Abstract

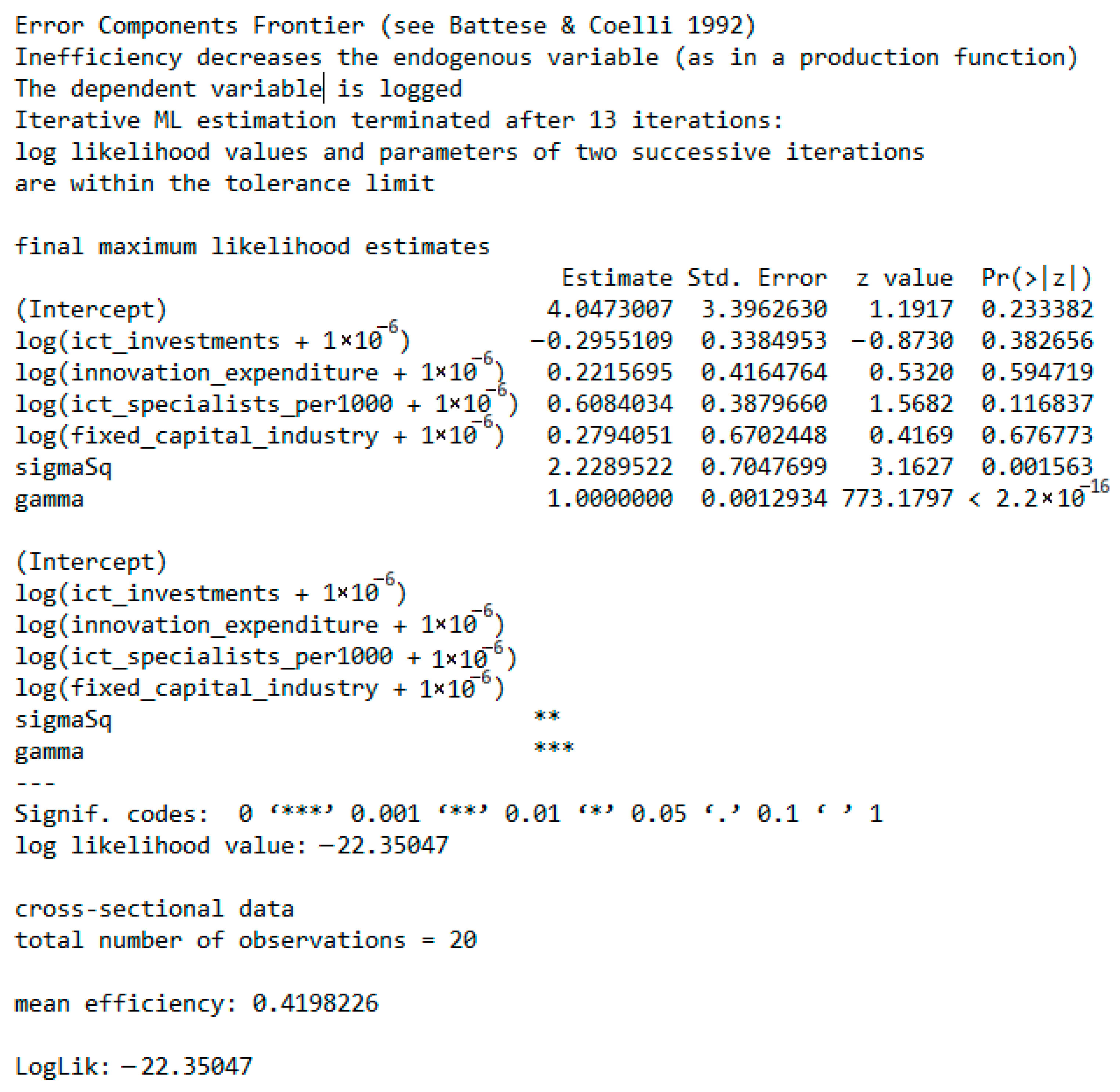

This scientific article examines the issue of the effectiveness of digital transformation in Kazakhstan’s industry from the perspective of how effectively enterprises are able to convert digital resources into economically measurable results in the context of the transition to a model of sustainable industrial growth. The aim of the study is to develop a comprehensive methodology for assessing the digital readiness of industrial enterprises to implement and adapt digital ecosystems based on a synthesis of conceptual and empirical approaches. The methodology developed by the authors combines a parametric diagnostic system and stochastic frontier analysis (SFA) tools, which allows for a quantitative assessment of not only the scale but also the effectiveness of digital transformations at the regional level. The empirical part of the study includes statistical data for 2023, reflecting the dynamics of the introduction of ICT, cloud technologies, big data analytics, etc., in the industrial sector. The results of the analysis showed the steady development of digitalization with the existing pronounced spatial asymmetry. The application of SFA made it possible to identify technological “frontiers” and reveal the hidden potential for increasing the effectiveness of digital investments at the regional level. The practical value of the study lies in its applicability for assessing the digital readiness of industrial enterprises for ecosystem adaptation, diagnosing regional digital disparities, and justifying targeted government policy measures aimed at strengthening the digital maturity and sustainability of the industrial sector.

1. Introduction

In today’s economic environment, digital transformation is becoming one of the key factors determining the trajectory of industrial development. Its essence lies not only in the automation of individual production or business processes but also in the profound restructuring of production and management systems, affecting all levels of economic activity—from the organization of production flows to the formation of new innovative business models of interaction between all participants in the industrial market. At the same time, the ability of industrial enterprises to integrate digital technologies into management decisions is now one of the main indicators of their competitiveness, sustainability, and innovative potential. In this context, the analysis of the digital readiness and adaptation capabilities of industrial companies is of strategic importance, as these parameters determine the ability of enterprises to integrate and effectively use digital ecosystems.

Kazakhstan’s industrial sector maintains its leading position in the structure of the national economy and demonstrates sustained positive dynamics in key macroeconomic indicators. The contribution of industry to GDP consistently exceeds a quarter of the total volume, and the manufacturing sector is strengthening its role as a key driver of added value and technological growth. At the same time, the authors’ findings show that digital transformation processes in the industry are developing unevenly. Despite a noticeable increase in the number of enterprises using computer technology, the Internet, and cloud services, the penetration of more complex tools—such as big data analytics, additive technologies, the industrial Internet of Things, or elements of artificial intelligence—is still limited and is observed mainly among large manufacturing structures, corporations, and joint international companies.

The identified asymmetry of digitalization confirms the need to create a comprehensive methodology capable of objectively assessing the real state of digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems. Of course, existing international approaches, methods, and indices (e.g., DESI, IMD, OECD, etc.) provide important benchmarks for comparative analysis and determining the level of digital maturity. However, in developing economies, they do not fully reflect institutional specifics, sectoral heterogeneity, and differences in the level of infrastructure provision, nor do they allow for a full assessment of the digital readiness of industrial enterprises for the digital transformation of all business processes. In this regard, it is necessary to develop a specialized approach that is adapted to the specifics of Kazakhstan’s industry and considers the interconnection between digital resources, organizational mechanisms, and the actual results of digitalization but at the same time is sufficiently universal and adaptable for other countries and regions of the world, considering the component of sustainability to a significant extent.

The purpose of this study is to develop and empirically test the authors’ methodology for assessing the digital readiness of industrial enterprises in Kazakhstan to implement and adapt digital ecosystems. The proposed approach combines parametric diagnostics of key indicators of digital development with the use of stochastic frontier analysis, which allows not only to record the degree of digital involvement but also to determine how effectively the resources used are transformed into economic results in the context of Kazakhstan’s regions.

The structure of the study reflects the progressive logic of the transition from theory to empiricism: thus, the Section 2, examines the theoretical and methodological foundations of digital transformation and its relationship to sustainable development and ecosystem integration of industry; the Section 3, contains a description of the authors’ methodology for assessing the digital readiness of enterprises and the stages of conducting a stochastic frontier analysis of the effectiveness of digitalization in the regions of Kazakhstan. The Section 4, presents the results of testing the methodology on the example of the regions of Kazakhstan, allowing us to identify spatial differences and the effectiveness of the use of digital resources. The Section 5, summarizes the main findings of the study and identifies areas for the practical application of the proposed toolkit in the context of state policy on the digitalization of industry.

2. Literature Review

2.1. Digital Transformation and Sustainability in Industry

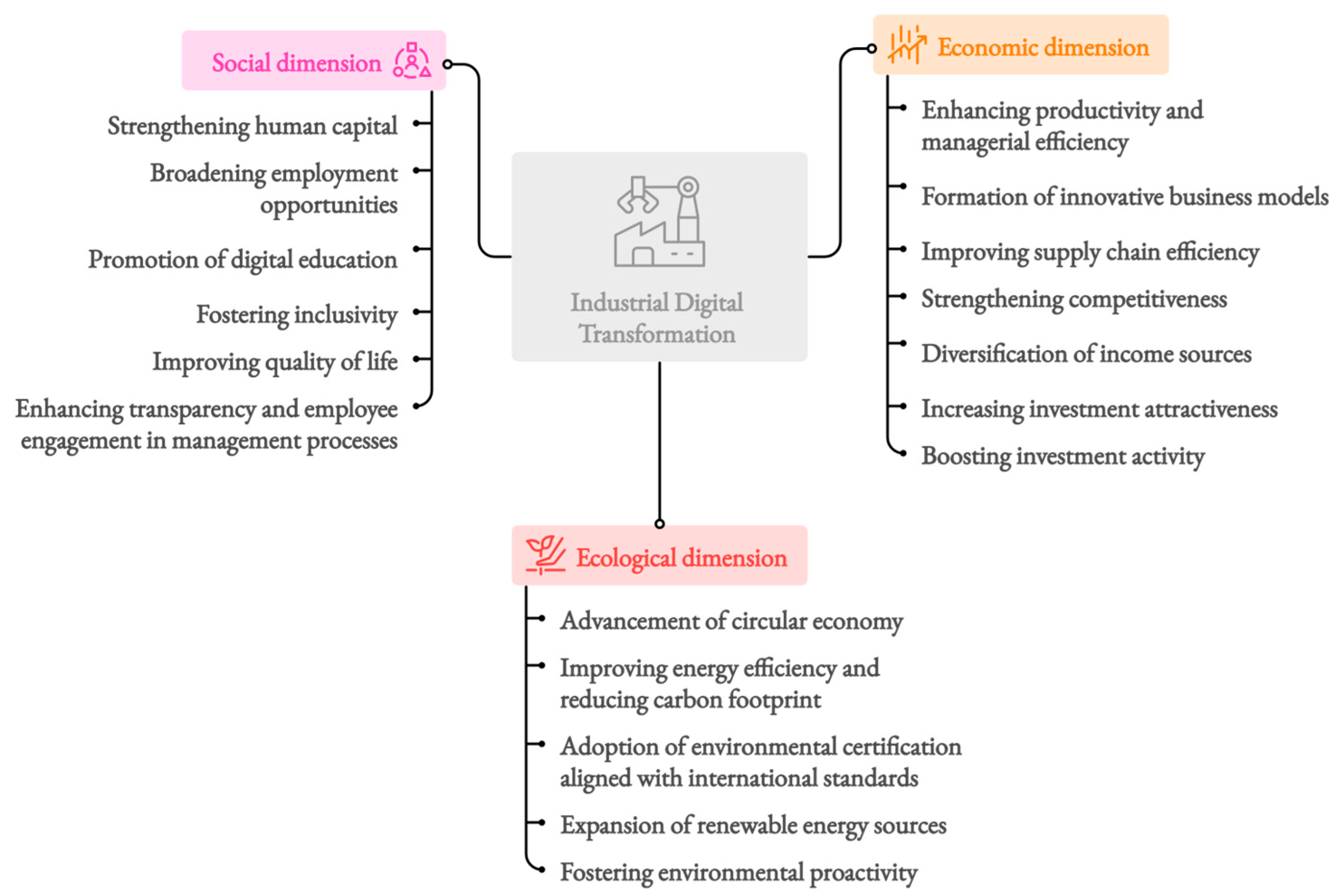

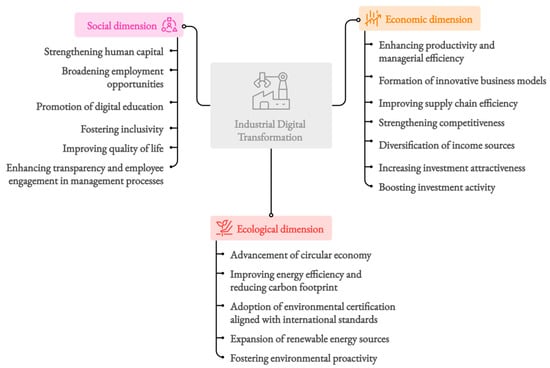

The digital transformation of industry in the context of modern economic reforms is a multifaceted process that can have a significant and complex impact on the key parameters of sustainable enterprise development [1]. It is worth noting that the impact of digital transformation is reflected in the multi-level dimensions that determine the trajectories of sustainable industrialization (Figure 1).

Figure 1.

The impact of digital transformation on ESG-oriented industrial development. Note: compiled by the authors.

First, the economic dimension is associated with growth in both production and management efficiency (for example, through the effective use of unified digital platforms and management systems operating at the enterprise, as well as data analytics and artificial intelligence capabilities) [2,3,4]; the formation of innovative business models, the rationalization of operational activities [5,6,7,8,9]; improving the efficiency of supply chains (by reducing transaction costs, forecasting demand using predictive analytics, etc.) [10,11,12,13]; increasing the competitiveness of industrial enterprises and complex integrated structures, including those represented by industrial clusters in the global market, by establishing customized production; diversification of income sources (through the use of big data, digital platforms, and ecosystem solutions to enter new markets and conquer new market niches) [14,15]; increasing investment attractiveness—today, more and more companies with a high level of digital readiness and maturity are attracting more investment and entering ESG ratings [16,17,18], thereby ensuring growth in capitalization, increased trust from stakeholders, and the creation of international competitive advantages; ensuring resilience to risks, as modern digital solutions adapted in production allow for faster adaptation to external shocks caused by macroeconomic factors [19,20]; strengthening innovation activity by using digital laboratories/factories, digital twin technologies, open innovation tools, and collaborative platforms in practical activities [21], integration of 3D printing and additive manufacturing, as well as cloud technologies and edge computing [22,23,24,25,26].

Secondly, the environmental dimension is linked to the development of the circular economy and the optimization of resource use, particularly when it comes to recycling and reusing materials, minimizing waste at all stages of the industrial production life cycle [8,27,28]; improving energy efficiency, reducing the carbon footprint, including through the introduction and adaptation of digital systems for monitoring and managing environmental indicators [29,30]; the use of environmental certification tools and bringing production processes into line with international environmental standards, as well as expanding the use of renewable energy resources in the industrial sector (e.g., solar energy (the use of solar panels and concentrated solar power to supply electricity to production facilities), wind energy (use of wind turbines to reduce dependence on traditional energy sources, especially in energy-intensive industries such as metallurgy, chemical and petrochemical industries, oil refining, etc.), small-scale hydropower (construction of mini and micro hydroelectric power plants to supply individual enterprises and industrial clusters), geothermal energy (use of geothermal heat for industrial processes and heating), hydrogen technologies/“green” hydrogen (e.g., as a reducing agent for iron ore, which allows steel to be produced with virtually no CO2 emissions, as well as iron oxides, forming water instead of carbon dioxide), etc.) [31,32,33]; increasing environmental initiative [34,35]. Overall, all the above directly support the implementation of environmental sustainability principles.

Thirdly, the social dimension covers human capital development, in particular the formation of new generation digital competencies (technical and technological skills—working with big data, programming and development, cloud technologies, cybersecurity and data management, working with digital twins; analytical competencies—systems thinking, digital modeling skills, simulation creation, use of artificial intelligence and machine learning in management; digital and management skills—project management in the context of digital transformation (Agile, Scrum, Kanban), working with digital platforms and ecosystems, etc. [36,37,38,39]; social and communication skills—the ability to collaborate in a virtual environment, form and use cross-cultural digital communications, comply with digital ethics, and effectively manage digital identity) [40,41,42,43], expanding employment in the digital economy/platform employment (through the widespread use of digital platforms capable of creating new forms of employment (hybrid and remote work) [44,45,46,47]; development of digital education and educational programs aimed at retraining personnel [48,49]; increased transparency and employee involvement in the management process [50,51,52]; processes of transforming forms of social partnership and corporate responsibility, expressed in the introduction of innovative digital mechanisms for interaction between business, government structures, and civil society, as well as the expansion of inclusive practices in the manufacturing sector and the strengthening of the overall level of social well-being of the population, expressed in ensuring equal access to jobs, reducing regional inequality, ensuring the possibility of flexible forms of employment for employees, creating new jobs, increasing occupational safety, and access to social benefits through digitalization (telemedicine, e-learning, digital government services, etc.), strengthening social cohesion, and developing the service sector [53,54,55].

Each of the areas considered directly correlates with the sustainable development goals outlined in the UN agenda, including SDG 8—promoting decent work and economic growth, SDG 9—developing industrial capacity, innovation, and infrastructure, and SDG 12, which aims to establish responsible production and consumption patterns.

Thus, digital transformation is a kind of integral driver of the ESG agenda, ensuring the transition to sustainable industrialization, including through its cumulative impact on the economic, environmental, and social components of industrial development.

It should be noted that scientific discourse in the field of digital transformation shows a noticeable bias towards the study of individual aspects, such as energy efficiency, environmental management, or the digitalization of employment. At the same time, integrative models that consider the ESG-oriented effects of the digitalization of industry in their interrelationships remain underrepresented. This existing lack of comprehensive research creates a research gap, which is the main task of this work.

2.2. Digital Readiness Models and Indices

In the current economic climate, the category of “digital readiness” is gradually becoming established in scientific and applied discourse as a tool for analyzing complex transformations affecting not only the field of digital technologies but also internal organizational changes taking place in industry and related economic sectors. It is worth noting that the meaning goes far beyond the technological dimension, since, as a rule, it refers to the abilities and capabilities of industrial enterprises, industries, and, in general, national economies to perceive, integrate, and effectively use a variety of information and communication tools to improve efficiency, productivity, innovation, and sustainable development.

Within the framework of this scientific article, it is appropriate to consider the component structure of both digital readiness and digital maturity of industrial enterprises, since these categories reflect different stages of a single process of digital transformation of industrial structures. As noted above, the concept of digital readiness focuses more on the potential of an enterprise—the set of initial conditions, resources, and institutional prerequisites that determine the system’s ability to perceive and implement digital technologies/digital platforms. In turn, digital maturity characterizes the level of development of digital processes already achieved and the degree of integration of technologies into management and production activities, as well as the effectiveness of using digital solutions in increasing sustainability and forming competitive advantages.

Thus, a sequential examination of the categories presented allows us not only to trace the trajectory of the transition from potential to result but also to identify the relationship between readiness factors and actual manifestations of maturity. In addition, a comparative analysis of the component structure of these concepts creates a fundamental basis for the formation of an integrated methodology for assessing digital transformation, combining prerequisites, processes, and results within a single conceptual model for the adaptation of digital ecosystems in industry.

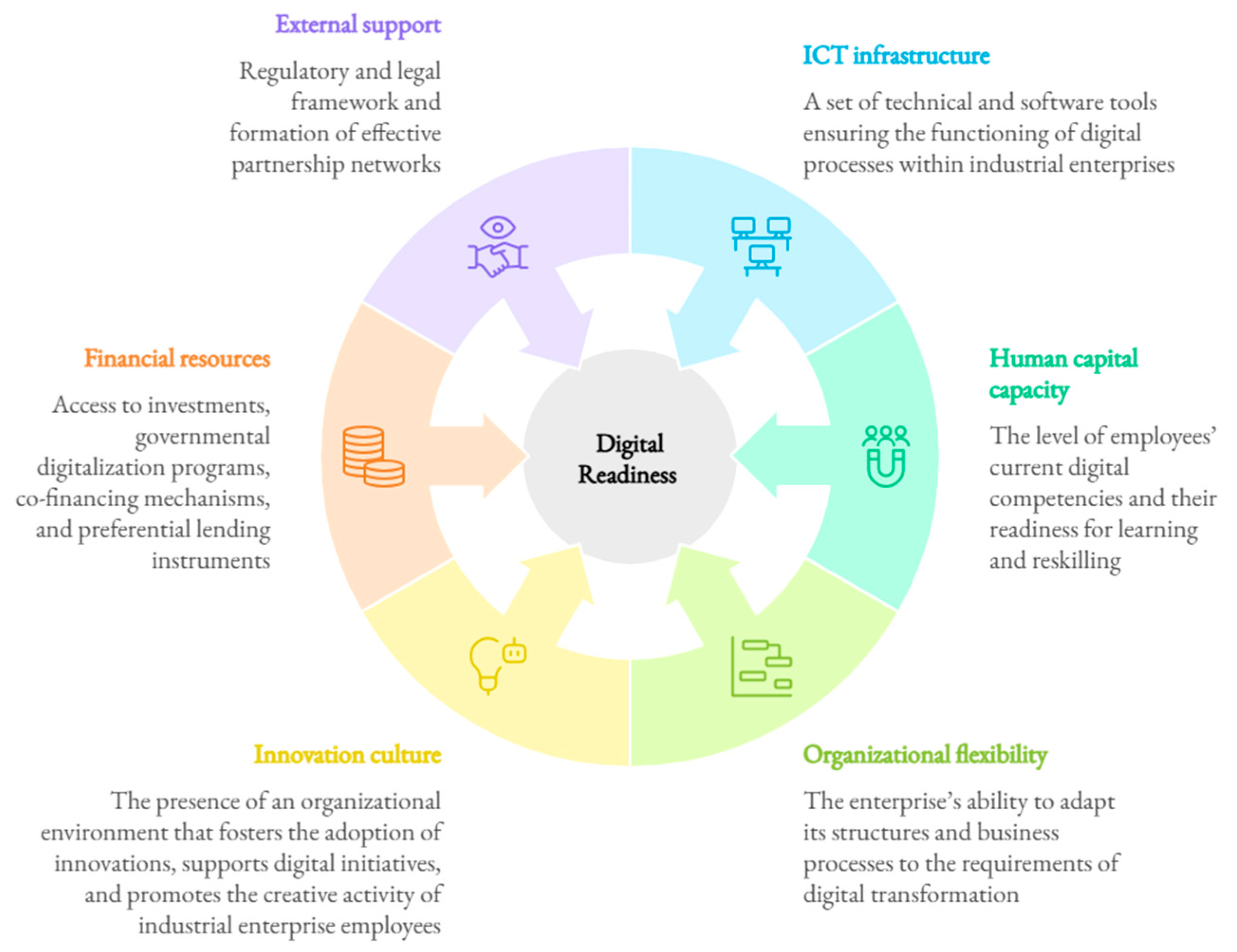

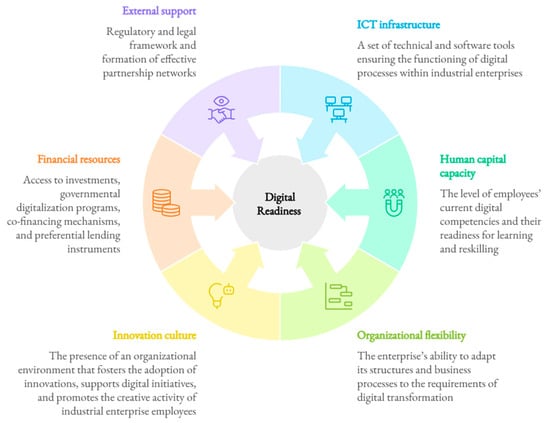

When considering the component structure of digital readiness, it is important to highlight: 1. external support, expressed in the regulatory framework and the formation of effective partnership networks; 2. financial resources, represented by access to investments, state digitalization programs, co-financing and preferential lending mechanisms, as well as opportunities to participate in grant financing and commercialization projects, actively using venture instruments (Figure 2); 3. an innovative culture, including an organizational environment that promotes the acceptance of innovation, support for digital initiatives, and the development of creative activity among industrial enterprise employees. 4. organizational flexibility related to the industrial enterprise’s ability to adapt existing structures, business processes, and digital solutions (including unified digital platforms) to the requirements of digital transformation; 5. human resources potential, which combines the level of current digital competencies of employees and their willingness to learn/retrain; 6. ICT infrastructure, defined as the set of technical and software tools that ensure the successful functioning of the digital processes of an industrial enterprise.

Figure 2.

Elements of digital readiness of an industrial enterprise. Note—compiled by the authors.

Although this study focuses on the development of methodological tools for assessing the digital readiness of industrial enterprises to implement and adapt digital ecosystems, reference to the category of “digital maturity” is essential to ensure the conceptual completeness of the analysis. Digital maturity in this context serves as a kind of target state towards which the digital readiness system is moving; this approach allows us to determine how the set of prerequisites, resources, and organizational mechanisms that form the readiness of an industrial enterprise should be transformed into sustainable results of digital development.

Thus, digital maturity acts as a link between the potential and the result of digital transformation, ensuring methodological continuity between the theoretical foundations and the applied stage of research. Its inclusion allows not only to specify the benchmarks for assessing digital readiness but also to correlate them with the target parameters for assessing the effectiveness of digital ecosystem adaptation, which, in turn, gives the methodology developed in the scientific article systematicity, practical applicability, and analytical depth.

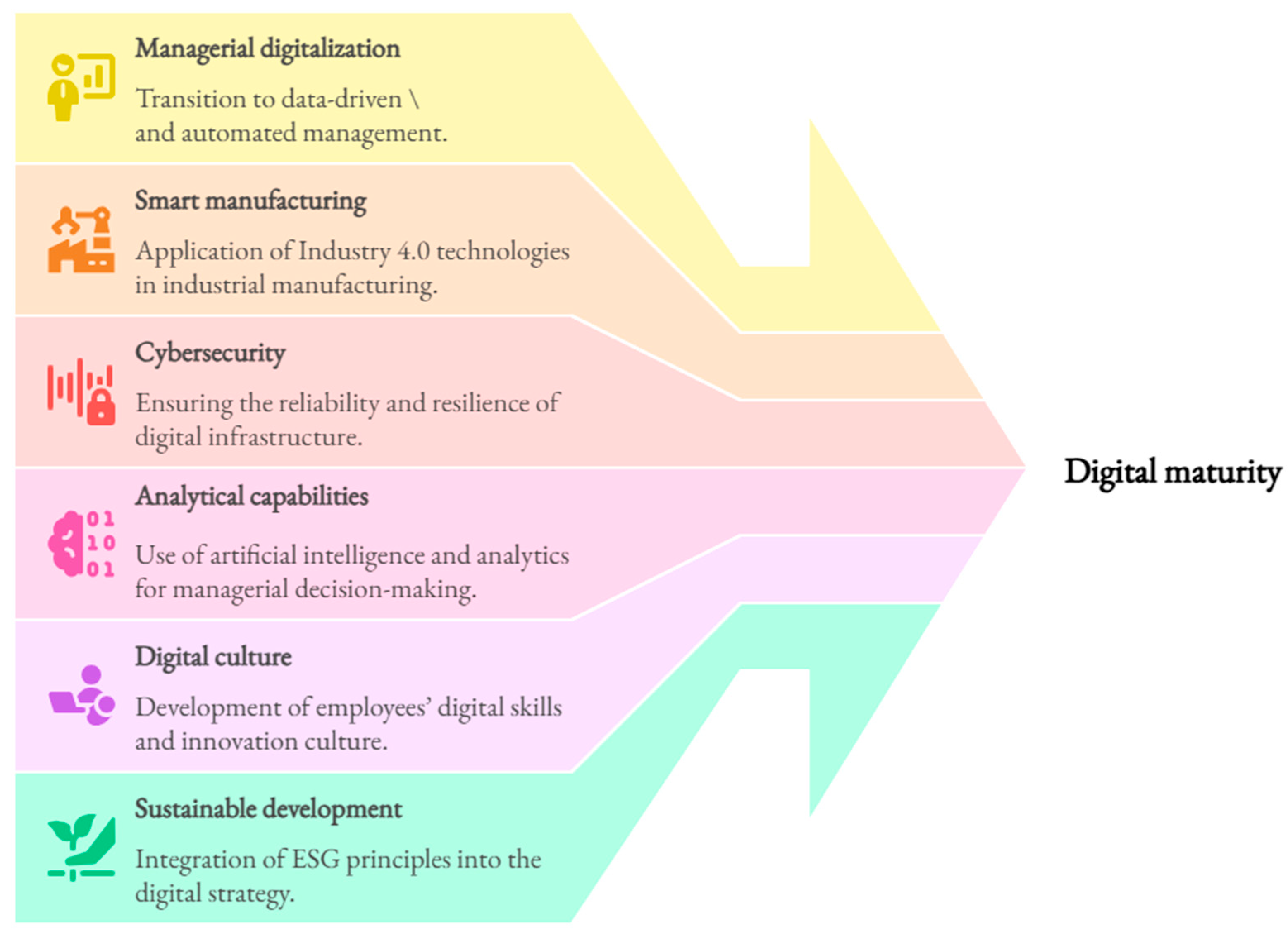

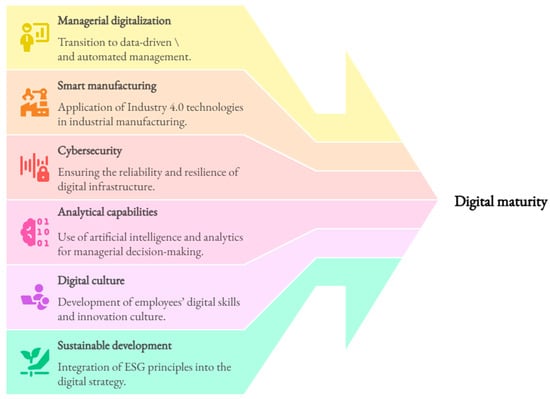

Figure 3 illustrates the components of digital maturity, reflecting the sustainable functioning of digital processes, their integration into the production and management system, and their alignment with the principles of sustainable development, represented by the following components: management digitalization, expressed in the transition of industrial enterprises to models based on data processing and interpretation (including big data) and the introduction of automated control systems; intellectualized production, focused on the use of Industry 4.0 technologies, ensuring the cyber–physical integration of production elements, the application of artificial intelligence and analytical tools, and the formation of end-to-end digital supply chains within a single ecosystem; increased flexibility of production processes, energy efficiency, and sustainability, as well as harmonious interaction between humans and technology; cybersecurity, ensuring the reliability and stability of digital infrastructure; analytical capabilities related to the use of AI and analytics for management decision-making; digital culture, which provides for the development of the necessary digital skills of an innovative staff culture; sustainable development, which involves the integration of ESG principles into the digital strategy of industrial enterprises.

Figure 3.

Elements of digital maturity of an industrial enterprise. Note—compiled by the authors.

Furthermore, to clarify the terminology and subsequently justify the methodological approach that forms the basis of the authors’ system for assessing the level of digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems, it is necessary to conduct a detailed comparative analysis of national and foreign models for assessing digital development, covering a range from nationwide approaches to corporate methodologies.

It should be noted that most of these models were originally developed for macro-level analysis and therefore mainly reflect the state of the digital economy. However, when the object of study is industrial enterprises, as well as, for example, complex integrated structures (e.g., industrial clusters), such generalized characteristics become insufficient; therefore, further assessment requires much greater detail, covering the technical and organizational features of the production environment, personnel specifics, and institutional mechanisms that determine the conditions for the digital transformation of industries, including the industrial sector.

Appendix A shows a comparison of digital readiness models and indices frequently used in global and national practice to diagnose the level of digital development, including industrial enterprises and clusters.

It is important to emphasize that this study focuses primarily on models and indices developed to assess the level of digital readiness, as this indicator allows us to record the initial state of the system and identify the set of factors that determine its ability to perceive, implement, and master digital technologies. In this regard, the analysis of the presented models is particularly significant, as the level of digital readiness forms the basis for the subsequent transition to the next higher stage—digital maturity.

Analyzing the data presented in the table, we can conclude that a review of existing approaches and digital readiness indices (DESI, IMD, OECD, Cisco, Industry 4.0 Readiness Index, etc.) showed that most of the models used are geared towards conducting macro-level analysis of digital readiness, so they allow for assessing the digital development of countries and industries but only reflect to a limited extent the specifics of industrial enterprises as independent entities of the digital ecosystem. Despite the complexity, systematicity, and universality of these methodologies, their practical application in the context of the development of Kazakhstan’s industry faces several challenges, ranging from the high heterogeneity of technological bases and differences in personnel structure to the imbalance of institutional support for digital initiatives, especially across regions.

Overall, given the identified limitations, this study proposes an author’s methodology for assessing the digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems, which comprehensively integrates elements of readiness and maturity concepts within a single systemic model.

The bidirectional nature of ecosystem adaptation is operationalized in the index architecture as follows: internal adaptation is represented by the MTE, ORGSTRPROC, PROD, CYBSEC, and MONCONTR; external ecosystem coordination is reflected through SCM and CUST; and the integration logic linking internal and external contours is enshrined in the STRSDE block (strategic management, goal setting, ESG orientation) and in the interrelationships between blocks. Consequently, these elements enable the measurement of not only the technological capabilities of enterprises but also the extent of their involvement in platform models for value creation and data exchange.

2.3. Digital Ecosystems and Industrial Integration

In the context of modern economic development, the concept of digital ecosystems has become particularly relevant in the industrial economy. Unlike existing traditional organizational models, the ecosystem-based comprehensive approach involves and includes processes related to the interaction of many participants—industrial manufacturers, suppliers, consumers, regulators, and other actors in the industrial sector of the economy, as well as digital platforms within a single space for the exchange of data and values. From a theoretical and practical point of view, an ecosystem can be viewed as a self-organizing and adaptive structure capable of forming and organizing information flows, technological connections, and management decisions.

In 1993, James Moore introduced the concept of a “business ecosystem”, meaning a network of interdependent entities united by the process of joint innovation [56]. Subsequently, a number of scientists and researchers clarified that a digital ecosystem is not just a technological network but a special format of coordination and cooperation, where digital platforms perform the function of adjusting the flows of information, data competencies, and resources [57,58]. Consequently, ecosystems in the digital environment represent a hybrid form of connectivity, as they are used at the intersection of the data economy, industrial platforms, and network management.

Speaking of industry in general, the concept of digital ecosystems has been widely developed within the framework of the Fourth and Fifth Industrial Revolutions (Industry 4.0, Industry 5.0), which perceive digitalization as the basis for the transition from linear production chains to flexible digital networks for the integration of production processes [59,60,61,62]. Within the framework of this approach, it becomes clear that the use of a variety of information and communication tools and digital solutions, such as those represented by artificial intelligence, the industrial Internet of Things, additive technologies, cloud computing, and many others, contributes to the formation of a unique, unified, closed, and effective digital circuit of an industrial enterprise, combining design, production, logistics, and sales functions [63,64,65,66,67,68]. This, in turn, creates the conditions for a completely new type of industrial integration, in which digital platforms begin to act as coordinators and intermediaries between all basic business operations and various stages of the production cycle.

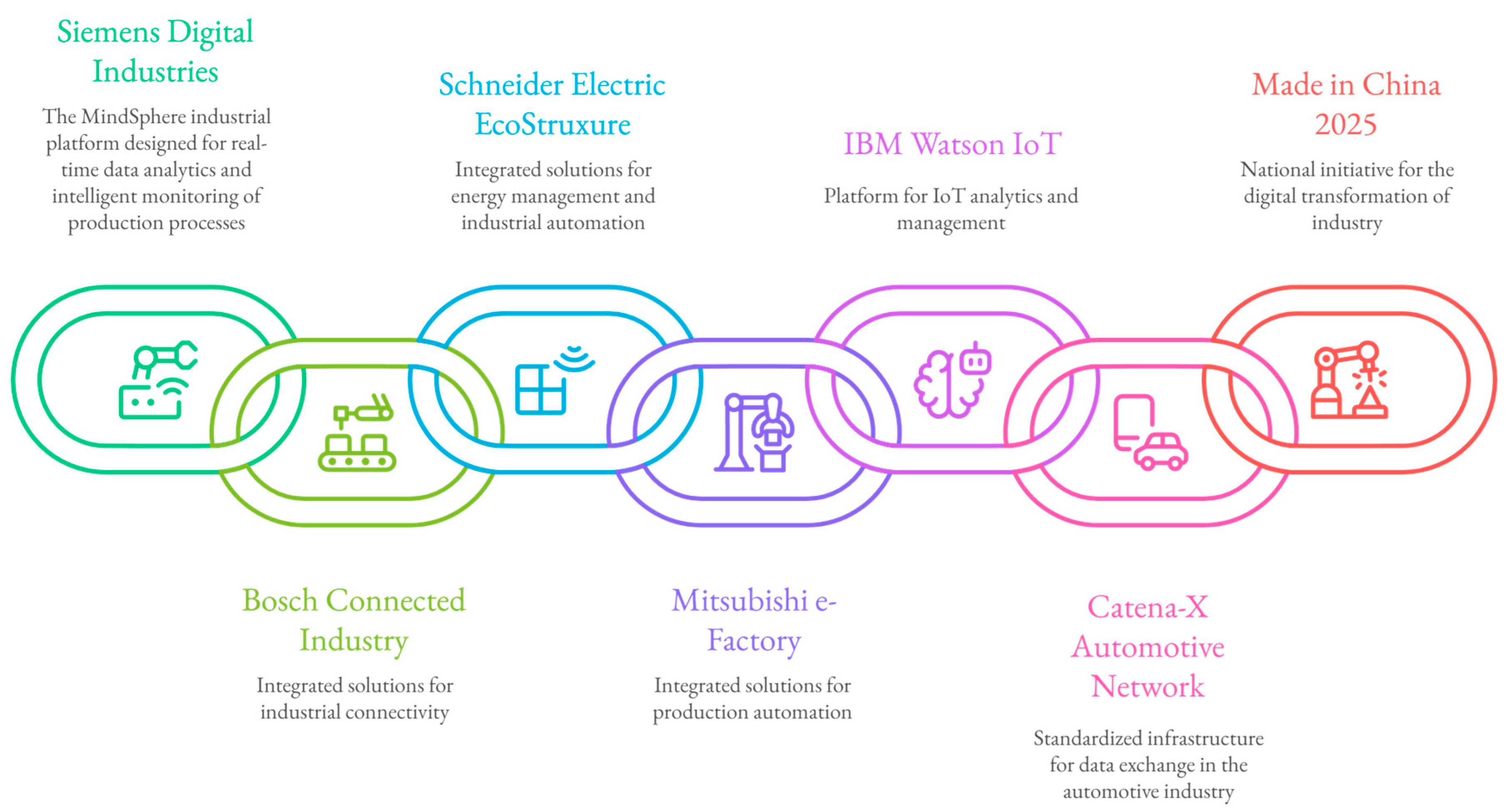

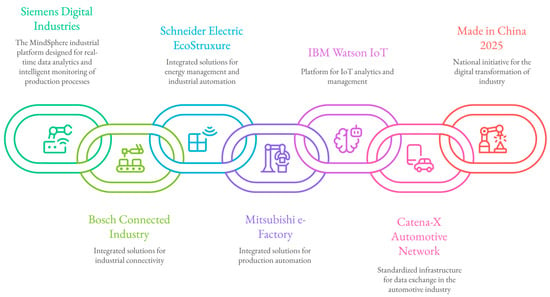

It is also important to note that foreign practice also demonstrates a wide variety of approaches to the formation of digital industrial ecosystems. One example is Siemens Digital Industries (Plano, TX, USA), built on the MindSphere platform, which provides real-time data collection, analysis, and visualization. Similar solutions have also been implemented by companies such as Bosch (Bosch Connected Industry, Stuttgart, Germany), Schneider Electric (Schneider Electric EcoStruxure Platform, Rueil-Malmaison, France), Mitsubishi (Mitsubishi e-Factory, Tokyo, Japan), and IBM (IBM Watson IoT Platform, Armonk, NY, USA) (Figure 4) [69,70,71,72].

Figure 4.

Foreign experience in the formation of digital industrial ecosystems. Note—compiled by the authors.

Another interesting initiative is the European Catena-X Automotive Network, which aims to integrate manufacturers and key suppliers in the German automotive industry by creating a unified, standardized infrastructure for data exchange and joint analytical research [73]. In Asia, the Made in China 2025 digital initiative, which focuses on the formation of digital industrial ecosystems using a variety of ICT tools [74], is significant from both a practical and theoretical point of view.

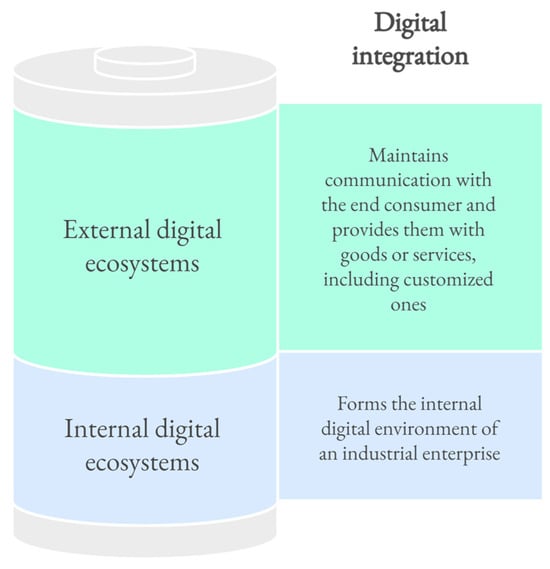

When considering digital ecosystems in the context of industrial integration, it is worth noting that they act as a link between all the processes of an industrial enterprise, both internal and external. At the micro level, they are capable of ensuring vertical integration, ensuring coordination between divisions, departments, and digital services within the company itself. At the meso and macro levels, they enable horizontal integration, which allows enterprises, suppliers, government agencies, research centers, and laboratories to be consolidated into a single digital infrastructure [75,76,77,78].

The analysis shows that theoretical and applied interpretations of the category “digital ecosystem” presented in contemporary literature remain heterogeneous; there is no single scientific approach that would allow for a comprehensive examination of the scientific category under study; in this regard, there is a need to clarify its content in relation to the industrial sphere: “The digital ecosystem of an industrial enterprise is a digital environment in which platform solutions, various digital technologies (usually performing supporting functions), partner services integrated into the unified digital platforms of industrial enterprises, as well as software products that enable the development of goods/services, including customized ones, the implementation of which creates value not only for the end consumer but also for the companies themselves, including in the form of high profit margins, the formation of significant competitive advantages, and, in general, increased competitiveness in the market”.

The following is an operational definition of ecosystem adaptation. In this study, ecosystem adaptation is conceptualized as a dual-direction process that integrates: The enterprise must undergo two fundamental changes. First, there must be an internal transformation of the enterprise’s management, organizational, and technological mechanisms. Second, there must be an external alignment of the industrial digital ecosystem—partners, suppliers, platforms, and infrastructure—with these changes. This interpretation ensures conceptual integrity and prevents discrepancies in meaning when developing a system of indicators, as it links the formation of internal capabilities of the enterprise with external coordination in network interaction.

At the same time, it is appropriate to understand a “digital platform for an industrial enterprise” as a unified digital platform, the functioning of which is implemented through the introduction and adaptation of standardized or specialized software (usually developed for the specific needs and requirements of an industrial enterprise), including a set of modern information and communication technologies for data collection, processing, and analysis, such as IIoT, Big Data, Blockchain, artificial intelligence, machine learning, digital modeling and prototyping, as well as other tools that ensure the functioning of digital processes necessary to provide effective connectivity between all services, departments, divisions, partner services, and customers of the company.

The paper also identified the characteristics and implemented a classification of digital ecosystems:

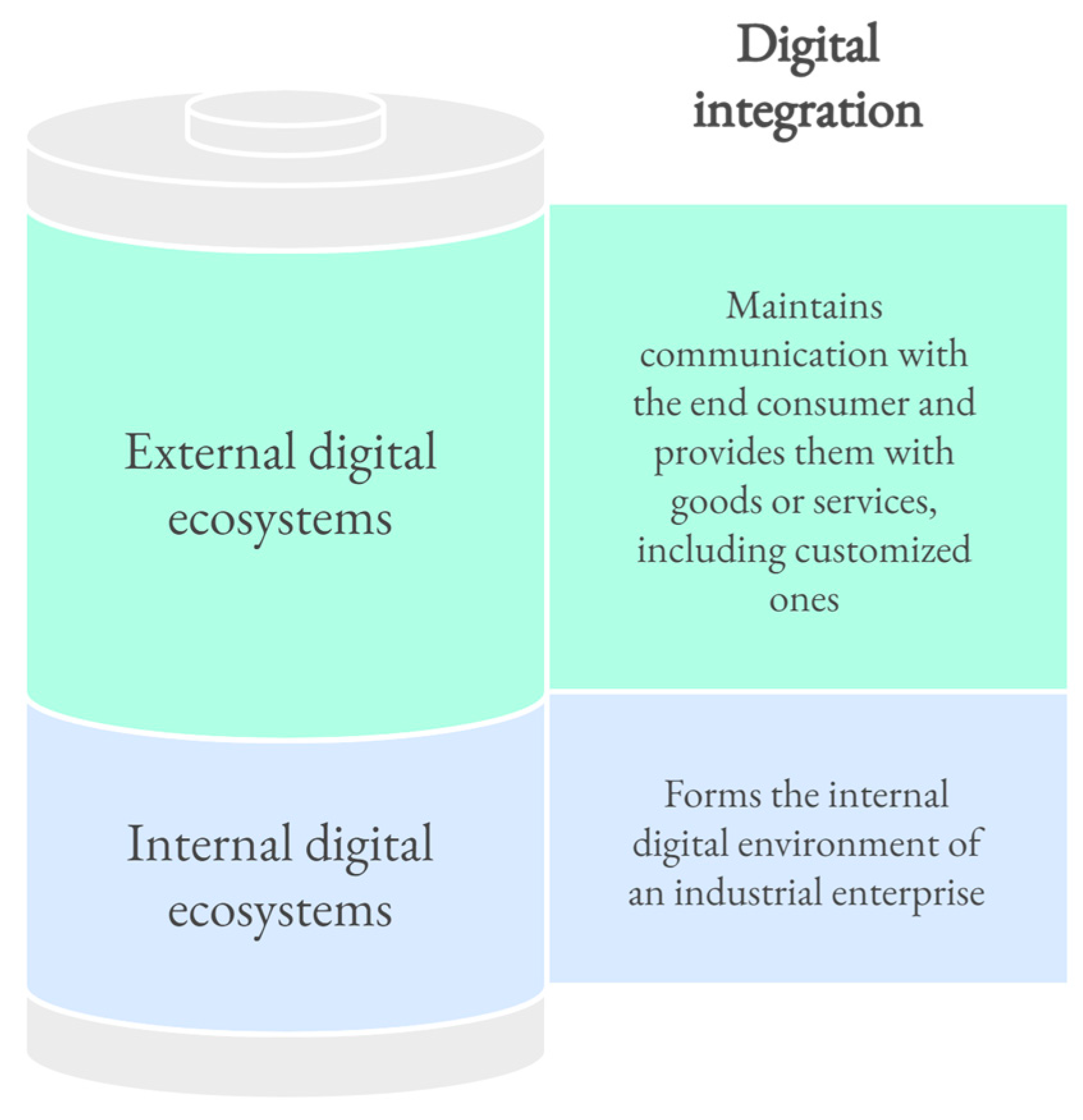

- (1)

- Functional levels: The first is represented by digital platforms and tools that form the internal information and digital environment of an industrial enterprise, cluster, or other integrated production structure; they ensure the coordination and efficiency of interaction between all participants in the ecosystem. The second level covers external digital platforms—marketplaces, corporate websites, social media pages, and other online channels used to communicate with end consumers and sell products or services, including individualized and customized offers (Figure 5).

Figure 5. Classification of digital ecosystems by functional levels. Note—compiled by the authors.

Figure 5. Classification of digital ecosystems by functional levels. Note—compiled by the authors.

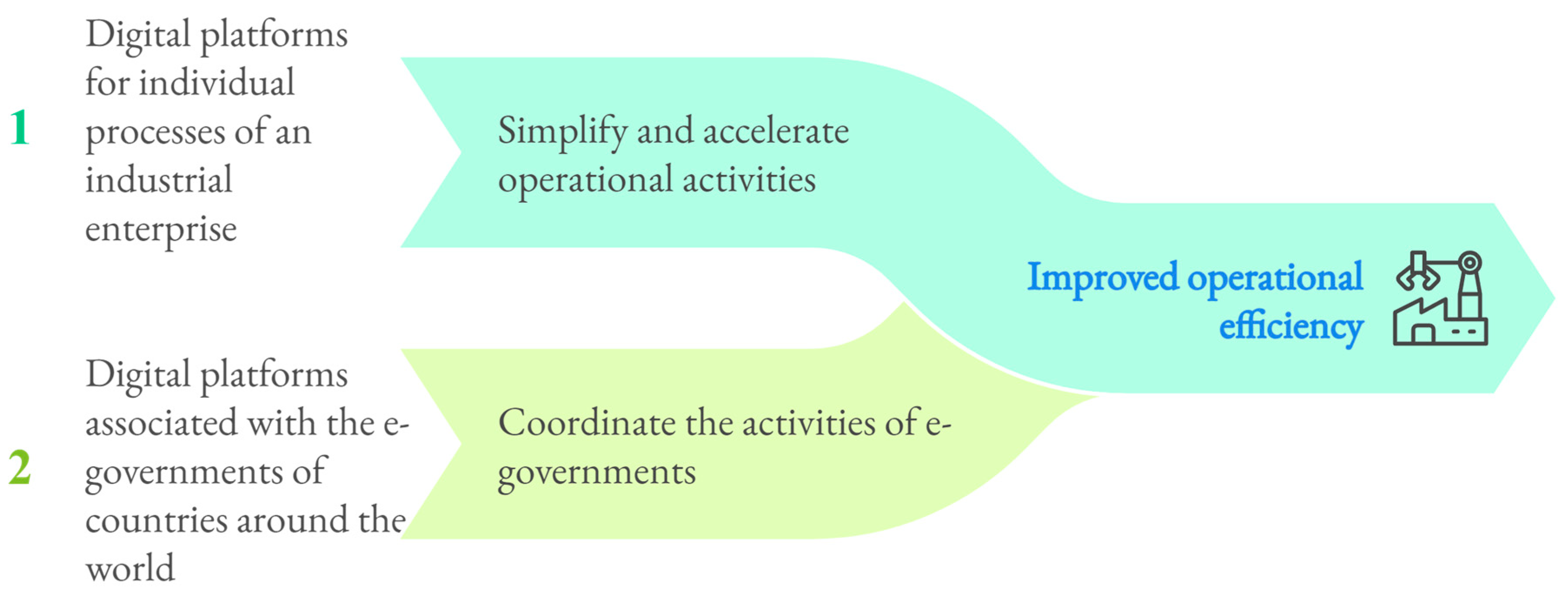

- (2)

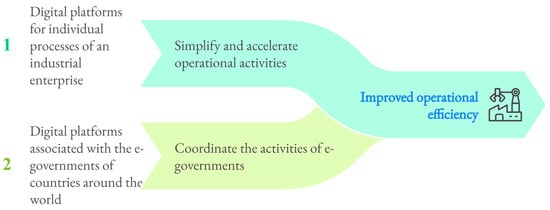

- Application level: This includes digital platforms designed to support individual business processes and aimed at improving their efficiency and effectiveness, as well as comprehensive digital solutions that coordinate the activities of e-governments in different countries and facilitate interaction between government, corporate, and public structures in the digital space (Figure 6).

Figure 6. Classification of digital ecosystems by application level. Note: compiled by the authors.

Figure 6. Classification of digital ecosystems by application level. Note: compiled by the authors.

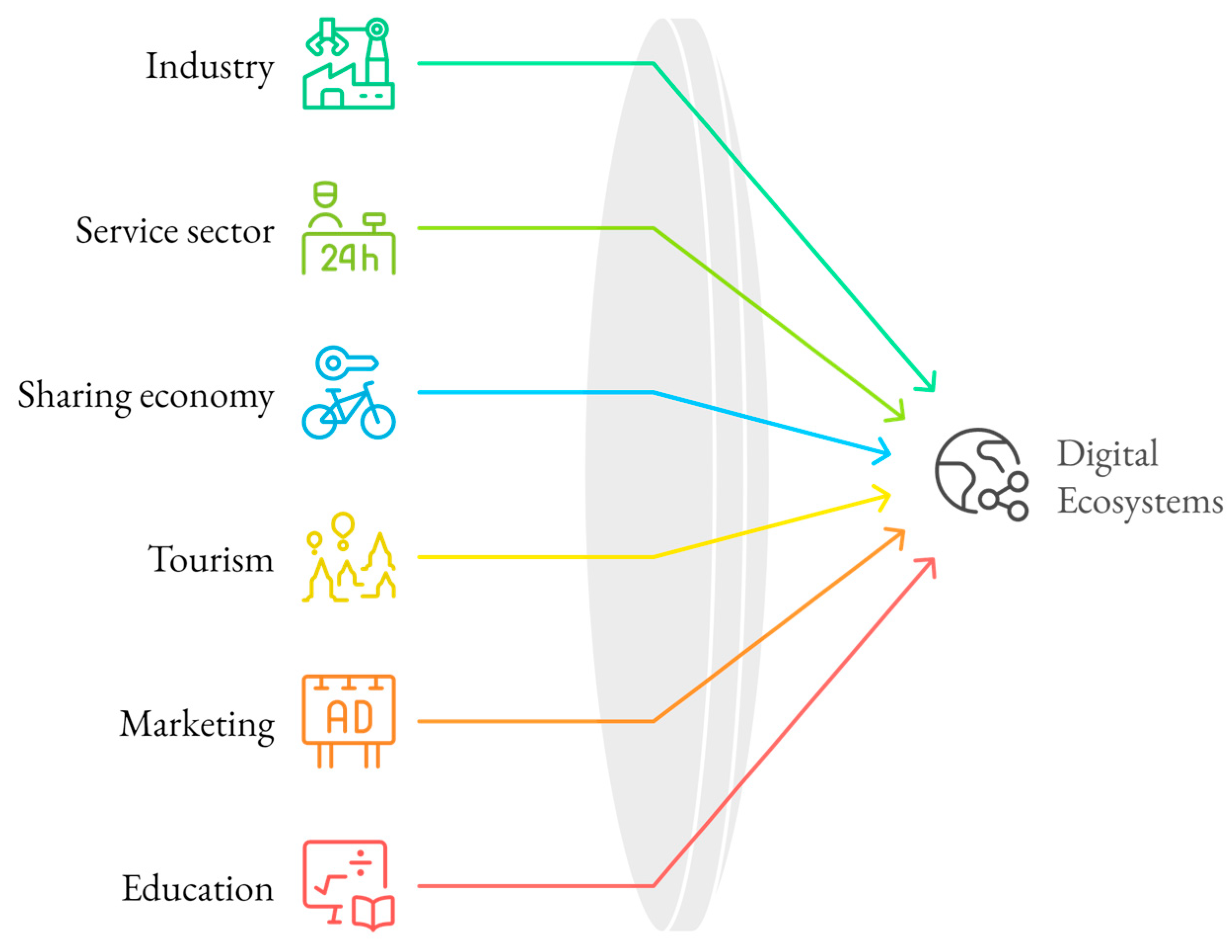

- (3)

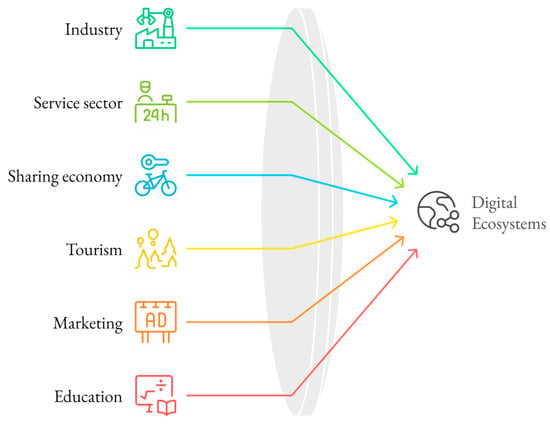

- Scope of application: Industry, services, sharing economy, tourism, marketing, education, transport, technical design and development of architecture for various software products and applications, smart systems, and many others (Figure 7).

Figure 7. Classification of digital ecosystems by area of application. Note—compiled by the authors.

Figure 7. Classification of digital ecosystems by area of application. Note—compiled by the authors.

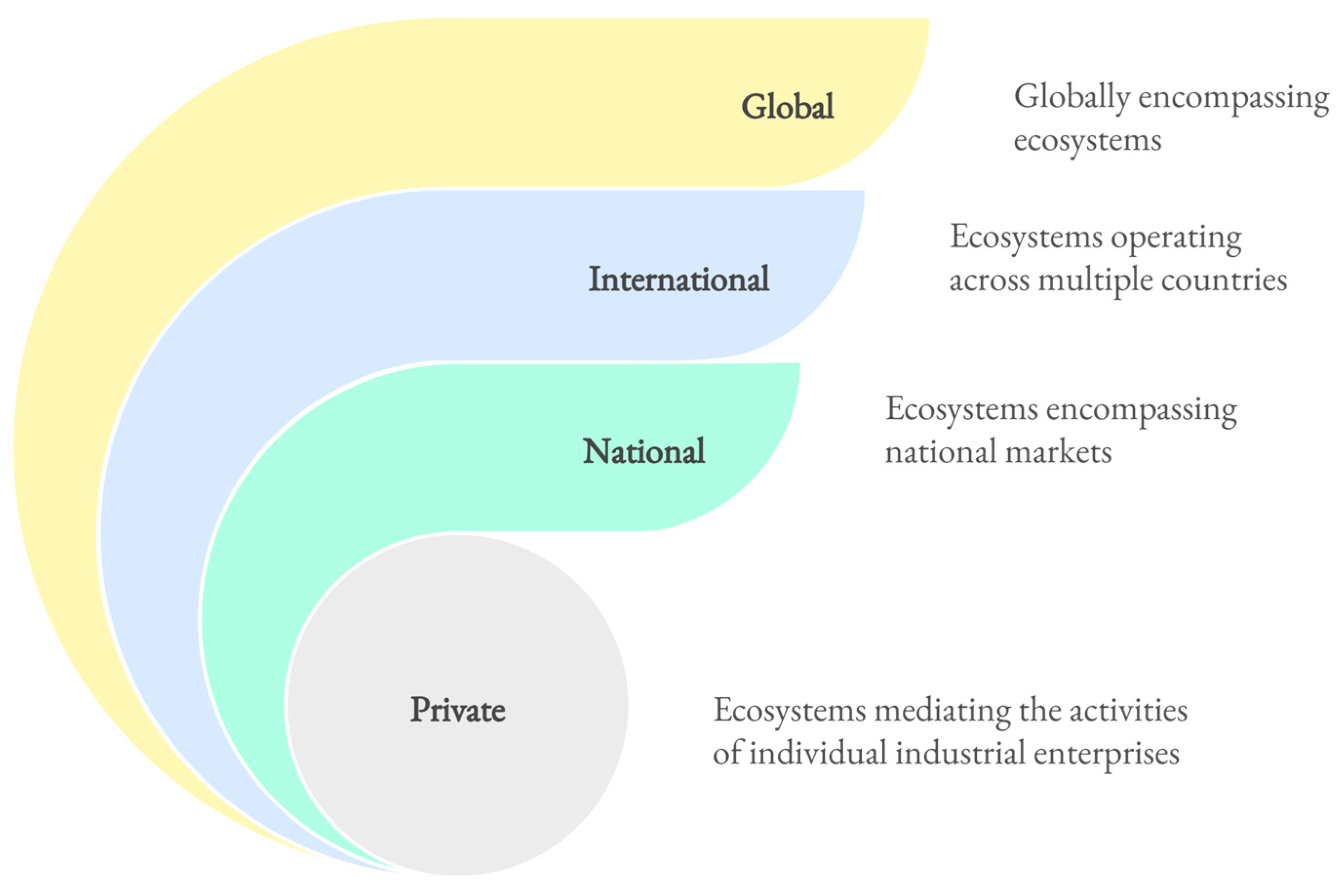

- (4)

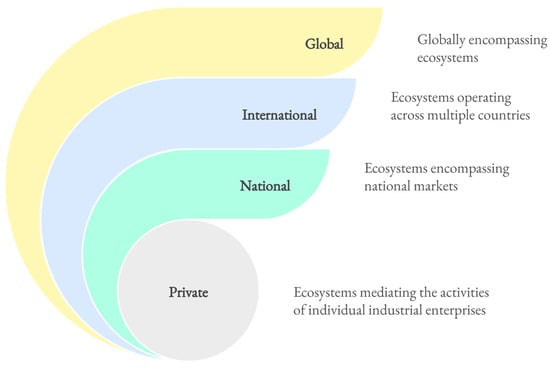

- The scale of an industrial enterprise’s operations: A distinction is made between global and international digital ecosystems, which encompass transnational connections and the integration of global market participants; national and regional systems that provide digital interaction within a country and between its individual territories; as well as local or corporate ecosystems that operate in the internal digital environment of a specific enterprise and serve its internal production and management processes (Figure 8);

Figure 8. Classification of digital ecosystems by scale of industrial enterprise activity. Note—compiled by the authors.

Figure 8. Classification of digital ecosystems by scale of industrial enterprise activity. Note—compiled by the authors.

- (5)

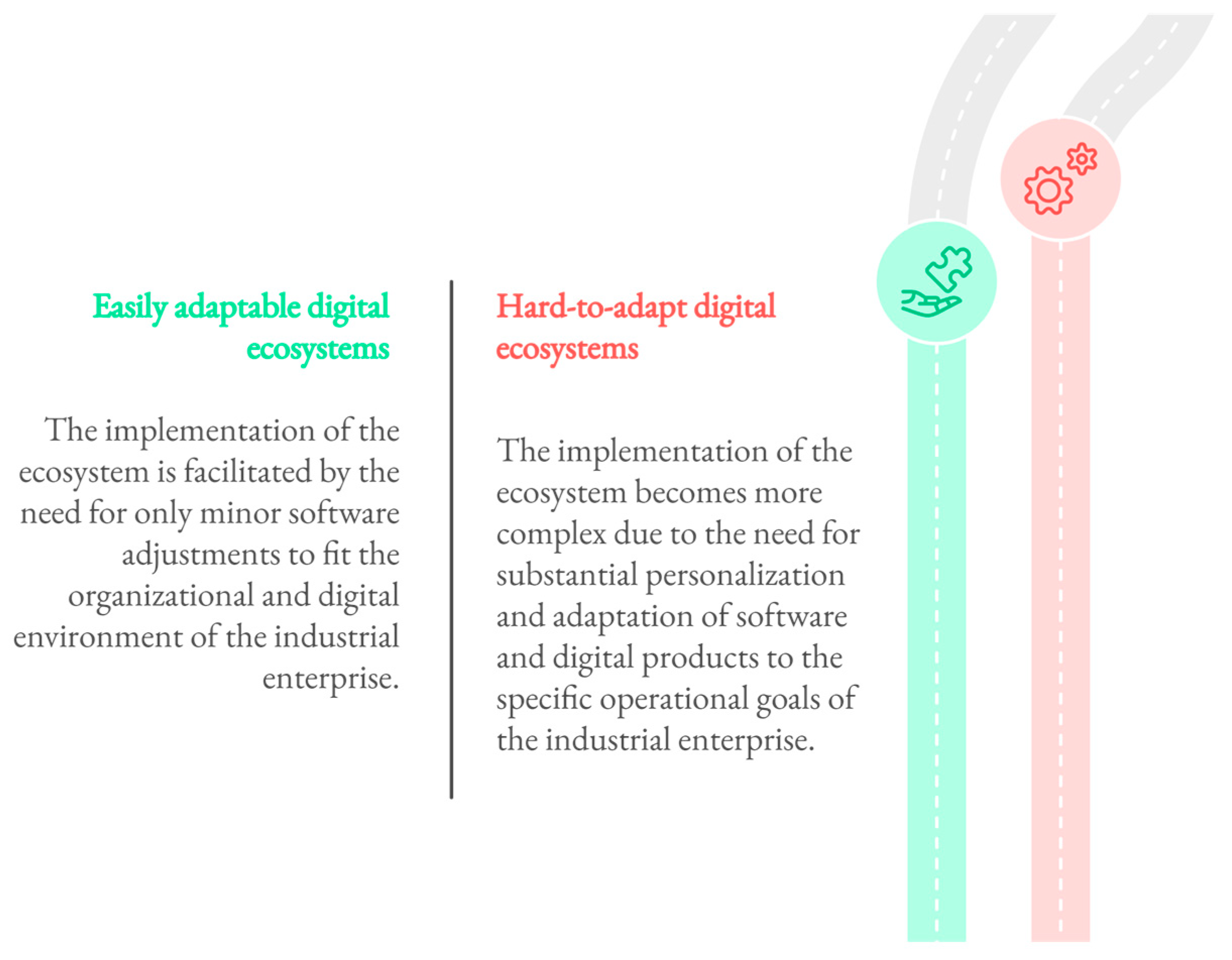

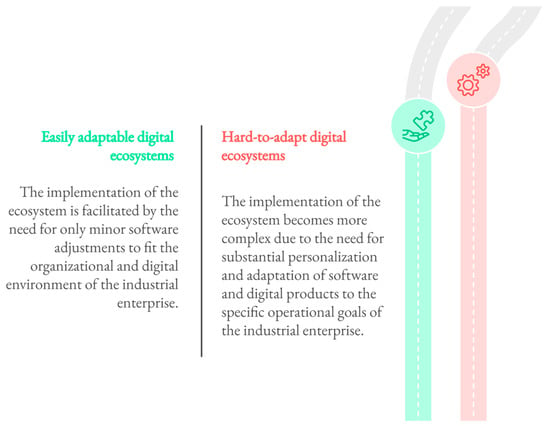

- Adaptability (in the context of developing and implementing digital ecosystems): Easily adaptable digital ecosystems, characterized by the ability to integrate into the organizational and digital infrastructure of an industrial enterprise without significant modifications, limited to minimal software configuration for specific user requirements; difficult-to-adapt digital ecosystems that require deep personalization, reworking of software modules, and refinement of digital solutions in accordance with the characteristics of the production processes, management structure, and technological capabilities of a particular enterprise (Figure 9);

Figure 9. Classification of digital ecosystems based on their adaptability. Note—compiled by the authors.

Figure 9. Classification of digital ecosystems based on their adaptability. Note—compiled by the authors.

- (6)

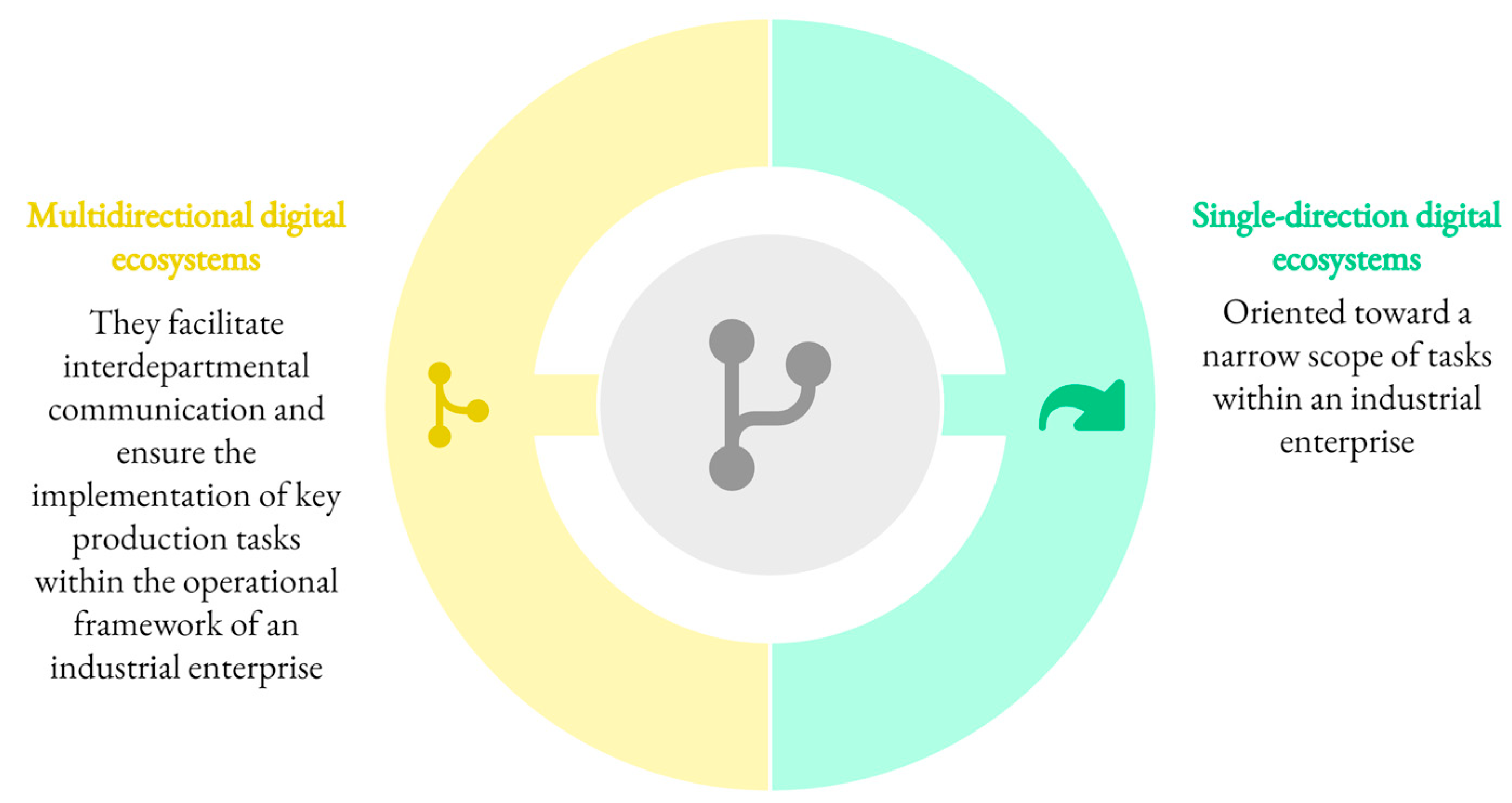

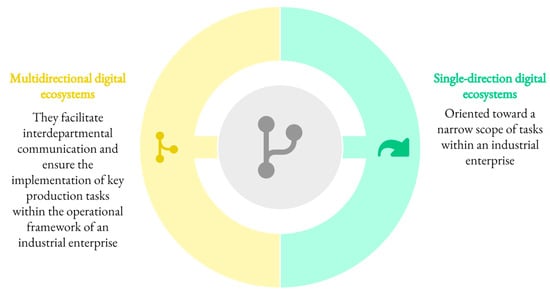

- Qualitative composition (nature of ICT included in the architecture of the digital ecosystem): Unidirectional, focused on solving a limited range of tasks of an industrial enterprise, for example, increasing the efficiency of individual production sites or automating a specific technological process (as in the case of robotic workshop management); multi-vector, ensuring comprehensive interaction between different divisions of the enterprise, integration of production, management, and analytical functions, as well as support for key business processes, including development, production, and sales of products (including on the basis of the “digital factory” concept) (Figure 10).

Figure 10. Classification of digital ecosystems according to their qualitative composition. Note—compiled by the authors.

Figure 10. Classification of digital ecosystems according to their qualitative composition. Note—compiled by the authors.

It should be noted that the expanded number of graphic materials in this section is not excessive but represents a conscious methodological choice by the authors of this scientific work, since in the absence of systematic and large-scale comprehensive studies devoted to the study of the essence and classification of digital ecosystems in industry, visualization performs not only an illustrative but also a conceptualizing function, allowing us to build a holistic view of the multi-level structure of the scientific problem under study. Thus, the graphic design used serves not so much as an auxiliary element of presentation but rather as an independent tool for analytical interpretation, forming the methodological basis for the next stage of research.

The data from the analysis show that digital ecosystems are gradually forming the basis of the modern model of industrial development, acting as a systemic element of market reforms and digital transformation. They contribute to the integration of technological, organizational, managerial, financial, economic, logistical, innovative, research, marketing (including communication), information and analytical, environmental, and social processes. This integration creates conditions for the joint development of ecosystem participants, increasing their competitiveness and the sustainable inclusion of industrial enterprises in the digital economy.

The proposed system for assessing the digital readiness of enterprises is directly correlated with the theoretical model of digital ecosystems. Each type of ecosystem—internal, external, and multi-vector—is reflected in the index structure through corresponding groups of indicators.

Internal ecosystems characterize the level of digitization of production and management processes, as well as the degree of integration of digital solutions into the internal contours of the enterprise.

External ecosystems reflect the ability of organizations to network, exchange data, and participate in platform models that form new channels of communication and cooperation.

Multi-vector ecosystems describe a high level of organizational flexibility, where digital technologies become a connecting element between different functions, partner structures, and value chains.

This expansion of the theoretical framework has bridged the gap between the conceptual apparatus of the ecosystem approach and the empirical tools for measuring digital readiness.

In other words, the digital readiness index reflects not only the technological capabilities of enterprises but also the degree of their involvement in ecosystem connections, which form the basis for assessing their adaptive potential in the context of digital transformation.

2.4. Customization and Flexible Manufacturing as Drivers of Digital Ecosystem Adaptation

In the context of Industry 4.0, the industrial sector is witnessing a transition from traditional business models of mass production to systems characterized by a customized component focused on individual consumer demands in the B2B, B2G, and B2C markets. This transition largely reflects the need to form a new production structure, within which customization does not perform an additional function but becomes an integral part of the modern system of industrial enterprise organization. The essential characteristics of customization allow us to conclude that it involves maintaining the scale of mass production while simultaneously adapting the final product to the needs of a specific customer [79,80,81,82,83,84]. This approach can be implemented using modern digital solutions, including those represented by digital ecosystems, which ensure the effective and flexible integration of processes related to design, production, and market interaction in a unified information space.

It should be noted that it is in the ecosystem environment that connectivity between manufacturers, suppliers, and end users is created, which allows for the timely exchange of data, making it possible to ensure the rapid adjustment of all production processes taking place at an industrial enterprise. For example, the widespread use of unified digital industrial platforms that combine elements of smart manufacturing, digital twins, predictive analytics, big data, and many others within their infrastructure contributes to the synchronization of decisions in real time. Thus, enterprises receive a kind of universal “resource” for quickly responding to current, latent, and potential market demands, building new forms of partnership, and transitioning to innovative business models based on joint value creation [85,86,87,88,89,90,91].

In turn, flexible manufacturing in the context of the digital industrial ecosystems under consideration and study acts as an adaptation mechanism, as it reduces dependence on the impact of macroenvironmental factors, minimizes costs, and ensures the rational use of resources, which, in turn, contributes to the sustainability of industrial enterprises, forming a competitive advantage for the rapid restructuring of technological, logistical, and management processes. Flexibility is a key element not only of economic efficiency but also of environmental balance, which is particularly important in the context of the transition to sustainable development principles [92,93,94,95,96].

To summarize, it can be concluded that in today’s economic realities, customization and flexible production approaches are key factors determining the ability of digital industrial ecosystems to adapt and develop sustainably, as they enable enterprises to set up effective processes for interaction in a network environment, integration into digital value chains, and timely response to changing market conditions.

Overall, given the significance of the trends identified, it seems necessary to ascertain the extent to which issues related to digital transformation and industrial sustainability are being explored in contemporary scientific discourse, assessing the digital readiness and maturity of enterprises, the formation and functioning of digital ecosystems, industrial integration, customization, flexible production systems, and ensuring their sustainable functioning. In this regard, we turn to scientometric analysis, which will allow us not only to record the quantitative parameters of publication activity but also to identify areas of scientific focus, the dynamics of the development of the terminological field, and the degree of integration of the concepts under consideration into the international research space. It is precisely this comprehensive approach, in the opinion of the authors of this work, that can provide a holistic understanding of the degree to which the problem has been studied and serves as the basis for the subsequent generalization of scientific results in the context of assessing the readiness of industrial enterprises to implement and adapt digital ecosystems in the context of globalization, digital transformation, and ensuring the principles of sustainability in the industrial sector of the economy.

2.5. Bibliometric Evidence of the Research Gap

The theoretical and analytical review above formed a conceptual basis that reflects and, to some extent, explains the existing relationship between digital readiness, maturity, digital transformation, and industrial integration; customization of industrial production (including the essence of the “flexible manufacturing” approach); and ecosystem adaptation of industrial enterprises. However, despite the obvious logical connection between the identified economic categories, there is still a methodological disconnect in their study in the global scientific literature. Thus, publications on digital transformation, digital readiness, and ecosystem mechanisms are mainly developed in parallel directions (IT and manufacturing), which undoubtedly complicates the development of a unified methodology and algorithm for assessing the digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems. In this regard, to empirically confirm this position, a bibliometric analysis was conducted, the task of which was to record the scale and nature of research activity within the framework of the scientific problem under study to identify thematic links between key identified concepts, as well as gaps based on which such an adaptive methodology could be formed.

The analysis was conducted using data from the Web of Science scientometric database (period: 2010–2025); to ensure the comparability of results, obtain a representative sample, and identify research gaps, a three-level search principle was used, which allowed us to narrow down the research array step by step from the general context of the digital transformation of industry to a highly specialized one related to issues of digital readiness and adaptation of industrial enterprises to the introduction of digital ecosystems, especially with regard to ensuring the achievement of sustainable development goals (Table 1).

Table 1.

Comparative characteristics of search levels within the framework of the scientometric analysis.

It should be noted that the choice of the time range—2010–2025—is dictated by the logic of the evolution of scientific discourse, since it was during this period that the concept of Industry 4.0 acquired practical significance and laid the foundation for the transition from scattered research on digitalization to a systematic understanding of issues of digital readiness and ecosystem integration in industry.

At the first level, a generalized query (broad context) was used, including such key terms as “digital transformation”, “digitalization”, and “Industry 4.0”, in combination with indicators of sustainable development (sustainability, ESG, SDG) and industrial production (manufacturing, industry). The resulting data set (7708 works) made it possible to identify general trends and dynamics of scientific interest in digital transformations in industry, as well as to determine the extent to which the issues under study are involved in the ESG agenda.

At the second level (refined context), the search was narrowed down by focusing on the categories of digital readiness and digital maturity, which made it possible to identify works related to issues of measuring and diagnosing the level of digital readiness of enterprises and industries, including the industrial sector.

At the third, most narrow level (narrow context), the search query was aimed at identifying publications in which digital readiness and maturity were correlated with the concepts of digital ecosystem and ecosystem adaptation, as well as with the components, elements, and methods of sustainable development. This approach made it possible to empirically identify the degree of correlation between the categories under study and to determine the presence or absence of a comprehensive approach to assessing the readiness of industrial enterprises to adapt to digital ecosystems, i.e., to identify a research gap.

A comparative analysis of three levels of search queries revealed a clearly identifiable asymmetry in the research on the degree of study of the issue under consideration. Despite the rapid growth in the number of publications on digital transformation and ESG-oriented development, the number of studies combining the categories of digital readiness, digital maturity, and ecosystem adaptation remains low. Thus, the identified gap between theoretical approaches and applied methodologies confirms the need to develop a comprehensive system for assessing the digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems, which determines the relevance and novelty of the authors’ methodology.

For further processing of the obtained data arrays, VOSViewer software (version 1.6.18.0, Centre for Science and Technology Studies, Leiden University, Leiden, The Netherlands) was used, which made it possible to construct maps of joint mentions of key terms (co-word analysis method), identify thematic clusters, and analyze the degree of connectivity between the basic concepts identified. The visualizations obtained also made it possible to establish the process of forming a conceptual intersection of the areas under study and the degree of integration in international literature of such concepts as “digital readiness”, “digital maturity”, and “ecosystem adaptation”.

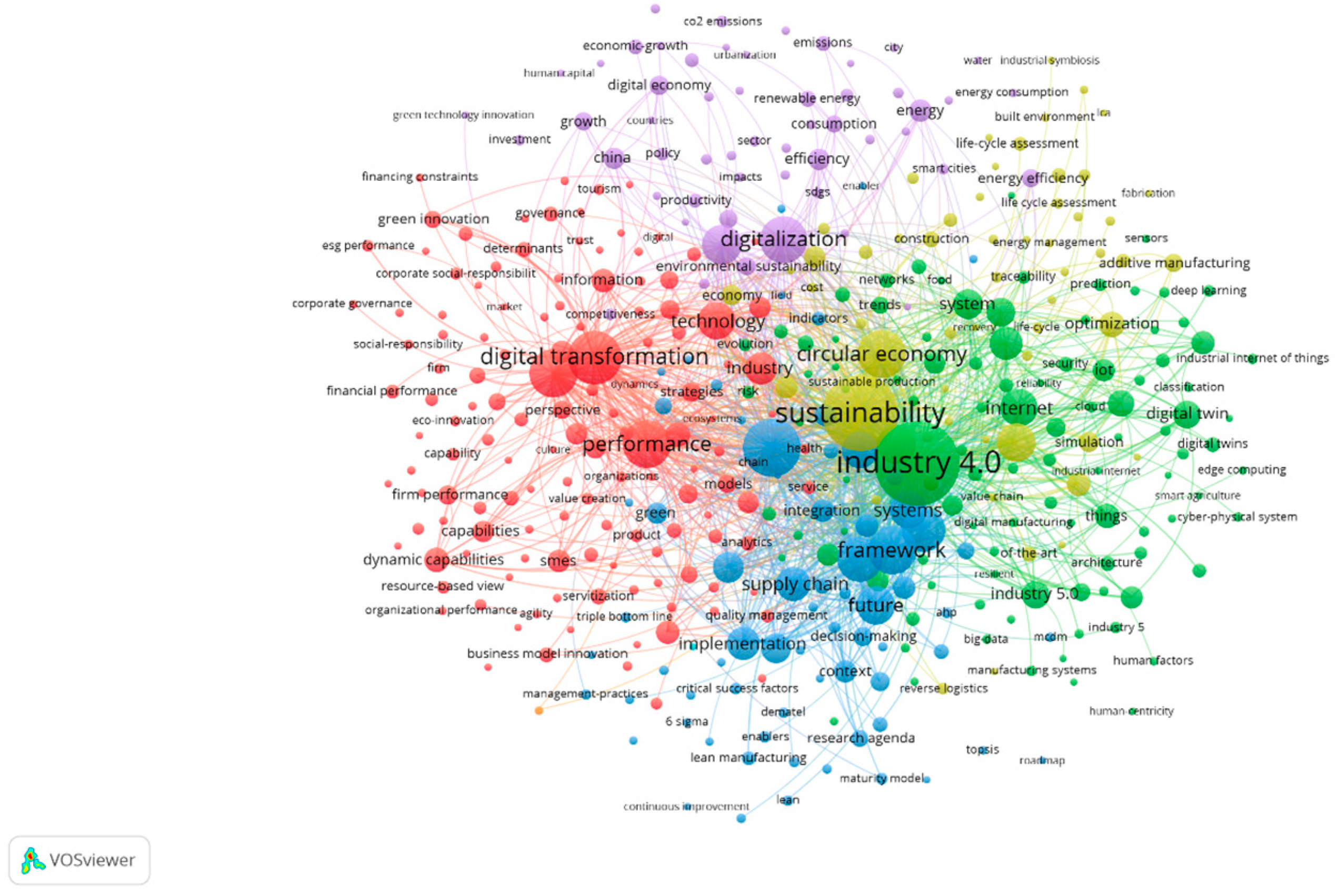

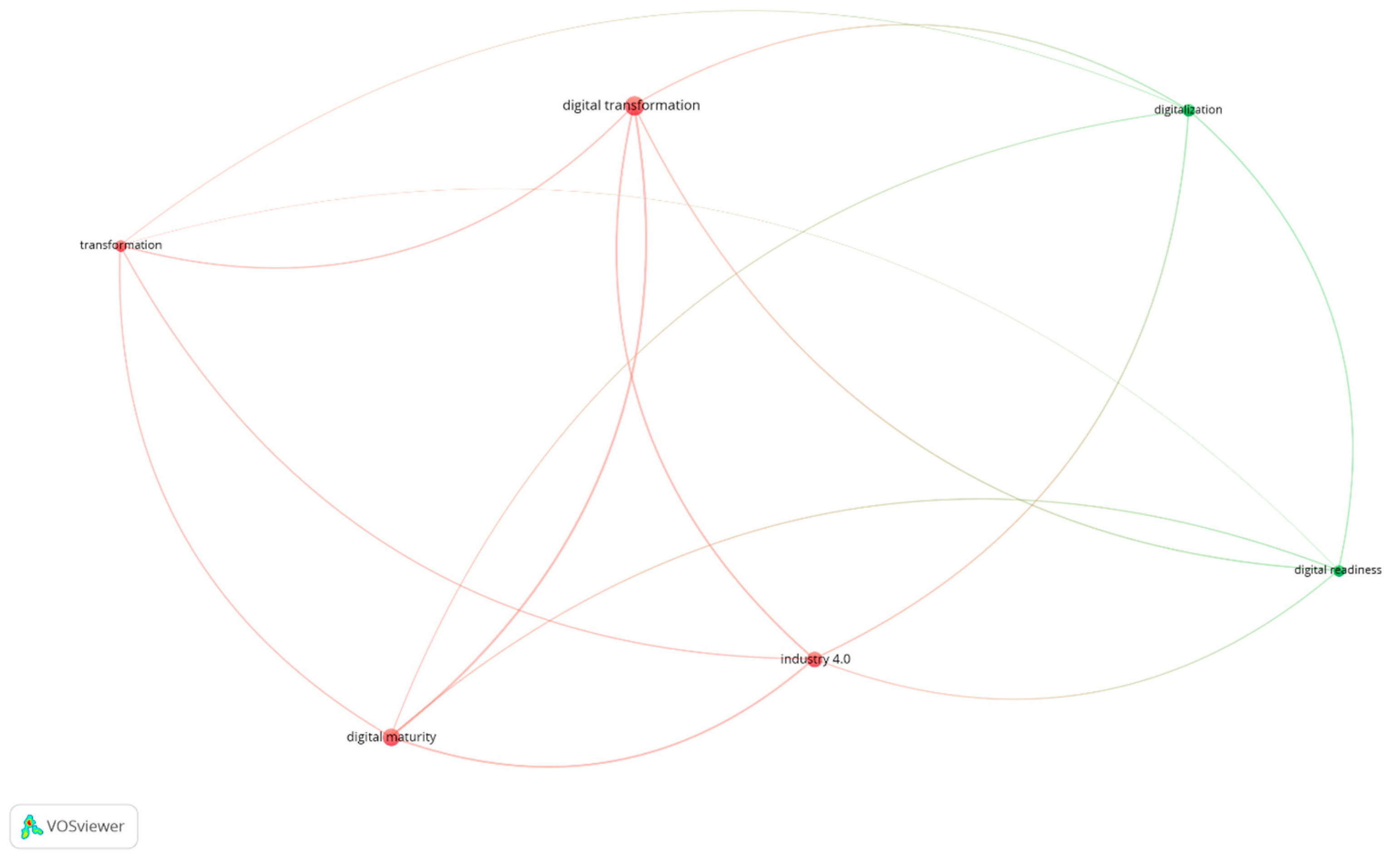

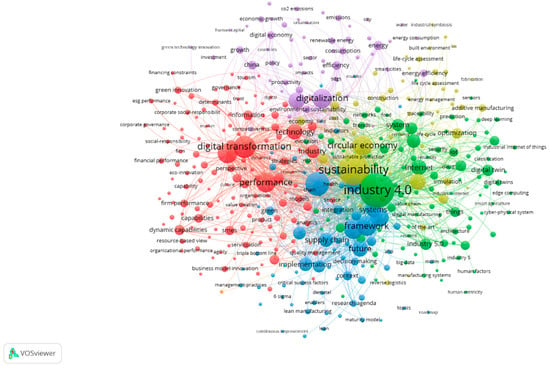

To identify the internal structure of the broad context research field, an analysis of the co-occurrence of keywords in 7708 publications indexed in the Web of Science database was performed. The map, constructed in VOSViewer and presented in Figure 11, reflects the semantic connections between the most frequently used terms and allows us to visualize the dominant directions of scientific discourse in the field of digital transformation and sustainable industrial development.

Figure 11.

Map of co-occurrence of keywords (co-word analysis) in publications of a broad context (n = 7708). Note—compiled by the authors based on data from the Web of Science scientometric database using VOSViewer software.

Figure 11 allows us to identify several stable clusters, each of which represents a separate thematic area; thus, the largest node is formed by the concepts of “Industry 4.0”, “sustainability”, and “digital transformation”, which define the core of the entire research field. The red cluster, in turn, includes terms related to performance management and corporate strategies (performance management, dynamic capabilities, firm performance), which are closely linked to the managerial interpretation of digital transformation. The third cluster, green, covers technological aspects and modern digital solutions—smart manufacturing, digital twin, cyber–physical systems, and machine learning—representing the digital, technological, and engineering production aspects of research. The blue cluster brings together topics related to framework, implementation, and integration, indicating a desire to develop methodological models for digital industrialization.

It is interesting to note that the spatial proximity of the concepts of “sustainability” and “Industry 4.0” shows the interconnection between the agendas of digitalization and sustainable development, while categories reflecting ecosystem mechanisms (“ecosystem”, “adaptation”) are located on the periphery, which indicates that ecosystem logic has not yet been systematically developed in the data set under consideration.

The peripheral position of the terms “ecosystem” and “adaptation” on the co-occurrence map reflects the specifics of the current stage of research into digital transformation.

These concepts do not yet have uniform quantitative definitions and are more often used in conceptual rather than empirical contexts.

The complexity of their operationalization is related to the multi-level nature of ecosystem connections and adaptation processes, which go beyond the scope of traditional business statistics.

At the same time, the methodology proposed in the study includes parameters that capture the ecosystem aspects of digitalization, the use of cloud technologies, participation in digital platforms, and data exchange between organizations.

This allows these categories to be transferred from the theoretical level to a measurable analytical space and partially overcomes the identified imbalance.

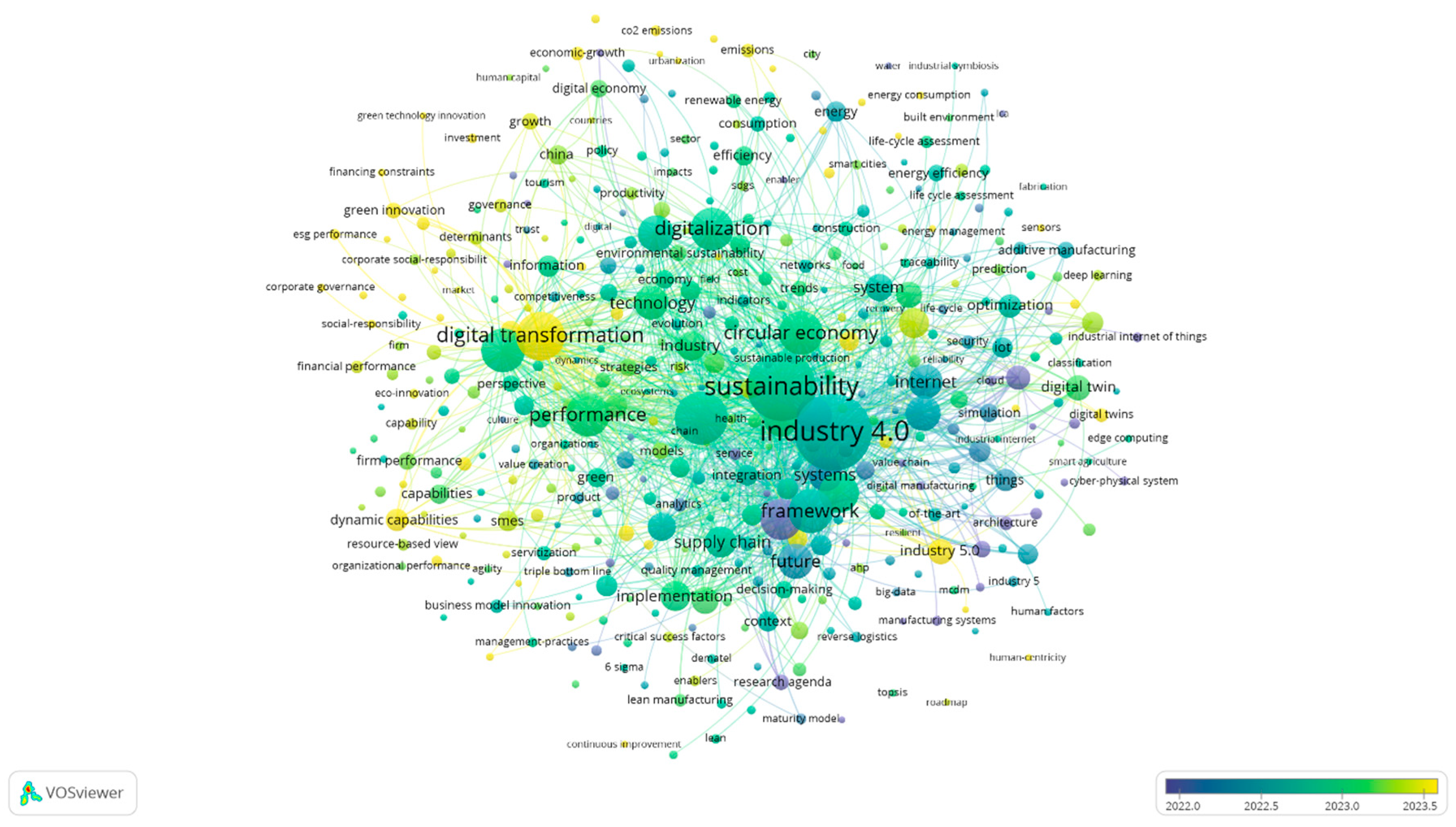

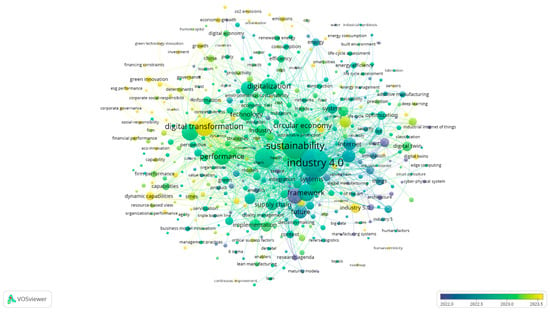

Next, to analyze the temporal evolution of key research areas, we used an overlay visualization map based on the same publications, where color gradation reflects the average year of appearance of terms and allows us to trace how the focus of scientific attention shifted between 2010 and 2024 (Figure 12).

Figure 12.

Temporal dynamics of scientific development in a broad context (based on VOSViewer data; n = 7708). Note—compiled by the authors based on data from the Web of Science scientometric database using VOSViewer software.

The chronological structure presented in the figure shows a gradual transition from early technological concepts to more complex socio-economic interpretations of digitalization. The terms in the blue spectrum, which appeared mainly before 2016 (“digitalization”, “technology”, “efficiency”), reflect the emergence of interest in the technical possibilities of automation and digitalization. Since approximately 2018, interest in issues of sustainable development and corporate responsibility has been growing, as reflected in the dominance of green-yellow contextual nodes (“sustainability”, “ESG performance”, “circular economy”).

In the final stage (2021–2024), new areas directly related to the concept of Industry 5.0 are established in the structure under consideration, and digital tools—“digital twin” and “resilient manufacturing”—emphasize the shift in research focus towards a human-centered and adaptive model of industry in the context of digital transformation and market globalization. The resulting dynamics confirm that the scientific agenda is gradually and consistently moving beyond technological digitalization to include issues of sustainability, integration, and the readiness of enterprises to implement and adapt digital ecosystems.

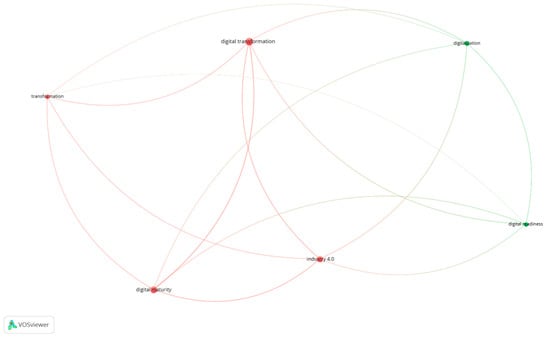

Furthermore, to clarify the logic of forming a conceptual field reflecting the issues of digital readiness and maturity of industrial enterprises, a second-level bibliometric analysis was conducted based on 328 publications. Based on Web of Science data, using the VOSViewer software product, a map of key terms was constructed, visualizing the structure of the scientific field and highlighting the main thematic nodes that form the conceptual core of the direction (Figure 13).

Figure 13.

Map of co-occurrence of keywords (co-word analysis) in publications within a refined context (n = 328). Note—compiled by the authors based on data from the Web of Science scientometric database using VOSViewer software.

The data in the figure demonstrate the formation of a stable semantic core, in which the key nodes are the categories “digital transformation”, “industry 4.0”, and “digital maturity”, which form the basis of modern approaches to the study of digital development in industry, combining the managerial and technological dimensions of transformation processes.

The results obtained in the analysis indicate that areas related to the measurement and diagnosis of digital readiness are developing mainly within the framework of maturity models, while the integration of these approaches with ecosystem and adaptation logic remains insufficiently developed. This once again confirms the existence of a methodological gap and emphasizes the need for its further consideration within the framework of the authors’ concept of assessing the readiness of enterprises to implement and adapt digital ecosystems.

The final stage of the scientometric analysis was aimed at clarifying the research niche and identifying points of intersection between digital readiness, maturity, ecosystem adaptation, and sustainable development of industrial enterprises using the search formula TS = ((“digital readiness” OR “digital maturity”) AND (“digital ecosystem*” OR “ecosystem adaptation” OR “industrial ecosystem*”) AND (sustainab* OR “sustainable development” OR ESG OR SDG*)). The result was a small but content-rich array of three publications representing the most targeted areas of scientific discourse. This level of analysis allows us to move from general conceptual constructs to understanding the specific tools and methodological approaches used to assess and manage digital ecosystems in industry.

Despite the limited number of sources, the identified publications form a conceptually interconnected space in which digital maturity and the ecosystem approach are considered complementary elements of industrial development.

Thus, Koenig examines the specifics of applying the concept of a “digital ecosystem” to understand the role of information and communication technologies in ensuring sustainable development. In particular, the authors note that there are several interpretations of this term in the scientific literature—descriptive, functionally oriented, and actor-centered—and emphasize that digital ecosystems can be viewed as an analytical tool for assessing the level of digital maturity and the socio-economic effects of digitalization at various levels of development [97].

At the same time, the study by Babkin, Glukhov, and Barabaner presents a methodological approach to measuring the maturity of industrial ecosystems, in which digitalization is considered not in isolation but within the framework of the transformation of management and production processes, where maturity is an indicator of the effectiveness of interaction between ecosystem elements and the enterprise’s ability to self-develop [98].

The third work, authored by Babkin, Shkarupeta, Mamrayeva, Tashenova, Umarov, and Karimov, proposes a structural–functional model for managing digital maturity in the context of Industry 5.0. The authors consider digital maturity not only as a reflection of the technological level but also as a tool for achieving sustainability and increasing the competitiveness of industrial systems, which ensures the transition to an ecosystem-based management logic [99].

An analysis of three works shows that a new line of scientific research is emerging, within which the categories of “digital readiness” and “digital maturity” are acquiring an ecosystem dimension and are linked to the concept of sustainable development.

At the same time, the small number of publications and their weak methodological consistency once again confirm that the issue of integrating digital readiness and ecosystem adaptation mechanisms remains insufficiently studied, which suggests the existence of a research niche within which the development of an author’s methodology for assessing the digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems becomes a pressing task.

To sum up, we can conclude that the three-level bibliometric analysis allowed us to trace the evolution of scientific discourse in the field of digital transformation of industry, as well as to identify the degree of development of research areas related to digital readiness, maturity, and ecosystem adaptation of industrial enterprises. In particular, the results showed that a significant part of the publications focuses on the technological aspects of digitalization and innovation management within the Industry 4.0 and Industry 5.0 paradigms, while methodological approaches to measuring the readiness of enterprises and their ability to integrate digital ecosystems remain underdeveloped. Thus, the identified research gap lies in the absence of a holistic concept that combines the assessment of the digital readiness of industrial enterprises with their ability to adapt to ecosystems and function sustainably.

3. Materials and Methods

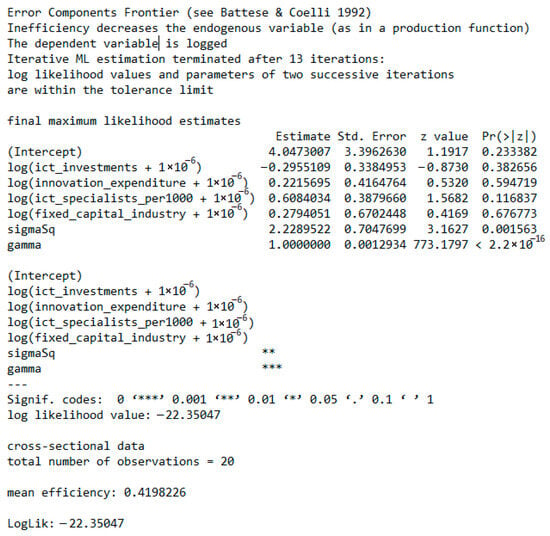

The methodological basis of the study is built on the integration of two interrelated but different approaches in terms of the level of analysis. At the first stage, the authors’ methodology, developed for a comprehensive assessment of the digital readiness of industrial enterprises and their ability to adapt to ecosystems, is applied. Its structure includes several parametric blocks, among which the “Strategies and Goals for Sustainable Enterprise Development (STRSDE)” block is of particular importance, reflecting the coupling of digitalization processes with the principles of sustainable production and corporate responsibility. This stage performs a diagnostic task aimed at identifying technological, organizational, institutional, and sustainability factors that shape the direction of digital transformations and create the conditions for their long-term adaptation.

The second stage is implemented using the stochastic frontier analysis (SFA) method, which focuses on assessing regional differences in the level of digital integration of industry. This method makes it possible to determine how the heterogeneity of digital infrastructure and the degree of technological development affect the economic productivity and spatial sustainability of regions. The combined application of the two approaches provides a comprehensive view of the digital transformation of industry, integrating the micro level of enterprises and the meso level of regional systems into a single analytical model of sustainable industrial development.

3.1. Methodology for Assessing the Level of Digital Readiness of Industrial Enterprises for the Implementation and Adaptation of Digital Ecosystems

In the current context of rapid digital transformation of industry, the issue of objectively assessing the readiness of enterprises to implement and adapt digital ecosystems is becoming particularly important. Despite the active development of digitalization concepts and the widespread use of various digital maturity indices at the international level, most existing approaches do not consider the industry-specific characteristics and peculiarities of industrial enterprises. A scientometric analysis has shown that there are virtually no comprehensive tools in scientific literature and applied research that allow for the systematic measurement of digital readiness at the enterprise level, rather than at the level of the economy as a whole or individual technological areas.

Existing assessment models tend to focus either on individual aspects of digitalization (e.g., technical equipment or staff competencies) or on aggregated macroeconomic indicators, which reduces their practical value for business. Moreover, empirical research has confirmed the existence of a significant gap between declared digital development strategies and the actual state of enterprises. This points to the need to develop a methodology that combines scientific rigor and systematicity with practical applicability, ensuring that it can be used in management decisions.

The methodology presented in this section fills this gap. It combines key parameters covering the strategic, organizational, production, human resources, and technological aspects of digitalization and considers such critically important areas as cybersecurity and customized production. Thus, the methodology represents a new step in the development of the instrumental base for digital transformation research, allowing not only to record the current state of the enterprise but also to form an objective basis for forecasting and strategic planning.

The methodology for assessing the level of digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems includes a set of sub-parameters (115) broken down into nine key blocks: enterprise sustainable development strategies and goals—10 sub-parameters; material and technical resources—22 assessment sub-parameters; organizational structure and business processes—17 sub-parameters; production—15 sub-parameters; personnel—12 sub-parameters; supply chain management—11 sub-parameters; consumers—11 sub-parameters; control—7 sub-parameters; and cybersecurity—10 sub-parameters. These largely characterize the level of digital maturity of the company, as it is inextricably linked to the stages and characteristics of the digital transformation of industrial production (Table 2).

Table 2.

Parameters and sub-parameters for assessing the level of digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems, presented within the framework of the developed methodology.

In the authors’ methodology, a special role is assigned to the first parametric block—“Strategies and Sustainable Development of the Enterprise (STRSDE)”, which is singled out due to the fact that sustainable development is becoming an integral part of the modern model of digital transformation of industry in general and industrial enterprises in particular. Unlike blocks focused primarily on measuring technological, human resource, or infrastructure characteristics, this component focuses on the strategic and managerial foundations of an enterprise’s digital evolution.

The STRSDE block allows assessing the extent to which digital transformation is embedded in an organization’s sustainable development strategy, as well as determining the degree of alignment of its goals with ESG principles and international corporate governance standards. The analysis considers parameters such as the existence of a formalized digitalization strategy, its connection to environmental and social priorities, systematic planning, and the integration of sustainability mechanisms into production and management processes.

The separation of this block has not only methodological but also conceptual significance. It allows digital transformation to be viewed not as an isolated technological process, but as part of a broader trajectory of sustainable industrial development. In this way, STRSDE becomes a link between digital ecosystems and sustainable management models, reflecting the strategic maturity of enterprises and their ability to combine innovation with social and environmental responsibility.

It should also be noted that the distinctive features of the presented methodology are:

- 1.

- Considering all organizational components and business processes involved in digital transformations, including in the context of the implementation and adaptation of digital ecosystems;

- 2.

- Using a comprehensive approach to assess all parameters characterizing digital maturity (reflecting digital readiness for the implementation and adaptation of digital ecosystem products) and the dynamic digital potential (digital foresight characterizing digital capabilities) of an industrial enterprise;

- 3.

- Including the assessment parameters of sub-parameters relating to aspects of customized production, cybersecurity, and monitoring and control, which are the most important stages in the process of implementing and adapting digital ecosystems;

- 4.

- Working with integral indicators in terms of selected assessment parameters that simplify the calculation of the level of digital readiness, including through the standardization of values;

- 5.

- Clearly systematizing the assessment parameters, allowing the development of an effective algorithm characterized by:

- −

- Discreteness, manifested in the fact that the entire assessment process is based on a sequential chain of operations, each of which has an independent meaning and is performed strictly in a given order. This eliminates the blurred boundaries between the stages of analysis and allows you to fix the logic of movement from the initial data to the final result. Thanks to this property, the methodology becomes resistant to errors and provides the ability to verify each step in detail.

- −

- Effectiveness, characterized by the algorithm’s focus on obtaining a specific, practically significant result, namely an integral indicator of digital readiness. This indicator is formed based on a generalization of a set of specific parameters and can serve as a tool for diagnosing the state of an enterprise, developing strategic decisions, and comparing it with other companies. Thus, the algorithm is not limited to the process of information processing but ends with the formation of a measurable product suitable for further use.

- −

- Completeness, meaning that the algorithm has logically defined boundaries and is guaranteed to lead the researcher to the result. This property is important from both a methodological and practical point of view, as it ensures the predictability of the procedure and eliminates the possibility of obtaining incomplete or uncertain assessments. The presence of a clear final stage enhances confidence in the methodology and makes it convenient to use in applied research and management practice.

- −

- Versatility, expressed in the ability to apply the algorithm to various categories of industrial enterprises and complex integrated systems—from large corporations and medium-sized manufacturing companies to system-forming, innovation-active industrial clusters—regardless of their specialization, organizational and legal form, and level of digitalization. This makes it applicable in a wide range of research and practical contexts, increasing its adaptability.

- −

- Scalability, which is particularly relevant in the context of expanding the assessment base with new groups of parameters and sub-parameters; this, in turn, ensures compliance with the principle of adaptability and modularity of the algorithm for assessing the level of digital readiness of industrial enterprises.

- −

- Reliability, which implies the stability of the algorithm in assessing the variability of input data and external conditions. Even when individual sub-parameters or blocks change, the final result remains stable, which ensures the reliability of conclusions and eliminates random fluctuations that could distort the overall picture of digital readiness.

- −

- Parallelism, a characteristic of the algorithm associated with the ability to process multiple operations and perform a series of actions in parallel with the main task, which is very important in the context of digital readiness assessment, especially in terms of determining separate static (current digital potential) and dynamic characteristics (dynamic digital potential).

- −

- Portability, meaning that the algorithm presented in the structure of the developed methodology can be implemented on various software and technology platforms, from specialized analytical packages to standard office solutions. This opens the possibility of using it not only in an academic environment but also directly at the level of industrial enterprises and clusters, where it is important to integrate the methodology into existing management accounting and monitoring systems.

- −

- Reproducibility and reliability of the result, meaning that the application of the algorithm in different conditions and on different data samples leads to comparable values, which confirms its stability and scientific reliability. Reproducibility allows the methodology to be used repeatedly, including repeated measurements over time (as part of monitoring) and cross-industry comparisons, while maintaining the same logic of calculations and interpretations. Reliability indicates the correspondence of the estimates obtained to the actual state of the enterprise: the integral indicator is not formed randomly but because of consistent processing of verified parameters. In general, these characteristics provide the researcher with confidence in the correctness of the conclusions made, and also create a basis for applying the results in management practice and strategic planning.

- −

- Parameterizability, reflecting the flexibility of the algorithm in terms of adjusting the initial data, weights, and scaling intervals for specific research or applied tasks. This makes it possible to adapt the developed algorithm to new cycles of digital transformations, industry specifics, or changes in international standards for assessing digital maturity.

The methodology for calculating the integral value of the digital readiness level of industrial enterprises for the implementation and adaptation of digital ecosystems includes the following stages:

- Collecting data in terms of selected blocks of parameters and sub-parameters that form them (Table 1), based on a survey of middle and senior management representatives of industrial enterprises.

- Normalizing data to bring the obtained values to a single assessment range (0–1) using Formula (1):where —normalized evaluation subparameter; —minimum value of the subparameter in the group; —maximum value of the subparameter in the group of evaluation parameters.

To enhance the transparency of the calculations, it is imperative to acknowledge that data normalization was executed through the utilization of the min–max scaling method, whereby all values were constrained to the range of [0; 1]. The weighting coefficients of the blocks were determined based on expert assessments by specialists in the field of digital transformation, which ensured a balance between subjective and objective factors. To verify the stability of the model, a comparison of additive and geometric aggregation was performed; discrepancies did not exceed 3%, thereby confirming the stability of the index structure.

- 3.

- Obtaining the final value for each parameter block based on the weighted geometric mean calculation formula, which allows avoiding “dips” and large differences between values that can significantly affect the integral indicator (Formula (2)):

Within the framework of the methodology under consideration, the weight of all sub-parameters in the block structure is assumed to be equal to 1, since in the case of calculating the integral value, an important aspect is determining the weight of the parameter blocks themselves.

- 4.

- Determining the weight of the criteria blocks in the integral assessment structure based on an expert survey. In our case, 42 people acted as experts—representatives of the industrial sector (company management), specialists in the field of the digital economy, digital transformation and industrial clustering, and IT specialists—whose aggregate weight assessments in terms of criterion blocks were distributed as follows:

- −

- Strategies and goals for sustainable development of the enterprise—STRSDE (B1)—0.12;

- −

- Material and technical resources—MTE (B2)—0.15;

- −

- Organizational structure and business processes—ORGSTRPROC (B3)—0.1;

- −

- Production—PROD (B4)—0.15;

- −

- Personnel—PERS (B5)—0.12;

- −

- Supply chain management—SCM (B6)—0.1;

- −

- Consumers—CUST (B7)—0.08;

- −

- Monitoring and control—MONCONTR (B8)—0.08;

- −

- Cybersecurity—CYBSEC (B9)—0.1.

- 5.

- Calculating the final integral value of the digital readiness level of industrial enterprises for the implementation and adaptation of digital ecosystems using Formula (3):where —the integral value of the digital readiness level of industrial enterprises for the implementation and adaptation of digital ecosystems; —the final value for the parameter block; —the weight of the parameter block.

Considering the existing weighting indicators for parameter blocks, the final calculation formula will be as follows (Formula (4)):

- 6.

- Correlating the obtained value with the corresponding range of the digital readiness (DRL) assessment scale:

- −

- 0.0 ≤ DRL ≤ 0.4 points—low level of digital readiness of an industrial enterprise for the implementation and adaptation of digital ecosystems: as a rule, enterprises with such an assessment do not have a systematic digital strategic development program and do not implement, or sporadically implement, individual digital solutions, without using unified digital platforms; in addition, the staff lacks the necessary digital skills. Furthermore, company management may be aware of the need for digital transformation but lack the material and technical capabilities to implement these tasks; the fragmented use of ICT has virtually no significant impact on the company’s performance.

- −

- 0.41 ≤ DRL ≤ 0.8—average level of digital readiness of an industrial enterprise for the implementation and adaptation of digital ecosystems. Companies with this level of digital readiness are distinguished by the presence of an approved digital development program with a clear understanding of which modern digital solutions will be implemented, how to adapt them to different business processes, and how to integrate them with the existing digital skills of the staff. The digital potential of such enterprises is usually quite high, but difficulties with the implementation and adaptation of digital ecosystems may still be observed due to the lack of sufficient funding, infrastructure solutions (which do not allow for the effective and uninterrupted operation of the digital ecosystem), and customized software (for specific requests and needs of the company); widespread training and retraining of personnel to work with new software products and equipment is also characteristic, and investments in the digital transformation of all business processes are increasing, as management clearly sees the prospects for a return on investment.

- −

- 0.81 ≤ DRL ≤1 —high level of digital readiness of industrial enterprises for the implementation and adaptation of digital ecosystems: at this level, enterprises are innovation-active, resulting in the dynamic implementation of various information and communication tools, including digital ecosystems, whose interface and software are designed for the specific tasks and goals of the company, as well as the existing digital strategic development program; at this level, a digital corporate culture has been virtually formed, the staff has the necessary digital skills, and training and retraining of personnel in the use of new technologies is carried out on an ongoing basis; The implemented digital ecosystem mediates all business processes, including its full integration into production cycles, supply chains, and partner networks, thus ensuring effective communication between all departments. Investments in digital transformation ensure the company’s competitive growth in the market. The organizational structure of the new formation is more flexible and adaptable to the development and subsequent commercialization of new products. A very high level of cybersecurity is ensured.

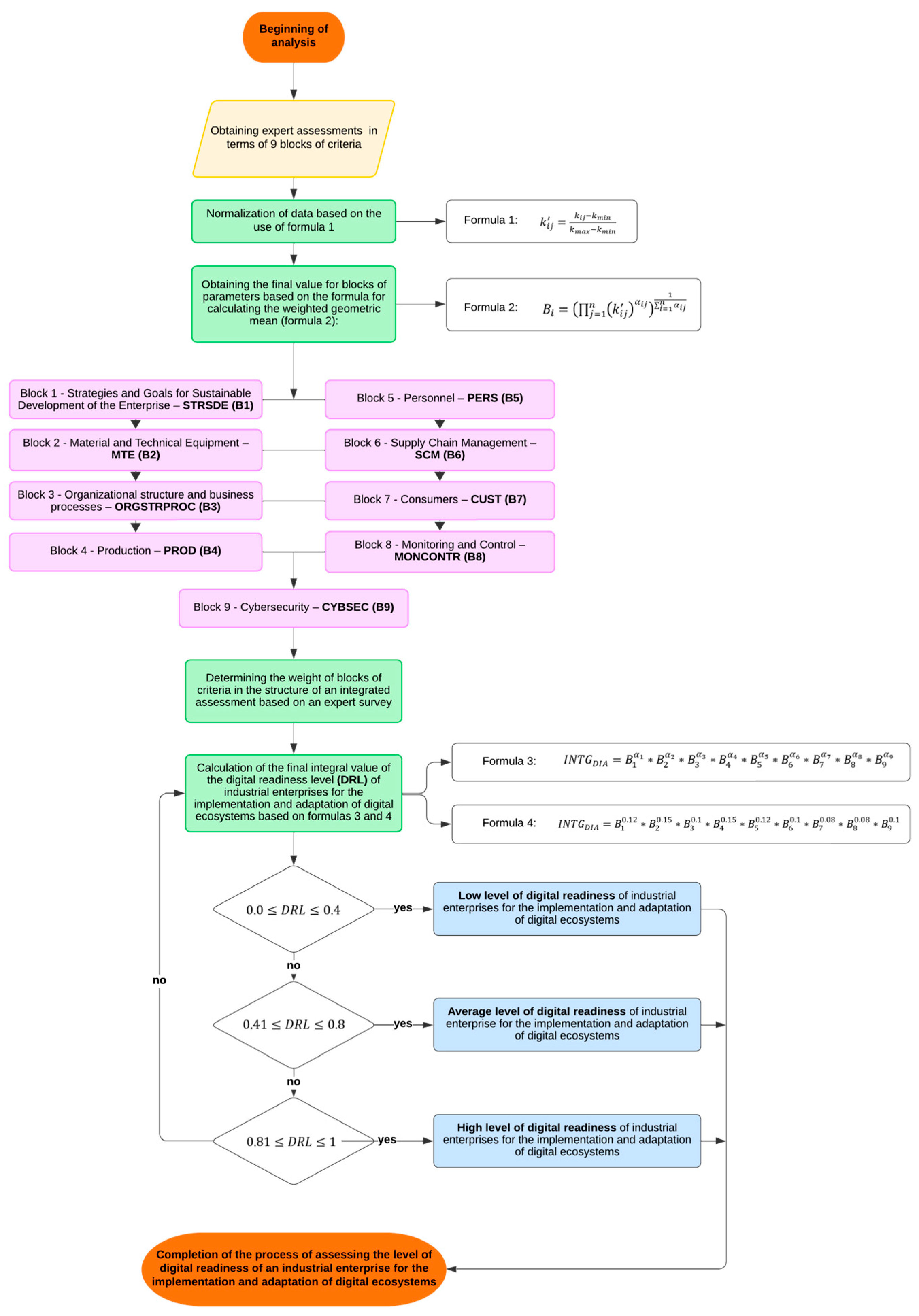

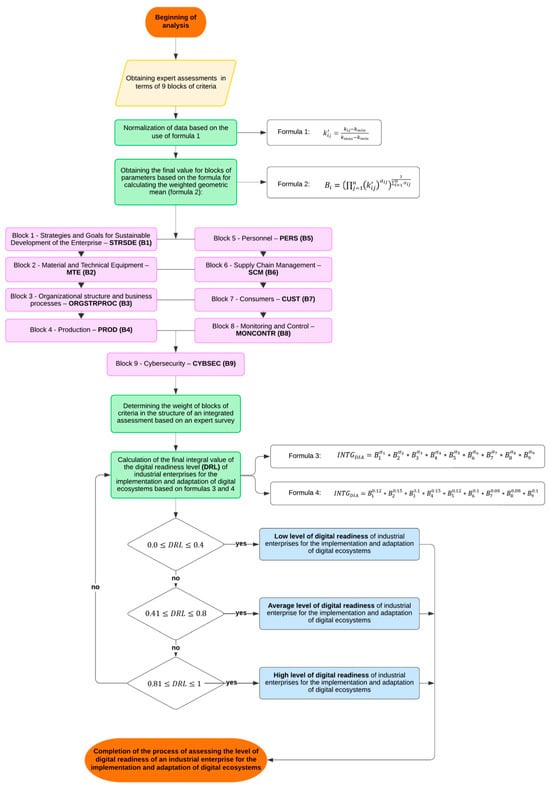

The authors’ algorithm for assessing the level of digital readiness of an industrial enterprise for the implementation and adaptation of digital ecosystems is presented in Figure 14.

Figure 14.

Algorithm for assessing the level of digital readiness of an industrial enterprise for the implementation and adaptation of digital ecosystems. Note—compiled by the authors.

It includes the following blocks: terminators—blocks for starting and ending the assessment of the level of digital readiness; data input blocks—values for 9 groups of criteria and 115 subcriteria; process blocks within which the obtained data is normalized, and integral values are calculated; and decision blocks that allow the obtained result to be correlated with the three levels of digital readiness identified by the authors of the methodology based on the use of an interval scale.

In addition, the algorithm has auxiliary blocks—formulas based on which step-by-step calculations are performed; this approach ensures compliance with the principles of reproducibility of scientific results and comprehensiveness.

At the first stage of the algorithm, data is collected on nine blocks of criteria and 115 sub-parameters. Next, the indicators are normalized, and the final values for each block are calculated based on the weighted geometric mean. The next step involves determining the weight of the blocks in the integral assessment structure using an expert survey. After that, the final integral indicator is calculated, which is correlated with the established scale (low, medium, and high level of digital readiness).