder climates.

Alternatively, H2 production can be achieved through a variety of material sources such as carbonaceous materials (e.g., biomass) and fossil fuels (fossil fuels or biofuels) by employing one or a combination of thermal, electrical, photonic, and biochemical technologies []. The most promising scheme for renewable H2 production, so-called green H2, involves utilizing surplus renewable energy to electrochemically split water into hydrogen and oxygen []. Water electrolysis can be performed using several technologies: alkaline electrolysis, proton exchange membrane (PEM) electrolysis, solid oxide electrolysis, and anion exchange membrane (AEM) electrolysis. These technologies differ in their maturity, efficiency, and operational characteristics, with AEM electrolysis representing an emerging alternative whose manufacturing is scaling up []. Table 2 summarizes the main characteristics of these technologies.

Table 2.

Summary of the main characteristics of the water electrolysis technologies [,].

2.2.2. Biocatalysts

Given the pronounced impact of CO2 and H2 concentrations on the biochemical equilibrium, the introduction of external H2 imposes strong selective pressure on the AD microbiota, resulting in a considerable rise in hydrogenotrophic species []. Previous studies suggest that the introduction of external H2 promotes the enrichment of methanogens, consequently leading to their predominance []. Nevertheless, these microbiomes typically harbor a considerable bacterial component, and further elucidation of bacterial species and their roles in both ex situ and in situ systems remains necessary. Bacterial diversity can vary strongly depending on the feeding substrate utilized and the presence of carbon sources other than CO2 [,]. Specifically, the presence of other carbon sources may serve specific metabolic reactions, e.g., catalyzing the conversion of CO2 to acetate, or may influence the production of intermediate compounds such as amino acids and formate []. Additionally, they may play an indirect role through biofilm formation, which is pertinent to the process since CO2 biomethanation is often mediated by microbiota adhered to solid supports [].

An investigation performed on CO2 biomethanation publications enabled the identification of trends regarding the presence of methanogens in terms of average relative abundance (~RA) based on operational parameters (for example, reactor type, temperature, and in situ or ex situ configuration) (only taxa above 0.5 RA were considered, Supplementary Table). The analysis focused on the ex situ configuration because, in the in situ setup, modifications induced by the feedstock composition on the microbiome are dominant and tend to obscure the effects of gas supplementation. The primary orders of hydrogenotrophic methanogens, Methanobacteriales and Methanomicrobiales, were identified as distinctive features of biomethanation systems, particularly in the ex situ configuration [,]. Unexpectedly, the Methanotrichales order, predominantly represented by acetoclastic Methanothrix species (~4% RA), was observed with a preference for mesophilic conditions (40 °C), most probably depending on homoacetogens for substrate provision []. Other taxa such as Methanolinea and Candidatus Methanosuratus were identified at low abundance (<1%) irrespective of operational parameters [].

The Methanobacteriales order, recognized for its hydrogenotrophic activity under both mesophilic (~44% RA) and thermophilic temperatures (~24% RA has seen an increasing number of its species identified and characterized in recent years [,,]. Above 50 °C, Methanothermobacter and Methanobacterium spp. are prevalent, whereas Methanobrevibacter sp. dominates under mesophilic conditions (~36% RA) [,,,]. The distribution of individual species across reactor configurations remains largely unexplored. Many individual species have been identified in specific reactor configurations; however, a comprehensive understanding of how microbial species are distributed across various systems remains limited. For example, Methanothermobacter thermautotrophicus has long been observed in ex situ biogas upgrade, demonstrating stable performance [,]. Recent studies have identified novel species of the genera Methanobacterium and Methanothermobacter as predominant in various reactor types, including TBR, CSTR, and batches, with RA ranging from 10% to 40% [,,]. Interestingly, Methanobacterium has shown no strict preference for specific reactor configurations, demonstrating resilience even in environments with elevated hydrogen sulfide concentrations or trace levels of oxygen [,].

Finally, the Methanomicrobiales order, primarily represented by Methanoculleus sp., typically maintains a lower RA (~9% RA) compared to the Methanobacteriales order, regardless of temperature []. Methanoculleus has been consistently identified across operational conditions, including high-salt and high-ammonia digestions, suggesting the adaptability to different stressors []. In particular, Methanoculleus bourgensis and Candidatus Methanoculleus thermohydrogenotrophicum are two of the most relevant species both in standard AD and in in situ biogas upgrade systems [,].

2.2.3. Configuration

CO2 biomethanation is a process that occurs naturally in an anaerobic digester as part of methanogenesis []. This step can be intensified by providing extra H2 and/or CO2 into the system, enabling the proliferation of hydrogenotrophic methanogens and thereby enhancing the conversion of CO2 to CH4, accomplishing biogas upgrading.

The bioreactor configurations in which biological hydrogen-assisted biogas upgrade occurs can be categorized into three types: in situ, ex situ, and hybrid designs [].

In situ configuration: In the in situ configuration, the H2 is directly introduced into the digester to enhance the hydrogenotrophic methanogenic community and thereby promoting the conversion of CO2 into CH4 []. This strategy can potentially be integrated into existing infrastructure as it requires only one reactor and thereby reduces investment costs []. Although the configuration can result in high methane yields reaching up to 99%, it significantly impacts the reactor’s stability, posing challenges in maintaining stable process performance []. The most important challenge is maintaining a stable pH, since CO2 consumption disrupts the carbonate equilibrium resulting in alkaline conditions with a pH that may exceed 8.5 [,]. Therefore, appropriate pH control strategies are required to ensure stable operation. Reported approaches include (i) dosing of weak acids (e.g., CO2 recirculation and organic acid addition) to partially restore the carbonate system and buffer capacity; (ii) optimization of H2 dosing rates and mass transfer to avoid excessive CO2 depletion; (iii) co-digestion with substrates generating sufficient alkalinity or VFAs to counterbalance pH rise; and (iv) process monitoring with automated control loops to enable real-time adjustment of H2 supply [,,,,]. The selection of a suitable pH regulation strategy depends on feedstock characteristics, buffer capacity, and hydraulic retention time, and remains a key aspect requiring further technological refinement.

Moreover, the introduction of H2 increases the partial H2 pressure in the digester, which makes volatile fatty acid (VFA) degradation thermodynamically less feasible, and can thereby lead to their accumulation []. The increase in VFAs has a direct impact on acidogenesis and methanogenesis, which may slow down [], affecting the overall AD process. From the above, it is evident that strict monitoring and control of the operational parameters are essential in such a setup.

Ex situ configuration: Ex situ biomethanation was introduced as a solution to the challenges posed by the in situ configuration. This process takes place in a separate bioreactor, where CO2 (obtained from sources like biogas or syngas) and H2 are introduced into its liquid phase. This reactor houses either a mixed or a pure culture of hydrogenotrophic methanogens which metabolize the gaseous substrates to CH4 []. Various types of reactors are used for ex situ biomethanation, each with its own design and operational characteristics suited to different scales and process requirements (Table 3). Ex situ technology is considered more expensive due to the need for extra equipment and materials, making it feasible primarily in full-scale plants []. Despite its configuration cost, the ex situ strategy is characterized by many important advantages such as the microbial community being simpler, reducing the apt of processing imbalances; the absence of organic matter degradation simplifies the whole process and there is flexibility in the sources from which CO2 can be obtained [,].

Table 3.

Reactor types, mass transfer coefficients, and methane productivity for gas fermentation.

Hybrid configuration: Hybrid biomethanation is a combination of in situ and ex situ biomethanation, forming an integrated system which aims to maximize the benefits of both methods. Initially, biogas generated in the in situ digester is recirculated with exogenous H2 for partial upgrading. Afterwards, the enriched biogas is introduced to the ex situ methanation reactor to further enhance its CH4 concentration to roughly 96% []. Hybrid technology provides an innovative solution by efficiently controlling pH levels throughout the in situ process while necessitating a much smaller dedicated reactor for the ex situ step [].

2.2.4. Challenges

Hydrogenotrophic CO2 methanation has several challenges that limit its widespread adoption. Challenges that need to be addressed are inter alia:

- The improvement of gas–liquid mass transfer, thereby promoting the availability of gases to microbes performing the conversion reaction.

- The intermittent availability of renewable H2.

- The establishment of a finely balanced microbial consortium within the anaerobic ecosystem.

- The increase in the competitiveness of methanogens compared to competing reactions (e.g., homoacetogenesis).

Finally, the integration of methanation with existing energy systems, such as power-to-gas or biogas upgrading, requires overcoming technical and economic barriers to ensure that the process is both efficient and cost-effective in real-world applications.

2.3. Enzymatic Capture of CO2 Coupled with Autotrophic Algae Cultivation (Pathway 3)

2.3.1. Description

Pathway 3 involves a novel approach to carbon capture and utilization (CCU) that integrates enzymatic CO2 capture with autotrophic algae cultivation. This pathway leverages the efficiency of enzymes to accelerate CO2 capture from the post-combustion flue gases of biogas, followed by the use of this captured CO2 as a carbon source for algae growth. Algae play a crucial role in capturing CO2 from the atmosphere, flue gases, or chemically bound forms such as soluble carbonates, converting it into organic matter via photosynthesis. The resulting microalgal biomass is rich in lipids, carbohydrates, proteins, and other high-value compounds, including pigments, minerals, and vitamins []. As such, it can be further utilized for various applications, such as biofuel, biomaterials, or biofertiliser production, as well as for phytopharmaceuticals for agriculture (biostimulants and biopesticides) or other active ingredients within regulatory frameworks [,].

Post-combustion capture, the most popular method removes CO2 from this gas mixture (most commonly flue gases) and is the only commercialized carbon capture technique [] due to its flexibility []. Post-combustion technologies are the only ones that can currently be integrated into existing power plants [,]. One major drawback of post-combustion CO2 capture is the low pressure and low CO2 concentration of flue gas, which is diluted with large amounts of nitrogen from air. This makes CO2 capture difficult and energy intensive []. After combustion, the flue gas discharged at atmospheric pressure (1 bar) and high temperatures (up to 200 °C) is predominantly nitrogen (up to 70% by volume), with a low percentage of CO2 (3% to 15% by volume), and high moisture. Several methods and processes for CO2 capture have been reported. These can be categorized into absorption processes (physical and chemical), gas–solid reaction processes, adsorption processes, cryogenic processes, membrane processes, and natural inclusion (biological methods) [,,].

Post-combustion CO2 capture technologies face several challenges, with one of the primary issues being the high operational cost associated with the energy-intensive desorption stage typically required to concentrate CO2 for storage or utilization. Beyond energy demands, a major obstacle to widespread adoption lies in the toxicity and corrosivity of the capture media, which can damage equipment and raise environmental concerns. These drawbacks can be mitigated by using green solvents or enzyme-based systems, which offer more sustainable and less hazardous alternatives. Importantly, desorption is not always necessary. In applications such as algae cultivation for carbon valorization, CO2 can be directly utilized in its dissolved form, eliminating the need for energy-intensive concentration steps. This makes algae-based systems an attractive and low-impact option for integrating carbon capture with resource recovery.

The overall cost of CO2 capture can be lowered by employing aqueous solvents that require less energy for desorption, particularly when combined with carbonic anhydrases (CAs), enzymes known for accelerating the absorption of CO2 [,]. The use of enzymes in carbon capture is a rapidly developing field, offering a biologically inspired and environmentally friendly solution to reduce CO2 emissions. Mimicking natural cellular CO2 processing, this enzymatic approach stands out for its high efficiency, thanks to its exceptional stereo-specificity and chemical selectivity, making it a promising method for sustainable CO2 transformation [].

CA can be utilized to accelerate two different processes: (1) CO2 capturing and concentration for industrial utilization, and (2) CO2 capturing and use for algal cultivation to enhance the efficiency of carbon capture and the productivity of algal biomass [,,]. In algae biomass production systems, CO2 availability can be a limiting factor for growth, as these systems are often designed for optimal light or nutrients utilization, rather than CO2 supply. The addition of CA into the culture enhances CO2 capture efficiency by catalyzing the hydration of CO2 at a remarkably high rate, thus improving carbon availability for photosynthesis in algae systems, resulting in increased algal growth rates and biomass productivity, particularly in high-density cultures [,] when nutrients are available in sufficient concentrations. The concept was patented in 1980s, based on the biomass yield increase from 0.25 g/L to 0.375 g/L in a Dunaliella salina pond after the addition of CA extract [].

Microalgae possess multiple CA isozymes, which can be found in various locations within and around the cell, including the chloroplast, cytosol, external periplasmic space or cell wall, and thylakoid lumen [,,]. These CAs belong to different genetic classes, including α, β, γ, δ, ε, η, and θ, and the specific types and locations can vary depending on the microalgal species []. CAs have been successfully isolated from many algae species, including easily maintained cultures of Chlorella vulgaris, Scenedesmus obliquus, Dunaliella tertiolecta, D. salina, Phaeodactylum, and many others [,,,]. Ores et al. [] investigated and characterized carbonic anhydrase (CA) production from various microalgae species. Their study included marine strains such as Tetraselmis suecica, Dunaliella tertiolecta, Isochrysis galbana, Phaeodactylum tricornutum, and Nannochloropsis oculata, as well as freshwater species like Chlorella vulgaris and Scenedesmus obliquus. Among these, C. vulgaris exhibited the highest enzyme yield, reaching an activity of 44.0 U/L. In the group of marine microalgae, P. tricornutum showed the greatest enzyme activity at 19.9 U/L. When specific activity was considered, D. tertiolecta and P. tricornutum recorded the highest values, at 44.6 U/g and 24.5 U/g, respectively.

An effective approach for extracting CA from microalgae involves the use of deep eutectic solvents (DESs). This method was successfully demonstrated on species such as Tisochrysis lutea, Chlorella vulgaris, and Spirulina sp. by Craveiro et al. []. Their findings suggest that DESs provide a suitable medium for CA extraction from microalgal biomass while maintaining enzyme activity, with specific CA activity reaching up to 0.70 mU mg−1. Additionally, the study revealed that the efficiency of CA extraction varies according to both the type of DES used and the microalgal species involved. This implies that the effectiveness of DESs in extracting CA is not uniform across all solvent–microalgae combinations. Different DES formulations may interact differently with the cell walls and intracellular components of various microalgal species, affecting the yield, purity, and activity of the extracted CA. Therefore, optimizing the choice of DES for each specific microalgal species is important to achieving high extraction efficiency while maintaining enzyme activity.

Approaches such as the immobilization of microalgae or extracted CA have been proposed to enhance enzyme stability and facilitate easier harvesting from algal cultures. Immobilization helps maintain enzyme activity over time by providing a more stable environment, reducing enzyme loss, and allowing for potential reuse in bioprocesses [].

2.3.2. Biocatalysts

Carbonic anhydrases (CAs, EC 4.2.1.1) constitute a group of metalloenzymes responsible for catalyzing the reversible hydration of carbon dioxide and the dehydration of bicarbonate. These enzymes influence only the reaction kinetics of both directions without altering the thermodynamic equilibrium []. The catalytic mechanism involves a nucleophilic attack by the Zn-bound hydroxide ion (Zn–OH−) on CO2. The process proceeds through a two-step, bidirectional mechanism as described by [,]:

EZnOH− + CO2 ⇌ EZn(OH−)CO2 ⇌ EZnHCO3− ⇌ EZnH2O + HCO3−

EZnH2O ⇌ H+ + EZnOH− + B ⇌ EZnOH− + BH+

Within the enzyme’s active site, CO2 binds to a hydrophobic region adjacent to the zinc ion, facilitating nucleophilic attack by Zn–OH−. This reaction yields bicarbonate (HCO3−), which is subsequently displaced by water molecules diffusing randomly into the active site [,]. The proton acceptor (B) is the chemical foundation for incorporating CA into CO2 separation through reactive absorption [].

CAs have attracted industrial interest as biocatalysts for the capture of carbon from the flue gases of coal-fired power plants [], and in the use of CAs to enhance algae growth for the capture of CO2 and its conversion to biofuels or other valuable products. CAs have become attractive for various industrial and medical applications due to their fast reaction kinetics (requiring smaller enzyme quantities), ease of expression, high solubility, and moderate heat resistance []. Additionally, CAs function as biomimetic CO2-sequestering agents, offering a cost-effective and reusable solution for carbon capture. As biological catalysts, they operate efficiently at ambient temperatures and mild experimental conditions, making them suitable for sustainable CO2 management [].

The stability of the enzyme depends on the enzyme source, and for CA harvesting to be economically viable, the enzyme must remain stable and functional over time [,]. Consequently, CAs exhibiting activity at elevated temperatures attract considerable attention [,,,]. Moreover, immobilizing CA in/on suitable supports or modifying the absorption process may help overcome process limitations such as enzyme instability, deactivation, loss during use, and difficult recovery, all of which can reduce the efficiency and cost effectiveness of the CO2 sequestration process [,]. The advantages of CA immobilization are increased enzyme stability, enzyme reusability, and easy enzyme recovery, leading to reduced process operation costs [,,].

The growing demand for industrial carbonic anhydrases (CAs) is reflected in the increasing number of patents and biotechnology companies focusing on this enzyme. These companies are actively developing enhanced versions of CA for diverse applications, including integration into engineered systems aimed at capturing CO2 directly from the atmosphere [,].

Despite their potential, the widespread industrial use of enzymes like CA is limited by their high cost and sensitivity to environmental conditions. To address these challenges, various strategies such as bench-scale modifications and enzyme immobilization have been pursued to reduce expenses while improving enzyme stability and activity. There is a pressing need to screen these methods and scale them for industrial implementation, alongside the development of simple, energy-efficient pathways for CO2 conversion leveraging affordable enzyme-based technologies [,].

In general, CAs exhibit compatibility with amine-based solvents and carbonates, where they can enhance CO2 absorption kinetics. However, controlling and characterizing the orientation and conformation of CA immobilized on solid surfaces remains complex due to intricate enzyme–surface interactions []. Future studies should also investigate the presence of industrial exhaust gases, including NOₓ, SOₓ, and other trace compounds, not only for their potential inhibitory effects on carbonic anhydrase activity [], but also for their impact on downstream valorization processes such as algae cultivation. These impurities may affect biomass composition and product quality, potentially constraining high-value applications, including nutritional or pharmaceutical products [,,].

2.3.3. Configurations

When designing reactors for enzymatic capture of CO2 using CA, several configurations can be employed to optimize the efficiency of CO2 capture, enzyme stability, and overall process economics. The design of reactors for this process must consider factors such as mass transfer, enzyme immobilization, and reactor scalability. Up until now, various reactor configurations have been suggested such as Packed Bed Reactor (PBR), Membrane Reactor, Stirred Tank Reactor (STR), Trickling Bed Reactor (TBR), Bubble Column Reactor, Fluidized Bed Reactor, and Monolithic Reactor. Each reactor configuration offers specific advantages and challenges depending on the application. Table 4 presents various reactor configurations for enzymatic CO2 capture using carbonic anhydrase.

Table 4.

Comparison of reactor configurations for enzymatic CO2 capture using carbonic anhydrase.

The selection of the appropriate reactor configuration depends on operational scale, desired CO2 capture performance, enzyme stability, and associated economic constraints. Current research is focused on enhancing enzyme immobilization, improving mass transfer efficiency, and reducing operational costs to enable large-scale deployment of enzymatic CO2 capture systems using carbonic anhydrase.

The CA extraction from algae and its activity in the extract depends on many factors, including the algae cell-disruption technique and extracting solvent, in combination with algae strains and conditions of operation (temperature, illumination, and CO2 concentration). Thus, each algal culture needs to be tested with a variety of extraction techniques and solvents, adjusted to the climatic conditions in the case of outdoor cultures. The final protocol of CA extraction and utilization will further depend on the energy and financial cost: for example, less energy-demanding techniques of cell disruption might be chosen in the large-scale systems, even at the cost of lower CA concentration in the extract. On the other hand, a CA solution might be preferred to immobilized enzymes to keep the efficiency of CO2 capture at a higher level, even if the enzyme cannot be recycled (but can be sustainably extracted at a low cost).

2.3.4. Challenges

Although enzyme immobilization is many times preferable because of enzyme stability and recycling possibilities, using CA in a liquid solution is preferable due to significant diffusion-related challenges. In immobilized systems, the reaction rate is often limited by the diffusion of CO2 through the boundary layer and the immobilizing matrix, such as alginate. These additional barriers slow the transport of CO2 to the enzyme, reducing the overall efficiency of the reaction. In contrast, when CA is in a liquid, it can interact directly with dissolved CO2, avoiding these diffusion bottlenecks. This leads to faster and more efficient conversion of CO2, as the enzyme continuously lowers the concentration of dissolved CO2, driving further gas absorption. Hence, using CA in liquid enhances reaction rates by minimizing diffusion limitations. Extracting sufficient amounts of enzyme from microalgae is a challenge due to variability between algal strains. As the extraction protocol should be adjusted for each strain or mixed culture, high biomass concentration significantly improves CA yield from the biomass []. This approach is especially interesting in large-scale production, where there is sufficient biomass production and at the same time the need for large amounts of the enzyme.

2.4. Digestate Management via Biochar Production and Syngas Upgrade (Pathway 4)

2.4.1. Description

Pathway 4 presents an alternative management scheme of digestate, since this is one of the key challenges of AD plants.

Prior to pyrolysis, digestate typically undergoes dewatering and thermal drying to reduce moisture content and improve process efficiency. Recent studies have demonstrated that these pretreatment steps significantly enhance the yield and quality of syngas, bio-oil, and biochar from digestate despite the energy cost [,,].

Pyrolysis of digestate has been suggested as an alternative for the valorization of digestate, apart from its use as organic fertilizer and soil conditioner. Among the products generated from pyrolysis, biochar finds use in various environmental applications; bio-oil serves as a potential fuel or additive in petroleum refining and syngas can be utilized for heat and power generation (combined heat and power, CHP) or further processed into biomethane [].

The biomethanation of syngas is an alternative carbon capture and utilization technological route that has attracted considerable attention in recent years [,]. This interest takes root in the possibility of unlocking the full conversion of recalcitrant biomass and its potential integration in current bioenergy systems. In this sense, this technology emerges as a cost-effective syngas-upgrading method, re-routing the use of biomass for conventional heat and power generation towards the synthesis of biomethane, a more versatile and energy-dense energy carrier.

The most distinctive merits of the combination of pyrolysis and the syngas biomethanation process lie in its hybrid nature as it integrates the strengths of both thermochemical and biochemical conversion technologies. On one hand, pyrolysis enables the complete conversion of the feedstock into a directly fermentable and homogeneous gas, bio-oil (which can be converted into biofuel) and biochar (which can be applied as a soil amendment that is considered carbon storage, circumventing the often slow and incomplete biological conversion of complex and recalcitrant biomass. On the other hand, the biological conversion of syngas into biomethane offers a number of advantages over its catalytic counterpart, such as mild operational pressure and temperature conditions, inexpensive biocatalysts as compared to traditional Ni-based and other catalysts, higher tolerance to syngas impurities, and very-high methane selectivity [,].

Beyond enhancing biomethane production from digestate conversion, this approach also aligns with the dynamics of the renewable electricity market. By integrating surplus renewable electricity via electrolysis-derived hydrogen, the system can optimize the electron donor/acceptor ratio (H2:CO2 = 4:1) for enhanced methane yield. This not only improves energy efficiency but also enables pyrolysis and gasification plants to act as flexible energy storage hubs, converting excess electricity into storable and transportable biomethane. Consequently, this hybrid scheme prevents grid overload and strengthens the role of biomethane as a versatile biofuel adaptable to fluctuating energy demands.

In addition to the primary components of syngas—hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), and methane (CH4)—raw syngas generated via pyrolysis or gasification also contains various volatile compounds. These include acetylene (C2H2), ethylene (C2H4), ethane (C2H6), benzene (C6H6), hydrogen sulfide (H2S), sulfur oxides (SOx), ammonia (NH3), hydrogen cyanide (HCN), and carbonyl sulfide (COS). Certain impurities, such as tars and nitrogen-containing compounds, have been found to inhibit the activity of acetogenic bacteria, while the impact of sulfur gases varies depending on the specific bacterial and archaeal strains involved [,,,,]. More recent studies also proved a double-edged effect of tars on methanogenic microbial communities, where the addition of tars promoted methane production at low dosages and inhibited their activity as tar dosage increased []. More knowledge on the effect of raw syngas on these microbial communities is key for further advancing syngas biomethanation processes since the costs of syngas cleaning will likely have a major effect on the economic viability of the process []. To date, there is only one case study at a semi-pilot scale, where a gasification and a syngas biomethanation unit were connected online, showing encouraging results as the bioreactor presented no obvious signs of inhibition []. Nevertheless, further dedicated studies in this direction are still needed to establish the optimal syngas composition for this process.

2.4.2. Biocatalysts

Methanogenic archaea play a pivotal role in the conversion of gaseous substrates into methane in AD-MECs (pathway 1), biogas upgrading (pathway 2), and syngas biomethanation (pathway 4). The relevant methanogenic pathways used by these archaeal populations are in all cases analogous to the Wood–Ljungdahl pathway of gas-fermenting acetogens, where H2 or CO are used as electron donors for the reduction of CO2 into methane through multiple coenzyme-bound intermediates specific to methanogens such as methanofuran and tetrahydromethanopterin []. The highly diverse archaeal hydrogenotrophic microcosmos has been well documented in numerous studies on CO2 biomethanation, where Methanothermobacter spp., Methanobacterium spp., Methanobrevibacter spp., and Methanoculleus spp. were typically systematically enriched in multiple reactor settings and operational conditions. On the other hand, electrotrophic and carboxydotrophic archaea are still rather poorly characterized. To date, there are only a handful of methanogenic archaea reported to be able to utilize CO as the sole carbon and energy source, with these including Methanothermobacter marburgensis [], Methanothermobacter thermoautotrophicus [], Methanosarcina acetivorans [], and Methanosarcina barkeri [], among a few others. However, their role as carboxydotrophs in open microbial communities is typically deemed insignificant, owing to the faster activity rates of carboxydotrophic bacteria []. Similarly, acetoclastic methanogenesis constitutes an essential reaction in AD performed exclusively by the order Methanosarcinales [] that is often relegated to a marginal role in the above-mentioned biomethanation processes.

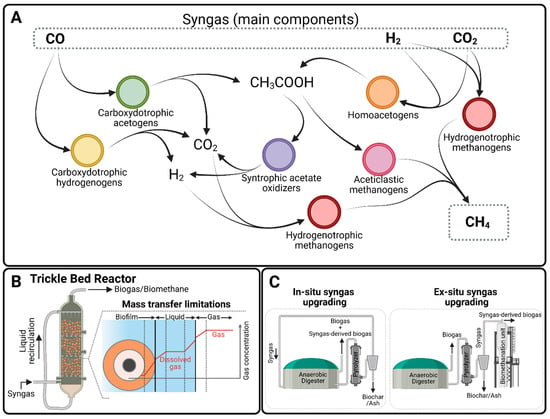

Besides the archaeal population, all these microbial communities typically exhibit a considerable bacterial segment often associated with a complex network of bacteria–archaea interactions (Figure 3A). In the case of syngas-converting microbial communities, the synthesis of methane as end-product involves a rather intricate interspecies metabolic network including the biological water–gas shift reaction, acetogenesis, hydrogenotrophic methanogenesis, syntrophic fatty acid oxidation, and acetoclastic methanogenesis (Figure 3). Pathway redundancy is a key feature of their metabolic network, which allows these communities to harness a wide range of cross-feeding, symbiotic, and mutual exclusion interactions, ultimately leading to high culture robustness and adaptive capacity []. In fact, the reactor temperature has been shown to drive drastic changes in the microbial composition and pathways used by these microbial communities, with these having major implications in the biomethane productivity of the bioreactors [,,]

Figure 3.

Relevant features of the syngas biomethanation process. (A). Simplified interspecies metabolic network converting syngas into methane. (B) Reactor schematic of a typical trickle bed reactor used in syngas biomethanation and description of mass transfer limitations including gas–liquid and liquid–solid interphases. (C) Possible simplified process schemes for upgrading syngas into biogas or biomethane.

2.4.3. Configurations

The main challenges to achieving compact bioreactors with high volumetric productivity in gas fermentation processes are mass transfer and growth limitations. Both syngas biomethanation and biogas upgrading involve relatively insoluble gases, H2 and CO. This leaves the microbes involved in the process having to scavenge H2 and CO at very low concentrations from the liquid phase, limiting their capacity to convert them. Mass transfer from the gas phase to the liquid phase from which H2 and CO can be taken up by microbes is thus considered one of the most important bottlenecks in the process (Figure 3B). However, recent findings also indicate that diffusion through the biofilm may be the rate-limiting step in attached-growth bioreactors typically employed in syngas biomethanation (Figure 3B) []. Additionally, the strictly anaerobic nature of the microorganisms involved means that the energy available from their metabolic processes is limited. This typically leads to low biomass yields and low cell concentrations in reactors, limiting volumetric productivity.

At process-level configurations, the syngas biomethanation process is analogous to the CO2-hydrogenation process (pathway 2) and could be operated under in situ, ex situ, and hybrid production schemes when coupled with AD systems (Figure 3C) [,,]. At the bioreactor level, a variety of bioreactor configurations has been studied for gas fermentation: continuously stirred tank reactors, bubble column reactors, hollow fiber membrane reactors, and TBRs [,,,,]. The main strategies applied to overcome mass transfer limitations have included increasing the mass transfer driving force (often by increasing the operating pressure) and increasing the volumetric mass transfer coefficient. A variety of strategies have been applied to increase the concentration of cells in the reactor, including long hydraulic retention times, sludge recirculation, and the immobilization of biomass on packing material []. Table 3 shows a comparison of reactor types, mass transfer coefficients and methane productivity. It is worth noting that the CH4 production rates presented in the table are expressed per day (L CH4 L−1 d−1) and mostly represent laboratory-scale systems, which generally exhibit lower productivities (≤10 L CH4 L−1 d−1) compared to state-of-the-art H2/CO2 biomethanation systems that can achieve hourly productivities exceeding 10 NL CH4 L−1 h−1 under optimized conditions [,].

TBRs stand out from Table 3 as the most competitive reactor configuration, although bubble columns also perform well. They are columns filled with high specific surface area packing material, over which a liquid medium is trickled, but where most of the reactor volume is filled with gas (Figure 3B). Packing material breaks the fast movement of the gas and facilitates its contact with the liquid phase, increasing the volumetric mass transfer coefficient. The movement of the liquid is the other main driver of gas–liquid mass transfer. The packing material in TBRs immobilizes biomass in the form of a biofilm, making the system much less vulnerable to wash-out and allowing operation at shorter hydraulic retention times []. TBRs can be operated with gas flowing co-current or counter-current to the liquid. The co-current mode of operation is generally favored, as it prevents flooding of the bottom of the reactor and the breakthrough of unconverted gas [,]. A disadvantage particular to TBRs is a phenomenon known as channeling. Liquid medium follows preferential pathways through the packing material, resulting in unequal growth of the biofilm in the packing material []. The current proposed strategy to overcome channeling is to increase the liquid recirculation rate []. Future research efforts are required in this aspect of reactor design and operation to fulfill the need for more compact reactor designs that improve the productivity of these systems in a cost-effective manner.

2.4.4. Challenges

Syngas biomethanation faces several challenges that affect its viability and efficiency. One of the key challenges is the optimization of microbial communities to efficiently convert the raw syngas into methane. The toxicity of syngas components, particularly CO and tars, can inhibit microbial activity, especially in mixed culture setups; however, pure culture ex situ biomethanation approaches may offer improved tolerance and more stable methane yields under controlled conditions [,,]. Maintaining the stability and robustness of the microbial community under varying syngas compositions and operational conditions is another significant challenge. Mass transfer limitations also pose difficulties in syngas biomethanation. The solubility of syngas components in the liquid phase is low, which can limit the availability of these gases to the microbes and thus reduce the overall reaction rate. Reactor design plays a critical role in addressing these limitations, but optimizing reactor configurations for effective gas–liquid mass transfer while maintaining an environment conducive to microbial growth remains challenging. Furthermore, the scale-up of the syngas biomethanation processes from laboratory to industrial levels presents challenges related to maintaining consistent performance and ensuring economic feasibility. Integrating syngas biomethanation with existing industrial processes, such as waste-to-energy systems, also requires overcoming technical and economic hurdles to make the process competitive and sustainable in real-world applications.

3. Integrated Systems for Zero Emissions AD Plants

A critical challenge in large-scale anaerobic digestion (AD) facilities is reducing CO2 emissions while maintaining energy efficiency. Therefore, it is essential to develop integrated solutions that simultaneously address technical, economic, and environmental sustainability. In this regard, advancing innovative carbon capture and utilization (CCU) technologies to meet commercial viability is a key priority. Current popular strategies focus on combining bioenergy generation with the recovery of bio-based materials. Technology itself is not the sole challenge; rather, the integration of the most advanced methods into a cohesive valorization system is fundamental. Equally important is the close collaboration among all stakeholders across the supply chain, including farmers, AD operators, researchers, engineers, and policymakers.

Aligned with circular economy principles, three scenarios were explored and compared to a baseline to enhance the sustainability of AD processes. These scenarios focus on minimizing CO2 emissions and reusing them within the process to maximize both energy and material efficiency. Based on the extensive literature review and assuming the deployment of proven technologies, approximate mass balances were calculated using moderate assumptions. The proposed integrated approach aims to close the loop in AD by optimizing biomethane production and digestate management within the agri-food supply chain. Additionally, it supports the creation of new sustainable value chains that yield high-quality energy and bio-based products.

Since most anaerobic digesters in Europe are within the small-to-medium scale, with capacities between 500 to 2000 m3 and installed power ranging from 150 kW to 1 MW, a plant of 1 MW has been selected as the baseline scenario []. This plant was assumed to treat 120 tn/d organic waste producing 4500 m3/d biogas (55% CH4 and 45% CO2) and 110 tn/d digestate (60% liquid fraction and 40% solid fraction).

The three scenarios refer to the combination of the implementation of pathways 1, 2, and 3 with pathway 4, respectively.

Regarding the common digestate treatment, in all scenarios, the liquid fraction is recycled as a nutrient source within the bioprocesses. For the solid digestate fraction, its management includes pyrolysis and syngas upgrade, and the mass balances are presented in Table 5, assuming that the solids content of digestate is 25–35% []. As far as the pyrolysis of digestate is concerned, the temperature was considered as 500 °C, biochar yield 45%, pyrolysis oil yield 36%, and syngas yield 19% [,,,]. A typical syngas composition was assumed (22% H2, 17% CO, 52% CO2, 7%CH4, 1% C2H4, and 1% C2H6) [,,]. Exogenous H2 addition was assumed based on stoichiometric needs.

Table 5.

Mass balances of baseline and scenarios studied.

More specifically, scenario 1 includes an AD-MEC system where the digestate is treated via pyrolysis and syngas upgrade. The AD-MEC system could enhance biomethane production by 75% and reduce CO2 by 90% compared to the baseline scenario []. In scenario 2, the biogas produced from the conventional system is treated in a biomethanation reactor by adding green hydrogen applying Power2Gas technology and the resulting digestate from the AD is treated via pyrolysis and syngas upgrade. Assuming the stoichiometric requirements for hydrogen addition and 95% efficiency in the biomethanation process (in terms of CO2 conversion), the respective mass balances were estimated and are presented in Table 5. In scenario 3, the biogas produced is burned in a CHP engine with an overall efficiency of 83% (38% electric and 45% thermal) [,], while the digestate is managed via pyrolysis and syngas upgrade. The flue gases from the CHP engine were estimated, assuming 100% excess air input and complete CH4 combustion [] and they are led into a scrubbing system for CO2 dissolution (85% dissolution efficiency) []. The dissolved CO2 stream was used as a carbon source for algae cultivation, assuming 80% efficient carbon use []. The main mass balances were estimated and presented in Table 5 for the operation of one day.

To evaluate the sustainability and efficiency of the proposed valorization scenarios, four key indices were calculated (Table 6). The first index, CO2 emissions (S/I), quantifies the amount of carbon dioxide released into the atmosphere relative to the input feedstock, providing insight into the environmental burden of each process. The second index, CO2 captured/utilized (CC), measures the proportion of carbon dioxide that is either sequestered or converted into useful products, thereby reflecting the system’s contribution to carbon circularity and mitigation. The third index, bioenergy efficiency (%BE), evaluates how effectively the bioenergy is extracted from the feedstock, taking into account the lower heating values (LHVs) of methane, hydrogen, and organic waste as energy carriers. This index helps assess the conversion performance from a thermodynamic perspective. Finally, the biomass resource utilization (%BR) index examines how efficiently the biomass is converted into both energy products (e.g., biofuels) and material products (e.g., biochar, pyrolysis oil, and algal biomass). This broader index captures the holistic resource valorization of the system.

Table 6.

Reference values and equations for assessment of scenarios’ indicators.

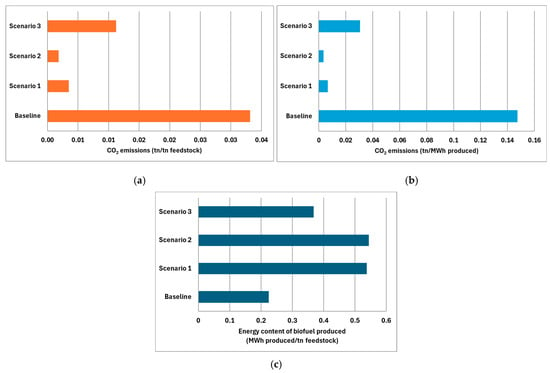

Based on the mass balances, the calculated indices are presented in Table 7. Notably, the carbon sequestered in biochar is excluded from the index calculations to maintain focus on the gaseous CO2 fraction dynamics, which are central to this study.

Table 7.

Indicators for all valorization scenarios (baseline: conventional AD, scenario 1: AD-MEC system with digestate treatment via pyrolysis and syngas upgrading, scenario 2: conventional AD with Power-to-Gas biomethanation using green hydrogen and digestate treated via pyrolysis and syngas upgrading, scenario 3: conventional AD with biogas used in CHP engine; flue gas CO2 captured for algae cultivation. Digestate managed via pyrolysis and syngas upgrading).

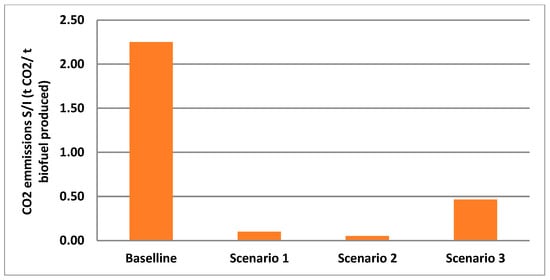

The adoption of advanced configurations significantly reduces CO2 emissions. It should be noted that the CO2 emissions reported in Table 7 correspond to direct process emissions. Upstream emissions associated with the production of green hydrogen in scenario 2 are not included in this analysis. Incorporating such life cycle emissions would require a dedicated LCA study, which is beyond the scope of the present review. The integrated scenario analysis examines pathways to enhance bio-based CH4 production through targeted configurations that aim to achieve zero-emission biofuels. This investigation incorporates advanced resource utilization and carbon management strategies. The benchmark for this assessment is the performance of conventional AD systems, which emit 2.25 t of CO2 for every t of biofuel. By employing advanced technologies, emissions from these systems can be reduced to as low as 0.05 t of CO2 per t of biofuel produced, as evidenced in scenario 2. Scenario 1 follows closely with 0.10 t CO2 per t of biofuel, while scenario 3 attains a moderate reduction of 0.47 t CO2 per t of biofuel. These findings highlight the effectiveness of integrating hydrogenotrophic CO2 methanation (scenario 2) and AD-MECs (scenario 1) in biofuel enhancement (Figure 4).

Figure 4.

Comparison of CO2 emissions per ton of biofuel from each scenario (baseline: conventional AD, scenario 1: AD-MEC system with digestate treatment via pyrolysis and syngas upgrading, scenario 2: conventional AD with Power-to-Gas biomethanation using green hydrogen and digestate treated via pyrolysis and syngas upgrading, scenario 3: conventional AD with biogas used in CHP engine; flue gas CO2 captured for algae cultivation. Digestate managed via pyrolysis and syngas upgrading).

The CO2 capture/utilization index further illustrates these improvements. While the baseline scenario does not incorporate carbon capture, scenario 1 and scenario 2 exhibit superior performance (0.03 each), indicating their potential for carbon valorization. Scenario 3 achieves a lower index of 0.02, suggesting lower carbon conversion efficiency compared to the other pathways.

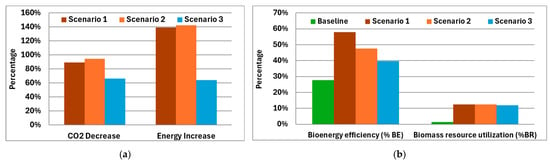

The baseline scenario emits 3.98 t/d of CO2 for the production of 1.77 t/d of bio-based CH4 in the form of biogas while treating 120 t of organic waste. Using this core system, the implementation of the proposed configurations would reduce CO2 emissions from 94% to 66%, while simultaneously increasing the total energy content of the produced biofuels from 64% in scenario 3, to 139% and 142% in scenarios 1 and 2, respectively (Figure 5a).

Figure 5.

Comparison of energy, emissions (a), bioenergy efficiency, and biomass resource utilization (b) for each scenario versus the baseline (baseline: conventional AD; scenario 1: AD-MEC with digestate pyrolysis and syngas upgrading; scenario 2: AD with Power-to-Gas biomethanation using green H2, digestate pyrolysis, and syngas upgrading; scenario 3: AD with biogas to CHP, CO2 capture for algae, digestate pyrolysis, and syngas upgrading).

Furthermore, the advanced scenarios can valorize the energy content of the initial raw materials up to two times more efficiently (scenario 1) than the baseline scenario, while utilizing biomass resources 12 times more effectively (Figure 5b). The low utilization factor of simple AD systems underscores the necessity for improved recovery and valorization strategies to enhance system sustainability.

An important outcome of this analysis is the potential that each scenario contributes to existing AD systems in terms of carbon capture and reduced reliance on fossil-based methane sources, while also achieving optimal valorization of the biomass in use. The integration of all advanced scenarios has significantly enhanced the initial performance of the baseline scenario. For each ton of feedstock utilized, scenarios 1 and 2 can produce more than double the energy output with nearly zero CO2 emissions. Although scenario 3 shows notable improvement over the baseline scenario, it still falls short compared to scenarios 1 and 2. This discrepancy can be attributed to the nature of this configuration, which can only produce one stream of bio-based methane, thus generating less energy compared to the other scenarios. Additionally, when considering the two primary functions of AD systems, energy production and waste treatment, it is crucial to assess the impact of integrating various CCUS technologies on CO2 reduction based on each function. In this regard, scenario 2 excels, achieving emissions as low as 3.3 kg of CO2 per MWh of energy produced and just 1.8 kg of CO2 per t of feedstock treated. This scenario outperforms alternative scenarios 1 and 3. In contrast, the baseline scenario exhibited significantly higher emissions, recording 147 kg of CO2 per MWh produced and 30 kg of CO2 per ton of waste treated. Figure 6 illustrates the correlation between these functions across the scenarios examined.

Figure 6.