Advancing Sustainability Through an IoT-Driven Smart Waste Management System with Software Engineering Integration

Abstract

1. Introduction

1.1. Waste Management Phases

- (1)

- Waste Generation and Collection: Waste is generated from households, industries, and commercial activities. A significant portion—approximately 33% of waste—is not managed sustainably [10].

- (2)

- Waste Acquisition and Transport: Waste is collected and transported to designated facilities, often requiring significant human and logistical resources.

- (3)

- Waste Segregation: Sorting of waste is essential for effective recycling and reducing environmental impacts.

- (4)

- Waste Recycling: Converts waste into reusable materials, reducing landfill use and conserving resources.

1.2. Research Goals and Contributions

1.3. Research Questions

- What strategies or techniques are commonly used in SWM systems?

- What types of sensors are typically utilized in the development of SWM systems?

- What technology and networking tools facilitate the creation of SWM systems?

1.4. Objectives

- Conduct a comprehensive review of current IoT-based SWM technologies, including both hardware and software aspects, and benchmark the proposed solution against advanced alternatives.

- Develop a novel, scalable system architecture that integrates:

- ○

- Real-time monitoring of bin fill-levels and fire detection using BLMUs;

- ○

- A centralized City Command and Control Center (4C) with automated alerts and optimized collection routing;

- ○

- A dual-platform software solution including a role-based Android mobile app (Flutter-based) and a desktop/web interface connected to Google Cloud Firestore.

- Perform a comparative analysis of system components, including sensors, network topology, microcontrollers, and visualization tools.

- Deliver a working prototype that demonstrates real-time operations in urban scenarios under varied conditions.

- Identify and address real-world implementation constraints such as sensor accuracy, scalability, and data security.

- Contribute to the field by bridging the gap between conceptual research and real-world deployment in sustainable urban infrastructure.

2. Literature Review

3. The Proposed System

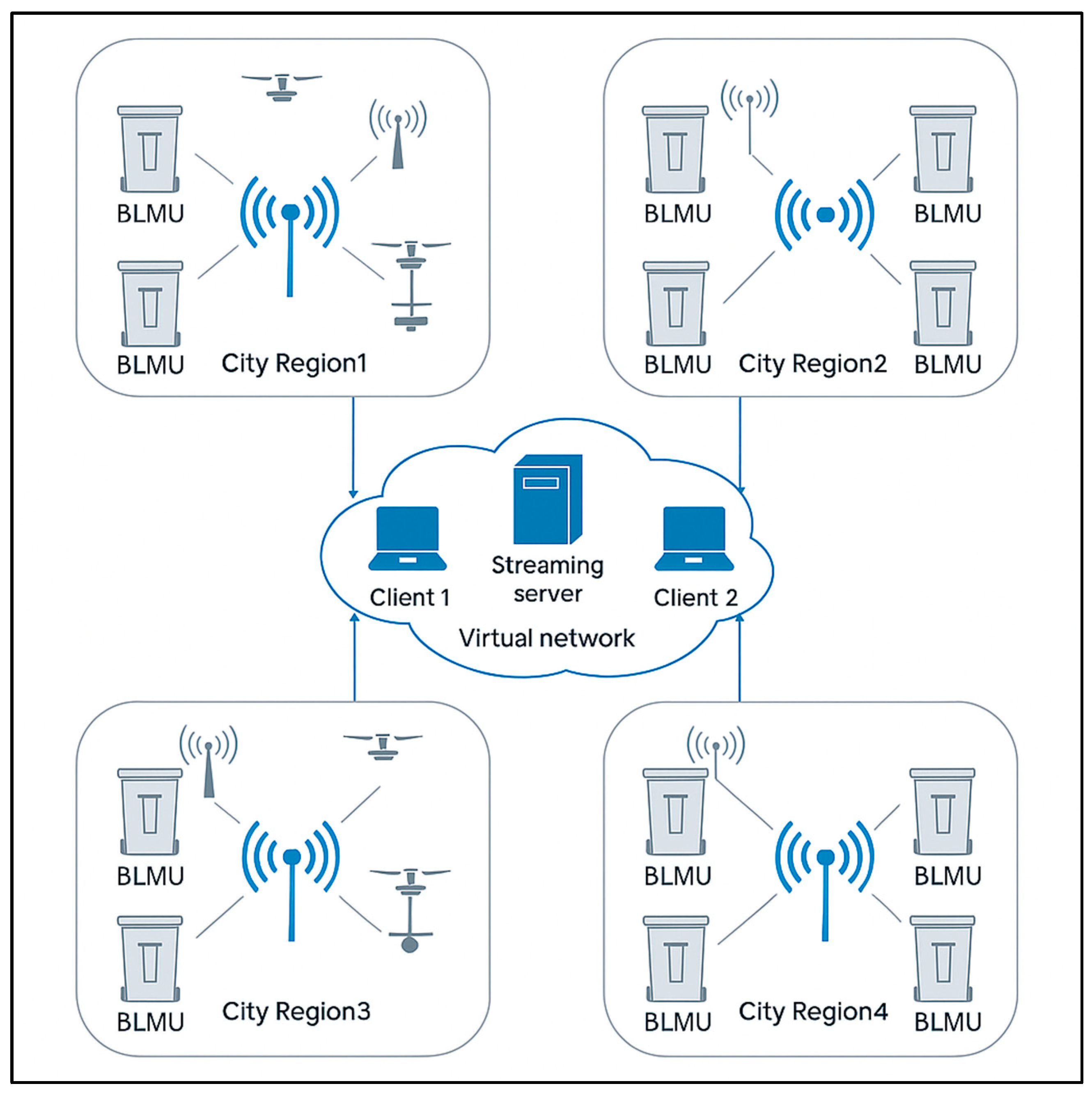

3.1. Architecture of the Proposed System and Its Implementation

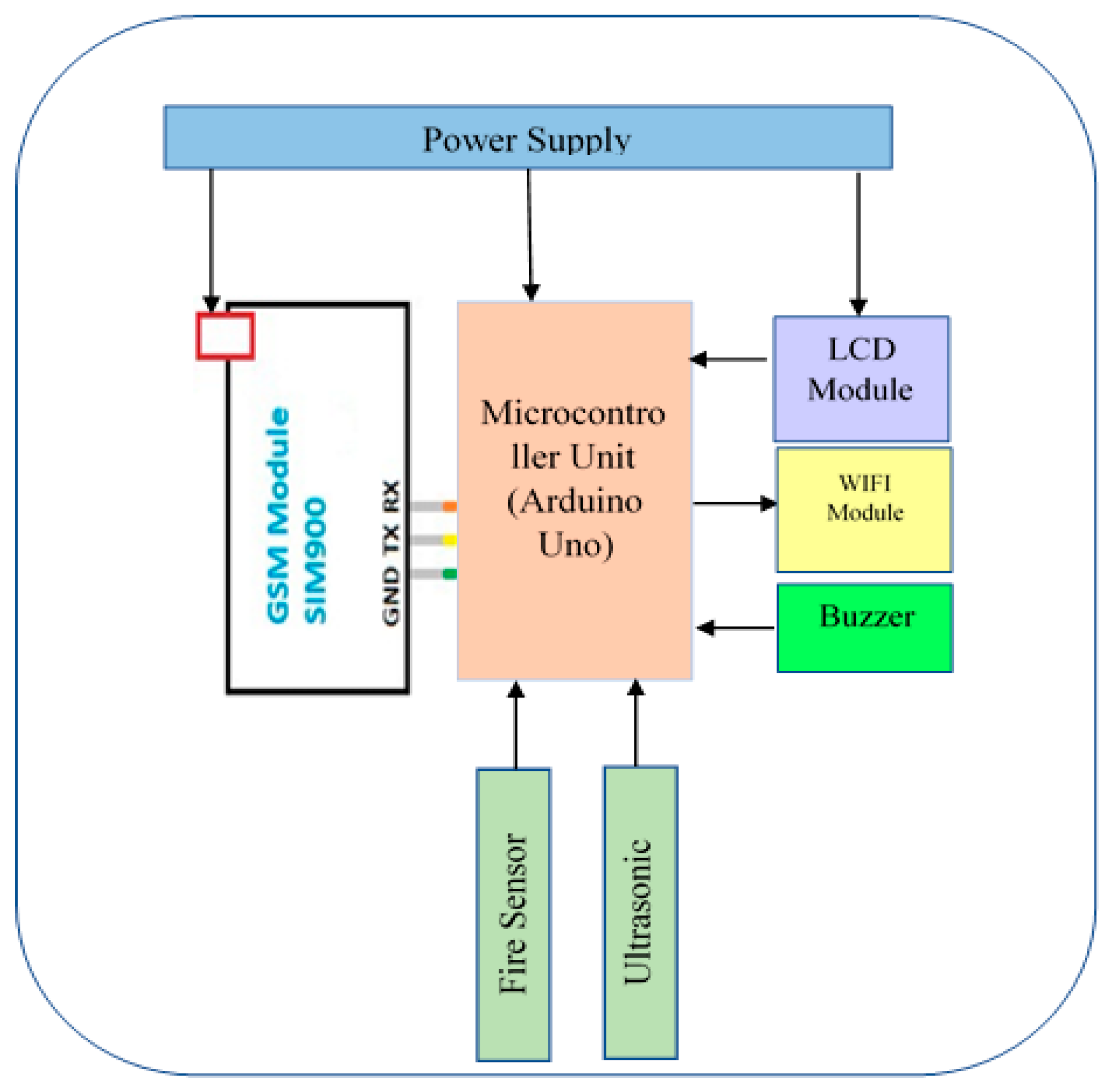

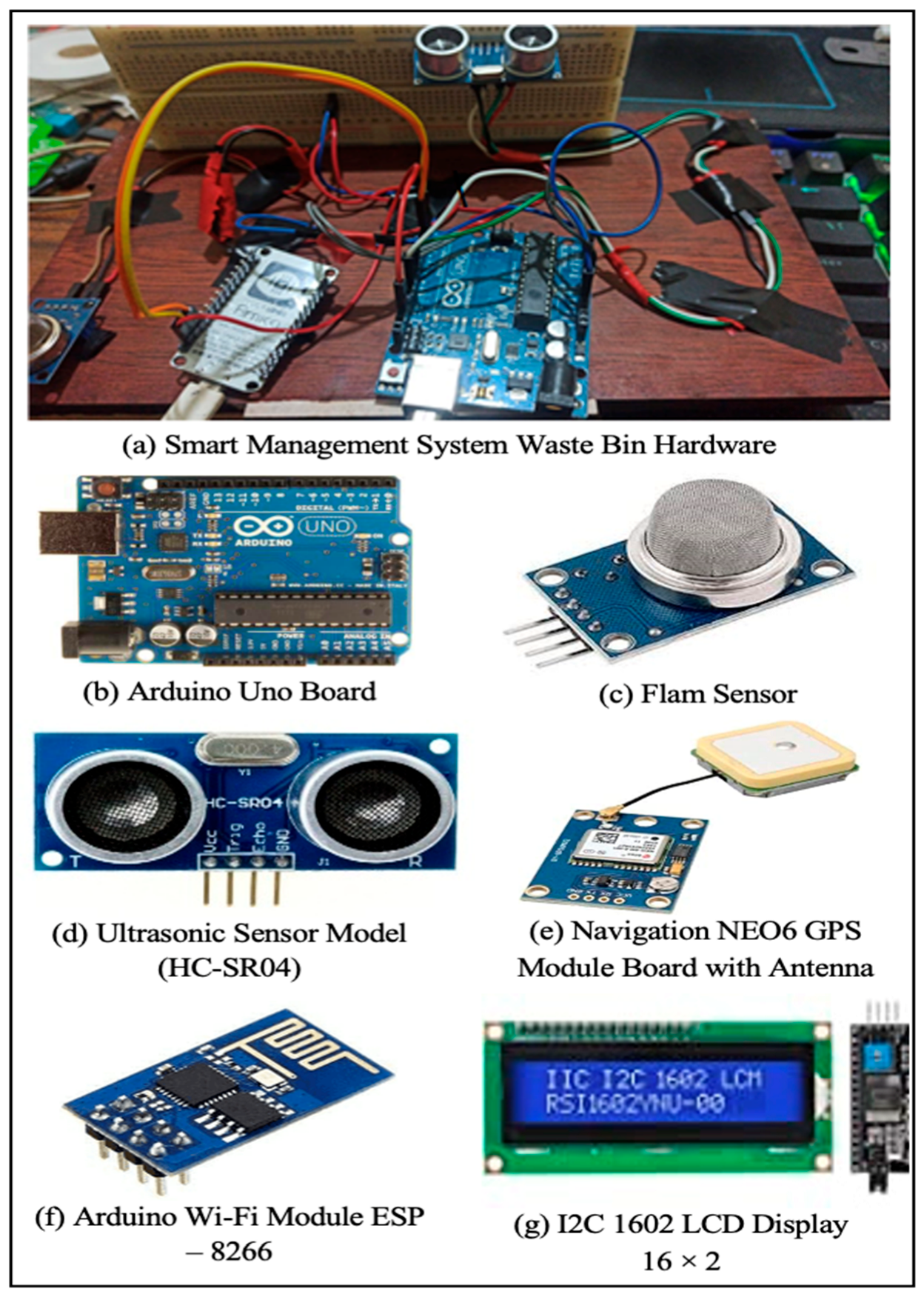

3.1.1. Hardware-Based Data Acquisition Layer

- Bin Level Monitoring Unit (BLMU):

- ▪

- Arduino Uno microcontroller:

- ▪

- Flame Sensor (Smoke and gas sensor):

- ▪

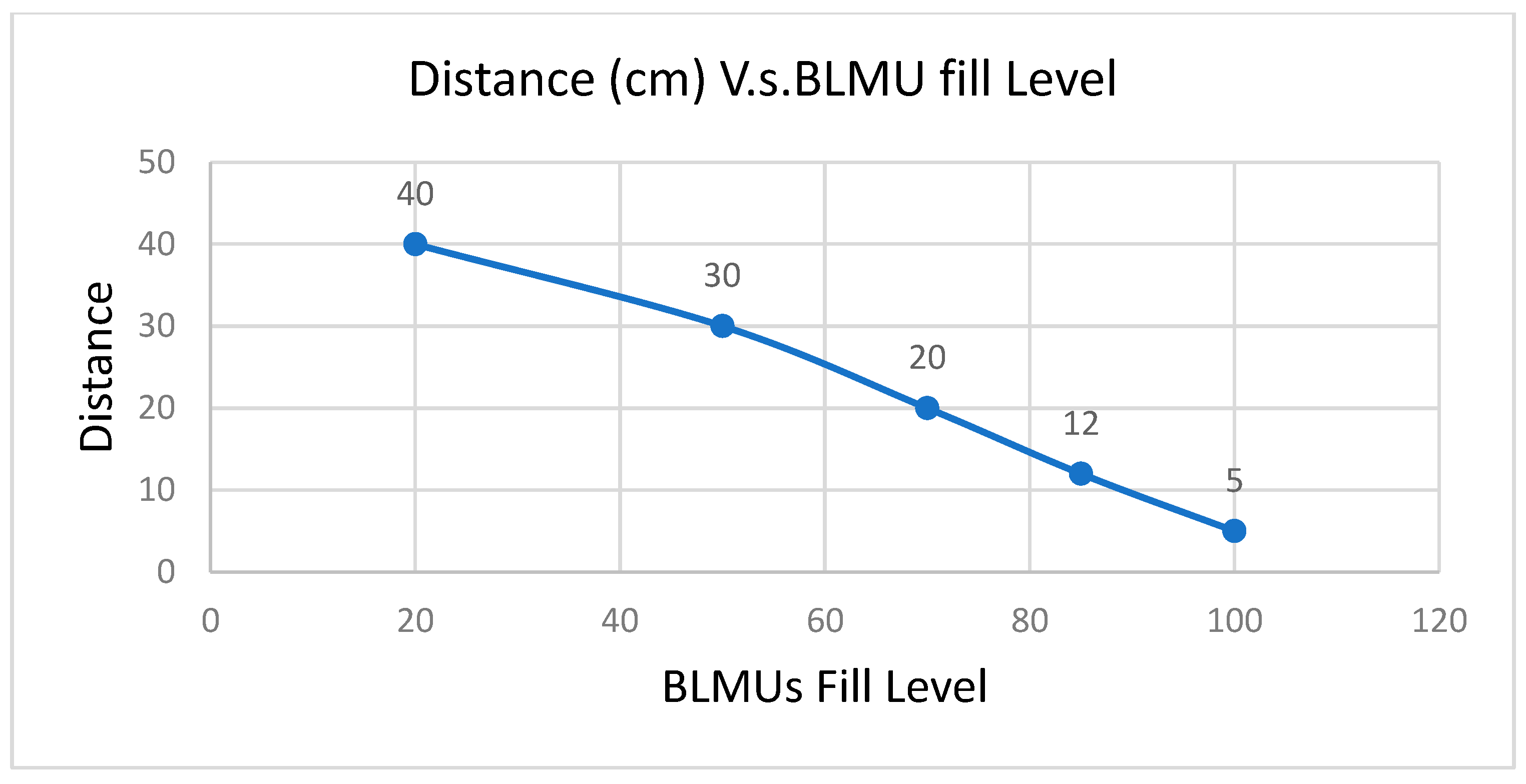

- Ultrasonic Sensor (HC-SR04):

- ▪

- GPS module:

- ▪

- Buzzer:

- ▪

- ESP8266 Wi-Fi Module:

- ▪

- Liquid Crystal Display (LCD):

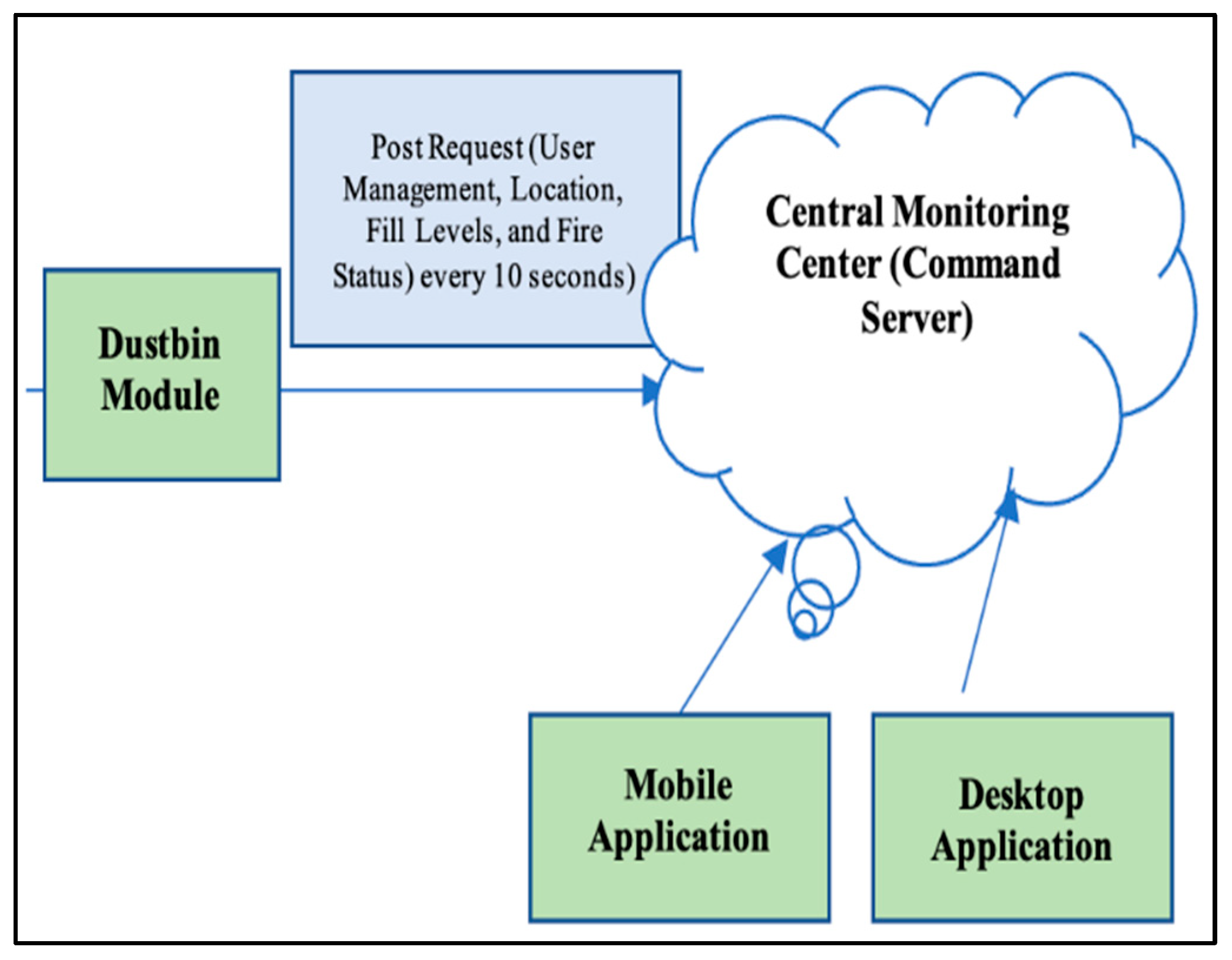

3.1.2. Software-Based Data Acquisition Layer

- (a)

- Centralized City Command and Control Center (4C) software:

- Waste bin, garbage truck, and fire event documents share a similar schema, including the following:

- ○

- Address: Region code of the city;

- ○

- NC-MA: Waste bin identifier;

- ○

- Alarm: Boolean flag indicating fire status;

- ○

- Capacity: Boolean flag indicating fill-level;

- ○

- Longitude: X-coordinate of the bin’s location;

- ○

- Latitude: Y-coordinate of the bin’s location.

- User documents include attributes such as the following:

- ○

- Token: Unique user identifier;

- ○

- DisplayName: User’s name;

- ○

- Email: Encoded email address;

- ○

- Nationality: National ID number;

- ○

- PhoneNumber: User’s contact number;

- ○

- Type: Role classification (e.g., user, employee, administrator).

- (b)

- SWS desktop application:

- (c)

- SWS Mobile Application:

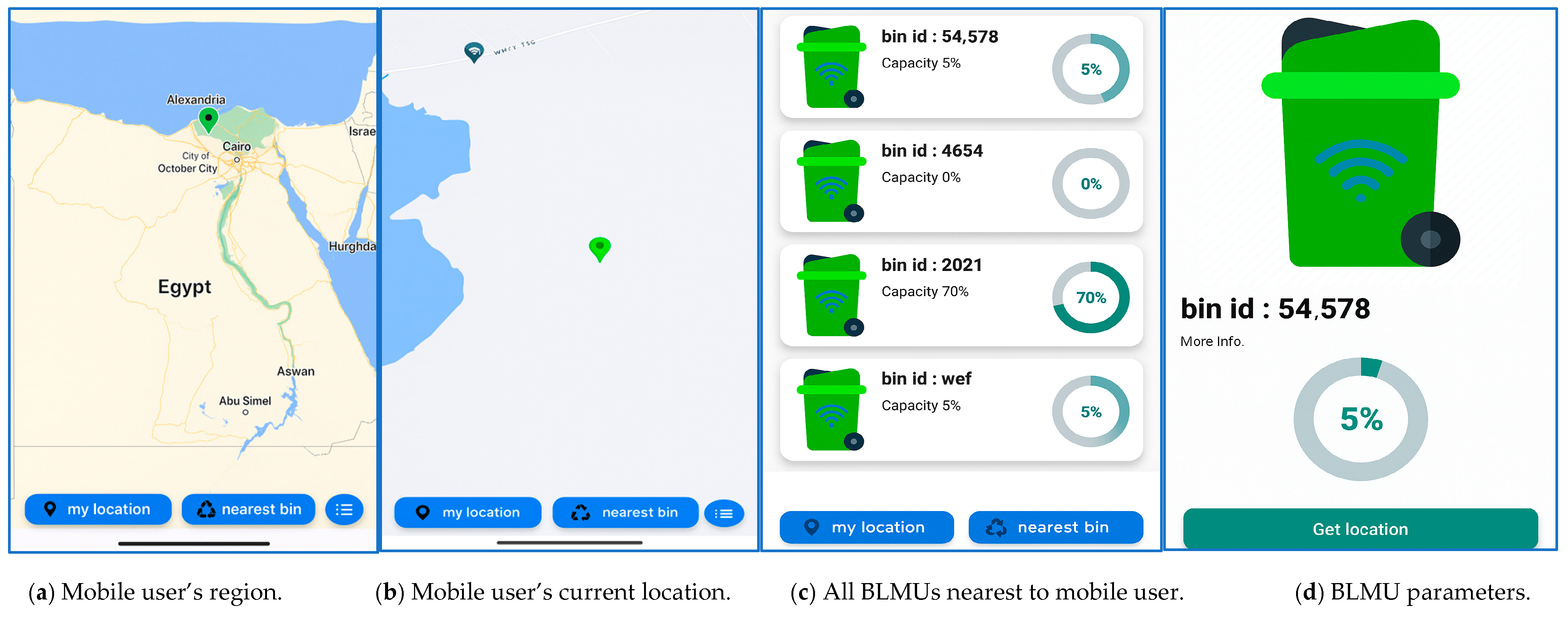

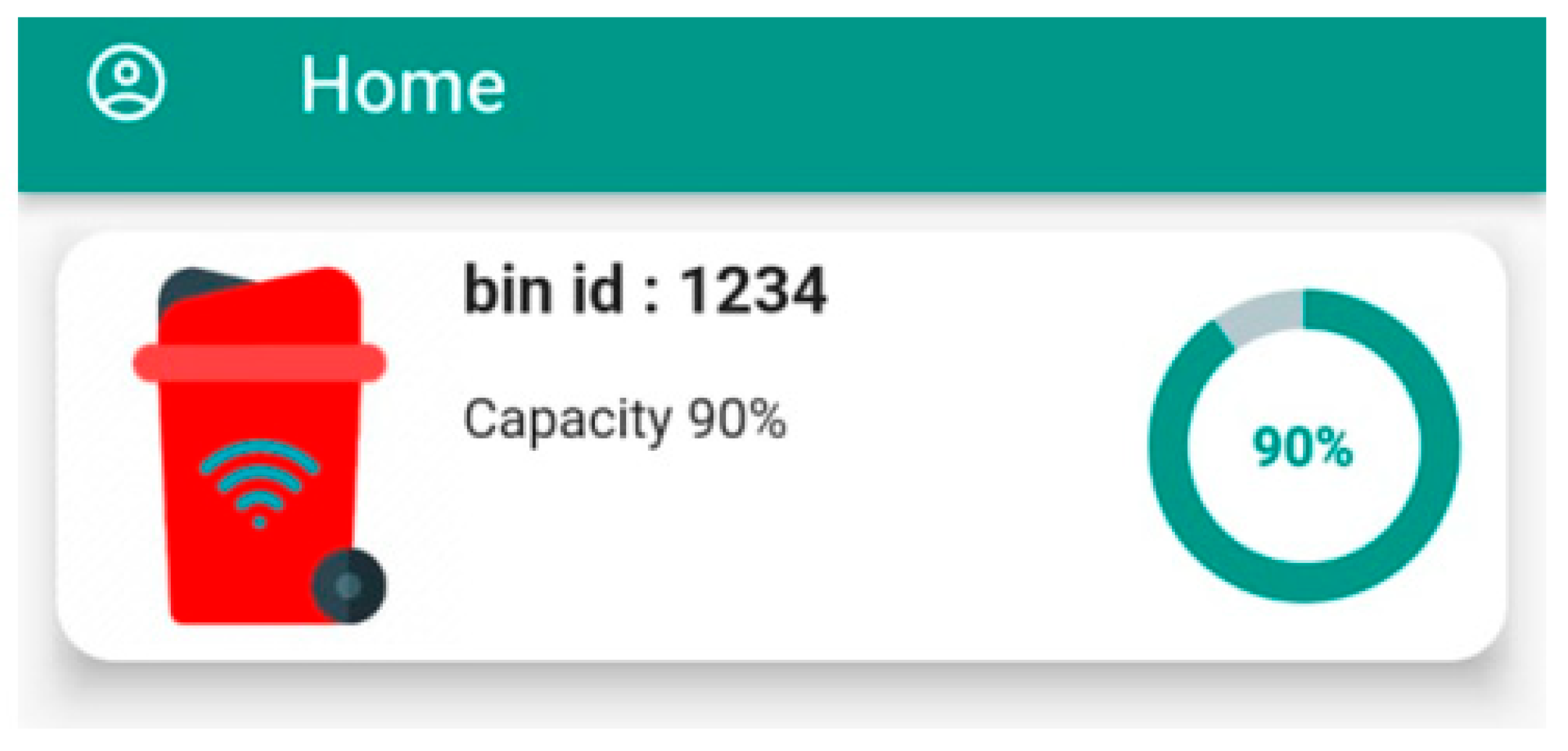

- Nearest Bin: This option displays all nearby BLMUs (Figure 6c). Upon selecting a BLMU, the app provides navigation via Google Maps and displays the bin’s current status (Figure 6d). Users may also capture and upload photos of bins surrounded by trash. Bin icons are dynamically color-coded according to fill status:

- ○

- Green: below 90%

- ○

- Red: 90% or above

- If the Staff Member button is selected, the staff login screen appears (Figure 7a). Users specify their role—administrator or worker—and log in using their credentials. Staff accounts are registered by the Ministry of Municipal and Rural Affairs.

- Managing users, creating new regions, and adding BLMU bins;

- Assigning jobs to workers and evaluating their performance;

- Handling task allocation and setting capacity thresholds for trucks and burners (Figure 8b);

- Reassigning workers and reallocating BLMU bins across regions via the Recycling Sector (Rec-Sector) page;

- Sending notifications to nearby Rec-Sector units when relevant (Figure 8c).

- Regular Users:Can request information about nearby waste bins and view their current fill-levels.

- Authorized Workers:Must log in with a username and password to receive assigned tasks, such as collecting waste from filled bins. Once tasks are completed, workers report updates through the mobile app, ensuring bin status is synchronized in real-time.

- System Administrators:Have full access to system-wide statistics and dashboards. They can monitor bin statuses, track worker activities, and analyze waste collection frequency (daily, weekly, monthly, annually). Based on these insights, administrators can assign or reassign tasks to optimize operational performance.

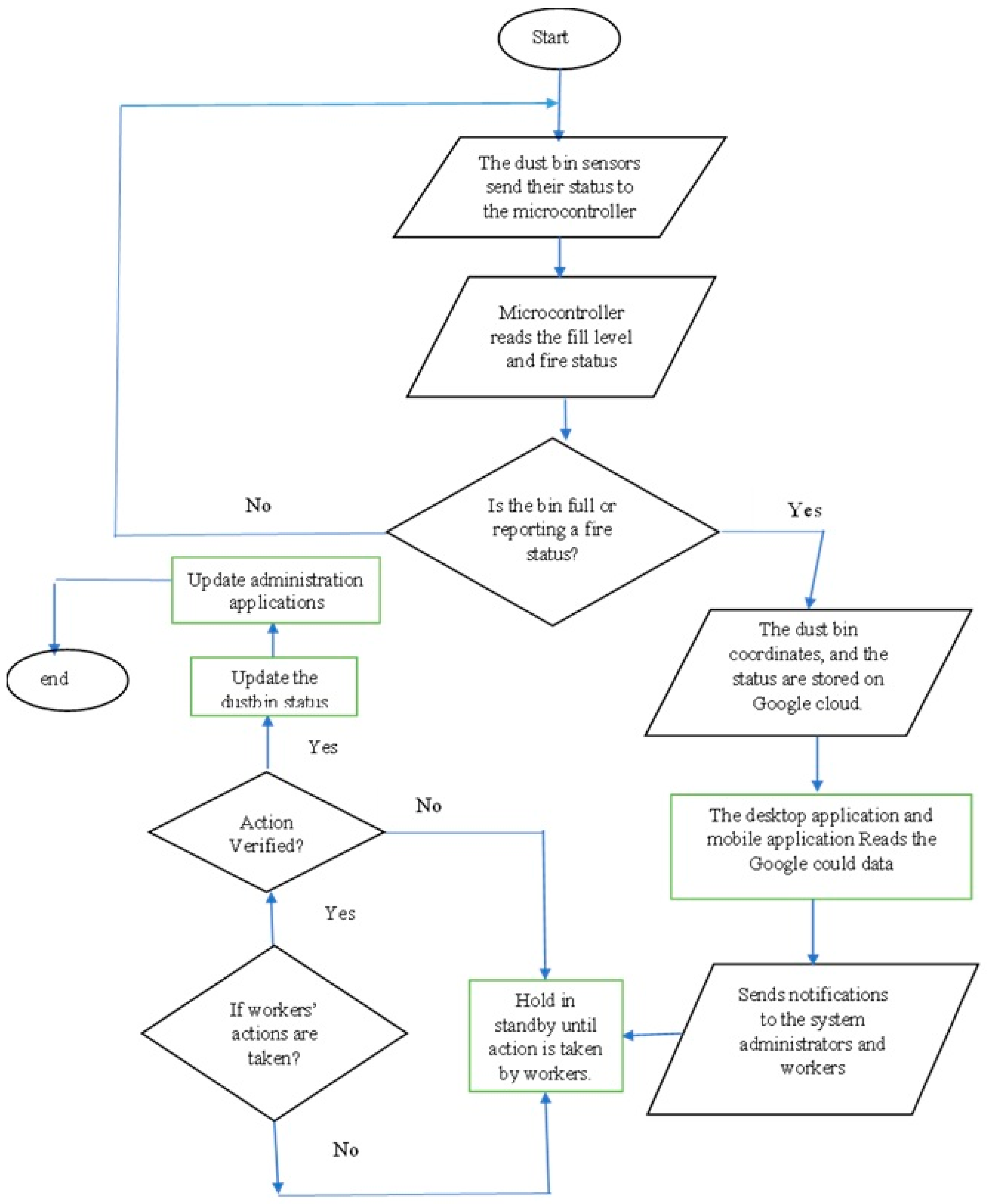

- System Workflow:The proposed SWM system operates according to the algorithm described in Algorithm 1 and the flowchart illustrated in Figure 9. The workflow follows sequential phases that ensure effective data collection, task allocation, and real-time monitoring.

| Algorithm 1 Waste management system algorithm |

| Input: |

|

| Output: |

|

| BEGIN |

| For each region in City: |

| Initialize BLMU network |

| Assign waste bins and region attributes |

| LOOP (Every reporting_interval seconds) |

| For each BLMU in active_regions: |

| Read fill_level, fire_status, location, timestamp |

| IF (fire_status == TRUE) OR (fill_level ≥ bin_threshold): |

| TRANSMIT alert to Centralized City Command and Control Center (4C) |

| UPDATE cloud database with anomaly record |

| DISPATCH notification to Administrator and assigned Worker |

| WAIT for resolution confirmation |

| IF resolution received: |

| UPDATE bin status to normal on all platforms |

| ENDIF |

| ELSE: |

| LOG normal bin status in cloud database |

| ENDIF |

| For each Worker: |

| RECEIVE task allocations (bins needing attention) |

| IF assigned_bin fill_level < cleanup_threshold: |

| LOG completed task |

| UPDATE worker activity profile |

| ENDIF |

| For Administrators: |

| MONITOR system dashboard |

| ANALYZE statistics [waste generation rates, worker performance] |

| ASSIGN tasks or adjust thresholds as needed |

| For Regular Users: |

| ACCESS nearest bin status via mobile app |

| VIEW location and fill status |

| SUBMIT reports/photos of overflow or hazards (optional) |

| ENDLOOP |

| END |

- (1)

- Setup Phase

- Regional Division: The city is divided into multiple zones, each equipped with BLMUs.

- Administrator Configuration: Admins configure system parameters (bin registration, regions, fill thresholds, recycling and burn sectors) via the mobile app.

- Centralized Data Transmission: Each region has a ZigBee-enabled base station that forwards data to the 4C.

- Vehicle Tracking: Trucks send GPS data to the 4C for efficient routing.

- Waste Generation: Residents and workers deposit waste into monitored bins.

- (2)

- Sensor Data Transmission Phase

- BLMUs transmit data every 10 s (ID, timestamp, location, fire status, fill-level).

- The microcontroller forwards processed information to the regional base station and then to the 4C.

- (3)

- Microcontroller Processing

- Analyzes incoming sensor data to classify bin status.

- Sends immediate alerts to the 4C if anomalies (e.g., fire, full bin) are detected.

- Logs bins in “normal” state when no anomalies are found.

- (4)

- Data Storage

- The 4C stores all incoming data (timestamps, fire alerts, fill-levels, location) in Google Firebase.

- (5)

- Conditional Status Check

- Anomaly Detected:

- ○

- Stores bin coordinates and abnormal status in the cloud.

- ○

- Provides real-time access via desktop and mobile apps.

- ○

- Sends alerts to admins and workers.

- ○

- Holds in standby until workers confirm the issue is resolved.

- No Anomaly Detected or Resolved:

- ○

- Updates bin status to “normal” across all platforms.

- ○

- Dispatches trucks for scheduled waste collection and logistics.

- (6)

- Task Assignment and Escalation

- Tasks are assigned automatically or manually by administrators.

- Triggered by events such as reaching capacity thresholds or detecting hazards.

- Notifications and SMS alerts are sent to the nearest vehicles for immediate action.

- (7)

- System Testing and Optimization

- Fire sensors were tested using controlled smoke simulations (e.g., burned cloth) with results shown in Figure 7.

- Applications were evaluated under varied bin fill-levels and fire scenarios.

- Analysis included the following:

- ○

- Identifying high-waste regions,

- ○

- Estimating optimal worker distribution,

- ○

- Monitoring allocation and reassignment of bins.

- A graphical LCD interface provided local status updates to nearby staff, enhancing coordination.

4. Testing and Results

- A.

- Estimated Overall Deployment Cost:

- B.

- Ultrasonic Sensor Accuracy Testing

- ○

- Status Monitoring: Testing involves monitoring the status levels of BLMU waste bins and fire detection. For instance, smoke and flame sensors are tested by simulating high concentrations of decomposing smoke, with results visualized in Figure 6d. Testing includes the following:

- (1)

- Fire Alarm Sensor Testing:

- (2)

- Wi-Fi Module Testing:

- (3)

- Bandwidth Requirement Analysis:

- (4)

- Mobile and Desktop Application Testing:

- (5)

- Load and Performance Testing:

- (1)

- Sensors accurately monitored waste levels and detected fires in real-time;

- (2)

- Communication via the Wi-Fi module was reliable across tested ranges;

- (3)

- Mobile and desktop applications met usability and functionality requirements;

- (4)

- The system maintained stable performance under heavy data loads.

- (6)

- Bandwidth Calculation across Various Scales of Deployments:

- ○

- Packet size: 100 bytes (800 bits);

- ○

- Packet frequency: 6 packets per minute (0.1 packets per second);

- ○

- Per BLMU resulting bandwidth requirement: approximately 80 bits per second (bps).

- (7)

- Data Synchronization and Latency Testing:

5. Discussion

5.1. Environmental and Human Impacts on Sensor Reliability

5.2. Technical Scalability and Networking Challenges

5.3. Economic Viability Analysis

5.4. Data Security and Ethical Considerations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | Abbreviations |

| 4C | City Command and Control Center |

| AI | Artificial Intelligence |

| BaaS | Backend-as-a-Service |

| BLE | Bluetooth Low Energy |

| BLMU | Bin Level Monitoring Unit |

| FCM | Firebase Cloud Messaging |

| GDPR | General Data Protection Regulation |

| GPS | Global Positioning System |

| GSM | Global System for Mobile Communications |

| GUI | Graphical User Interface |

| HBLMU | Home Bin Level Monitoring Unit |

| HTTP | Hypertext Transfer Protocol |

| IoT | Internet of Things |

| LCD | Liquid Crystal Display |

| LoRa | Long Range (wireless communication) |

| MQTT | Message Queuing Telemetry Transport |

| PBLMU | Public Bin Level Monitoring Unit |

| PoC | Proof of Concept |

| RFID | Radio Frequency Identification |

| SPWMU | Smart Portable Waste Monitoring Unit |

| SWM | Smart Waste Management |

| TCP | Transmission Control Protocol |

| UDP | User Datagram Protocol |

| WAPU | Waste Analysis Processing Unit |

| WEEE | Waste Electrical and Electronic Equipment |

| Wi-Fi | Wireless Fidelity |

| WLAN | Wireless Local Area Network |

References

- Ramson, S.J.; Bhavanam, D.; Draksharam, S.; Kumar, R.; Moni, D.J.; Kirubaraj, A.A. Radio Frequency Identification and Sensor Networks based Bin Level Monitoring Systems-A Review. In Proceedings of the 2018 4th International Conference on Devices, Circuits and Systems (ICDCS), Coimbatore, India, 16–17 March 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 17–20. [Google Scholar]

- Hossein, K.M.; Esmaeili, M.E.; Dargahi, T.; Khonsari, A.; Conti, M. BCHealth: A novel blockchain-based privacy-preserving architecture for IoT healthcare applications. Comput. Commun. 2021, 180, 31–47. [Google Scholar] [CrossRef]

- Zobel, T. ISO 14001 adoption and industrial waste generation: The case of Swedish manufacturing firms. Waste Manag. Res. 2015, 33, 107–113. [Google Scholar] [CrossRef]

- Ferrari, F.; Striani, R.; Minosi, S.; De Fazio, R.; Visconti, P.; Patrono, L.; Catarinucci, L.; Corcione, C.E.; Greco, A. An innovative IoT-oriented prototype platform for the management and valorisation of the organic fraction of municipal solid waste. J. Clean. Prod. 2020, 247, 119618. [Google Scholar] [CrossRef]

- Kapucu, N.; Bilim, M. Internet of Things for Smart Homes and Smart Cities. In Proceedings of the Smart Grid 3.0: Computational and Communication Technologies; Springer: Cham, Switzerland, 2023; pp. 331–356. [Google Scholar]

- Babu, B.R.; Parande, A.K.; Basha, C.A. Electrical and electronic waste: A global environmental problem. Waste Manag. Res. 2007, 25, 307–318. [Google Scholar]

- Krzywoszynska, A. ‘Waste? You mean by-products!’ From bio-waste management to agro-ecology in Italian winemaking and beyond. Sociol. Rev. 2012, 60, 47–65. [Google Scholar] [CrossRef]

- Bacot, H.; McCoy, B.; Plagman-Galvin, J. Municipal commercial recycling: Barriers to success. Am. Rev. Public Adm. 2002, 32, 145–165. [Google Scholar] [CrossRef]

- Seyring, N.; Dollhofer, M.; Weißenbacher, J.; Bakas, I.; McKinnon, D. Assessment of collection schemes for packaging and other recyclable waste in European Union-28 Member States and capital cities. Waste Manag. Res. 2016, 34, 947–956. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Bakhouch, M.; Salsabil; Ayad, S.; Terrissa, L.S. Smart Waste Management System Based on IoT. In Proceedings of the International Conference on Smart City Applications, Paris, France, 4–6 October 2023; Springer Nature: Cham, Switzerland, 2023; pp. 322–331. [Google Scholar]

- Talari, S.; Shafie-Khah, M.; Siano, P.; Loia, V.; Tommasetti, A.; Catalão, J.P.S. A review of smart cities based on the internet of things concept. Energies 2017, 10, 421. [Google Scholar] [CrossRef]

- Duhayyim, M.A.; Elfadil Eisa, T.A.; Al-Wesabi, F.N.; Abdelmaboud, A.; Hamza, M.A.; Zamani, A.S.; Rizwanullah, M.; Marzouk, R. Deep Reinforcement Learning Enabled Smart City Recycling Waste Object Classification. Comput. Mater. Contin. 2022, 71, 5699–8715. [Google Scholar] [CrossRef]

- Anagnostopoulos, T.; Zaslavsky, A.; Ntalianis, K.; Anagnostopoulos, C.; Ramson, S.R.J.; Shah, P.J.; Behdad, S.; Salmon, I. IoT-enabled tip and swap waste management models for smart cities. Int. J. Environ. Waste Manag. 2021, 28, 521–539. [Google Scholar] [CrossRef]

- Avancini, D.B.; Rodrigues, J.J.P.; Rabêlo, R.A.L.; Das, A.K.; Kozlov, S.; Solic, P. A new IoT-based smart energy meter for smart grids. Int. J. Energy Res. 2021, 45, 189–202. [Google Scholar] [CrossRef]

- Bhattacharya, A. Blockchain and IoT: A Paradigm Shift for Supply Chain Management. In Blockchain for Business: How It Works and Creates Value; Treiblmaier, H., Clohessy, T., Eds.; Springer: Cham, Switzerland, 2021; pp. 159–178. [Google Scholar]

- Saha, S.; Chaki, R. IoT based smart waste management system in aspect of COVID-19. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100048. [Google Scholar] [CrossRef]

- Ali, T.; Irfan, M.; Alwadie, A.S.; Glowacz, A. IoT-based smart waste bin monitoring and municipal solid waste management system for smart cities. Arab. J. Sci. Eng. 2020, 45, 10185–10198. [Google Scholar] [CrossRef]

- Ramson, S.R.J.; Moni, D.J. Wireless sensor networks based smart bin. Comput. Electr. Eng. 2017, 64, 337–353. [Google Scholar] [CrossRef]

- Popa, C.L.; Carutasu, G.; Cotet, C.E.; Carutasu, N.L.; Dobrescu, T. Smart city platform development for an automated waste collection system. Sustainability 2017, 9, 2064. [Google Scholar] [CrossRef]

- Rohit, G.S.; Chandra, M.B.; Saha, S.; Das, D. Smart dual dustbin model for waste management in smart cities. In Proceedings of the 2018 3rd International Conference for Convergence in Technology (I2CT), Pune, India, 6–8 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Vishnu, S.; Ramson, S.R.J.; Senith, S.; Anagnostopoulos, T.; Abu-Mahfouz, A.M.; Fan, X.; Srinivasan, S.; Kirubaraj, A.A. IoT-enabled solid waste management in smart cities. Smart Cities 2021, 4, 1004–1017. [Google Scholar] [CrossRef]

- Arthur, M.P.; Shoba, S.; Pandey, A. A survey of smart dustbin systems using the IoT and deep learning. Artif. Intell. Rev. 2024, 57, 56. [Google Scholar] [CrossRef]

- Hussain, I.; Elomri, A.; Kerbache, L.; El Omri, A. Smart city solutions: Comparative analysis of waste management models in IoT-enabled environments using multiagent simulation. Sustain. Cities Soc. 2024, 103, 105247. [Google Scholar] [CrossRef]

- Pal, M.S.; Bhatia, M. Smart solid waste management system using IoT technology: Comparative analysis, gaps, and challenges. In International Conference on Intelligent Cyber Physical Systems and Internet of Things; Springer International Publishing: Cham, Switzerland, 2022; pp. 795–811. [Google Scholar]

- Belhiah, M.; El Aboudi, M. An IoT-Based Sensor Mesh Network Architecture for Waste Management in Smart Cities. J. Commun. 2025, 20, 153–165. [Google Scholar] [CrossRef]

- Jino Ramson, S.R.; Moni, D.J.; Kirubaraj, A.A.; Senith, S. Self-powered wireless sensor network framework to monitor bin level. J. Solid Waste Technol. Manag. 2017, 43, 295–304. [Google Scholar] [CrossRef]

- Folianto, F.; Low, Y.S.; Yeow, W.L. Smartbin: Smart waste management system. In Proceedings of the 2015 IEEE Tenth International Conference on Intelligent Sensors, Sensor Networks and Information Processing (ISSNIP), Singapore, 7–9 April 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–2. [Google Scholar]

- Ramson, S.R.J.; Moni, D.J.; Vishnu, S.; Anagnostopoulos, T.; Kirubaraj, A.A.; Fan, X. An IoT-based bin level monitoring system for solid waste management. J. Mater. Cycles Waste Manag. 2021, 23, 516–525. [Google Scholar] [CrossRef]

- Lundin, A.C.; Özkil, A.G.; Schuldt-Jensen, J. Smart cities: A case study in waste monitoring and management. In Proceedings of the 50th Hawaii International Conference on System Sciences (HICSS 2017), Hilton Waikoloa Village, HI, USA, 4–7 January 2017; pp. 1392–1401. [Google Scholar]

- Sinha, R.S.; Wei, Y.; Hwang, S.-H. A survey on LPWA technology: LoRa and NB-IoT. ICT Express 2017, 3, 14–21. [Google Scholar] [CrossRef]

- Pendão, C.; Silva, I. Optical fiber sensors and sensing networks: Overview of the main principles and applications. Sensors 2022, 22, 7554. [Google Scholar] [CrossRef]

- Raaju, V.A.; Meeran, J.M.; Sasidharan, M.; Premkumar, K. IOT based smart garbage monitoring system using ZigBee. In Proceedings of the 2019 IEEE International Conference on System, Computation, Automation and Networking (ICSCAN), Pondicherry, India, 29–30 March 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–7. [Google Scholar]

- Karthikeyan, S.; Rani, G.S.; Sridevi, M.; Bhuvaneswari, P.T.V. IoT enabled waste management system using ZigBee network. In Proceedings of the 2017 2nd IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT), Bangalore, India, 19–20 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2182–2187. [Google Scholar]

- Kumar, N.S.; Vuayalakshmi, B.; Prarthana, R.J.; Shankar, A. IOT based smart garbage alert system using Arduino UNO. In Proceedings of the 2016 IEEE Region 10 Conference (TENCON), Singapore, 22–25 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1028–1034. [Google Scholar]

- Monika, K.A.; Rao, N.; Prapulla, S.B.; Shobha, G. Smart dustbin-an efficient garbage monitoring system. Int. J. Eng. Sci. Comput. 2016, 6, 7113–7116. [Google Scholar]

- Hassan, S.A.; Jameel, N.G.M.; Şekeroğlu, B. Smart solid waste monitoring and collection system. Int. J. 2016, 6, 7–12. [Google Scholar]

- Yan, K.; Si, W.; Hang, J.; Zhou, H.; Zhu, Q. Multi-label garbage image classification based on deep learning. In Proceedings of the 2020 19th International Symposium on Distributed Computing and Applications for Business Engineering and Science (DCABES), Xuzhou, China, 16–19 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 150–153. [Google Scholar]

- Beall, J.D.; Jhunjhunwala, R.; Garnet, A.S. “The SLICCVac Medical Vacuum Cleaner” Worcester Polytechnic Institute. Available online: https://digital.wpi.edu/concern/student_works/6w924c472?locale=zh (accessed on 1 April 2025).

- Ijemaru, G.K.; Ang, L.M.; Seng, K.P. Transformation from IoT to IoV for waste management in smart cities. J. Netw. Comput. Appl. 2022, 204, 103393. [Google Scholar] [CrossRef]

- Endah, S.N.; Shiddiq, I.N. Xception architecture transfer learning for garbage classification. In Proceedings of the 2020 4th International Conference on Informatics and Computational Sciences (ICICoS), Semarang, Indonesia, 10–11 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–4. [Google Scholar]

- Lu, X.; Pu, X.; Han, X. Sustainable smart waste classification and collection system: A bi-objective modeling and optimization approach. J. Clean. Prod. 2020, 276, 124183. [Google Scholar] [CrossRef]

- Karia, G.L.; Christian, R.A.; Jariwala, N.D. Wastewater Treatment: Concepts and Design Approach; PHI Learning Pvt. Ltd.: New Delhi, India, 2023. [Google Scholar]

- Abusukhon, A. IOT bracelets for guiding blind people in an indoor environment. J. Commun. Softw. Syst. 2023, 19, 114–125. [Google Scholar] [CrossRef]

- Flutter Development Platform. Available online: https://flutter.dev/ (accessed on 30 August 2025).

- Mahalakshmi, G.; Vigneshwaran, M. IOT based home automation using Arduino. Int. J. Eng. Adv. Res. Technol. 2017, 3, 7–11. [Google Scholar]

- Electronics Tutorials. Available online: https://www.electronics-tutorials.ws/ (accessed on 30 August 2025).

| Criteria | Studies | Key Findings |

|---|---|---|

| Optimization and Cost Efficiency | [15,21,22,37] | Reduced costs and improved fuel efficiency using solar units and optimized routes. |

| Energy Efficiency | [22,23,30] | Renewable energy sources (e.g., solar, ZigBee) cut operating costs. |

| Technological Integration | [24,25,32] | Integration of GPS, RFID, and LoRa enhances tracking and real-time management. |

| Machine Learning Applications | [35,36] | Improved waste classification accuracy through Artificial Intelligence (AI) models and image processing. |

| Communication Protocols | [27,31,33] | Use of LoRa, ZigBee, MQTT, and GSM supports scalability and real-time updates. |

| Ref. | Microcontroller | Wireless Technology | Network Topology | Wireless Range | GPS | Visualization |

|---|---|---|---|---|---|---|

| [1] | ARM Cortex M0 with Wi-Fi network processor ATWINC1500 | Wi-Fi module (ATSAMW25) | Star | Up to 100 m indoors Up to 400 m outdoors | Yes | Yes. |

| [15] | Arduino Uno | Wi-Fi, wireless communication, Ethernet communication | Client-server architecture | Short-range Wi-Fi No more than 100 m for Ethernet | Yes | Yes |

| [16] | Arduino Uno | Wi-Fi | Star | Short | Yes | No |

| [22] | MSP430F2274 | SimpliciTI | WLAN | Short | No | Yes |

| [23] | Arduino Uno | Wireless radio | Star | Short | Yes | No |

| [24] | MSP430F2274 | Wi-Fi | WLAN | Short | Yes | Yes |

| [29] | MSP430F1611 | SimpliciTI | WLAN | Short | No | Yes |

| [30] | Arduino Pro Mini | ZigBee | Star | Short | Yes | No |

| [31] | Arduino Uno | ZigBee | Mesh | Short | Yes | No |

| [32] | Arduino Uno | Wi-Fi, Bluetooth, cellular networks | Client-server architecture | Short | No | Yes. |

| [33] | Arduino Uno | Wi-Fi | Star | Short | No | Yes |

| [34] | Arduino Uno | Wi-Fi | Short | Yes | Yes (Android app) | |

| This paper | Arduino Uno | Wi-Fi | Star | Short | Yes | Yes (Flutter and desktop app) |

| Ref. | Place | Sensors | Features |

|---|---|---|---|

| [1] | Outdoor waste bin | Ultrasonic sensor (MB1010, LV-MaxSonar-EZ1) Wi-Fi module (ATSAMW25) |

|

| [15] | Outdoor waste bin | Flame sensor (HC-SK026) Ultrasonic sensor (HC-SR04) Temperature and humidity sensors (HW-505) Weight sensor GPS module GSM module |

|

| [16] | Indoor and outdoor waste bin | Ultrasonic sensors Proximity sensors Fire sensors |

|

| [22] | Outdoor waste bin | Ultrasonic sensor |

|

| [23] | Outdoor waste bin | Sensor nodes (ultrasonic sensor; GPS/Wi-Fi module) Gateway nodes (Wi-Fi module) |

|

| [24] | Outdoor waste bin | BLMU based on ultrasonic sensor. WAPU GPS module |

|

| [29] | Outdoor waste bin | Interfaced ultrasonic sensor (HC-SR04) |

|

| [30] | Outdoor waste bin | Ultrasonic sensor GPS Module |

|

| [31] | Outdoor waste bin | Ultrasonic sensor |

|

| [32] | Outdoor waste bin | Ultrasonic sensor RFID technology |

|

| [33] | Outdoor waste bin | Ultrasonic sensor GSM modem Smartphone app |

|

| [34] | Outdoor waste bin | Ultrasonic sensor RF transmitter GSM/GPRS module |

|

| This paper | Indoor and outdoor waste bin | Ultrasonic sensor Fire sensor GPS module Wi-Fi module |

|

| Ref. | Software | Software Features | Cloud-Based |

|---|---|---|---|

| [1] | GUI without specifying the software used to create it | Smart monitoring of dust levels | No |

| [15] | Lab view, Java, and C++ software | The system revolves around an IoT sensing prototype that measures garbage levels in bins and transmits the data to the server via Internet services | Yes |

| [16] | Azure platform, web page for desktop app, and mobile application | The web app service delivers content of a web page for desktop and mobile Azure platform offers three services for web service deployment: cloud services, virtual machines, and service fabric | Yes |

| [22] | Microsoft C# for GUI | Displays status level of dust bins | No |

| [24] | Eclipse Mosquito, Redis, PostgreSQL, and a smart GUI. | The IoT-SWM server package consists of Eclipse Mosquito, Redis, PostgreSQL, and a smart GUI

| No |

| [29] | Uses C# programming language based on the NET architecture | Measures the unfilled level of bins | No |

| [30] | Android application | Notifies truck drivers when waste bins are full, including bin position | Yes |

| [31] | MQTT | Listen to MQTT protocol to determine filled status of garbage containers | No |

| [34] | Android software using C and C++ programming languages | Android App displays dustbin status Smart waste monitoring and control system developed using C and C++ programming languages. Output shown on GLCD screen displaying the number of smart bins and their fill status | No |

| This paper | Flutter based on Dart and desktop app | Mobile app features:

| Yes |

| Parameter | Proposed IoT-Based SWM System | System A [18] | System B [19] | System C [20] |

|---|---|---|---|---|

| Technology | Arduino Uno, Wi-Fi module | MSP430F2274, Wi-Fi, GSM | MSP430F1611, SimpliciTI | Arduino Pro Mini, ZigBee |

| Network Topology | Star | WLAN | WLAN | Star |

| Effectiveness | Real-time waste level and fire alerts, optimized route planning | Monitors bin fullness, sends SMS alerts | Real-time data collection, remote monitoring | Selects waste type using touchscreen, video recognition for waste types |

| Cost | Low | Moderate | High | Moderate |

| Data Integration | Google Cloud Firestore | Local server storage | PostgreSQL | Azure Cloud |

| Scalability | High (cloud-based, adaptable to larger areas) | Limited (requires extensive infrastructure) | Moderate (local setup) | High (Azure integration) |

| Energy Source | Battery-powered, future renewable integration | Battery | Mains | Battery |

| Environmental Impact | Reduced truck fuel consumption, lower emissions | Limited (no route optimization) | Moderate (saves resources but limited optimization) | Improved resource use via video recognition |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnanih, R.; Elrefaei, L.; Al-Ahwal, A. Advancing Sustainability Through an IoT-Driven Smart Waste Management System with Software Engineering Integration. Sustainability 2025, 17, 9803. https://doi.org/10.3390/su17219803

Alnanih R, Elrefaei L, Al-Ahwal A. Advancing Sustainability Through an IoT-Driven Smart Waste Management System with Software Engineering Integration. Sustainability. 2025; 17(21):9803. https://doi.org/10.3390/su17219803

Chicago/Turabian StyleAlnanih, Reem, Lamiaa Elrefaei, and Ayman Al-Ahwal. 2025. "Advancing Sustainability Through an IoT-Driven Smart Waste Management System with Software Engineering Integration" Sustainability 17, no. 21: 9803. https://doi.org/10.3390/su17219803

APA StyleAlnanih, R., Elrefaei, L., & Al-Ahwal, A. (2025). Advancing Sustainability Through an IoT-Driven Smart Waste Management System with Software Engineering Integration. Sustainability, 17(21), 9803. https://doi.org/10.3390/su17219803