Abstract

To advance “bamboo-as-plastic-substitute” initiatives and the sustainable use of furniture materials, this study investigates flattened bamboo sheets by determining their principal-direction elastic constants and evaluating two common furniture T-joints—dowel-jointed panel-type and right-angle mortise-and-tenon frame-type—through tensile and bending load-bearing tests alongside finite element (FE) comparisons. The results show a pronounced anisotropy, with the longitudinal elastic modulus markedly higher than in other directions. At the joint level, the average ultimate load-bearing capacities were 4.06 kN (panel-type tension), 3.70 kN (frame-type tension), 0.264 kN (panel-type bending), and 0.589 kN (frame-type bending). Under identical structural configurations and boundary conditions, the tensile and bending capacities of flattened bamboo sheets were comparable to or exceeded those of the comparator materials (MDF, cherry wood, bamboo-based composites), and failures predominantly occurred in the adhesive layer rather than the bamboo substrate. Across four representative cases, FE predictions achieved a mean absolute percentage error (MAPE) of 6.5% with a maximum relative error of 12.5%; the regression correlation was R2 ≈ 0.999 based on four paired observations, which should be interpreted with caution due to the small sample size. The study validates that FE models driven by experimentally measured anisotropic parameters can effectively reproduce the mechanical response of flattened bamboo T-joints, providing a basis for structural design, lightweighting, and parameter optimization in furniture applications. Further work should characterize adhesive systems, environmental durability, and interfacial failure mechanisms to enhance the model’s general applicability.

1. Introduction

In recent years, the global pursuit of sustainable development has stimulated increasing interest in replacing traditional plastics with renewable resources. In October 2021, China formally proposed its “dual carbon” target. With the shortage of wood resources and the growing imbalance between supply and demand, bamboo has attracted considerable attention as a fast-growing and renewable natural material. Bamboo-based panels, featuring large dimensions, small deformation, dimensional stability, and high material utilization, have become a promising pathway to achieve the “dual carbon” goal [1,2,3].

Bamboo is characterized by exceptionally rapid growth (up to 30–100 cm/day in favorable conditions), short renewal cycles, and high strength-to-weight ratios. Typical densities range from 600 to 900 kg/m3, and axial tensile strengths can reach 250–500 MPa, yielding favorable specific stiffness and strength compared with many timbers. Bamboo is widely distributed across East and Southeast Asia, parts of Africa, and tropical regions of South America. Its extensive rhizome network and perennial culm replacement enable resilience to certain climate stressors. Moreover, bamboo plantations can sequester CO2 efficiently, supporting climate mitigation. These attributes, coupled with efficient processing routes, underpin its potential as a sustainable substitute for wood and plastics in furniture applications [4,5,6].

However, the development of bamboo processing remains relatively short, and many issues require further resolution. The flattened bamboo sheet industry is still immature and limited mainly to small household products such as chopping boards and mobile phone stands. Given the growing demand for sustainable furniture materials, it is essential to expand their application to structural and load-bearing components. With the rapid growth of the furniture industry, traditional structural mechanics methods can no longer meet the increasingly complex requirements of modern furniture design. To address this, computer-aided approaches and the finite element method (FEM) have been widely adopted in other countries. Applying the FEM to the optimization and structural performance analysis of flattened bamboo sheet furniture—starting from the stress–strain behavior of joints and structural members—allows for efficient improvement of chair-type furniture. This approach avoids destructive testing of entire prototypes, enables accurate simulation, and supports rational optimization of furniture structure, thereby reducing material consumption and shortening the design cycle. In particular, improving the structural performance and realizing lightweight design of flattened bamboo sheet furniture is crucial for advancing its market adoption and promoting sustainable utilization of bamboo resources.

Eckelman and Suddarth first introduced the FEM into furniture structural design [7]. Subsequent applications include Kasal (2006), who compared and optimized glued sofa frames of solid wood versus wood-based composites [8]; Çolakoğlu and Apay (2012), who analyzed chair joint strength under free fall at varying heights [9]; and Haraga and Goanță (2017), who improved stress–strain prediction accuracy in an armchair model via mesh refinement [10]. For panels, İmirzi and Efe (2013) compared static load strength of L-shaped MDF and particleboard joints with the FEM, noting higher model stiffness [11]; Karaman (2016) studied bookcase stiffness under static loads for MDF and particleboard with different fasteners [12]; Krzyżaniak and Smardzewski (2021) combined the FEM and experiment to show installation force–energy absorption correlations in L-shaped joints [13].

The objective of this study is to examine the structural performance of chair-type furniture made from flattened bamboo sheets and to validate the feasibility of applying the FEM to its structural strength design. Tensile and bending resistance of joints were selected as key indicators of connection performance. Among common furniture joint structures, T-shaped and L-shaped joints are most representative. Compared with L-shaped joints, T-shaped joints provide more stable support in both longitudinal and transverse directions. In this work, the elastic constants of the flattened bamboo sheet in different directions were first determined. Two typical T-shaped joint types used in panel and solid wood furniture—dowel joints and mortise-and-tenon joints—were then prepared. For each joint type, eight specimens were tested on a universal testing machine to evaluate tensile and bending resistance, thereby clarifying their mechanical behavior. Finally, FEM simulations of the same T-shaped joints were conducted, and a comparison with experimental results was used to verify the applicability of the FEM in the structural optimization and sustainable lightweight design of flattened bamboo sheet furniture.

2. Materials and Methods

2.1. Elasticity Parameters of Flattened Bamboo Sheet

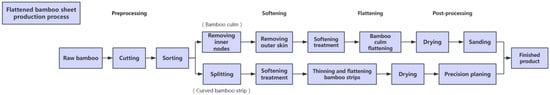

A flattened bamboo sheet is a recently developed bamboo-based composite panel. Through softening, flattening, drying, and shaping, bamboo culms or curved strips are processed into sheet-like materials [14]. At present, two main approaches are employed: culm flattening and strip flattening. Although the procedures differ slightly, both generally include pretreatment, softening, flattening, and post-treatment [15,16,17,18], as illustrated in Figure 1. Compared with traditional bamboo strip-based and bamboo sliver-based composites, the flattened bamboo sheet achieves higher raw material utilization. This method substantially reduces shaving volume and adhesive consumption, simplifies processing, facilitates continuous mechanized production, and thereby improves efficiency while lowering costs.

Figure 1.

Manufacturing process of the flattened bamboo sheet.

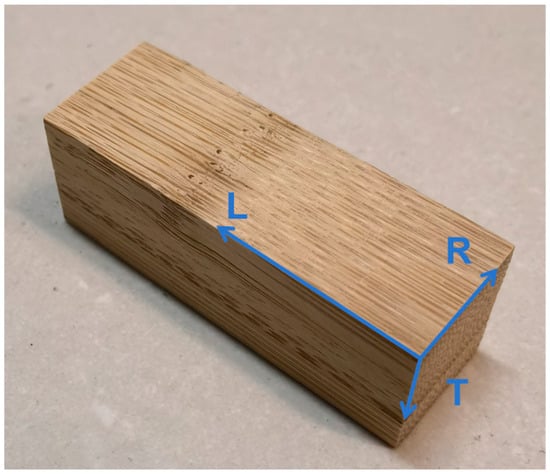

As there is currently no national standard for flattened bamboo sheets, it is regarded as an anisotropic material with mechanical parameters comparable to those of wood. Therefore, in this study, a simplified three-dimensional coordinate system was defined for a flattened bamboo sheet with reference to national standards for wood mechanical testing, as shown in Figure 2. The elastic constants and mechanical properties of the material in each principal direction were determined accordingly.

Figure 2.

Three-dimensional coordinate system for a flattened bamboo sheet.

For specimen preparation, commercially obtained flattened bamboo sheet veneers were first air-dried outdoors under ambient conditions (temperature range: 5–12 °C; relative humidity: 60%–75%). The bamboo material had an initial moisture content of 7.1% and a density of 0.655 g/cm3. A panel adhesive—comprising a specially formulated waterproof polyvinyl acetate (PVAc) emulsion and an isocyanate curing agent—was uniformly applied before assembling the veneers into two- and three-layer sheets. The assembled veneers were then hot-pressed at 145 °C under 5 MPa pressure for 1 h to form consolidated panels. After sufficient release of internal stress under static conditions, these sheets were used as raw materials for subsequent tests of mechanical properties and the tensile and bending resistance of T-shaped specimens. The multilayer flattened bamboo sheets were further processed by planing and cutting according to the required dimensions, and eight specimens were prepared for each test. The specimen sizes for elastic parameter testing are shown in Table 1.

Table 1.

Specimen dimensions for elastic property tests of the flattened bamboo sheet.

2.1.1. Mechanical Property Testing of Flattened Bamboo Sheet

The compressive elastic modulus and Poisson’s ratio of the flattened bamboo sheet in both longitudinal and transverse directions were measured using the electrical resistance strain method. The testing procedure followed the national standards for wood elastic modulus measurement, GB/T 15777-2017 and GB/T 1927.13-2022 [19,20]. A one-quarter bridge circuit was used to assemble the measuring bridge. Specimens were placed at the center of the spherical movable support of a universal testing machine.

For longitudinal specimens, monotonic loading was applied at a rate of 0.5 mm/min, with the lower and upper load limits set to 6000 N and 10,000 N, respectively. This cycle was repeated six times. For transverse specimens, monotonic loading was applied at a rate of 0.2 mm/min, with the lower and upper load limits set to 2000 N and 5000 N, respectively, also repeated six times. The average deformation values from the last three cycles were used for calculation.

The compressive elastic modulus of the flattened bamboo sheet was calculated using Equation (1):

The Poisson’s ratio of the flattened bamboo sheet was calculated using Equation (2):

Based on the elastic modulus and Poisson’s ratio, the shear modulus in each direction was calculated using Equation (3):

2.1.2. Elastic Constants of Flattened Bamboo Sheet

The results of the elastic constant measurements of the flattened bamboo integrated material specimens are shown in Table 2. The data indicate significant anisotropy in the flattened bamboo sheet. The elastic modulus in the longitudinal direction is much higher than in the other two directions. The shear modulus is highest in the GLR direction and lowest in the GLT direction. The elastic modulus follows the trend EL ≫ ER > ET, Poisson’s ratio follows μRT > μLT > μLR, and shear modulus follows GLR > GLT ≫ GRT.

Table 2.

Measured elastic constants of flattened bamboo sheet specimens.

Comparison with the mechanical parameters of commonly used bamboo and wood furniture materials listed in Table 3 [21,22,23,24] shows that the elastic modulus of the flattened bamboo sheet is closest to that of bamboo-based composites. Although slightly lower in strength, it is superior to other materials. Regarding shear modulus, the flattened bamboo sheet outperforms bamboo-based composites and spruce, though it is slightly inferior to certain other materials. Overall, the mechanical strength of the flattened bamboo sheet is sufficient to meet the requirements of furniture manufacturing.

Table 3.

Elastic constants of common furniture materials.

2.2. Research Methods

2.2.1. Strength Testing of T-Shaped Components

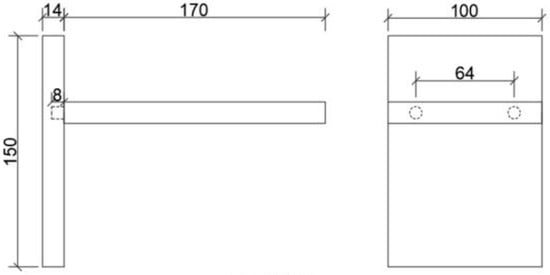

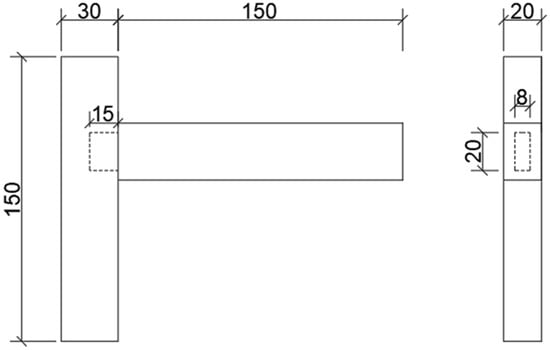

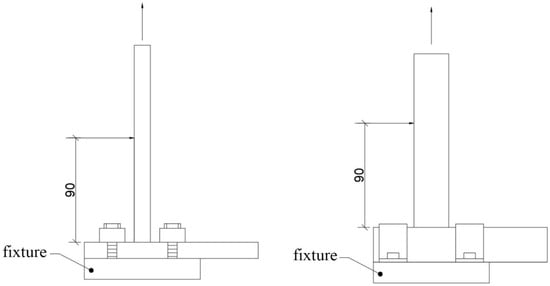

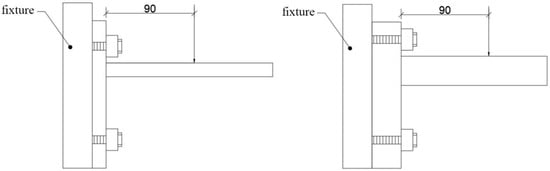

Two types of mechanical tests were conducted: tensile tests to evaluate the pure tensile strength of the joints and bending tests to assess the structural performance under combined stresses. Mechanical tests were conducted on both panel-type and frame-type T-shaped components made of flattened bamboo sheet, with other commonly used furniture materials selected for comparison. The panel-type T-shaped components were assembled using dowel joints, while the frame-type T-shaped components were assembled using right-angle mortise-and-tenon joints. Adhesive was applied evenly with a brush to each slot and bonding surface, ensuring uniform glue distribution at all joints. After assembly, the specimens were conditioned indoors for seven days. For each type of connection, eight specimens were prepared for tensile and bending resistance testing. The dimensions of the panel-type and frame-type T-shaped components are shown in Figure 3 and Figure 4.

Figure 3.

Dimensions of panel-type T-shaped components.

Figure 4.

Dimensions of right-angle mortise-and-tenon T-shaped components.

Panel-type T-shaped components were tested using three materials: flattened bamboo sheet, bamboo-based composites, and medium-density fiberboard (MDF). Frame-type right-angle mortise-and-tenon T-shaped components were tested using flattened bamboo sheets, bamboo-based composites, and cherry wood.

The universal testing machine was set to a loading speed of 10 mm/min, with the loading point located 90 mm away from the joint. The loading directions for tensile and bending tests are shown in Figure 5 and Figure 6. Each joint type and material combination was tested with eight specimens. The test was terminated when specimen failure occurred or when the load dropped below 100 N. During tensile testing, the maximum load and the load–displacement curve were recorded. The average maximum load was taken as the tensile and bending load-bearing capacity of the T-shaped component.

Figure 5.

Loading direction for tensile testing of T-shaped components.

Figure 6.

Loading direction for bending testing of T-shaped components.

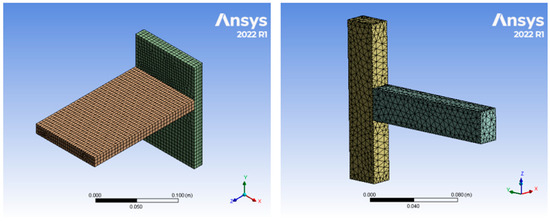

2.2.2. Finite Element Analysis of T-Shaped Component Strength

Finite element (FE) models of T-shaped components made of flattened bamboo sheet were established in SolidWorks(Version 2019), based on the specimen dimensions used in mechanical testing. The experimentally measured elastic moduli and Poisson’s ratios of the flattened bamboo sheet in different directions were used to define the anisotropic material properties. The mesh element size was set to 5 mm for general models. For right-angle mortise-and-tenon T-shaped components, tetrahedral elements with a mesh size of 3 mm were used, as shown in Figure 7.

Figure 7.

Mesh division of flattened bamboo sheet T-shaped component models.

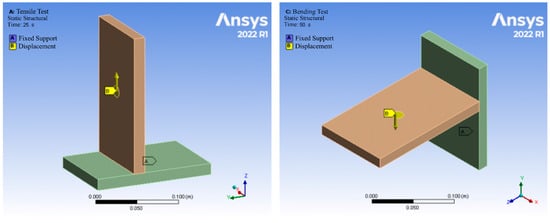

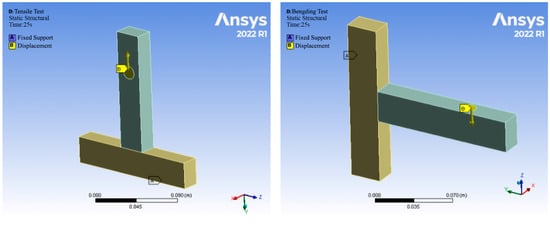

According to the above mechanical test program, the constraints and loading aspects of the flattened bamboo sheet T-member model were defined in the software, as shown in Figure 8 and Figure 9. The equivalent force and total deformation data were output, and the load–displacement graphs were derived.

Figure 8.

Load settings for tensile and bending tests of dowel-jointed T-shaped components.

Figure 9.

Load settings for tensile and bending tests of right-angle mortise-and-tenon T-shaped components.

3. Results and Discussion

3.1. Tensile Strength Test Results of T-Shaped Components

The tensile strength distribution of panel-type T-joints with different materials is summarized in Table 4. One-way ANOVA indicated significant differences among the groups (p < 0.05).

Table 4.

Tensile test data of panel-type T-joints.

The statistical analysis reveals that the flattened bamboo sheet exhibits significantly higher tensile resistance than both MDF and bamboo-based composite, with a strength improvement of 16.3% over MDF and 15.0% over bamboo-based composite.

For mortise-and-tenon joints, the tensile performance is presented in Table 5, with ANOVA also showing significant differences (p < 0.05).

Table 5.

Tensile test data of mortise-and-tenon T-joints.

A flattened bamboo sheet demonstrates a substantial performance advantage, showing a 32.6% increase in ultimate tensile load over cherry wood and a 23.7% increase over bamboo-based composite.

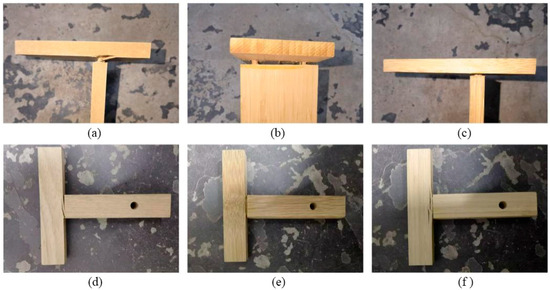

As shown in Figure 10, in the tensile tests of panel-type T-shaped components, the primary failure mode was adhesive layer failure at the round bar tenon joint interface, while the bamboo substrate itself remained intact; in contrast, failure occurred in the particleboard substrate. For frame-type T-shaped components, failure also mainly occurred in the adhesive layer of the mortise-and-tenon joints, with different degrees of failure observed in both cherry wood and bamboo-based composite. This indicates that flattened bamboo sheets exhibit superior bonding performance and seam stability compared to particleboard, cherry wood, and bamboo-based composite.

Figure 10.

Failed T-shaped tensile specimen. (a) MDF (b) Bamboo-based composite (c) Flattened bamboo sheet (d) Cherry Wood (e) Bamboo-based composite (f) Flattened bamboo sheet.

3.2. Bending Strength Test Results of T-Shaped Components

The bending strength results for panel-type T-joints are shown in Table 6. Statistical analysis confirmed significant differences among the materials (p < 0.05).

Table 6.

Bending test data of panel-type T-joints.

The ultimate bending load of the flattened bamboo sheet was 78.4% higher than that of MDF, though it was 34.3% lower than that of the bamboo-based composite.

The bending performance of frame-type T-joints is summarized in Table 7. In this case, no significant differences were found among the groups (p > 0.05).

Table 7.

Bending test data of mortise-and-tenon T-joints.

The flattened bamboo sheet showed comparable bending performance to the other two materials, with its average load being slightly higher than that of cherry wood and bamboo-based composite.

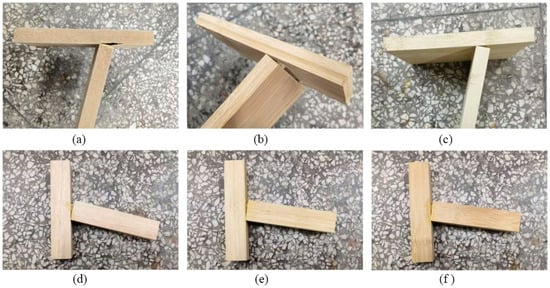

As shown in Figure 11, in the bending tests of panel-type T-shaped components, the primary failure mode was structural fracture of the dowel, whereas in the frame-type components, failure occurred in the adhesive layer of the mortise-and-tenon joints. In both cases, the bamboo substrate itself did not fracture, while failure was observed in the particleboard. This indicates that the structural reliability of flattened bamboo sheets is superior to that of particleboard.

Figure 11.

Failed T-shaped bending specimen. (a) MDF (b) Bamboo-based composite (c) Flattened bamboo sheet (d) Cherry Wood (e) Bamboo-based composite (f) Flattened bamboo sheet.

3.3. Comparison Between Mechanical Test Results and Finite Element Analysis of T-Shaped

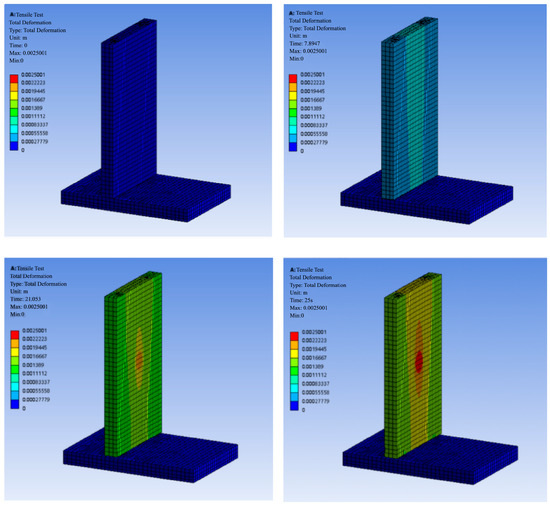

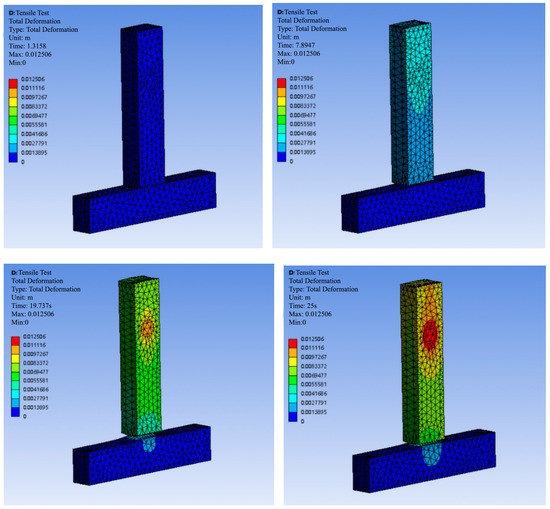

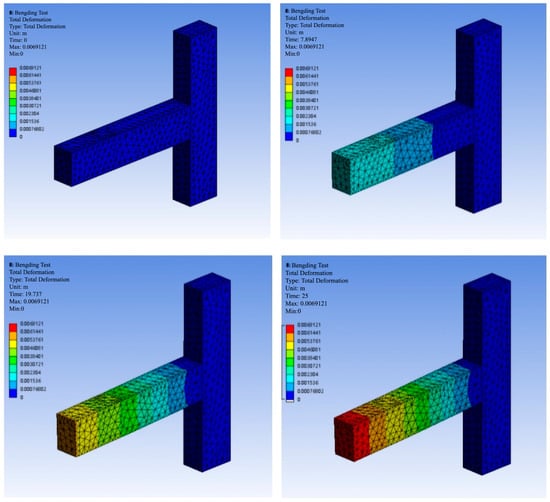

The stress distribution contours of the flattened bamboo dowel-jointed and right-angle mortise-and-tenon T-shaped components under increasing tensile load in the finite element simulations are shown in Figure 12 and Figure 13.

Figure 12.

Stress distribution of panel-type T-joint under tensile load.

Figure 13.

Stress distribution of mortise-and-tenon T-joint under tensile load.

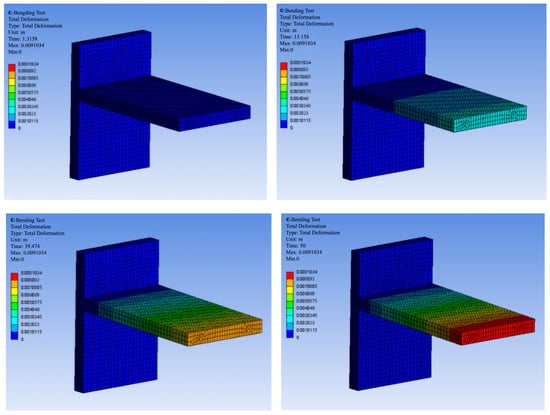

The stress distribution contours of the flattened bamboo dowel-jointed and right-angle mortise-and-tenon T-shaped components under increasing bending load in the finite element simulations are shown in Figure 14 and Figure 15.

Figure 14.

Stress distribution of panel-type T-joint under bending load.

Figure 15.

Stress distribution of mortise-and-tenon T-joint under bending load.

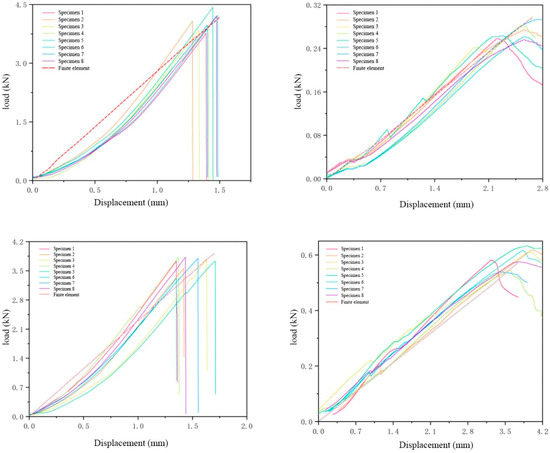

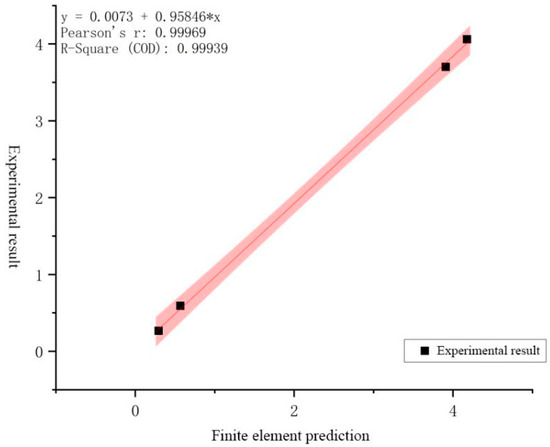

As shown in Figure 16, the comparison between experimental and FE results indicates that the FE analysis provides a good fit for the tensile and bending performance of flattened bamboo sheet T-joints.

Figure 16.

Comparison of tensile and bending performance between experimental and FE results.

From the load–displacement curves, it can be observed that the experimental curves of panel-type and mortise-and-tenon T-joints under tensile loading exhibit a more gradual initial slope compared with the FE simulation curves. This difference is attributed to the influence of the adhesive layer. Once the adhesive layer fails, the slope of the load–displacement curve increases. In contrast, under bending loads, the adhesive layer has less influence, and the slopes of the experimental and FE simulation curves show close agreement.

3.4. Error Analysis

The comparison of experimental results and FE predictions for flattened bamboo sheet T-joints is summarized in Table 8. The goodness-of-fit was quantified using root mean square error (RMSE = 0.122 kN) and mean absolute percentage error (MAPE = 6.05%), confirming a close agreement between the FE predictions and experimental results.

Table 8.

Comparison between experimental and FE results.

A linear regression analysis was performed on the tensile and bending results of both panel-type and mortise-and-tenon joints, as shown in Figure 17.

Figure 17.

Linear regression between experimental and FE results. Note: The regression is based on four paired observations. Therefore, the correlation should be interpreted with caution due to the limited dataset.

The regression equation obtained is:

y = 0.0073 + 0.95846x, R2 = 0.99939.

The coefficient of determination R2 is very close to 1, indicating that the regression model provides an excellent fit to the data. However, it should be noted that the high R2 value may be influenced by the small sample size (n = 4), which can lead to overfitting. The model explains 99.94% of the variance, but the results should be interpreted with caution due to the limited number of data points. The model explains 99.94% of the variance, demonstrating strong predictive capability. As shown in Figure 17, all data points fall within the 95% confidence interval, confirming that the FE simulations almost perfectly reproduce the experimental data. Therefore, the tensile and bending test results of flattened bamboo sheet T-joints and their FE predictions exhibit consistent trends and reliable collinearity.

4. Conclusions

This study investigated the mechanical performance of T-shaped components made from flattened bamboo sheets through tensile and bending tests, failure mode analysis, and finite element modeling. The main conclusions are as follows:

Flattened bamboo sheets exhibit tensile and bending strengths comparable to or higher than those of solid wood and wood-based panels. Both dowel-jointed panel-type and mortise-and-tenon frame-type T-components showed reliable structural performance, confirming their feasibility for furniture applications.

Failure analysis indicated that the weak point of flattened bamboo joints lies primarily in the adhesive interface, while the bamboo substrate itself remains intact. Compared with solid wood, MDF, and particleboard, flattened bamboo sheets demonstrate superior structural integrity and stability.

The finite element models accurately reproduced the experimental load–displacement responses. The correlation analysis between simulated and experimental peak loads yielded an R2 value of 0.99939, demonstrating excellent agreement between the two. All data points fell within the 95% confidence interval, further confirming the reliability of the FE predictions.

Flattened bamboo sheets combine mechanical reliability with renewability and sustainability advantages, making them a promising alternative material in furniture design. Nevertheless, further research on adhesive systems, joint configurations, and environmental durability is necessary to fully leverage their potential.

Author Contributions

Conceptualization, S.S.; Software, C.W.; Validation, C.W.; Investigation, Y.L. (Yan Li) and R.C.; Writing—original draft, C.W.; Writing—review & editing, Y.L. (Yi Liu) and H.L.; Supervision, Y.L. (Yi Liu); Project administration, S.S. and H.L.; Funding acquisition, S.S. and H.L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge financial support from the Fourth Batch of Forestry and Grassland Science and Technology Young Talents Project—Research on the Interface Properties of Bamboo (grant No. 2024132030), Ministry of Education, Social Sciences Department Special Project on Chinese Outstanding Traditional Culture (Category A) (grant No. 23JDTCA003).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

We would like to express our sincere gratitude to everyone who provided assistance and support throughout the development of this paper. Special thanks to the International Center for Bamboo and Rattan for providing us with the necessary research equipment and technical support, which were essential to the successful completion of this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zheng, L.; Wu, Y.; Zuo, Y. Research Status and Prospects of Bamboo Residues Utilization. World For. Res. 2021, 34, 82–88. [Google Scholar]

- Liao, K. Exploitation, Utilization and Prospect of Bamboo Materials in Artificial Lumber Industry. Guizhou For. Sci. Technol. 2009, 37, 51–54. [Google Scholar]

- Gao, L.; Wang, Z.; Lin, T.; Yang, L. Study on Structural Bamboo-Based Panels Made from Highland Bamboo. Chin. J. Wood Sci. Technol. 2011, 25, 8–10. [Google Scholar]

- Bari, E.; Sistani, A.; Taghiyari, H.R.; Morrell, J.J.; Cappellazzi, J. Influence of test method on biodegradation of bamboo-plastic composites by fungi. Maderas. Cienc. Tecnol. 2017, 19, 455–462. [Google Scholar] [CrossRef][Green Version]

- Yuan, T.; Wang, X.; Liu, X.; Lou, Z.; Mao, S.; Li, Y. Bamboo flattening technology ebables efficient and value-added utilization of bamboo in the manufacture of furniture and engineered composites. Compos. Part B Eng. 2022, 242, 110097. [Google Scholar] [CrossRef]

- Vogtländer, J.G.; van der Velden, N.M.; van der Lugt, P. Carbon sequestration in LCA, a proposal for a new approach based on the global carbon cycle; cases on wood and on bamboo. Int. J. Life Cycle Assess. 2014, 19, 13–23. [Google Scholar] [CrossRef]

- Eckelman, C.A.; Suddarth, S.K. Analysis and design of furniture frames. Wood Sci. Technol. 1969, 3, 239–255. [Google Scholar] [CrossRef]

- Kasal, A. Determination of the strength of various sofa frames with finite element analysis. Gazi Univ. J. Sci. 2006, 19, 191–203. [Google Scholar]

- Çolakoğlu, M.H.; Apay, A.C. Finite element analysis of wooden chair strength in free drop. Int. J. Phys. Sci. 2012, 7, 1105–1114. [Google Scholar] [CrossRef]

- Haraga, G.; Goanță, A.M. FEA analysis and design optimization for a multifunctional piece of furniture. MATEC Web Conf. 2017, 112, 06009. [Google Scholar] [CrossRef]

- İmirzi, H.Ö.; Efe, H. Analysis of strength of corner joints in cabinet type furniture by using finite element method. In Proceedings of the XXVIth International Conference Research for Furniture Industry, Poznań, Poland, 19–20 September 2013; Warsaw University of Life Sciences Press: Warsaw, Poland, 2013; pp. 49–55. [Google Scholar]

- Karaman, A. Stiffness analysis of knockdown bookcases with finite element method. Bartın Orman Fak. Derg. 2016, 18, 9–19. [Google Scholar] [CrossRef]

- Krzyżaniak, Ł.; Smardzewski, J. Impact damage response of L-type corner joints connected with new innovative furniture fasteners in wood-based composites panels. Compos. Struct. 2021, 255, 113008. [Google Scholar] [CrossRef]

- Li, Y.J.; Lou, Z.C.; Jiang, Y.J.; Wang, X.Z.; Yuan, T.C.; Yang, M.F. Flattening Technique Without Nicked in Curved Bamboo Strips. For. Mach. Woodwork. Equip. 2020, 48, 28–30+34. [Google Scholar]

- Yang, X. Study on Bamboo Grading, Flattening and Preparation and Performance of Dimension Bamboo. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2019. [Google Scholar]

- Yuan, T.; Wang, X.; Lou, Z.; Zhang, T.; Han, X.; Wang, Z.; Hao, X.; Li, Y. Comparison of the fabrication process and macro and micro properties of two types of crack-free, flatten bamboo board. Constr. Build. Mater. 2022, 317, 125949. [Google Scholar] [CrossRef]

- Yuan, T.; Han, X.; Wu, Y.; Hu, S.; Wang, X.; Li, Y. A new approach for fabricating crack-free, flattened bamboo board and the study of its macro-/micro-properties. Eur. J. Wood Wood Prod. 2021, 79, 1531–1540. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.; Chrusciel, L.; Na, B.; Lu, X. Study on a bamboo stressed flattening process. Eur. J. Wood Wood Prod. 2013, 71, 291–296. [Google Scholar] [CrossRef]

- GB/T 15777-2017; Method for Determination of the Modulus of Elasticity in Compression Parallel to Grain of Wood. National Forestry and Grassland Administration: Beijing, China, 2017.

- GB/T 1927.13-2022; Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens—Part 13: Determination of the Modulus of Elasticity in Compression Perpendicular to Grain. National Forestry and Grassland Administration: Beijing, China, 2022.

- Zhang, F. Research on Structural Mechanics of Solid Wood Framework Furniture Based on Finite Element Method. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2012. [Google Scholar]

- Wang, H. Study on Mechanical Properties and Structural Optimization Design of Tenon Joint of Reassembled Bamboo Furniture. Master’s Thesis, Beijing Forestry University, Beijing, China, 2022. [Google Scholar]

- Liu, Y. Research on the Design of Folding Tables and Chairs Furniture Based on Flattened Bamboo Laminate. Master’s Thesis, Central South University of Forestry and Technology, Changsha, China, 2021. [Google Scholar]

- Kretschmann, D. Mechanical properties of wood. In Wood Handbook: Wood as an Engineering Material: Chapter 5. Centennial ed. General Technical Report FPL; GTR-190; Forest Products Laboratory, Forest Service, US Department of Agriculture: Madison, WI, USA, 2010; Volume 190, pp. 5.1–5.46. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).