Abstract

The concepts of sustainable development, triple bottom line, and ESG have a strong influence on the process of formation and operation of supply chains today. This requires the implementation of various green solutions and practices to improve supply chain sustainability. An analysis of supply chain research did not reveal a universally accepted methodology to systematize green solutions and practices for their effective use in chain management. It was revealed that there are many views on the content of green solutions, in addition to insufficient specificity of their description, as well as fragmentation of the use of green solutions in relation to the elements and functions of supply chains (procurement, production, warehousing, transportation, and distribution). This reduces the effectiveness of the implementation of green solutions. In this study, based on the literature review, a systematization of currently existing green solutions and practices was carried out. The systematization was performed according to the affiliation of supply chain elements and the functions performed by the elements to promote and process the material flow from supplier to consumer. The proposed system of methods (GLMs) and instruments (GLIs) of green logistics covers all known functional areas of logistics and includes 27 methods and 105 instruments. We performed a ranking of methods and instruments using TOPSIS, MABAC, and MARCOS methods. The most and least significant GLM and GLI for each element of the supply chain, as well as for chains of complex structure in general, were determined. The results of GLM and GLI ranking can be used as a basis for the implementation of management decisions to improve the sustainability of supply chains.

Keywords:

green logistics; green supply chain; green practices; green solution; instruments; methods; MCDM; ranking 1. Introduction

The functioning of supply chains includes a set of processes of procurement, production, and distribution of material flows to the final consumer. The classical concept of supply chain management synthesizes the tasks of minimizing the logistics costs of the total costs in the chain, operational management-effective inventory and production management, and marketing focused on creating value for the customer. However, the broad dissemination of concepts such as sustainable development, triple bottom line, and ESG (environmental, social, and governance) all over the world is changing views and approaches to supply chain management. For example, a total of 3038 investors representing over USD 100 trillion in combined assets have signed a commitment to integrate ESG information into their investment decisions [1]. Along with the economic benefits of companies, policies related to people’s welfare and environmental protection are an integral part of supply chain management (SCM) nowadays [2]. Companies around the world are implementing green practices in supply chain management, trying to transform supply chains into sustainable supply chains or green supply chains. National governments and company management are implementing various programs and projects to achieve sustainability goals. This is because over 75% of a company’s carbon footprint is attributed to logistics activities and transportation related to the acquisition, production, and distribution of materials and goods [3]. Green or sustainable supply chain management is one of the most relevant topics in modern research of operations management, logistics, and sustainability [2,4].

The analysis of papers in the field of green or sustainable supply chain management shows an increase in the number of scientific papers devoted to theoretical and practical problems of implementing green practices. The existing approaches can be divided into two groups. The first one is related to the research of supply chains as a single system [5,6,7], while the second one is related to the research of individual green operations [8] or elements of supply chains. The latter include, for example, studies of sustainable supply [9,10], sustainable production [11,12], sustainable warehousing [13,14], sustainable transportation [15,16], and sustainable consumption [17]. One of the key research questions is the challenges of implementing green solutions and practices in logistics. Such practices encompass the integration of sustainable approaches into forward and reverse logistics operations to promote balanced social, environmental, and economic performance [4]. Such practices can be supported through public reports, such as environmental, social, and governance (ESG) reports, and government policies, including government certification [18].

Nevertheless, some gaps in research have been noted in recent papers, despite the growing attention to green logistics. Thus, in [4], the authors note that the prerequisites for green logistics, green practices, and methods for assessing their effectiveness remain poorly regulated. Research [19] indicates that, from a scientific standpoint, the understanding of the concept of green logistics has not yet been based on a systematic approach. The authors of [20] point to gaps in the interaction between various participants in supply chains performing logistics functions in the field of green logistics. Another study [21] shows the imbalance between academic science and industry practice in implementing the concept of green logistics. It is noted that this imbalance hinders the integration of theoretical ideas and practical solutions, slowing progress in reducing the environmental impact of supply chains. The problems of the impact of environmentally friendly practices on green servitization, Industry 4.0 solutions in green supply chains on ESG compliance [22], and artificial intelligence technologies on management decisions and the formation of sustainable supply chains [23,24] are poorly studied. Insufficient consistency in the selection of green instruments, vague wording, and the lack of standards and enforcement create a favorable environment for unscrupulous practices and greenwashing [25,26].

The main objective of our study is to categorize the currently used green solutions and practices in logistics activities to develop a universal system of green logistics instruments. This study makes both theoretical and practical contributions to the field of green logistics and green supply chain management. Firstly, based on the analysis of scientific publications and a structural–functional approach, we identified green solutions and practices and developed a universal system of green logistics methods and instruments. The main idea of the systematization was to compare and group different green solutions and practices with the functions of structural (logistics) elements of green supply chains. The proposed system could form the basis for standardizing green instruments and monitoring their implementation to prevent greenwashing. Secondly, we developed a methodology to rank green logistics instruments in the supply chain using multi-criteria decision-making (MCDM) techniques. This methodology will help stakeholders make effective decisions to implement green logistics methods and instruments in supply chain elements based on the ranking of instruments.

The rest of the paper is as follows: The second section contains the literature review. The third section describes the methodology for systematization and ranking of green logistics methods and instruments. The fourth section presents a calculation example of the proposed methodology implementation. The fifth section, Discussion, contains a comparison of the results obtained with previous studies in this field and a description of the theoretical contribution of our research. The final section presents the main results, limitations, and directions for further research.

2. Literature Review

2.1. Overview of Green Practices in Logistics and Supply Chain Management

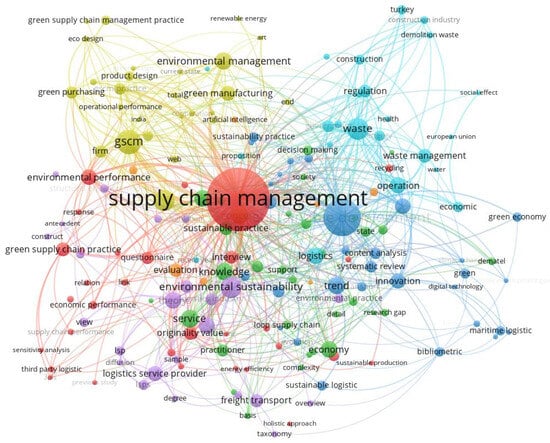

To understand the terminology used in relation to green practices in logistics and to identify the most common keywords, we used a combination of keywords to search for review articles in Scopus: “Practices” AND “Review” AND “Green AND supply AND chains” OR “Green AND Logistics” in their titles, abstracts, or keywords (Figure 1).

Figure 1.

The network of keyword co-occurrences.

The analysis of articles indicated that different terms are used in the research in relation to green practices: criteria, GSCM practices, factors, measures, green logistics practices, activities, initiatives, drivers, practices, green practices, green activities, decision, attributes, sustainable practices, solution, policies, GSCM initiatives, green logistics activities, green initiative.

We analyzed review papers in which the authors attempted to group and systematize various green solutions and practices as applied to supply chain and logistics activities.

A previous study [27] compared green and lean practices on supply chain management performance. The authors grouped 17 practices into two groups and presented their brief characterization of the practices. The 14 solutions were grouped into 4 types of activities: green office, inventory control and material handling, green warehousing, and green transportation [28]. The authors in [29] identified three levels of dimensions and categories for different green activities and operations aimed at improving the efficiency of green logistics. The authors grouped 18 green activities and operations into three categories: network design, product and inventory, and reverse logistics. In another study [30], the authors grouped 36 activities/practices for all activities in the supply chain, such as raw material procurement, inbound logistics, transformation, outbound logistics, marketing, after-sales, and appropriate product disposal.

The reviews in [6,31] present a list of 58 green supply chain practices that were grouped into 16 aspects of green supply chain management (GSCM): reverse logistics, industrial symbiosis, eco-innovation practices, green information technology and systems, green design, carbon management, supplier environmental collaboration, customer environmental collaboration, ISO 14001:2015 [32] certification, internal management, green purchasing, green manufacturing, green packaging, green logistics, green outsourcing, and green warehousing. The authors of [5] analyzed the frequency of GSCM practices in the scientific papers. They identified 46 different practices. The five most frequently mentioned were green purchasing/procurement, collaboration/cooperation with customers, internal GSCM practices/environmental management, green/eco-design, and investment recovery. Another paper [33] identified the major research fields in circular supply chain management and calculated the frequency of mentioning 25 alternative solutions in scientific publications. The authors of [4] pointed to two approaches in the existing research: green logistics practices can be considered a composite construction for improving sustainability, or publications focus on individual practices. As an example, the authors identified 33 green logistics practices: green manufacturing, green marketing, green consumption, green reverse logistics, green transportation, green communication, information sharing, logistics emissions, green warehouse, green packaging, green vehicle technologies, alternative fuels, eco-driving, green transport management, green logistics systems, green modal shift, eco-friendly technologies, environmental standards, green administration and logistics data management, sustainable waste management, eco-friendly transportation, waste reduction, energy-efficient operations, sustainable transport, green ware housing and building, eco-design, green purchasing, reverse logistics, responsive packaging, green monitoring and evaluation, sustainable information sharing, sustainable packaging and distribution, and waste management.

In another literature review [34], all articles were categorized into two groups of mitigation actions and adaptation actions, and included seven green actions to improve environmental sustainability in third-party logistics service providers. The authors of [35] sought to identify the standpoint of determinants (motivations, pressures, and incentives) and modalities (practices conducting greening transportation from shippers and logistics service providers (LSPs)). Based on a review of publications, the authors identified 14 green logistics practices and described them. According to the authors, these practices were green modal shifts, green transportation management, green logistics systems, green vehicle technologies, eco-driving, alternative fuels, environmental management systems (EMS), reverse logistics, green administration, green packaging, green warehousing, emission data, cooperation with shippers, and choice of partners.

Another literature review [36] explores the relationship between GSCM pressures, practices, and performance. The authors grouped the literature on GSCM practices—eco-design, internal environmental management, waste management, green purchasing aspect, quality, and product recovery. The authors [37] studied the relationship between green human resource management practices and green supply chain management practices.

In another systematic review [14], the papers on green practices were grouped into three macro themes: green warehouse management, the environmental impact of warehouse construction, and energy saving in warehousing. In [15], the literature on sustainable transportation is classified into six dimensions: network design, profit sharing, inventory, distribution organization, and routing. Another study [13] focuses on sustainable inventory management in green supply chains. The authors considered 25 solutions to improve the sustainability of inventory management. In [38], the authors considered Industry 4.0 technologies divided by GSC aspects. The authors grouped 10 green practices into 5 aspects: reverse logistics, green design, green manufacturing, carbon emissions management, and green warehousing.

In several research studies, the authors have not considered green practices as activities but as criteria against which to evaluate individual logistics processes to improve the sustainability of the supply chain. For example, we can point to the criteria for evaluating suppliers (12 practices) [39], green practices and initiatives for sustainable hotel operations (27 attributes of green practices and initiatives for sustainable hotel operations) [40]; assessing green supply chain management (13 criteria and 79 subcriteria) [41]; and assessing the feasibility of implementing Industry 4.0 technologies in sustainable supply chains (17 criteria and 59 attributes) [42].

2.2. Analysis of Multi-Criteria Decision-Making in Green Logistics

MCDM is an important component of decision-making theory and analysis. Its main purpose is to solve the following key problems [43]: selecting the best solution from a set, ranking and sorting solutions, describing and systematizing solutions, and assessing the consequences of their implementation for management. MCDM is used to solve problems of sales planning, selection of green suppliers, reverse logistics, assessment of the logistics infrastructure facilities location, and organization and planning of transportation [44].

The most used methods in the field of green logistics and green practices are AHP, ANP, TOPSIS, and DEMATEL. AHP and fuzzy AHP methods are usually used in combination with other MCDM methods. Table 1 presents the results of the analysis of the use of MCDM in green and sustainable supply chains.

Table 1.

MCDM in green logistics practice.

The analysis of the MCDM models’ structure presented in Table 1 shows a significant variation in the number of alternatives (green solutions and practices) and attributes (criteria for evaluating alternatives). The number of alternatives varies from 3 to 79 (18 on average) and depends on the type of supply chain, the functional area of logistics, or the study area. The number of attributes depends on the number of levels in the MCDM model—single-level (criteria only) or two-level (criteria and subcriteria) approach. In a single-level grouping, the number of criteria varies from 2 to 32 (12 on average). In a two-level grouping, the first level contains 2 to 19 criteria (5 on average), and the second level contains 3 to 63 subcriteria (21 on average). This diversity of MCDM models is explained by the complexity of the process of evaluating and selecting green practices and solutions to improve the sustainability of supply chains.

A review of research on the use of green practices in logistics and supply chain management revealed the following problems:

- Multiple views on the content of green solutions and, consequently, insufficient systematic implementation in supply chains;

- Different understanding and interpretation of green practices Insufficient specificity of green solutions and practices (lack of description in 71% of publications);

- Fragmented use of green solutions and practices in relation to elements and functions of supply chains (procurement, production, warehousing, transportation, and distribution);

- The complexity of the decision-making process for implementing green practices is due to the large number of green solutions and the variety of criteria used to evaluate them. This makes it advisable to use multi-criteria analysis and expert methods and, as a result, to develop new MCDM models for implementing green practices.

3. Methodology for Systematization and Ranking of Green Logistics Methods and Instruments

The proposed methodology is based on the structural–functional approach to the green supply chain formalization. This approach defined the principles of green logistics methods and instruments systematization. Multi-criteria decision-making methods are used to rank the methods and instruments. MCDM and a system of criteria for evaluating logistics flows, the achievement of which ensures the fulfillment of sustainable supply chain development goals, are applied for ranking.

3.1. Structural–Functional Approach to the Green Supply Chain Formalization

The structural–functional approach involves the identification of supply chain-based logistics functions and the identification of corresponding abstract logistics elements. The basic logistics functions are proposed to include the following main actions with logistics flows (a) acceleration and movement, (b) deceleration and accumulation, (c) quality change and processing, (d) input into the system, (e) output from the system, and (f) coordination of logistics functions. The relevant logistics elements realizing these basic functions are (a) transport, (b) cumulative, (c) processing, (d) input, (e) output, and (f) control. The basic functions of each logistics element or supply chain element are concretized by a set of so-called supporting functions, i.e., specific actions to change the parameters of logistics flows.

With the help of a combination of abstract logistic elements that realize the corresponding basic and supporting functions, it becomes possible to model any real infrastructural element of the supply chain. It also becomes possible to formalize supply chains or logistics systems at any level of detail.

The structural–functional approach is fundamentally different from the generally accepted way of identifying functional areas of logistics, such as transportation, sales, production, supply, and warehousing logistics. The disadvantage of the traditional functional approach is the “binding” of logistics functions and operations to infrastructural elements of logistics chains—warehouses, industrial enterprises, supply and sales departments, and transportation. This makes it difficult to identify and systematize the methods and instruments of logistics flow management, since the same method or instrument can be implemented in different functional areas of logistics [108].

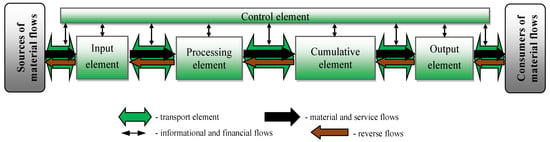

The model of the green supply chain (GSC) formed using the structural–functional approach is presented in Figure 2. The GSC model is a set of logistics elements linearly ordered along with the material and accompanying financial, information, and work (service) flow. The model used in this study is the result of developing ideas about the possibility of coordinating various functional areas of logistics [109,110] within three-stage [111] or four-stage (echelon) [112] supply chains. Our model is a generalized multi-echelon supply chain consisting of five echelons–logistics elements coordinated by a control element. The idea of coordinating various functional areas of logistics within a multi-echelon supply chain is implemented both within large commercial companies and by several cooperating companies within the framework of partnerships. Within a single enterprise, such a chain functions using enterprise resource planning (ERP) systems [113,114]. The coordination [115] of all logistics functions is carried out in the case of long supply chains from raw materials to distribution. Examples of such multi-echelon supply chains are known in mechanical engineering [116], metallurgy [117], the chemical [118] and pharmaceutical [119] industries, as well as in e-commerce [120] in large economies. The main task of management (the controlling element) in such multi-echelon green supply chains is to coordinate the actions of the functional elements of the supply chain [121] for changing the parameters of logistics flows to achieve sustainable development goals.

Figure 2.

The green supply chain model according to the structural–functional approach to the identification of logistics elements.

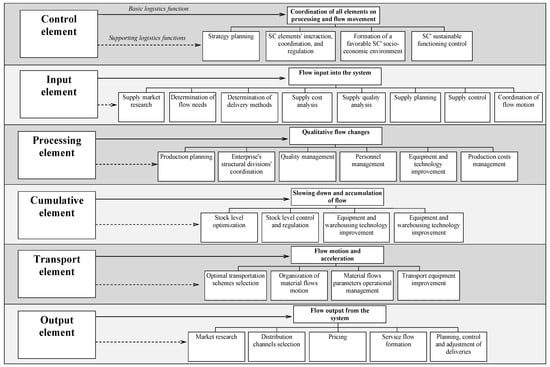

The achievement of sustainable development goals is ensured by fulfillment of each GSC element of its supporting functions with the help of green logistics methods and instruments (Figure 3).

Figure 3.

The basic and supporting functions of green supply chain elements.

3.2. Systematization of Green Logistics Methods and Instruments

The study of scientific research allowed us to establish that different terminology has been used in relation to solutions to reduce negative environmental impact in logistics. The most common terms are “green practices”, “GSCM practices”, “green factors”, “green measures”, “green activities”, “green initiatives”, “green drivers”, “solution”, etc.

We propose to use the terms “green logistics methods” and “green logistics instruments” as generalized concepts for various green solutions in the field of logistics activities. The main purpose of the implementation of green logistics methods and instruments is to identify and eliminate deviations of their parameters that hinder the achievement of sustainable development goals (SDGs).

In a previous paper [122], we proposed a system of green logistics methods and instruments. This system consists of 27 methods and 105 instruments. We established which specific SDGs were achieved by the realization of each method and instrument. Subsequent studies [44,108,123,124,125,126] allowed us to clarify, adjust, and extend the original system through a detailed description of each instrument.

Structural–functional and systemic approaches have been used to systematize green logistics methods and instruments. According to these approaches, supporting logistics functions are identified for each structural element of the green supply chain (see Figure 2). Each supporting logistics function corresponds to a specific green logistics method, which is a consolidated set of green solutions. Smaller specific solutions that are part of each such set are green logistics instruments. The authors of [122,127] described in detail the basic principles, methodology, and results of the systematization of green logistics methods and instruments for achieving sustainable development goals.

The systematization of methods and instruments presented in this study was made using the following features:

- Correspondence to the elements of the supply chain to avoid duplication of methods and instruments at different stages of the logistics process, as well as to identify missing and promising methods and instruments.

- Correspondence to supporting functions of supply chain elements. Traditionally, logistics functional areas are focused on cost reduction and quality improvement. Additionally, specialization of green logistics methods and instruments by supporting functions is necessary to achieve social and environmental goals.

- Correspondence of instruments to the green logistics methods, i.e., realization of a certain method by a set of instruments.

In addition, the proposed systematization is based on the following principles:

- Consideration of green logistics methods and instruments as a unified system for achieving SDGs. The object of management is the logistics flows in the supply chain.

- Using the best green practices, eco-programs, and projects with the participation of political, social, and economic institutions, scientific organizations, international unions, and organizations to form and improve the system of green logistics methods and instruments.

- Thus, we propose the following concepts:

- Green Logistics Method (GLM)—a set of solutions to achieve the SDGs by realizing the basic and supporting logistics functions of a certain element of the logistics system or supply chain.

- Green Logistics Instrument (GLI)—a specific solution for changing the parameters of logistics flows to implement the corresponding green logistics method.

3.3. Multi-Criteria Ranking of Green Logistics Methods and Instruments

A GLM and GLI system can consist of multiple methods and instruments specialized by logistics elements and functions. Different elements of the supply chain may have different objectives in changing the parameters of logistics flows by GLMs and GLIs. Therefore, the ranking and selection of GLMs and GLIs are proposed to be performed using multi-criteria decision-making (MCDM) techniques.

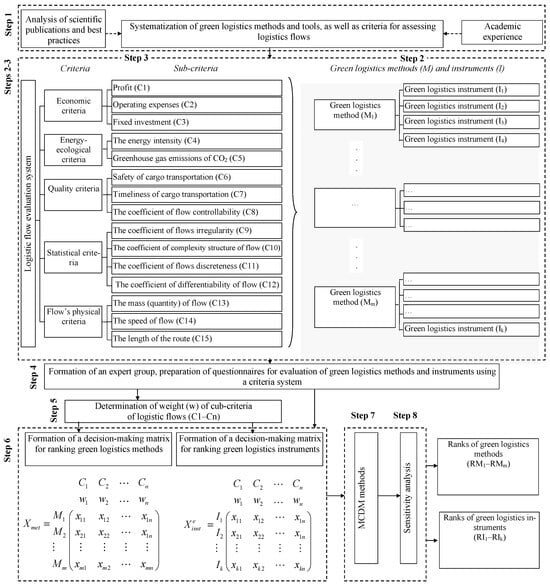

The methodology for multi-criteria assessment and ranking of GLMs and GLIs consists of the following steps:

Step 1. Design a list of methods and instruments based on the results of analyzing scientific papers in the field of green solutions and practices as applied to supply chains.

Step 2. Establish GLM and GLI systems by observing systematization attributes and principles presented in Section 3.2. Group GLMs by supporting functions of logistics elements. Group GLIs by GLM compliance.

Step 3. Select the criteria system and establish a set of multi-criteria models for GLM and GLI ranking.

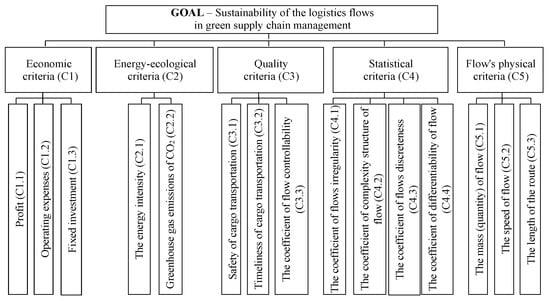

We propose to use estimates of logistic flow parameters (Figure 4) as a system of criteria. This choice is based on the ultimate influence of instruments on these parameters, as a result of which the achievement of the SDGs is ensured. A detailed description of the selected two-level criteria system is presented in [108,128]. Our previous study [128] presents an example of ranking logistics flow indicators for a multi-echelon supply chain by degree of importance using a combined DEMATEL-ANP method. Another study [108] presents an example of selecting green logistics instruments based on an analysis of the impact of these instruments on logistics flow indicator values. Initial data from open sources were used for a calculated example of cargo delivery by road over 1850 km. The assessment of changes in material flow indicator values as a result of the application of various instruments was performed using a fuzzy model in the fuzzyTECH 8.0 software.

Figure 4.

Logistic flow evaluation system [128].

In practice, the initial data on logistics flow indicators can be obtained from the statistical reports of the logistics company coordinating the flows within the supply chain. In the case of multi-echelon supply chains, it is necessary to organize standardized registration and exchange of initial data between companies participating in the supply chain within the framework of partnership agreements [129], including the use of blockchain technology [130].

The set of multi-criteria models includes one GLM ranking model for the entire supply chain and six GLI ranking models, one for each logistics element.

Step 4. Form an expert group and prepare questionnaires for GLM and GLI assessment using a system of criteria. The expert group should include representatives of the academic community, as well as businesses in the field of logistics and supply chain management. It is desirable that the experts’ qualifications allow them to adequately assess the importance of methods and instruments for different elements of the supply chain. The minimum composition of the expert group should be at least three experts, in accordance with existing studies [82,131]. An ideal sample size is one that has around 5–50 respondents/experts [72]. In this study, we used the experts’ qualifications (academic degree), field of professional activity, and total work experience as selection criteria.

Step 5. Calculate the weights of the criteria for the evaluation of green logistics methods and instruments. Since impacts on different parameters of logistics flows using GLMs and GLIs have different impacts on the achievement of SDGs, it is necessary to calculate the weights of the criteria for assessing logistics flows. The most common methods for calculating criteria weights in green supply chains are AHP, ANP, BWM, CRITIC, DEMATEL, FUCOM, and others [126]. The input data for calculations using these methods are expert estimates of criteria weights. Multiple scales can be used to improve the accuracy of the estimation, for example, with fuzzy, rough, and gray numbers. To verify the degree of agreement among expert opinions, it is recommended to use various methods, such as calculating the averages or weighted averages of experts’ judgments, the Delphi method, the standard deviation, the Kappa statistic, Spearman’s rank-order correlation coefficient, Cronbach’s alpha coefficient, and Kendall’s coefficient of concordance.

Step 6. Obtain expert evaluations of alternatives. Assessment can be performed using a variety of scales. The initial decision-making matrices are then established for ranking methods (1) and instruments (2), considering the criteria weights. The initial matrices, in general, have the following form:

where M = {M1, M2 …Mm}—green logistics methods; m—number of methods; I = {I1, I2 …Ik}—green logistics instruments; k—number of instruments; C = {C1, C2 …Cn}—criteria of logistics flows; n—number of criteria; w = {w1, w2 …wn}—weight of criteria; xij or xgj—the evaluation value of i—method and g—instruments, respectively, according to j—criterion C.

Step 7. Perform multi-criteria ranking of green logistics methods and instruments using MCDM. The selection of a specific MCDM is necessary in this step. MCDMs differ in their data aggregation methods and algorithms, accuracy of results, and computational labor intensity. Common methods for ranking green supply chain solutions are SAW, TOPSIS, PROMETHEE, COPRAS, ARAS, WASPAS, EDAS, MABAC, CODAS, MARCOS, etc. [44].

Step 8. Perform a sensitivity analysis of the ranking results. The following methods can be used at this stage: comparison of results obtained by different MCDM methods followed by calculation of Spearman’s rank correlation coefficient; analysis of various scenarios of criteria change; construction of dynamic decision matrices and change in the number of alternatives in the MCDM model [132]; calculation of mean relative error of the ranking (MRER) [133].

The results obtained using one of the selected MCDMs are compared with those calculated by other multi-criteria methods. The ranked GLMs and GLIs are used by decision makers to align sustainability programs and projects across all elements of the supply chain.

The multi-criteria assessment framework for GLMs and GLIs is presented in Figure 5. The criteria system (Figure 4) is shown for this framework as an example.

Figure 5.

The multi-criteria assessment framework for GLMs and GLIs.

4. Calculation Example

This section presents an example of ranking green logistics methods and instruments. In the first step, we analyzed 184 research papers on the use of various green solutions and practices in supply chains. The identified green solutions and practices were grouped according to the supporting functions of green supply chain elements. The results of the research analysis are presented in Table 2.

Table 2.

Grouping of scientific papers in relation to logistic elements and by mention of green logistics methods (M) and instruments (I).

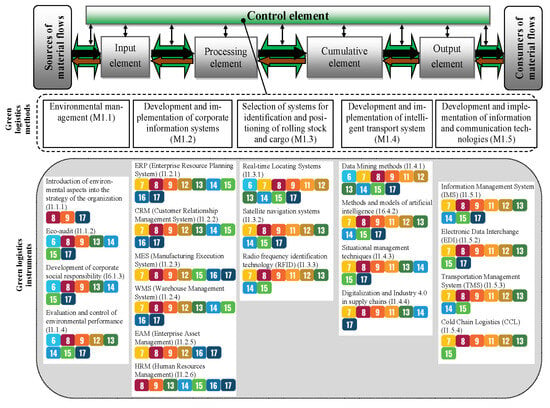

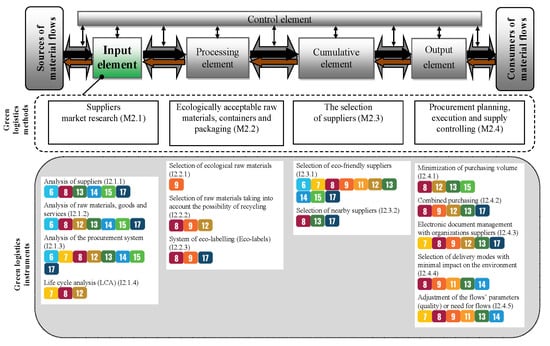

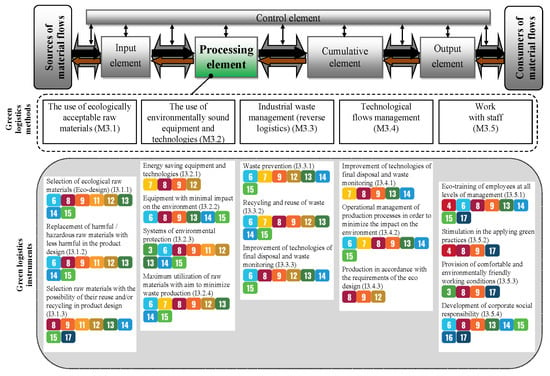

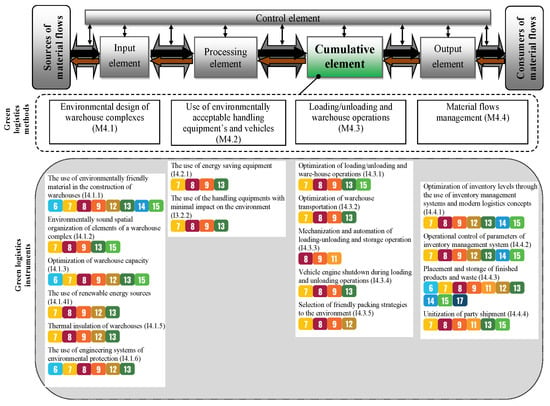

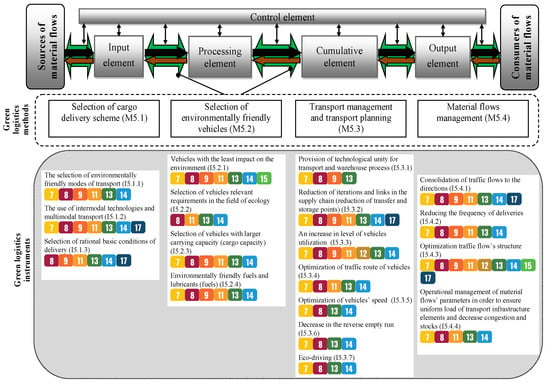

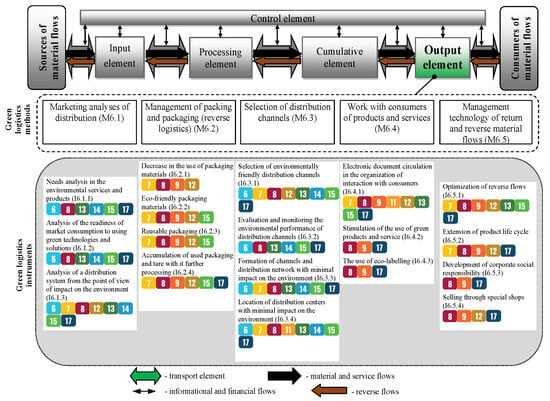

Figure 6, Figure 7, Figure 8, Figure 9, Figure 10 and Figure 11 show the results of the systematization of green logistics methods and instruments separately for each logistic element. The corresponding elements are highlighted in color. A detailed description of each green logistics instrument is given in Table 3, Table 4, Table 5, Table 6, Table 7 and Table 8. The names of the instruments are close to the formulations of traditional logistics support functions and tasks. However, from the perspective of green logistics, they should be considered methods and instruments for achieving sustainable development goals. These goals are indicated in the figures by the corresponding well-known pictograms [235].

Figure 6.

Geen logistics methods and instruments for the control logistics element.

Figure 7.

Green logistics methods and instruments for the input logistics element.

Figure 8.

Green logistics methods and instruments for the processing logistics element.

Figure 9.

Green logistics methods and instruments for the cumulative logistics element.

Figure 10.

Green logistics methods and instruments for the transport logistics element.

Figure 11.

Green logistics methods and instruments for the output logistics element.

Table 3.

Description of green logistics instruments for the control logistics element.

Table 4.

Description of green logistics instruments for the input logistics element.

Table 5.

Description of green logistics instruments for the processing logistics element.

Table 6.

Description of green logistics instruments for the cumulative logistics element.

Table 7.

Description of green logistics instruments for the transport logistics element.

Table 8.

Description of green logistics instruments for the output logistics element.

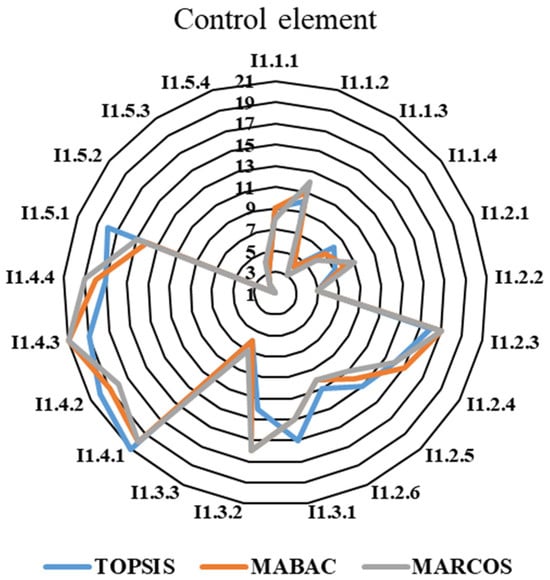

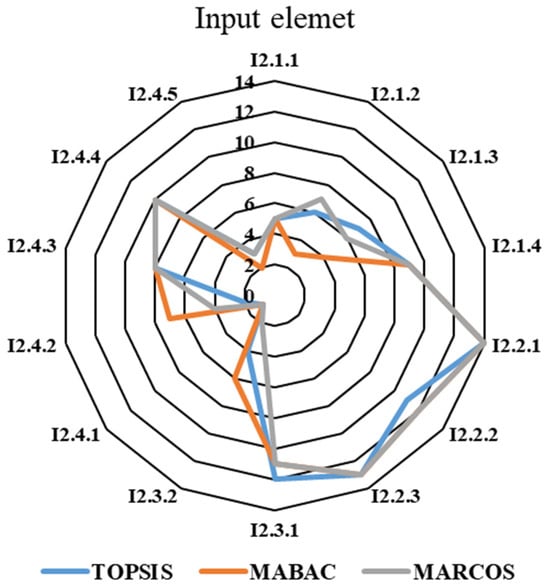

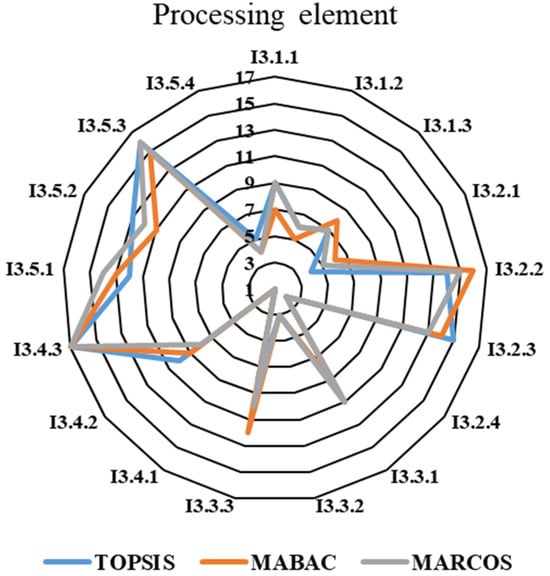

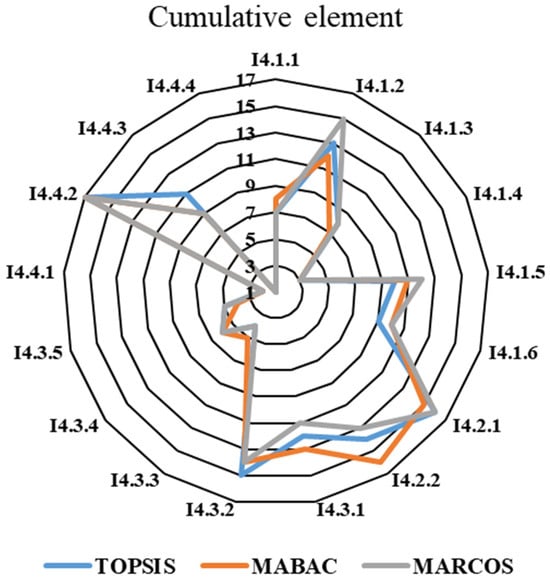

Seven MCDM models were formed to rank green logistics methods and instruments:

- Supply chain model (27 methods—M1.1–M6.5);

- Control element model (21 instruments—I1.1.1–I1.5.4);

- Input element model (14 instruments—I2.1.1–I2.4.5);

- Processing element model (17 instruments—I3.1.1–I3.5.4);

- Cumulative element model (17 instruments—I4.1.1–I4.4.4);

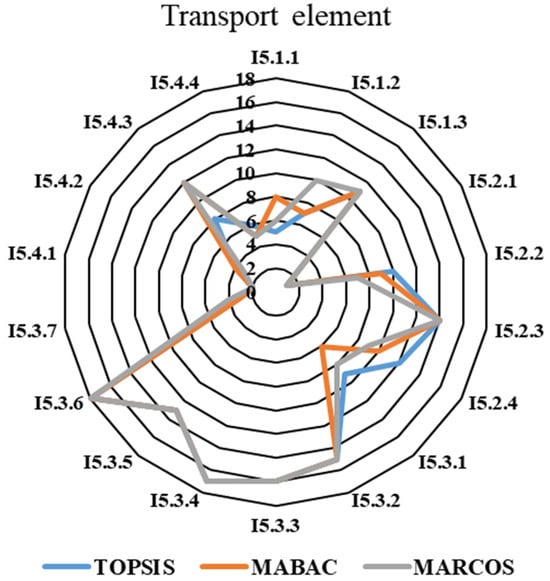

- Transport element model (18 instruments—I5.1.1–I5.4.4);

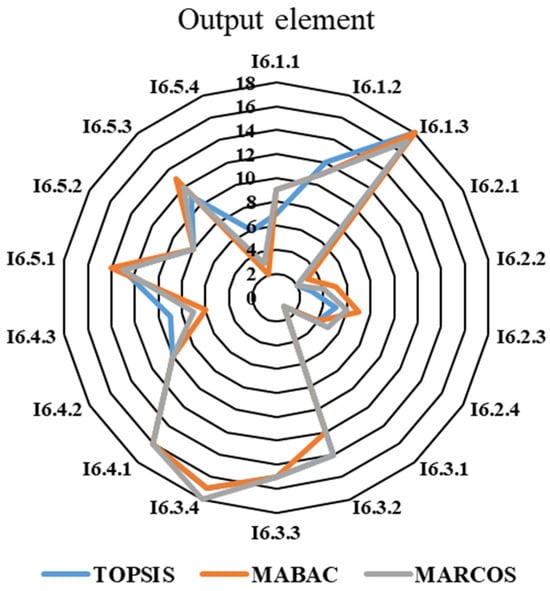

- Output element model (18 instruments—I6.1.1–I6.5.4).

A system of 15 logistics flow criteria was used to evaluate green logistics methods and instruments. The weight values of the criteria of logistic flows were taken from [108]. Fuzzy Analytic Hierarchy Process (Fuzzy AHP) was used to evaluate the weight of the criteria. Seven academic experts with scientific degrees and at least 15 years of experience were selected as decision-making experts. The experts assessed the parameters and indicators of logistics flows using linguistic variables and triangular fuzzy numbers. The main steps of the methodology for assessing the weight of logistics flow criteria using Fuzzy AHP can be found in [108]. Table 9 presents the results.

Table 9.

Weight of logistic flows’ criteria and subcriteria.

We compared the results presented in Table 9 with the results of other multi-criteria methods that we used to evaluate logistics flow indicators in our previous studies: DEMATEL-ANP [128] and Crisp DEMATEL, Fuzzy DEMATEL, and Gray DEMATEL [126]. A comparison of the results of assessing the stability of using different methods showed a high correlation. Spearman’s rank correlation coefficient ranged from 0.7357 to 0.9976.

A group of five academic experts in the field of supply chain management, transport systems, and logistics was formed to perform the assessment. The average length of service of the experts was 25.4 years. The experts evaluated the impact of green logistics methods and instruments on logistics flow criteria on a five-point scale: 1—very low, 2—low, 3—medium, 4—high, and 5—very high. The results of expert assessments are presented in Table 10.

Table 10.

Results of expert assessment of green logistics methods and instruments.

For ranking green logistics methods and instruments, we used MCDM methods, including Technique for Order Preference by Similarity area Comparison Ideal Solution (TOPSIS) [239], Multi-Attributive Border Approximation Area Comparison (MABAC) [240], and Measurement of Alternatives and Ranking according to Compromise Solution (MARCOS) [241]. These methods have been widely used for multi-criteria evaluation of various aspects of sustainable and green supply chains. The main steps of each method can be found in [239,240,241].

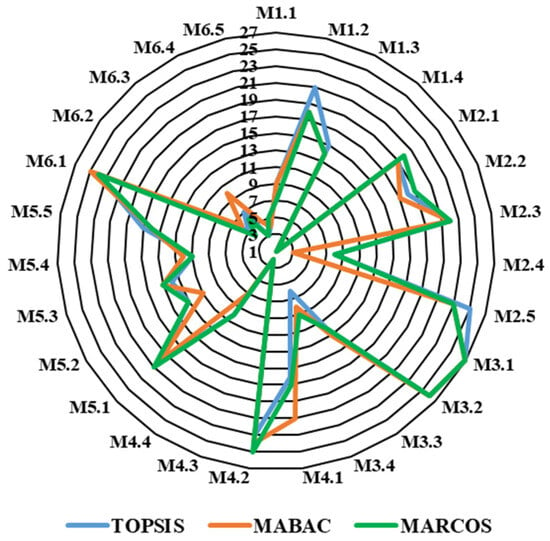

Table 11, Table 12, Table 13, Table 14, Table 15, Table 16 and Table 17 and Figure 12, Figure 13, Figure 14, Figure 15, Figure 16, Figure 17 and Figure 18 present the ranking results. Sensitivity assessment of the ranking results was performed based on the calculation of Spearman’s rank correlation coefficient. The average correlation coefficient was 0.984 for the MCDM model of green logistics methods. For the MCDM model of green logistics instruments, the values were as follows: control element—0.982; input element—0.947; processing element—0.979; cumulative element—0.983; transport element—0.974; and output element—0.980. The values of the coefficients showed a high correlation, indicating the reliability of the obtained results.

Table 11.

Results of ranking green logistics methods by different MCDMs.

Table 12.

Ranks of green logistics instruments of the control element.

Table 13.

Ranks of green logistics instruments of the input element.

Table 14.

Ranks of green logistics instruments of the processing element.

Table 15.

Ranks of green logistics instruments of the cumulative element.

Table 16.

Ranks of green logistics instruments of the transport element.

Table 17.

Ranks of green logistics instruments of the output element.

Figure 12.

Comparison of ranking results of green logistics methods by TOPSIS, MABAC, and MARCOS methods.

Figure 13.

Comparison of ranking results of green logistics instruments for the control element.

Figure 14.

Comparison of ranking results of green logistics instruments for the input element.

Figure 15.

Comparison of ranking results of green logistics instruments for the processing element.

Figure 16.

Comparison of ranking results of green logistics instruments for the cumulative element.

Figure 17.

Comparison of ranking results of green logistics instruments for the transport element.

Figure 18.

Comparison of ranking results of green logistics instruments for the output element.

Additionally, we calculated the value of the mean relative error of the ranking results (MRER) for each MCDM model using the following formula [133]:

where Ril—rank of the i-th alternative (GLM or GLI), calculated by the l-th method; M—number of alternatives; and L—number of ranking methods, L ≥ 3.

The MRER values for GLM were 1.135. The MRER values for GLI were as follows: control element —1.015; input element—0.904; processing element—0.901; cumulative element—0.745; transport element—0.814; and output element—0.851. The calculated MRER values showed minimum deviation in the ranks obtained in the evaluation by the different methods.

The two most significant green logistics methods were M2.4 “Procurement planning, implementation, and control” (rank #1) and M5.3 “Transportation management and transportation planning” (rank #2). Rank #3 was assigned to two green logistics methods—M1.4 “Design and implementation of intelligent transportation system” (MABAC, MARCOS assessment) and M3.4 “Process flow management” (TOPSIS assessment). The two least significant green logistics methods were M4.1 “Environmental design of warehouse complexes” (rank #27) and M4.2 “Use of environmentally acceptable handling equipment and vehicles” (rank #26). Rank #25 was assigned to three green logistics methods—M1.1 “Environmental management” (TOPSIS score), M3.5 “Human resource management” (MARCOS score), and M5.2 “Selection of environmentally friendly vehicles” (MABAC score).

Ranking the green logistics instruments separately by supply chain elements allowed us to establish the most important instruments (Rank #1): I1.5.2 “Electronic data interchange” (control element), I2.4.1 “Minimization of procurement volume” (input element), I3.4.1 “Optimization of process flow parameters” (processing element), I4.4.4 “Unification of batch shipment” (cumulative element), I5.2.1 “Vehicles with the least environmental impact” (transportation element), and I6.3.1 “Selection of green distribution channels (Output Element)”.

Green logistics instruments with the lowest rank were I1.4.1. “Data mining techniques” and I1.4.3. “Situational management techniques” (control element); I2.2.1. “Selection of environmentally friendly raw materials” (input element); I3.4.3. “Production according to eco-design requirements” (processing element); I4.4.2. “Operational control of inventory management system parameters” (cumulative element); I5.3.6. “Reduction in return empty mileage” (transport element), I6.1.3. “Analysis of the distribution system in terms of environmental impact”, and I6.3.4. “Location of distribution centers with minimal environmental impact” (output element).

5. Discussion

This paper analyzes green practices and solutions in logistics based on a review of research in the field of green logistics and green supply chain management. Today, this is the most comprehensive and comprehensive analysis of green practices and solutions in GSC. The number of papers analyzed in this study amounted to 184 publications. In previous reviews on the research topic, the number of studies analyzed was smaller, for example, 28 in [35], 38 in [14], 45 in [4], 89 in [15], 91 in [31], 150 in [36], and 180 in [28]. We found a study that analyzed 215 papers [5] about green practices and MCDM in green supply chain management. However, this analysis was limited to determining the number of papers describing a particular green practice or MCDM. Another review [6] presents the results of grouping green practices in supply chains based on an analysis of 236 papers. But the methodology for grouping green practices in this study is not presented in sufficient detail.

A distinctive feature of our analysis compared to existing studies is the use of a multi-echelon supply chain structure, the functions of all its elements, and MCDM for the implementation of green practices as the basis for grouping green practices. Thus, this approach distinguishes this study from previous reviews, in which the authors focus on specific subject areas or aspects of supply chain management. For example, ref. [206] analyzes the application of MCDM to three areas of logistics: distribution, production, and inventory. Several studies are devoted only to specific areas of logistics, such as green warehousing [14], sustainable [15] or green transportation [35], and green business [28]. Therefore, previous methodologies do not allow for a comprehensive assessment of the implementation of GLM and GLI for the entire multi-echelon green supply chain.

One issue that came up during our research was the variety of terms used. We found 64 unique terms related to green logistics practices and solutions. Terms with similar meanings, such as green practices, green measures, green activities, green initiatives, green decisions, and green solutions, are very similar to the term green logistics instruments. Meanwhile, the terms criteria, drivers, and factors, when applied to GLMs or GLIs, create confusion in the process of analysis, systematization, formation of decision-making models, and their practical use. In addition, the content of several green instruments can be interpreted in different ways. A typical example is the term “eco-design,” which is interpreted as GSCM practices [5,90,139,166,172,191,199,200,223], criteria [86,92] or subcriteria [174], factor [142,201], green practices [215], green activities [80], GSCM initiatives [62], SSC practices [225], measurement items [154], pathways to implementing GSCM [49], GSC processes [45], sustainable attributes [102], CSCM research field [33], dimensions of GSCM [52], and GSC performance measurement [45]. Such various views on the use of the terms show the lack of a unified, comprehensive approach to understanding them. This complicates the formation of decision-making models and, as a result, reduces the effectiveness of practical implementation in supply chains.

The main negative consequence of the identified terminological diversity is the difference in understanding and interpretation of “green” practices. The results of our study showed that 71% of the analyzed papers do not provide a clear definition of green practices or solutions. In recent papers, clear definitions were found only in some papers, for example, in studies of the supply chain as a whole [2,54,57,69,74,145,159], input [88], cumulative [231], and transport [214] elements. Descriptions of green solutions for the output and processing elements were not found in the analyzed papers. Such terminological diversity makes it difficult to understand the essence of each solution and, as a result, reduces the effectiveness of its evaluation by experts and its implementation by decision-makers. Our study provides clear definitions and descriptions of each green logistics instrument for all elements of the green supply chain. This approach complements and expands on our previous study [122], which established the impact of green logistics instruments on sustainable development goals.

The identified lack of clarity regarding the content of “green” solutions and practices as they apply to the elements and functions of supply chains (procurement, production, warehousing, transportation, and distribution) is the main reason for the inconsistent application and duplication of these solutions at various stages of the logistics process. Authors use different approaches to the assessment and use of green practices and solutions in studies of multi-echelon supply chains. In [54], 16 green practices were assessed according to four dimensions (environmental, social, economic, and organizational). In [159], green practices were considered supply chain management variables, along with employee job satisfaction, operational efficiency, relational efficiency, and business performance. The authors of [57] did not specify the elements of supply chains for the implementation of green lean practices. In [6], 58 green practices were grouped according to 15 aspects of logistics activities. In another literature review [5], all existing GSCM practices were listed with an indication of their frequency of appearance in papers without grouping or systematization. The author of another review [36] defined the term “practice” as “the actual application or use of an idea, belief, or method.” He proposed a formula for green practices in the context of GSCM: “Green supply chain practices = Eco-design + Internal environmental management + Waste management + Green purchasing aspect + Quality + Product recovery.” Thus, there are various approaches to the systematization of green practices in previous studies. We concluded that a comprehensive approach to systematizing these practices and solutions for multi-echelon supply chains has not yet been clearly formed.

We used a structural–functional approach to describe SSC and to systematize GLMs and GLIs. The idea of such systematization was proposed in [133] to identify drivers of supply chain sustainability. We identified universal elements of the supply chain, each of which performs specific functions in promoting and processing the material flow. This approach eliminates the duplication of GLMs and GLIs at different stages of the logistics process. The proposed approach is novel and differs from the methods of systematizing environmental practices presented in recent studies in this scientific field.

The need to choose green instruments in a multi-echelon supply chain in a coordinated manner for all elements of the chain makes the selection task difficult. The complexity of the decision-making process in such conditions makes it advisable to use multi-criteria analysis and expert methods, as well as to develop new MCDM models for the implementation of green practices. The complexity of selecting a set of green instruments is due, for example, to difficulties in collecting reliable raw data, possible data losses during aggregation, shortcomings in expert assessment methods, and the significant labor intensity of the decision-making process in such conditions [242,243]. This thesis is noted in [242,244], which points out that there are no universal MCDM methods suitable for all decision-making situations, which leads to the problem of selecting an MCDM method. Studies [244,245] provide recommendations for such a choice. We summarized previous studies and proposed a universal framework and a combined MCDM model for evaluating and ranking logistics instruments for GSC. We used a combination of common methods, Fuzzy AHP-TOPSIS-MABAC-MARCOS, in the example of the framework implementation. The reliability of the Fuzzy AHP results was assessed by comparison with the results of DEMATEL-ANP [128], Crisp DEMATEL, Fuzzy DEMATEL, and Gray DEMATEL [126]. For ranking GLMs and GLMs, we used classic TOPSIS and compared the results with those of modern MABAC and MARCOS.

Thus, the theoretical contribution of our research is as follows:

First, we propose new concepts: “green logistics method (GLM)” and “green logistics instrument (GLI).” The “green logistics method” is a set of solutions to achieve the SDGs by realizing the basic and supporting logistics functions of a certain element of the logistics system or supply chain. The “green logistics instrument” is a specific solution for changing the parameters of logistics flows to implement the corresponding green logistics method. It has been shown that these concepts can be rationally used as generalized universal categories instead of the multitude of diverse “green terms” currently used in logistics activities.

Secondly, a system of green logistics methods and instruments was substantiated based on the results of a review of 184 scientific studies in the field of logistics and supply chain management practices. This system includes 27 methods and 105 instruments. The supporting functions of the elements of a multi-echelon supply chain, i.e., a set of specific functions of each element for changing the parameters of the material flow, were used as a sign of systematization.

Thirdly, a universal framework for evaluating and ranking green logistics methods and instruments was presented. The framework includes methods for describing the structure and functions of a multi-echelon green supply chain, a system of green logistics methods and instruments, a logistic flow evaluation system, and a set of multi-criteria decision-making methods. In our opinion, this framework is the most valuable practical result of our research. We recommend using the GLM and GLI rankings obtained in the calculation example for each functional element of a multi-echelon green supply chain as a basis for justifying management decisions on achieving sustainable development goals in supply chains.

6. Conclusions

The methodology of the systematization and ranking of methods and instruments of green logistics in supply chains was presented. The defining feature of the proposed approach is its representation of the supply chain as a universal six-element model (control, input, processing, cumulative, transport, and output) that collectively encompasses all established functional areas of logistics governing the movement and processing of material flows. Each element performs a set of supporting functions that are exclusive to it. To improve the sustainability of the supply chain, the performance of supporting functions by elements should be based on the implementation of methods and instruments of green logistics.

Based on the literature review, the systematization of currently existing green solutions and practices by supporting functions of supply chain elements was performed. A universal system of green logistics methods and instruments was proposed, and definitions of each instrument were given. This system includes 27 methods and 105 instruments.

The system of criteria for assessing logistics flows was used as the criteria for the effectiveness of the implementation of green logistics methods and instruments. The implementation of green logistics instruments has an impact on the criteria of logistics flows and allows for achieving the goals of sustainable development of supply chains. To assess the impact of green logistics methods and instruments on the criteria of logistics flows, we proposed to use multi-criteria decision-making methods.

Ranking green logistics methods and instruments using MCDM methods was performed. Fuzzy AHP was used to estimate the weight of the criteria of logistic flows. TOPSIS, MABAC, and MARCOS methods were used to rank the methods and instruments. The ranking results by different MCDM showed high convergence—the average Spearman rank correlation coefficient was 0.975, and the value of the mean relative error of the ranking results was 0.909.

The most significant methods of green logistics were “Procurement planning, execution and supply controlling”, “Transport management and transport planning”, “Development and implementation of intelligent transport system”, and “Technological flows management”. The most significant instruments of green logistics in the supply chain elements were “Electronic data interchange” (control element), “Minimization of purchasing volume” (input element), “Optimization of technological flows’ parameters” (processing element), “Unitization of party shipment” (cumulative element), “Vehicles with the least impact on the environment” (transport element), and “Selection of environmentally friendly distribution channels” (output element).

The limitations of this study are as follows:

- The small number of experts used to determine the weights of logistics flow criteria and the rankings of green logistics instruments limits the ability to interpret the results for global supply chains.

- There is a need to specify the conditions for implementing the selected GLMs and GLIs in accordance with their rankings. The results of this study provide an understanding of the importance of GLMs and GLIs for improving supply chain resilience. The rankings obtained form the basis for the implementation of GLMs and GLIs. Next, it is necessary to determine the characteristics of the selected instruments. For example, if an environmentally friendly vehicle is required, which model should be chosen? If a nearby supplier is selected, which one will be selected? The answers to these questions will require the selection of a specific method for implementing the instruments, using, for example, simulation and optimization models that take resource constraints, among other factors.

Promising areas for future research to overcome the limitations identified in this study are as follows:

- Additional research is required on the barriers and drivers of the practical implementation of green logistics instruments in dynamic supply chains in the context of economic, geopolitical, and technological changes, including the development of artificial intelligence and the introduction of Industry 4.0 solutions.

- The expert group should be expanded to include industry experts.

- A combined multi-criteria optimization and simulation model should be developed for selecting a combination of green logistics instruments and calculating their parameters.

- The list of instruments should be supplemented based on monitoring research in this area using large language models and artificial intelligence, as well as using a larger number of scientific databases.

Author Contributions

Conceptualization, A.R. and N.O.; methodology, A.R. and N.O.; software, N.O.; validation, N.O. and A.R.; formal analysis, N.O.; investigation, N.O.; resources, A.R.; data curation, N.O.; writing—original draft preparation, N.O.; writing—review and editing, A.R.; visualization, N.O.; supervision, A.R.; project administration, N.O.; funding acquisition, N.O. and A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work was carried out with the financial support of the Russian Science Foundation, No. 23-21-10038, https://rscf.ru/en/project/23-21-10038/ (accessed on 2 May 2025) and No. 23-11-00164, https://rscf.ru/en/project/23-11-00164/ (accessed on 2 May 2025).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Berg, F.; Kölbel, J.F.; Rigobon, R. Aggregate confusion: The divergence of ESG ratings. Rev. Financ. 2022, 26, 1315–1344. [Google Scholar] [CrossRef]

- Chakraborty, A.; Al Amin, M.; Baldacci, R. Analysis of internal factors of green supply chain management: An interpretive structural modeling approach. Clean. Logist. Supply Chain 2023, 7, 100099. [Google Scholar] [CrossRef]

- Karaman, A.S.; Ellili, N.O.D.; Uyar, A. Do sustainable supply chain practices mitigate carbon emissions? The role of supplier environmental, social and governance training. Bus. Strategy Environ. 2024, 33, 8126–8148. [Google Scholar] [CrossRef]

- Tetteh, F.K.; Owusu Kwateng, K.; Mensah, J. Green logistics practices: A bibliometric and systematic methodological review and future research opportunities. J. Clean. Prod. 2024, 476, 143735. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Gangwani, K.K. Green supply chain management: Scientometric review and analysis of empirical research. J. Clean. Prod. 2021, 284, 124722. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Islam, M.S.; Karia, N.; Fauzi, F.A.; Afrin, S. A literature review on green supply chain management: Trends and future challenges. Resour. Conserv. Recycl. 2019, 141, 145–162. [Google Scholar] [CrossRef]

- Lazar, S.; Klimecka-Tatar, D.; Obrecht, M. Sustainability orientation and focus in logistics and supply chains. Sustainability 2021, 13, 3280. [Google Scholar] [CrossRef]

- Tozanli, O.; Duman, G.; Kongar, E.; Gupta, S. Environmentally concerned logistics operations in fuzzy environment: A literature survey. Logistics 2017, 1, 4. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Liu, R.; Liu, H.-C.; Shi, H. Green supplier evaluation and selections: A state-of-the-art literature review of models, methods, and applications. Math. Probl. Eng. 2020, 2020, 1783421. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Schultmann, F. Sustainable supplier management—A review of models supporting sustainable supplier selection, monitoring and development. Int. J. Prod. Res. 2016, 54, 1412–1442. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T.N. A systematic literature review to map literature focus of sustainable manufacturing. J. Clean. Prod. 2020, 256, 120345. [Google Scholar] [CrossRef]

- Roy, V.; Singh, S. Mapping the business focus in sustainable production and consumption literature: Review and research framework. J. Clean. Prod. 2017, 150, 224–236. [Google Scholar] [CrossRef]

- Becerra, P.; Mula, J.; Sanchis, R. Green supply chain quantitative models for sustainable inventory management: A review. J. Clean. Prod. 2021, 52, 129544. [Google Scholar] [CrossRef]

- Bartolini, M.; Bottani, E.; Grosse, E.H. Green warehousing: Systematic literature review and bibliometric analysis. J. Clean. Prod. 2019, 226, 242–258. [Google Scholar] [CrossRef]

- Aloui, A.; Hamani, N.; Derrouiche, R.; Delahoche, L. Systematic literature review on collaborative sustainable transportation: Overview, analysis and perspectives. Transp. Res. Interdiscip. Perspect. 2021, 9, 100291. [Google Scholar] [CrossRef]

- Zhao, X.; Ke, Y.; Zuo, J.; Xiong, W.; Wu, P. Evaluation of sustainable transport research in 2000–2019. J. Clean. Prod. 2020, 256, 120404. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T.; Childe, S.J. Green supply chain management enablers: Mixed methods research. Sustain. Prod. Consum. 2015, 4, 72–88. [Google Scholar] [CrossRef]

- Kim, D.; Na, J.; Ha, H.-K. Exploring the impact of green logistics practices and relevant government policy on the financial efficiency of logistics companies. Heliyon 2024, 10, e30916. [Google Scholar] [CrossRef]

- Jefimovaitė, L.; Vienažindienė, M. Green logistics concept and the impact of its implementation in the organisation: A systematic literature review and meta-analysis. Eng. Manag. Prod. Serv. 2025, 17, 39–51. [Google Scholar] [CrossRef]

- Simm, N. Greener logistics through resource sharing—A resource dependency lens on supply chain interaction. Res. Transp. Bus. Manag. 2025, 61, 101405. [Google Scholar] [CrossRef]

- Jazairy, A.; Pohjosenperä, T.; Prataviera, L.B.; Juntunen, J. Innovators and transformers: Revisiting the gap between academia and practice: Insights from the green logistics phenomenon. Int. J. Phys. Distrib. Logist. Manag. 2024, 55, 341–360. [Google Scholar] [CrossRef]

- Kumar, M.; Raut, R.D.; Mangla, S.K.; Chowdhury, S.; Choubey, V.K. Moderating ESG compliance between industry 4.0 and green practices with green servitization: Examining its impact on green supply chain performance. Technovation 2024, 129, 102898. [Google Scholar] [CrossRef]

- Musau, E.G. Optimizing transportation and distribution for environmental sustainability. In Green Supply Chain Management Practice and Principles; Wang, J., Martínez-Falcó, J., Marco-Lajara, B., Sánchez-García, E., Millán-Tudela, L.A., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 84–101. ISBN 9798369334867. [Google Scholar]

- Ramasamy, I.; Natarajan, S.; Sathyamoorthy, V.K.P. Does disruptive technology and AI (Artificial Intelligence) influence logistics management? Multidiscip. Sci. J. 2024, 6, 2024259. [Google Scholar] [CrossRef]

- He, Q.; Marshall, B.R.; Nguyen, J.H.; Nguyen, N.H.; Qiu, B.; Visaltanachoti, N. Greenwashing: Measurement and Implications. 2024. Available online: https://sustainablefinancealliance.org/wp-content/uploads/2024/02/Greenwashing_Measurement_and_Implications_2024_GRASFI.pdf (accessed on 7 April 2025).

- Chava, S.; Du, W.; Malakar, B. Do Managers Walk the Talk on Environmental and Social Issues? SSRN Electron. J. 2021, 3900814. [Google Scholar] [CrossRef]

- Carvalho, H.; Garrido Azevedo, S.; Cruz-Machado, V. Supply chain performance management: Lean and green paradigms. Int. J. Bus. Perform. Supply Chain Model. 2010, 2, 304–333. [Google Scholar] [CrossRef]

- Hasan, M.M.; Nekmahmud, M.; Yajuan, L.; Patwary, M.A. Green business value chain: A systematic review. Sustain. Prod. Consum. 2019, 20, 326–339. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, C.; Chan, H.K.; Choy, K.L.; Wu, Z. Swarm intelligence applied in green logistics: A literature review. Eng. Appl. Artif. Intell. 2015, 37, 154–169. [Google Scholar] [CrossRef]

- Sezen, B.; Çankaya, S.Y. Green supply chain management theory and practices. In Ethics and Sustainability in Global Supply Chain Management; Akkucuk, U., Ed.; IGI Global: Hershey, PA, USA, 2017; pp. 92–114. ISBN 978-1-5225-2036-8. [Google Scholar]

- Islam, S.; Karia, N.; Fauzi, F.; Soliman, M. A review on green supply chain aspects and practices. Manag. Marketing. Chall. Knowl. Soc. 2017, 12, 12–36. [Google Scholar] [CrossRef]

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. ISO copyright office: Geneva, Switzerland, 2015. Available online: https://webstore.ansi.org/standards/iso/iso140012015 (accessed on 20 January 2025).

- Lahane, S.; Kant, R.; Shankar, R. Circular supply chain management: A state-of-art review and future opportunities. J. Clean. Prod. 2020, 258, 120859. [Google Scholar] [CrossRef]

- Evangelista, P.; Santoro, L.; Thomas, A. Environmental sustainability in third-party logistics service providers: A systematic literature review from 2000–2016. Sustainability 2018, 10, 1627. [Google Scholar] [CrossRef]

- Bilek, G.M.; Calvi, R.; Erhel, D.; Mechouar, Y. Towards green transportation practices using a buyer/supplier perspective: A systematic literature review. Logistics 2024, 8, 68. [Google Scholar] [CrossRef]

- Balon, V. Green supply chain management: Pressures, practices, and performance—An integrative literature review. Bus. Strategy Dev. 2019, 3, 226–244. [Google Scholar] [CrossRef]

- Ahmed, T.; Yousaf, A.; Clavijo, R.C.; Sanders, K. Entrepreneurial pathways to sustainability: A theoretical paper on green human resource management, green supply chain management, and entrepreneurial orientation. Sustainability 2024, 16, 6357. [Google Scholar] [CrossRef]

- Morella, P.; Lambán, M.P.; Royo, J.; Sánchez, J.C.; Latapia, J. Technologies associated with Industry 4.0 in green supply chains: A systematic literature review. Sustainability 2023, 15, 9784. [Google Scholar] [CrossRef]

- Villanueva-Ponce, R.; Avelar-Sosa, L.; Alvarado-Iniesta, A.; Cruz-Sánchez, V.G. The green supplier selection as a key element in a supply chain: A review of cases studies. DYNA 2015, 82, 36–45. [Google Scholar] [CrossRef]

- Khalil, N.; Che Abdullah, S.N.; Haron, S.N.; Hamid, M.Y. A review of green practices and initiatives from stakeholder’s perspectives towards sustainable hotel operations and performance impact. J. Facil. Manag. 2024, 22, 653–682. [Google Scholar] [CrossRef]

- Sharma, V.K.; Chandna, P.; Bhardwaj, A. Green supply chain management related performance indicators in agro industry: A review. J. Clean. Prod. 2017, 141, 1194–1208. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of internet of things (IoT) embedded sustainable supply chain for Industry 4.0 requirements. Comput. Ind. Eng. 2018, 127, 925–953. [Google Scholar] [CrossRef]

- Pardalos, P.; Horst, R.; Roy, B. Multicriteria Methodology for Decision Aiding; Springer: Boston, MA, USA, 1996; ISBN 978-1-4419-4761-1. [Google Scholar]

- Osintsev, N. Multi-criteria decision-making methods in green logistics. World Transp. Transp. 2021, 19, 231–240. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Mohapatra, P.; Kumar, V.; Dey, P.K.; Brady, M.; Tiwari, M.K.; Nudurupati, S.S. Green supply chain performance measurement using fuzzy ANP-based balanced scorecard: A collaborative decision-making approach. Prod. Plan. Control 2014, 25, 698–714. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Identifying and ranking of strategies to implement green supply chain management in Indian manufacturing industry using Analytical Hierarchy Process. J. Ind. Eng. Manag. 2013, 6, 930–962. [Google Scholar] [CrossRef]

- Shen, L.; Muduli, K.; Barve, A. Developing a sustainable development framework in the context of mining industries: AHP approach. Resour. Policy 2015, 46, 15–26. [Google Scholar] [CrossRef]

- de Souza, E.D.; Kerber, J.C.; Bouzon, M.; Rodriguez, C. Performance evaluation of green logistics: Paving the way towards circular economy. Clean. Logist. Supply Chain 2022, 3, 100019. [Google Scholar] [CrossRef]

- Uddin, S.; Ali, S.M.; Kabir, G.; Suhi, S.A.; Enayet, R.; Haque, T. An AHP-ELECTRE framework to evaluate barriers to green supply chain management in the leather industry. Int. J. Sustain. Dev. World Ecol. 2019, 26, 732–751. [Google Scholar] [CrossRef]

- Anand, K.R.; Ramalingaiah; Parthiban, P. Evaluation of green supply chain factors using DEMATEL. Appl. Mech. Mater. 2014, 592–594, 2619–2627. [Google Scholar] [CrossRef]

- Bai, C.; Kusi-Sarpong, S.; Sarkis, J. An implementation path for green information technology systems in the Ghanaian mining industry. J. Clean. Prod. 2017, 164, 1105–1123. [Google Scholar] [CrossRef]

- Mumtaz, U.; Ali, Y.; Petrillo, A.; de Felice, F. Identifying the critical factors of green supply chain management: Environmental benefits in Pakistan. Sci. Total Environ. 2018, 640–641, 144–152. [Google Scholar] [CrossRef]

- Chou, Y.-C.; Yang, C.-H.; Lu, C.-H.; van Dang, T.; Yang, P.-A. Building criteria for evaluating green project management: An integrated approach of DEMATEL and ANP. Sustainability 2017, 9, 740. [Google Scholar] [CrossRef]

- Tsai, J.-F.; Shen, S.-P.; Lin, M.-H. Applying a hybrid MCDM model to evaluate green supply chain management practices. Sustainability 2023, 15, 2148. [Google Scholar] [CrossRef]

- Özaşkın, A.; Görener, A. An integrated multi-criteria decision-making approach for overcoming barriers to green supply chain management and prioritizing alternative solutions. Supply Chain Anal. 2023, 3, 100027. [Google Scholar] [CrossRef]

- Boutkhoum, O.; Hanine, M.; Boukhriss, H.; Agouti, T.; Tikniouine, A. Multi-criteria decision support framework for sustainable implementation of effective green supply chain management practices. Springerplus 2016, 5, 664. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.I.; Al Amin, M.; Baldacci, R.; Rahman, M.H. Identification and prioritization of green lean supply chain management factors using fuzzy DEMATEL. Sustainability 2023, 15, 10523. [Google Scholar] [CrossRef]

- Malviya, R.K.; Kant, R. Hybrid decision making approach to predict and measure the success possibility of green supply chain management implementation. J. Clean. Prod. 2016, 135, 387–409. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.-L.; Chiu, A.S. Exploring decisive factors in green supply chain practices under uncertainty. Int. J. Prod. Econ. 2015, 159, 147–157. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Q. Evaluating the green practice of food service supply chain management based on fuzzy DEMATEL-ANP model. In Seventh International Conference on Electronics and Information Engineering, Proceedings of the Seventh International Conference on Electronics and Information Engineering, Nanjing, China, 17 September 2016; Chen, X., Ed.; SPIE: Pune, MA, USA, 2017; p. 103222J. [Google Scholar]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Comput. Ind. Eng. 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Govindan, K.; Esmaeili, A.; Sabaghi, M. Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecol. Indic. 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Sarkis, J.; Wang, X. Assessing green supply chain practices in the Ghanaian mining industry: A framework and evaluation. Int. J. Prod. Econ. 2016, 181, 325–341. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Lim, M.; Wu, K.-J.; Zhou, L.; Bui, D.T.D. A novel approach for enhancing green supply chain management using converged interval-valued triangular fuzzy numbers-grey relation analysis. Resour. Conserv. Recycl. 2018, 128, 122–133. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K. Integration of AHP-TOPSIS method for prioritizing the solutions of reverse logistics adoption to overcome its barriers under fuzzy environment. J. Manuf. Syst. 2015, 37, 599–615. [Google Scholar] [CrossRef]

- Chen, Z.-S.; Zhang, X.; Govindan, K.; Wang, X.-J.; Chin, K.-S. Third-party reverse logistics provider selection: A computational semantic analysis-based multi-perspective multi-attribute decision-making approach. Expert Syst. Appl. 2021, 166, 114051. [Google Scholar] [CrossRef]

- Ortiz-Barrios, M.; La Miranda-De Hoz, C.; López-Meza, P.; Petrillo, A.; de Felice, F. A case of food supply chain management with AHP, DEMATEL, and TOPSIS. J. Multi-Criteria Decis. Anal. 2019, 27, 104–128. [Google Scholar] [CrossRef]

- Nag, U.; Sharma, S.K.; Govindan, K. Investigating drivers of circular supply chain with product-service system in automotive firms of an emerging economy. J. Clean. Prod. 2021, 319, 128629. [Google Scholar] [CrossRef]

- Balouei Jamkhaneh, H.; Shahin, R.; Tortorella, G.L. Analysis of Logistics 4.0 service quality and its sustainability enabler scenarios in emerging economy. Clean. Logist. Supply Chain 2022, 4, 100053. [Google Scholar] [CrossRef]

- Zhou, L.; Zhu, J.; Guo, J. Research on construction of the green logistics evaluation index system and determination of index weight. Am. J. Theor. Appl. Stat. 2014, 3, 96–99. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Kumar, A.; Moktadir, M.A.; Khan, S.A.R.; Garza-Reyes, J.A.; Tyagi, M.; Kazançoğlu, Y. Behavioral factors on the adoption of sustainable supply chain practices. Resour. Conserv. Recycl. 2020, 158, 104818. [Google Scholar] [CrossRef]

- Soltanmohammadi, A.; Andalib Ardakani, D.; Dion, P.A.; Hettiarachchi, B.D. Employing total quality practices in sustainable supply chain management. Sustain. Prod. Consum. 2021, 28, 953–968. [Google Scholar] [CrossRef]

- Sharma, Y.K.; Sharma, S. IT success factors in sustainable food supply chain management. Mater. Today Proc. 2022, 56, 43–45. [Google Scholar] [CrossRef]

- Akman, G.; Pışkın, H. Evaluating green performance of suppliers via analytic network process and TOPSIS. J. Ind. Eng. 2013, 2013, 915241. [Google Scholar] [CrossRef]

- Tsai, J.-F.; Wu, S.-C.; Pham, T.K.L.; Lin, M.-H. Analysis of key factors for green supplier selection: A case study of the electronics industry in Vietnam. Sustainability 2023, 15, 7885. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. Int. J. Prod. Econ. 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Haeri, S.A.S.; Rezaei, J. A grey-based green supplier selection model for uncertain environments. J. Clean. Prod. 2019, 221, 768–784. [Google Scholar] [CrossRef]

- Falatoonitoosi, E.; Ahmed, S.; Sorooshian, S. A multicriteria framework to evaluate supplier’s greenness. Abstr. Appl. Anal. 2014, 2014, 396923. [Google Scholar] [CrossRef]

- Fu, X.; Zhu, Q.; Sarkis, J. Evaluating green supplier development programs at a telecommunications systems provider. Int. J. Prod. Econ. 2012, 140, 357–367. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Kuo, T.-C.; Chen, S.-H.; Hu, A.H. Using DEMATEL to develop a carbon management model of supplier selection in green supply chain management. J. Clean. Prod. 2013, 56, 164–172. [Google Scholar] [CrossRef]

- Jayant, A.; Neeru; Agarwal, A. A novel hybrid MCDM approach based on DEMATEL, AHP and TOPSIS to evaluate green suppliers. J. Phys. Conf. Ser. 2019, 1240, 12010. [Google Scholar] [CrossRef]

- Mubarik, M.S.; Kazmi, S.H.A.; Zaman, S.I. Application of gray DEMATEL-ANP in green-strategic sourcing. Technol. Soc. 2021, 64, 101524. [Google Scholar] [CrossRef]

- Liou, J.J.; Tamošaitienė, J.; Zavadskas, E.K.; Tzeng, G.-H. New hybrid COPRAS-G MADM Model for improving and selecting suppliers in green supply chain management. Int. J. Prod. Res. 2016, 54, 114–134. [Google Scholar] [CrossRef]

- Pourjavad, E.; Shahin, A. Green supplier development programmes selection: A hybrid fuzzy multi-criteria decision-making approach. Int. J. Sustain. Eng. 2020, 13, 463–472. [Google Scholar] [CrossRef]

- Gupta, S.; Soni, U.; Kumar, G. Green supplier selection using multi-criterion decision making under fuzzy environment: A case study in automotive industry. Comput. Ind. Eng. 2019, 136, 663–680. [Google Scholar] [CrossRef]

- Wu, K.-J.; Tseng, M.-L.; Vy, T. Evaluation the drivers of green supply chain management practices in uncertainty. Procedia-Soc. Behav. Sci. 2011, 25, 384–397. [Google Scholar] [CrossRef]

- Puška, A.; Božanić, D.; Nedeljković, M.; Janošević, M. Green supplier selection in an uncertain environment in agriculture using a hybrid MCDM model: Z-Numbers–Fuzzy LMAW–Fuzzy CRADIS model. Axioms 2022, 11, 427. [Google Scholar] [CrossRef]

- Đalić, I.; Stević, Ž.; Karamasa, C.; Puška, A. A novel integrated fuzzy PIPRECIA—Interval rough SAW model green supplier selection. Decis. Mak. Appl. Manag. Eng. 2020, 3, 126–145. [Google Scholar] [CrossRef]

- Kannan, D.; Jabbour, A.B.L.d.S.; Jabbour, C.J.C. Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company. Eur. J. Oper. Res. 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Keshavarz Ghorabaee, M.; Zavadskas, E.K.; Amiri, M.; Esmaeili, A. Multi-criteria evaluation of green suppliers using an extended WASPAS method with interval type-2 fuzzy sets. J. Clean. Prod. 2016, 137, 213–229. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P.; Pardasani, K.R.; Mardani, A. A novel hesitant fuzzy WASPAS method for assessment of green supplier problem based on exponential information measures. J. Clean. Prod. 2019, 238, 117901. [Google Scholar] [CrossRef]

- Akcan, S.; Taş, M.A. Green supplier evaluation with SWARA-TOPSIS integrated method to reduce ecological risk factors. Environ. Monit. Assess. 2019, 191, 226. [Google Scholar] [CrossRef]

- Mousakhani, S.; Nazari-Shirkouhi, S.; Bozorgi-Amiri, A. A novel interval type-2 fuzzy evaluation model based group decision analysis for green supplier selection problems: A case study of battery industry. J. Clean. Prod. 2017, 168, 205–218. [Google Scholar] [CrossRef]

- Rajesh, R.; Ravi, V. Supplier selection in resilient supply chains: A grey relational analysis approach. J. Clean. Prod. 2015, 86, 343–359. [Google Scholar] [CrossRef]

- Matić, B.; Jovanović, S.; Das, D.K.; Zavadskas, E.K.; Stević, Ž.; Sremac, S.; Marinković, M. A new hybrid MCDM model: Sustainable supplier selection in a construction company. Symmetry 2019, 11, 353. [Google Scholar] [CrossRef]