Implications of New Environmental Product Declarations Standards in Ordinary Portland Cement Life Cycle Assessment Procedures and Results

Abstract

1. Introduction

1.1. Literature Gap

1.2. Technical Description of the Product

1.2.1. Main Constituents

|

|

- Portland Cement Clinker (K)—Material with hydraulic properties and the main constituent. At least 2/3 by mass are calcium silicates (3CaO.SiO2 and 2CaO.SiO2). The ratio CaO/SiO2 must not be lower than 2 and the magnesium oxide (MgO) content must not exceed 5% [24].

- Fly Ashes (V, W)—Dust-like particles from pulverised coal furnaces flue gases with pozzolanic and hydraulic properties. By-product that may be silicious (SiO2 > 25%) or calcareous (CaO > 10%) [24].

- Limestone (L, LL)—Common carbonate sedimentary rock, its calcium carbonate (CaCO3) content shall be larger than 75% by mass and the clay content must be less than 1.2% [24].

- Calcium Sulphate—Natural or by-product material that is added to cement to control setting. It can be either gypsum (calcium sulphate dihydrate, CaSO4. 2H2O), anhydrite (anhydrous calcium sulphate, CaSO4), or hemihydrate (CaSO4. ½H2O) [24].

- Ground Granulated Blast Furnace Slag (S)—Product obtained by rapid cooling of molten iron slag of suitable composition from blast furnace operations with hydraulic properties. The sum of CaO, MgO, and SiO2 constitutes at least two-thirds by mass, with (CaO + MgO)/SiO2 ratio exceeding 1.0 [24].

- Other Minor Constituents—Designation that covers other constituents, its total quantity must not exceed 5% of the cement mass [24].

1.2.2. Manufacturing Process

- Dry Process—Raw materials (already with low moisture content) are dried while being ground to a fine powder denoted raw meal. The dry feed is fed to a pre-heater or pre-calciner rotary kiln system to produce clinker.

- Semi-Dry Process—The dried raw meal is pelletised with water and fed to a preheater.

- Semi-Wet Process—A slurry of raw materials is dewatered in filter presser, resulting in a ‘cake’ that is extruded into pellets and fed into a pre-heater.

- Wet Process—A slurry of raw materials with very high levels of moisture are crushed in water and fed to a kiln or a slurry dryer.

1.3. Analysis Context and Research Questions

- (a)

- What is the environmental impact of manufacturing Ordinary Portland cement?

- (b)

- What are the environmental hotspots within the production chain?

- (c)

- Could the chosen electricity mix influence the environmental profile of cement?

- (d)

- Would different LCIA methods affect the impact assessment results?

- (e)

- Does the revised EN 15804:2012+A2:2019 specification produce a significant difference in results when compared to the previous A1 revision?

2. Environmental Assessment Procedures and Methods

- Goal and scope describe the target of the assessment and establishes the context in which the analysis will be implemented and what is its limits.

- Inventory analysis (LCI) identifies and quantifies the inputs and outputs within the system (energy and material consumption, emissions and others).

- Impact assessment (LCIA) calculates and quantifies the ecological and human health effects of the system inputs and outputs stipulated in the Inventory Analysis.

- Interpretation stage gathers the results, interprets them and delivers deductions that can provide the recipients of the report the ability to make informed decisions about the product’s environmental status considering its production system.

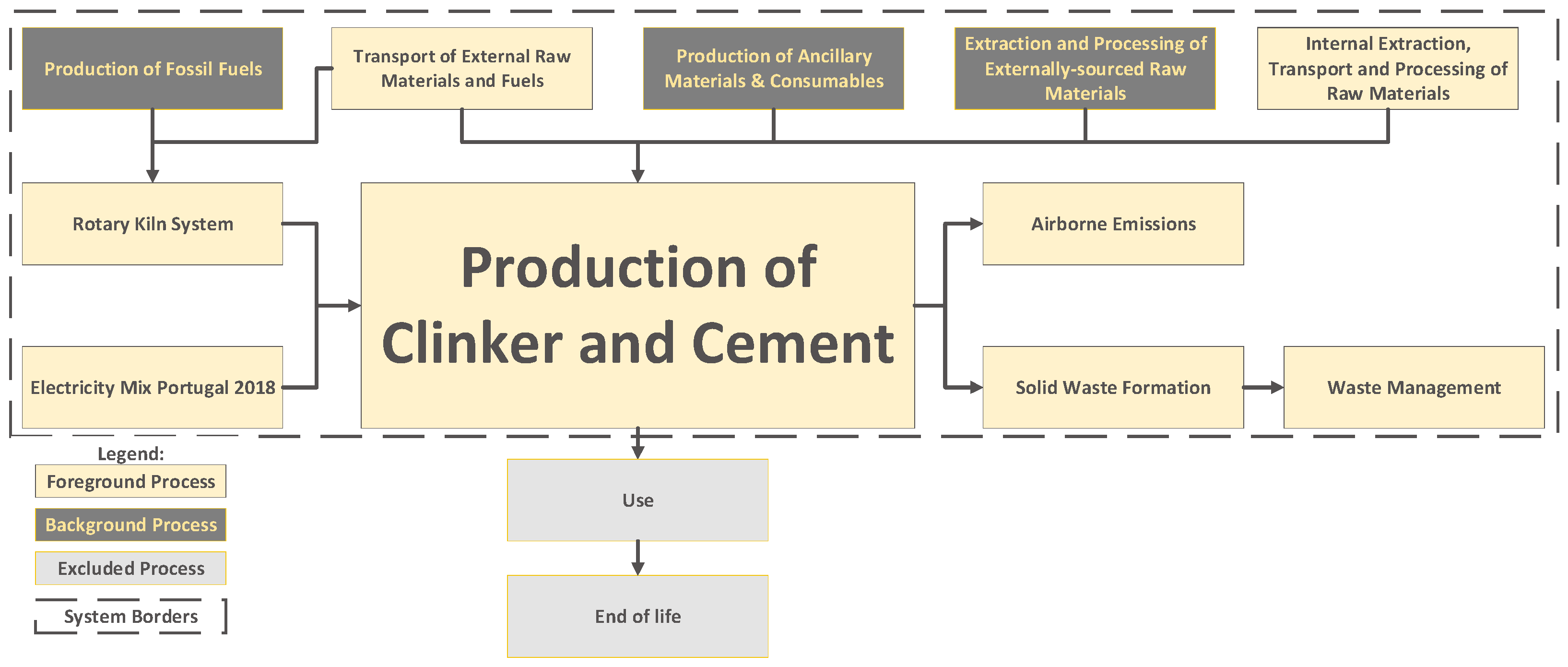

System Boundaries

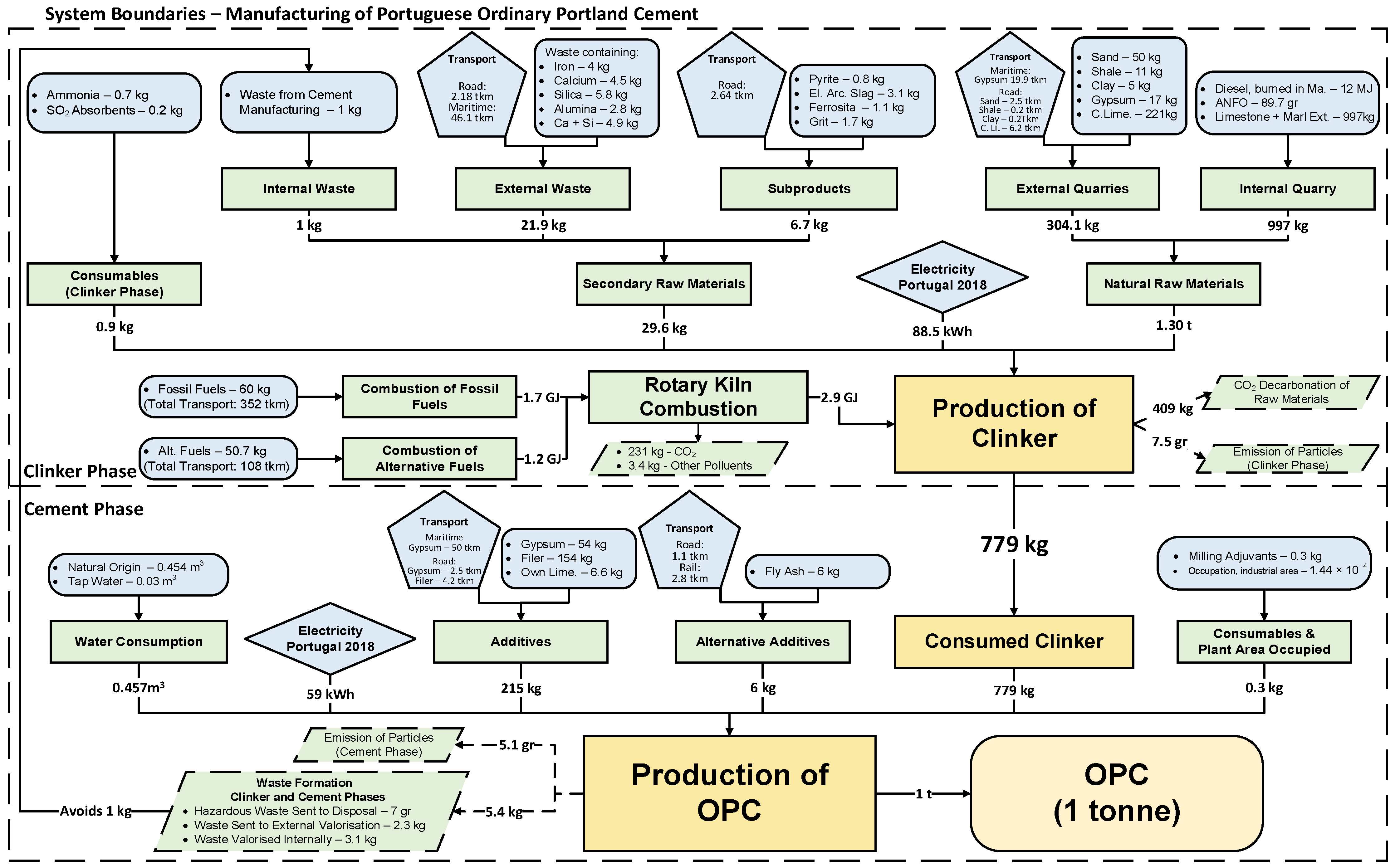

3. Life Cycle Inventory (LCI)

3.1. Geographic and Temporal Coverage

3.2. Representativeness and Significance

3.3. Missing Data

3.4. Clinker-to-Cement Ratio

3.5. Mass and Energy Balances

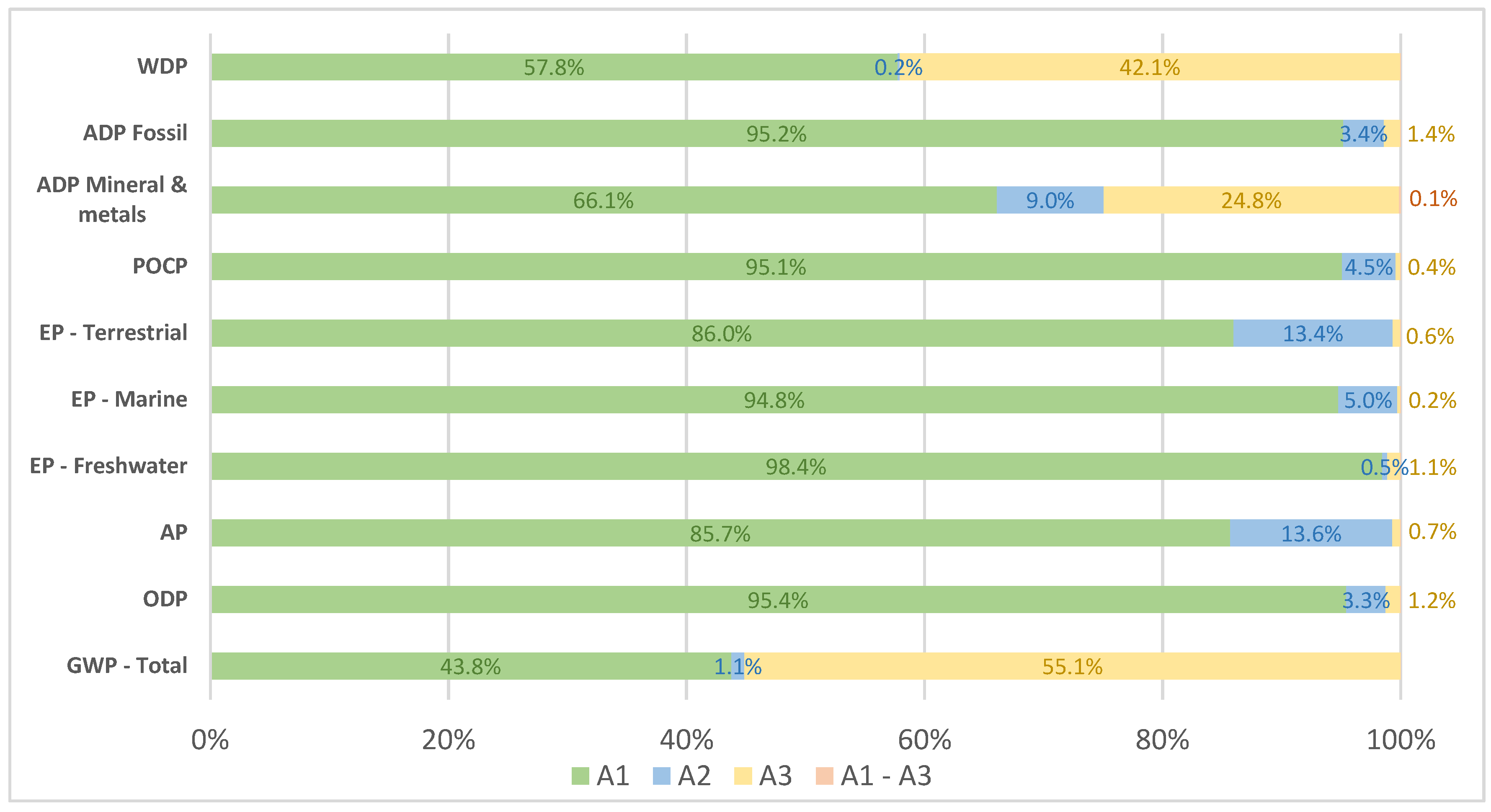

3.5.1. Module A1—Supply of Raw Materials and Primary Energy

3.5.2. Modules A2—Transport

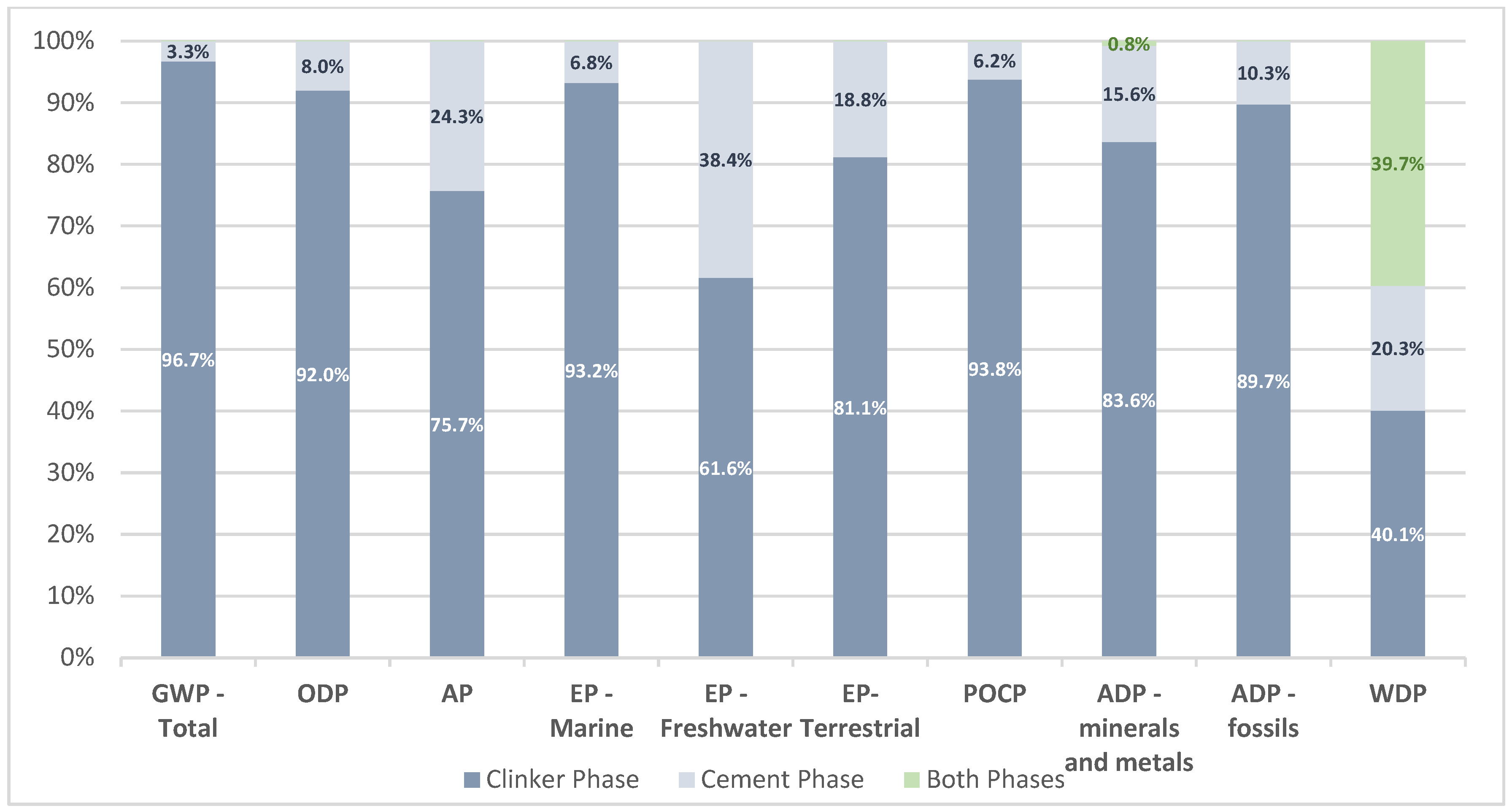

3.5.3. Modules A3—Manufacturing

3.5.4. Modules A1–A3—Solid Waste Management

3.5.5. Energy and Mass Flowchart

3.6. Lifecycle Impact Analysis (LCIA)

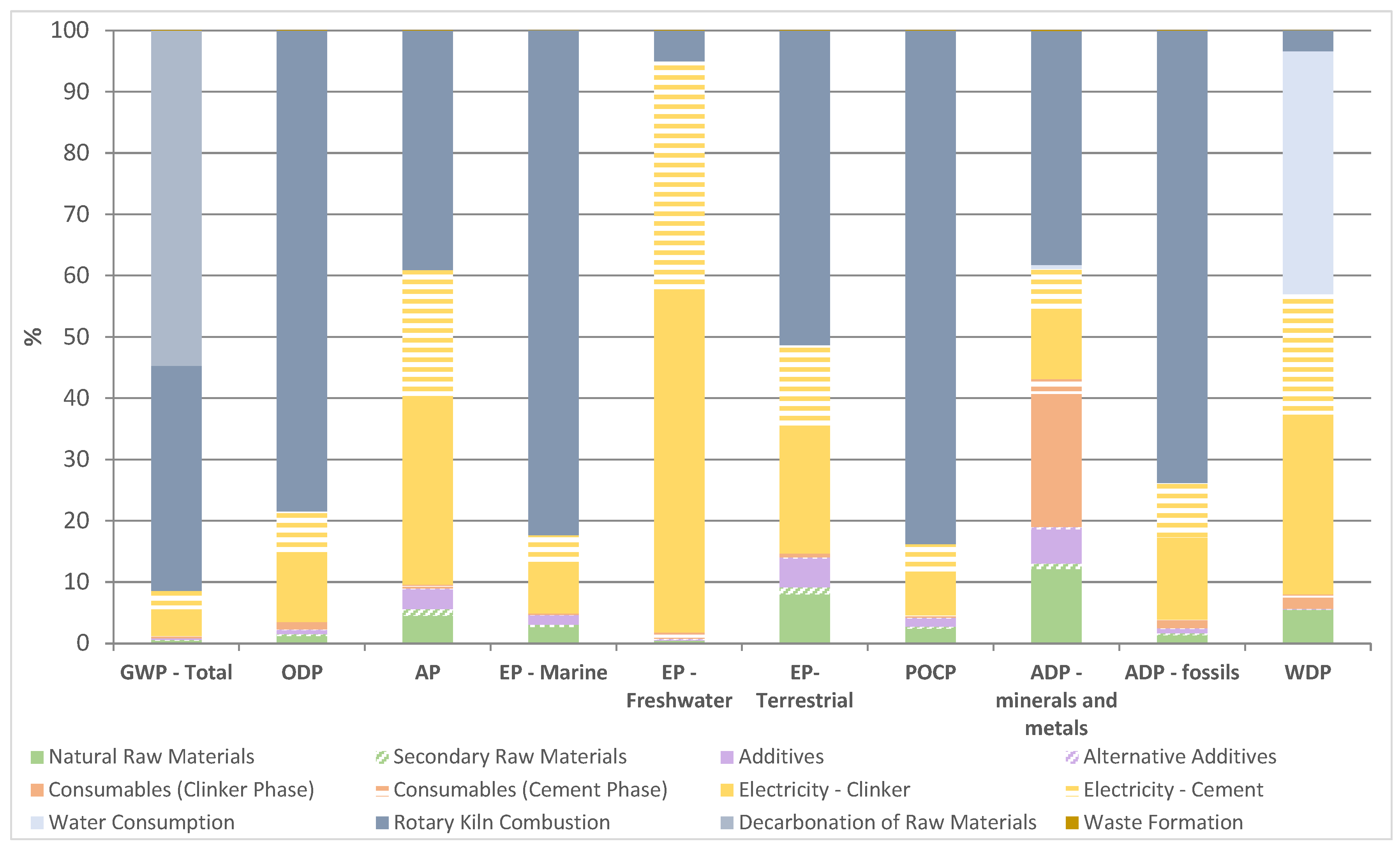

4. Results

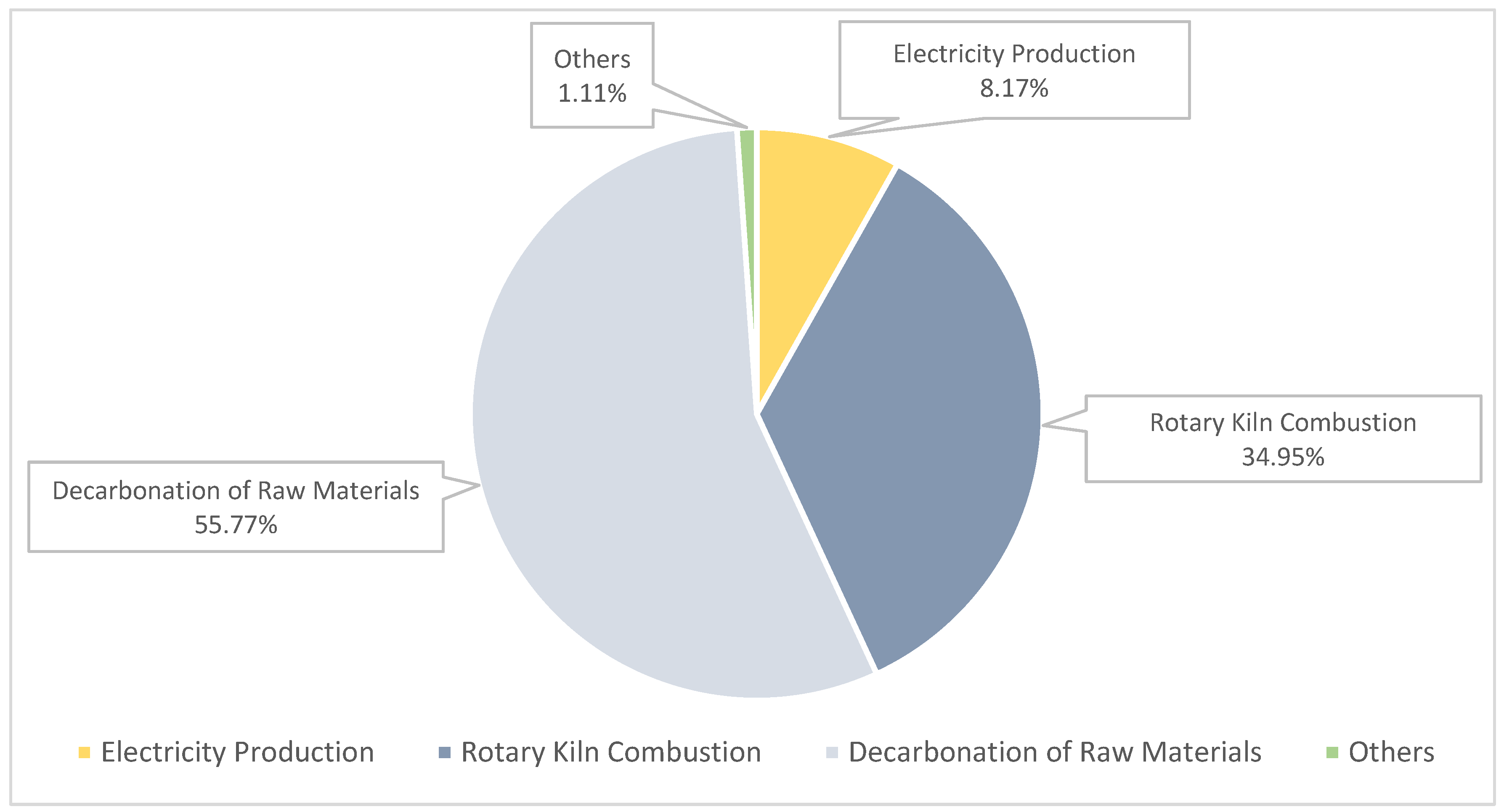

4.1. Carbon Footprint Analysis

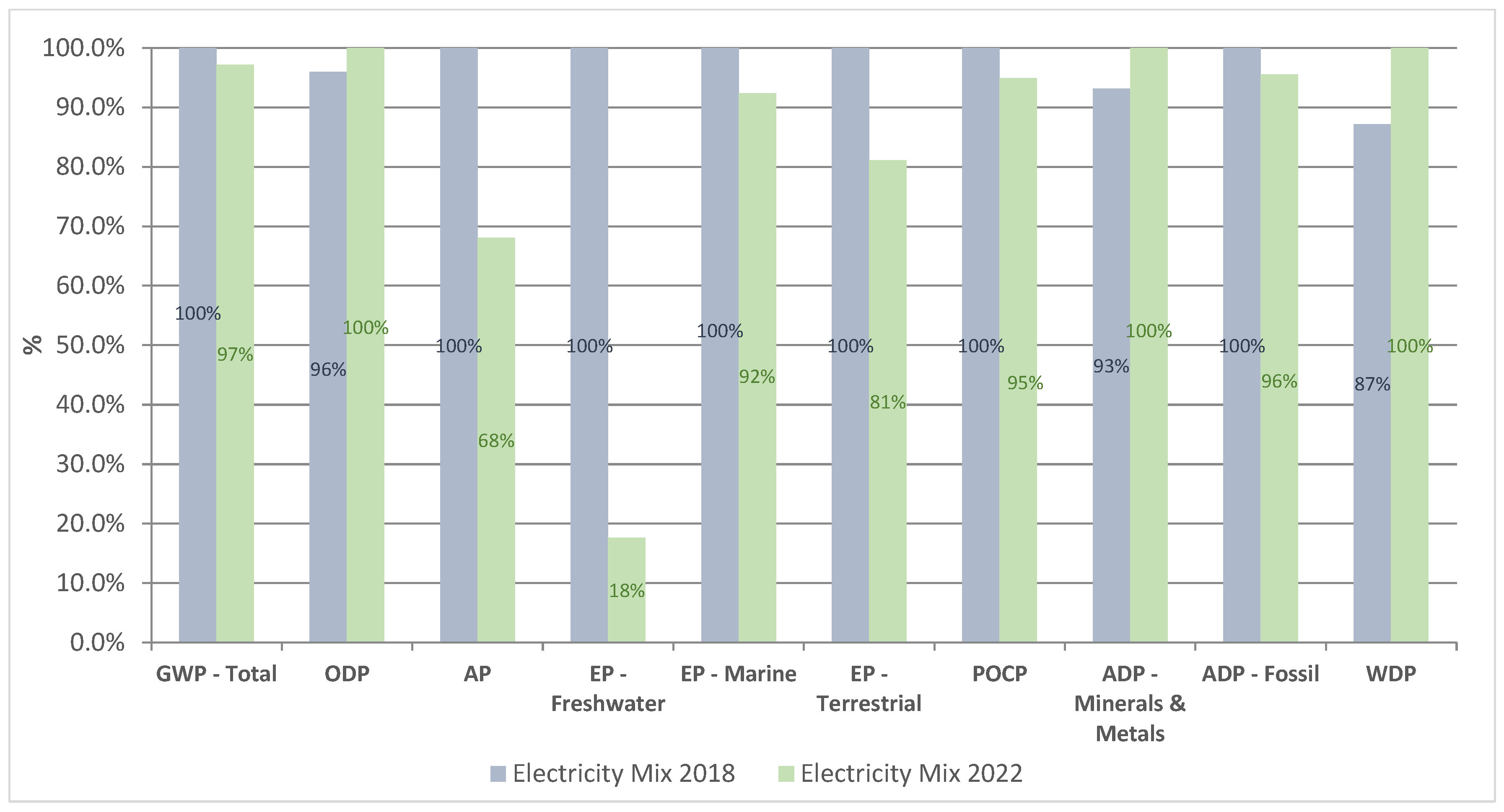

4.2. Electricity Generation Mix Sensitivity Analysis

4.3. Effect of Using Alternate Impact Assessment Methodologies

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Acronyms

| AD | (Non-Clinker Main Constituents) Additives |

| ADP–Fossil | Impact Category, Abiotic Depletion—Fossil |

| ADP–Minerals and Metal | Impact Category, Abiotic Depletion Potential—Minerals and Metals |

| ALT. AD | Alternative Additives |

| ANFO | Explosive, Ammonium Nitrate diesel Fuel Oil |

| AP | Impact Indicator, Acidification Potential |

| ATIC | Technical Association for the Portuguese Cement Industry |

| BEES+ | LCIA Method, Building for Environmental and Economic Sustainability |

| CaO | Calcium Oxide; Lime; Quicklime |

| CCUS | Carbon Capture, Use and Storage |

| CEM | Cement |

| CF | Characterisation Factor |

| CO2 | Carbon Dioxide |

| CML-IA | LCIA Method, Center of Environmental Science |

| CON. CEM. | Consumables (Cement Phase) |

| CON. CLK. | Consumables (Clinker Phase) |

| CtCr | Clinker to Cement Ratio; Clinker Content |

| DAP | Declaração Ambiental de Produto in Portuguese (EPD in english) |

| DRW | Decarbonation of Raw Materials |

| EF | LCIA Method, Environmental Footprint 3.0 or 3.1 |

| EL | Electricity Generation |

| EP–Freshwater | Impact Indicator, Eutrophication–Freshwater |

| EP–Marine | Impact Indicator, Eutrophication–Marine |

| EP–Terrestrial | Impact Indicator, Eutrophication–Terrestrial |

| EU | European Union |

| EPD | Environmental Product Declaration |

| GHG | Greenhouse Gases |

| GWP–Biogenic | Impact Category, Climate Change Biogenic |

| GWP–Fossil | Impact Category, Climate Change Fossil |

| GWP–Luluc | Impact Category, Climate Change Land Use and Land Use Change |

| GWP–Total | Impact Category, Climate Change Total |

| IMPACT+ | LCIA Method, IMPACT World+ |

| IPCC | Intergovernmental Panel on Climate Change |

| LC3 | Limestone Calcined Clay |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| NRW | Natural Raw Materials |

| ODP | Impact Category, Ozone Depletion |

| PCR | Product Category Rules |

| POCP | Impact Category, Photochemical Ozone Creation Potential |

| RDF | Residue Derived Fuel |

| RKC | Rotary Kiln Combustion |

| SiO2 | Silicon Dioxide |

| SRW | Secondary Raw Materials |

| TRACI | LCIA Method, Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts |

| WC | Water Consumption |

| WDP | Impact Category, Water Depletion |

| WF | Waste Formation |

References

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Wei, Y.M.; Chen, K.; Kang, J.N.; Chen, W.; Wang, X.Y.; Zhang, X. Policy and Management of Carbon Peaking and Carbon Neutrality: A Literature Review. Engineering 2022, 14, 52–63. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global Strategies and Potentials to Curb CO2 Emissions in Cement Industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Bosoaga, A.; Masek, O.; Oakey, J.E. CO2 Capture Technologies for Cement Industry. Energy Procedia 2009, 1, 133–140. [Google Scholar] [CrossRef]

- European Commission. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- European Comission. Green Deal. In Solar Power; University of California Press: Oakland, CA, USA, 2019; pp. 47–65. [Google Scholar] [CrossRef]

- Cavalett, O.; Watanabe, M.D.B.; Voldsund, M.; Roussanaly, S.; Cherubini, F. Paving the Way for Sustainable Decarbonization of the European Cement Industry. Nat. Sustain. 2024, 7, 568–580. [Google Scholar] [CrossRef]

- Stafford, F.N.; Dias, A.C.; Arroja, L.; Labrincha, J.A.; Hotza, D. Life Cycle Assessment of the Production of Portland Cement: A Southern Europe Case Study. J. Clean. Prod. 2016, 126, 159–165. [Google Scholar] [CrossRef]

- Stafford, F.N.; Raupp-Pereira, F.; Labrincha, J.A.; Hotza, D. Life Cycle Assessment of the Production of Cement: A Brazilian Case Study. J. Clean. Prod. 2016, 137, 1293–1299. [Google Scholar] [CrossRef]

- Ali, A.A.M.M.; Negm, A.M.; Bady, M.F.; Ibrahim, M.G.E.; Suzuki, M. Environmental Impact Assessment of the Egyptian Cement Industry Based on a Life-Cycle Assessment Approach: A Comparative Study Between Egyptian and Swiss Plants. Clean Technol. Environ. Policy 2016, 18, 1053–1068. [Google Scholar] [CrossRef]

- Valderrama, C.; Granados, R.; Cortina, J.L.; Gasol, C.M.; Guillem, M.; Josa, A. Implementation of Best Available Techniques in Cement Manufacturing: A Life-Cycle Assessment Study. J. Clean. Prod. 2012, 25, 60–67. [Google Scholar] [CrossRef]

- Song, D.; Yang, J.; Chen, B.; Hayat, T.; Alsaedi, A. Life-Cycle Environmental Impact Analysis of a Typical Cement Production Chain. Appl. Energy 2016, 164, 916–923. [Google Scholar] [CrossRef]

- García-Gusano, D.; Herrera, I.; Garraín, D.; Lechón, Y.; Cabal, H. Life Cycle Assessment of the Spanish Cement Industry: Implementation of Environmental-Friendly Solutions. Clean Technol. Environ. Policy 2015, 17, 59–73. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental Impact of Cement Production: Detail of the Different Processes and Cement Plant Variability Evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Su, Q.; Latypov, R.; Chen, S.; Zhu, L.; Liu, L.; Guo, X.; Qian, C. Life Cycle Assessment and Environmental Load Management in the Cement Industry. Systems 2025, 13, 611. [Google Scholar] [CrossRef]

- Georgiades, M.; Shah, I.H.; Steubing, B.; Cheeseman, C.; Myers, R.J. Prospective Life Cycle Assessment of European Cement Production. Resour. Conserv. Recycl. 2023, 194, 106998. [Google Scholar] [CrossRef]

- Moretti, L.; Caro, S. Critical Analysis of the Life Cycle Assessment of the Italian Cement Industry. J. Clean. Prod. 2017, 152, 198–210. [Google Scholar] [CrossRef]

- Capucha, F.; Henriques, J.; Ferrão, P.; Iten, M.; Margarido, F. Analysing Industrial Symbiosis Implementation in European Cement Industry: An Applied Life Cycle Assessment Perspective. Int. J. Life Cycle Assess. 2023, 28, 516–535. [Google Scholar] [CrossRef]

- Rhaouti, Y.; Taha, Y.; Benzaazoua, M. A Comparative Life Cycle Assessment of Ordinary Portland Cement, Limestone Calcined Clay Cement and Mining Waste Marl Cement. In Proceedings of the 1st International Conference on Net-Zero Built Environment, Oslo, Norway, 19–21 June 2024; Kioumarsi, M., Shafei, B., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 551–562. [Google Scholar]

- Generowicz-Caba, N.; Kulczycka, J. LCA of Cement with Alternative Additives: Pathways to Sustainable Production. Materials 2025, 18, 3057. [Google Scholar] [CrossRef]

- Xiong, L.; Palomo, A.; Maltseva, O.; Fernandez-jimenez, A.; Wan, Z. Transforming Landfilled Coal Ash in Ultralow Clinker Binders. J. Am. Ceram. Soc. 2025, 108, e20661. [Google Scholar] [CrossRef]

- de Oliveira, A.R.; Bento, S.; Partidário, M.; Morrison-Saunders, A. Understanding Stakeholder Experiences with Visual Communication in Environmental Impact Assessment. Environ. Impact Assess. Rev. 2023, 102, 107210. [Google Scholar] [CrossRef]

- CEN/TC 350 NP EN 15804:2012+A2:2019; Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Products. Technical Committee: Brussels, Belgium, 2019.

- EN 197-1:2012; Cement—Part 1: Composition, Specifications, and Conformity Criteria for Common Cements. 2012th–04 ed. European Commitee for Standardization: Brussels, Belgium, 2011.

- EN 197-5:2021; Cement—Part 5: Portland-Composite Cement CEM II/C-M and Composite Cement CEM VI. European Commitee for Standardization: Brussels, Belgium, 2021.

- European Cement Association. Cembureau Cementing the European Green Deal, Reaching Climate Neutrality Along the Cement and Concrete Value Chain by 2050; European Cement Association: Brussels, Belgium, 2020; pp. 1–38. [Google Scholar]

- ATIC-Associação Técnica da Indústria do Cimento. Roteiro Para A Neutralidade Carbónica 2050; ATIC: Oeiras, Portugal, 2025; Volume 2050. [Google Scholar]

- Cement Sustainability Initiative (CSI). List of Constants and Default CO2 Emission Factors; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2025. [Google Scholar]

- Cement Sustainability Initiative (CSI). Cement Sustainability Initiative (CSI) CO2 and Energy Accounting and Reporting Standard for the Cement Industry May 2011 the Cement CO2 and Energy Protocol; World Business Council for Sustainable Development (WBCSD): Genève, Switzerland, 2011. [Google Scholar]

- CEMBUREAU The European Cement Association. From Ambition to Deployment—The Road Travelled, Pathways and Levers to Scale up or Net Zero Ambition; CEMBUREAU: Brussels, Belgium, 2024. [Google Scholar]

- EPD®. General Programme Instructions for the International EPD® System; Version 4.0; EPD International: Stockholm, Sweden, 2021; p. 80. [Google Scholar]

- ISO 14040:2006; The International organization for standardization Environmental Management—Life Cycle Assessment—Principles and Framework. Environmental Management System: Geneva, Switzerland, 2004; p. 44.

- Blengini, G.A. Life Cycle Assessment Tools for Sustainable Development: Case Studies for the Mining and Construction Industries in Italy and Portugal; Instituto Superior Técnico: Lisbon, Portugal, 2006. [Google Scholar]

- ISO 14044; Environmental Management—Life Cycle Assessment-Requirements and Guidelines. The International organization for standardization: Geneva, Switzerland, 2006; p. 7.

- DAPHabitat Regras Para a Categoria de Produto (RCP)—Modelo Base—Produtos e Serviços de Construção. CentroHabitat—Plataforma Para A Construção Sustentável. Available online: https://www.daphabitat.pt/assets/Uploads/RCP/pdfs/62c6115e92/RCP-DAPHABITAT_V3-v4.1-Junho-2025-PT.pdf (accessed on 5 November 2025).

- DAPHabitat System General Instructions for the DAPHabitat System. 2015. Available online: https://www.daphabitat.pt/assets/Uploads/Instrucoes-Gerais-do-Programa/efdf6ca37a/IGP-DAPHABITAT_V3.1-Junho-2025-PT.pdf (accessed on 5 November 2025).

- Ecoinvent Database, v3.9.1. 2023. Available online: https://ecoinvent.org/ (accessed on 5 November 2025).

- BauMineral GmbH. Environmental Product Declaration as per ISO 14025 and EN 15804: EFA-Füller® MR3; BauMineral GmbH: Herten, Germany, 2017. [Google Scholar]

- SECIL Declaração Ambiental 2018—Outão. Available online: https://www.secil-group.com/content/dam/secilInstitucional/documentos/pt/documentos/declaracao-ambiental/Declaracao-Ambiental-Outao-2018.pdf (accessed on 3 November 2025).

- SECIL Declaração Ambiental 2018—Maceira. Available online: https://www.secil-group.com/content/dam/secilInstitucional/documentos/pt/documentos/declaracao-ambiental/Declaracao-Ambiental-Maceira-2018.pdf (accessed on 3 November 2025).

- SECIL Declaração Ambiental 2018—Pataias. Available online: https://www.secil-group.com/content/dam/secilInstitucional/documentos/pt/documentos/declaracao-ambiental/Declaracao-Ambiental-Cibra-2018.pdf (accessed on 3 November 2025).

- Cimpor Declaração Ambiental 2018—Alhandra. Available online: https://www.cimpor.com/documents/20124/158764/Novo_DeclaracaoAmbientalEMAS_CPAlhandra_2018.pdf/703e228a-7679-ccc3-509b-fe5f7c372cb0?t=1602155669328 (accessed on 3 November 2025).

- Cimpor Declaração Ambiental 2018—Souselas. Available online: https://www.cimpor.com/documents/20124/158764/Novo_DeclaracaoAmbientalEMAS_CPSouselas_2018.pdf/0023f51c-834d-d91b-dd0f-3d698f494cb3?t=1602155698284 (accessed on 3 November 2025).

- Cimpor Declaração Ambiental 2018—Loulé. Available online: https://www.cimpor.com/documents/20124/158764/Novo_DeclaracaoAmbientalEMAS_CPLoule_2018.pdf/6f9d5245-2efc-25b0-e923-dcf1e94da116?t=1602155647539 (accessed on 3 November 2025).

- SECIL Declaração Ambiental 2023—Outão. Available online: https://www.secil.pt/content/dam/secilComercial/documents/pt/outros-documentos/Declaração Ambiental EMAS Outao 2023.pdf (accessed on 3 November 2025).

- SECIL Declaração Ambiental 2023—Maceira. Available online: https://www.secil.pt/content/dam/secilComercial/documents/pt/outros-documentos/Declaração Ambiental EMAS Maceira 2023.pdf (accessed on 3 November 2025).

- SECIL Declaração Ambiental 2023—Pataias. Available online: https://www.secil.pt/content/dam/secilComercial/documents/pt/outros-documentos/Declaração Ambiental EMAS Pataias 2023.pdf (accessed on 3 November 2025).

- Cimpor Declaração Ambiental 2023—Loulé. Available online: https://www.cimpor.com/documents/20124/1130341/Declaração_Atualizada_Loulé_2023.pdf (accessed on 3 November 2025).

- Cimpor Declaração Ambiental 2023—Alhandra. Available online: https://www.cimpor.com/documents/20124/1130338/Declaração_Atualizada_Alhandra_2023.pdf/63b40724-9c4d-a6bb-988a-29020f57dad9?t=1726475575898 (accessed on 3 November 2025).

- Cook, M.A. The Science of Industrial Explosives; IRECO: Elmhurst, IL, USA, 1974; ISBN ASIN B0000EGDJT. [Google Scholar]

- REN Diagrama de Carga. 2018. Available online: https://datahub.ren.pt/pt/eletricidade/balanco-mensal/?date=2018-12-31 (accessed on 1 June 2025).

- European Comission Environmental Footprint v3.1. Available online: https://eplca.jrc.ec.europa.eu/LCDN/developerEF.html (accessed on 1 June 2025).

- EN 15804:2012+A1:2013; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction ProductsM. European Commitee for Standardization: Brussels, Belgium, 2013.

- UN Environment Programme. Eco-Efficient Cements: Potential, Economically Viable Solutions for a Low-CO2 Cement Based Industry; United Nations Environment Programme: Nairobi, Kenya, 2016; p. 64. [Google Scholar]

- Ramão, A.; Modolo, R.C.E.; Figueiredo, A.; Vicente, R. Exploring the Potential of Belitic Cement Produced from Industrial Waste: Systematic Mapping of the Literature. Sustainability 2025, 17, 2377. [Google Scholar] [CrossRef]

- CIMPOR CIMPOR—Portugal. Available online: https://www.cimpor.com/en/portugal (accessed on 28 February 2025).

- Ekinci, E.; Kantarcı, F.; Mara, M.M. Historiography, Current Practice and Future Perspectives: A Critical Review of Geopolymer Binders. Sustainability 2025, 17, 9204. [Google Scholar] [CrossRef]

- Myllyviita, T.; Leskinen, P.; Seppälä, J. Impact of Normalisation, Elicitation Technique and Background Information on Panel Weighting Results in Life Cycle Assessment. Int. J. Life Cycle Assess. 2014, 19, 377–386. [Google Scholar] [CrossRef]

- van Deventer, J.S.J.; White, C.E.; Myers, R.J. A Roadmap for Production of Cement and Concrete with Low-CO2 Emissions; Springer: Dordrecht, The Netherlands, 2021; Volume 12, ISBN 0123456789. [Google Scholar]

- Trusiewicz, E.; Capital, C.V. Investing in Low Carbon Technologies in the Cement Sector Perspectives from Cleantech Venture Capital. 2020. Available online: https://www.cemnet.com/Conference/Item/185884/cemtech-2020-decarbonising-the-cement-industry.html (accessed on 5 November 2025).

- Li, C.; Gong, X.Z.; Cui, S.P.; Wang, Z.H.; Zheng, Y.; Chi, B.C. CO2 Emissions Due to Cement Manufacture. Mater. Sci. Forum 2011, 685, 181–187. [Google Scholar] [CrossRef]

- Feiz, R.; Ammenberg, J.; Baas, L.; Eklund, M.; Helgstrand, A.; Marshall, R. Improving the CO2 Performance of Cement, Part I: Utilizing Life-Cycle Assessment and Key Performance Indicators to Assess Development within the Cement Industry. J. Clean. Prod. 2015, 98, 272–281. [Google Scholar] [CrossRef]

- International Energy Agency. Ine Global Warming Potential Kept Decreasing in 2019, Despite the Economic Growth in 2019; International Energy Agency: Paris, France, 2021; pp. 2–5. [Google Scholar]

- REN Dados Técnicos. 2022. Available online: https://www.ren.pt/media/onzbcegp/dados-tecnicos-2022.pdf (accessed on 1 June 2025).

- Chen, X.; Matthews, H.S.; Griffin, W.M. Uncertainty Caused by Life Cycle Impact Assessment Methods: Case Studies in Process-Based LCI Databases. Resour. Conserv. Recycl. 2021, 172, 105678. [Google Scholar] [CrossRef]

- Esnouf, A.; Latrille, É.; Steyer, J.P.; Helias, A. Representativeness of Environmental Impact Assessment Methods Regarding Life Cycle Inventories. Sci. Total Environ. 2018, 621, 1264–1271. [Google Scholar] [CrossRef]

- European Commission Enviromental Footprint 3.1. 2022. Available online: https://simapro.com/wp-content/uploads/2020/06/DatabaseManualMethods.pdf (accessed on 1 June 2025).

- Center of Environmental Science (CML) CML-IA Baseline 2016. Available online: https://simapro.com/wp-content/uploads/2020/06/DatabaseManualMethods.pdf (accessed on 1 June 2025).

- EN 15804 + A2; PRé Sustainability. (Adapted EF3.1). European Commission: Brussels, Belgium, 2022.

- EN 15804 + A2; PRé Sustainability. (EF3.0). European Commission: Brussels, Belgium, 2019.

- SEMC EPD. 2018. Available online: https://simapro.com/wp-content/uploads/2020/06/DatabaseManualMethods.pdf (accessed on 1 June 2025).

- IMPACT World+ IMPACT World+ Midpoint. Available online: https://simapro.com/wp-content/uploads/2020/06/DatabaseManualMethods.pdf (accessed on 1 June 2025).

- US-EPA TRACI 2.1. Available online: https://simapro.com/wp-content/uploads/2020/06/DatabaseManualMethods.pdf (accessed on 1 June 2025).

- NIST BEES+. Available online: https://simapro.com/wp-content/uploads/2020/06/DatabaseManualMethods.pdf (accessed on 1 June 2025).

- IPCC IPCC 2021 GWP100. Available online: https://simapro.com/wp-content/uploads/2020/06/DatabaseManualMethods.pdf (accessed on 1 June 2025).

- Johnson, E. Goodbye to Carbon Neutral: Getting Biomass Footprints Right. Environ. Impact Assess. Rev. 2009, 29, 165–168. [Google Scholar] [CrossRef]

- European Comission Guidance on Classification of Waste According to EWC-Stat Categories. Eurostat 2010, 2150/2002, 82. Available online: https://unece.org/fileadmin/DAM/stats/documents/ece/ces/ge.33/2012/mtg2/Supplement_Manual_on_Waste_Statistics.pdf (accessed on 5 November 2025).

- Bouabid, G.; Nahya, D.; Azzi, M. Determination of Heating Value of Industrial Waste for the Formulation of Alternative Fuels. MATEC Web Conf. 2013, 5, 04031. [Google Scholar] [CrossRef]

- Caracol, P.M.d.O. Avaliação Da Viabilidade Dos Combustíveis Derivados de Resíduos Caso de Estudo Da Indústria Cimenteira. Master’s Thesis, Instituto Superior técnico, Lisboa, Portugal, 2016. [Google Scholar]

- Psomopoulos, C.S. Residue Derived Fuels as an Alternative Fuel for the Hellenic Power Generation Sector and Their Potential for Emissions ReductionConstantinos S. Psomopoulos. AIMS Energy 2014, 2, 321–341. [Google Scholar] [CrossRef]

| Clinker Phase | |||

| Assembly | Unit Process | Amount (in kg) | |

| Primary Raw Materials (Total Input: 1.30 t) | Internal Quarry | Diesel, Burned in Machinery | (12 MJ) 0.3 |

| Explosives (ANFO) | 0.1 | ||

| Limestone and Marl Extraction | 997 | ||

| External Quarries | Sand | 49.7 | |

| Shale | 11.3 | ||

| Clay | 5.1 | ||

| Gypsum (For Clinker Production) | 17 | ||

| Corrective Limestone | 221 | ||

| Secondary Raw Materials (Total Input: 29.6 kg) | External Waste | Waste containing Iron | 4 |

| Waste containing Calcium | 4.5 | ||

| Waste containing Silica | 5.8 | ||

| Waste containing Alumina | 2.8 | ||

| Waste containing Ca and Si | 4.9 | ||

| Internal Waste | Waste from Cement Manufacturing | 1 | |

| ‘Subproducts’ | Pyrite Ash | 0.8 | |

| Electric Arc Kiln Slag | 3.1 | ||

| Slag from Zinc Production | 1.1 | ||

| Grit | 1.7 | ||

| Cement Phase | |||

| Assembly | Unit Process | Amount (in kg) | |

| Non-Clinker Main Constituents (Additives) (Total Input: 222.8 kg) | Conventional | Gypsum (For Cement Production) | 54.2 |

| Filer (Limestone) | 156 | ||

| Limestone (Internal Quarry) | 6.6 | ||

| Alternative | Fly Ash | 6 | |

| Rotary Kiln Combustion Reaction | Emissions to Air | ||||

|---|---|---|---|---|---|

| Combustion Categories | Amount (kg) | Thermal Output (MJ) | Pollutant | Amount (kg) | |

| Fossil Fuel | Petcoke | 60.6 | 1742 | CO2–Fossil | 210.1 |

| Fuel oil | 0.3 | CO2–Biogenic | 13 | ||

| Biomass | Vegetable | 4.4 | 106 | Carbon monoxide (CO) | 8.2 × 10−4 |

| Animal | 1.3 | Nitrogen oxides (NOx) | 2.7 × 10−4 | ||

| Veg. Coal | 0.06 | Sulphur dioxide (SO2) | 4.8 × 10−5 | ||

| Industrial Waste | Common | 25.5 | 608 | Total Organic Carbon (TOC) | 1.8 × 10−4 |

| Hazardous | 0.9 | NMVOC | 9.9 × 10−6 | ||

| Residue- Derived Fuel | Common | 15 | 456 | Ammonia (NH3) | 9.1 × 10−6 |

| Hazardous | 3.6 | Methane (CH4) | 5.3 × 10−6 | ||

| Total | 112 | 2913 | Dinitrogen monoxide (N2O) | 2.9 × 10−6 | |

| Hydrogen chloride (HCl) | 9.5 × 10−7 | ||||

| Benzene (C6H6) | 6.4 × 10−7 | ||||

| Hydrogen fluoride (HF) | 1.7 × 10−7 | ||||

| Hydrogen cyanide (HCN) | 7.4 × 10−8 | ||||

| Chloroethylene (CH2CHCL) | 5.9 × 10−8 | ||||

| Co + Ni + Cu + Zn + Cr + Mn | 3.93 × 10−8 | ||||

| Naphthalene (C10H8) | 3.3 × 10−8 | ||||

| Pb + Cd + Hg + Tl + Sb + As + V | 2.11 × 10−8 | ||||

| Phthalate, diisooctyl- (C24H38O4) | 1.1 × 10−9 | ||||

| Polycyclic Aromatic Hydrocarbons (PAH) | 5.5 × 10−12 | ||||

| External Raw Materials | ||

| Raw Material Type | Transportation Method | Freight Transport (tkm) |

| Natural Raw Materials | Road | 8.48 |

| Maritime | 15.6 | |

| Secondary Raw Materials | Road | 3.76 |

| Maritime | 35.9 | |

| Conventional Additives | Road | 6.63 |

| Maritime | 50.5 | |

| Alternative Additives | Rail Transport | 2.79 |

| Road Transport | 1.08 | |

| Rotary Kiln Fuels | ||

| Fuel Type | Transportation Method | Freight Transport (tkm) |

| Conventional Fuels | Road | 6.29 |

| Maritime | 286 | |

| Alternative Fuels | Road | 10.92 |

| Maritime | 73.25 | |

| Intermediate Product Manufacture: Clinker Phase | |||||

| Input in Manufacturing Process | Emissions to Air | ||||

| Assembly/Unit Processes | Amount | Unit | Pollutant | Amount | Unit |

| Natural Raw Materials | 1.30 | t | CO2 (Decarbonation) | 409 | kg |

| Secondary Raw Materials | 29.6 | kg | Particulates | 7.5 | gr |

| Rotary Kiln Combustion | 2.9 | GJ | |||

| Electricity | 88.5 | kWh | |||

| Ammonia | 0.7 | kg | |||

| SO2 Absorbents | 0.2 | kg | |||

| Product Manufacture: Cement Phase | |||||

| Input in Manufacturing Process | Emissions to Air | ||||

| Assembly/Unit Processes | Amount | Unit | Pollutant | Amount | Unit |

| Clinker | 779 | kg | Particulates | 5.1 | gr |

| Non-Clinker Main Constituents (Additives) | 215 | kg | |||

| Alternative Additives | 6 | kg | |||

| Electricity | 59 | kWh | |||

| Milling Adjuvants | 0.3 | kg | |||

| Water, Natural Portugal | 0.45 | m3 | |||

| Tap Water, Portugal | 26.3 | kg | |||

| Specific Area Occupied by Factory | 1.44 × 10−4 | ha | |||

| Product | Solid Waste Management | ||

|---|---|---|---|

| Input | Amount (t) | Output to Technosphere: Waste Treatment | Amount (kg) |

| Portland Cement | 1 | Hazardous Waste Sent to Disposal | 0.07 |

| Waste Sent to External Valorisation | 2.29 | ||

| Waste Valorised Internally | 3.09 | ||

| Output to Technosphere, Avoided Products | Amount (kg) | ||

| Waste from Cement Manufacturing (Internal) | 0.98 | ||

| Impact Categories | Indicators | Unit |

|---|---|---|

| Climate change—total | Global Warming Potential total (GWP-total) | kg CO2 eq. |

| Climate change—fossil | Global Warming Potential fossil fuels (GWP-fossil) | kg CO2 eq. |

| Climate change—biogenic | Global Warming Potential biogenic (GWP-biogenic) | kg CO2 eq. |

| Climate change—land use and land use change | Global Warming Potential land use and land use change (GWP-luluc) | kg CO2 eq. |

| Ozone depletion | Depletion potential of the stratospheric ozone layer (ODP) | kg CFC 11 eq. |

| Acidification | Acidification potential, Accumulated Exceedance (AP) | mol H+ eq. |

| Eutrophication aquatic freshwater | Eutrophication potential, fraction of nutrients reaching freshwater end compartment (EP-freshwater) | kg P eq. |

| Eutrophication aquatic marine | Eutrophication potential, fraction of nutrients reaching marine end compartment (EP-marine) | kg N eq. |

| Eutrophication terrestrial | Eutrophication potential, Accumulated Exceedance (EP-terrestrial) | mol N eq. |

| Photochemical ozone formation | Formation potential of tropospheric ozone (POCP) | kg NMVOC eq. |

| Depletion of abiotic resources—minerals and metals | Abiotic depletion potential for non-fossil resources (ADP-minerals and metals) | kg Sb eq. |

| Depletion of abiotic resources—fossil fuels | Abiotic depletion for fossil resources potential (ADP-fossil) | MJ, net calorific value |

| Water use | Water (user) deprivation potential, deprivation-weighted water consumption (WDP) | m3 world eq. deprived |

| Core Impact Categories | Unit | A1 | A2 | A3 | A1−A3 | Total |

|---|---|---|---|---|---|---|

| GWP-Total | kg CO2 eq. | 3.3 × 102 | 8.3 × 100 | 4.1 × 102 | 1.8 × 10−2 | 7.5 × 102 |

| GWP-Fossil | kg CO2 eq. | 3.1 × 102 | 8.3 × 100 | 4.1 × 102 | 2.0 × 10−2 | 1.2 × 101 |

| GWP-Biogenic | kg CO2 eq. | 1.2 × 101 | 3.1 × 10−3 | 6.7 × 10−3 | -2.6 × 10−3 | 7.3 × 102 |

| GWP-Luluc | kg CO2 eq. | 8.2 × 10−1 | 2.7 × 10−4 | 7.3 × 10−4 | 1.6 × 10−4 | 8.2 × 10−1 |

| ODP | kg CFC 11 eq. | 4.6 × 10−6 | 1.6 × 10−7 | 5.9 × 10−8 | 4.2 × 10−10 | 4.8 × 10−6 |

| AP | mol H+ eq. | 5.6 × 10−1 | 8.9 × 10−2 | 4.5 × 10−3 | 8.9 × 10−5 | 6.6 × 10−1 |

| EP-Freshwater | kg P eq. | 1.7 × 10−2 | 7.9 × 10−5 | 1.8 × 10−4 | 6.3 × 10−6 | 1.7 × 10−2 |

| EP-Marine | kg N eq. | 4.0 × 10−1 | 2.1 × 10−2 | 1.0 × 10−3 | 2.8 × 10−5 | 4.2 × 10−1 |

| EP-Terrestrial | mol N eq. | 1.5 × 100 | 2.3 × 10−1 | 1.1 × 10−2 | 2.9 × 10−4 | 1.7 × 100 |

| POCP | kg NMVOC eq. | 1.5 × 100 | 7.0 × 10−2 | 6.0 × 10−3 | 1.2 × 10−4 | 1.5 × 100 |

| ADP- Minerals and Metals | kg Sb eq. | 1.6 × 10−6 | 2.2 × 10−7 | 6.0 × 10−7 | 2.7 × 10−9 | 2.4 × 10−6 |

| ADP-Fossil | MJ, P. C. I | 3.0 × 103 | 1.1 × 102 | 4.4 × 101 | 2.5 × 10−1 | 3.1 × 103 |

| WDP | m3 world eq. dep. | 3.5 × 101 | 1.0 × 10−1 | 2.5 × 101 | 2.6 × 10−3 | 6.0 × 101 |

| Impact Categories | GWP | ODP | AP | EP-F | EP-M | EP-T | POCP | ADP-M&M | ADP-Fossil | WDP |

|---|---|---|---|---|---|---|---|---|---|---|

| Materials Supply | 1.2% | 3.5% | 9.6% | 4.9% | 1.8% | 14.7% | 4.6% | 43.8% | 3.9% | 47.7% |

| Energy | 44.1% | 96.5% | 90.4% | 95.1% | 98.2% | 85.3% | 95.4% | 56.1% | 96.1% | 52.3% |

| Electricity | 7.3% | 18.0% | 51.3% | 12.7% | 93.1% | 34.0% | 11.7% | 18.0% | 22.3% | 48.9% |

| Rotary Kiln Comb. | 36.7% | 78.5% | 39.0% | 82.4% | 5.0% | 51.3% | 83.8% | 38.1% | 73.8% | 3.4% |

| Calcining Reaction | 54.7% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% |

| Waste Formation | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% |

| Process (Percentage) | NRW | SRW | AD | ADAL | ELC | ELCL | RKC | CCL | CC | WC | DRW | WF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CO2—Biogenic (3.2%) | 3.7 × 10−2 | 6.0 × 10−4 | 2.5 × 10−2 | 3.7 × 10−3 | 4.5 | 6.8 | 12.3 | 1.2 × 10−2 | 6.8 × 10−3 | 9.4 × 10−4 | 0 | 4.8 × 10−4 |

| CO2—Fossil (40.9%) | 3.03 | 0.715 | 1.57 | 0.207 | 19.1 | 28.7 | 244 | 1.97 | 0.54 | 4.8 × 10−3 | 409 | 1.8 × 10−2 |

| CO2—Others * (55.8%) | 3.6 × 10−4 | 1.9 × 10−5 | 1.4 × 10−4 | 6.9 × 10−5 | 8.1 × 10−1 | 2.8 × 10−3 | 1.3 × 10−4 | 5.5 × 10−4 | 6.2 × 10−5 | 0 | 1.6 × 10−4 | |

| Total | 3.07 | 0.72 | 1.60 | 0.21 | 23.9 | 36 | 256.3 | 1.98 | 0.55 | 0.01 | 409.00 | 0.02 |

| Legend: NRW—Natural Raw Materials SRW—Secondary Raw Materials AD—Non-Clinker Main Constituents (Additives) ADAL—Alternative Additives ELCL—Electricity Consumption (Clinker Phase) * Land Use and Decarbonation | ELC—Electricity Consumption (Cement Phase) RKC—Rotary Kiln Combustion CCL—Consumables (Clinker Phase) CC—Consumables (Cement Phase) WC—Water Consumption DRW—Decarbonation of Raw Materials WF—Waste Formation | |||||||||||

| Impact Assessment Method | Region | Observations | |

|---|---|---|---|

| A | Environmental Footprint, EF 3.1 (Adapted to EN 15804:2012+A2:2019) | Europe | Used by EN 15804:2012+A2:2019 |

| B | CML-IA Baseline | Europe | Used by EN 15804:2012+A2:2019 |

| C | Environmental Footprint, EF 3.0 (Adapted to EN 15804:2012+A2:2019) | Europe | Used by EN 15804:2012+A2:2019 |

| D | Environmental Footprint, EF 3.1 | Europe | Original Version |

| E | EPD 2018 | Europe | |

| F | IMPACT World+ | Global | |

| G | Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts, TRACI 2.1 | North America | |

| H | Building for Environmental and Economic Sustainability, BEES + | North America | |

| I | Intergovernmental Panel on Climate Change, IPCC 2021 | Global | Single Issue |

| Impact Category | Unit | A | B | C | D | E | F | G | H | I | VAR |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Climate change | kg CO2 eq. | 746.8 | 733.1 | 760.7 | 734.6 | 733.1 | 739.4 | 731.3 | 729.4 | 733.6 | 4.2% |

| Ozone depletion | kg CFC11 eq. | 4.8 × 10−6 | 3.8 × 10−6 | 4.8 × 10−6 | 4.8 × 10−6 | 3.8 × 10−6 | 5.0 × 10−6 | 5.0 × 10−6 | 3.1 × 10−6 | NA | 44.2% |

| Resource use, fossils | MJ | 3144 | 3092 | 3144 | 3144 | 3092 | 3375 | NA | NA | NA | 8.9% |

| Resource use, minerals, and metals | kg Sb eq. | 2.4 × 10−6 | 2.6 × 10−6 | 2.4× 10−6 | 2.4 × 10−6 | 2.6 × 10−6 | NA | NA | NA | NA | 5.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capucha, F.; Bacatelo, M.; Ferrão, P.; Margarido, F. Implications of New Environmental Product Declarations Standards in Ordinary Portland Cement Life Cycle Assessment Procedures and Results. Sustainability 2025, 17, 10346. https://doi.org/10.3390/su172210346

Capucha F, Bacatelo M, Ferrão P, Margarido F. Implications of New Environmental Product Declarations Standards in Ordinary Portland Cement Life Cycle Assessment Procedures and Results. Sustainability. 2025; 17(22):10346. https://doi.org/10.3390/su172210346

Chicago/Turabian StyleCapucha, Francisco, Melissa Bacatelo, Paulo Ferrão, and Fernanda Margarido. 2025. "Implications of New Environmental Product Declarations Standards in Ordinary Portland Cement Life Cycle Assessment Procedures and Results" Sustainability 17, no. 22: 10346. https://doi.org/10.3390/su172210346

APA StyleCapucha, F., Bacatelo, M., Ferrão, P., & Margarido, F. (2025). Implications of New Environmental Product Declarations Standards in Ordinary Portland Cement Life Cycle Assessment Procedures and Results. Sustainability, 17(22), 10346. https://doi.org/10.3390/su172210346