Abstract

The complexity and shortening of development cycles in the automotive industry, particularly with the rise in hybrid electric vehicle sales, increases the need for efficient calibration and testing methods. Virtualization using hardware-in-the-loop testbenches has the potential to counteract these trends, specifically for the calibration of hybrid operating strategies. This paper presents a dynamic closed-loop validation of a hardware-in-the-loop testbench designed for the virtual calibration of hybrid operating strategies for a plug-in hybrid electric vehicle. Requirements regarding the hardware-in-the-loop testbench accuracy are defined based on the investigated use case. From this, a dedicated hardware-in-the-loop testbench setup is derived, including an electrical setup as well as a plant simulation model. The model is then operated in a closed loop with a series production hybrid control unit. The closed-loop validation results demonstrate that the chassis simulation reproduces driving resistance closely aligning with the reference data. The driver model follows target speed profiles within acceptable limits, achieving an R2 = 0.9993, comparable to the R2 reached by trained human drivers. The transmission model replicates the gear ratios, maintaining rotational speed deviations below 30 min−1. Furthermore, the shift strategy is implemented in a virtual control unit, resulting in a gear selection comparable to reference measurements. The energy flow simulation in the complete powertrain achieves high accuracy. Deviations in the high-voltage battery state of charge remain below 50 Wh in a WLTC charge-sustaining drive cycle and are thus within the acceptable error margin. The net energy change criterion is satisfied with the hardware-in-the-loop testbench, achieving a net energy change of 0.202%, closely matching the reference measurement of 0.159%. Maximum deviations in cumulative high-voltage battery energy are proven to be below 10% in both the charging and discharging directions. Fuel consumption and CO2 emissions are modeled with deviations below 3%, validating the simulation’s representation of vehicle efficiency. Real-time capability is achieved under all investigated operating conditions and test scenarios. The testbench achieves a real-time factor of at least 1.104, ensuring execution within the hard real-time criterion. In conclusion, the closed-loop validation confirms that the developed hardware-in-the-loop testbench satisfies all predefined requirements, accurately simulating the behavior of the reference vehicle.

1. Introduction and Motivation

The current rate of technological progress in the automotive sector is considerable, resulting in a reduced duration of product development cycles and a corresponding reduction in time to market [1]. Furthermore, the complexity of powertrains is increasing, as evidenced by the growing number of calibration labels [2,3]. This trend is intensified by the increasing share of powertrain electrification [4,5]. In 2023, the total sales of hybrid powertrains in the European Union reached 3.530 million units, representing ~35% of total passenger car sales [6]. The share of hybrid vehicles in global passenger car sales is estimated to have been 25% in the year 2023 [7]. In addition, the global market for plug-in hybrid electric vehicles is forecasted to increase even further, with an annual growth of 1.94% [8]. However, the combination of electric and conventional drive components in one powertrain introduces additional complexity to the development and calibration process [9]. The determination of the energy split is a decision with a significant impact on the entire drivetrain [9,10,11]. The targeted component operating points determined by the hybrid operating strategy (HOS) have a significant influence on various calibration disciplines [12,13]. As a result, the optimization of an HOS calibration can only be realized in multiple iterative loops and with considerable effort.

Despite the rising complexity of powertrains, development productivity is not increasing at a comparable rate, resulting in a significant development capacity deficit [3,14]. In this context, the virtualization of development tasks is of high importance, as it can accelerate the development process considerably [15] while simultaneously reducing costs [16]. X-in-the-loop testbenches can allow for the efficient testing and validation of design and calibration changes, reducing the need for physical prototype vehicles [17]. In this context, the testing and calibration of the complex interactions between the system components can be virtualized [16,18,19,20,21,22].

To deploy a hardware-in-the-loop (HiL) testbench for virtual testing and calibration, the testbench needs to simulate measurement data comparable to the investigated physical vehicle. The model accuracy necessary for virtualization is strongly dependent on the targeted use case. Some scientific publications have already investigated the question of the minimum modeling accuracy required for certain calibration use cases [19,20,21,22]. However, a systematic and specific assessment of the required simulation accuracy for the virtual calibration of HOS functions on an HiL testbench is yet to be performed. To establish the necessary model accuracy, this publication systematically defines the requirements. This is achieved with a forward-looking analysis, where the initial requirements are derived directly from the specific calibration use case, as well as from the characteristics of the vehicle under investigation. By identifying and incorporating these requirements, the plant simulation model is tailored to support accurate and reliable measurement data from the HiL testbench. Nevertheless, it has to be assured that the developed plant simulation model is real-time-capable during execution on the target real-time systems.

To validate the requirements and the developed HiL platform, a dedicated analysis of HiL results against measurements from a real prototype vehicle is performed in this publication. Due to the high number of simulation models required and the complex interactions between them, an open-loop validation alone, similar to that in DÜZGÜN et al. [23], is not sufficient. The error propagation between models, as well as the interdependencies in the context of the device under test (DUT), must be taken into account. This is the motivation for evaluating the system’s accuracy in a closed-loop environment after completing the open-loop validation.

2. Materials and Methods

This study is based on the methodology for virtual calibration presented in DÜZGÜN et al. [23]. For this purpose, the calibration use-case is analyzed and requirements regarding the necessary testbench setup are derived in this section. Further, the developed testbench is described.

2.1. Hardware-in-the-Loop Testbench Requirements

The requirements for the HiL testbench are defined to evaluate the model accuracy while still maintaining real-time capability. The requirements described in more detail below were derived directly from the investigated calibration work package. The definition is based primarily on the characteristics of the reference vehicle as well as legal requirements.

The basis of a comparable operation between the HiL and the reference vehicle is the simulation of the chassis. For the simulation of the vehicle on a chassis dynamometer, a consideration of the longitudinal dynamics is sufficient. The simulation of the resistive forces at wheel level must be compliant with the legislative regulation. Hence, a virtual coast down test has to be performed analogous to the reference vehicle on a chassis dynamometer. The test is successful if the difference between the target torque and the measured torque at wheel level is below the defined threshold [24]:

The behavior of the driver has to be simulated, including all interfaces to the vehicle. This primarily includes the accelerator and brake pedal position as well as the gear lever actuation. The virtual driver needs to be able to follow a target speed profile according to the legal requirements defined as follows [24,25]:

Model accuracy for all powertrain components such as the internal combustion engine (ICE), high-voltage (HV) electric machine (EM), high-voltage battery (HVB), transmission, and differentials is essential. Not only the individual components, but also the interaction regarding torque and rotational speed between them has to be evaluated. The transmission model is validated by verifying the rotational speeds of the rotating components against reference measurements. Based on engineering judgment, the rotational speeds of all powertrain components must align with the reference measurements within a tolerance < ±50 min−1 when the vehicle operates at the same velocity and the transmission is in the same gear:

The shift strategy is evaluated by defining the delay shift time for shift event i and the average delay shift time for gear j . A distinction is made between upshifts and downshifts into the specified target gear. The criteria are calculated as follows:

The shifting decision depends on the current vehicle speed and the accelerator pedal position and, thus, on the driver and overall vehicle simulation. This is the reason why a general limitation of the shift delay does not make sense.

Achieving high accuracy in energy flow and loss simulation is particularly important for HOSs. Previous studies on an NEDC in charge-depleting operation have demonstrated that the deviation of the cumulative HVB energy in the charging direction should be <±15%. Analogously, in the discharging direction, the simulation deviation should be <±3% [26].

In charge-sustaining operation, complying with the net energy change (NEC) criterion is a legal requirement that aims to prove that the vehicle, combined with an HOS, can maintain the state of charge (SOC) of the HV battery [24]. Building on this foundation, the testbench has to provide measurement data so that the NEC criterion is evaluable. Consequently, the discrepancy in NEC between the reference measurements and those obtained from the HiL testbench must not exceed 0.25%, which translates to approximately 50 Wh in electric energy for the given vehicle.

Moreover, this deviation threshold must be maintained consistently throughout the entire evaluation scope. To evaluate this, the Root Mean Square Error (RMSE) is used to verify that the energy difference remains within the specified limits throughout the cycle duration.

In addition to the assessment of the electrical system, an energy-based evaluation of the ICE is necessary for the investigated calibration use-case. Specifically, the modeling of fuel consumption and CO2 emissions must achieve a defined level of accuracy to provide reliable calibration results. Platner et al. previously established specific criteria for the required model fidelity essential for virtual calibration purposes [27]:

This criterion will be analyzed both across the complete drive cycle as well as during the individual drive cycle phases to rule out the possibility of compensating for deviations over the cycle.

The physical heat-up behavior of the powertrain and operating fluids must be implemented in a thermal system simulation. The temperature of the engine oil and the correlated higher friction in cold state can have a significant influence on the energy flow simulation. Furthermore, the temperatures of the operating fluids are inputs into the HOS to influence the start–stop decision, for example. In the field of vehicle development, the development of temperature models frequently uses the RMSE and the absolute deviation to quantify model accuracy. Due to different absolute temperature levels, the requirements are differentiated for operating fluids and exhaust gas temperatures. The maximum deviations allowed are defined as follows within industry standards [28,29]:

Deployed simulation models have to achieve model accuracy within the defined requirements, while the real-time capability of the plant simulation model on the target testbench hardware must be ensured. The real-time criterion needs to be fulfilled at every timestep i [30]. This is evaluated by calculating the real-time factor (RTF) [28,29]:

The real-time capability has to be taken into account, especially when selecting simulation approaches and setting up individual simulation models.

2.2. Test Vehicle and Developed Testbench Setup

This section gives an overview of the test vehicle and its key specifications. Based on this and the previously defined requirements, the testbench setup is derived. This not only includes the physical testbench setup, but also the definition of simulation model approaches and their design.

The vehicle is equipped with a high-performance gasoline ICE and a permanent magnet synchronous EM [23]. The EM is located on the input shaft of the automatic transmission (P2 configuration). The ICE can be decoupled from the rest of the powertrain using a clutch (K0), allowing both purely electric and hybrid driving. Further details of the reference vehicle are listed in Table 1. Additional details about hybrid vehicles, the general working principle, the powertrain features, and possible system states are presented in [31,32,33,34]. The operating strategy deployed in the reference vehicle is implemented as a master in the drivetrain control system. The operating strategy is composed of the following function packages:

- ICE start-stop coordination;

- HVB state of charge control;

- Charge torque determination.

A state-of-the-art rule-based approach is used for making all required decisions. Similar approaches have already been published [26,34]. Inputs into the operating strategy are the driver request as well as vehicle parameters, such as the SOC of the HVB, the vehicle speed, and the engine coolant temperature.

Table 1.

Test vehicle specifications.

Table 1.

Test vehicle specifications.

| Vehicle Segment according to [35] | J—Sport Utility Vehicle (SUV) |

| Powertrain Topology | Plug-in hybrid, P2 configuration, all-wheel drive |

| Legislation | EU-6-AP |

| Vehicle Weight | 2500 kg |

| Power/Torque ICE | 455 kW/800 Nm |

| Power/Torque EM | 140 kW/480 Nm |

| Total Power/Torque Vehicle | 580 kW/950 Nm |

| HVB Capacity | 22 kWh |

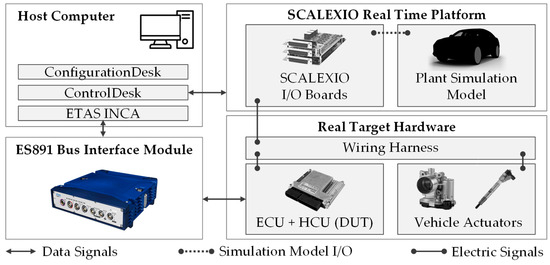

Based on the defined requirements, an HiL testbench is developed specifically for the virtual calibration of a P2 PHEV vehicle. The hardware structure of the developed HiL testbench consists of four main components (see Figure 1). The dSPACE SCALEXIO real-time platform contains a QNX-based multi-core processor system consisting of four physical processor cores [36]. The calculation is automatically split between the 4 available cores. One of the cores is reserved for the execution of the ICE model implemented as a one-dimensional GT suite model converted to an S-function. Comparable approaches have been implemented before [37,38,39]. The SCALEXIO platform generates all electrical signals that are sent to the DUT. In this case, the DUT is a Hybrid Control Unit (HCU) with a fully integrated engine control unit. Electrical signals sent out by the DUT are measured and interpreted by the SCALEXIO and made available in the plant simulation model. During the simulation, the user interface for the HiL operator is established via the host computer. Measurement and calibration access to the DUT is realized via the bus interface module ETAS ES891 and the software ETAS INCA 7.4.

Figure 1.

Simplified HiL testbench setup.

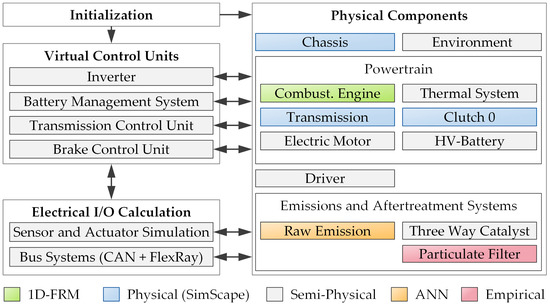

A simplified structure of the developed plant simulation model is depicted in Figure 2. The plant simulation model is a forward dynamic simulation model with a fixed discrete time step of 1 ms. This has been proven sufficient for the virtual testing of hybrid powertrains [40,41]. The complete model was developed in MATLAB Simulink 2023a. To solve the differential equations on the target hardware, an ODE solver based on the Dormand–Prince method used. The plant model is structured into four main modules.

Figure 2.

Simplified structure of the plant simulation model developed for use on the HiL testbench.

The Physical Components module includes various simulation models that reproduce the physical behavior of vehicle components and functionalities. Detailed information on modeling approaches and references is given in Table A1 in Appendix A.

The Virtual Control Units module contains the simplified logical relationships of the controllers, which are not present at the testbench in physical form. The control units considered are the transmission control unit (TCU), the inverter as the control instance of the EM, the battery management system (BMS), and the brake control unit for friction brake actuation and electric recuperation.

The Electrical I/O Calculation includes sensor simulation and actuator interpretation. In addition to this, the simulation of the CAN and FlexRay bus communication is located in this sub-model. Apart from the basic structure of the bus communication, signals are exchanged between the simulation environment and the DUT.

The developed model environment was parameterized with physical parameters as well as empirical data from component testbenches and a prototype vehicle. The results of the open-loop validation of the individual sub-models are described in DÜZGÜN et al. [23].

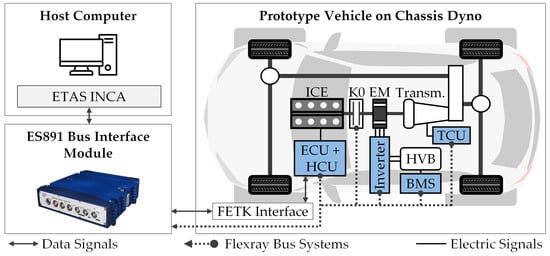

The measurements used as a reference for the validation in this publication were obtained on a chassis dynamometer. The simplified structure of the measurement setup is illustrated in Figure 3. The measurement data are recorded via an ETAS ES891, analogous to the HiL testbench. In addition to the direct connection to the DUT via an FETK interface, a connection to the FlexRay bus system is also available. Via this method, it is possible to measure all transmitted measurement signals from control units, such as the BMS and the TCU. Via the two previously mentioned measurement interfaces, signal traces from the series production sensors were recorded. Thus, the vehicle was not equipped with external measurement equipment.

Figure 3.

Simplified structure of the measurement setup used for the chassis dynamometer testing.

3. Dynamic Closed-Loop Simulation Results

This section presents the results of the closed-loop validation, which were generated on the described HiL testbench. To evaluate the sub-models as independently as possible, the testbench was evaluated in different testing scenarios, as defined in Table 2. An analysis of the results provides valuable insights into the suitability of the HiL testbench for use in virtual testing and calibration. The closed-loop simulation results were compared to reference measurements from the physical prototype vehicle on a chassis dynamometer to analyze the overall performance of the HiL testbench.

Table 2.

Investigated evaluation scopes, respective testing scenarios, and boundary conditions.

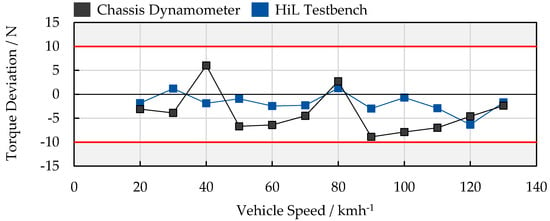

3.1. Chassis and Environment Simulation

The evaluation of the chassis and environment, specifically concerning the necessary resistive forces at the wheels, was conducted through a coast-down test. This approach mirrors the methodology employed in chassis dynamometer testing. Figure 4 illustrates the torque deviations relative to the reference coast-down behavior across various vehicle speed breakpoints. The raw measurement data are given in Table A2 in Appendix A. The results demonstrate that the HiL simulation consistently satisfies the quality criteria established by Equation (1). Notably, in nearly all data points, the deviations observed in the HiL testbench are smaller than those recorded in the vehicle measurement. The results prove that the simulation of resistive forces and rotational inertias is highly comparable to the physical reference system.

Figure 4.

Torque deviation in comparison to target coast-down for the vehicle on a chassis dynamometer and HiL testbench.

3.2. Driver Simulation

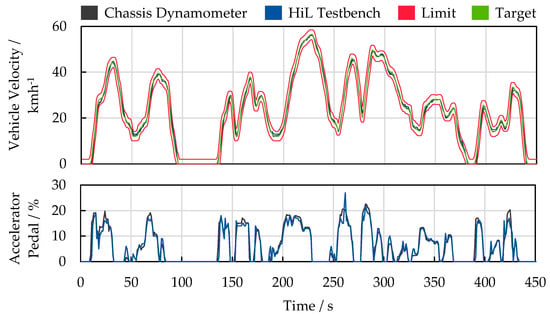

The driver model behavior was validated during dynamic driving. The analysis was carried out using both the complete WLTC and an excerpt of the drive cycle. The performance of the driver in the closed-loop setup is highly dependent on the system’s dynamic response to driver inputs. To assess the driver’s performance in both purely electric and hybrid operating mode, the vehicle was operated in charge-sustaining mode. Figure 5 presents an excerpt from the WLTC executed on the HiL testbench in comparison to the reference measurement. The results indicate that the virtual driver on the HiL testbench successfully follows the target speed profile by actuating the accelerator pedal comparably to the reference measurement. This demonstrates the sufficient accuracy of the driver model alongside the high accuracy of the overall system dynamics. Notably, the largest deviations from the target speed occur during drive-off events. The cause of this is the overall structure of the driver model. When the vehicle is at a standstill, the brake is held at a constant high level. During the drive-off event, the brake release occurs with a low gradient. This leads to delayed drive-off and reduced acceleration in the virtual vehicle. However, the vehicle speed stays within the acceptable limits according to Equation (2).

Figure 5.

Comparison of driver behavior on vehicle and HiL testbench, excerpt WLTC 0–450 s.

The virtual driver is capable of completing the entire cycle without violating the defined speed limits, similar to a trained professional operating the vehicle on a chassis dynamometer. Furthermore, the coefficient of determination (R2) between the target speed and the actual speed of the virtual vehicle was calculated to be 0.9993, closely reproducing the behavior of the human driver with an R2 of 0.9997.

3.3. Transmission Simulation

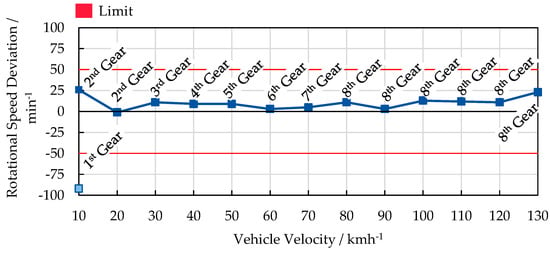

The validation of the transmission behavior is conducted using two criteria. The gear ratio across all available gears is validated by analyzing the rotational speeds at defined steady-state speed points. This analysis ensures that the simulated transmission accurately reflects the mechanical gear ratio characteristics of the physical system. The results are illustrated in Figure 6, presenting the rotational speed deviation between the reference and the HiL measurement at a given gear and vehicle velocity. All deviations from the reference measurements remain within the quality thresholds defined by Equation (3). The most significant outlier occurs in first gear at a vehicle speed of 10 km/h. It is important to note that in first gear, the torque converter lock-up clutch has not been engaged yet, which introduces slip in the torque converter. Due to the simplified simulation of the torque converter, this leads to a higher deviation of the rotational speed of the transmission input in first gear.

Figure 6.

Rotational speed deviation for defined gears in comparison to reference measurement.

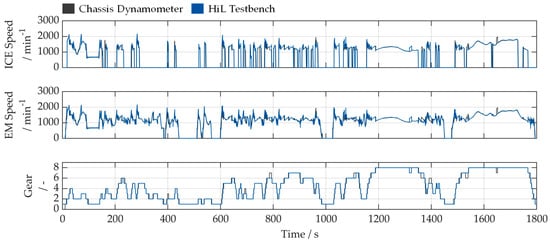

The evaluation of the behavior of the virtual TCU in the closed loop is carried out in hybrid charge-sustaining mode. This means that the shift strategy is validated both during purely electric and hybrid phases. The transmission shift timings and selected gears are comparable between the reference and the HiL measurement (see Figure 7). Derived from this, the ICE and EM speed confirm the previous findings regarding the gear ratios, also in dynamic operation. This is evidence for the high simulation quality of not only the physical transmission model, but also the virtual TCU. In phases with increased dynamics, deviations in the shifting strategy may occur, e.g., at t = 780 s and t = 1370 s. This can be traced back to the simplified implementation of the shift strategy. Delays in the controls as well as in the physical transmission model are not considered properly, thus leading to deviations in the shift timings. In addition, small deviations in the actuation of the accelerator pedal influence the shift strategy as well. Especially when the vehicle is operated close to the threshold for the next gear, the driver has a non-negligible influence. A detailed analysis of the shift time offsets between reference and HiL measurement during a WLTC is given in Figure 8.

Figure 7.

Closed-loop results of transmission simulation in hybrid charge-sustaining mode.

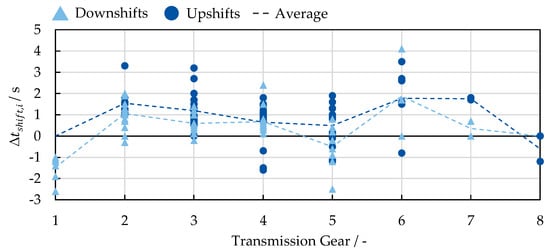

Figure 8.

for HiL and reference measurement.

The average delay shift time is below 2 s for both upshifts and downshifts in every individual gear. This already includes all closed-loop deviations from virtual driver and powertrain models. Over a complete WLTC, three missing upshifts were identified in the HiL measurement in comparison to the reference measurement. In addition, two missing downshifts occurred. Another notable event is a single downshift in the HiL measurement, which did not occur in the reference measurement. This is due to the driving profile being very close to the velocity threshold for up or down shifting. However, the different gear selection is resolved after a short deviation and does not lead to noticeable deviations for the HOS. These results present the overall high quality of the shift strategy simulation even in a closed loop. In the following sections, it can be seen that the observed deviations in the shift strategy do not have a significant influence on vehicle performance.

3.4. Electric Energy Flow and Efficiency Simulation

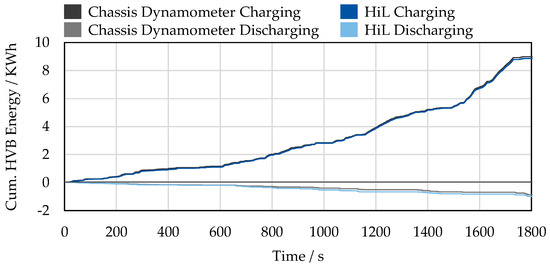

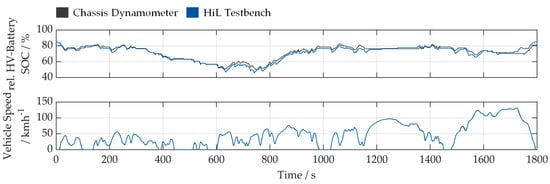

Figure A1 shows the HVB SOC in the purely electric charge-depleting mode. The general trend of the electric energy stored in the HVB can be simulated. The SOC simulation reaches an RMSE of 0.67% against the reference measurement. Figure 9 further underlines this statement. The trends of the cumulated electric energy in both charging and discharging direction can be simulated with high accuracy. In general, the electric consumption in the closed-loop simulation is underestimated by approximately 1.3%. The cumulated recuperation energy, however, is overestimated by 14.2% in the virtual environment. This is mainly due to one deceleration event at t ≈ 800 s, in which deviation from the virtual brake control unit and the driver accumulate.

Figure 9.

Cumulated electric energy of the HVB in a charge-depleting WLTC drive cycle.

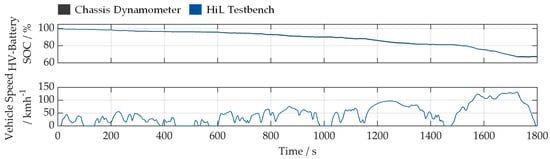

Figure A2 depicts the HVB SOC for the charge-sustaining scenarios. For better visualization, the SOC for the charge-sustaining scenario is depicted in relation to a window of 1000 Wh. Over the complete drive cycle, the SOC correlation between reference and HiL measurements in charge-sustaining operation can be rated as high, with an RMSE = 2.7%. This accounts for approximately 26.5 Wh. The largest difference in the cycle occurs at 600 s < t < 750 s. This deviation in the relative SOC is mainly due to different ICE start and stop timings. In multiple events, the ICE is started later or stopped earlier on the HiL so that more electrical power is required to propel the virtual vehicle. Contrary to this, the ICE on the HiL starts earlier at t = 745 s, resulting in the elimination of the SOC difference from the previous events.

The maximum allowed deviation of the NEC criterion, as defined in Equation (9), is also successfully achieved with the developed testbench. In the reference test, an NEC = 0.159% was recorded. The HiL testbench was able to reproduce this behavior closely with an NEC = 0.202%.

Figure 10 presents the cumulated electric energy of the HVB during a charge-sustaining WLTC drive cycle. In this analysis, charging and discharging phases are differentiated to provide a clear overview of the energy flow dynamics. Notably, the HiL testbench tends towards higher electric energy consumption during the last phase of the drive cycle. This behavior is counteracted by the HOS, resulting in an increased energy charging requirement. The maximum deviation observed in the positive charging direction reaches 9.98%, while the negative discharging direction shows a maximum deviation of 9.98%. This underlines the accuracy of the HiL testbench in simulating the electric energy flow and efficiency of the hybrid electric vehicle, both in purely electric as well as hybrid operating conditions.

Figure 10.

Cumulated electric energy of the HVB in a charge-sustaining WLTC drive cycle.

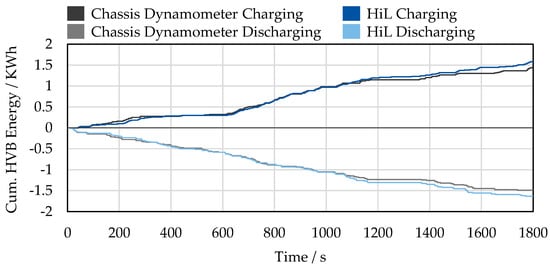

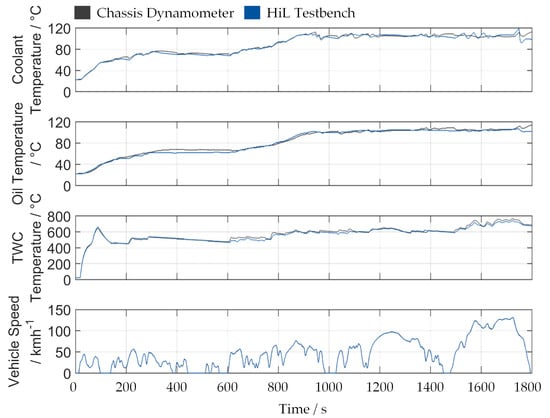

3.5. Thermal System Simulation

Figure 11 illustrates the coolant, oil, and catalytic converter temperatures during the charge-sustaining WLTC. The high accuracy of the individual semi-physical thermal system models is evident both during purely electric driving phases and when the ICE is running. The simulation maintains high accuracy after reaching the target operating temperature, with the thermostat opening after t = 900 s. Between 1500 s and 1700 s, fluctuations in the modeled coolant temperature around the reference measurements are observed. The cause of this is the complex thermal interactions between the radiator and the coolant at high vehicle velocities. The semi-physical map-based approach used for simulating the heat transfer between coolant and air flow within the radiator presents challenges in the simulation accuracy. However, the impact on the closed-loop simulation performance remains minimal and acceptable, specifically keeping computational effort in mind. The thermal system behavior is reproduced not only during phases with a running ICE, but also during purely electric operation. Heat losses to the environment, as a function of vehicle speed, are adequately accounted for, resulting in temperature profiles that closely match the reference data.

Figure 11.

Closed-loop simulation results of the thermal system in hybrid charge-sustaining mode.

A comprehensive evaluation using the defined requirements was conducted over the WLTC cycle investigated. Based on the established equations, the results summarized in Table 3 were obtained. The RMSE for both coolant and oil temperatures is below the maximum acceptable RMSE defined in Equation (13). Further, the maximum acceptable temperature deviations also remain within the specified limits defined in Equation (14). Additionally, the TWC temperature meets both criteria outlined in Equations (15) and (16). This indicates that the thermal system simulation provides reliable results. These findings confirm that the developed testbench simulates the thermal dynamics of the hybrid electric vehicle with acceptable accuracy in the closed-loop environment.

Table 3.

Results of the evaluation of the thermal system simulations.

3.6. Fuel Consumption and CO2 Emission Simulation

A high degree of correlation is observed both for simulated fuel consumption and CO2 emissions. The integrated fuel consumption at the end of the cycle shows a deviation of +0.0875 L. This marks the highest deviation over the cycle. With a total consumption of 2.9 L, this results in a percentage deviation at the end of the cycle of 3.0%. The emitted CO2 emissions on the chassis dynamometer and the HiL testbench are presented in Table 4. Contrary to the fuel consumption, the simulated CO2 emissions in general are lower than in the reference measurement. This is most evident in phases with higher vehicle speeds and engine loads. The maximum percentage difference in the CO2 emissions is −2.0%, which is below the defined maximum simulation error in Equation (12). The evaluation of the total CO2 emissions confirms this finding, with a total percentage difference of −1.04%. Due to the neural network approach used to simulate CO2 emissions, the interpretation of the cause of error is difficult. However, it can be said that the training of the neural network was carried out with data from multiple engines, and thus, the training data include component scattering as well as different states of component wear. This could be one of the reasons for the higher deviation at high vehicle speeds compared to the measurement of the reference vehicle.

Table 4.

CO2 emission over the hybrid charge-sustaining WLTC.

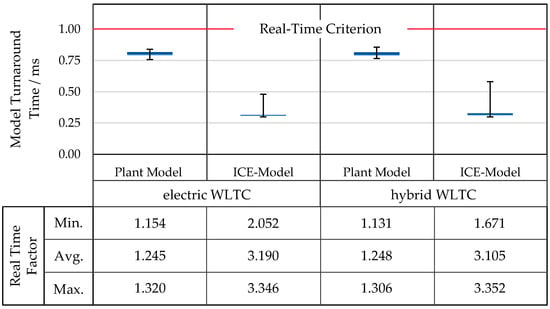

3.7. Real-Time Capability

Boxplots for the model turnaround times and the RTF of the individual models in both described scenarios are presented in Figure 12. In general, the turnaround time is slightly higher in the test scenario in hybrid mode. This is due to the increased calculation effort in both models while the ICE is running. The ICE model, which is executed on a separate core, runs with a minimum RTF ≈ 1.7. The remaining plant simulation model achieves a minimum RTF ≈ 1.1, well below the real-time criterion. All models performed below the hard real-time criterion. Further testing in a wider operating range has proven this. Due to the high computational effort to solve the differential equation at the wheel, the braking into a standstill has been identified as the most critical scenario. It can be concluded that the testbench is real-time-capable in all relevant scenarios. Further, no simulation errors or implausible model states are observed during run-time.

Figure 12.

Model turnaround time and RTF of the used simulation models in the testing scenarios.

4. Conclusions and Outlook

The results presented in this study provide evidence that the developed plant simulation model operating within the closed-loop environment successfully meets the defined requirements outlined in Section 2. This, coupled with the satisfaction of the hard real-time criterion, is proof that the developed HiL testbench is capable of accurately reproducing test scenarios under comparable boundary conditions. Moreover, the closed-loop test results affirm that the performance of the investigated HOS control functions and their inputs are consistent with the reference vehicle in dynamic tests.

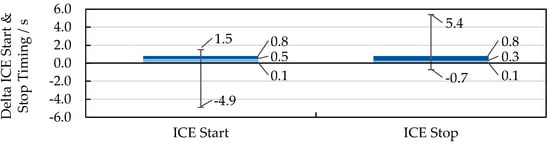

This is confirmed by a dedicated evaluation of the HOS controller outputs. Both the start-and-stop decisions and the torque split across the available torque sources closely match the reference measurements. The evaluation of the start and stop timings of the ICE, depicted as a boxplot in Figure 13, shows overall low start and stop delays in comparison to the reference measurement. They have been calculated according to Equation (4). Additionally, the scattering is low, as evidenced by the first and third quartiles being close to the median. Individual outliers both for start and stop occur and are caused by closed-loop model deviations.

Figure 13.

Boxplot of delta ICE start and stop timings in a WLTC charge-sustaining test.

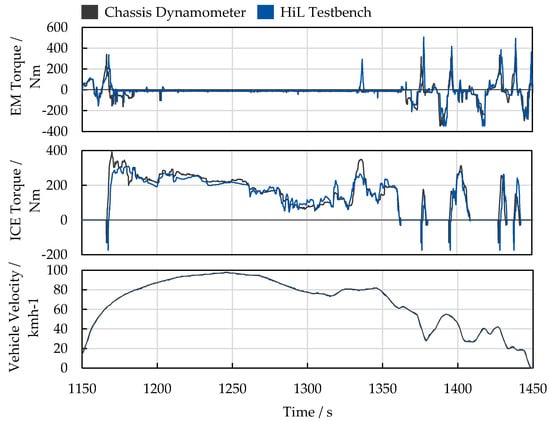

Furthermore, the torque split within the hybrid system aligns closely with the reference measurements. The driver-requested wheel torque is distributed between the two torque sources during hybrid operation comparable to the reference data. This has already been proven in the energy flow analysis in Section 3. The torque traces of both drive components during a representative dynamic segment are illustrated in Figure 14. This consistency underscores the findings.

Figure 14.

Closed-loop simulation results for component torque during an excerpt of a WLTC.

Closed-loop HiL measurements do not aim to achieve an exact reproduction of the reference measurement, but rather a reproduction of the test scenario. This can be understood as a repetition of the test scenario on the conventional testbench. In a real-world application, the overall system behavior shows variations, for example, due to different driver behavior. It has been observed that this variability in the measurement data generated on a physical system is higher in comparison to an automated virtualized testbench [42,43]. For the successful realization of the planned use-case, the testbench needs to provide results within the acceptable variation of the real system.

5. Summary

The virtualization of development tasks, notably through HiL testbenches, has become crucial for the efficient calibration, testing, and validation of hybrid powertrains, reducing reliance on physical prototypes. To substitute conventional testing approaches with virtualized solutions, the developed HiL testbench must be validated in detail. Further, it has to be proven that virtually generated measurement data are applicable for the use-case.

This study focuses on the dynamic closed-loop validation of an HiL testbench designed for the virtual testing and calibration of an HOS for PHEVs. Based on the described use-case, requirements regarding the testbench are developed. The testbench setup, as well as the plant simulation model, are derived. The model operates in a closed-loop HiL testbench, integrating a series-production HCU.

The validation results cover several scopes and testing scenarios. The chassis simulation accurately simulates wheel resistive forces, aligning closely with reference data from a physical prototype. The driver model follows target speed profiles within acceptable limits comparable to professional human drivers. Transmission simulation replicates gear ratios and shift strategies with high accuracy. The energy flow simulation stays within acceptable accuracy limits, ensuring reliable fuel and energy consumption data, which are essential for HOS calibration. Thermal simulations reproduce powertrain heat-up behavior, with temperature deviations falling within specified limits. Fuel consumption and CO₂ emissions are modeled with deviations below the defined acceptable errors, validating the simulation of vehicle component efficiency. The results achieved ensure real-time capability in the operating conditions investigated.

In conclusion, the closed-loop validation confirms that the developed HiL testbench satisfies all predefined requirements, accurately simulating the behavior of the reference vehicle. This is the first step to enable the virtual calibration of HOSs, addressing development capacity challenges and enhancing efficiency in hybrid powertrain optimization. To deploy the developed testbench in a virtual calibration use-case, however, further validation is needed. It is necessary to perform a variation of calibration data on both testing platforms. An analysis of the system response based on the calibration changes needs to be performed in the future.

Author Contributions

Conceptualization, M.T.D., C.H., S.K. and C.D.; methodology, M.T.D., C.H., S.K. and C.D.; validation, M.T.D. and C.H.; investigation, M.T.D.; resources, C.D., S.-Y.L. and J.A.; writing—original draft preparation, M.T.D.; writing—review and editing, M.T.D., C.H., S.K., C.D. and S.-Y.L.; visualization, M.T.D.; supervision, C.D., S.-Y.L., J.A. and S.P.; project administration, J.A. and S.P.; funding acquisition, J.A. and S.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data is not publicly available due to confidentiality restrictions.

Conflicts of Interest

Authors Sascha Krysmon and Christian Dönitz were employed by the company FEV Europe GmbH. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Appendix A

Table A1.

Overview of used simulation model approaches.

Table A1.

Overview of used simulation model approaches.

| Simulation Model | Simulation Approach | Details and References |

|---|---|---|

| Chassis | Physical, component-based | Based on MATLAB Simscape Driveline incl. custom extensions

|

| Combustion Engine | 1D GT-Suite FRM | Similar approaches: [38,39]

|

| Thermal System | Semi-physical, map based | Multiple 0D simulations based on [44,45]

|

| Transmission | Physical | Based on MATLAB Simscape Driveline incl. custom extensions

|

| Clutch 0 | Physical | Based on MATLAB Simscape Drivelineincl. custom extensions |

| Electric Motor | Semi-physical, map based | Custom multiphysics simulation incl.

|

| High-Voltage Battery | Semi-physical, map based | Custom equivalent electric circuit

|

| Driver | Map based | Model predictive controller combined with PID controller based on [46] |

| Raw Emission | Neural Network | Based on [47] incl. custom extensions |

| Three-way Catalyst | Semi-physical, map based | Thermal and chemical simulation based on [39] |

| Particulate Filter | Empirical, map based | Back pressure model |

Table A2.

Results of the coast down tests.

Table A2.

Results of the coast down tests.

| Vmax | Vmin | ttarget | tvehicle | ∆tvehicle | tHiL | ∆tHiL |

|---|---|---|---|---|---|---|

| 135 | 125 | 6.23 | 6.24 | +0.01 | 6.24 | +0.01 |

| 125 | 115 | 7.00 | 7.03 | +0.03 | 7.04 | +0.04 |

| 115 | 105 | 7.90 | 7.95 | +0.05 | 7.92 | +0.02 |

| 105 | 95 | 8.94 | 9.02 | +0.08 | 8.95 | +0.01 |

| 95 | 85 | 10.16 | 10.28 | +0.12 | 10.2 | +0.04 |

| 85 | 75 | 11.57 | 11.53 | −0.04 | 11.55 | −0.02 |

| 75 | 65 | 13.19 | 13.29 | +0.10 | 13.24 | +0.05 |

| 65 | 55 | 15.01 | 15.2 | +0.19 | 15.08 | +0.07 |

| 55 | 45 | 16.99 | 17.25 | +0.26 | 17.03 | +0.04 |

| 45 | 35 | 19.06 | 18.79 | −0.27 | 19.15 | +0.09 |

| 35 | 25 | 21.06 | 21.28 | +0.22 | 20.99 | −0.07 |

| 25 | 15 | 22.77 | 22.98 | +0.21 | 22.89 | +0.12 |

Figure A1.

Closed-loop simulation results of HVB SOC in hybrid charge depleting mode.

Figure A2.

Closed-loop simulation results of HVB SOC in hybrid charge-sustaining mode.

Appendix B

References

- Sabadka, D.; Molnár, V.; Fedorko, G. Shortening of Life Cycle and Complexity Impact on the Automotive Industry. TEM J. 2019, 8, 1295–1301. [Google Scholar] [CrossRef]

- Meli, M.; Wang, Z.; Bailly, P.; Pischinger, S. Neural Network Modeling of Black Box Controls for Internal Combustion Engine Calibration. In SAE Technical Paper Series, Proceedings of the 2024 Stuttgart International Symposium, Stuttgart, Germany, 2–3 July 2024; SAE International: Warrendale, PA, USA, 2024. [Google Scholar]

- Fletcher, R.; Mahindroo, A.; Santhanam, N.; Tschiesner, A. The Case for an End-To-End Automotive-Software Platform. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/the-case-for-an-end-to-end-automotive-software-platform#/ (accessed on 12 June 2024).

- Fischer, R.; Kücükay, F.; Jürgens, G.; Pollak, B. Der Fahrzeugantrieb. In Das Getriebebuch, 2nd ed.; Springer Vieweg: Wiesbaden, Germany, 2016; ISBN 978-3-658-13103-6. [Google Scholar]

- Kokalj, G.; Schatz, P.; Zach, C. Challenges and Opportunities in Variant Calibration of Hybrid Vehicles. In SAE Technical Paper Series, Proceedings of the SAE 2014 International Powertrain, Fuels & Lubricants Meeting, Birmingham, UK, 20 October 2014; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- European Automobile Manufacturers’ Association Press Release Car Registrations August 2024: New Car Registrations: −18.3% in August 2024; BEV Market Share down by Almost One Third. Available online: https://www.acea.auto/pc-registrations/new-car-registrations-18-3-in-august-2024-bev-market-share-down-by-almost-one-third/ (accessed on 19 November 2024).

- Impey, B. Anteil von Hybridfahrzeugen an Globaler Automobilproduktion bis 2023. Available online: https://de.statista.com/statistik/daten/studie/875099/umfrage/anteil-von-hybridfahrzeugen-an-globaler-automobilproduktion/ (accessed on 18 November 2024).

- Statista Market Insights, Mobility, Elektrofahrzeuge: Plug-in-Hybrid Elektrofahrzeuge. Available online: https://de.statista.com/outlook/mmo/elektrofahrzeuge/plug-in-hybrid-elektrofahrzeuge/weltweit (accessed on 18 November 2024).

- Hu, X.; Han, J.; Tang, X.; Lin, X. Powertrain Design and Control in Electrified Vehicles: A Critical Review. IEEE Trans. Transp. Electrif. 2021, 7, 1990–2009. [Google Scholar] [CrossRef]

- Buttes, A.G.D.; Jeanneret, B.; Kéromnès, A.; Le Moyne, L.; Pélissier, S. Energy management strategy to reduce pollutant emissions during the catalyst light-off of parallel hybrid vehicles. Appl. Energy 2020, 266, 114866. [Google Scholar] [CrossRef]

- Dimauro, L.; Tota, A.; Galvagno, E.; Velardocchia, M. Torque Allocation of Hybrid Electric Trucks for Drivability and Transient Emissions Reduction. Appl. Sci. 2023, 13, 3704. [Google Scholar] [CrossRef]

- Morra, E.P. A Comprehensive Methodology for the Optimization of the Operating Strategy of Hybrid Electric Vehicles. Ph.D. Dissertation, Politecnico di Torino, Turin, Italy, April 2012. [Google Scholar]

- Fundamentals of automotive and engine technology: Standard drives, hybrid drives, brakes, safety systems. In Bosch Professional Automotive Information; Reif, K., Ed.; Springer Vieweg: Wiesbaden, Germany, 2014; ISBN 978-3-658-03972-1. [Google Scholar]

- Dhingra, S.; Hernandez, D.N. Accelerating JLR’s Propulsion Development Using Rig Based Testing Methodologies. Available online: https://fpc-event.co.uk/wp-content/uploads/2023/03/SulabhDhingra_DanielNavarro_DigitalEngineering.pdf (accessed on 12 June 2024).

- Merl, R.; Kokalj, G.; Wultsch, B.; Klumaier, K.; Eberhard, F.; Ivarson, M. Innovative Lösungen zur Applikation hybrider Antriebe. In Experten-Forum Powertrain: Simulation und Test 2020; Liebl, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 121–134. ISBN 978-3-662-63605-3. [Google Scholar]

- Llopart Vázques, G.; Weck, T.R.; Kolar, A.; Jones, S. Multi-XiL as a Central Tool for the Integration, Calibration and Validation of Hybrid Powertrains. In VPC–Simulation und Test 2015: Methoden der Antriebsentwicklung im Dialog 17; Liebl, J., Beidl, C., Eds.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2018; pp. 81–95. ISBN 978-3-658-20735-9. [Google Scholar]

- Trampert, S.; Nijs, M.; Huth, T.; Guse, D. Simulation von realen Fahrszenarien am Prüfstand. MTZ Extra 2017, 22 (Suppl. 1), 12–19. [Google Scholar] [CrossRef]

- Qiu, W.; Ashta, S.; Shaver, G.M.; Johnson, S.C.; Frushour, B.C.; Rudolph, K. Expediting Hybrid Electric Wheel Loader Prototyping: Real-Time Dynamic Modeling and Power Management Through Advanced Hardware-in-the-Loop Simulation. IEEE Trans. Veh. Technol. 2024, 74, 2682–2691. [Google Scholar] [CrossRef]

- Kuznik, A.; Steinhaus, T.; Stumpp, M.; Beidl, C. Optimierung des Emissionsverhaltens innerhalb der hybriden Betriebsstrategie am Prüfstand mittels Co-Simulation. In Experten-Forum Powertrain: Simulation und Test 2020; Liebl, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 31–45. ISBN 978-3-662-63605-3. [Google Scholar]

- Boumans, M.; Fischer, U. Entwicklung von Energiemanagementfunktionen für Hybridfahrzeuge. In VPC.Plus 2014; Liebl, J., Rainer, G., Eds.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2018; pp. 191–206. ISBN 978-3-658-23774-5. [Google Scholar]

- Karabiyik, E.; Özkaynak, S.; Kerpel Nde Pichler, A. Energy Management Trade-off: Virtual Optimization of Hybrid Electric Vehicles. In Proceedings of the 2023 10th International Conference on Electrical and Electronics Engineering (ICEEE), Istanbul, Turkiye, 8–10 May 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 475–479, ISBN 979-8-3503-0429-9. [Google Scholar]

- Altun, Y.E.; Kutlar, O.A. Energy Management Systems’ Modeling and Optimization in Hybrid Electric Vehicles. Energies 2024, 17, 1696. [Google Scholar] [CrossRef]

- Düzgün, M.T.; Dorscheidt, F.; Krysmon, S.; Bailly, P.; Lee, S.-Y.; Dönitz, C.; Pischinger, S. Virtual Multi-Criterial Calibration of Operating Strategies for Hybrid-Electric Powertrains. Vehicles 2023, 5, 1367–1383. [Google Scholar] [CrossRef]

- European Union Commission Regulation (EU) 2017/1151. 2017. Available online: https://eur-lex.europa.eu/eli/reg/2017/1151/oj/eng (accessed on 7 May 2025).

- United Nations Worldwide harmonized Light vehicles Test Procedure: ECE/TRANS/180/Add.15. 2014. Available online: https://www.transportpolicy.net/wp-content/uploads/2021/08/GTR-No-15.pdf (accessed on 7 May 2025).

- Manheller, P. Mehrkriterielle Optimierung und Untersuchung Regelbasierter Betriebsstrategien für Plug-in Hybridfahrzeuge. Dissertation, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2016. [Google Scholar]

- Platner, S.; Kordon, M.; Fakiolas, E.; Atzler, H. Modellbasierte Serienkalibrierung-der effiziente Weg für Variantenentwicklung. MTZ-Mot. Z. 2013, 74, 754–761. [Google Scholar] [CrossRef]

- Yuan, R.; Price, C.; Kasurkar, R.; Spenley, M.; Dutta, N.; Ebrahimi, K. Numerical Investigation of Heat Retention and Warm-Up with Thermal Encapsulation of Powertrain. In SAE Technical Paper Series, Proceedings of the WCX SAE World Congress Experience, Detroit, MI, USA, 21 April 2020; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Ranjan, R.; Jha, K.K.; Brahmasani, L.; Khan, P. Prediction of Engine Thermal Behavior during Emission Cycle Using 1D Four Point Mass Model. In SAE Technical Paper Series, Proceedings of the SAE 2016 World Congress and Exhibition, Detroit, MI, USA, 12 April 2016; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Zöbel, D. Echtzeitsysteme: Grundlagen der Planung, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-662-60420-5. [Google Scholar]

- Elektrifizierung des Antriebsstrangs: Grundlagen-vom Mikro-Hybrid zum vollelektrischen Antrieb. In ATZ/MTZ-Fachbuch; Tschöke, H., Gutzmer, P., Pfund, T., Eds.; Springer Vieweg: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-662-60355-0. [Google Scholar]

- Enang, W.; Bannister, C. Modelling and control of hybrid electric vehicles (A comprehensive review). Renew. Sustain. Energy Rev. 2017, 74, 1210–1239. [Google Scholar] [CrossRef]

- Sittig, A. Optimierung und Applikation von Betriebsstrategien in Hybridfahrzeugen. Ph.D. Dissertation, Technische Universität München, München, Germany, 2013. [Google Scholar]

- Yue, H.; Lin, J.; Dong, P.; Chen, Z.; Xu, X. Configurations and Control Strategies of Hybrid Powertrain Systems. Energies 2023, 16, 725. [Google Scholar] [CrossRef]

- Commision of the European Communities Regulation (EEC) No 4064/89: 4064/89. vol. 1999. 1999. Available online: https://eur-lex.europa.eu/eli/reg/1989/4064/oj/eng (accessed on 7 May 2025).

- Lee, S.Y. Virtuelle Kalibrierung von Motorsteuergeräten Mittels Hardware-in-the-Loop Simulationen. Ph.D. Dissertation, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2023. [Google Scholar]

- Xia, F. Real-Time Capable One-Dimensional Models for Internal Combustion Engines in X-in-the-Loop Applications. Ph.D. Dissertation, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2020. [Google Scholar]

- Xia, F.; Dorscheidt, F.; Lücke, S.; Andert, J.; Gardini, P.; Scheel, T.; Walter, V.; Tharmakulasingam, J.K.R.; Böhmer, M.; Nijs, M. Experimental Proof-of-Concept of HiL Based Virtual Calibration for a Gasoline Engine with a Three-Way-Catalyst. In SAE Technical Paper Series, Proceedings of the 2019 JSAE/SAE Powertrains, Fuels and Lubricants, Kyoto, Japan, 26–29 August 2019; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Dorscheidt, F.; Düzgün, M.; Claßen, J.; Krysmon, S.; Pischinger, S.; Görgen, M.; Dönitz, C.; Nijs, M. Hardware-in-the-Loop Based Virtual Emission Calibration for a Gasoline Engine. In SAE Technical Paper Series, Proceedings of the SAE WCX Digital Summit, Online, 12–15 April 2021; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Schmidt, H.; Büttner, K.; Prokop, G. Methods for Virtual Validation of Automotive Powertrain Systems in Terms of Vehicle Drivability—A Systematic Literature Review. IEEE Access 2023, 11, 27043–27065. [Google Scholar] [CrossRef]

- Vadamalu, R.S.; Beidl, C. Explicit MPC PHEV energy management using Markov chain based predictor: Development and validation at Engine-In-The-Loop testbed. In Proceedings of the 2016 European Control Conference (ECC), Aalborg, Denmark, 29 June–1 July 2016; IEEE: Piscataway, NJ, USA; pp. 453–458, ISBN 978-1-5090-2591-6. [Google Scholar]

- Kaven, L.; Frehn, A.; Basler, M.; Jassmann, U.; Röttgers, H.; Konrad, T.; Abel, D.; Monti, A. Impact of Multi-Physics HiL Test Benches on Wind Turbine Certification. Energies 2022, 15, 1336. [Google Scholar] [CrossRef]

- Ramosaj, N.; Fusco, C.; Viennet, E. Development of a Hardware-in-the-Loop Test Bench for Validation of an Anti-lock Braking System on an E-Bike. In The Evolving Scholar-BMD 2023, 5th ed.; The Evolving Scholar: Delft, The Netherlands, 2023. [Google Scholar]

- Hoppe, M. Model-Based Development and Calibration of Diagnosis Functions in the Cooling Circuit of a Vehicle. Ph.D. Dissertation, RWTH Aachen University, Aachen, Germany, 2017. [Google Scholar]

- Varga, P. Thermisches Modell eines Verbrennungsmotors zur Untersuchung des Warmlaufverhaltens. Ph.D. Dissertation, Otto-von-Guericke-Universität Magdeburg, Magdeburg, Germany, 2014. [Google Scholar]

- Al Tarooti, A.; Meyer, N.; Guse, D.; Klein, S. Driver Modeling and Simulation for RDE Testing: Effect of driver behavior on representative test results. JSAE Tech. Pap. 2019, 5–167. [Google Scholar]

- Dorscheidt, F.; Aachen, G.V.R.; Meli, M.; Claßen, J.; Krysmon, S.; Pischinger, S.; Görgen, M.; Dönitz, C.; Bailly, P.; Nijs, M.; et al. Modelling of Gasoline Engine-Out Emissions Using Artificial Neural Networks. In Proceedings of the FISITA World Congress 2021, Prague, Czech Republic, 13–17 September 2021; ISBN 9781916025929. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).