Influencing Factors and Prediction Model for the Carbon Footprint of Textile Finishing Production: Case Study of 672 Textile Products

Abstract

1. Introduction

- (1)

- It shifts the assessment paradigm from ex-post accounting to real-time, predictive modeling by utilizing process-level energy data from 672 actual production cases, moving beyond simplified database averages.

- (2)

- It enables design-phase carbon forecasting by systematically integrating product specifications, process parameters, environmental conditions, machine and management factors into a comprehensive predictive model.

- (3)

- The GA-SVR architecture specifically overcomes the limitations of conventional models through automated hyperparameter optimization and enhanced capability to capture complex non-linear relationships between textile production and CF data, achieving superior predictive accuracy compared to standard approaches.

2. Literature Review

2.1. Methods and Applications for Accounting CF in Textile Products

2.2. Influencing Factors for CF in Textile Products

2.3. Methods and Applications for Prediction of CF in Textile Products

3. Methodology and Data

3.1. The Surveyed Enterprises

3.2. System Boundary Description and Functional Unit

- (1)

- Inspection: Refers to the darning of reparable defects on the gray fabric.

- (2)

- Singeing: Passing the fabric over flames to burn off surface fuzz, resulting in a smoother fabric surface without damaging the material.

- (3)

- Desizing: Removing residual impurities from the gray fabric.

- (4)

- Mercerizing: Treating the fabric under tension with concentrated caustic soda solution to enhance its luster.

- (5)

- Setting: Stabilizing the dyed fabric to achieve consistent width, stable dimensions, and a desirable fabric handle.

- (6)

- Pre-shrinking: Utilizing physical and chemical methods to prevent deformation and distortion of the fabric, thereby improving its serviceability for garment making.

- (7)

- Washing: Removing sizing agents and enhancing the softness of the fabric or garment.

3.3. The Calculation Model for Process-Level CF

3.4. Extracting Factors Affecting from ERP System

3.4.1. Product Factors

3.4.2. Environmental Factors

3.4.3. Process Parameter Factors

3.4.4. Management Level Factors

3.5. Data Preprocessing

3.6. Prediction Model Used for Calculating CF

4. Results and Discussion

4.1. Results of CF for Products

4.2. Comparison with Other Cases

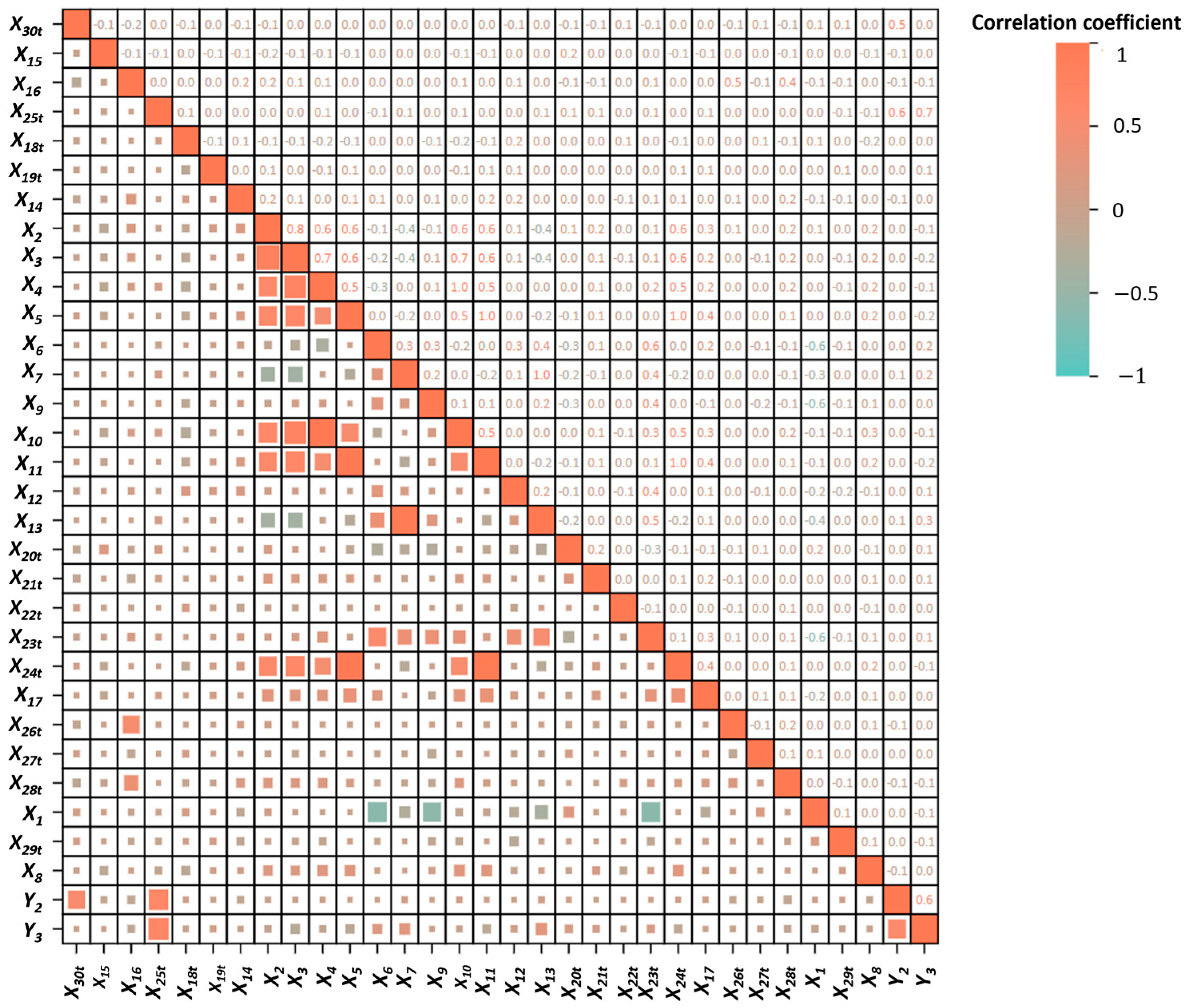

4.3. Correlation Factor Analysis for Energy Consumption of Each Process

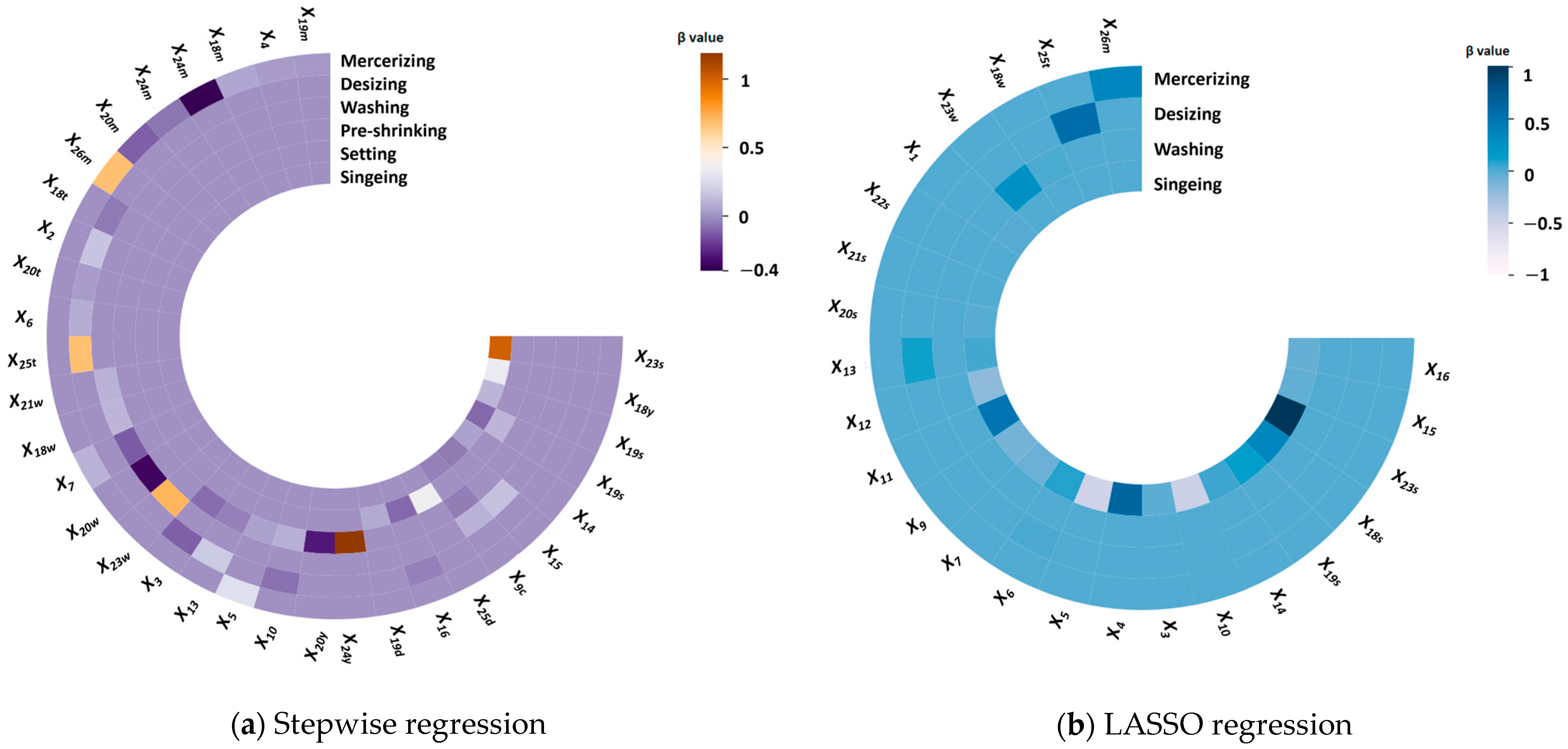

4.4. Correlation Factor Analysis for CF of Each Process

4.5. Predictive Model Comparison

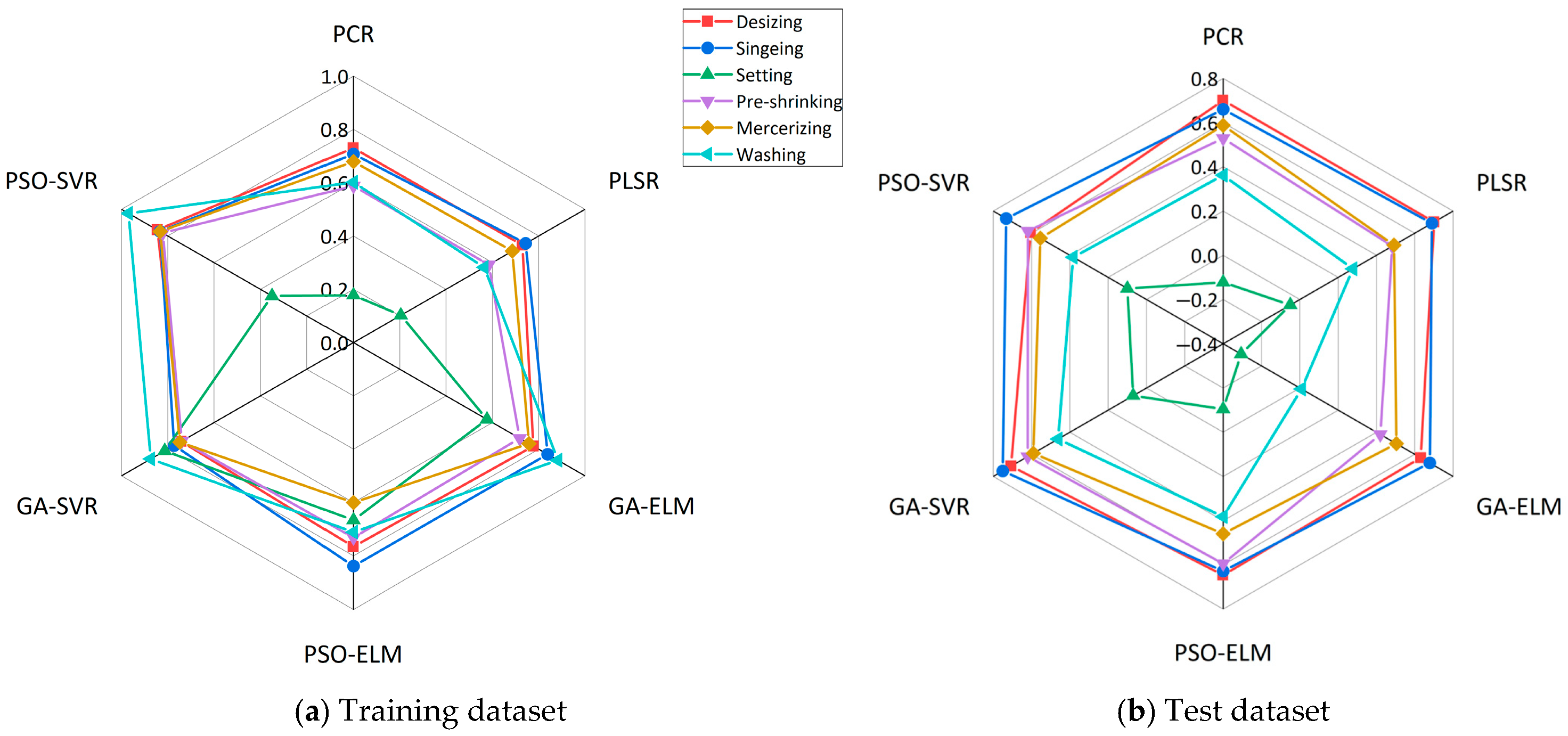

4.5.1. Comparison of the R2 for the Prediction Model

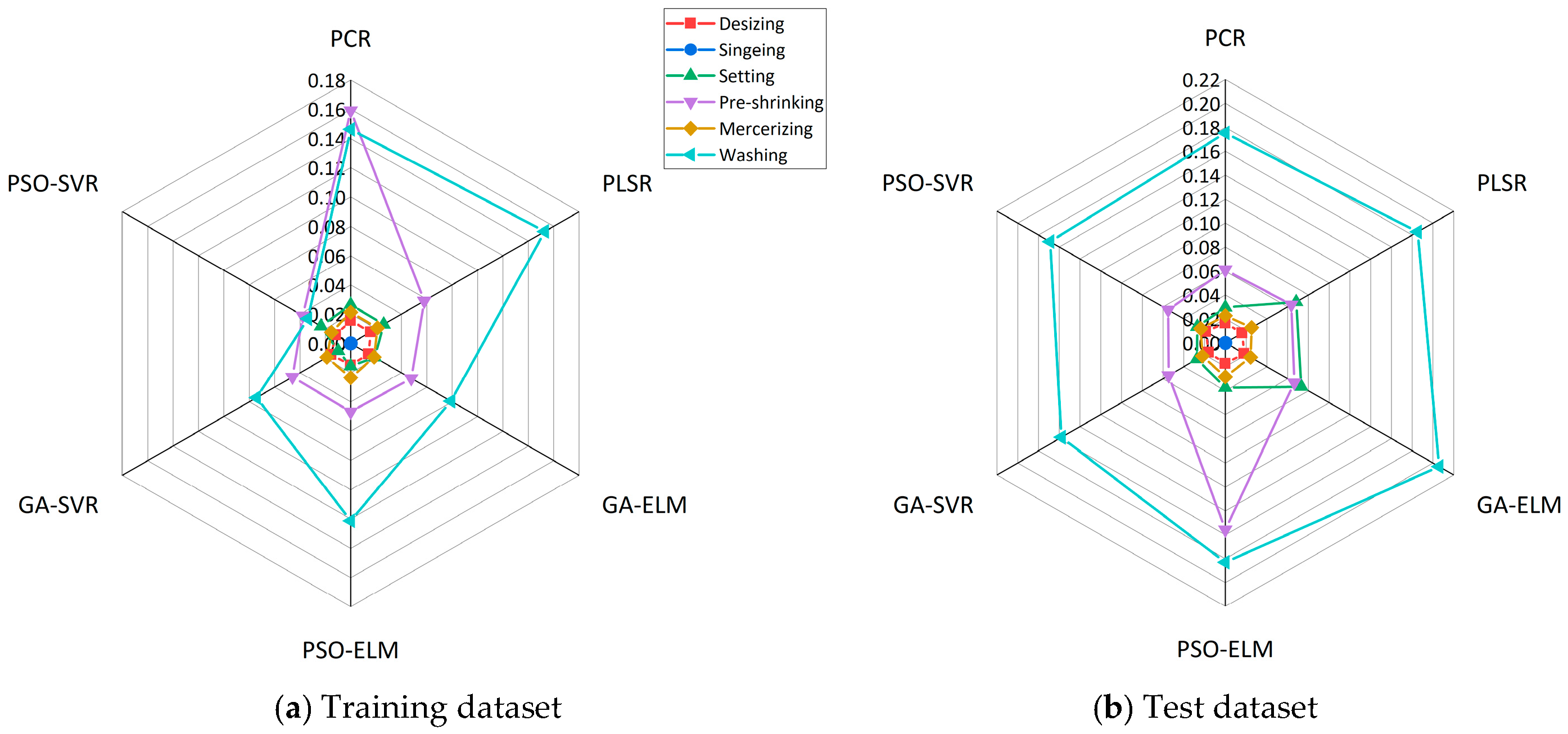

4.5.2. Comparison of the RSME for the Prediction Model

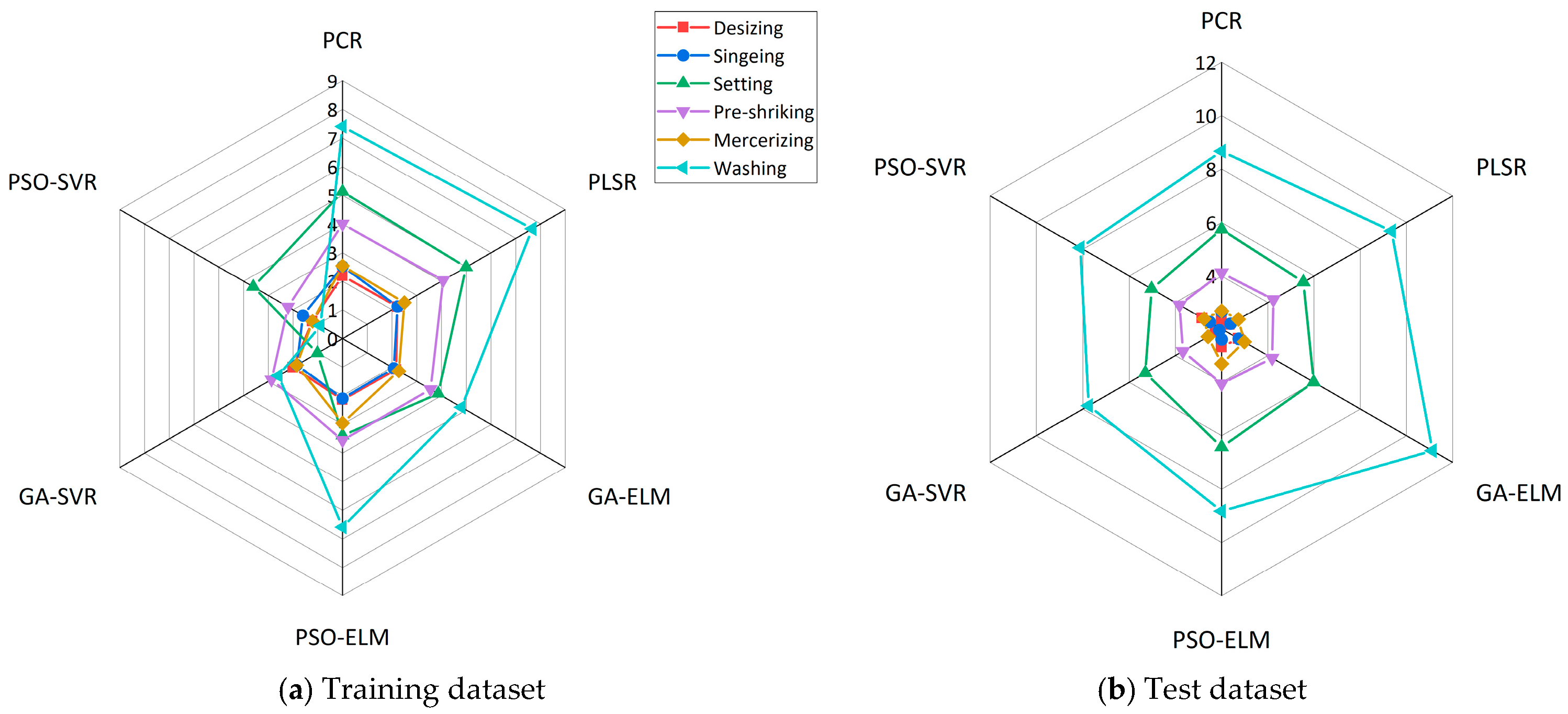

4.5.3. Comparison of the SMAPE for the Prediction Model

4.5.4. Comparison Results of the Prediction Model

- (1)

- The R2 during the training phase demonstrated suboptimal performance for some processes due to the limited dataset (e.g., 206 samples for setting process), the lack of data for specific equipment parameters, and the exclusion of certain equipment-related factors from the input variables. Factor screening identified equipment-related parameters as substantial contributors to the CF. Consequently, the regression prediction models for some processes exhibited lower fitting accuracy. The SMAPE for the washing process was the highest, likely due to the limited number of samples and the inherent variability in the process. The limited number of training samples for certain processes may lead to inadequate model training, and the test samples might also be insufficient or unevenly distributed.

- (2)

- The SVR approach demonstrated superior performance compared to PCR, PLSR, and ELM in terms of R2, RMSE, and SMAPE. Among the SVR methods, the GA-SVR approach exhibited the best performance, while the PSO-SVR approach was slightly inferior. In most cases, the GA-SVR method achieved the lowest RMSE and SMAPE values, along with the highest R2 value. This finding suggests that the GA-SVR model provides a better fit and generates smaller prediction errors compared to the other methods. Consequently, the GA-SVR model is recommended for predicting the CF at the process level.

5. Conclusions

- (1)

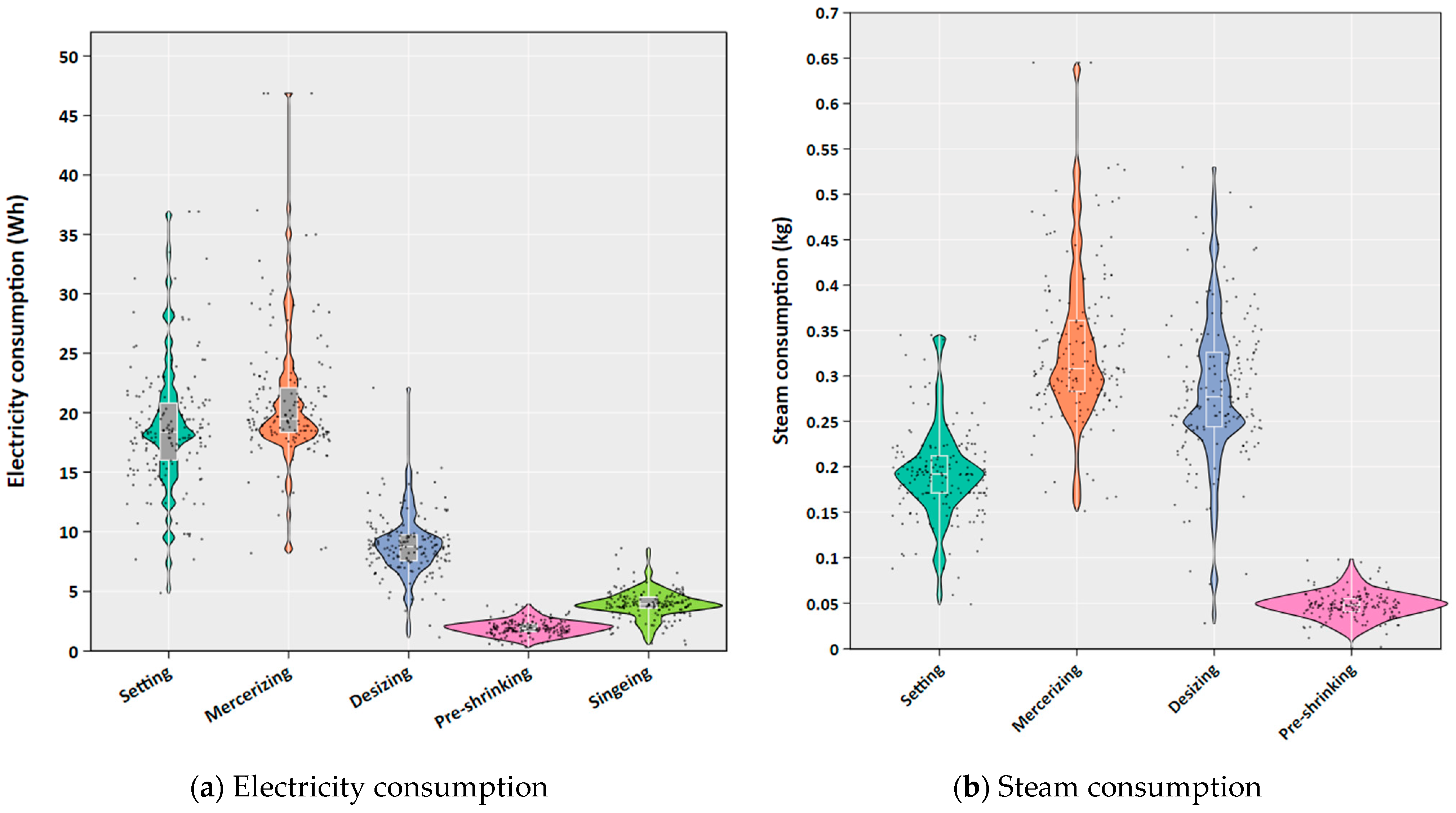

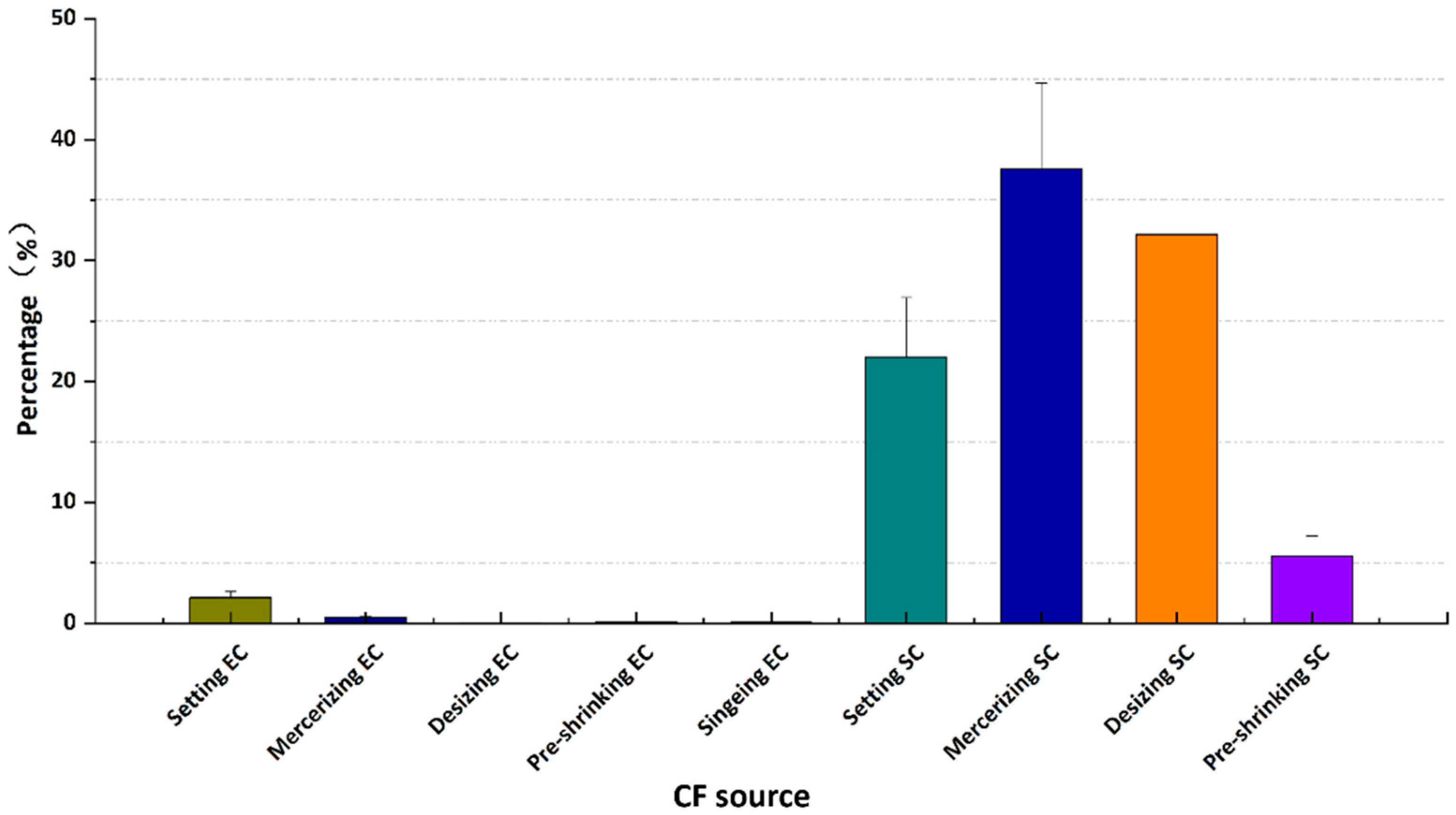

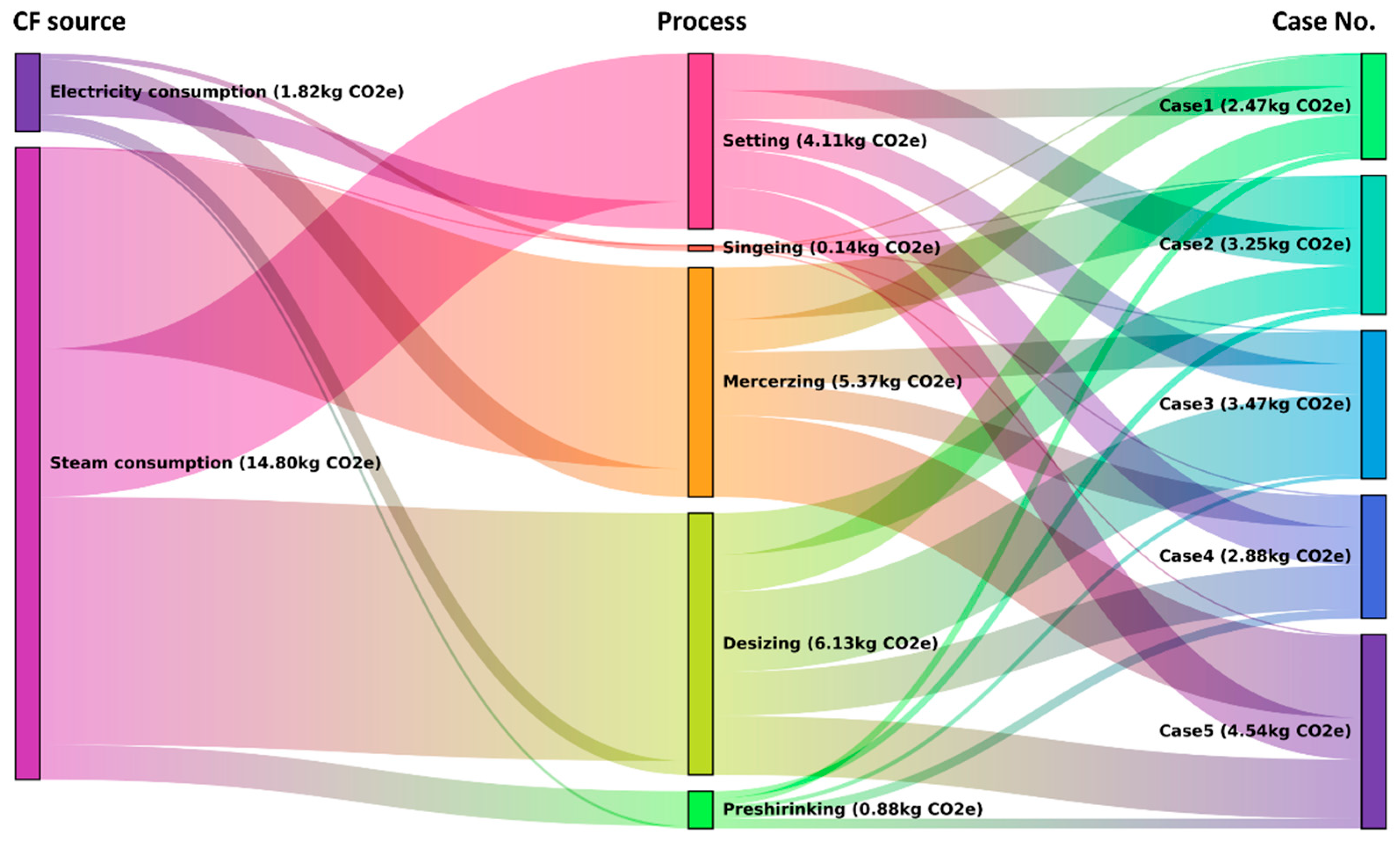

- For electricity consumption per unit product, the mercerizing, setting, and desizing processes are relatively high, followed by singeing and preshrinking, which aligns with the trend of the equipment’s active power. As for steam consumption per unit product, the order from highest to lowest is mercerizing, desizing, setting, and preshrinking, while the singeing process does not use steam. The CF per unit product is almost entirely derived from steam consumption (97.24%), with electricity consumption contributing only 2.76%. Therefore, processes involving steam consumption play a dominant role in the CF per unit product, and the main factors affecting steam consumption in each process significantly influence the CF value per unit product.

- (2)

- For most processes, the main influencing factors are the job allowance ratio and the machine speed. The job allowance ratio has the most significant impact on electricity, steam consumption and CF.

- (3)

- Among the studied manufacturing processes, the regression prediction model demonstrated the poorest performance for the setting process, while the washing process exhibited the largest prediction errors. Comparative analysis of the modeling methods revealed that SVR consistently outperformed PCR, PLSR, and ELM. Notably, the GA-SVR approach showed superior performance across most processes, achieving simultaneously the lowest RMSE and SMAPE, along with R2. These results indicate that the GA-SVR model provides better fitting accuracy and smaller prediction errors compared to alternative methods. Consequently, the GA-SVR model is recommended for accurate prediction of CF at the individual process level in manufacturing systems.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Imran, S.; Mujtaba, M.; Zafar, M.M.; Hussain, A.; Mehmood, A.; Farwa, U.E.; Korakianitis, T.; Kalam, M.; Fayaz, H.; Saleel, C.A. Assessing the potential of GHG emissions for the textile sector: A baseline study. Heliyon 2023, 9, e22404. [Google Scholar] [CrossRef]

- Sharpe, S.; Dominish, E.; Martinez-Fernandez, M.C. Taking Climate Action: Measuring Carbon Emissions in the Garment Sector in Asia; ILO Working Paper: Geneva, Switzerland, 2022. [Google Scholar]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-food systems: A review of the challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon footprint: Current methods of estimation. Environ. Monit. Assess. 2011, 178, 135–160. [Google Scholar] [CrossRef]

- Muthu, S.S. Environmental Footprints and Eco-Design of Products and Processes; SGS Hong Kong Limited: Hong Kong, China, 2016. [Google Scholar]

- Huynh, N.-T.; Chien, C.-F. A hybrid multi-subpopulation genetic algorithm for textile batch dyeing scheduling and an empirical study. Comput. Ind. Eng. 2018, 125, 615–627. [Google Scholar] [CrossRef]

- Savin, I.-I.; Butnaru, R. Wastewater characteristics in textile finishing mills. Environ. Eng. Manag. J. 2008, 7, 859–864. [Google Scholar] [CrossRef]

- Peng, M.; Liu, C.; Chen, S.; Gao, S.; Jiang, L.; Ma, J. Development and performance study of a new shrink-proof and non-iron cotton blended fabric. Text. Res. J. 2018, 89, 3269–3279. [Google Scholar] [CrossRef]

- Kumar, V.; Koehl, L.; Zeng, X.; Ekwall, D. Coded yarn based tag for tracking textile supply chain. J. Manuf. Syst. 2017, 42, 124–139. [Google Scholar] [CrossRef]

- Cheng, Y.; Liang, H.-E. Calculation and evaluation of industrial carbon footprint of cotton denim jacket. J. Eng. Fibers Fabr. 2021, 16, 15589250211020387. [Google Scholar] [CrossRef]

- Dominish, E.; Sharpe, S. Reducing the Footprint? How to Assess Carbon Emissions in the Garment Sector in Asia; International Labour Organization: Geneva, Switzerland, 2021. [Google Scholar]

- Jain, M. Ecological approach to reduce carbon footprint of textile industry. Int. J. Appl. Home Sci. 2017, 4, 623–633. [Google Scholar]

- Costa, I.; Martins, F.; Alves, I. Ecological Footprint as a sustainability indicator to analyze energy consumption in a Portuguese textile facility. Int. J. Energy Environ. Eng. 2019, 10, 523–528. [Google Scholar] [CrossRef]

- Dal, A.; Yesil, E.S.; Ozturk, E.; Kitis, M. Investigation of water and carbon footprint reductions employing best available techniques in the textile sector. J. Clean. Prod. 2024, 466, 142913. [Google Scholar] [CrossRef]

- Muthu, S.S.; Gardetti, M.A. Sustainability in the Textile and Apparel Industries; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Mikucioniene, D.; Mínguez-García, D.; Repon, M.R.; Milaius, R.; Priniotakis, G.; Chronis, I.; Kiskira, K.; Hogeboom, R.; Belda-Anaya, R.; Díaz-García, P. Understanding and addressing the water footprint in the textile sector: A review. AUTEX Res. J. 2024, 24, 20240004. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X.; Du, E.; Liu, Y.; Zhang, S.; Yang, C.; Zhang, N.; Liu, C. A review on carbon emission accounting approaches for the electricity power industry. Appl. Energy 2024, 359, 122681. [Google Scholar] [CrossRef]

- Li, X.; Ren, J.; Wu, Z.; Wu, X.; Ding, X. Development of a novel process-level water footprint assessment for textile production based on modularity. J. Clean. Prod. 2021, 291, 125884. [Google Scholar] [CrossRef]

- Uddin, F. Introductory chapter: Textile manufacturing processes. In Textile Manufacturing Processes; IntechOpen: London, UK, 2019. [Google Scholar]

- Fonseca, A.; Ramalho, E.; Gouveia, A.; Henriques, R.; Figueiredo, F.; Nunes, J. Systematic Insights into a Textile Industry: Reviewing Life Cycle Assessment and Eco-Design. Sustainability 2023, 15, 15267. [Google Scholar] [CrossRef]

- Selli, F.; Şen, K.; Kaya, A.; Erdoğan, Ü.H. Effect of Reprocess on the Sustainability of T-Shirt Production. Tekst. Ve Mühendis 2022, 29, 70–80. [Google Scholar]

- Zhang, S.; Xu, C.; Xie, R.; Yu, H.; Sun, M.; Li, F. Environmental assessment of fabric wet processing from gate-to-gate perspective: Comparative study of weaving and materials. Sci. Total Environ. 2023, 857, 159495. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wang, L.; Liu, X.; Du, C.; Ding, D.; Jia, J.; Yan, Y.; Wu, G. Carbon footprint of textile throughout its life cycle: A case study of Chinese cotton shirts. J. Clean. Prod. 2015, 108, 464–475. [Google Scholar] [CrossRef]

- Moreira, N.; de Santa-Eulalia, L.A.; Aït-Kadi, D.; Wood–Harper, T.; Wang, Y. A conceptual framework to develop green textiles in the aeronautic completion industry: A case study in a large manufacturing company. J. Clean. Prod. 2015, 105, 371–388. [Google Scholar] [CrossRef]

- Onlu, N. Sustainability by design in textile products and fashion. New Des. Ideas 2017, 1, 37–49. [Google Scholar]

- van der Voet, E. Books: Our Ecological Footprint: Reducing Human Impact on the Earth; Wiley Online Library: Hoboken, NJ, USA, 1999. [Google Scholar]

- Wiedmann, T.; Minx, J. A definition of ‘carbon footprint’. Ecol. Econ. Res. Trends 2008, 1, 1–11. [Google Scholar]

- ISO 14067: 2018; Greenhouse Gases—Carbon Footprint of Products-Requirements and Guidelines for Quantification. International Organization for Standardization: Geneva, Switzerland, 2018.

- PAS 2050: 2011; Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services. British Standards Institution: London, UK, 2011.

- Long, Y.; Yoshida, Y.; Liu, Q.; Zhang, H.; Wang, S.; Fang, K. Comparison of city-level carbon footprint evaluation by applying single-and multi-regional input-output tables. J. Environ. Manag. 2020, 260, 110108. [Google Scholar] [CrossRef]

- Penaloza, D.; Erlandsson, M.; Berlin, J.; Wålinder, M.; Falk, A. Future scenarios for climate mitigation of new construction in Sweden: Effects of different technological pathways. J. Clean. Prod. 2018, 187, 1025–1035. [Google Scholar] [CrossRef]

- ISO 14040: 2006; Environmental Management—Life Cycle Assessment-Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Liu, C.; Li, X.; Li, Q.; Chen, Y.; Liu, J.; Liu, S.; Wang, L. Carbon footprint calculation and evaluation of mulberry silk quilts. Text. Res. J. 2024, 95, 471–484. [Google Scholar] [CrossRef]

- Bianco, I.; Picerno, G.; Blengini, G.A. Life Cycle Assessment (LCA) of Worsted and Woollen processing in wool production: ReviWool® noils and other wool co-products. J. Clean. Prod. 2023, 415, 137877. [Google Scholar] [CrossRef]

- Li, C.; Zhang, T.; Zhou, X.; Cheng, Z.; Xu, T.; Li, Z.; Hong, J. Carbon–water–energy footprint impacts of dyed cotton fabric production in China. J. Clean. Prod. 2024, 467, 142898. [Google Scholar] [CrossRef]

- Kılıç, E.; McLaren, S.J.; Holmes, G.; Fullana-i-Palmer, P.; Puig, R. Product environmental footprint of New Zealand leather production. Int. J. Life Cycle Assess. 2023, 28, 349–366. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Zhang, Y.; Sun, L.; Huang, Q.; Zhu, L.; Wang, L. Carbon footprint and oxygen footprint assessment of hemp yarn. Int. J. Glob. Warm. 2024, 32, 361–373. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, X.; Ding, X. Carbon and water footprints assessment of cotton jeans using the method based on modularity: A full life cycle perspective. J. Clean. Prod. 2022, 332, 130042. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, Y.; Zhao, M.; Guan, D.; Yang, Z. The carbon footprint of fast fashion consumption and mitigation strategies-a case study of jeans. Sci. Total Environ. 2024, 924, 171508. [Google Scholar] [CrossRef]

- Chen, B.; Qian, W.; Yang, Y.; Liu, H.; Wang, L. Carbon footprint and water footprint of cashmere fabrics. Fibres Text. East. Eur. 2021, 4, 94–99. [Google Scholar] [CrossRef]

- Chen, Y.; Bi, Y.; Wu, X.; Ding, X. Impact of additional carbon storage of natural plant fiber on product carbon footprint: A case study of cotton/kapok blended T-shirt VS pure cotton T-shirt. J. Clean. Prod. 2024, 434, 140237. [Google Scholar] [CrossRef]

- Zhu, D.; Bao, Y.; Ding, X.; Wu, X. Unveil the carbon footprint of textiles dyed with different reactive dyestuff recipes from an industrial manufacturing perspective. Int. J. Life Cycle Assess. 2024, 29, 1598–1620. [Google Scholar] [CrossRef]

- Qian, W.; Ji, X.; Xu, P.; Wang, L. Carbon footprint and water footprint assessment of virgin and recycled polyester textiles. Text. Res. J. 2021, 91, 2468–2475. [Google Scholar] [CrossRef]

- He, B.; Duan, H.; Yang, W.; Yabar, H.; Song, J. Decarbonizing polyamide textile production in China: Footprints and mitigation pathways from life cycle perspective. Resour. Conserv. Recycl. 2024, 208, 107705. [Google Scholar] [CrossRef]

- Gomez-Campos, A.; Vialle, C.; Rouilly, A.; Sablayrolles, C.; Hamelin, L. Flax fiber for technical textile: A life cycle inventory. J. Clean. Prod. 2021, 281, 125177. [Google Scholar] [CrossRef]

- Li, D.; Feng, S.; Tao, J.; Yu, S.; He, Y.; Yu, R.; Xiang, H.; Wang, C.; Zhu, M. Optimizing Sustainability in Textile Recycling: Life Cycle Assessment of Recycled Polyester Staple Fibers with a Focus on Carbon Emissions, Energy Efficiency, and Water Conservation. ACS Sustain. Chem. Eng. 2024, 12, 17347–17356. [Google Scholar] [CrossRef]

- Suarez, A.; Ford, E.; Venditti, R.; Kelley, S.; Saloni, D.; Gonzalez, R. Rethinking the use of bio-based plastics to accelerate the decarbonization of our society. Resour. Conserv. Recycl. 2022, 186, 106593. [Google Scholar] [CrossRef]

- Angelis-Dimakis, A.; Whitehouse, A.; Vyrkou, A.; Hebden, A.; Rana, S.; Goswami, P. Life cycle environmental impact and economic assessment of British Wool face masks. Clean. Environ. Syst. 2022, 6, 100084. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L. A review of energy use and energy efficiency technologies for the textile industry. Renew. Sustain. Energy Rev. 2012, 16, 3648–3665. [Google Scholar] [CrossRef]

- Pérez, L.A.E.; Pérez, A.T.E.; Vásquez, Ó.C. Exploring an alternative to the Chilean textile waste: A carbon footprint assessment of a textile recycling process. Sci. Total Environ. 2022, 830, 154542. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Chong, C.; Huang, W.; Guo, S.; Wang, Y.; Zhang, Y.; Pan, Z.; Wang, J.; Li, X.; Zhao, W. Tracing the carbon footprint of cotton garments from seed to garment: Evidence from an empirical study of multiple sites in China. Resour. Conserv. Recycl. 2025, 217, 108200. [Google Scholar] [CrossRef]

- Moazzem, S.; Crossin, E.; Daver, F.; Wang, L. Environmental impact of apparel supply chain and textile products. Environ. Dev. Sustain. 2021, 24, 1–19. [Google Scholar] [CrossRef]

- Mailley, D.; Hébraud, A.; Schlatter, G. A review on the impact of humidity during electrospinning: From the nanofiber structure engineering to the applications. Macromol. Mater. Eng. 2021, 306, 2100115. [Google Scholar] [CrossRef]

- Fallahi, A.; Shahidi-Zadeh, B.; Niaki, S.T.A. Unrelated parallel batch processing machine scheduling for production systems under carbon reduction policies: NSGA-II and MOGWO metaheuristics. Soft Comput. 2023, 27, 17063–17091. [Google Scholar] [CrossRef]

- Bashir, T.; Iftikhar, T.; Majeed, H. Bulk industrial textile production of bio scouring for cellulosic fabric utilizing indigenous hot springs triacylglycerol acylhydrolases from Bacillus toyonensis and Bacillus thuringiensis. Cellulose 2024, 31, 1353–1381. [Google Scholar] [CrossRef]

- Xu, X.; Cui, X.; Zhang, Y.; Chen, X.; Li, W. Carbon neutrality and green technology innovation efficiency in Chinese textile industry. J. Clean. Prod. 2023, 395, 136453. [Google Scholar] [CrossRef]

- Xiao, Q.; Li, C.; Tang, Y.; Chen, X. Energy efficiency modeling for configuration-dependent machining via machine learning: A comparative study. IEEE Trans. Autom. Sci. Eng. 2020, 18, 717–730. [Google Scholar] [CrossRef]

- Nepal, B.; Yamaha, M.; Yokoe, A.; Yamaji, T. Electricity load forecasting using clustering and ARIMA model for energy management in buildings. Jpn. Archit. Rev. 2020, 3, 62–76. [Google Scholar] [CrossRef]

- Asadi, M.; McPhedran, K.N. Greenhouse gas emission estimation from municipal wastewater using a hybrid approach of generative adversarial network and data-driven modelling. Sci. Total Environ. 2021, 800, 149508. [Google Scholar] [CrossRef]

- Runge, J.; Zmeureanu, R. Forecasting energy use in buildings using artificial neural networks: A review. Energies 2019, 12, 3254. [Google Scholar] [CrossRef]

- Wen, L.; Cao, Y. Influencing factors analysis and forecasting of residential energy-related CO2 emissions utilizing optimized support vector machine. J. Clean. Prod. 2020, 250, 119492. [Google Scholar] [CrossRef]

- Ciulla, G.; D’Amico, A. Building energy performance forecasting: A multiple linear regression approach. Appl. Energy 2019, 253, 113500. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Zeng, R.; Srinivasan, R.S.; Ahrentzen, S. Random Forest based hourly building energy prediction. Energy Build. 2018, 171, 11–25. [Google Scholar] [CrossRef]

- T/CNTAC 11-2018; General Requirements for Quantifying the Greenhouse Gas Emissions of Textile Products. China National Textile and Apparel Council: Beijing, China, 2018.

- Limb, J.; Rubinstein, C.; Thompson, J. Digital coding of color video signals-a review. IEEE Trans. Commun. 1977, 25, 1349–1385. [Google Scholar] [CrossRef]

- Muqaddim, N.; Ahmed, S.; Azad, M.M. Impact of Work Study on Productivity: A Study on Athletic Shirt Manufacturing Process in the Apparel Industry. Int. J. New Technol. Res. 2021, 7, 23–29. [Google Scholar]

- Dewi, R.G.; Parinderati, R.; Hendrawan, I.; Dewantoro, M.W.B.; Bayuwega, W.D. Energy Efficiency Monitoring in Textile Industries to Achieve GHG Emissions Reduction Target in Indonesia. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 012019. [Google Scholar]

- Uddin, M.; Bhuiya, K.M.S.; Udoy, S.A.; Ahmed, M.M.; Hossan, M.N. Investigation of the energy consumption and emission for a readymade garment production and assessment of the saving potential. Energy Effic. 2024, 17, 100. [Google Scholar] [CrossRef]

- Hasanbeigi, A. Energy-Efficiency Improvement Opportunities for the Textile Industry. 2010. Available online: https://www.energystar.gov/sites/default/files/buildings/tools/EE_Guidebook_for_Textile_industry.pdf (accessed on 7 November 2025).[Green Version]

| No. | Product Types | System Boundary | Results |

|---|---|---|---|

| 1 | Silk quilts | From cocoons to silk quilt packaging | 32.9078–62.6696 kg CO2e/functional unit |

| 2 | Wool products | From shearing to spinning | 25–30 kg CO2e/kg |

| 3 | Cotton printed and dyed textiles | From cotton cultivation to finishing | 15.6272 kg CO2e/kg |

| 4 | Leather | From rawhide transportation to tannery to waste disposal | 8.54 kg CO2e/kg |

| 5 | Linen yarns | From linen cultivation to spinning | 3.9731 kg CO2e/kg, carbon storage −4.0733 kg CO2e/kg |

| 6 | Denim jeans | From cotton cultivation to denim waste management | 90.37 kg CO2e/kg |

| 7 | Fast-fashion branded jeans | From fiber acquisition to disposal | 2.50 kg CO2e/kg |

| 8 | Cashmere fabrics | From raw wool to cashmere fabrics | 12–16 kg CO2e/kg |

| 9 | Cotton T-shirts | From raw material acquisition to disposal | 9.469 kg CO2e/kg, carbon storage −15.653 kg CO2e/kg |

| 10 | Cotton/kapok blended T-shirts | From raw material acquisition to disposal | −24.249 kg CO2e kg, carbon storage −43.442 kg CO2e/kg |

| 11 | Dyed fabrics | From weaving to wastewater treatment | 3.547–4.438 kg CO2e/kg |

| 12 | Denim jackets | From raw material acquisition to disposal | 1.75 kg CO2e/piece |

| 13 | Polyester textiles | From fiber acquisition to weaving | 1.20 kg CO2e/kg |

| 14 | Recycled polyester textiles | From fiber acquisition to weaving | 1.15 kg CO2e/kg |

| 15 | Polyamide textiles | From fiber acquisition to finishing | 35.37 kg CO2e/kg |

| 16 | Linen fabrics | From cultivation to weaving | 21.64 kg CO2e kg, carbon storage 1.485 kg CO2e/kg |

| Type of Factors | Specific Indicators | Acquisition Frequency | Data Sources |

|---|---|---|---|

| Product factors | Gray fabric: width, warp and weft density, composition, yarn fineness, mass, weave types | Per product/session | ERP System |

| Finished products: shrinkage rate, mass, width, warp and weft density, color, yield, quality (pilling, rubbing color fastness, sweat color fastness, water color fastness, flatness, color fastness to sunlight, non-chlorine bleaching color fastness), type of finishing | Per product/session | ERP System | |

| Environmental factors | Temperature, relative air humidity | 3 h/session | https://www.timeanddate.com/ (accessed on 7 November 2025). |

| Singeing process parameters | Machine speed, singeing level, singeing pressure, singeing method | Per product/session | ERP System |

| Desizing process parameters | Machine speed, machine temperature, amylase temperature, average width of drop cloth, weft density of drop cloth | Per product/session | ERP System |

| Mercerizing process parameters | Machine speed, average mercerizing lye concentration, middle door width, pH value, weft density of drop cloth, average width of drop cloths | Per product/session | ERP System |

| Setting process parameters | Machine speed, temperature of drying room, pH value, average width of drop cloth, weft density of drop cloth | Per product/session | ERP System |

| Pre-shrinking process parameters | Machine speed, pre-shrinkage rate, average width of drop cloth, weft density of drop cloth | Per product/session | ERP System |

| Washing process parameters | Machine speed, washing temperature, pH value | Per product/session | ERP System |

| Management level factors | Job allowance ratio, color difference between front and back (washing, desizing, mercerizing), fluorescence (washing, desizing, mercerizing), rush order | Per product/session | Machine start-ups, video footage, questionnaires |

| Processing equipment factors | Average active power | Per machine/session | ERP System |

| Case No.: | Type of Finishing | Electricity | Steam | Natural Gas | Oil | Total kg CO2e/kg | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| kg CO2e/kg | % | kg CO2e/kg | % | kg CO2e/kg | % | kg CO2e/kg | % | |||

| 1 | Mercerized finishing | 0.2850 | 11.53 | 2.1874 | 88.47 | / | / | / | / | 2.4724 |

| 2 | Mercerized and silky finish | 0.3797 | 11.68 | 2.8717 | 88.32 | / | / | / | / | 3.2514 |

| 3 | Mercerized and liquid ammonia | 0.3613 | 10.42 | 3.1055 | 89.58 | / | / | / | / | 3.4668 |

| 4 | Mercerized and tapping | 0.3097 | 10.74 | 2.539 | 89.26 | / | / | / | / | 2.8835 |

| 5 | Mercerized, liquid ammonia wrinkle-free (moisture-cure) and silk protein | 0.4841 | 10.65 | 4.0593 | 89.35 | / | / | / | / | 4.5434 |

| A | Woven fabric final finishing | 0.108 | 5.68 | 1.729 | 91.00 | 0.063 | 3.32 | / | / | 1.900 |

| B | Knitted fabric finishing | 0.490 | 7.62 | 5.939 | 92.38 | / | / | / | / | 6.429 |

| C | Knitted fabrics finishing | 0.8633 | 23.91 | 2.7468 | 76.09 | / | / | / | / | 3.6101 |

| D | T-shirt fabrics finishing | 0.1746 | 34.20 | / | / | 0.3345 | 65.52 | 0.0014 | 2.79 | 0.5106 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhang, K.; Gao, Z.; Xu, J. Influencing Factors and Prediction Model for the Carbon Footprint of Textile Finishing Production: Case Study of 672 Textile Products. Sustainability 2025, 17, 10350. https://doi.org/10.3390/su172210350

Li X, Zhang K, Gao Z, Xu J. Influencing Factors and Prediction Model for the Carbon Footprint of Textile Finishing Production: Case Study of 672 Textile Products. Sustainability. 2025; 17(22):10350. https://doi.org/10.3390/su172210350

Chicago/Turabian StyleLi, Xin, Ke Zhang, Zhiyuan Gao, and Jingxuan Xu. 2025. "Influencing Factors and Prediction Model for the Carbon Footprint of Textile Finishing Production: Case Study of 672 Textile Products" Sustainability 17, no. 22: 10350. https://doi.org/10.3390/su172210350

APA StyleLi, X., Zhang, K., Gao, Z., & Xu, J. (2025). Influencing Factors and Prediction Model for the Carbon Footprint of Textile Finishing Production: Case Study of 672 Textile Products. Sustainability, 17(22), 10350. https://doi.org/10.3390/su172210350